Submitted:

23 July 2024

Posted:

24 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Panels

2.3. Characterization of the Elaborated Panels

2.4. Statistical Analyses

3. Results and Discussion

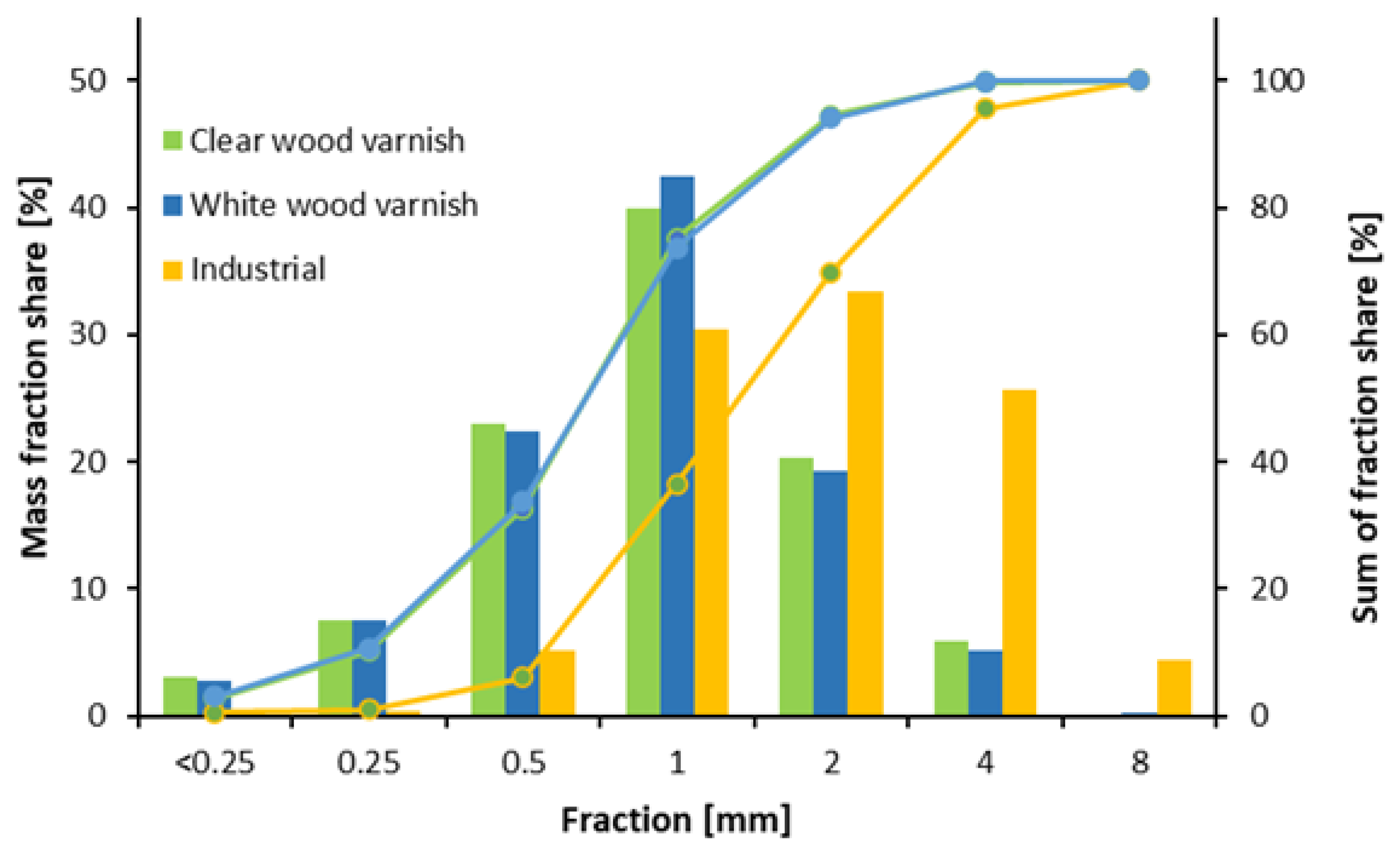

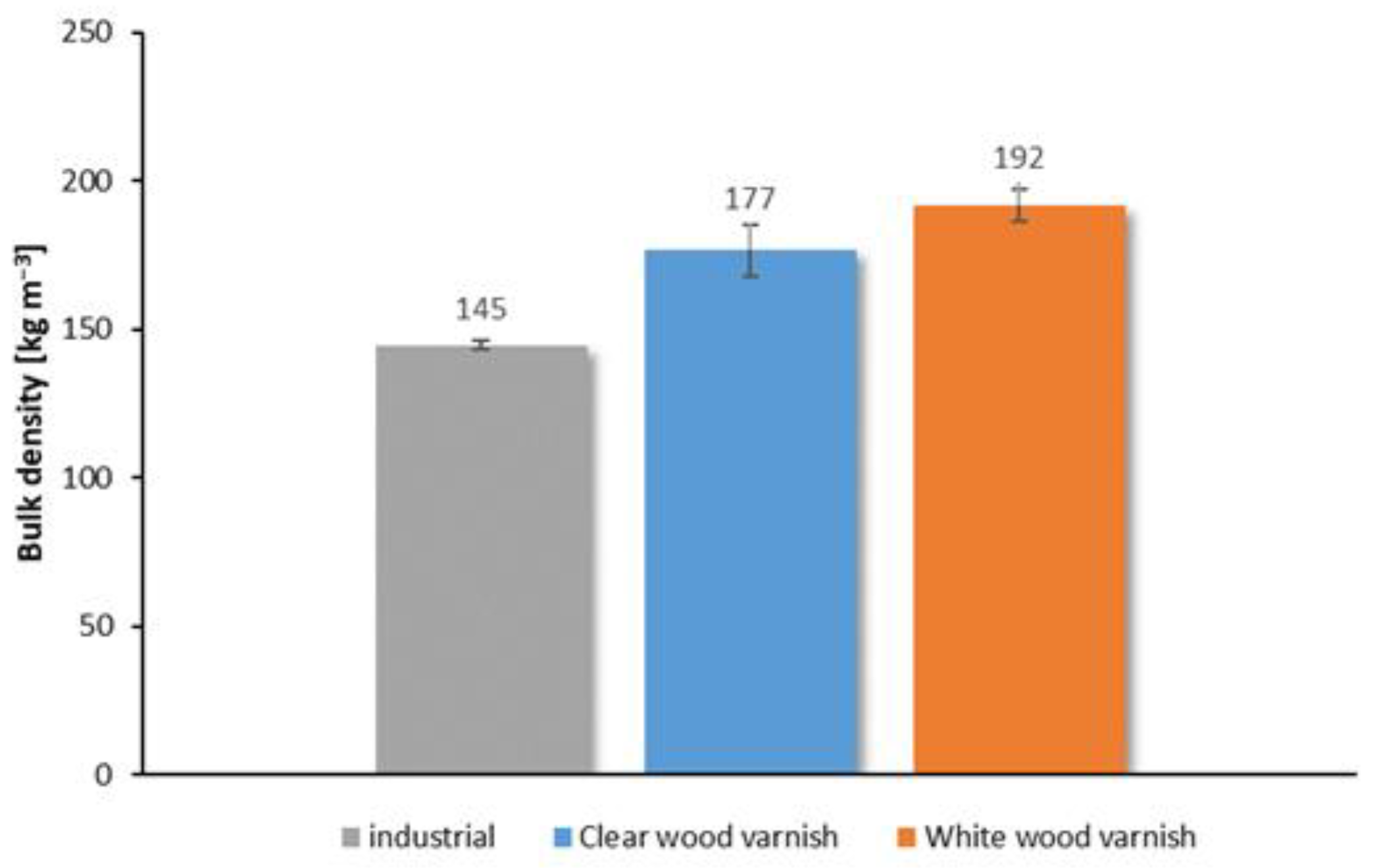

3.1. Fraction Share and Bulk Density of Particles

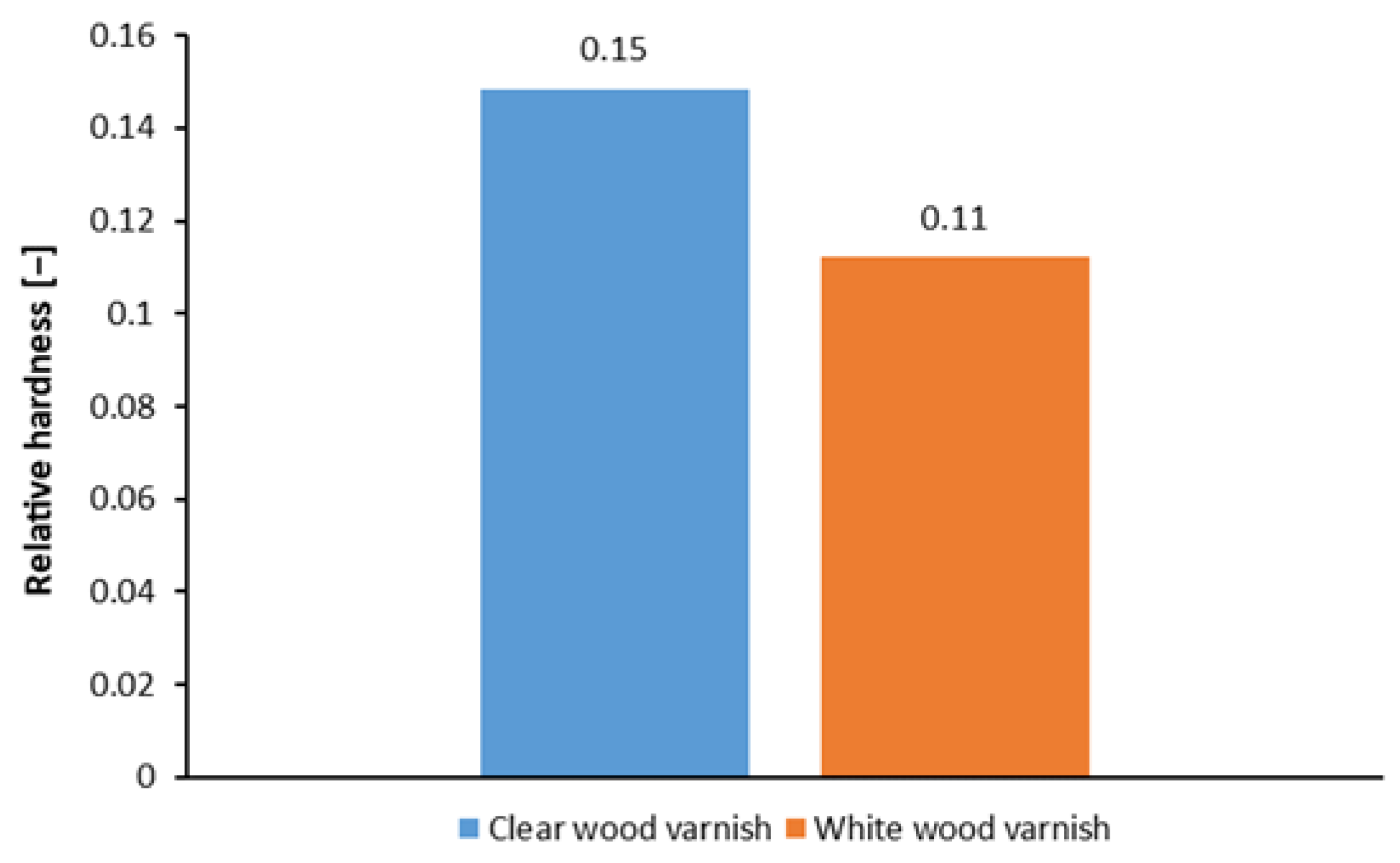

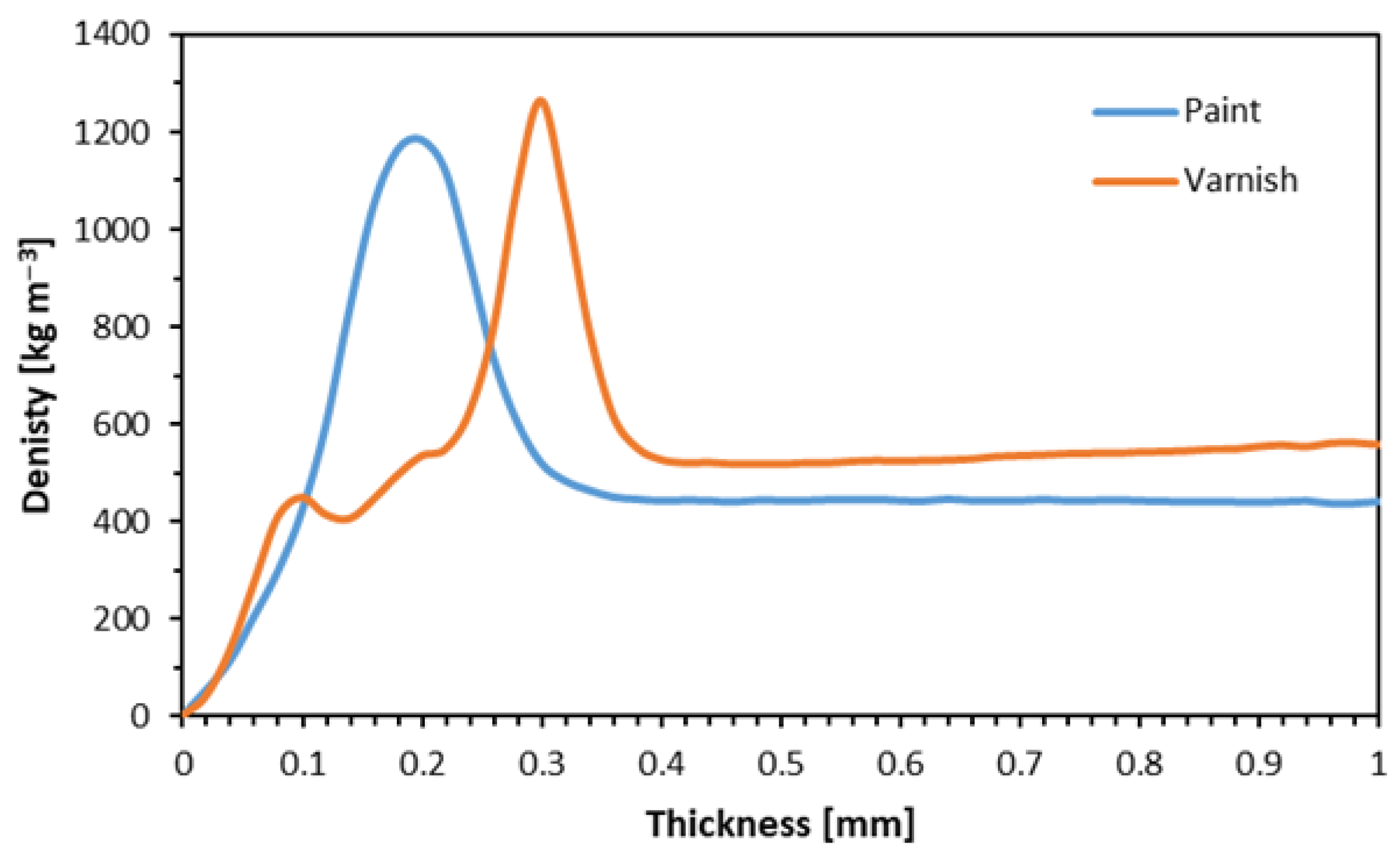

