1. Introduction

Products made of titanium and its alloys are widely used in various areas of modern industry. These materials are actively used in aircraft and rocket engineering, medicine and power engineering [

1,

2,

3,

4,

5,

6,

7]. The intensive use of titanium alloys as structural materials is associated with such properties as high strength with a relatively low specific gravity, good corrosion resistance (due to the spontaneously forming oxide film), and reasonable cost. During operation, parts made of titanium alloys experience various external influences, leading to their wear and, ultimately, failure. Such impacts include, first, abrasive and cavitation wear, as well as corrosion. Abrasive wear is associated with the impact of particles that have greater hardness than titanium (for example, sand particles). Wear also occurs during the operation of friction pairs as a result of the formation and rupture of adhesive interaction zones. The natural oxide film formed on the surface of titanium is easily destroyed by friction due to high specific loads due to the high ductility of titanium [

8,

9]. The presence of zones with a destroyed oxide film increases the tendency for the possibility of active adhesive interaction to occur in local areas of contact between two surfaces. The high propensity for adhesion is also facilitated by the relatively low elastic modulus and low thermal conductivity of titanium and its alloys. Titanium alloys are prone to significant strengthening during plastic deformation; therefore, upon contact in a friction pair, a strengthened surface layer can form [

10,

11]. In addition to the above factors, it is worth noting that due to heating during friction, diffusion of nitrogen and oxygen from the environment into the surface layer can be observed, due to which this layer is also strengthened. Due to the influence of these factors, damage on the contact surfaces of products made of titanium alloys can be quite deep and accompanied by tearouts of material fragments and the formation of adhesives, which, in turn, increase adhesion between the contact surfaces and intensify the wear process [

11]. When titanium parts work in tandem with parts made of other metals and alloys, titanium sticks to the surface of the harder material, which increases the coefficient of friction and wear rate. When titanium works in tandem with a softer material, soft material sticks to the surface of titanium parts, which also leads to an increase in the coefficient of friction and increased wear [

11].

One of the effective methods for eliminating these problems is the deposition of modifying coatings on the working surfaces of parts made of titanium alloys. Application of such coatings can extend the service life of parts made of titanium alloys and increase their reliability. These coatings must have the following properties:

high hardness and wear resistance,

corrosion resistance and chemical passivity,

high strength of adhesive bond with titanium substrate,

low adhesion to the contacting material in a tribological pair,

high strength.

One of the possible coating materials that meets the listed requirements is zirconium nitride (ZrN). The introduction of additional elements such as titanium (Ti), niobium (Nb) and hafnium (Hf) into the ZrN composition can further improve its properties. The ZrN coating itself has been studied in sufficient detail, its properties are described in a number of publications. Good wear-resistant properties and corrosion resistance in various environments are noted [

12,

13,

14,

15,

16]. Another useful property of the ZrN coating is its strength and crack resistance, which make it possible to effectively resist brittle fracture [

17,

18,

19,

20,

21], while this coating is characterized by fairly high heat resistance [

22]. There is experience in the successful use of ZrN coating to increase the wear resistance and corrosion resistance of parts made of various materials: stainless steel [

18,

19], magnesium alloys [

17], as well as titanium alloys of various compositions [

15,

23,

24,

25,

26]. While the ZrN coating mainly has an fcc structure [

27,

28,

29], under certain deposition conditions the formation of w-ZrN and h-ZrN phases is also observed [

30]. The key parameters affecting the structure and properties of the ZrN coating include nitrogen pressure in the chamber [

13,

31,

32] and substrate temperature [

33,

34]. Further improvement in the properties of the coating based on the ZrN system is ensured by increasing the complexity of its composition. The effect of the introduction of elements such as hafnium (Hf) and niobium (Nb) on the property of the coating was studied [

35,

36,

37,

38,

39]. It was found that the introduction of Hf into the ZrN structure provides a noticeable increase in wear resistance and corrosion resistance [

35,

36,

37,

38,

39,

40,

41]. In this case, an Hf content of more than 20 at% can reduce the oxidative resistance of the coating [

42]. The introduction of Nb into the ZrN composition provides a similar effect. At the same time, in addition to increasing wear resistance, a decrease in the friction coefficient is also noted [

38,

43,

44,

45]. The low coefficient of friction may be due to the reduction in grain size and surface roughness [

45]. The introduction of Nb increases the heat resistance of the coating [

46,

47,

48]. A decrease in the level of residual stresses was also noted [

49]. It was found that a high Nb content in the coating reduces corrosion resistance [

38].

Another element, the introduction of which into the composition of the ZrN coating can improve its properties, is titanium (Ti). With the introduction of Ti, wear resistance increases, and the friction coefficient decreases [

50,

51,

52,

53,

54,

55]. Anti-corrosion properties are also improved [

56,

57]. The ZrN coating with introduced Ti has better hardness and wear resistance not only compared to the ZrN coating, but also compared to the TiN coating [

53,

58,

59,

60], but has a higher level of residual stresses [

61].

Due to the difference in the mechanical properties of the coating and the substrate, it is rational to use a coating structure that includes a metal adhesion layer, which allows for good adhesion to both the titanium substrate and the coating [

62,

63,

64,

65].

The objective of this study was to compare such an important parameter of coatings as resistance to destruction during the scratch test. Coatings based on the ZrN system were selected, also including Hf, Nb and Ti in various combinations. In this way, ZrN, (Zr,Ti)N, (Zr,Hf)N, (Zr,Nb)N, (Ti,Zr,Hf)N and (Ti,Zr,Nb)N coatings deposited on titanium alloy Ti-6Al-4V were studied, which is widely used in various technological solutions. The scratch test was chosen as a research method, allowing to evaluate not only the adhesion between the coating and the substrate, but also to study the nature of destruction and strength characteristics of the coating.

2. Materials and Methods

For the deposition of coatings, a modernized VIT-2 ion-plasma unit was used (IDTI RAS – MSUT “STANKIN”, Russia) [

66,

67,

68,

69,

70,

71,

72]. Special Controlled Accelerated Arc (CAA-PVD) evaporators were used to reduce the formation of the microparticle phase [

73,

74,

75]. The cathodes had the following compositions: Zr (99.98 %) and Ti (99.99 %), Zr-Nb (50:50 %) and Zr-Hf (50:50 %).

Before the technological process of coating deposition, the samples were prepared as follows:

washing with ultrasonic stimulation in a special solution,

washing in a stream of purified water,

drying with a stream of purified air.

During coating deposition, the arc current of the titanium and zirconium cathodes was, respectively, 75 and 80 A. The arc current of the Zr-Nb (50:50 %), Zr-Hf (50:50 %) cathodes was, respectively, 85 and 90 A. Other parameters of the deposition process for all samples: Nitrogen pressure 0.42 Pa, Voltage on substrate –150 V, tool rotation speed 0.7 rpm.

The studies were carried out using a scanning electron microscope (SEM) Carl Zeiss (Germany) EVO 50, with EDX system X-Max – 80 mm

2 (OXFORD Instruments, UK). Hardness was measured on a nanotester SV-500 (Nanovea, USA), using a Berkovich indenter, at a maximum load of 200 mN. The average values were determined based on the results of 20 measurements. The scratch test was carried out using a CB-500 tester (Nanovea, USA) in accordance with the ASTM C1624-22 method [

76], measuring the load from 0 to 40 N.

3. Results

The (Zr,Hf)N and (Ti,Zr,Nb)N coatings have the highest hardness (HV 3350 ± 120 and HV 3110 ± 135 respectively). The average values among the studied coatings are for ZrN (HV 2993 ± 145), (Ti,Zr,Hf)N (HV 2860 ± 95) and (Zr,Ti)N (HV 2727 ± 86). The least hard coating was (Zr,Nb)N (HV 2336 ± 115).

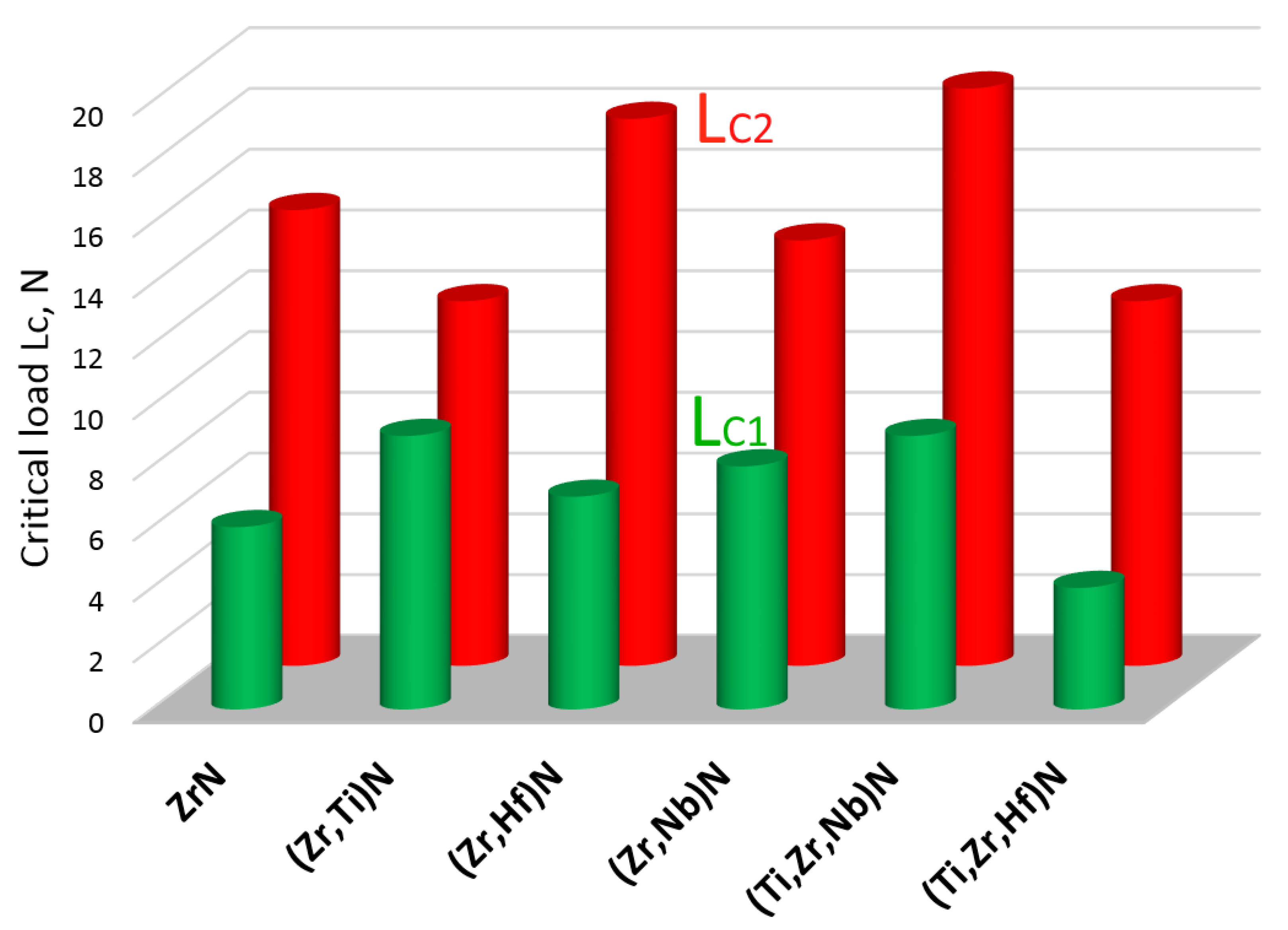

Traditionally, the scratch test method is used to determine the adhesion strength of a coating and a substrate. However, this method also allows one to study the overall strength of the coating under the influence of a hard and sharp indenter. To some extent, this method makes it possible to simulate abrasive wear under the influence of small-sized and hard particles (for example, sand particles). Studying the nature of coating destruction under such an impact can be useful in determining the scope of application of coatings and their strength under various conditions of mechanical impact. Below are the quantitative results of the study of coatings using the scratch test method (

Figure 1). The values of the critical points L

C1 and L

C2 were determined by comparing the acoustic emission data and the results of studying the scribe groove using SEM. The (Ti,Zr,Nb)N and (Zr,Hf)N coatings showed the greatest strength, and the (Zr,Ti)N, (Ti,Zr,Hf)N and (Zr,Nb)N coatings deteriorated the fastest.

