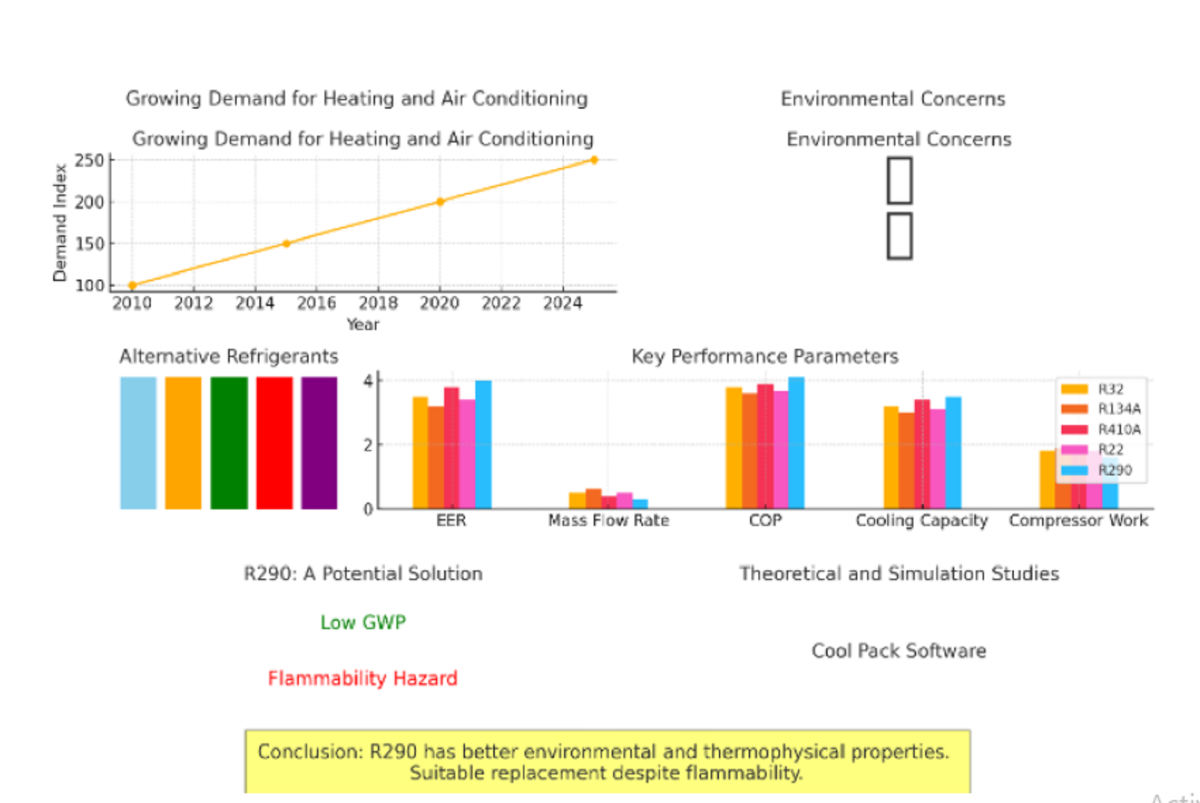

1. Introduction

As the need for heating, ventilation, and air conditioning (HVAC) continues to expand to improve human comfort, air conditioning (AC) and heat pump technology has become mature and widely available solutions for sustaining suitable indoor settings in fluctuating ambient temperature conditions. A detailed study on the performance analysis of a solar milk refrigerator using R290 refrigerant was carried out by Shailendra Kasera et al. [

1]. For 14 kg of milk, they talked about performance metrics including Solar Coefficient of Performance, Coefficient of Performance (COP), and Cooling Capacity. According to the study, when temperature rises, cooling capability falls and electricity consumption rises in tandem. As would be expected, COP falls as temperature rises, from 0.61 to 0.23. The milk refrigerator is made to meet needs for both heating and cooling.

Wichakan Ketwong et al. [

2] investigated to increasing the Energy Efficiency Ratio (EER) and the possibility of Direct Evaporative Cooling (DEC) to generate cool air for space cooling and condenser cooling of air conditioners. The Key research demonstrated that DEC is more effective in wet climates and air cooling in hot region. It has been observed that after the experiment lowering the mass ratio of feed water to circulating air when the feed water temperature exceeded the wet-bulb air temperature and to reduce the ambient air temperature.

An investigation on the R32/R290 refrigerant mixture (67%/33% by weight) as a drop-in substitute for R410A in residential air conditioners was carried out by Tian Q et al. [

3]. They conducted theoretical and experimental studies on the performance of air conditioning system which employing both R290/R32 and R410A, with a Global Warming Potential (GWP) of just 22% of R410A. According to experimental results, heating and cooling capacities increased by 15.0% to 24.7% while refrigerant charge amount decreased by 30.0% to 35.0%. The theoretical simulation and performance assessment of R290, R744 and their mixture commonly employed in the auto-cascade refrigeration cycle were covered by Li Zhang et al. [

4] in their study work. The findings suggest that R290 and R744 have potential as refrigerants. However, because of its high pressure and low temperature, R744 has very high equipment requirements, especially in terms of tightness and pressure bearing capability.

According to Kashif Nawaz et al. [

5]’s study report, natural refrigerants propane and ammonia have the potential to replace R134a and R410A refrigerants in heat pump applications. Ammonia trumps the other refrigerants in terms of least irreversibility when used in the simplest setup. Overall, propane and ammonia are effective replacements for R134a and R410A refrigerants. Lucia U et al. [

6] discuss various Ground Source Heat Pump (GSHP) systems, their thermodynamic analysis, and the application of the entropy generation approach to GSHP. GSHP technologies are rapidly being validated. Their Coefficient of Performance (COP) usually falls in the range of 3–3.8. The seasonal average exergy efficiency of GSHP has been calculated at around 70%, suggesting significant optimization potential. Moreover, entropy generation optimization can reduce the installation costs of the system by 6.5%.

