Submitted:

26 July 2024

Posted:

29 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

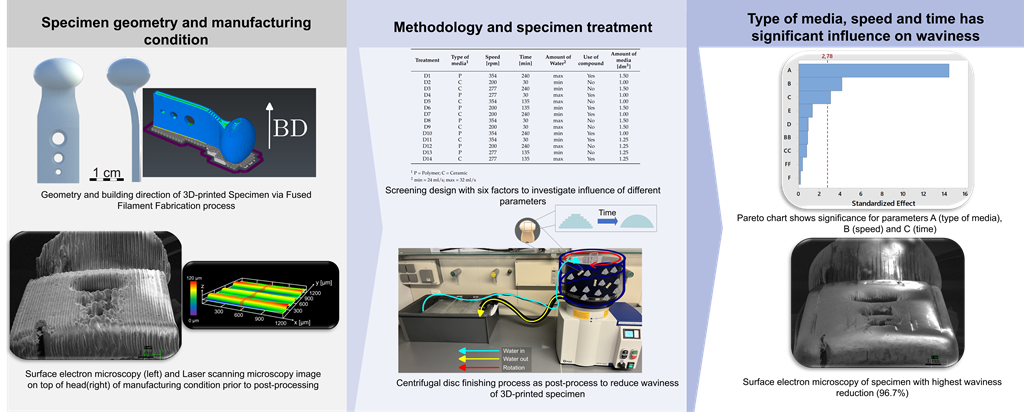

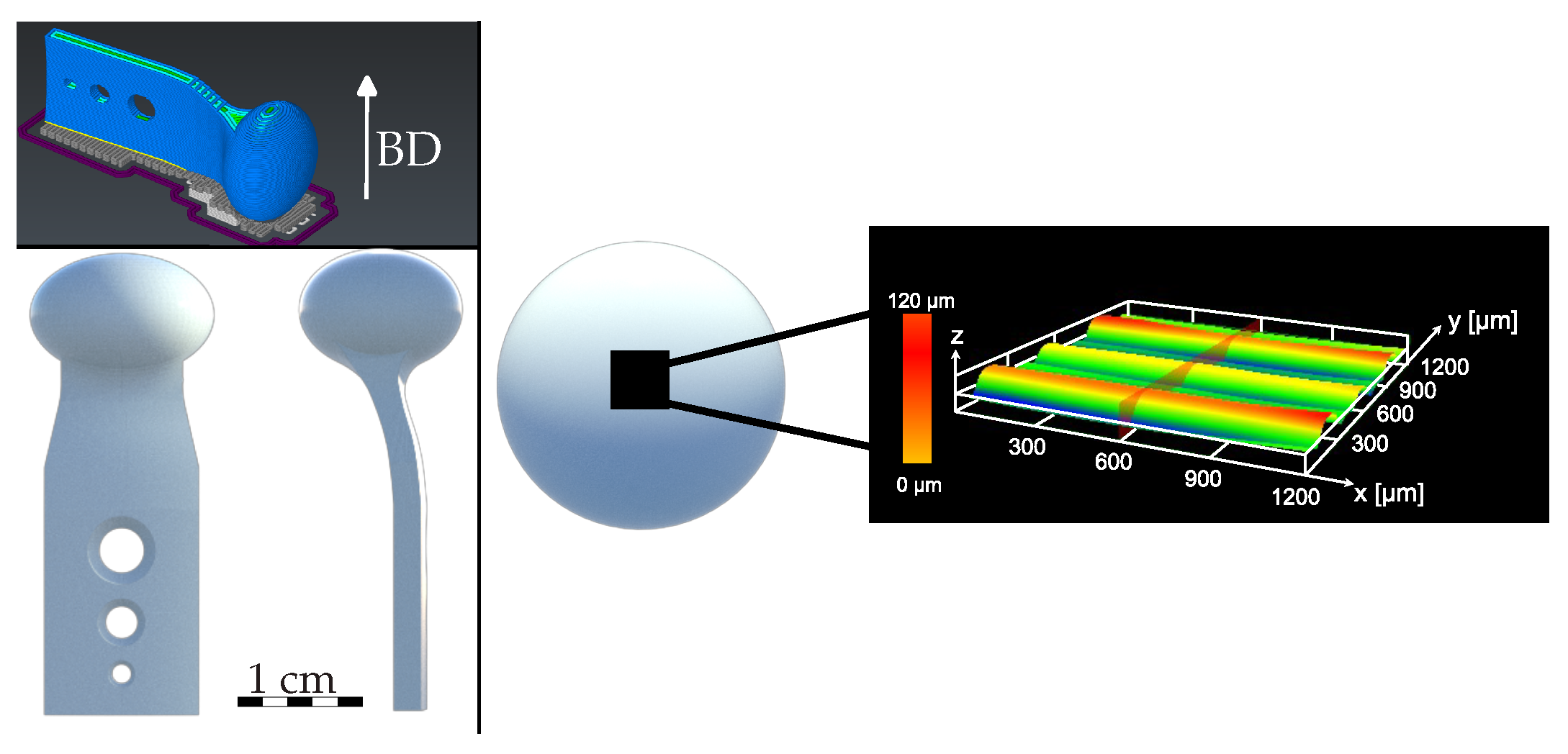

2.1. 3D-Printing Specimen