The strength of the coating is affected not only by the composition and thickness of the adhesive sublayer (for (Zr,Hf)N and (Ti,Zr,Hf)N coatings it is the same – Zr, Hf), but also by the properties of the main coating layer. The best resistance to destruction is shown by coatings that also have greater hardness. The values of the critical fracture load LC2 for the samples under study do not exceed 20 N, which is significantly lower compared to coatings deposited on a carbide or silicon substrate. Since the titanium substrate has relatively low hardness and good ductility, a zone of plastic deformation is formed during the scratch test. The coating deposited on the substrate is destroyed due to active crack formation.

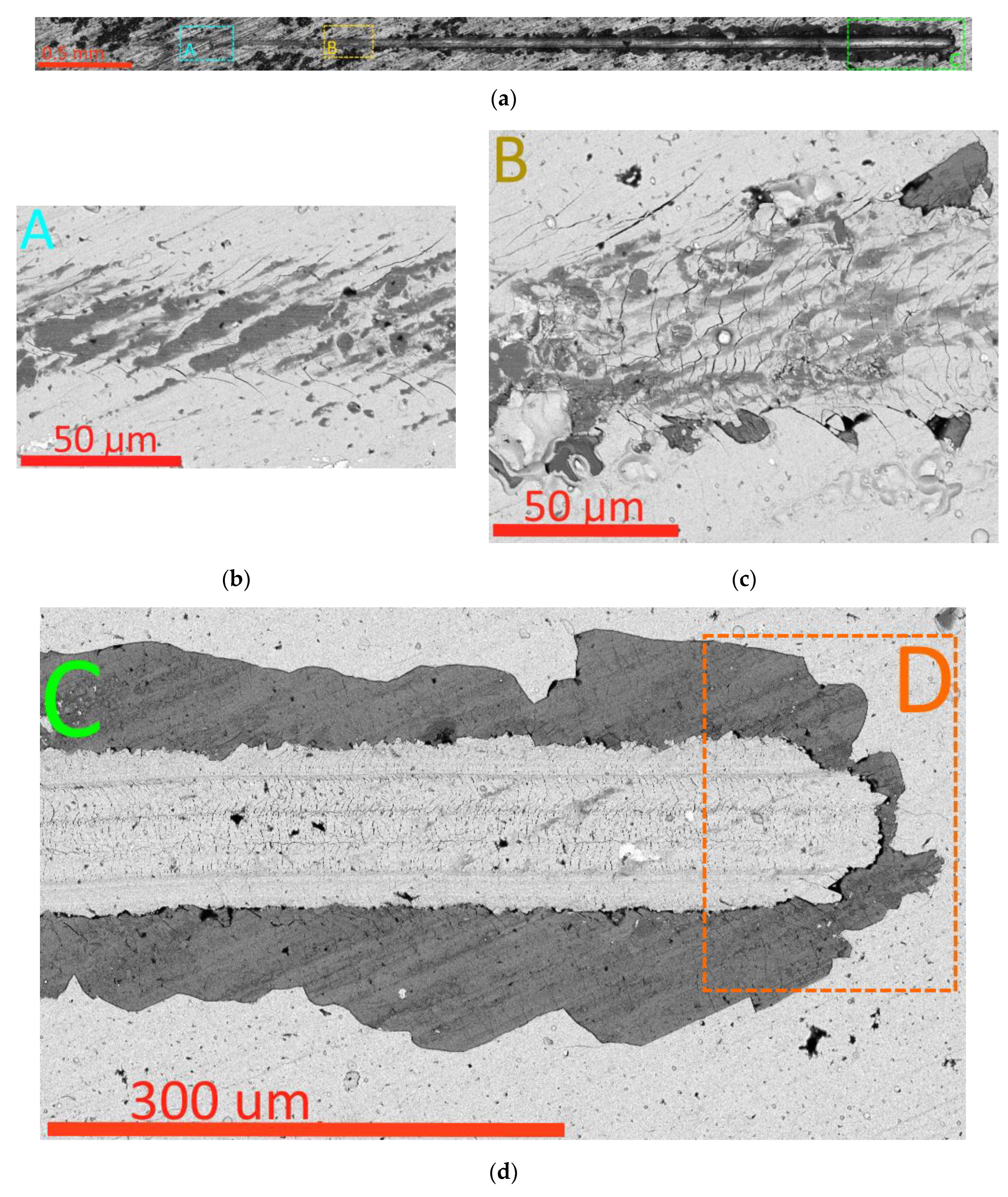

ZrN Coating

This coating has an average critical fracture value among the studied samples (L

C2 = 15 N).

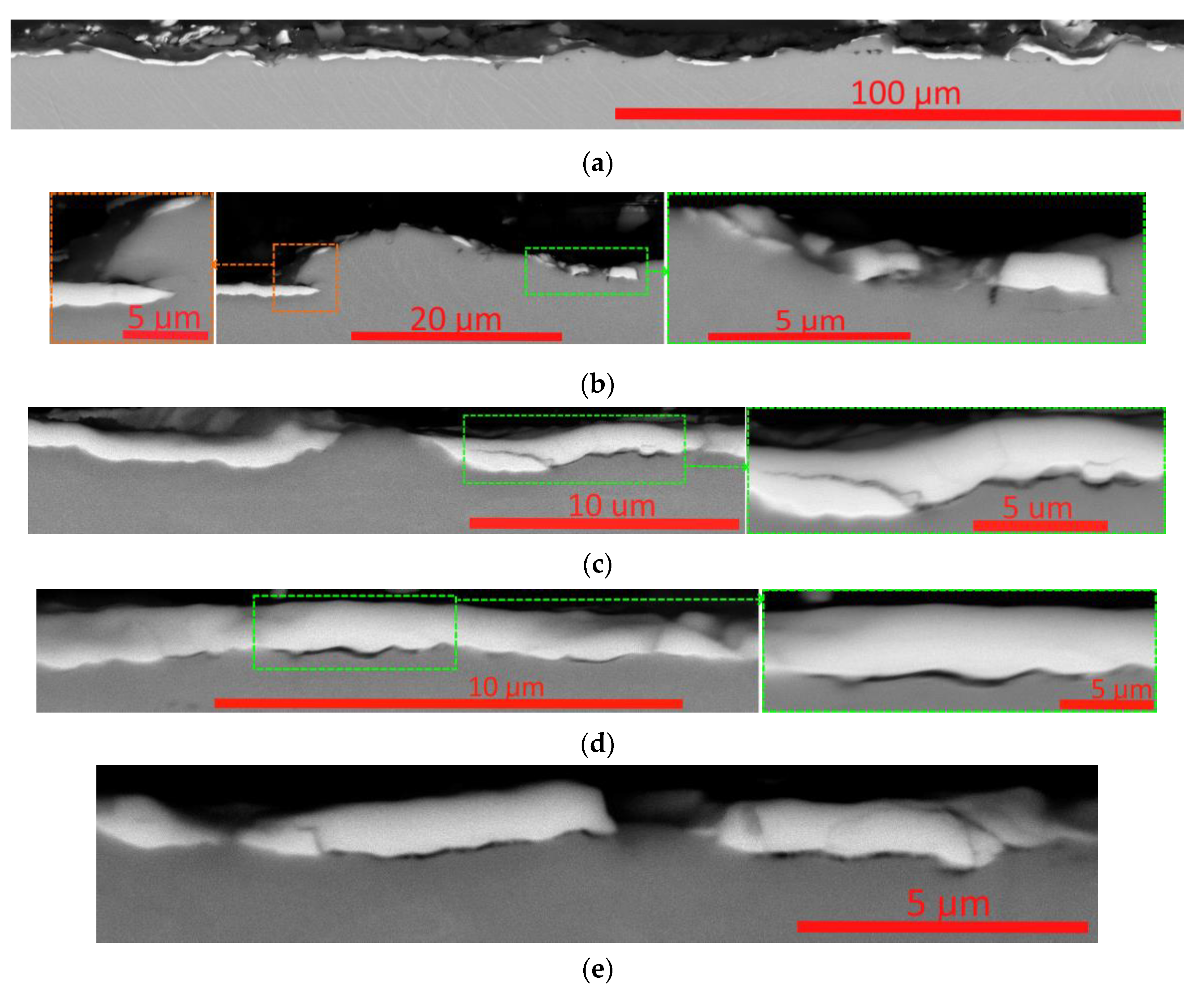

Figure 2 shows a general view of the scribing groove and a view of the characteristic areas of destruction of the ZrN coating. When the critical load L

C2 is reached, the coating actively collapses with the formation of chips along the scribing groove (

Figure 2 (b)–(e)). In addition to cracking, peeling of coating fragments from the substrate is also observed (

Figure 2 (d),(e)). In this case, the broken fragments of the coating are pressed into the substrate material under the influence of a moving indenter (

Figure 2 (c),(d)).