Byrne P et al. [

7] investigated that using the same electric energy to create hot and chilled water a heat pump for simultaneous heating and cooling could minimize operating costs and greenhouse gas emissions. By switching during the defrosting sequences, between an air and water evaporator, the heating and cooling machine can reduce the performance loss of air-to-water heat pumps in low ambient temperatures. It improves heating efficiency and enables the air evaporator without interrupting the heat output. Colder climates benefited more from the winter alternating sequence of performance improvement and defrosting. In such instances, the HPS overtook the traditional reversible air-to-water heat pump by 20% in terms of COP. Byrne P et al. [

8] focused on heat pumps for heating and cooling that use CO2 as a refrigerant, emphasizing the continuing improvement of present heat pump technology, which has a little reduced impact on global warming. However, HFC heat pumps for space cooling and heating are still more efficient and cost-effective in terms of energy usage.

Shin D. U et al. [

9] conducted a study with thermal storage tanks on a simultaneous cooling and heating system, taking into account energy-saving potential derived from various operation modes with a heat pump system. The findings suggest that using a radiant cooling and heating system with thermal storage tanks as a terminal system for the simultaneous cooling and heating system can reduce heat loss during the heat transportation period. This enables for the implementation of a low-lifting heat pump, permitting the generation of equivalent cooling and heating energy while also enhancing the efficiency of the heat source device itself. R P Dhivakar et al. [

10] tested a traditional VCRS-based Air Condition Test Rig with several refrigerants including R410a, R134a, R22 and R290. R22 was found to function better than the other refrigerants tested in the study. However, due to its high Global Warming Potential (GWP) and Ozone Depletion Potential (ODP), R22 has a deleterious influence on the environment. R290, on the other hand, has zero GWP and ODP qualities, resulting in reduced power consumption and environmental benefits.

Zhennan Zhu et al. [

11] studied the economic, thermal, and environmental performance of a refrigeration system equipped with a variable displacement compressor containing R1234yf, R152a, and R134a. Their experiments demonstrated that conventional refrigerators and those equipped with a variable displacement compressor had a considerable benefit in terms of energy savings, cost reduction, and CO2 emissions reduction by reducing the stroke at part load. For example, changing the stroke of a refrigerator employing a variable displacement compressor with R134a from 13 mm to 10 mm reduces power consumption, total cost, and life cycle CO2 emissions by 86.3%, 56.7%, and 59.9%, respectively. Running costs account for 88% of the overall economic cost of operating a refrigerator with a variable displacement compressor over its lifetime, and indirect emissions account for the majority of these refrigerators’ life cycle CO2.

Pavel Makhnatcha et al. [

12] presented Lifetime Climate Change Performance (LCCP), a comprehensive methodology for quantifying the refrigerant’s effect on overall system emissions over its lifetime. However, in fact, the LCCP is more complex than TEWI (Total Equivalent Warming Impact), and the impact of newly accounted emissions is small. TEWI is sensitive to the energy performance of a system. Thus, the refrigeration system’s efficiency, as proved for each refrigerant candidate, is the most essential parameter when calculating a system’s environmental impact. Other characteristics, when adjusted within tolerable limitations, have a less substantial impact on the comparative study of refrigerant choices based on TEWI. According to the current study, the environmental benefits of refrigerants R152a, R290, and R1270 in heat pumps are all comparable. Despite the fact that many refrigerants are utilized for heat pump air conditioning, they are typically used independently for heating and cooling, with only R32 refrigerant now used for both applications. A comparison of several refrigerants, such as R32, R134A, R410A, R22, and R290, has not yet been conducted.

After optimizing R290 for parameters such as refrigerant mass flow rate, LCCP, TEWI, COPh, COPC, atmospheric lifespan, Global Warming Potential, Ozone Depletion Potential, and power consumption in comparison to R32, R134A, R410A, and R22 refrigerants under nominal conditions and integrated part load values (IPLV), experimental measurements of the R290 heat pump were performed and compared. Furthermore, comparison tests between heat pumps using all of the aforementioned refrigerants were performed using Ph charts and validated with the CoolPack Software. These findings can provide useful information for the research and development of R290 air-source heat pump systems in both cold and hot climates.