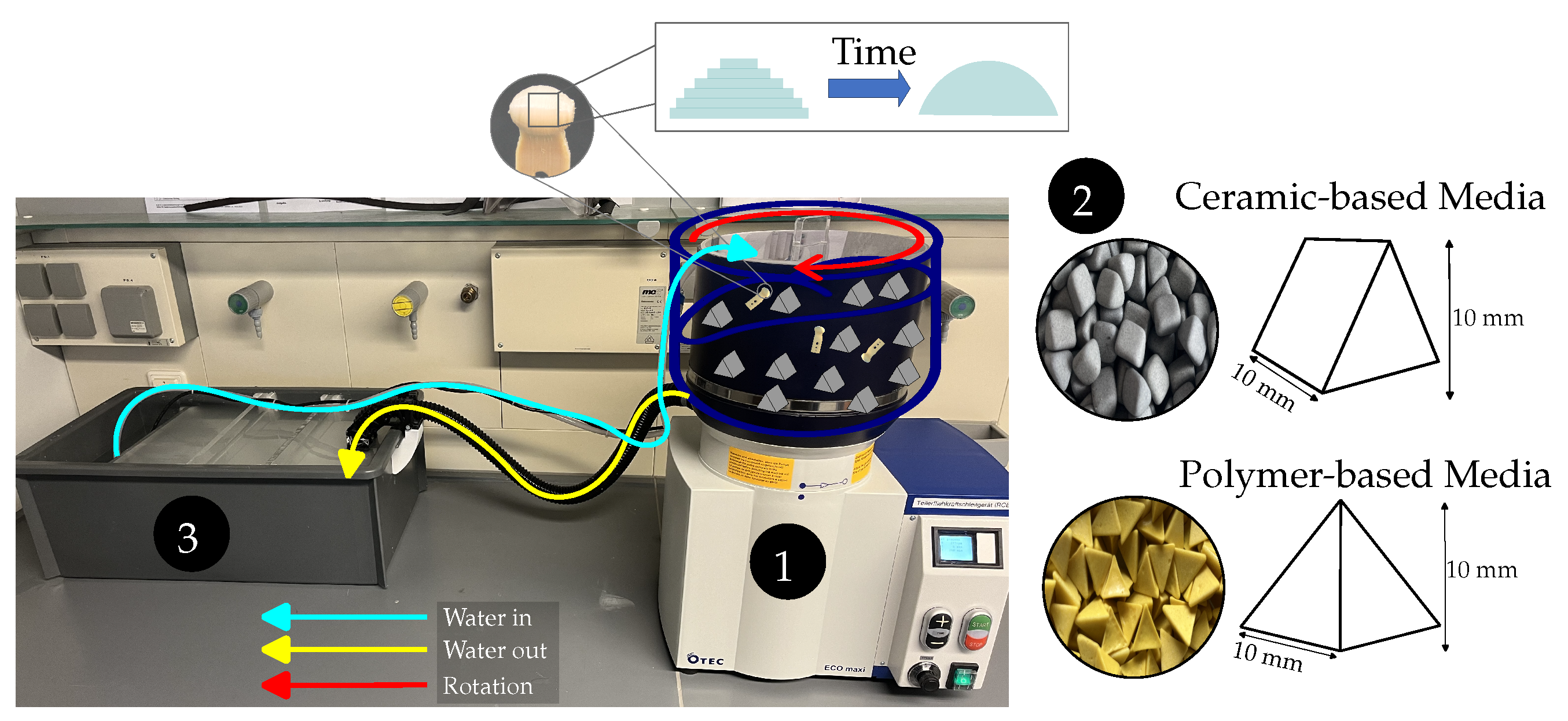

2.2. Centrifugal Disc Finishing Process

- The centrifugal disc finishing machine (OTEC Präzisionsfinish GmbH, ECO-MAXI, Straubenhardt-Conweiler, Germany)