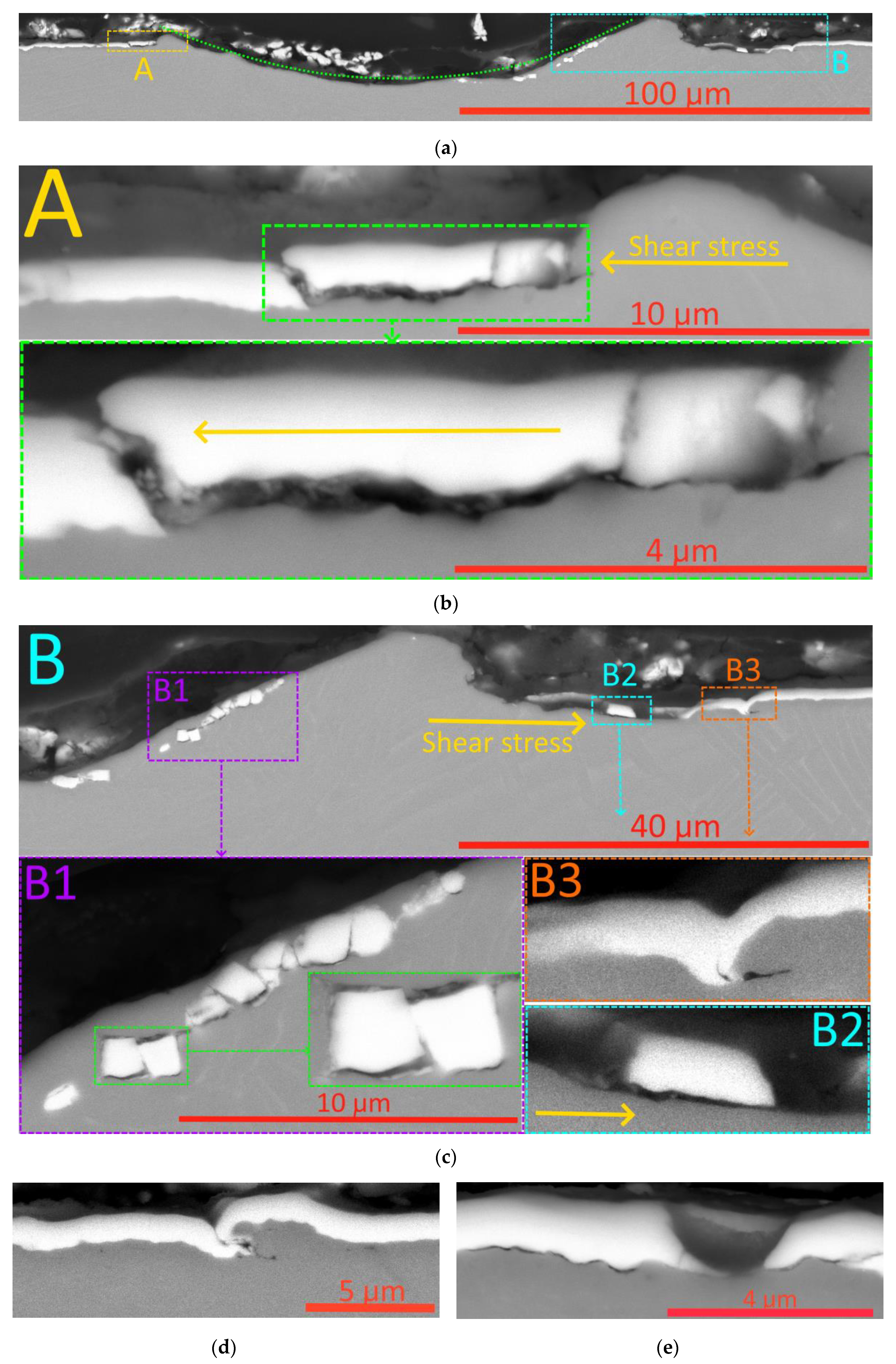

Consider a cross section of a coated sample taken perpendicular to the direction of the scribing groove in the area close to point L

C2 (

Figure 3). In the areas immediately adjacent to the scribing groove (

Figure 3 (b),(c),(e),(f)), peeling of coating fragments from the substrate is observed. In this case, the coating in these areas is affected by shear forces (indicated by arrows), while the coating in the groove itself is affected predominantly by compressive stresses. Fragments of the coating are pressed into the substrate material (

Figure 3 (c)). In areas slightly further from the scribing groove, the coating can maintain a strong adhesive bond to the substrate even with noticeable plastic deformations (

Figure 3 (c),(d)). Delamination of the coating from the substrate is accompanied by chipping of nanometric fragments of the coating from the interface with the substrate (

Figure 3 (b),(f)). The right inset shows how the coating is formed, covering the initial defect of the substrate surface (fragment B3 in

Figure 3 (c)).

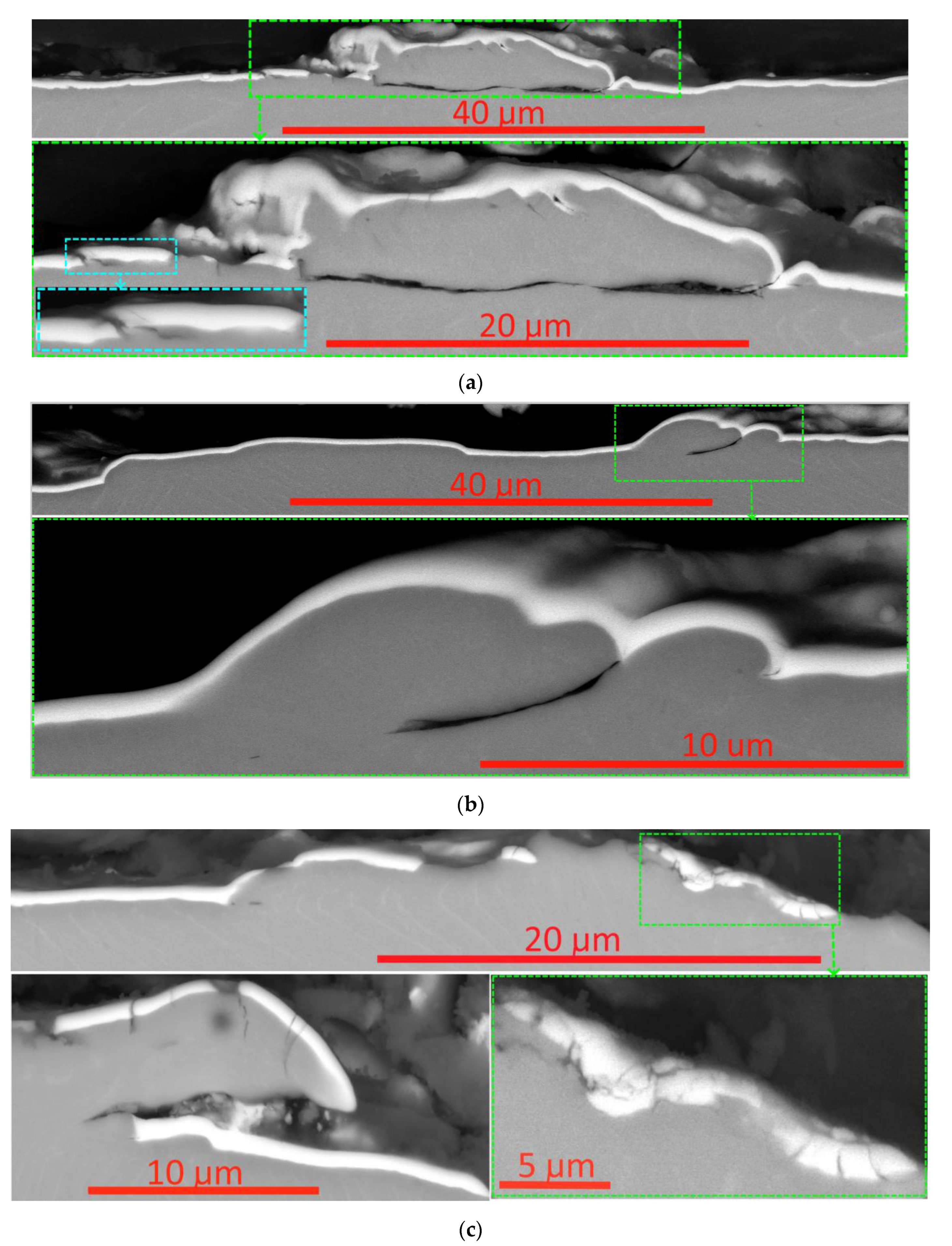

(Zr,Ti)N Coating

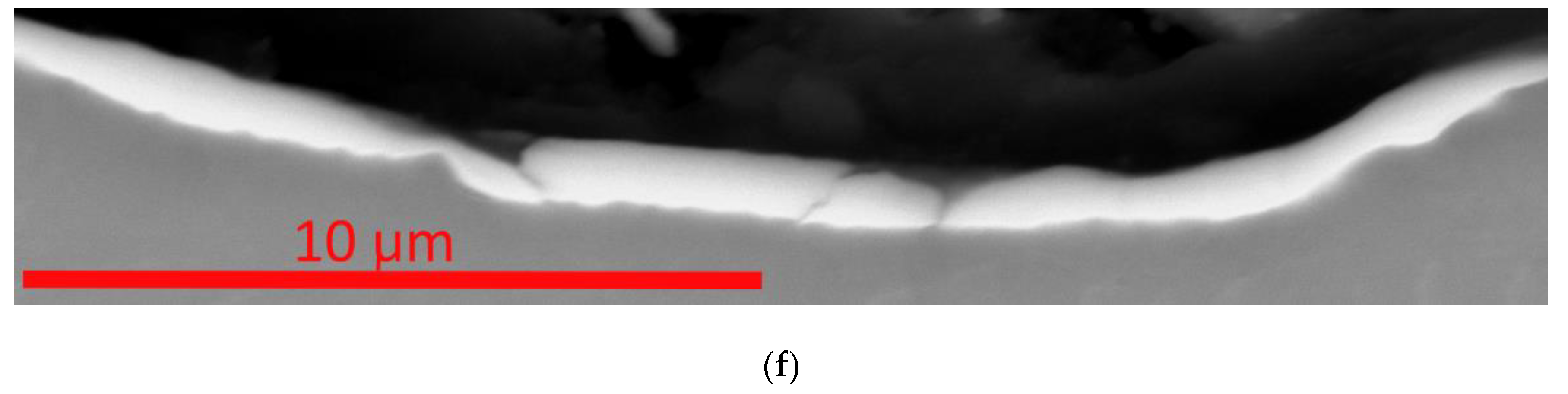

The (Zr,Ti)N coating showed low resistance to destruction in the scratch test (

Figure 4). Even at low loads, peeling of the coating from the substrate is observed along the boundaries of the scribing groove (

Figure 4 (b),(f)). Directly in the furrow, the coating cracks and the coating elements are pressed into the substrate material. With increasing loads in the furrow, the coating is completely destroyed, and along the edges of the furrow, peeling of the coating from the substrate is observed (

Figure 4 (c),(d),(e)).

Analysis of a transverse section made perpendicular to the scribing groove in the area where the critical load L

C1 is reached confirms the rather low adhesion between the coating and the substrate (

Figure 5 (a),(b)). Extended delamination can be seen, and in the area of the interface between the coating and the substrate, coloring of the coating is observed with the formation of a nanometric-sized fragment. A similar type of destruction is also observed in samples with ZrN and (Ti,Zr,Hf)N coatings.