2. Methodology

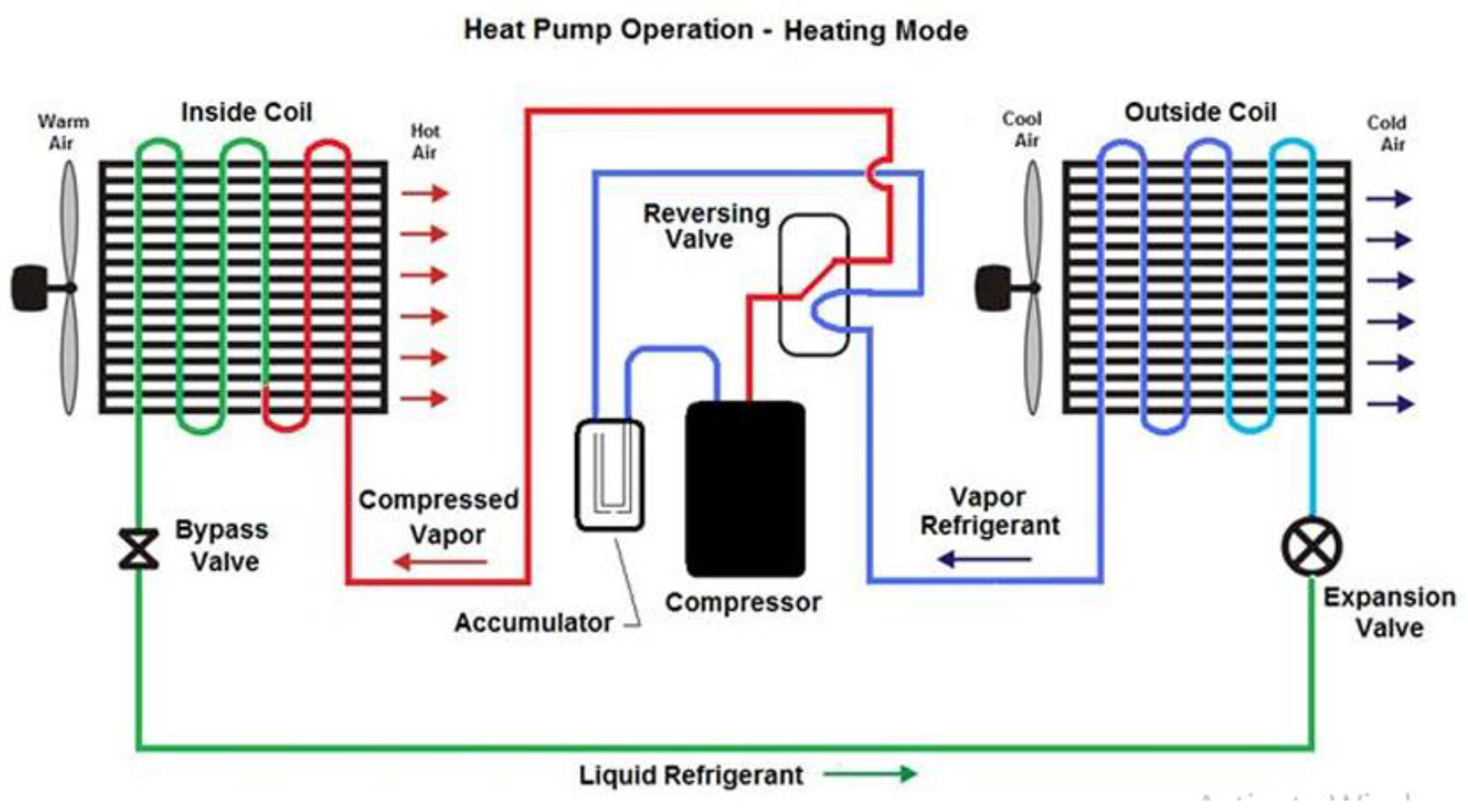

Heat pumps provide similar functions like an air conditioning system in terms of refrigerant condensing in the condenser and boiling in the evaporator, pressure increase and drop, and refrigerant flow throughout the system. It is easier to distinguish between the coils as the “inside coil” and the “outside coil” rather than the condenser coil and the evaporator coil, because their duties vary from heating to cooling utilizing a 4-way Reversing Valve. A volatile liquid known as the operational fluid or refrigerant travels throughout the system. [

13]

Figure 1.

Heat pump air conditioning system in the heating mode [

13].

Figure 1.

Heat pump air conditioning system in the heating mode [

13].

Initially, the outside coil (evaporator) absorbs heat from the outside air, causing the refrigerant to change from a low-pressure liquid to a low-pressure gas. As the liquid working fluid’s temperature remains lower than that of the heat source, heat flows from the source to the liquid, causing the working fluid to evaporate. The low-pressure gas is then compressed by a compressor, resulting in a high-pressure gas. When heat leaves the compressor, it is discharged into the interior coil (condenser) and circulated throughout the home. As heat is released, the vapor condenses into a high-pressure liquid. After leaving the inside unit, the liquid flows via an expansion valve, where it expands from high pressure to low pressure, and the cycle repeats..

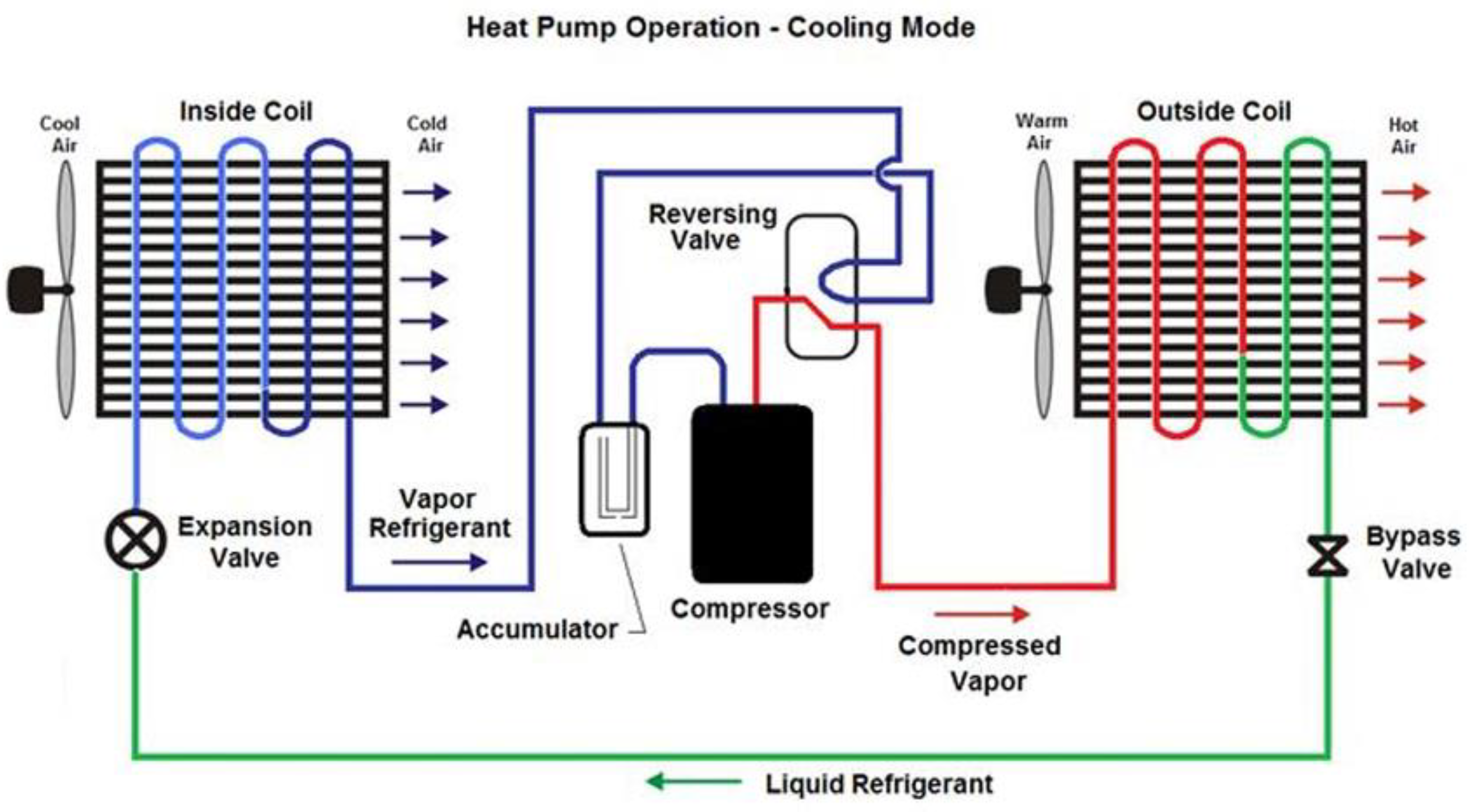

Figure 2.