- The abrasive media

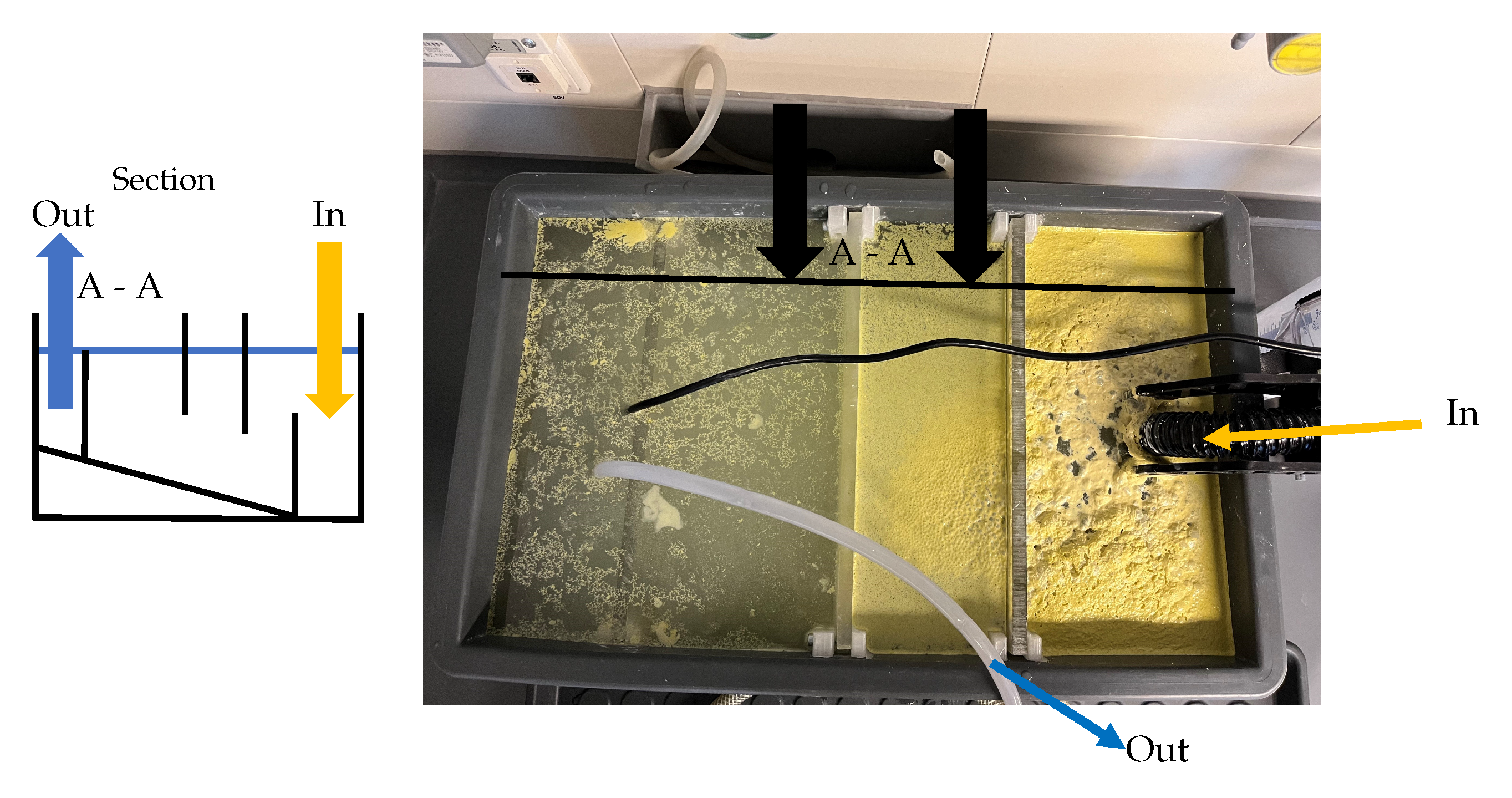

- A sedimentation box with a pump to reuse water

2.3. Specimen Preparation

- Ultrasonic cleaning for one hour at room temperature with acetone

- Ultrasonic cleaning for four hours at 80 °C with cleaning agent

- Ultrasonic cleaning for one hour with deionized water at 80 °C

- Drying at 100 °C for eight hours

2.4. Weight Measurements

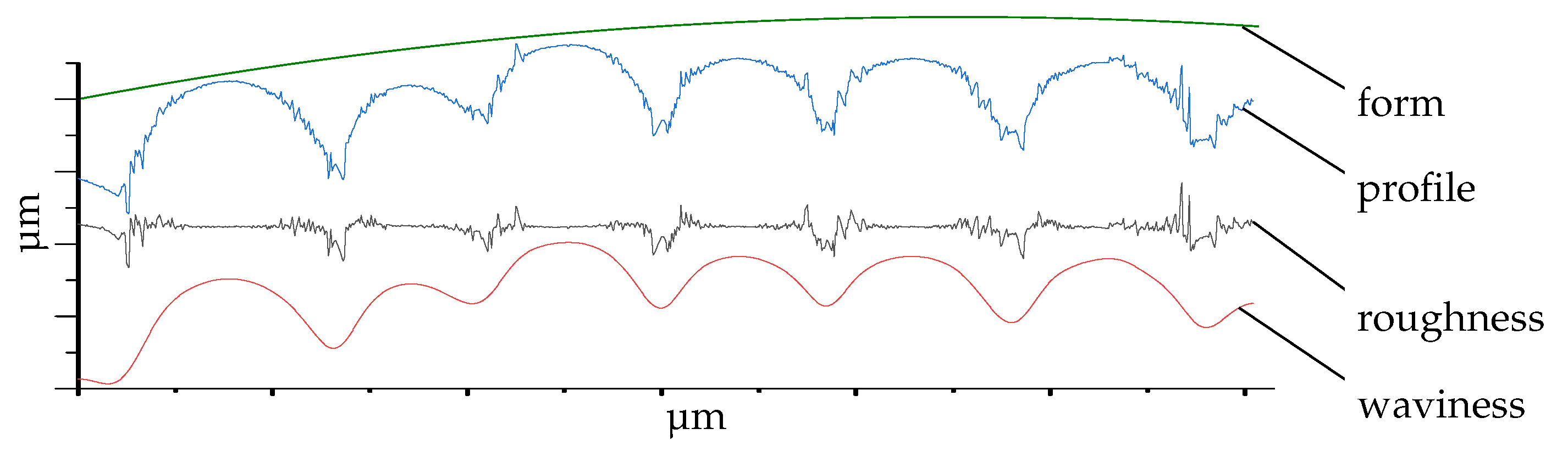

2.5. Surface Waviness Measurements

2.6. Experimental Design

3. Results and Discussion

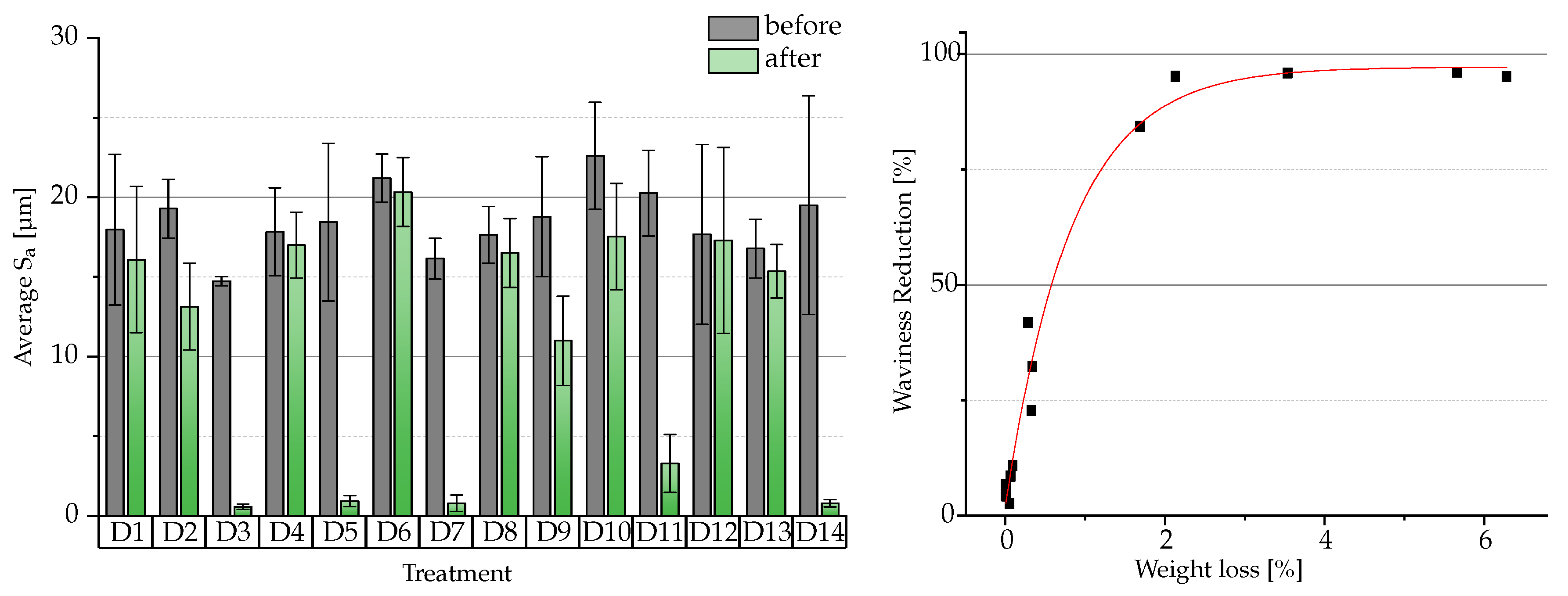