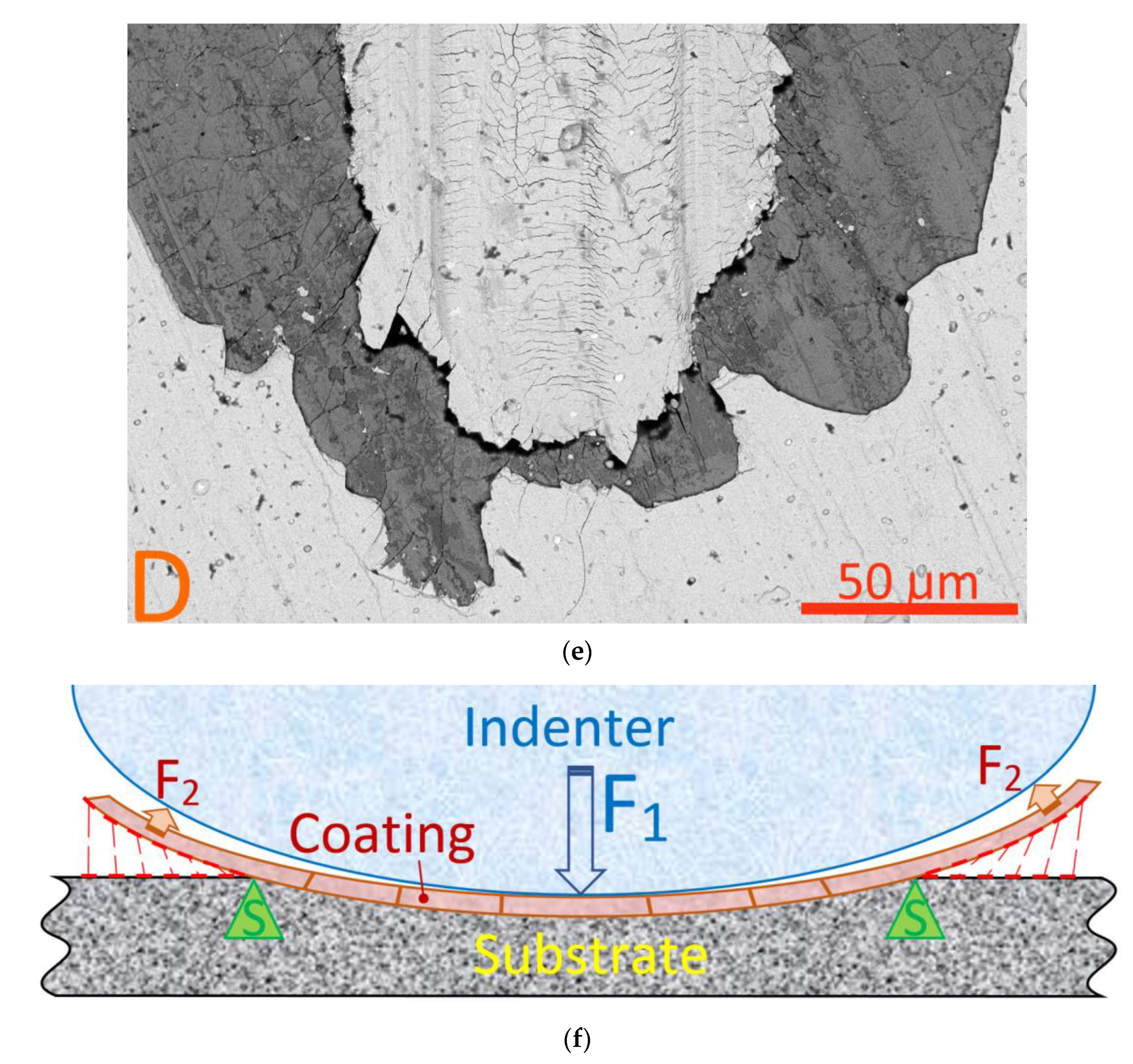

(Zr,Hf)N Coating

The nature of destruction of the (Zr,Hf)N coating is characterized by a certain duality. On the one hand, the coating remains in the scribing furrow up to the maximum load (20 N). On the other hand, already at insignificant (about 4 N) loads on the surface of the coating, the formation of cracks is observed (

Figure 6 (b)), and at a load of the order of 7 N, peeling of coating fragments from the substrate begins along the boundaries of the furrow, while in the furrow itself such peelings do not occur. are observed. Thus, assessing the strength of this coating during a scratch test is somewhat difficult. From the point of view of acoustic emission, the destruction of this coating (point L

C2) occurs at a load of 18 N. At this load the coating in the groove itself is preserved (that is, it has high compressive strength). But extensive areas of destruction and delamination form along the furrow. These areas are the most extensive among all the studied coatings. One can make an assumption (which requires additional research) that the (Zr,Hf)N coating itself has a fairly high strength, but rather low adhesion to the substrate. Thus, to simplify the model, we can consider the coating as an elastic beam (

Figure 6 (f)) resting on two supports (marked as S). Under the influence of force F

1 applied from the indenter, the beam bends, and forces F

2 (tearout forces) act at the ends of the beam. If the F

2 value is greater than the strength of the adhesive bond with the substrate, the coating detaches from the substrate. Of course, the real model is much more complex; it is obvious that factors of plastic deformation and shear force can also influence, but the authors consider the proposed model acceptable for a qualitative explanation of the process. Another reason for poor adhesion of the coating to the substrate may be the formation of the possible Zr, Ti, Hf intermetallic sublayer discussed above.

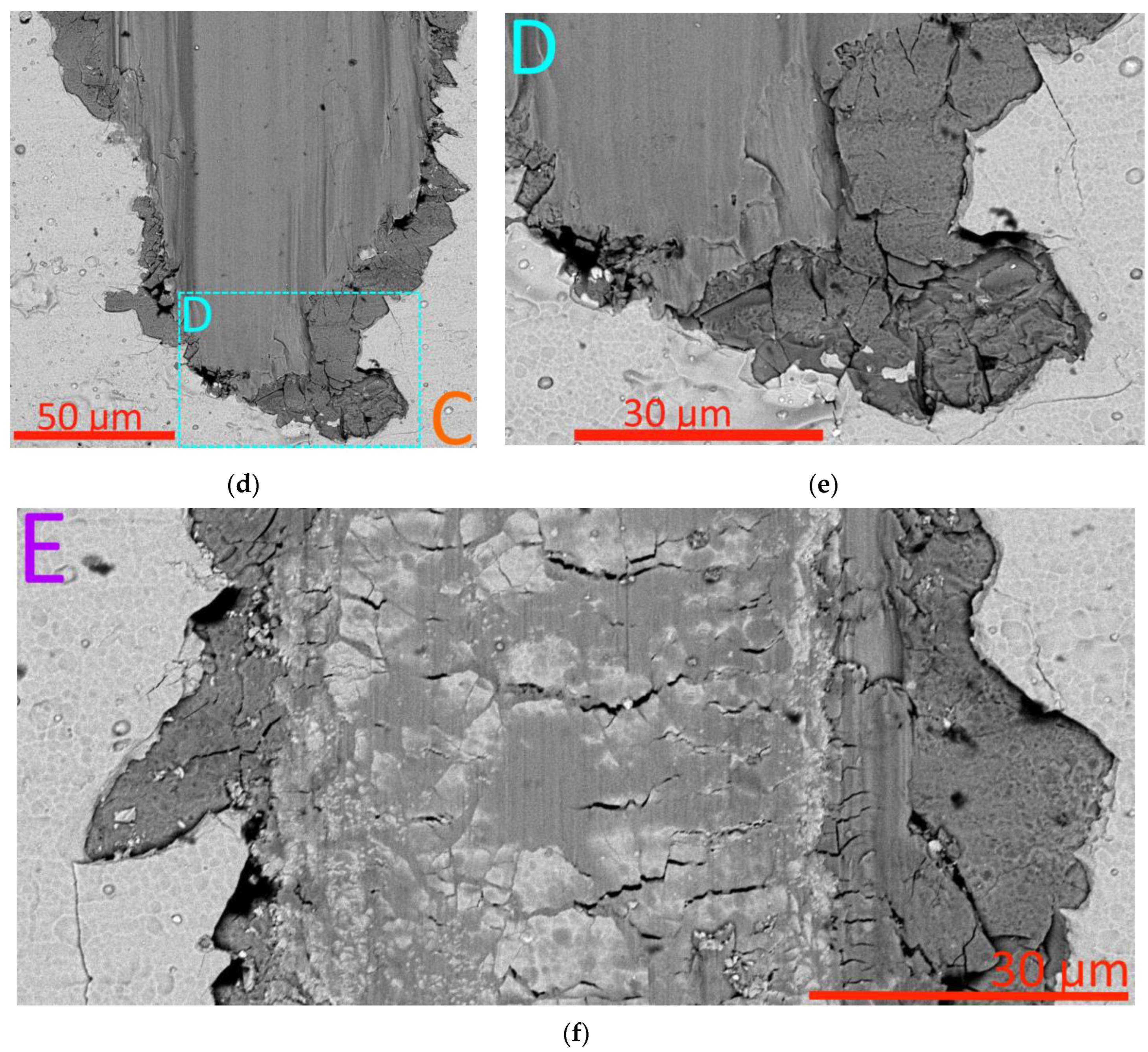

The above assumptions are largely confirmed by examining a cross section taken perpendicular to the scribe groove in the area close to point L

C2 (

Figure 7). In particular, the coating in the area of the bottom of the scribe groove (area D,

Figure 7 (a)) maintains its integrity (despite several transverse cracks). There are no signs of peeling of the coating from the substrate in this area. At the same time, at the boundaries of the groove (areas B and C,

Figure 7(a); figure 7 (b)), peeling of the coating from the substrate is observed, and behind the delamination area there is an area in which the coating is completely absent.