Heat pump air conditioning system in the Cooling mode [

13].

Figure 2.

Heat pump air conditioning system in the Cooling mode [

13].

The cooling cycle mirrors the heating cycle in reverse. During cooling mode, the reversing valve is triggered, which changes the direction of refrigerant flow. In this mode, the interior coil (evaporator) collects heat as warm air travels over it, while the outside coil emits it into the atmosphere. The refrigerant cycle remains constant in both heating and cooling modes; only the function of the heat exchanger coils changes. [

13]

3. Designing and Estimation of Capacity of the Heat Pump System

Any refrigeration system design must start with an estimation of the heat load. Let’s say for the sake of convenience that our fictitious refrigerated room needs a cooling capacity of 3.5 kW (

). The temperature at which this 3.5 kW of heat must be absorbed will also need to be known. Depending on the application, the refrigerant fed into the evaporator will evaporate at a different temperature. Different systems require different evaporation temperatures, including freezing, blast freezing, and chilling. With 3.5 kW of refrigeration capability, cooling would require 3.5 kJ of energy to be absorbed from the room each second at the necessary evaporation temperature. To rephrase the previous sentence, (

). Would stand for the amount of heat (kW) that the evaporator will absorb from the room. We must introduce a refrigerant into the evaporator at the proper flow rate in order to remove this heat from it [

14].

The equation below describes how the heat transfer relates to the flow of refrigerant:

Where, Qref – Rate of heat that can be absorbed by a refrigerant kW, - mass flow rate of refrigerant supplied to the evaporator kg/sec,

∆h – Enthalpy change at the specified evaporating temperature, kJ/kg

It always helps to see if the units check out i.e., kW = kg/sec x kJ/kg

The terms m’ & ∆h are properties associated with the refrigerant.

I s the heat absorption capability of the refrigerant.

This must be equated to the heat load of the refrigerated space under consideration.

Note: We will ignore the effects of area of heat exchange, overall heat transfer coefficients & other losses that are associated with heat exchangers absorbing heat from the room. For the purpose of simplicity.

Combining Equation (1) & [

2] we get,

From Equation (3) it is clear that the cooling capacity of the evaporator is dependent on the 2 factors.

Several variables affect the amount of alternating current consumed. Some of them are listed below:

The number of people in the room affects the amount of AC power used. For example, a room with 20 to 25 people needs multiple air conditioners, while a room with 3 to 5 people needs only one. When it comes to the amount of air conditioning used, room size is very important. AC power consumption will increase as room size increases. Likewise, smaller rooms do not use more AC power. The amount of electricity used by the air conditioner depends on the temperature outside and inside the room. Air conditioners use more electricity to cool a room if the outside temperature is above 35°c. The total number of electrical appliances in the room generates more heat, which ultimately increases the electricity consumption of the air conditioner to cool the room. Air conditioners with a 5-star rating consume less energy than 1- or 2-star air conditioners, which consume more energy. The type of AC we choose (window, inverter, split, or central) affects the amount of energy it uses. [

15].

3.1. Trade-Off Relationship between GWP and Flammability

One of the most important issues is switching from HFCs to lower GWP refrigerants in order to limit the emission of greenhouse gases, particularly HFCs, from refrigerating and air-conditioning equipment. Much lower GWPs than R410A are found for R1234yf, R32, and R290. R1234yf, R32, and R290 are flammable while R410A is not. R1234yf and R32 are considered to be mildly flammable and fall under the ASHRAE’s A2L class because their burning velocities are less than 10 cm/s [

16].

Table 1.

Lower flammability limit (LFL) and Upper flammability limit (UFL) of Refrigerants.

Table 1.

Lower flammability limit (LFL) and Upper flammability limit (UFL) of Refrigerants.

Refrigerant →

Properties ↓

|

R290 |

R32 |

R410A |

R717 |

R1234yf |

| Boiling temperature, ºC |

-41.1 |

-49.8 |

-50.9 |

-34.3 |

-30.1 |

| Critical temperature, ºC |

96.7 |

77.2 |

70.8 |

132.4 |

94.7 |

| GWP (100 years) |

<3 |

675 |

2088 |

<1 |

4 |

| Burning velocity (cm/s) |

38.7 |

6.7 |

- |

7.2 |

1.5 |

| LFL [vol %] |

1.8 |

13.3 |

- |

15 |

6.2 |

| UFL [vol %] |

9.5 |

29.3 |

- |

28 |

12.3 |

| Minimum ignition energy (mJ) |

0.246 |

15 |

- |

21 |

500 |

| Flammability |

3 |

2L |

1 |

2L |

2L |

4. Detailed Description about Thermal and Physical Properties of the Refrigerant

A refrigerator’s performance is expressed as a coefficient of performance, which is the ratio of heat absorbed by the cold body to work generated by the compressor. The system performance is assessed in this way:

The effort per kilogramme of refrigerant, expressed in terms of isentropic compression, is given by

The refrigerant effect or heat absorbed or extracted by the liquid-vapor refrigerant during evaporation, is calculated and represented for each kg of refrigerant.

The Coefficient of Performance (C.O.P.) is the ratio of heat removed from inside the refrigerator to work done on it.

Where,

The compressor’s input and exit refrigerant enthalpies, or h1 and h2, are expressed in kJ/kg.

The refrigerant enthalpies at the input and output of the expansion valve are expressed as = kJ/kg.

Under the following operating conditions, the system’s performance for the air conditioning system with a 1 TR capacity can be calculated as follows:

The condenser temperature of 54.5˚C and the evaporator temperature of 16˚C have been selected as the operating parameters for a vapour compression cycle with three distinct types of refrigerants (R290, R32, R134A, R401A, and R22).