3.1. Statistical Analysis

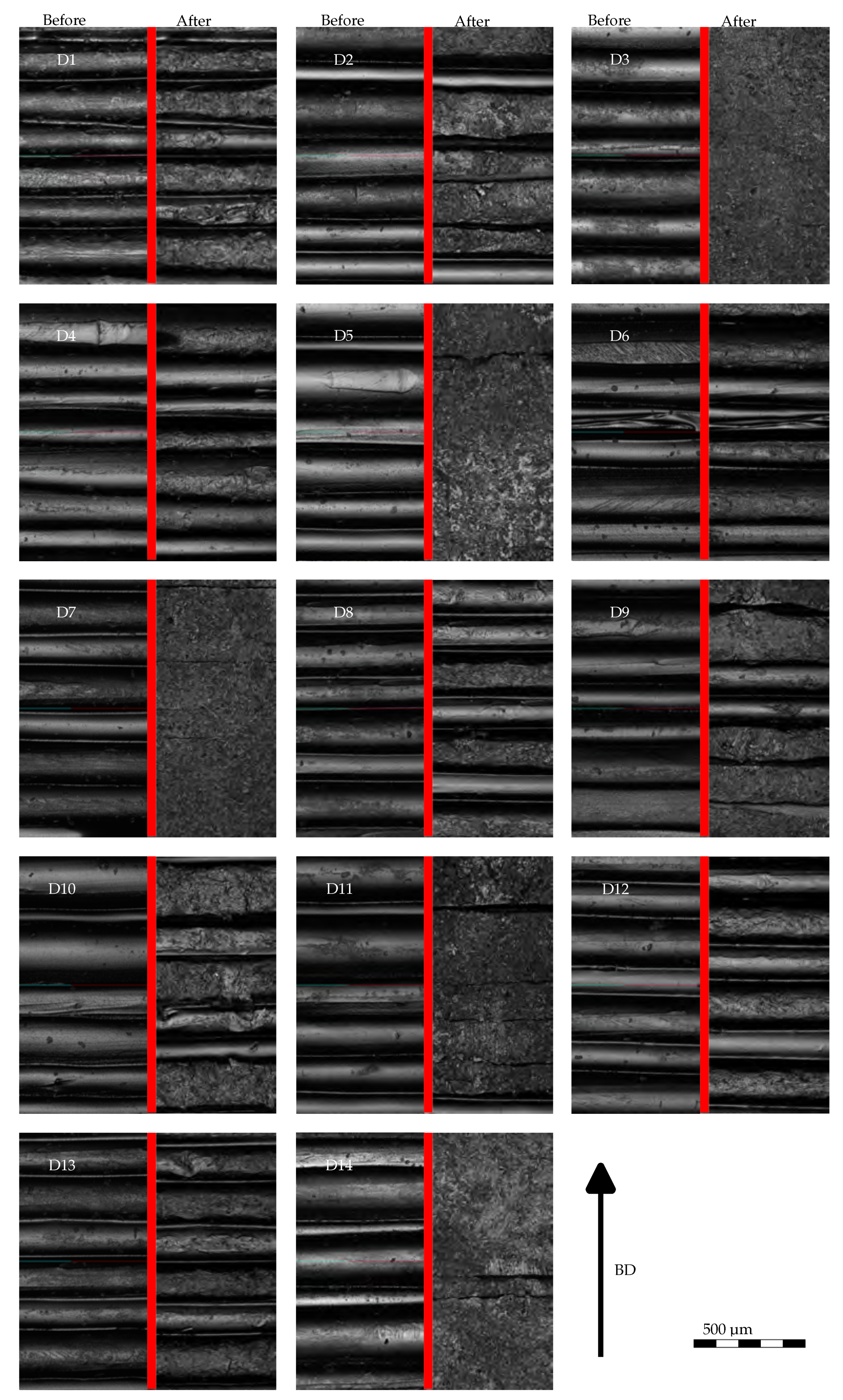

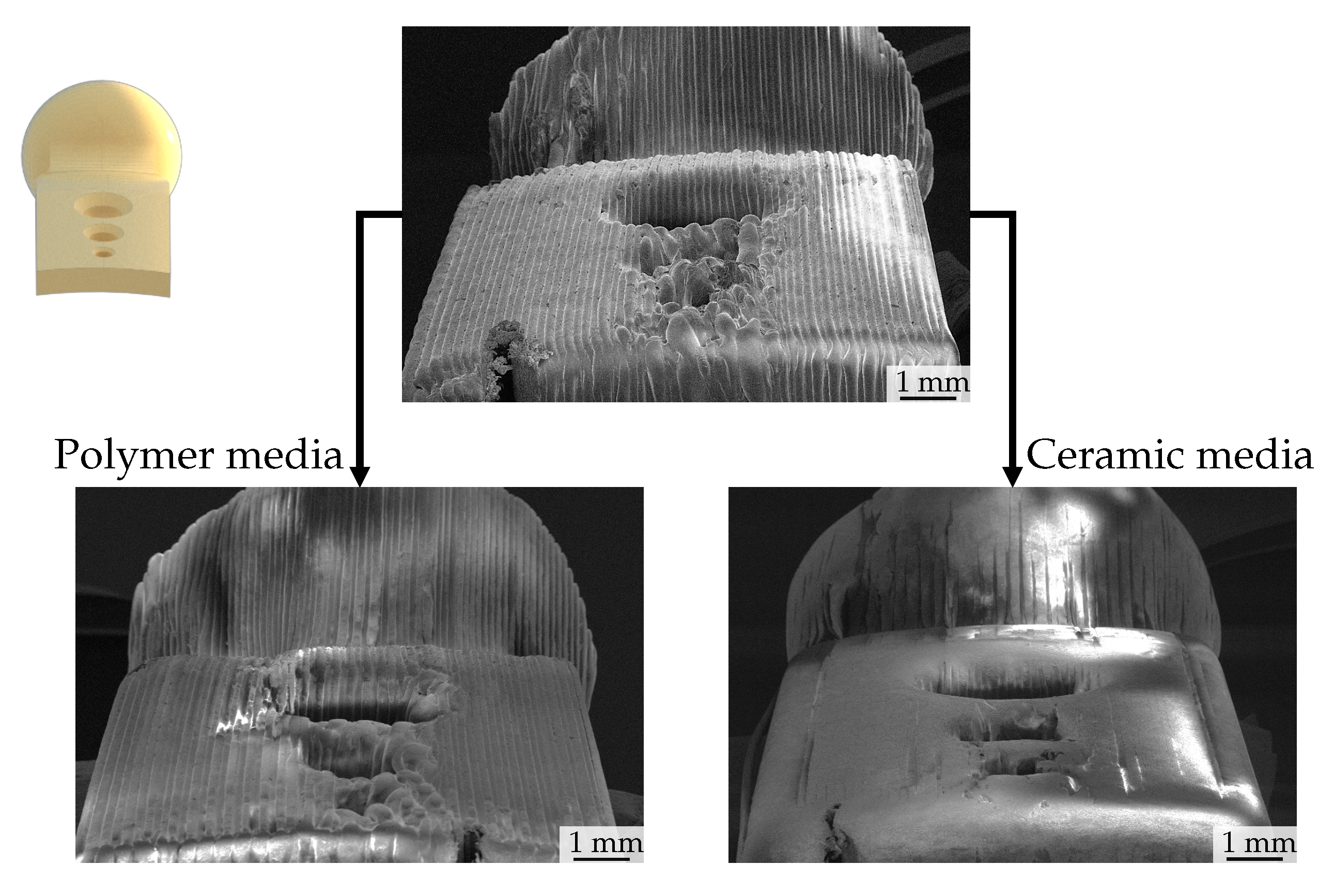

3.2. Optical Analysis

4. Conclusions

- The waviness was reduce by up to 98 by centrifugal disc finishing, even if process parameters are not optimized yet.

- Centrifugal Disc finishing can reduce waviness of additively manufactured PEEK parts

- Significant process parameters of CDFP for weight loss and waviness reduction are typ of media, speed and time

- Waviness reduction correlates with weight loss exponential