3.2. Relative Hardness and Density Profile

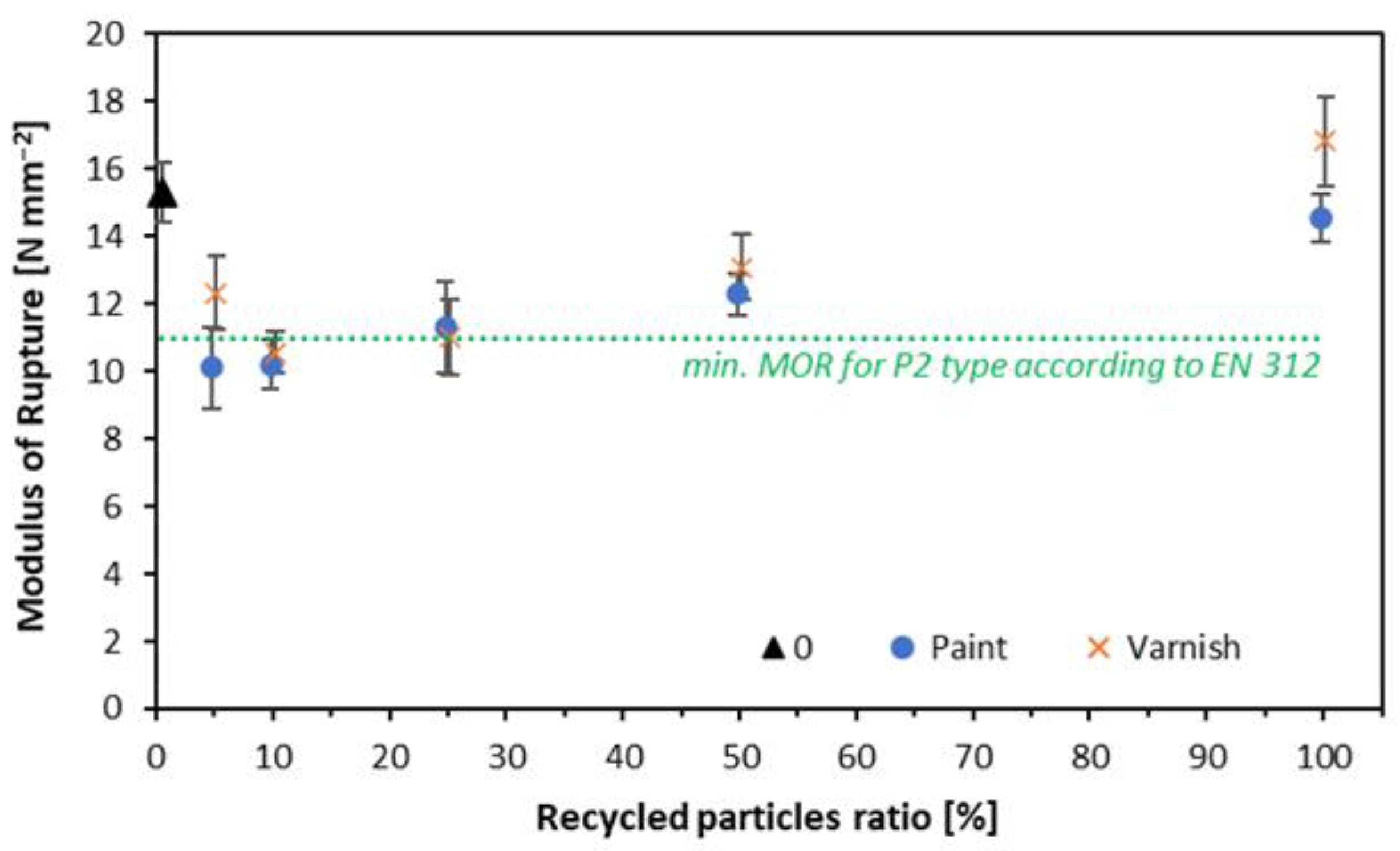

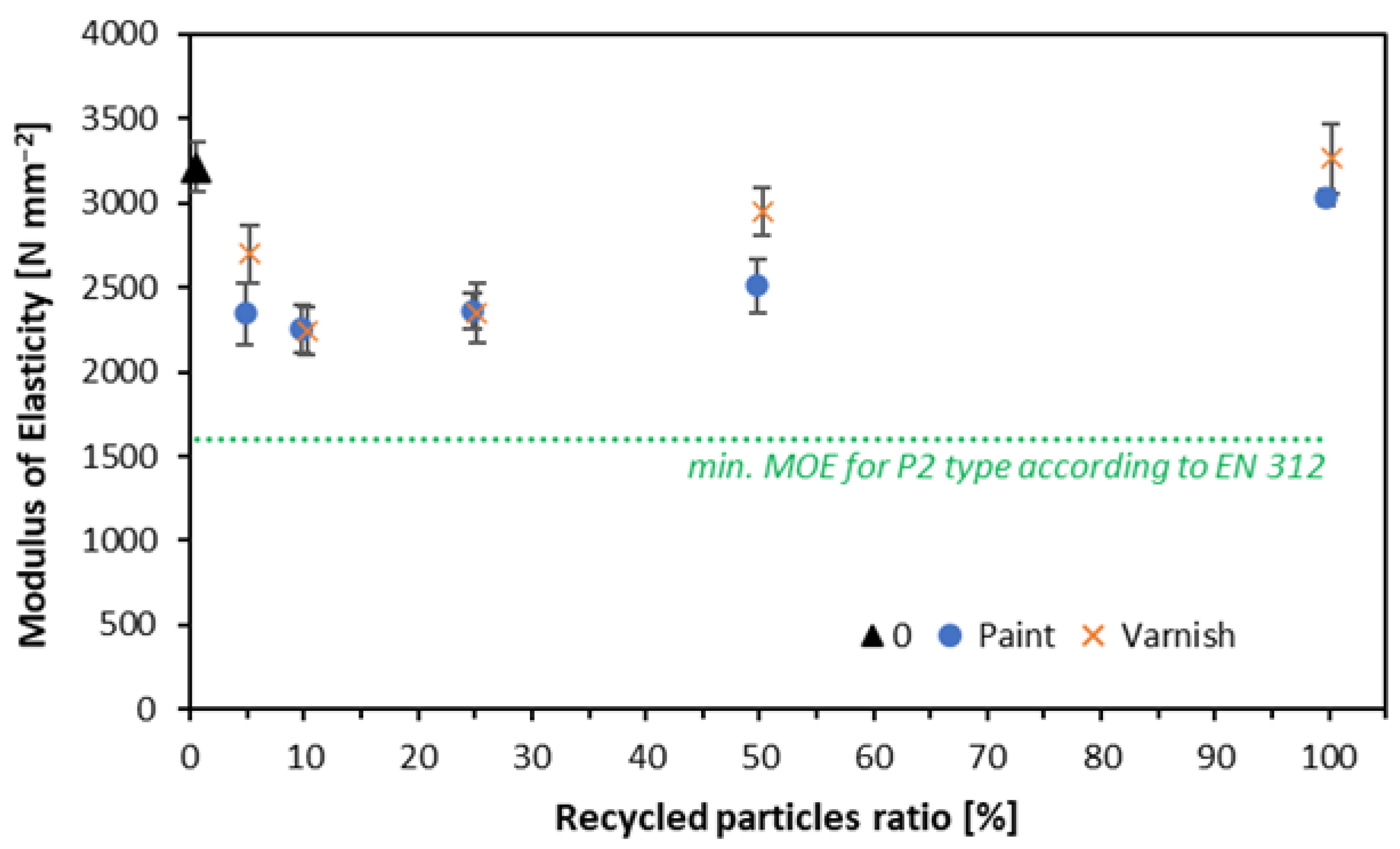

3.3. Modulus of Rupture and Modulus of Elasticity

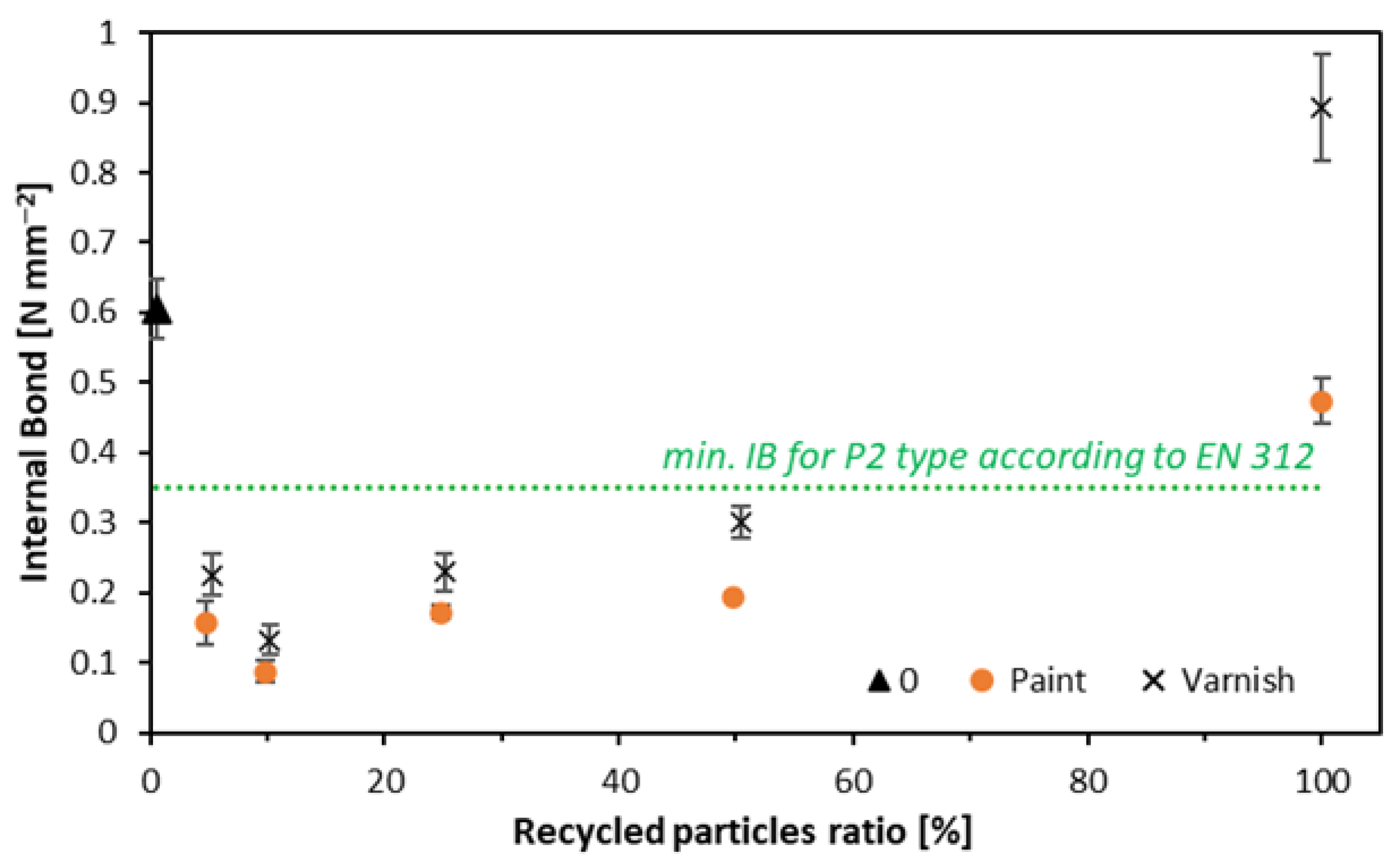

3.4. Internal Bond

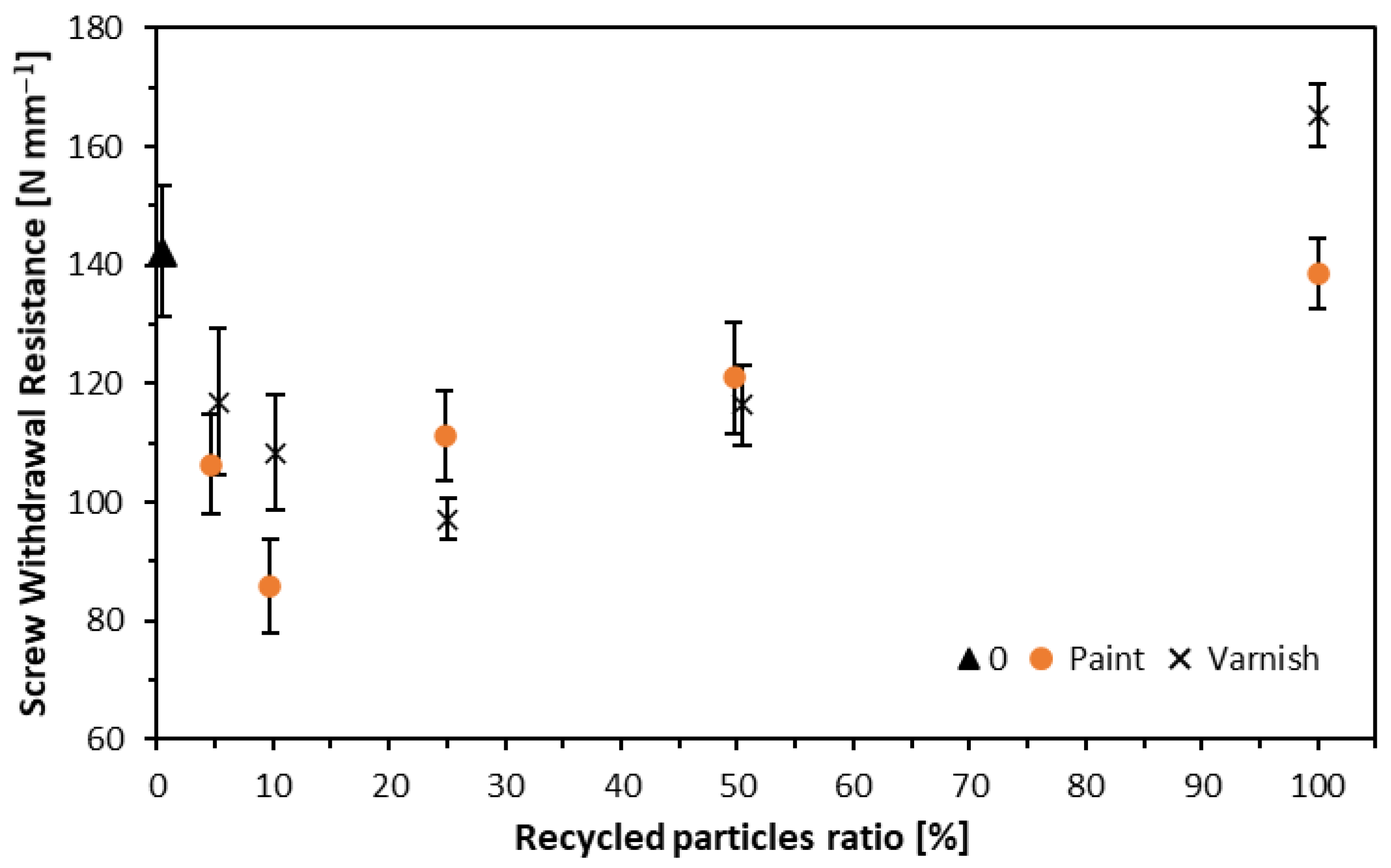

3.5. Screw withdrawal Resistance

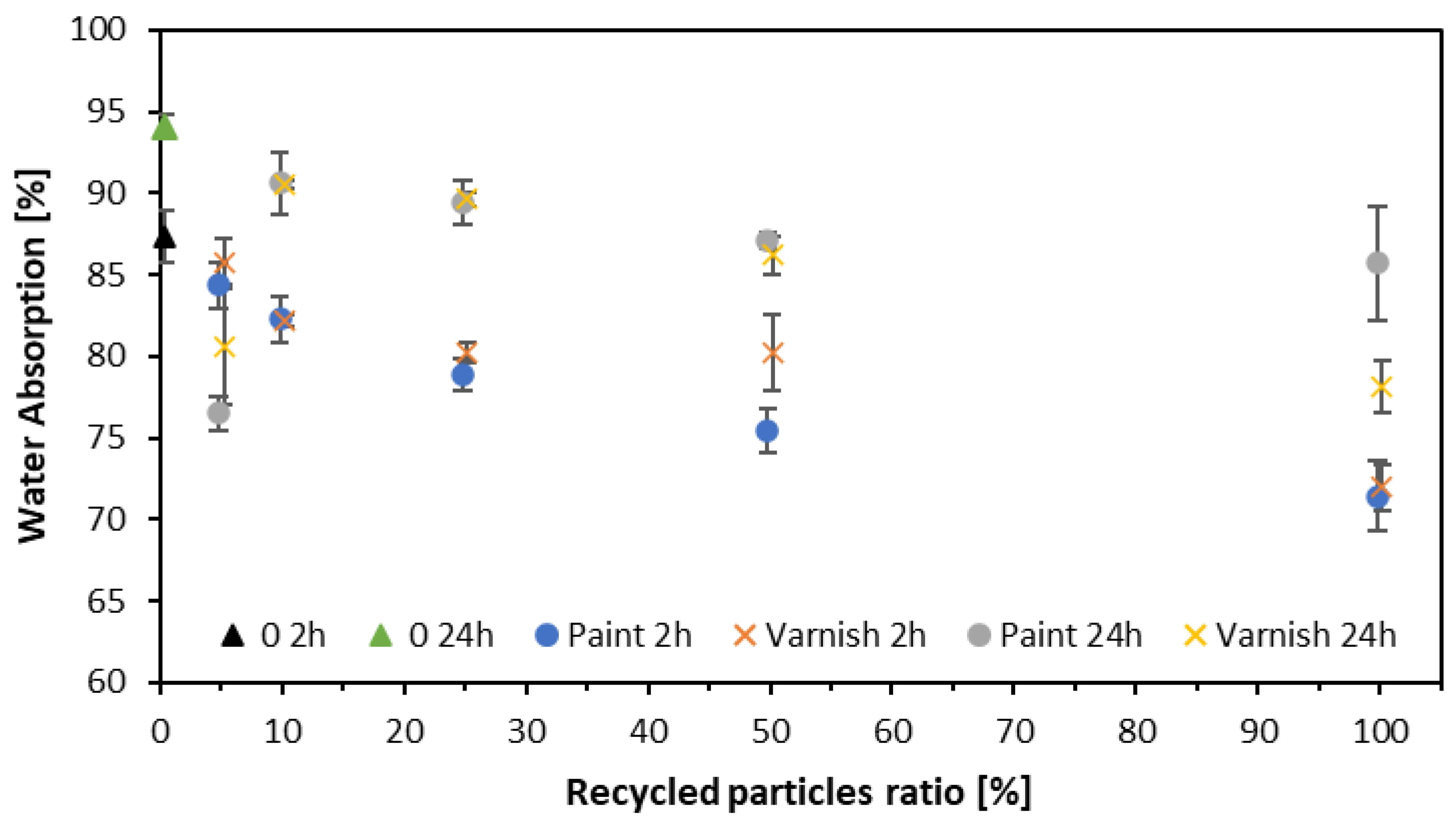

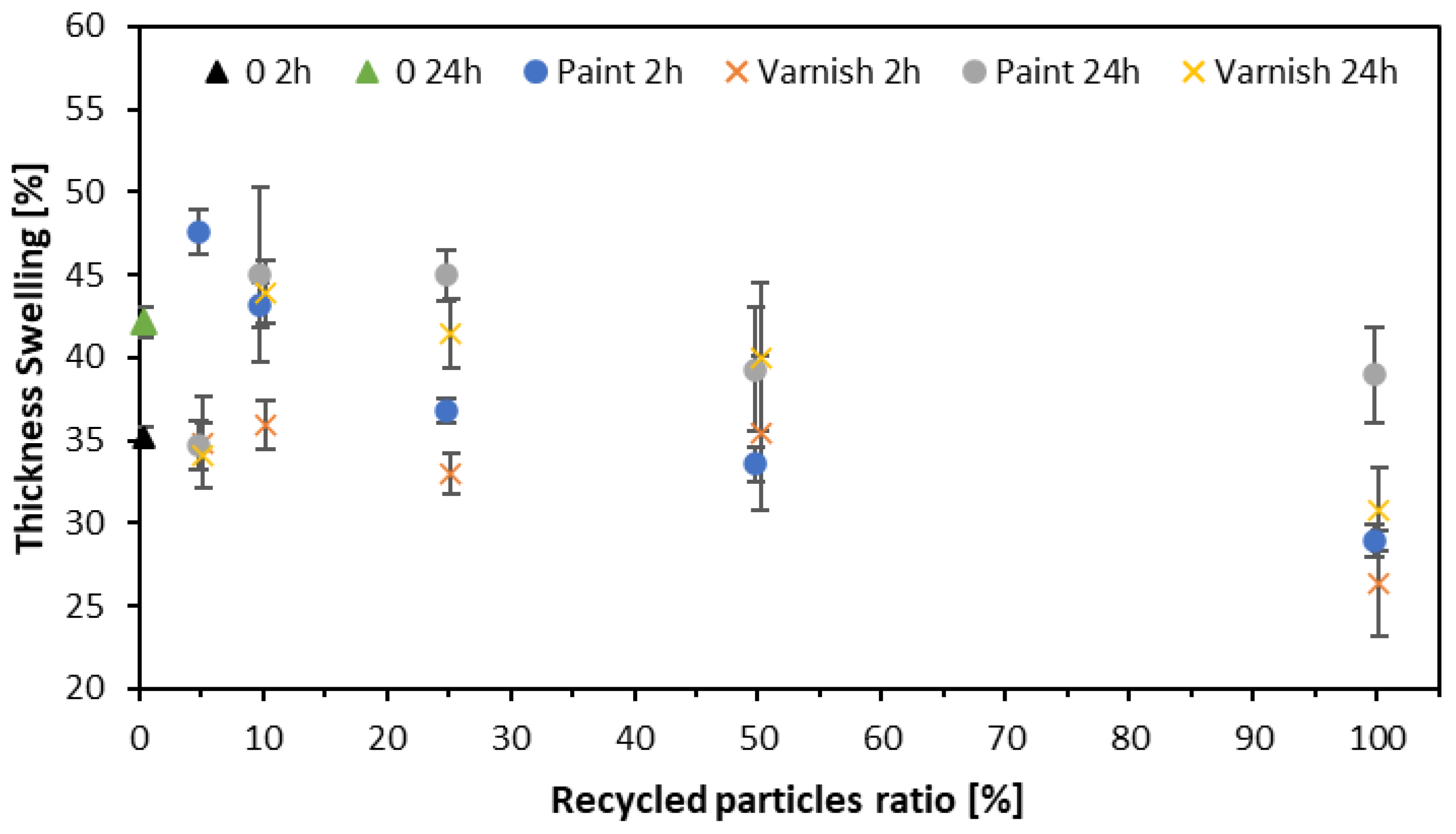

3.6. Water Absorption and Thickness Swelling