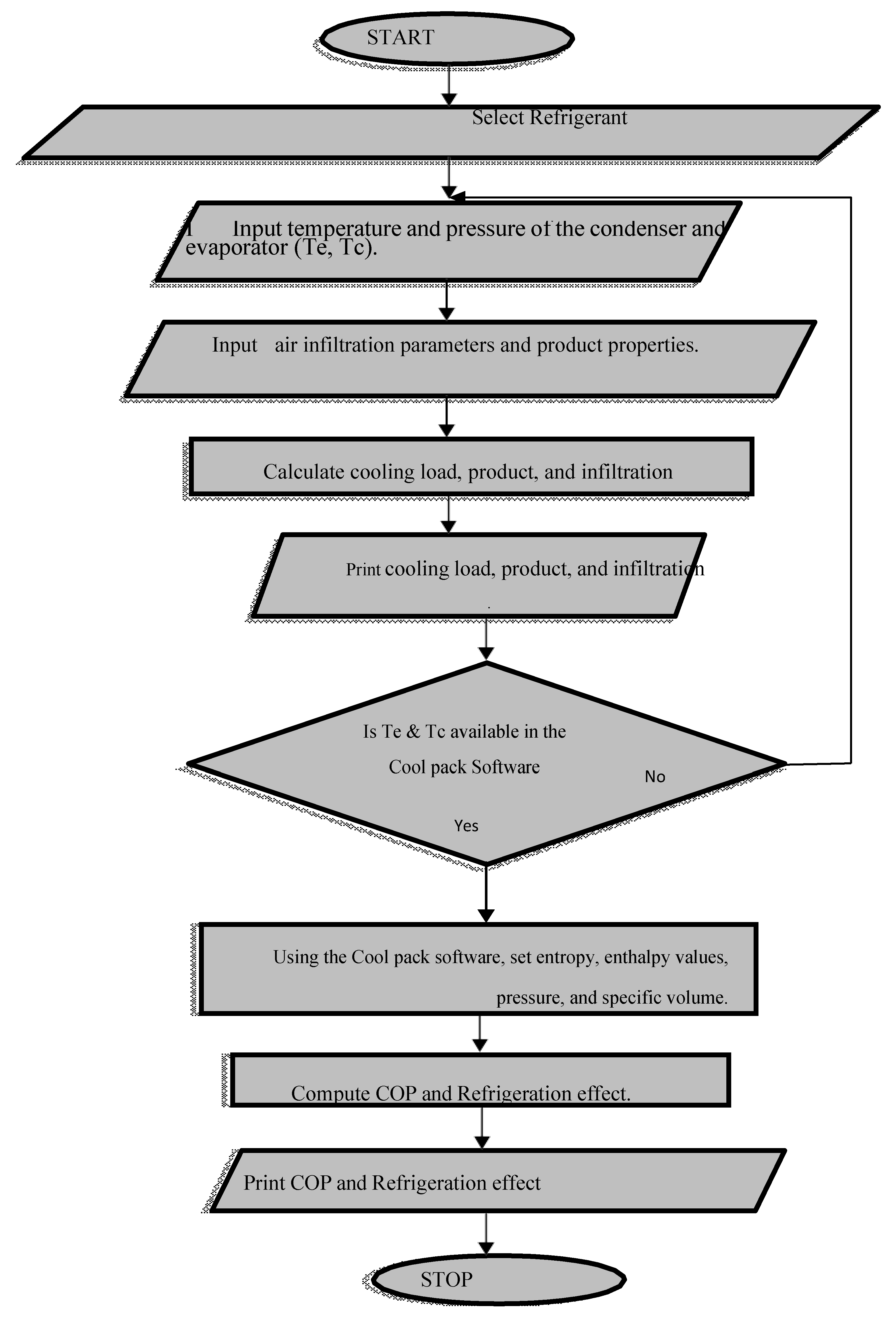

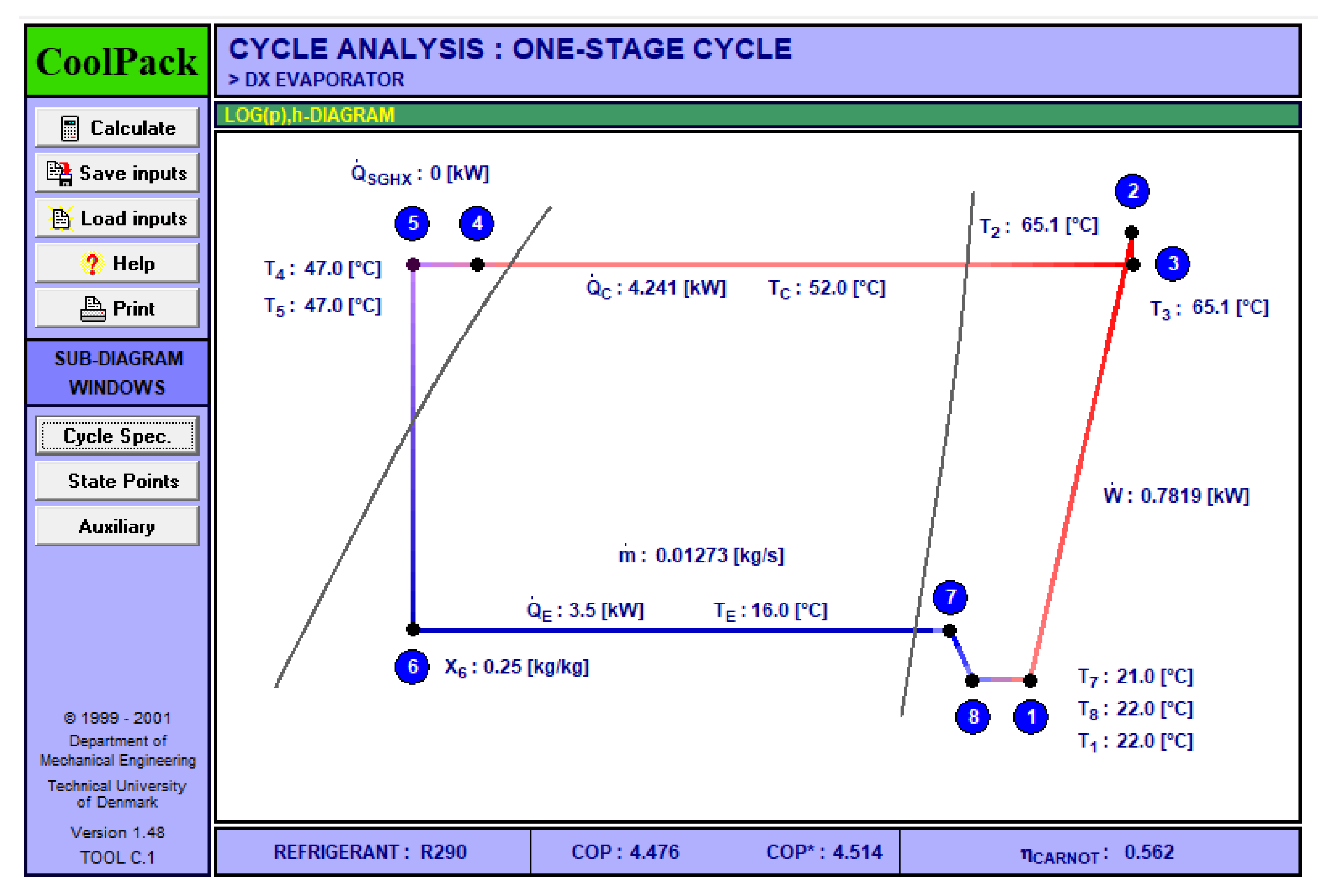

5. Numerical Analysis in Coolpack Tool

Using the CoolPack Software and theoretical results from a Ph Chart, a detailed discussion of the system’s performance evaluation is provided, focusing on the effects of evaporation and condensation temperatures with the chosen refrigerants serving as the working fluid in a vapour compression refrigeration system. In terms of the effect of condensation temperature on the system refrigerating effect, the simulation of the system utilizing R290 outperformed the other refrigerants considered in this study. Furthermore, the simulation results given in the figure show that the system’s performance when using R134a is comparable to that of the systems when using R32 and R22. It is noteworthy to emphasis that, in comparison to the other refrigerants taken into consideration in this study, R290’s performance evaluation simulation findings show a higher refrigerating effect. These findings support the theory behind the system’s improved performance when R290 and other refrigerants are used, as demonstrated [

16].

Figure 3.

Flow chart of the simulation program using Coolpack [

14].

Figure 3.

Flow chart of the simulation program using Coolpack [

14].

The proposed mathematical model using Ph chart has been effectively implemented to predict the behavior of key components in a single-stage vapor compression refrigeration system. The compressor, condenser, expansion valve (capillary tube), and evaporator are all parts of the system. The simulation model, shown in

Figure 4, runs in the following scenarios:

There is a steady-state operation of the refrigeration system. (ii) The compressor, condenser, and evaporator’s irreversibility are ignored. (iii) Frictional pressure drops are not taken into account. (iv) There is very little heat loss to the environment as the refrigerant passes through the condenser and evaporator heat exchangers at a steady pressure. It is assumed that the compression process is isentropic [

15].The information flow diagram in

Figure 4 shows the model’s solution algorithm. The software requires the kind of refrigerant, product attributes, evaporation temperature, and condensation temperature as input data. The selected refrigerants’ thermodynamic parameters (P, h, v, and s) are taken from the COOLPACK saturation table [

