Submitted:

25 July 2024

Posted:

25 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction and Background

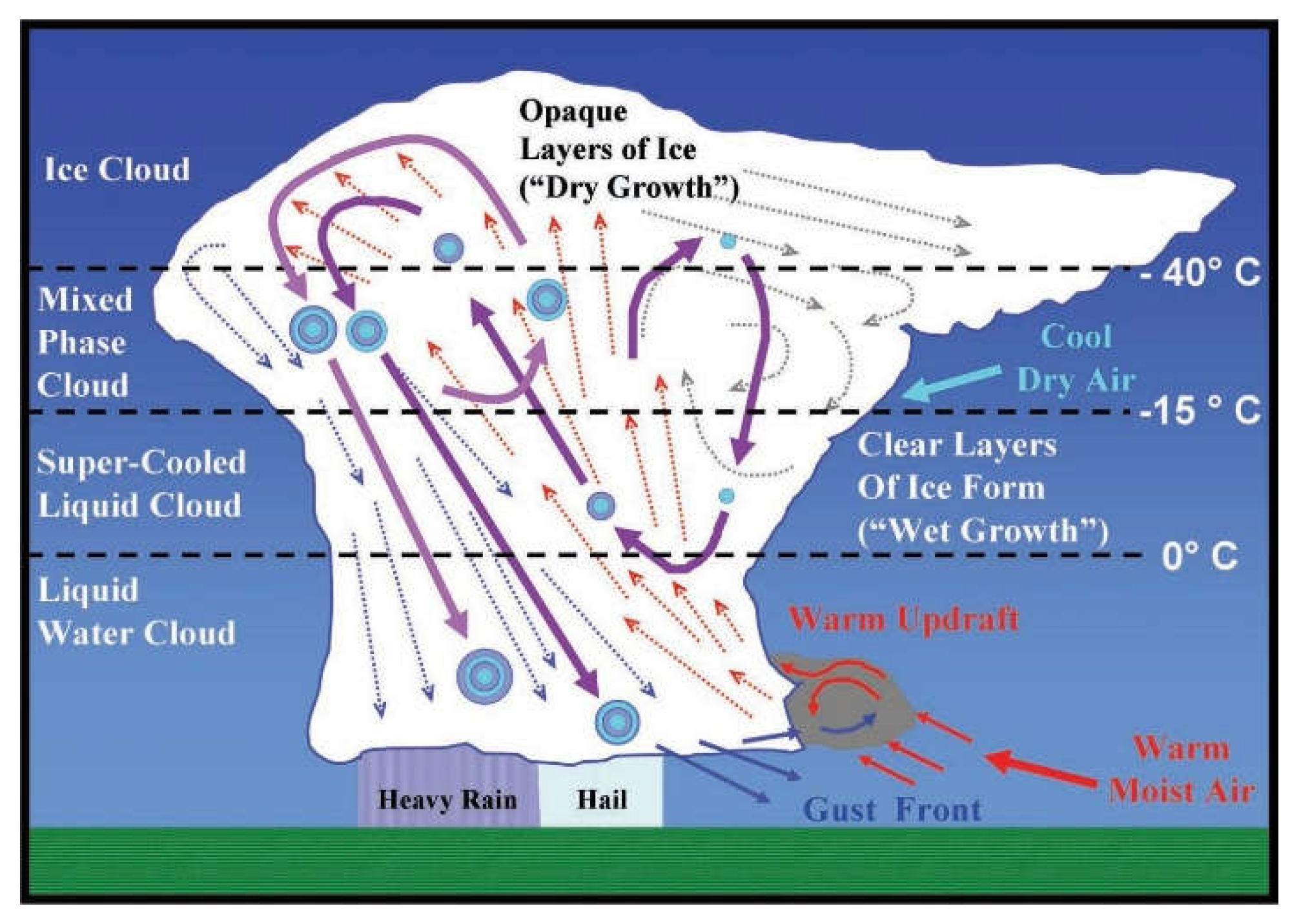

1.1. Physics Laws and Basics of Energy Transfer for a Hailstone