- Centrifugal Disc finishing has a leveling effect when material removal is high enough

- Use of compound is recommended for process stability reasons

- The more even the surface after manufacturing, the more even the surface after post-processing. Good manufacturing parameters are highly recommended.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| DSD | Definitive Screening Design |

| DOE | Design of Experiment |

| PEEK | Polyetheretherketone |

| PEKK | Polyetherketoneketone |

| CDFP | Centrifugal Disc Finishing Process |

| FFF | Fused Filament Fabrication |

| SEM | Scanning Electron Microscope |

| CLSM | Confocal Laser Scanning Microscope |

| ANOVA | Analysis of Variance |

| TMJ | Tempormandibular Joint |

Appendix A

Appendix B.

| Answer | Parameter | Method | p-value |

|---|---|---|---|

| Waviness Reduction | |||

| Type of media | F-Test | 0.772 | |

| Speed | Bartlett | 0.900 | |

| Time | Bartlett | 0.851 | |

| Amount of water | F-Test | 0.776 | |

| Use of compound | F-Test | 0.908 | |

| Amount of media | Bartlett | 0.853 | |

| Weight loss | |||

| Type of media | F-Test | 0.741 | |

| Speed | Bartlett | 0.632 | |

| Time | Bartlett | 0.796 | |

| Amount of water | F-Test | 0.575 | |

| Use of compound | F-Test | 0.910 | |

| Amount of media | Bartlett | 0.964 |

References

- Verma, S.; Sharma, N.; Kango, S.; Sharma, S. Developments of PEEK (Polyetheretherketone) as a biomedical material: A focused review. European Polymer Journal 2021, 147, 110295. [Google Scholar] [CrossRef]

- Mian, S.H.; Moiduddin, K.; Elseufy, S.M.; Alkhalefah, H. Adaptive Mechanism for Designing a Personalized Cranial Implant and Its 3D Printing Using PEEK. Polymers 2022, 14, 1266. [Google Scholar] [CrossRef] [PubMed]