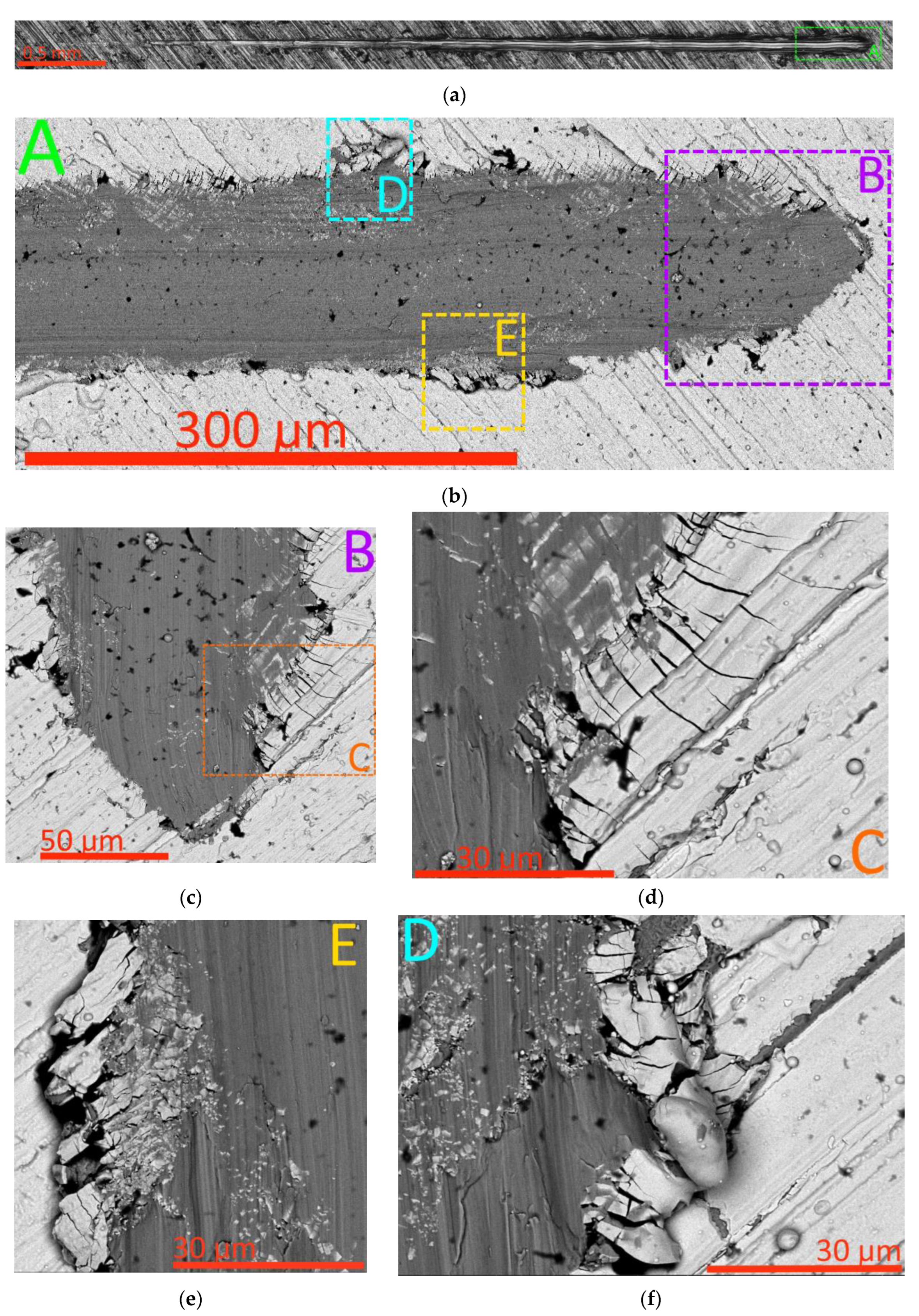

(Zr,Nb)N Coating

The (Zr,Nb)N coating showed a fairly low value of the critical fracture load L

C2. However, the nature of destruction of this coating has significant differences from the previously considered (Zr,Ti)N coating, which also showed rather low resistance to destruction in the scratch test. It is obvious that the (Zr,Nb)N coating has good adhesion strength to the substrate; no noticeable delamination of this coating from the substrate is observed even at extreme loads (

Figure 8). Along the scribing groove, the formation of several cracks is observed, directed at an acute angle to the direction of movement of the indenter. The destroyed fragments of the coating in the scribing furrow are pressed into the substrate material (

Figure 8 (d),(e),(f)).

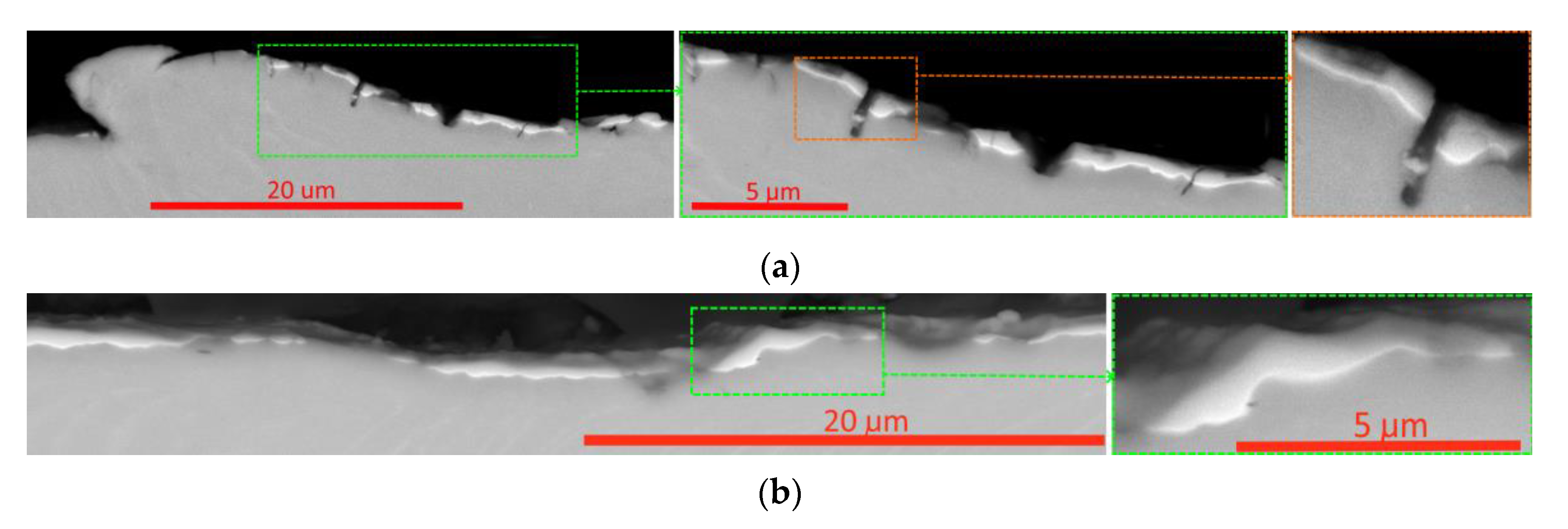

Data on the high strength of adhesive bonds between the coating and the substrate are confirmed when studying a transverse section made perpendicular to the scribing groove (

Figure 9 (a)–(c)). Detachment of the coating from the substrate is not observed even under conditions of extreme plastic deformation. Directly in the scribing furrow, both transverse and longitudinal cracks are formed in the coating structure, as well as cracks of a combined type (

Figure 9 (c),(e)).

(Ti,Zr,Hf)N Coating

Complete destruction of the (Ti,Zr,Hf)N coating (critical load L

C2) is observed already at a load of 12 N. This coating has one of the lowest resistance to destruction among the studied samples. A general view of the ribbing groove and characteristic areas of destruction are shown in

Figure 10. When destroyed, a network of cracks is formed in this coating, and peeling of coating fragments from the substrate is also observed in areas adjacent to the scribing groove (

Figure 10 (d),(e)).

A study of a transverse section passing through a ribbing groove is presented in

Figure 11. In

Figure 11 (a) there is a shaft of plastic deformation of the substrate at the boundary of the scribing groove (left side of the image). The shaft formed as a result of plastic deformation floats onto the coating. On the other (right) side you can see the imprinting of coating fragments into the substrate material. The destruction of the coating occurs both as a result of the formation of cracks (oblique and transverse, see

Figure 11 (b) and (e)) and as a result of detachment from the substrate (

Figure 11 (b),(c),(d)).

(Ti,Zr,Nb)N Coating

The sample with (Ti,Zr,Nb)N coating has the maximum L

C2 value among the studied samples. At the initial stage of coating destruction, cracks begin to form in the scribing groove and at its boundaries (

Figure 12 (b),(c)). At the boundary of the groove, cracks are formed, directed at an acute angle to the direction of movement of the indenter and having a length of 10–15 μm. In the furrow itself, smaller cracks are formed, directed perpendicular to the furrow. In the area of the end of the groove (corresponding to the fracture load L

C2,

Figure 12 (d)–(g)), cracking is also observed, while no significant delamination of the coating from the substrate is observed. It is obvious that this coating has good adhesion to the substrate.

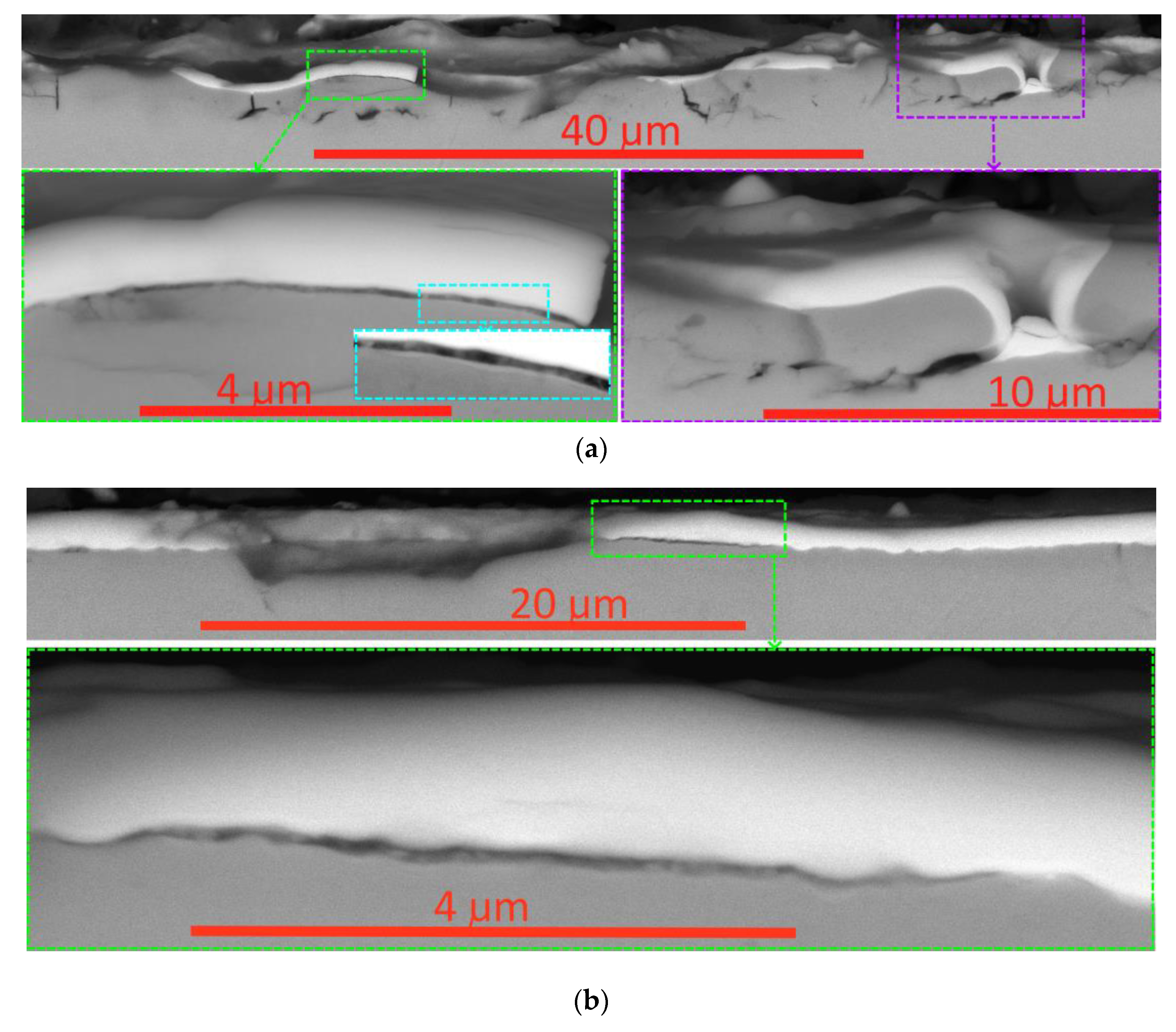

Data on good adhesion to the substrate are also confirmed by the results obtained when studying a transverse section running perpendicular to the scribing groove (

Figure 13). In particular, even under conditions of significant plastic deformation of the substrate, the adhesive bond between the coating and the substrate is maintained (

Figure 13 (a),(b)). In this case, transverse cracks are formed in the coating, passing into the substrate (

Figure 13 (a)).