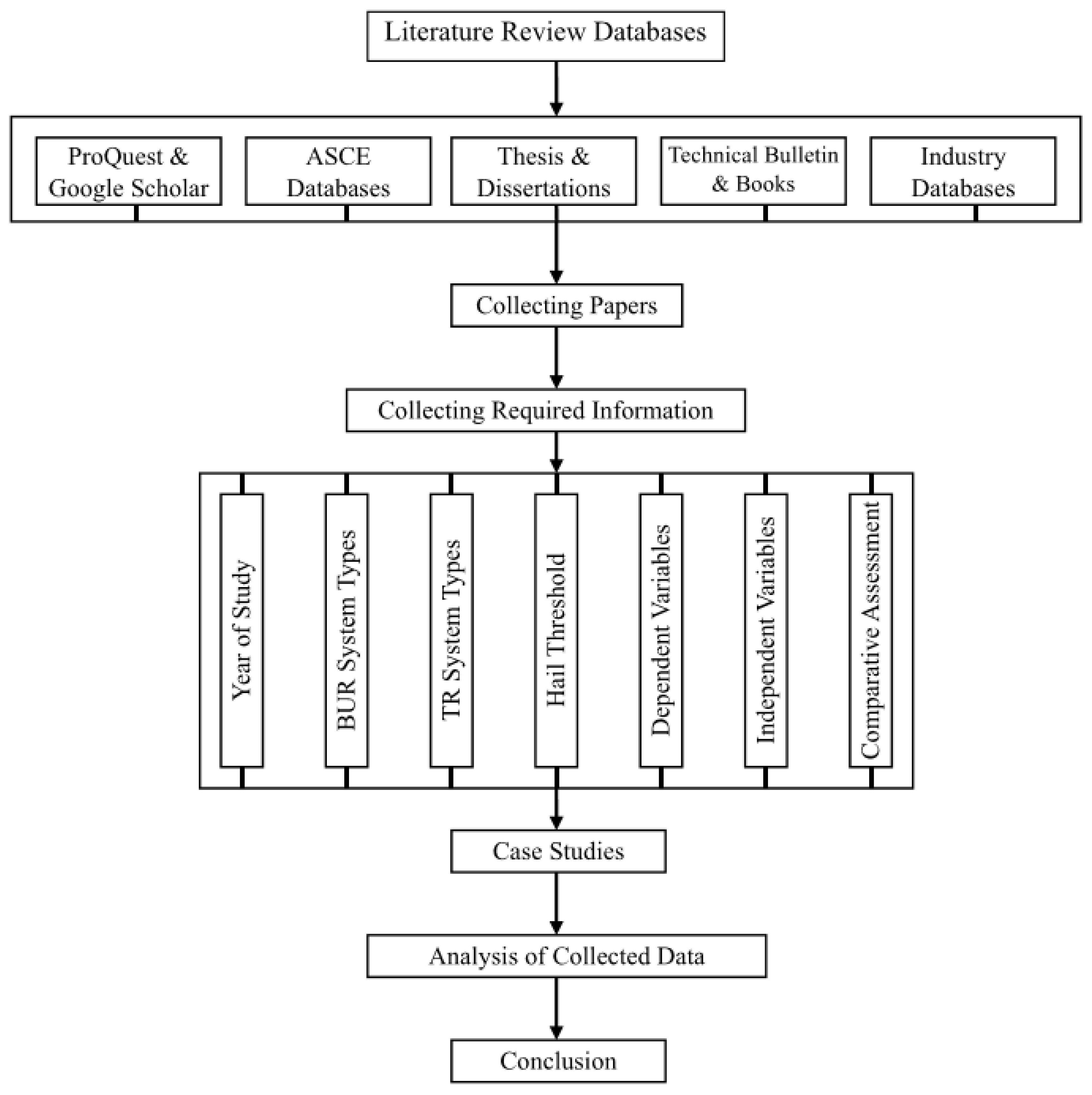

2. Objectives and Methodology

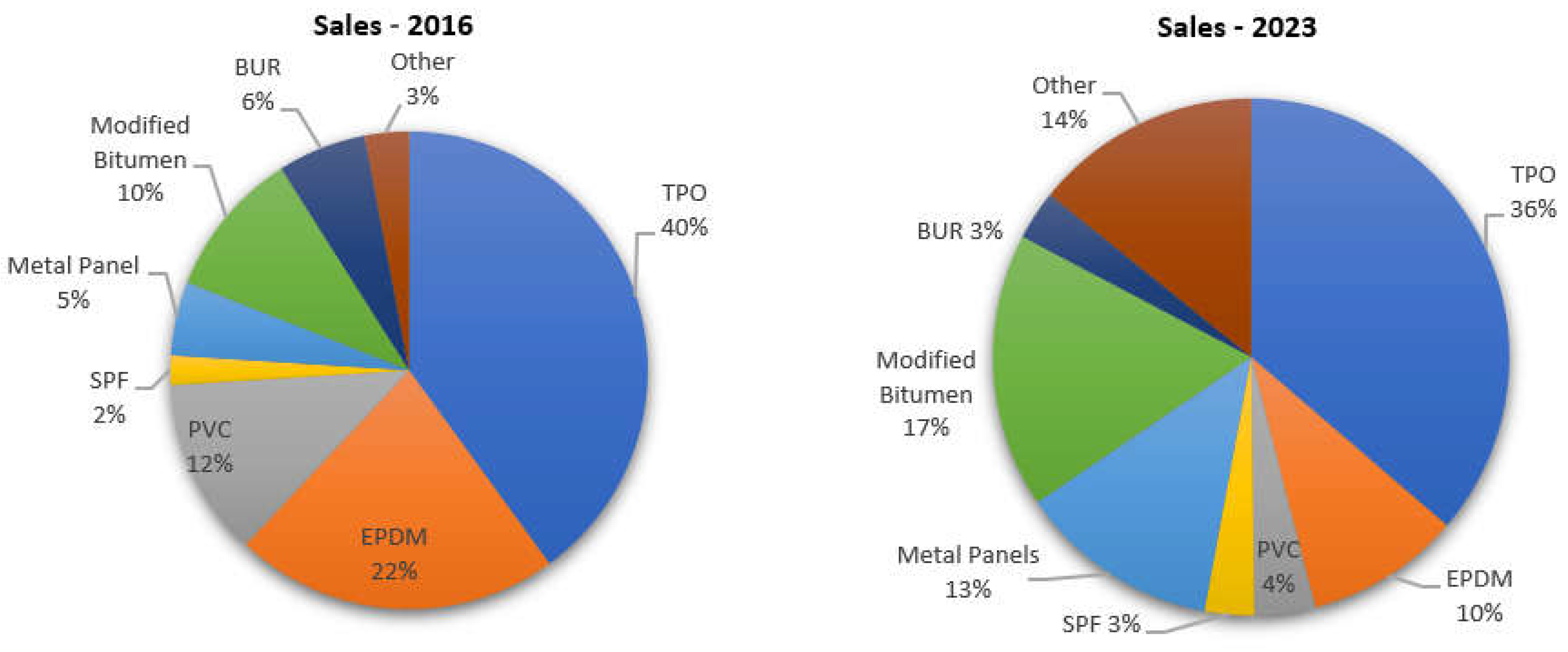

3. Roofing Systems

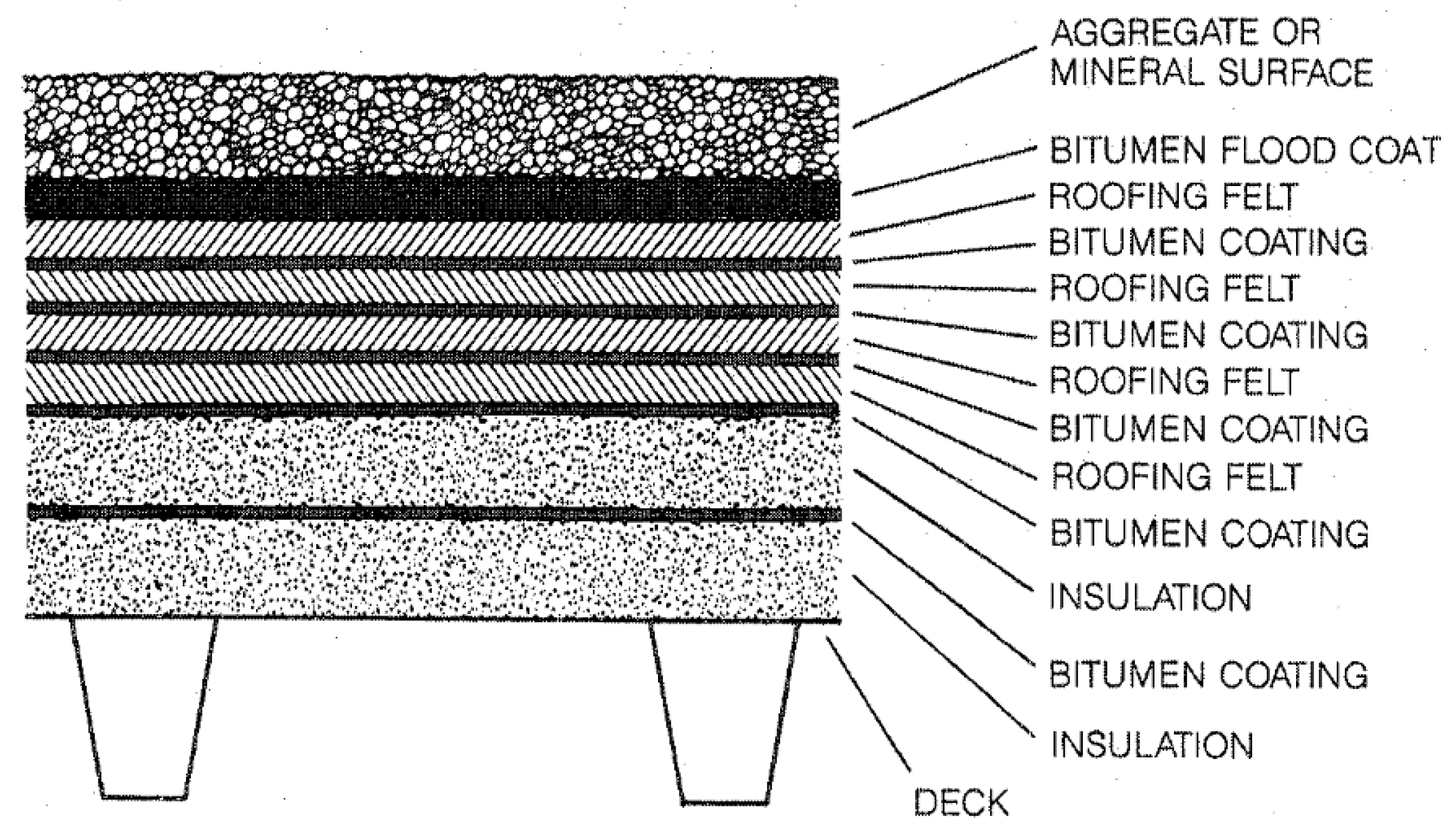

3.1. Built-Up Roof Systems

3.2. Tile Roofing System (TR)

- Flat Tiles: These are the most common concrete roofing tiles. For the clay flat tiles, the durability of terracotta clay.