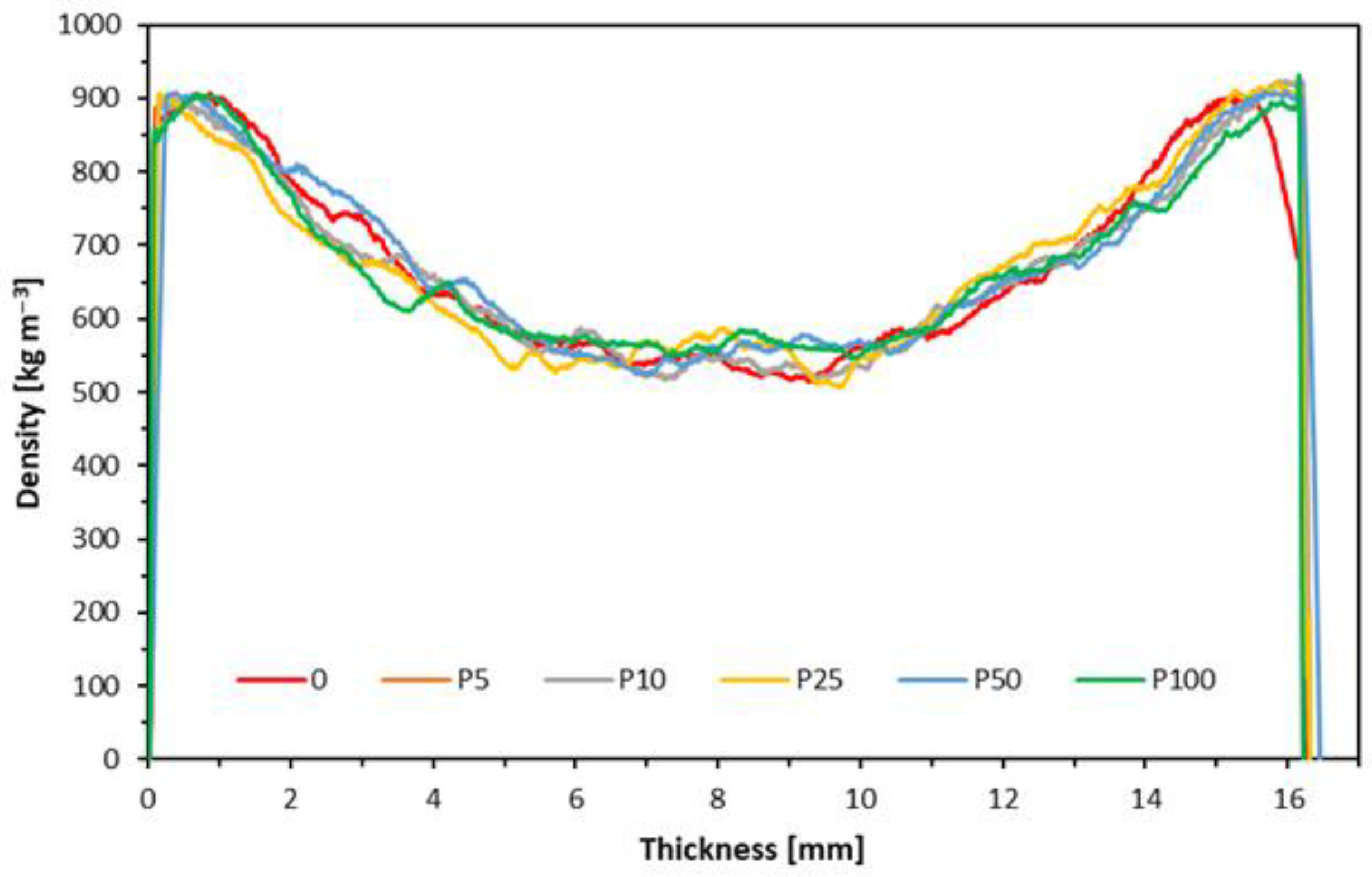

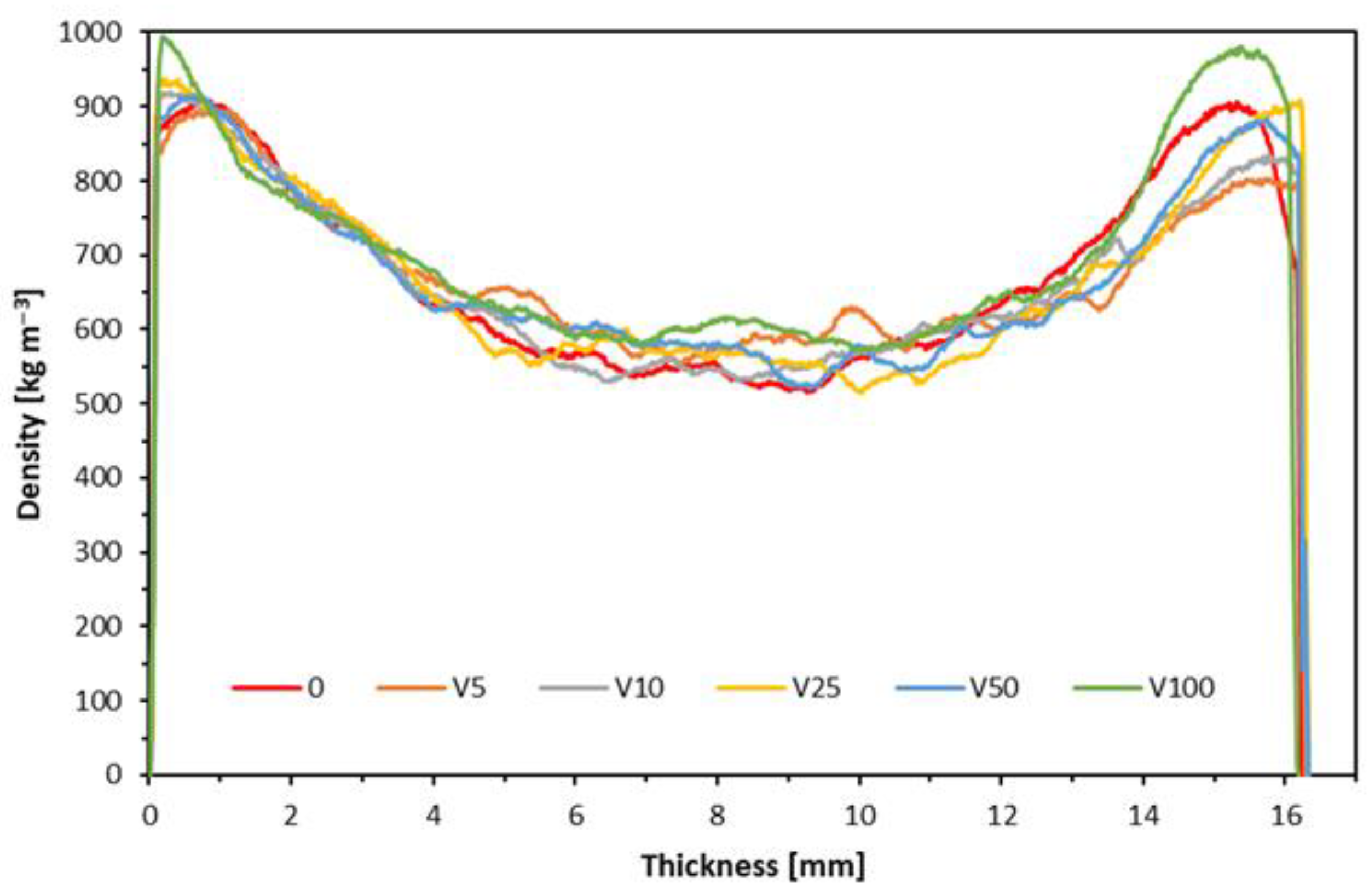

3.7. Density Profile

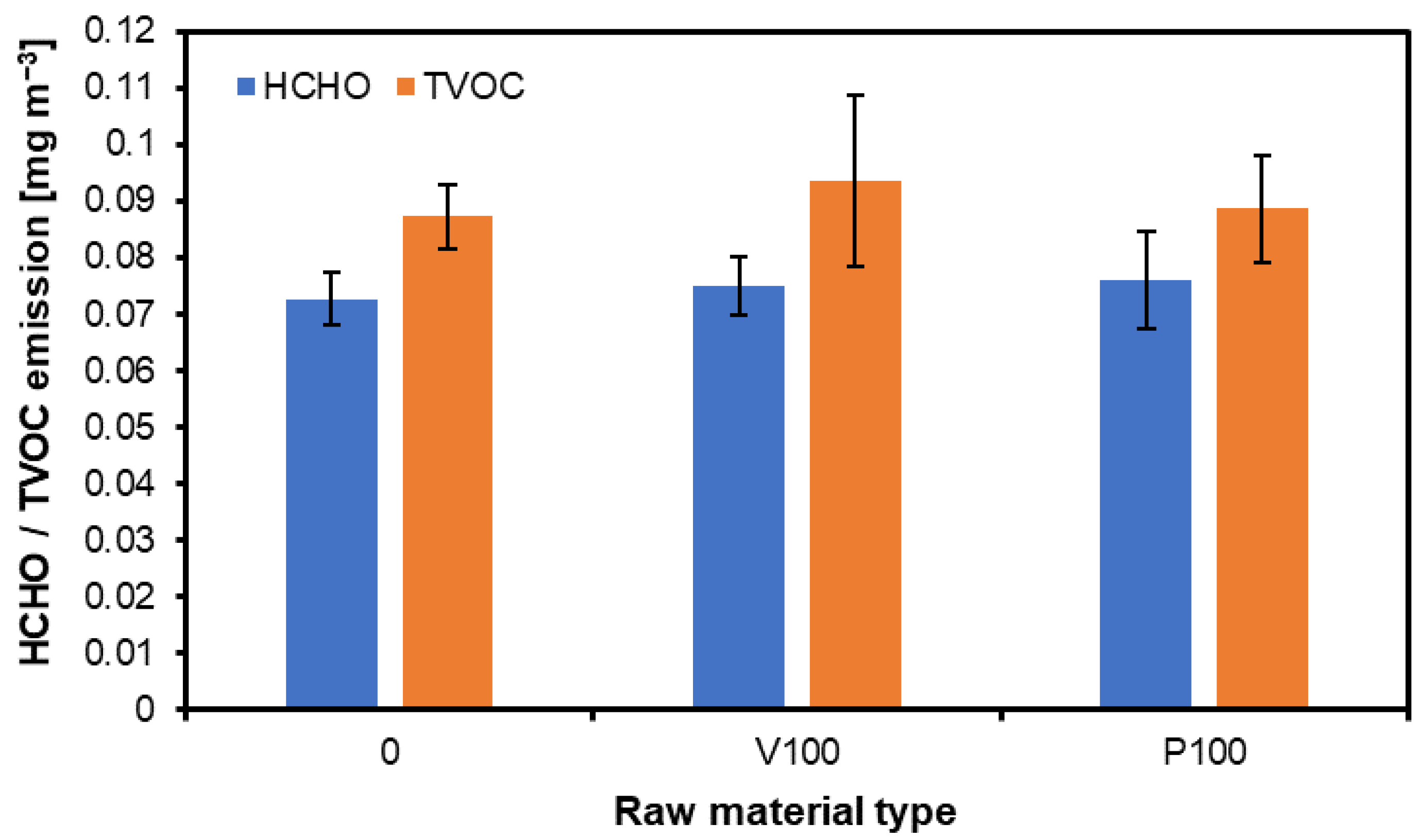

3.8. Formaldehyde and TVOC Emission

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sobotková, A.; Šimek, M.; Pařil, P.; Fictum, L.; Szökeová, S. Mechanical and Physical Properties of Boards Made from Recycled Paper. BioResources 2021. [Google Scholar] [CrossRef]