4. Discussion

Thus, two factors have a key influence on the destruction of the coating: the strength of the coating and the adhesion strength of the coating and the substrate. With different combinations of these factors, four different behaviors of the coating under external influence can be assumed:

low strength and poor adhesion to the substrate (the coating collapses and peels off),

enough strength with poor adhesion to the substrate (the coating peels off),

low strength with enough adhesion to the substrate (the coating is destroyed),

enough strength with enough adhesion to the substrate (the coating can resist destruction for a enough time).

Let us analyze the resistance to destruction and the nature of destruction of all studied coatings (

Table 1). The (Ti,Zr,Nb)N coating has the best resistance to destruction. The (Zr,Hf)N coating, which has the greatest hardness and resistance to destruction, has the problem of poor adhesion to the substrate. In solving this problem, (Zr,Hf)N coating has high application potential.

5. Conclusions

1. The greatest hardness (3100 – 3300 HV) is found in (Zr,Hf)N and (Ti,Zr,Nb)N coatings.

2. A comparison of two coatings, (Ti,Zr,Nb)N and (Zr,Hf)N, which formally have the best resistance to destruction during the scratch test among the samples under study, shows a significant difference in the mechanism of their destruction. The (Zr,Hf)N coating looks more durable, but has worse adhesion to the substrate. As a result, although the coating is retained directly in the scribing groove, a large area of delamination and destruction is formed around the groove.

3. The (Ti,Zr,Nb)N coating, although possibly lower in strength, has a high strength of adhesive bond with the substrate; no noticeable delamination is observed along the groove boundary.

4. The task of further research will be to increase the adhesion of the (Zr,Hf)N coating, which has high strength. Improved adhesion can be achieved by changing the composition of the adhesive sublayer (for example, by using pure Zr or a Zr-Ti mixture).

This section is not mandatory but can be added to the manuscript if the discussion is unusually long or complex.

Author Contributions

Conceptualization, A.M. and A.V; Methodology, A.V., C.S. and N.S.; Resources, S.G.; Data curation, C.S. and K.M.; investigation, C.S., N.S., and K.M.; Writing—original draft preparation, A.V. and C.S.; Writing—review and editing, A.V., C.S., S.G. and A.M.; Project administration, C.S.. All authors have read and agreed to the published version of the manuscript.

Funding

This work is funded by the state assignment of the Ministry of Science and Higher Education of the Russian Federation, project No FSFS-2021-0006.

Data Availability Statement

Not applicable.

Acknowledgments

The study used the equipment from the Center for Collective Use of Moscow State Technological University STANKIN (agreement no. 075-15-2021-695, 26/07/2021).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kaur, M.; Singh, K. Review on titanium and titanium based alloys as biomaterials for orthopaedic applications. Mat Sci Eng C-Mater 2019, 102, 844–862. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.-C.; Chen, L.-Y. A Review on Biomedical Titanium Alloys: Recent Progress and Prospect. Adv Eng Mater 2019, 21(4), 1801215. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Hu, J. Recent advances in the development of aerospace materials. Prog Aerosp Sci 2018, 97, 22–34. [Google Scholar] [CrossRef]

- Nicholson, J.W. Titanium Alloys for Dental Implants: A Review. Prosthesis 2020, 2(2), 100–116. [Google Scholar] [CrossRef]

- Sotova, C.; Yanushevich, O.; Kriheli, N.; Grigoriev, S.; Evdokimov, V.; Kramar, O.; Nozdrina, M.; Peretyagin, N.; Undritsova, N.; Popelyshkin, E.; Peretyagin, P. Dental Implants: Modern Materials and Methods of Their Surface Modification. Materials 2023, 16(23), 7383. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, S.; Qiu, D.; Gibson, M.A.; Dargusch, M.S.; Brandt, M.; Qian, M.; Easton, M. Metal Alloys for Fusion-Based Additive Manufacturing. Adv Eng Mater 2018, 20(5), 1700952. [Google Scholar] [CrossRef]

- Pierce, D.; Haynes, A.; Hughes, J.; Graves, R.; Maziasz, P.; Muralidharan, G.; Shyam, A.; Wang, B.; England, R.; Daniel, C. High temperature materials for heavy duty diesel engines: Historical and future trends. Prog Mater Sci 2019, 103, 109–179. [Google Scholar] [CrossRef]

- Xue, T.; Attarilar, S.; Liu, S.; Liu, J.; Song, X.; Li, L.; Zhao, B.; Tang, Y. Surface modification techniques of titanium and its alloys to functionally optimize their biomedical properties: Thematic review. Front Bioeng Biotechnol 2020, 8, 603072. [Google Scholar] [CrossRef]

- Hanawa, T. Titanium-tissue interface reaction and its control with surface treatment. Front Bioeng Biotechnol 2019, 7, 170. [Google Scholar] [CrossRef]

- Ilyin, A.A.; Kolachev, B.A.; Polkin, I.S. Titanium alloys. Composition, structure, properties: a reference book; Publisher: WILS–MATI, Moscow, Russia, 2009. [Google Scholar]

- Chechulin, B.B.; Ushkov, S.S.; Razuvaev, I.N. Titanium alloys in mechanical engineering; Publisher: Mashinostroenie, Leningrad, USSR, 1977. [Google Scholar]

- Jianxin, D.; Jianhua, L.; Jinlong, Z.; Wenlong, S.; Ming, N. Friction and wear behaviors of the PVD ZrN coated carbide in sliding wear tests and in machining processes. Wear 2008, 264(3–4), 298–307. [Google Scholar] [CrossRef]

- Kuznetsova, T.; Lapitskaya, V.; Warcholinski, B.; Gilewicz, A.; Chizhik, S. Friction and Wear of ZrN Coatings under Conditions of Microcontact Using Atomic-Force Microscopy. J Frict Wear 2020, 41(4), 287–294. [Google Scholar] [CrossRef]

- Azibi, M.; Saoula, N.; Madaoui, N.; Aknouche, H. Effects of Nitrogen Content on the Structural, Mechanical, and Corrosion Properties of ZrN Thin Films Grown on AISI 316L by Radiofrequency Magnetron Sputtering. Cryst Res Technol 2021, 56(12), 2100096. [Google Scholar] [CrossRef]

- Wang, S.-S.; Xia, Y.; Zhang, L.-B.; Guang, H.-B.; Shen, M.; Zhang, F.-M. Effect of NbN and ZrN films formed by magnetron sputtering on Ti and porcelain bonding. Surf Coat Technol 2010, 205(7), 1886–1891. [Google Scholar] [CrossRef]

- Zambrano, D.F.; Hernández-Bravo, R.; Ruden, A.; Espinosa-Arbelaez, D.G.; González-Carmona, J.M.; Mujica, V. Mechanical, tribological and electrochemical behavior of Zr-based ceramic thin films for dental implants. Ceram Int 2023, 49(2), 2102–2114. [Google Scholar] [CrossRef]

- Musil, J.; Zenkin, S.; Kos, Š.; Čerstvý, R.; Haviar, S. Flexible hydrophobic ZrN nitride films. Vacuum 2016, 131, 34–38. [Google Scholar] [CrossRef]

- Huang, J.-H.; Chen, Y.-H.; Wang, A.-N.; Yu, G.-P.; Chen, H. Evaluation of fracture toughness of ZrN hard coatings by internal energy induced cracking method. Surf Coat Technol 2014, 258, 211–218. [Google Scholar] [CrossRef]

- Zhu, F.; Zhu, K.; Hu, Y.; Ling, Y.; Wang, D.; Peng, H.; Xie, Z.; Yang, R.; Zhang, Z. Microstructure and Young's modulus of ZrN thin film prepared by dual ion beam sputtering deposition. Surf Coat Technol 2019, 374, 997–1005. [Google Scholar] [CrossRef]

- Cai, F.; Zhou, Q.; Chen, J.; Zhang, S. Effect of inserting the Zr layers on the tribo-corrosion behavior of Zr/ZrN multilayer coatings on titanium alloys. Corros Sci 2023, 213, 111002. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, N.; Kuppusami, P.; Prasanthi, T.N.; Chandramohan, P.; Dash, S.; Srinivasan, M.P.; Mohandas, E.; Tyagi, A.K. Tribological properties of sputter deposited ZrN coatings on titanium modified austenitic stainless steel. Wear 2012, 280–281, 22–27. [Google Scholar] [CrossRef]

- Huang, J.-H.; Kuo, K.-L.; Yu, G.-P. Oxidation behavior and corrosion resistance of vacuum annealed ZrN-coated stainless steel. Surf Coat Technol 2019, 358, 308–319. [Google Scholar] [CrossRef]

- Ramoul, C.; Beliardouh, N.E.; Bahi, R.; Nouveau, C.; Djahoudi, A.; Walock, M.J. Surface performances of PVD ZrN coatings in biological environments. Tribol – Mater, Surf Interfaces 2019, 13, 12–19. [Google Scholar] [CrossRef]

- Corona-Gomez, J.; Sandhi, K.K.; Yang, Q. Wear and corrosion behaviour of nanocrystalline TaN, ZrN, and TaZrN coatings deposited on biomedical grade CoCrMo alloy. J Mech Behav Biomed Mater 2022, 130, 105228. [Google Scholar] [CrossRef]

- Tarek, A.H.J.; Lai, C.W.; Razak, B.A.; Wong, Y.H. Physical Vapour Deposition of Zr-Based Nano Films on Various Substrates: A Review. Curr Nanosci 2022, 18(3), 347–366. [Google Scholar] [CrossRef]

- Ul-Hamid, A. Microstructure, properties and applications of Zr-carbide, Zr-nitride and Zr-carbonitride coatings: A review. Mater Adv 2020, 1(5), 1012–1037. [Google Scholar] [CrossRef]

- Yu, S.; Zeng, Q.; Oganov, A.R.; Frapper, G.; Huang, B.; Niu, H.; Zhang, L. First-principles study of Zr–N crystalline phases: phase stability, electronic and mechanical properties. RSC Adv 2017, 7, 4697–4703. [Google Scholar] [CrossRef]

- Kakanakov, R.; Bahchedjiev, Hr.; Kolaklieva, L.; Cholakova, T.; Evtimova, Sv.; Polyhroniadis, E.; Pavlidou, E.; Tsiaoussis, I. Investigation of ZrN hard coatings obtained by cathodic arc evaporation. Solid State Phenom 2010, 159, 113–116. [Google Scholar] [CrossRef]

- Arias, D.F.; Arango, Y.C.; Devia, A. Study of TiN and ZrN thin films grown by cathodic arc technique. Appl Surf Sci 2006, 253(4), 1683–1690. [Google Scholar] [CrossRef]