- French Tiles: These tiles have deep locks on all four sides, plus two prominent flutes on the surface. French clay tiles are a low-profile option with two protruding flues per tile.

- Double Roman Tiles: The Double Roman is a standard profiled concrete roof. These Tiles have a small round roll and are also known as mission tiles.

- Spanish Tiles: These tiles provide a pattern of distinctive ripples across the roof and are popular in heavy rain regions. These have an S-shaped design similar to mission tiles. These can be clay or concrete.

- Scalloped Tiles: These concrete tiles have a curved bottom edge, which gives them a fish-scale appearance.

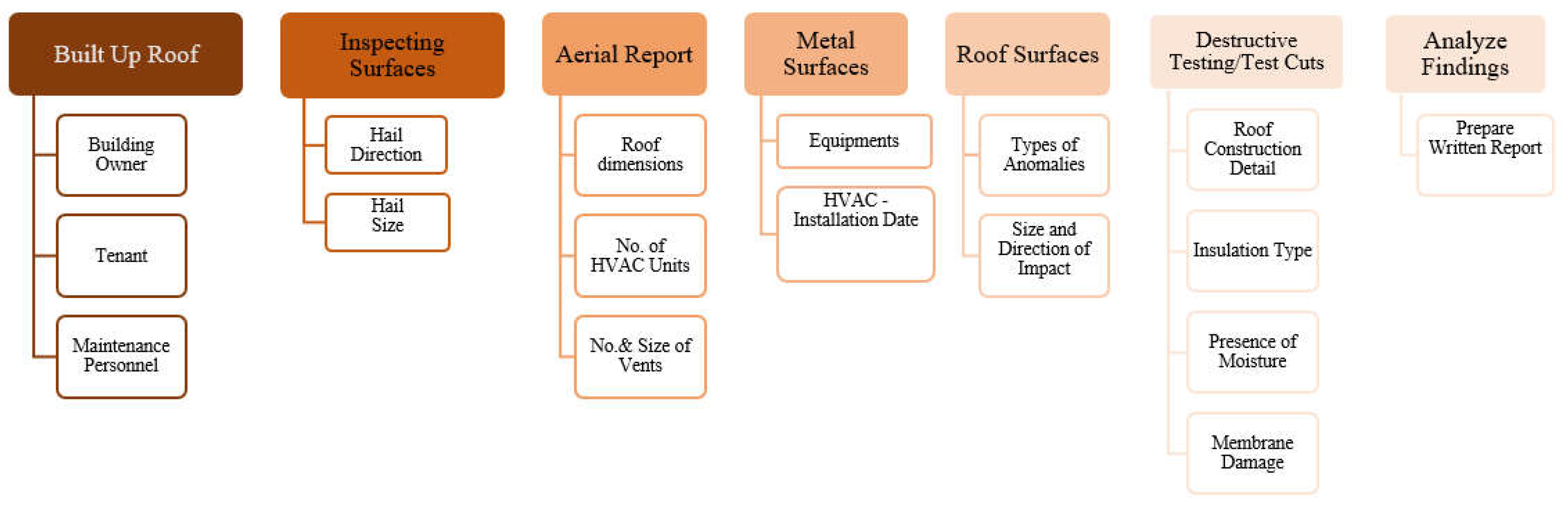

3.3. Inspection Protocol for Roof Damage Assessment

4. Comparative Impact Assessment and Discussion

4.1. Hail Threshold

- A radiating fracture or multiple irregular fractures radiating out from the point of impact.

- Complete shatter, penetration, or puncture through the tile.

- Cracks or breaks in the tile’s exposure or fractures above the head lap are functional damage as they inhibit the tiles’ ability to shed water.

- Crescent-shaped breaks along the thinner edges or corners of S-shaped tiles, particularly where they interface with adjacent tiles.

- Chips at the tile’s corners with the evidence of burnish mark.

- Substrate damage or discernable impressions left that broke through the surface layers.

4.2. Failure Modes

4.3. Case Studies on TR and BUR Systems

5. Contribution to the Body of Knowledge and Conclusions

6. Recommendations for Future Research

Notation

| Total energy of hailstone | |

| kinetic energy of hailstone | |

| potential energy of hailstone | |

| AI | Artificial Intelligence |

| BUR | Built-up roofing system |

| C | surface Cracked |

| D | Foamboard Delaminated |

| F | Felts Cracked |

| g | gravitational constant (i.e., 9.8 m/s2, 32.2 feet/s2) |

| h | height of hailstone above the ground |

| HVAC | Heating, ventilation, and air conditioning (HVAC) |

| m | mass of hailstone |

| N | No visible indentation |

| P | Penetrated Roofing |

| ND | No Damage |

| NRCA | National Roofing Contractor Association |

| NT | Not Tested |

| S | Surface Shattered |

| THR | Threshold for Damage |

| TR | Tile roofing system |

| UTA | University of Texas at Arlington |

| v | velocity of hailstone at any given time |

Author Contributions

Data Availability Statement

References

- CoreLogic. “Everything is Bigger in Texas-Hail Events 2016.” Accessed February 6, 2024 http://www.corelogic.com/about-us/researchtrends/everything-is-biggerin-texas-hail-events-2016.aspx#.