- Jeyaraj, D.; Kalimuthu, M.; Nagarajan, R.; Chithamparam, P.O.; Ismail, S.; Mohammad, F.; A. Al-Lohedan, H.; Krishnan, K. Biowaste Management: Comparison of Banana (Musa Acuminata) and Bamboo (Bambusa Vulgaris) Fibers. 2024, 1245–1259. [Google Scholar] [CrossRef]

- Priyadarshana, R.W.I.B.; Kaliyadasa, P.E.; Ranawana, S.R.W.M.C.J.K.; Senarathna, K.G.C. Biowaste Management: Banana Fiber Utilization for Product Development. J. Nat. Fibers 2022, 19, 1461–1471. [Google Scholar] [CrossRef]

- Wegener, C.; Aakjær, M. Upcycling – a New Perspective on Waste in Social Innovation. J. Comp. Soc. Work 2016, 11, 242–260. [Google Scholar] [CrossRef]

- Singh, J.; Sung, K.; Cooper, T.; West, K.; Mont, O. Challenges and Opportunities for Scaling up Upcycling Businesses – The Case of Textile and Wood Upcycling Businesses in the UK. 2019. [CrossRef]

- Farrant, L.; Irving Olsen, S.; Wangel, A. Environmental Benefits from Reusing Clothes. 2010. [CrossRef]

- Wronka, A.; Kowaluk, G. Upcycling of Wood Dust from Particleboard Recycling as a Filler in Lignocellulosic Layered Composite Technology. Materials (Basel). 2023, 16, 1–13. [Google Scholar] [CrossRef]

- Dasiewicz, J.; Wronka, A. Influence of the Use of Chestnut Starch as a Binder Filler in Plywood Technology. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 148, 137–148. [Google Scholar] [CrossRef]