- Yin, L.-C.; Saito, R. First principles calculations of the electronic structure of ZrN allotropes. J Phys Soc Jpn 2011, 80, 114707. [Google Scholar] [CrossRef]

- Kuznetsova, T.; Lapitskaya, V.; Khabarava, A.; Chizhik, S.; Warcholinski, B.; Gilewicz, A. The influence of nitrogen on the morphology of ZrN coatings deposited by magnetron sputtering. Appl Surf Sci 2020, 522, 146508. [Google Scholar] [CrossRef]

- Singh, A.; Kuppusami, P.; Khan, S.; Sudha, C.; Thirumurugesan, R.; Ramaseshan, R.; Divakar, R.; Mohandas, E.; Dash, S. Influence of nitrogen flow rate on microstructural and nanomechanical properties of Zr-N thin films prepared by pulsed DC magnetron sputtering. Appl Surf Sci 2013, 280, 117–123. [Google Scholar] [CrossRef]

- Saleh, A.S. Study of deposition temperature effect on defect density in ZrN thin films by positron annihilation. Procedia Engineering 2014, 75, 34–38. [Google Scholar] [CrossRef]

- Roman, D.; Bernardi, J.; de Amorim, C.L.; de Souza, F.S.; Spinelli, A.; Giacomelli, C.; Figueroa, C.A.; Baumvol, I.J.; Basso, R.L. Effect of deposition temperature on microstructure and corrosion resistance of ZrN thin films deposited by DC reactive magnetron sputtering. Mater Chem Phys 2011, 130, 147–153. [Google Scholar] [CrossRef]

- Fernandez, D.A.R.; Brito, B.S.S.; Santos, I.A.D.; Soares, V.F.D.; Terto, A.R.; de Oliveira, G.B.; Hubler, R.; Batista, W.W.; Tentardini, E.K. Effect of hafnium contaminant present in zirconium targets on sputter deposited ZrN thin films. Nucl Instrum Methods Phys Res B 2020, 462, 90–94. [Google Scholar] [CrossRef]

- Atar, E.; Sarioglu, C.; Cimenoglu, H.; Kayali, E.S. Residual stresses in (Zr,Hf)N films (up to 11.9 at.% Hf) measured by X-ray diffraction using experimentally calculated XECs. Surf Coat Technol 2005, 191, 188–194. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. Sliding wear behaviour of ZrN and (Zr, 12 wt% Hf)N coatings. Tribol Int 2006, 39(4), 297–302. [Google Scholar] [CrossRef]

- Wu, Z.T.; Qi, Z.B.; Jiang, W.F.; Wang, Z.C.; Liu, B. Influence of niobium addition on microstructure, mechanical properties and oxidation resistance of ZrN coatings. Thin Solid Films 2014, 570(PB), 256–261. [Google Scholar] [CrossRef]

- Kanoun, M.B.; Goumri-Said, S. Effect of alloying on elastic properties of ZrN based transition metal nitride alloys. Surf Coat Technol 2014, 255, 140–145. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. Reciprocating wear behaviour of (Zr, Hf) N coatings. Wear 2004, 257, 633–639. [Google Scholar] [CrossRef]

- Wu, Z.T.; Qi, Z.B.; Zhang, D.F.; Wang, Z.C. Microstructure, mechanical properties and oxidation resistance of (Zr, Hf)Nx coatings by magnetron co-sputtering. Surf Coat Technol 2015, 276, 219–227. [Google Scholar] [CrossRef]

- Atar, E.; Kayali, E.S.; Cimenoglu, H. The effect of oxidation on the structure and hardness of (Zr, Hf) N coatings. Defect Diffus Forum 2010, 297–301, 1395–1399. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Uglov, V.; Milovich, F.; Tabakov, V.; Cherenda, N.; Andreev, N.; Migranov, M. Influence of the tribological properties of the Zr,Hf-(Zr,Hf)N-(Zr,Me,Hf,Al)N coatings (where Me is Mo, Ti, or Cr) with a nanostructured wear-resistant layer on their wear pattern during turning of steel. Wear 2023, 518–519, 204624. [Google Scholar] [CrossRef]

- Volkhonskii, A.O.; Vereshchaka, A.A.; Blinkov, I.V.; Vereshchaka, A.S.; Batako, A.D. Filtered cathodic vacuum Arc deposition of nano-layered composite coatings for machining hard-to-cut materials. Int J Adv Manuf Technol 2016, 84, 1647–1660. [Google Scholar] [CrossRef]

- Krysina, O.V.; Ivanov, Y.F.; Prokopenko, N.A.; Shugurov, V.V.; Petrikova, E.A.; Denisova, Y.A.; Tolkachev, O.S. Influence of Nb addition on the structure, composition and properties of single-layered ZrN-based coatings obtained by vacuum-arc deposition method. Surf Coat Technol 2020, 387, 125555. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Migranov, M.; Andreev, N.; Bublikov, J.; Sitnikov, N.; Oganyan, G. Investigation of the tribological properties of Ti-TiN-(Ti,Al,Nb,Zr)N composite coating and its efficiency in increasing wear resistance of metal cutting tools. Tribol Int 2021, 164, 107236. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Kutina, N. Investigation of the properties of the Cr,Mo-(Cr,Mo,Zr,Nb)N-(Cr,Mo,Zr,Nb,Al)N multilayer composite multicomponent coating with nanostructured wear-resistant layer. Wear 2021, 468–469, 203597. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Tabakov, V.; Sitnikov, N.; Andreev, N.; Sviridova, T.; Bublikov, J. Investigation of multicomponent nanolayer coatings based on nitrides of Cr, Mo, Zr, Nb, and Al. Surf Coat Technol 2020, 401, 126258. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, N.; Li, D.J.; Dong, L.; Gu, H.Q.; Wan, R.X.; Sun, X. The synthesis of Zr-Nb-N nanocomposite coating prepared by multi-target magnetron co-sputtering. Nucl Instrum Methods Phys Res B 2013, 307, 119–122. [Google Scholar] [CrossRef]

- Hodak, S.K.; Seppänen, T.; Tungasmita, S. Growth of (Zr,Ti)N thin films by ion-assisted dual D.C. reactive magnetron sputtering. Solid State Phenom 2008, 136, 133–138. [Google Scholar] [CrossRef]

- Yan, P.; Deng, J.; Wu, Z.; Li, S.; Xing, Y.; Zhao, J. Friction and wear behavior of the PVD (Zr, Ti) N coated cemented carbide against 40Cr hardened steel. Int J Refract Hard Met 2012, 35, 213–220. [Google Scholar] [CrossRef]

- Yan, P.; Deng, J.; Rong, Y. Performance of PVD (Zr,Ti)N-coated cemented carbide inserts in cutting processes. Int J Adv Manuf Technol 2014, 73, 1363–1371. [Google Scholar] [CrossRef]

- Wang, D.-Y.; Chang, C.-L.; Hsu, C.-H.; Lin, H.-N. Synthesis of (Ti,Zr)N hard coatings by unbalanced magnetron sputtering. Surf Coat Technol 2000, 130, 64–68. [Google Scholar] [CrossRef]

- Knotek, O.; Barimani, A. On spinodal decomposition in magnetron-sputtered (Ti,Zr) nitride and carbide thin films. Thin Solid Films 1989, 174, 51–56. [Google Scholar] [CrossRef]

- El-Hossary, F.M.; El-Rahman, A.M.A.; Raaif, M.; Qu, S.; Zhao, J.; Maitz, M.F.; El-Kassem, M.A. Effect of DC-pulsed magnetron sputtering power on structural, tribological and biocompatibility of Ti–Zr–N thin film. Appl Phys A 2018, 124(1), 42. [Google Scholar] [CrossRef]

- Zhang, W.-Q.; Hu, S.-Q.; Li, F.; Du, S.-B. Ettect of sputtering parameters on corrosion resistance of (Zr,Ti)N composite film. Corros Prot 2008, 29(8), 464–466. [Google Scholar]

- Lin, M.T.; Wan, C.H.; Wu, W. Comparison of corrosion behaviors between SS304 and Ti substrate coated with (Ti,Zr)N thin films as Metal bipolar plate for unitized regenerative fuel cell. Thin Solid Films 2013, 544, 162–169. [Google Scholar] [CrossRef]

- Niu, E.W.; Li, L.; Lv, G.H.; Chen, H.; Li, X.Z.; Yang, X.Z.; Yang, S.Z. Characterization of Ti-Zr-N films deposited by cathodic vacuum arc with different substrate bias. Appl Surf Sci 2008, 254(13), 3909–3914. [Google Scholar] [CrossRef]

- Jeon, S.; Ha, J.; Choi, Y.; Jo, I.; Lee, H. Interfacial stability and diffusion barrier ability of Ti1-xZrxN coatings by pulsed laser thermal shock. Appl Surf Sci 2014, 320, 602–608. [Google Scholar] [CrossRef]

- Uglov, V.V.; Anishchik, V.M.; Khodasevich, V.V.; Prikhodko, Zh.L.; Zlotski, S.V.; Abadias, G.; Dub, S.N. Structural characterization and mechanical properties of Ti-Zr-N coatings, deposited by vacuum arc. Surf Coat Technol 2004, 180–181, 519–525. [Google Scholar] [CrossRef]

- Uglov, V.V.; Anishchik, V.M.; Zlotski, S.V.; Abadias, G.; Dub, S.N. Structural and mechanical stability upon annealing of arc-deposited Ti-Zr-N coatings. Surf Coat Technol 2008, 202(11), 2394–2398. [Google Scholar] [CrossRef]

- Huang, J.-H.; Ting, I.-S.; Zheng, T.-W. Evaluation of stress and energy relief efficiency of ZrN/Ti and ZrN/Zr. Surf Coat Technol 2022, 434, 128224. [Google Scholar] [CrossRef]

- Kuznetsova, T.A.; Andreev, M.A.; Markova, L.V. Research of wear resistance of the combined vacuum electroarc coatings on the basis of ZrHf. Trenie i Iznos 2005, 26(5), 521–529. [Google Scholar]