- Crenshaw, V., and J. D. Koontz. 2010. “Hail: Sizing it Up!”. Accessed February 10, 2024, http://www.hailtrax. com/hail_size_it_up.pdf.

- Cullen, W. C. 1997. “Hail damage to roofing: Assessment and classification.” In Proc., Fourth International Symposium on Roofing Technology, NRCA/NIST, Gaithersburg, Maryland, 211–216.

- Deiling, C., M. Smith, and M. Beruvides. 2020. “ Review of Impact Factors of the Velocity of Large Hailstones for Laboratory Hail Impact Testing Consideration.” Geosciences 2020.

- Dodson M. 2023. “Low Slope Roofing Market.” Accessed March 17, 2024. Western Roofing Market. https://www.westernroofing.net/2023/11/22/low-slope-roofing-market/.

- Fricklas, R. L. 1989. “Judging The Performance of Roofing Asphalt.” The Better Understanding Of Roofing Systems Institute (BURSI).

- Greenfeld, S. H. 1969. “Hail Resistance of Roofing Products.” National Bureau of Standards Inst. For Applied Technology: Washington D.C. (U.S.), Building Science Series #23, 1-11.

- Griffith, M. , and J. A. Morgan. 1976. “On the Role of Strong Winds in Damage to Crops by Hail and its Estimation with a Simple Instrument.” Journal Of Applied Meteorology Vol 15, 891-898.

- Haag Engineering. 2006. “Hailstorm Characteristics”. Accessed February 9, 2024. http://www.haagengineering.com/ehail/chas/ eHail/hailstorm.html.

- Heymsfield, A. J., I. M., Giammanco, and R. Wright. 2014. “Terminal velocities and kinetic energies of natural hailstones.” Geophysical research letters, American Geophysical Union. 8666–8672.

- Hill V. 2017. “Roofing Trends”. Accessed March 18, 2024, International Institute of Building Enclosures Consultants. https://iibec.org/wp-content/uploads/2017-03-hill.pdf.

- Hinojosa O., K. Kane. 2002. “A measure of the industry.” Accessed March 17, 2024. NRCA Professional Roofing. https://www.professionalroofing.net/Articles/A-measure-of-the-industry--04-01-2002/41.

- Koontz, J.D. 1991. “What are the Effects of Hail on Residential Roofing Products.” In Proc., Third International Symposium on Roofing Technology, 206-215.

- Laurie, J. A. P. 1960. “Hail and Its Effects on Buildings,” Research Report 176, NBRI, Pretoria, South Africa, 1960.

- Marshall, T. P. , and R. F. Herzog. 2002. “Protocol for Assessment of Hail-Damaged Roofing.” In Proc., Proceedings of the North American Conference on Roofing Technology. 40-46.

- Marshall, T. P., R. F. Herzog, S. J. Morrison, and S. R. Smith. 2002. “Hail Damage Threshold Sizes for Common Roofing Materials.” Dallas, TX: Haag Engineering Co.

- Marshall, T. P., R. F. Herzog, S. J. Morrison, and S. R. Smith. 2004. “Hail damage to tile roofing.” In Proc., 22nd Conference on Severe Local Storms.

- Mayercsik, N.P. , and P. J. Bennett. 2022. “Assessing Hail Damage to Concrete Tile Shingles: An Analytical Method and a Case Study.” In Proc., Ninth Congress on Forensic Engineering, Denver, Colorado. Sponsored by the Forensic Engineering Division of ASCE.

- Morrison, S. J. 1999. “Long-Term Effects of Hail Impact on Asphalt Shingles – An Interim Report.” In Proc., Proceedings of the North American Conference on Roofing Technology.

- Morrison, S. J. 2009. “Holy Hail.” National Roofing Contractors Association. Accessed February 7, 2024, https://www.professionalroofing.net/Articles/Holy-hail--06-01-2009/1506.

- NOAA NSSL (National Oceanic and Atmospheric Administration) (National Severe Storms Laboratory). “Hail Basics.” Accessed February 6, 2024. https://www.nssl.noaa.gov/education/svrwx101/hail/#:~:text=Hailstones%20are%20formed%20when%20raindrops,freeze%20onto%20the%20hailstone’s%20surface.

- Noon, R. K. 2001. Forensic Engineering Investigation. Boca Raton, FL: CRC Press.

- Petty, S. E. 2013. Forensic Engineering Damage Assessments for Residential and Commercial Structures. Boca Raton, FL: CRC Press, 103-115.

- Petty, S.E., M. A Petty., and T. Kasberg. 2009. “Evaluation of Hail-Strike Damage to Asphalt Shingles Based on Hailstone Size, Roof Pitch, Direction of Incoming Storm, and Facing Roof Direction.” Interface Magazine, 4–10.

- Rajeev, P., J. G. Sanjayan, and S. S. Seenuth. 2016. “Assessment of thermal cracking in concrete roof tiles.” Materials and Design 107. 470–477.