- Wojciechowska, M.; Kowaluk, G. Waste Banana Peel Flour as a Filler in Plywood Binder. Ann. WULS, For. Wood Technol. 2023, 123, 143–152. [Google Scholar] [CrossRef]

- Daniłowska, A.; Kowaluk, G. The Use of Coffee Bean Post-Extraction Residues as a Filler in Plywood Technology. Ann. Warsaw Univ. Life Sci. - SGGW, For. Wood Technol. 2020, 109, 24–31. [Google Scholar] [CrossRef]

- Pu, Z.; Jiang, J.; Li, Y.; Li, L.; Yang, S.; Wang, Q. Upcycling of Waste Artificial Turf for High-Performance Wood-Plastic Composites. 2022. [CrossRef]

- Addai, E.; Agyei, K.I.; Fening, P.A.; Adu-Agyem, J.; Addo-Danquah, S.O. The Use of Aluminium Solid Waste as an Alternative Material for Casting in Sculpture: The Case of Nkawie Senior High Technical School, Ghana. 2023. [CrossRef]

- Borysiewicz, I.; Kowaluk, G. Selected Properties of MDF Boards Bonded with Various Fractions of Recycled HDPE Particles. Ann. WULS, For. Wood Technol. 2023, 123, 18–29. [Google Scholar] [CrossRef]

- Kılıç, İ.; Avcı, B.; Atar, İ.; Korkmaz, N.; Yılmaz, G.; Mengeloğlu, F. Using Furniture Factory Waste Sawdust in Wood-Plastic Composite Production and Prototype Sample Production. 2023, 7212–7229. [Google Scholar] [CrossRef]

- Luo, P.; Yang, C.; He, Y.; Wang, T. Use of Scrap Particleboard to Produce Recycled Particleboard. BioResources 2024, 19, 3837–3844. [Google Scholar] [CrossRef]

- Lykidis, C.; Grigoriou, A. Hydrothermal Recycling of Waste and Performance of the Recycled Wooden Particleboards. Waste Manag. 2008, 28, 57–63. [Google Scholar] [CrossRef] [PubMed]

- Azambuja, R. da R.; de Castro, V.G.; Trianoski, R.; Iwakiri, S. Utilization of Construction and Demolition Waste for Particleboard Production. J. Build. Eng. 2018, 20, 488–492. [Google Scholar] [CrossRef]

- Nuryawan, A.; Rahmawaty; Tambun, K.D.; Risnasari, I.; Masruchin, N. Hydrolysis of Particleboard Bonded with Urea-Formaldehyde Resin for Recycling. Heliyon 2020, 6, e03936. [Google Scholar] [CrossRef] [PubMed]

- Bartoszuk, K.; Kowaluk, G. The Influence of the Content of Recycled Natural Leather Residue Particles on the Properties of High-Density Fiberboards. Materials (Basel). 2023, 16. [Google Scholar] [CrossRef] [PubMed]

- Bartoszuk, K.; Wronka, A. Influence of the Content of Recycled Artificial Leather Waste Particles in Particleboards on Their Selected Properties. Ann. WULS, For. Wood Technol. 2023, 134, 124–134. [Google Scholar] [CrossRef]

- Boonpracha, J.; Chanplin, P.; Ngampipat, C.; Sermsri, N. Upcycling for Repurposing Waste Into Creative Products. Creat. Stud. 2024, 17, 192–206. [Google Scholar] [CrossRef]

- Werner, F.; Taverna, R.; Hofer, P.; Thürig, E.; Kaufmann, E. National and Global Greenhouse Gas Dynamics of Different Forest Management and Wood Use Scenarios: A Model-Based Assessment. Environ. Sci. Policy 2010, 13, 72–85. [Google Scholar] [CrossRef]

- Carpenter, A.; Jambeck, J.R.; Gardner, K.; Weitz, K. Life Cycle Assessment of End-of-Life Management Options for Construction and Demolition Debris. J. Ind. Ecol. 2013, 17, 396–406. [Google Scholar] [CrossRef]

- Sandin, G.; Peters, G.M.; Svanström, M. Life Cycle Assessment of Construction Materials: The Influence of Assumptions in End-of-Life Modelling. Int. J. Life Cycle Assess. 2014, 19, 723–731. [Google Scholar] [CrossRef]

- Stelte, W.; Sanadi, A.R.; Shang, L.; Holm, J.K.; Ahrenfeldt, J.; Henriksen, U.B. Recent Developments in Biomass Pelletization - a Review. BioResources 2012, 7, 4451–4490. [Google Scholar] [CrossRef]

- Jafari, V.; Labafzadeh, S.R.; Jeihanipour, A.; Karimi, K.; Taherzadeh, M.J. Construction and Demolition Lignocellulosic Wastes to Bioethanol. Renew. Energy 2011, 36, 2771–2775. [Google Scholar] [CrossRef]

- Kharazipour, A.; Kües, U. Recycling of Wood Composites and Solid Wood Products. In Wood Production, Wood Technology, and Biotechnological Impacts; 2007; pp. 509–533 ISBN ISBN-13: 978-3-940344-11-3.

- Besserer, A.; Troilo, S.; Girods, P.; Rogaume, Y.; Brosse, N. Cascading Recycling of Wood Waste: A Review. Polymers (Basel). 2021, 13. [Google Scholar] [CrossRef] [PubMed]

- Larsen, A.W.; Petersen, C.; Christensen, T.H. Bulky Waste Quantities and Treatment Methods in Denmark. [CrossRef]

- Teacă, C.A.; Ignat, M.E.; Nechifor, M.; Tanasă, F.; Ignat, L. In-Soil Degradation of Polymer Materials Waste – a Survey of Different Approaches in Relation with Environmental Impact. BioResources 2023, 18, 2213–2261. [Google Scholar] [CrossRef]

- Crespo, A.I.; Raquel, G.; Pérez, V.E.M. URBANREC: New Approaches for the Valorisation of URBAN Bulky Waste into High Added Value Recycled Products.; 11th Conference on Sustainable Development of Energy, Water and Environment System, 2016.

- Höglmeier, K.; Weber-Blaschke, G.; Richter, K. Utilization of Recovered Wood in Cascades versus Utilization of Primary Wood—A Comparison with Life Cycle Assessment Using System Expansion. Int. J. Life Cycle Assess. 2014, 1755–1766. [Google Scholar] [CrossRef]

- Basalp, D.; Tihminlioglu, F.; Sofuoglu, S.C.; Inal, F.; Sofuoglu, A. Utilization of Municipal Plastic and Wood Waste in Industrial Manufacturing of Wood Plastic Composites. Waste and Biomass Valorization 2020, 11, 5419–5430. [Google Scholar] [CrossRef]

- Turku, I.; Keskisaari, A.; Kärki, T.; Puurtinen, A.; Marttila, P. Characterization of Wood Plastic Composites Manufactured from Recycled Plastic Blends. 2016. [CrossRef]

- Sharma, R.; Bansal, P.P. Use of Different Forms of Waste Plastic in Concrete - A Review. J. Clean. Prod. 2016, 112, 473–482. [Google Scholar] [CrossRef]

- Sharuddin, S.D.A.; Abnisa, F.; Daud, W.M.A.W.; Aroua, M.K. A Review on Pyrolysis of Plastic Wastes. 2016. [CrossRef]

- Teuber, L.; Osburg, V.-S.; Toporowski, W.; Militz, H.; Krause, A. Wood Polymer Composites and Their Contribution to Cascading Utilisation. 2015. [CrossRef]

- Sommerhuber, P.F.; Wang, T.; Krause, A. Wood-Plastic Composites as Potential Applications of Recycled Plastics of Electronic Waste and Recycled Particleboard. 2016. [CrossRef]

- Al-Salem, S.M.; Lettieri, P.; Baeyens, J. The Valorization of Plastic Solid Waste (PSW) by Primary to Quaternary Routes: From Re-Use to Energy and Chemicals. Prog. Energy Combust. Sci. 2010, 36, 103–129. [Google Scholar] [CrossRef]

- Kazemi Najafi, S. Use of Recycled Plastics in Wood Plastic Composites – A Review. Waste Manag. 2013, 33, 1898–1905. [Google Scholar] [CrossRef] [PubMed]

- Sommerhuber, P.F.; Welling, J.; Krause, A. Substitution Potentials of Recycled HDPE and Wood Particles from Post-Consumer Packaging Waste in Wood–Plastic Composites. Waste Manag. 2015, 46, 76–85. [Google Scholar] [CrossRef]

- Keskisaari, A.; Kärki, T. The Use of Waste Materials in Wood-Plastic Composites and Their Impact on the Profitability of the Product. 2018. [CrossRef]

- Ergün, M.E.; İstek, A.; Özlüsoylu, İ.; Koyuncu, F.; Bülbül, Ş. Low Formaldehyde-Emission Particleboards with the Addition of Scots Pine Wood Waste Derived Activated Carbon. Wood Mater. Sci. Eng. 2024. [Google Scholar] [CrossRef]

- EN 827 Adhesives - Determination of Conventional Solids Content and Constant Mass Solids Content; European Committee for Standardization, Brussels, Belgium, 2005.