16]. The first simulation concentrated on R12’s thermodynamic characteristics. Then, integrating the corresponding thermodynamic parameters of each refrigerant, such as ammonia, R22, R134a, R600a, and R290, more simulations were carried out. Notably, taking into account Equations (1)–(8), the model allows evaluation of the effect of the amount of refrigerated items on the operation of the vapor compression refrigeration system. As a result, this established model makes it easier to estimate performance and design refrigeration systems optimally [

19,

20]. The performance evaluation of the system, based on the simulation procedure for each refrigerant, involves calculating the coefficient of performance (COP). This quantitative measure provides insights into the efficiency and effectiveness of the vapor compression refrigeration system, allowing for informed decisions in optimizing its design and operation [

17,

18].

6. Results and Discussion

For the theoretical investigation, when the vapor refrigerant was in a dry saturated condition at the beginning of the compression, the following properties were obtained using the R290 P-h chart and the results based on that which we got is validated through the Cool Pack Software.

By referring to the above formula for the Refrigerant R32, R134A, R410A, and R22 just like the procedure to calculate the various factors which is calculated for the R290, We have calculated all the factors for other refrigerants like R32, R134A, R410A, and R22. After calculating the COP for Cooling and heating theoretically by using P-h Chart, the same results are validated for COP using the CoolPack Software student’s version (Free software). [

16]. The one stage cycle analysis is done for the Dx Evaporator which is used in the heat pump for heating and cooling using Refrigerant R290 as an indoor device, which is shown in the figure. The parameters are the same as using the Ph chart. The calculated values are validated through a cool pack. The results are shown in

Figure 4.

The one stage cycle analysis is done for the Dx Evaporator which is used in the heat pump for heating and cooling using Refrigerant R22, R410, and R134a as an indoor device is taken. The procedure and method using above for R290 is repeated for R22, R410, R134a refrigerant for Heat pump heating and cooling system and results are shown on the graph presented in the figure.

As the details cycle analysis of R32 Refrigerant for the heat pump air conditioning is not available in cool pack tool. So we have used the cycle DH tool for the analysis of this refrigerant. The procedure is same as we followed in the cool pack tool.