- RICOWI (The Roofing Industry Committee on Weather Issues, Inc.). 2004. Hailstorm Investigation Report Oklahoma City, OK, April 21, 2004.

- RICOWI (The Roofing Industry Committee on Weather Issues, Inc.). 2012. Hailstorm Investigation Report Dallas/Fort Worth, TX May 24, 2011.

- RICOWI (The Roofing Industry Committee on Weather Issues, Inc.). 2016. Hailstorm Investigation Report North Texas, TX April 11, 2016.

- Shephard K., N. Gromicko. 2006. “Mastering Roof Inspections: Hail Damage, Part 6.” International Association of Certified Home Inspectors®. Accessed February 9, 2024, https://www.nachi.org/hail-damage-part6-33.htm.

- Smith J. M., H. C. Van Ness. 1975. Introduction to Chemical Engineering Thermodynamics, 3rd ed. New York: McGraw-Hill Book Company.

- TRI (Tile Roof Institute). 1999. “Technical Brief: Chipped Tile.” Technical Brief. Accessed February 9, 2024. https://tileroofing.org/wp-content/uploads/19TRI036_99-002-chipped-tile_d2.pdf.

- TRI (Tile Roof Institute). 2010. “Hail Damage is Not indicative of a Manufacturing Defect.” Technical Brief. Accessed February 9, 2024. https://tileroofing.org/wp-content/uploads/19TRI036_2010-001-hail-damage_d2.pdf.

- TRI (Tile Roof Institute). 2014. “Concrete Roof Tiles.” Technical Brief. Accessed February 9, 2024. https://tileroofing.org/wp-content/uploads/19TRI036_PCATechBrief-concrete-homes_d2.pdf.

- TRI (Tile Roof Institute). 2014. “Technical Brief: Walkability on Concrete and Clay Roof Tiles.” Technical Brief. Accessed February 9, 2024. https://tileroofing.org/wp-content/uploads/19TRI036_Technical-Brief-2014-02-Walkability_d2.pdf.

- Verhulst, S. M. 2018. “Hail Sizing: A Comparison of On-Site Data with Weather Data”. In Proc., Forensic Engineering 8th Congress: Forging Forensic Frontiers. Austin, Texas. Sponsored by the Forensic Engineering Division of ASCE.

| Product | Types of Bitumen | Roof Grade | Softening PointMin. | Max. |

|---|---|---|---|---|

| 140°F (60°C) | Type I | Dead Level | 135°F (57°C) | 151 °F (66°C) |

| 170°F (77°C) | Type II | Flat Grade | 158°F (70°C) | 176 °F (80°C) |

| 190°F (88°C) | Type III | Steep Grade | 185°F (85°C) | 205 °F (96°C) |

| 220°F (104°C) | Type IV | Special Steep | 210°F (99°C) | 225 °F (107°C) |

| Hail Damage Indentation Size (mean diameter of indentation) | ||||

| Hailstone Size, in(cm) | 1 ½ (3.8) | 1 ¾ (4.5) | 2(5.1) | 2 ½ (6.4) |

| 1. Base sheet plus organic felt, asphalt flood coat on | ||||

| a. ½ inch (1.3 cm) plywood | 5/8 (1.6) | 5/8 (1.6) | 5/8 (1.6) C | 1 ¼ (1.6) C |

| b. 1-inch (2.5 cm) fiberboard on ½ inch (1.3 cm) plywood | 5/8 (1.6) | 1 (2.5) C | 1 ¼ (3.2) C | 1 5/8 (4.1) C |

| c. 1-inch (2.5 cm) Foamboard A on ½ inch (1.3 cm) plywood | 5/8 (1.6) | NT | 5/8 (1.6) | 2 ¼ (5.7) P |

| d. 1-inch (2.5 cm) Foamboard B on ½ inch (1.3 cm) plywood | ¾ (1.9) | NT | 1 ¼ (3.2) D | NT |

| e. 1-inch (2.5 cm) Asbestos Cement | 7/8 (2.2) | NT | 1 (2.5) C | 1 ¼ (3.2) C |

| f. 1-inch (2.5 cm) Fiberboard on 22 Ga. Steel Decking | ¾ (1.9) | 7/8 (2.2) | 1 ¼ (3.2) C | 1 ¾ (4.5) C |

| g. 1-inch (2.5 cm) Glass fiber insulation on 22 Ga. Steel Deck | N | 1 (2.5) C | 1 ¼ (3.2) C | 2 ¼ (5.7) FP |

| 2. Base sheet plus asbestos felt, asphalt flood coat on | ||||

| a. ½ inch (1.3 cm) plywood | N | NT | N | N |

| b. 1-inch (2.5 cm) Asbestos Cement | N | N | 1 (2.5) | N |

| c. 1-inch (2.5 cm) fiberboard on ½ inch (1.3 cm) plywood | N | N | 1 (2.5) C | NT |

| 3. Base sheet plus tarred felt, tar flood coat on | ||||

| a. ½ inch (1.3 cm) plywood | C | ½ (1.3) C | C | CS |

| b. 1-inch (2.5 cm) Asbestos Cement | C | NT | N | C |

| c. 1-inch (2.5 cm) fiberboard on ½ inch (1.3 cm) plywood | C | NT | C | 2 (5) C |