- ISO 1522 Paints and Varnishes — Pendulum Damping Test; European Committee for Standardization, Brussels, Belgium, 2022.

- EN 323 Wood-Based Panels - Determination of Density 1993.

- EN 310 Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization, Brussels, Belgium, 1993.

- EN 319 Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization, Brussels, Belgium, 1993.

- EN 320 Particleboards and Fibreboards - Determination of Resistance to Axial Withdrawal of Screws. 2011.

- EN 317 Particleboards and Fibreboards - Determination of Swelling in Thickness after Immersion in Water 1993.

- EN 312 Particleboards - Specifications; European Committee for Standardization, Brussels, Belgium, 2010.

- Wronka, A.; Kowaluk, G. The Influence of Multiple Mechanical Recycling of Particleboards on Their Selected Mechanical and Physical Properties. Materials (Basel). 2022, 15. [Google Scholar] [CrossRef] [PubMed]

- Wronka, A.; Kowaluk, G. Upcycling Different Particle Sizes and Contents of Pine Branches into Particleboard. Polymers (Basel). 2022, 14. [Google Scholar] [CrossRef] [PubMed]

- Zalewska, A.; Kowalik, J.; Tworek, M. Investigation of the Properties of a Water-Based Acrylic Dispersion Modified with an Ionic Liquid, Surfactant, and Thickener. Environ. Sci. Pollut. Res. 2023. [Google Scholar] [CrossRef] [PubMed]

- Çakicier, N.; Korkut, S.; Sevim Korkut, D. Varnish Layer Hardness, Scratch Resistance, and Glossiness of Various Wood Species as Affected by Heat Treatment. BioResources 2011, 6, 1648–1658. [Google Scholar] [CrossRef]

- Kaygin, B.; Akgun, E. Comparison of Conventional Varnishes with Nanolacke UV Varnish with Respect to Hardness and Adhesion Durability. Int. J. Mol. Sci. 2008, 9, 476–485. [Google Scholar] [CrossRef] [PubMed]

- Aksu, S.; Kelleci, O.; Aydemir, D.; Istek, A. Application of Acrylic-Based Varnishes Reinforced with Nano Fillers for Conservation of Weathered and Worn Surfaces of the Historical and Cultural Wooden Buildings. J. Cult. Herit. 2022, 54, 1–11. [Google Scholar] [CrossRef]

- Saranjam, N.; Chandra, S.; Mostaghimi, J.; Fan, H.; Simmer, J. Orange Peel Formation Due to Surface Tension-Driven Flows within Drying Paint Films. J. Coatings Technol. Res. 2016, 13, 413–426. [Google Scholar] [CrossRef]

- Palija, T.; Jaić, M.; Džinčić, I.; Šućur, A.; Dobić, J. Variability of Dry Film Thickness of a Coating Applied by Roller Coater on Wood in a Real Industrial Process. Drewno 2018, 61. [Google Scholar] [CrossRef]

- Dvořák, O.; Pánek, M.; Kvietková, M.S.; Pastierovič, F.; Štěrbová, I.; Kubista, K.; Sahula, L. Influence of Wood Species on Quality of Exterior Transparent Acrylic Coating During Outdoor Exposure. Wood Res. 2022, 67, 994–1004. [Google Scholar] [CrossRef]

- Çolak, S.; Nemli, G.; Demirkir, C.; Aydin, I.; Demirel, S. Utilization Potential of Waste from Window Joints for Particleboard. J. Compos. Mater. 2011, 45, 29–37. [Google Scholar] [CrossRef]

- Onat, S.M.; Coşkun, K.; Kelleci, O. Particleboard Density and Surface Quality. In Proceedings of the All Sciences Proceedings; 2023.

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from Recycled Wood. Forests 2020, 11, 1–16. [Google Scholar] [CrossRef]

- Martins, J.; Pereira, J.; Pinto, B.; Coelho, C. Effect of Recycled Wood on Formaldehyde Release of Particleboard. In Proceedings of the COST Action E49 Conference “Measurement and Control of VOC Emissions from Wood-Based Panels”; 2007; p. 10.

- Iždinský, J.; Vidholdová, Z.; Reinprecht, L. Particleboards from Recycled Thermally Modified Wood. Forests 2021, 12, 4–7. [Google Scholar] [CrossRef]

- Borysiuk, P.; Auriga, R. Thermally Modified Particles As Raw Material For.; 2016.

- Wronka, A.; Kowaluk, G. Influence of Density on Selected Properties of Furniture Particleboards Made of Raspberry Rubus Idaeus L. Lignocellulosic Particles. Ann. WULS, For. Wood Technol. 2019, 105, 113–124. [Google Scholar] [CrossRef]

- Wong, E.D.; Zhang, M.; Wang, Q.; Han, G.; Kawai, S. Formation of the Density Profile and Its Effects on the Properties of Fiberboard. J. Wood Sci. 2000, 46, 202–209. [Google Scholar] [CrossRef]

- Lubis, M.A.R.; Hong, M.K.; Park, B.D.; Lee, S.M. Effects of Recycled Fiber Content on the Properties of Medium Density Fiberboard. Eur. J. Wood Wood Prod. 2018, 76, 1515–1526. [Google Scholar] [CrossRef]

- Sackey, E.K.; Semple, K.E.; Oh, S.-W.; Smith, G.D. Improving Core Bond Strength of Particleboard through Particle Size Redistribution. Wood Fiber Sci. 2008, 40, 214–224. [Google Scholar]

- Wronka, A.; Kowaluk, G. Selected Properties of Particleboard Made of Raspberry Rubus Idaeus L. Lignocellulosic Particles. Ann. WULS, For. Wood Technol. 2019, 105, 113–124. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Ghamsari, F.A.; Salimifard, E. Effects of Adding Nano-Wollastonite, Date Palm Prunings and Two Types of Resins on the Physical and Mechanical Properties of Medium-Density Fibreboard (MDF) Made from Wood Fibres. Bois Forets des Trop. 2018, 335, 49–57. [Google Scholar] [CrossRef]

- Riegler, M.; Weigl, M.; Harm, M.; Rathke, J.; Müller, U. Influence of Hardwood on the Vertical Density Profile and Fracture Energy of Particleboards. “Hardwood Sci. Technol. 5th Conf. Hardwood Res. Util. Eur. 2012, 2012, 3–7. [Google Scholar]

- Wronka, A.; Robles, E.; Kowaluk, G. Upcycling and Recycling Potential of Selected Lignocellulosic Waste Biomass. Materials (Basel). 2021, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Sung, M.; Lee, S.-M.; Min, Y. Decreasing the Formaldehyde Concentration in Indoor Air by Improving the Adhesives Used in Engineered Wood Materials in Korean Apartment Buildings. J. Adhes. Sci. Technol. 2013, 27, 671–682. [Google Scholar] [CrossRef]

- Meng, M.; Hong, W. Mathematical Model for the Formaldehyde Emission from Wood Composites. For. Prod. J. 2017, 67, 126–134. [Google Scholar] [CrossRef]

- Szczurek, A.; Zajiczek, Ż.; Sibilak, D.; Maciejewska, M. Formaldehyde Removal by the Internal Wall Paint – Preliminary Study. In Proceedings of the E3S Web of Conferences; 2018; Vol. 44.

- Chen, W.; Mendell, M.; Li, N.; Kumagai, K. Formaldehyde Emissions from Seams and Cut Edges of Laminate Flooring: Implications for Emission Testing Protocols and Exposure Estimation. Build. Environ. 2018, 143, 652–660. [Google Scholar] [CrossRef]

| Test type | Alternative raw material particles share [%] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 5 | 10 | 25 | 50 | 100 | ||||||

| V | P | V | P | V | P | V | P | V | P | ||

| MOE | a | b | c | c | c | c | c | b | c | a | b |

| MOR | a | b | c | b | b | b, c | b, c | b | b | a | a |

| IB | a | b | c | c | d | b | c | e | b | f | g |

| SWR | a | b | b | b | c | b | b | b | b | d | a |

| TS 2h | a | a | a | a | b | c | a | a | b | d | d |

| TS 24h | a | b | b | a | a | a | c | a, b | a, b | d | a, b |

| WA 2h | a | a, b | b | c | b, c | d | d | c | e | f | f |

| WA 24h | a | b | b | c | c | c | c | d | d | b | d |

| HCHO | a | n.a. 2 | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | a | a |

| TVOC | a | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | n.a. | a | a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).