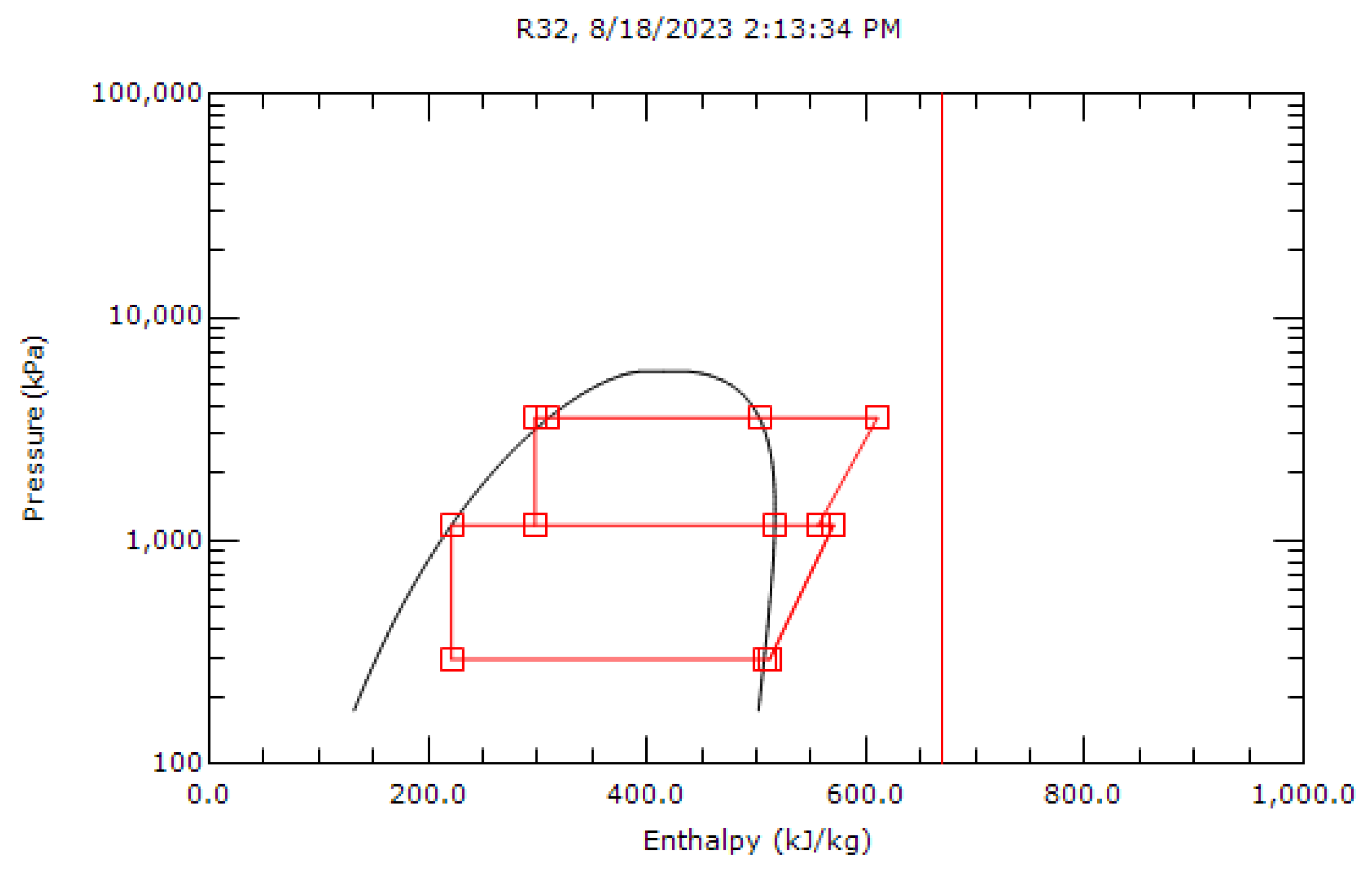

Figure 5.

Pressure enthalpy chart for R32 Refrigerant using cycle DHX.

Figure 5.

Pressure enthalpy chart for R32 Refrigerant using cycle DHX.

Table 2.

Physical and thermal and Properties of Different Refrigerant.

Table 2.

Physical and thermal and Properties of Different Refrigerant.

| Refrige-rant |

Chem-ical formula |

Atmos-pheric life in

Year |

GWP |

ODP |

Refrigerant mass flow

(kg/s) |

Power (kW/TR) |

TEWI

kg CO2-eq |

LCCP, kg CO2-eq |

|

|

| R290 |

C3H8 |

0.041 |

20 |

0 |

0.0119 |

1.194 |

35,124.13 |

37,342 |

4.389 |

4.47 |

| R32 |

CH2F2 |

4.9 |

677 |

0 |

0.0189 |

1.03 |

39,458 |

41,342 |

3.36 |

3.98 |

| R134A |

CH2FCF3 |

13.8 |

1300 |

0 |

0.006 |

0.684 |

36,629.80 |

40,125 |

3.23 |

4.43 |

| R410A |

- |

17 |

2088 |

0 |

0.0304 |

1.064 |

41,978.29 |

44,787 |

3.28 |

4.28 |

| R22 |

CHClF2 |

12 |

1700 |

0.055 |

0.0244 |

0.976 |

38,506.10 |

41,576 |

3.4 |

4.36 |

5. Analysis of 290 Refrigerant Compare with Other Refrigerant

R290 burns more easily than R32, but release energy are relatively smaller, the post - combustion products is not toxic. R32 burns more difficulty than R290, release energy is relatively larger, and post - combustion products (hydrogen fluoride) is highly toxic.

Table 3.

Thermal and Physical Properties of Different Refrigerant.

Table 3.

Thermal and Physical Properties of Different Refrigerant.

| Refrigerant |

Chemical formula |

using Ph- Chart |

Ph- Chart |

using CoolPack Software |

Ph- Chart |

Difference between theoretical and simulation |

| R290 |

C3H8 |

4.389 |

4.47 |

4.4 |

4.45 |

0.1 |

| R32 |

CH2F2 |

3.36 |

3.98 |

3.36 |

4.36 |

0.8 |

| R134A |

CH2FCF3 |

3.23 |

4.43 |

4.126 |

4.162 |

0.23 |

| R410A |

|

3.28 |

4.28 |

3.658 |

3.724 |

0.5 |

| R22 |

CHClF2 |

3.4 |

4.36 |

4.10 |

4.132 |

0.10 |

6. Conclusions

Using R-290 refrigerant, the heat pump unit will be converted to an air conditioning system and the performance of the new system is evaluated. The main findings of the study are summarized as follows:

The present work monitored and evaluated compressor power consumption and COP values at various load levels throughout the test period to determine the appropriate refrigerant charge in the refrigeration system.

The use of R290 contributes to promoting the “go green” movement, aiming to reduce the risk of ozone layer depletion and global warming. Combining the heat pump with the R290 provides significant energy savings and increased cooling capacity.

Industrial processes to increase cooling and heating efficiency and effectiveness with heat pump-controlled air conditioning systems which is carried out using the applied scientific method outlined in this article.

A heat pump for simultaneous cooling and heating was created for the purpose of producing domestic hot water while simultaneously heating and cooling small residential and office buildings.

R290 is a natural refrigerant with very low long-term global warming potential. Increase C.O.P. reached 22.92%, 19.12% and 15.84%.

Power usage was cut by 58.69%, 42% and 47%.

The discharge temperature was reduced by 23°C, 24°C, and 25°C, respectively.