| 4. 2 Glass felt + 1 glass cap sheet on | ||||

| a. ½ inch (1.3 cm) plywood | N | NT | ½ (1.3) | 1 (2.5) |

| b. 1-inch (2.5 cm) Asbestos Cement | N | NT | N | N |

| c. 1-inch (2.5 cm) fiberboard on ½ inch (1.3 cm) plywood | ¾ (1.9) | NT | 1 (2.5) | 1 ½ (3.8) C |

| d. 1-inch (2.5 cm) fiberboard on 1-inch (2.5 cm) Asbestos Cement | ½ (1.3) | NT | N | 1 ½ (3.8) C |

| e. ¾-inch (1.9 cm) Glass fiber insulation on 1/2-inch (1.3 cm) plywood | 5/8 (1.6) | NT | 1 1/8 (2.8) | 1 ¾ (4.5) C |

| f. ¾-inch (1.9 cm) Glass fiber insulation on 1-inch (2.5 cm) Asbestos Cement | ½ (1.3) | NT | 7/8 (2.2) | 1 ½ (3.8) C |

| 5. 2 Base sheets, asphalt flood coat on | ||||

| a. ½ inch (1.3 cm) plywood | ½ (1.3) C | NT | 7/8 (2.2) C | 1 ¼ (3.2) C |

| b. 1-inch (2.5 cm) Asbestos Cement | N | NT | N | N |

| c. 1-inch (2.5 cm) fiberboard on ½ inch (1.3 cm) plywood | ¾ (1.9) C | ¾ (1.9) C | 1 1/8 (2.8) C | NT |

| d. 1-inch (2.5 cm) fiberboard on 1-inch (2.5 cm) Asbestos Cement | 5/8 (1.6) C | 7/8 (2.2) C | 1 (2.5) C | NT |

| 6. 2 Base sheets, asphalt flood coat + slag on | ||||

| a. ½ inch (1.3 cm) plywood | N | NT | N | N |

| b. 1-inch (2.5 cm) Asbestos Cement | N | NT | N | N |

| c. 1-inch (2.5 cm) fiberboard on ½ inch (1.3 cm) plywood | N | NT | N | N |

| d. 1-inch (2.5 cm) fiberboard on 1-inch (2.5 cm) asbestos cement | N | NT | N | N |

| References | Hail Size (Inches) | Damage Classification |

| Marshall et al. (2004) | ||

| Concrete Tile | 1.0 | ND |

| 1.25 | 4 of the 13 tiles had corners damaged | |

| 1.5 | 7 of 13 tiles are damaged | |

| 2.5 | all the tiles are broken | |

| Clay S-Tile | 1.0 | ND |

| 1.25 | ND | |

| 1.5 | All tile corners broke | |

| Marshall et al. (2004a) | ||

| Flat Concrete Tile | 1.25 | 20 percent (%) tiles are damaged |

| 1.5 | 50 % of tiles are damaged | |

| 1.75 | 50 % of tiles are damaged | |

| 2 | 100 % of tiles are damaged | |

| S-Shaped Conc. Tile | 1-1.75 | ND |

| 2.0 | 80% of tiles are damaged | |

| Koontz J.D. (1991) | ||

| Concrete Tile | 2.5 | Fractures with multiple impacts |

| Haag (2006) | ||

| Clay | 1.5 | THR |

| Concrete Tile | 1.75 | THR |

| Greenfeld (1969) | ||

| Red Clay Tile | 1.5-1.75 | Unsupported edges |

| 2 | Center |

| Hail Diameter Literature |

Hail Threshold for Roofing Configuration Systems (inches) | ||||||||||||||||

| Built-up | Concrete and Clay Tile | ||||||||||||||||

| 1 | 1 ¼ | 1 ½ | 1 5/8 | 1 ¾ | 2 | 2 ¼ | 2 ½ | 1 | 1 ¼ | 1 ½ | 1 5/8 | 1 ¾ | 2 | 2 ¼ | 2 ½ | ||

| Greenfeld (1969) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | ☒ | ☒ | ☒ | ☐ | ☐ | |

| Mathey and Cullen (1974) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

| Haag (1988) | ☐ | ☐ | ☐ | ☒ | ☐ | ☒ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

| Koontz (1991) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | |

| Haag (1993) | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

| Cullen (1997) | ☐ | ☐ | ☒ | ☐ | ☐ | ☒ | ☒ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | |

| Crenshaw and Koontz (2000) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

| Noon (2002) | ☐ | ☐ | ☒ | ☒ | ☒ | ☒ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | |

| Marshall and Morrison (2004) | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

| Marshall et al. (2004) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | ☒ | ☐ | ☐ | ☐ | ☐ | ☒ | |

| Marshall et al. (2004a) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | ☒ | ☐ | ☒ | ☒ | ☐ | ☒ | |

| Haag (2006) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☒ | ☐ | ☒ | ☐ | ☐ | ☐ | |

| RICOWI (2011) | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

| Petty (2013) | ☐ | ☐ | ☒ | ☒ | ☒ | ☒ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

| Herzog, RICOWI (2016) | ☐ | ☐ | ☒ | ☒ | ☒ | ☒ | ☒ | ☒ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | ☐ | |