- Vereschaka, A.; Milovich, F.; Andreev, N.; Seleznev, A.; Alexandrov, I.; Muranov, A.; Mikhailov, M.; Tatarkanov, A. Comparison of properties of ZrHf-(Zr,Hf)N-(Zr,Hf,Cr,Mo,Al)N and Ti-TiN-(Ti,Cr,Al)N nanostructured multilayer coatings and cutting properties of tools with these coatings during turning of nickel alloy. J Manuf Process 2023, 88, 184–201. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Migranov, M.S.; Mosyanov, M.; Gusev, A.; Okunkova, A.A. The Effectiveness of Diamond-like Carbon a-C:H:Si Coatings in Increasing the Cutting Capability of Radius End Mills When Machining Heat-Resistant Nickel Alloys. Coatings 2022, 12, 206. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Seleznev, A.; Sotova, C.; Bublikov, J. Influence of the yttrium cathode arc current on the yttrium content in the (Ti, Y, Al) N coating and the coating properties. Vacuum 2024, 222, 113028. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Vereschaka, A.A.; Sitnikov, N.N.; Milovich, F. Properties of (Cr,Al,Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate. Ceram. Int. 2020, 46, 18241–18255. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Bublikov, J. Investigation of wear mechanisms for the rake face of a cutting tool with a multilayer composite nanostructured Cr–CrN-(Ti,Cr,Al,Si)N coating in high-speed steel turning. Wear 2019, 438–439, 203069. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Fedorov, S.V.; Okunkova, A.A.; Pivkin, P.M.; Peretyagin, P.Y.; Ershov, A. Development of DLC-Coated Solid SiAlON/TiN Ceramic End Mills for Nickel Alloy Machining: Problems and Prospects. Coatings 2021, 11, 532. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Volosova, M.A.; Batako, A.; Vereschaka, A.A.; Sitnikov, N.N.; Seleznev, A.E. Nano-scale multi-layered coatings for improved efficiency of ceramic cutting tools. Int J Adv Manuf Technol 2017, 90, 27–43. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Sotova, C.; Kutina, N. Investigation of the influence of the thickness of nanolayers in wear-resistant layers of Ti-TiN-(Ti,Cr,Al)N coating on destruction in the cutting and wear of carbide cutting tools. Surf Coat Technol 2020, 385, 125402. [Google Scholar] [CrossRef]

- Grigoriev, S.; Volosova, M.; Fyodorov, S.; Lyakhovetskiy, M.; Seleznev, A. DLC-coating application to improve the durability of ceramic tools. J. Mater. Eng. Perform. 2019, 28, 4415–4426. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Sotova, C. Investigation of the influence of the features of the deposition process on the structural features of microparticles in PVD coatings. Vacuum 2022, 202, 111144. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Mustafaev, E. Specific features of the structure and properties of arc-PVD coatings depending on the spatial arrangement of the sample in the chamber. Vacuum 2022, 200, 111047. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Bublikov, J.; Seleznev, A.; Sotova, C. Crack formation and oxidation wear in (Cr,Y,Al)N and (Mo,Y,Al)N nanolayer coatings with high content of yttrium. Wear 2023, 528–529, 204989. [Google Scholar] [CrossRef]

- ASTM C1624-22(2022) Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing. Available online: URL https://www.astm.org/c1624-22.html (accessed on 22 June 2024).

Figure 1.

Results of determining the values of critical points of destruction of coatings LC1 and LC2 using the scratch test method.

Figure 1.

Results of determining the values of critical points of destruction of coatings LC1 and LC2 using the scratch test method.

Figure 2.

Destruction of the ZrN coating during the scratch test: (a) general view of the scribing groove, (b) Area of complete destruction of the coating (point LC2), (c) destruction of the coating in the area of the end of the groove (area B), (d) area of destruction of the coating C, (e) area of destruction of the coating D.

Figure 2.

Destruction of the ZrN coating during the scratch test: (a) general view of the scribing groove, (b) Area of complete destruction of the coating (point LC2), (c) destruction of the coating in the area of the end of the groove (area B), (d) area of destruction of the coating C, (e) area of destruction of the coating D.

Figure 3.

Study of the nature of destruction of the ZrN coating during a scratch test on a transverse section in the area close to point LC2: (a) general view of a cross-section through a scribing groove, (b) peeling of a coating fragment under the influence of shear stresses, (c) pressing of coating fragments into the substrate in a scribing groove and destruction of the coating in the area adjacent to the groove, (d) preservation of the adhesive bond between the coating and the substrate with noticeable plastic deformation, (e,f) peeling of the coating from the substrate with chipping of nanofragments of the coating in the area of the interface with the substrate.

Figure 3.

Study of the nature of destruction of the ZrN coating during a scratch test on a transverse section in the area close to point LC2: (a) general view of a cross-section through a scribing groove, (b) peeling of a coating fragment under the influence of shear stresses, (c) pressing of coating fragments into the substrate in a scribing groove and destruction of the coating in the area adjacent to the groove, (d) preservation of the adhesive bond between the coating and the substrate with noticeable plastic deformation, (e,f) peeling of the coating from the substrate with chipping of nanofragments of the coating in the area of the interface with the substrate.

Figure 4.

Destruction of the (Zr,Ti)N coating during the scratch test: (a) general view of the scribing furrow, (b) area of the beginning of coating destruction (point LC1), (c) area of complete coating destruction (point LC2), (d,e) coating destruction in the area of the end of the groove (area B), (f) area where the coating begins to fail.

Figure 4.

Destruction of the (Zr,Ti)N coating during the scratch test: (a) general view of the scribing furrow, (b) area of the beginning of coating destruction (point LC1), (c) area of complete coating destruction (point LC2), (d,e) coating destruction in the area of the end of the groove (area B), (f) area where the coating begins to fail.

Figure 5.

Study of the nature of destruction of the (Zr,Ti)N coating during a scratch test on a transverse section in the area close to point LC2: (a,b) destruction of the coating due to the destruction of the adhesive bond between the coating and the substrate.

Figure 5.

Study of the nature of destruction of the (Zr,Ti)N coating during a scratch test on a transverse section in the area close to point LC2: (a,b) destruction of the coating due to the destruction of the adhesive bond between the coating and the substrate.

Figure 6.

Destruction of the (Zr,Hf)N coating during the scratch test: (a) general view of the scribing furrow, (b) the initial area of furrow formation, cracking of the coating, (c) the beginning of the destruction of the coating (point LC2), (d) the area of complete destruction of the coating (point LC2) (e) the nature of the destruction of the coating in the end area scribing grooves, (f) delamination formation scheme, in which the coating is treated as an elastic beam.

Figure 6.

Destruction of the (Zr,Hf)N coating during the scratch test: (a) general view of the scribing furrow, (b) the initial area of furrow formation, cracking of the coating, (c) the beginning of the destruction of the coating (point LC2), (d) the area of complete destruction of the coating (point LC2) (e) the nature of the destruction of the coating in the end area scribing grooves, (f) delamination formation scheme, in which the coating is treated as an elastic beam.

Figure 7.

Study of the nature of destruction of the (Zr,Hf)N coating during a scratch test on a transverse section in the area close to point LC2: (a) formation of through transverse cracks in the coating structure, (b) peeling of the coating from the substrate in the area adjacent to the scribing groove.

Figure 7.

Study of the nature of destruction of the (Zr,Hf)N coating during a scratch test on a transverse section in the area close to point LC2: (a) formation of through transverse cracks in the coating structure, (b) peeling of the coating from the substrate in the area adjacent to the scribing groove.

Figure 8.

Destruction of the (Zr,Nb)N coating during the scratch test: (a) general view of the scribing furrow, (b) Area of complete destruction of the coating (point LC2), (c) end of the scribing furrow, (d,e,f) destruction of the coating in the area of the end of the furrow.

Figure 8.

Destruction of the (Zr,Nb)N coating during the scratch test: (a) general view of the scribing furrow, (b) Area of complete destruction of the coating (point LC2), (c) end of the scribing furrow, (d,e,f) destruction of the coating in the area of the end of the furrow.

Figure 9.

Study of the nature of destruction of the (Zr,Nb)N coating during a scratch test on a transverse section in the area close to the point LC2: (a,b) strong adhesion to the substrate is maintained under significant plastic deformations of the substrate, (c,d) nature of crack formation in coating.

Figure 9.

Study of the nature of destruction of the (Zr,Nb)N coating during a scratch test on a transverse section in the area close to the point LC2: (a,b) strong adhesion to the substrate is maintained under significant plastic deformations of the substrate, (c,d) nature of crack formation in coating.

Figure 10.

Destruction of the (Ti,Zr,Hf)N coating during the scratch test: (a) general view of the scribing groove, (b) area of complete destruction of the coating (point LC2), (c) destruction of the coating in the area of the end of the groove (area B), (d) area of destruction of the coating C, (e) area of destruction of the coating D.

Figure 10.

Destruction of the (Ti,Zr,Hf)N coating during the scratch test: (a) general view of the scribing groove, (b) area of complete destruction of the coating (point LC2), (c) destruction of the coating in the area of the end of the groove (area B), (d) area of destruction of the coating C, (e) area of destruction of the coating D.

Figure 11.

Study of the nature of destruction of the (Ti,Zr,Hf)N coating during a scratch test on a transverse section in the area close to point LC1: (a) general view of a transverse section through the scribing groove, (b) a plastic deformation shaft at the boundary of the scribing groove, (c,d,e) the nature of the coating destruction – cracking and peeling from the substrate, (f) plastic deformation and cracking in the coating in the scribing groove.

Figure 11.

Study of the nature of destruction of the (Ti,Zr,Hf)N coating during a scratch test on a transverse section in the area close to point LC1: (a) general view of a transverse section through the scribing groove, (b) a plastic deformation shaft at the boundary of the scribing groove, (c,d,e) the nature of the coating destruction – cracking and peeling from the substrate, (f) plastic deformation and cracking in the coating in the scribing groove.

Figure 12.

Destruction of the (Ti,Zr,Nb)N coating during the scratch test: (a) general view of the scribing groove, (b,c) the area where cracking begins in the coating, (d) area of complete destruction of the coating, (e) failure of the coating at the end of the furrow (area B), (f) failure area of coating E, (g) area of failure of coating F.

Figure 12.

Destruction of the (Ti,Zr,Nb)N coating during the scratch test: (a) general view of the scribing groove, (b,c) the area where cracking begins in the coating, (d) area of complete destruction of the coating, (e) failure of the coating at the end of the furrow (area B), (f) failure area of coating E, (g) area of failure of coating F.

Figure 13.

Study of the nature of destruction of the (Ti,Zr,Nb)N coating during a scratch test on a transverse section in the area close to point LC2: (a) the adhesive bond between the coating and the substrate is maintained even with significant plastic deformations in the substrate and the formation of transverse cracks, (b) preservation of the adhesion of the coating and the substrate under conditions of plastic deformation.

Figure 13.

Study of the nature of destruction of the (Ti,Zr,Nb)N coating during a scratch test on a transverse section in the area close to point LC2: (a) the adhesive bond between the coating and the substrate is maintained even with significant plastic deformations in the substrate and the formation of transverse cracks, (b) preservation of the adhesion of the coating and the substrate under conditions of plastic deformation.

Table 1.

Assessment of the strength of coatings to fracture during scratch testing.

Table 1.

Assessment of the strength of coatings to fracture during scratch testing.

| Coating strength |

Adhesion strength to substrate |

Nature of destruction |

Coating |

| Low |

Low |

Destruction of the coating in the furrow, detachment from the substrate along the edges of the furrow |

ZrN

(Ti,Zr,Hf)N |

| Low |

High |

Destruction of the coating in the furrow, without noticeable detachment from the substrate along the edges of the furrow |

(Zr,Nb)N |

| High |

Low |

The coating remains in the furrow but flakes off and breaks down along the edges of the furrow |

(Zr,Ti)N

(Zr,Hf)N |

| High |

High |

The coating remains in the furrow and is slightly destroyed along the edges of the furrow |

(Ti,Zr,Nb)N |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).