Availability of Data and Material

All the data used to support the findings of this study are included within the article.

Competing Interests

Authors declare they have no financial interests.

Funding

The authors declare that no grants, funds, or other support were received during the preparation of this manuscript

Authors’ Contributions

All the data and work done given in the manuscript is written by the Author.

Acknowledgments

I am very much thankful to the other author Vaijanath N. Raibhole, Premendra J. Bansod, Akhya Kumar Behera and all the researchers whose paper I have referred and cited in the manuscript.

List of Abbreviations

| Sr. No. |

List of abbreviations |

Symbol |

| 1 |

Coefficient of performance |

COP |

| 2. |

Coefficient of performance(Cooling) |

|

| 3. |

Coefficient of performance(Heating) |

|

| 4. |

Lower flammability limit |

LFL |

| 5. |

Upper flammability limit |

UFL |

| 6. |

Global warming Potential |

GWP |

| 7. |

Ozone Depletion potential |

ODP |

| 8. |

Total Equivalent Warming Impact |

TEWI |

| 9. |

Life Cycle Climate Performance |

LCCP |

| 10. |

Air Conditioning |

AC |

| 11. |

Direct Evaporative Cooling |

DEC |

| 12. |

Energy efficiency ratio |

EER |

| 13. |

Ground source heat pump |

GSHP |

References

- Shailendra Kasera , Rajlakshmi Nayak , Shishir Chandra Bhaduri ,” Performance analysis of solar milk refrigerator using energy efficient R290”, Case Studies in Thermal Engineering 24 (2021) 100855. [CrossRef]

- Wichakan Ketwong , Thoranis Deethayat , Tanongkiat Kiatsiriroat,” Performance enhancement of air conditioner in hot climate by condenser cooling with cool air generated by direct evaporative cooling” Case Studies in Thermal Engineering 26 (2021) 101127. [CrossRef]

- Tian Q., Cai, D., Ren, L., Tang, W., Xie, Y., He, G., Liu, F., “An experimental investigation of refrigerant mixture R32/R290 as drop-in replacement for HFC410A in household air conditioners”, International Journal of Refrigeration (2015). [CrossRef]

- Li Zhang, Chunguang Yang , Huanying Liu , Ping Du , Hongyan Gao ,” Theoretical Investigation on the Properties of R744/R290 Mixtures”, 10th International Symposium on Heating, Ventilation and Air Conditioning, ISHVAC2017, 19- 22 October 2017, Jinan, China.

- Kashif Nawaz, Moonis Ally Raza, Omar Abdelaziz,” Ammonia And Propane As Natural Refrigerants For Heat Pump Applications”, 13th IIR Gustav Lorentzen Conference, Valencia, 2018.

- Lucia U, Simonetti M, Chiesa G, Grisolia G. “Ground-source pump system for heating and cooling: Review and thermodynamic approach”. Renewable and Sustainable Energy Reviews. 2017 Apr 1; 70:867-74. [CrossRef]

- Byrne P, Miriel J, Lénat Y. Modelling and simulation of a heat pump for simultaneous heating and cooling. In building simulation Heidelberg: Tsinghua Press,2012 Sep (Vol. 5, No. 3, pp. 219-232). [CrossRef]

- Byrne P, Miriel J, Lenat Y. Design and simulation of a heat pump for simultaneous heating and cooling using HFC or CO2 as a working fluid. International Journal of Refrigeration. 2009 Nov 1;32(7):1711-23. [CrossRef]

- Shin, D. U., Ryu, S. R., & Kim, K. W,. “Simultaneous Heating and Cooling System with Thermal Storage Tanks Considering Energy Efficiency and Operation method of the System. Energy and Buildings”, 109518. [CrossRef]

- R P Dhivakar, Raviram,D Vijayaganapathy , V Dhinakaran, Performance Consideration and Result Analysis Using Various Alternative Refrigerants in a Vapour-Compression Refrigeration System” IOP Conf. Ser.: Mater. Sci. Eng. l 2020 988 012126. [CrossRef]

- Zhu Liang, Kuan Liang, Zhaohua Li , Hanying Jiang , Zhongwei Meng Thermal-economic-environmental analysis on household refrigerator using a variable displacement compressor and low-GWP refrigerants”. International Journal of Refrigeration, (2021),” 123, 189–197. [CrossRef]

- Pavel Makhnatcha,, Rahmatollah Khodabandeh,” The role of environmental metrics (GWP, TEWI, LCCP) in the selection of low GWP refrigerant.”,The 6th International Conference on Applied Energy – ICAE2014.

- Heat Pump Systems 2020 Instructor: Lee Layton, PE, PDH Online | PDH Center 5272 Meadow Estates Drive Fairfax, VA 22030-6658 Phone: 703-988-0088 www.PDHonline.com.

- T. S. Mogaji, “Simulation and Comparison of the Performance of Refrigerant Fluids in Single Stage Vapour Compression Refrigeration System” Department of Mechanical Engineering, Federal University of Technology Akure, School of Engineering and Engineering Technology, P.M.B. 704, Ondo State, Nigeria.

- Arne J, Bjarne DR, Morten JS, Simon EA. COOPACK Technical University of Denmark Mechanical Engineering, Lyngby, Denmark. 2004;46.

-

https://www.ipu.dk/products/coolpack/.

- Kumar, Subhash, and Dr RR Arakerimath. “Comparative Study on Performance Analysis of Vapour Absorption Refrigeration System Using Various Refrigerants.” IPASJ International Journal of Mechanical Engineering (IIJME) 3.1 (2015).

- Kumar, Subhash, Vaijanath N. Raibhole, and Himadri Majumder. “Performance of Heat Pump Air Conditioning with R1234ze (HFO) as a Refrigerant.” Journal of Optimization 2024 (2024). [CrossRef]

- Kumar, S., & Raibhole, V. N “Performance of locomotive air conditioning using heat recovery by exhaust gas of CI engine. International Journal of Environmental Engineering, (2021) 11(2), 106-117. [CrossRef]

- Shivani Petkar, Bhim Wadikar, Kishor Sonavane ,Nandkumar suryakumar,Subhash Kumar,” Performance Analysis of Heat Pump Air Conditioning System for Heating and Cooling”, JETIR2306789 Journal of Emerging Technologies and Innovative Research (JETIR) www.jetir.org.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).