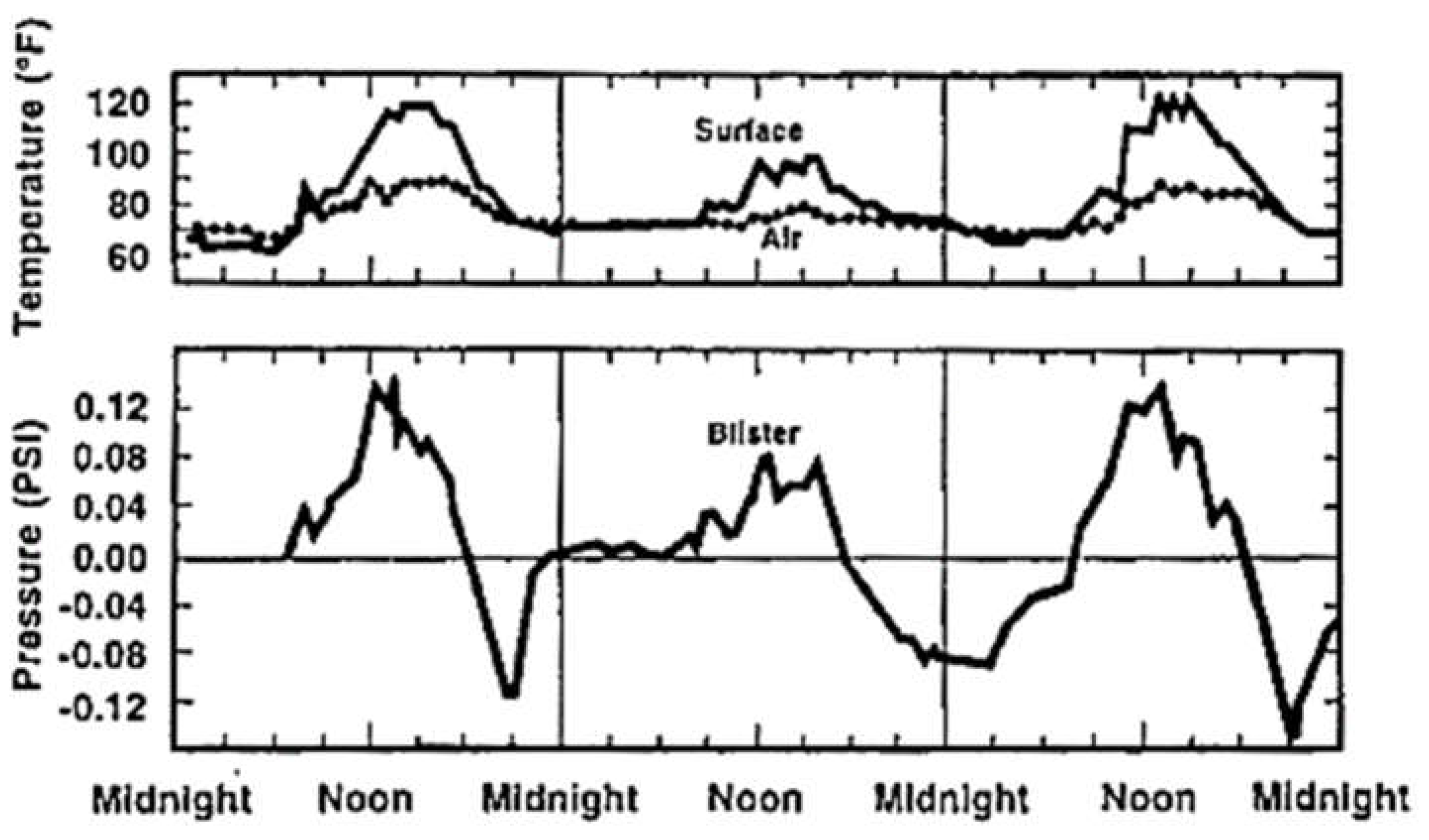

| Flashing | Membrane |

| Base Flashing | Blisters |

| Metal Cap Flashing | Ridges |

| Flashed Penetrations | Splits |

| Alligator Cracking | |

| Surface Deterioration | |

| Bare Spots on Gravel | |

| Ponding | |

| Fish mouths | |

| Slippage |

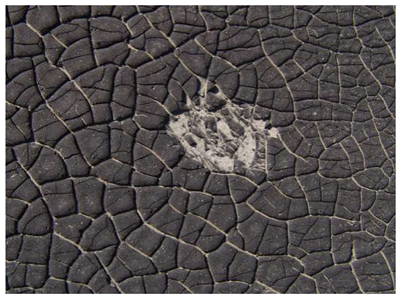

| Defects | Image |

| Hail-strike types of failures | |

| A crescent-shaped crack in concrete field tile with a central impact point |  |

| A crescent-shaped crack in concrete field tile with associated spatter mark |  |

| A finish displacement in the top coat of the BUR system |  |

| Circular cracks in BUR membrane with associated dull interiors exposed |  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).