- Najeeb, S.; Zafar, M.S.; Khurshid, Z.; Siddiqui, F. Applications of polyetheretherketone (PEEK) in oral implantology and prosthodontics. Journal of Prosthodontic Research 2016, 60, 12–19. [Google Scholar] [CrossRef] [PubMed]

- Siewert, B.; Plaza-Castro, M.; Sereno, N.; Jarman-Smith, M. Applications of PEEK in the Dental Field. In PEEK Biomaterials Handbook; Elsevier, 2019; pp. 333–342. [CrossRef]

- Haleem, A.; Javaid, M. Polyether ether ketone (PEEK) and its 3D printed implants applications in medical field: An overview. Clinical Epidemiology and Global Health 2019, 7, 571–577. [Google Scholar] [CrossRef]

- Berg-Johansen, B.; Lovald, S.; Altiok, E.; Kurtz, S.M. Applications of Polyetheretherketone in Arthroscopy. In PEEK Biomaterials Handbook; Elsevier, 2019; pp. 291–300. [CrossRef]

- Altiok, E.; Berg-Johansen, B.; Lovald, S.; Kurtz, S.M. Applications of Polyetheretherketone in Craniomaxillofacial Surgical Reconstruction. In PEEK Biomaterials Handbook; Elsevier, 2019; pp. 319–331. [CrossRef]

- Ozben, T.; Fragão-Marques, M.; Tomasi, A. A comprehensive review on PFAS including survey results from the EFLM Member Societies. Clinical Chemistry and Laboratory Medicine (CCLM) 2024, 62, 1070–1079. [Google Scholar] [CrossRef] [PubMed]

- Baek, I.; Kwon, O.; Lim, C.M.; Park, K.Y.; Bae, C.J. 3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF). Materials 2022, 15, 898. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B: Engineering 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wang, L.; Yang, C.; Sun, C.; Yan, X.; He, J.; Shi, C.; Liu, C.; Li, D.; Jiang, T.; Huang, L. Fused Deposition Modeling PEEK Implants for Personalized Surgical Application: From Clinical Need to Biofabrication. International Journal of Bioprinting 2022, 8, 615. [Google Scholar] [CrossRef] [PubMed]

- Dua, R.; Rashad, Z.; Spears, J.; Dunn, G.; Maxwell, M. Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers 2021, 13, 4046. [Google Scholar] [CrossRef] [PubMed]

- Brockett, C.L.; Carbone, S.; Fisher, J.; Jennings, L.M. PEEK and CFR-PEEK as alternative bearing materials to UHMWPE in a fixed bearing total knee replacement: An experimental wear study. Wear 2017, 374-375, 86–91. [Google Scholar] [CrossRef]

- Kurtz, S.M.; Nevelos, J. PEEK Bearing Materials for Total Joint Replacement. In PEEK Biomaterials Handbook; Elsevier, 2019; pp. 403–418. [CrossRef]

- Baykal, D.; Siskey, R.; Underwood, R.J.; Briscoe, A.; Kurtz, S.M. Biotribology of PEEK Bearings in Multidirectional Pin-on-Disk Testers. In PEEK Biomaterials Handbook; Elsevier, 2019; pp. 385–401. [CrossRef]

- Stratton-Powell, A.A.; Pasko, K.M.; Lal, S.; Brockett, C.L.; Tipper, J.L. Biologic Responses to Polyetheretherketone (PEEK) Wear Particles. In PEEK Biomaterials Handbook; Elsevier, 2019; pp. 367–384. [CrossRef]

- Pulipaka, A.; Gide, K.M.; Beheshti, A.; Bagheri, Z.S. Effect of 3D printing process parameters on surface and mechanical properties of FFF-printed PEEK. Journal of Manufacturing Processes 2023, 85, 368–386. [Google Scholar] [CrossRef]

- Castro-Casado, D. Chemical treatments to enhance surface quality of FFF manufactured parts: a systematic review. Progress in Additive Manufacturing 2021, 6, 307–319. [Google Scholar] [CrossRef]

- Alzyod, H.; Takacs, J.; Ficzere, P. Improving surface smoothness in FDM parts through ironing post-processing. Journal of Reinforced Plastics and Composites 2024, 43, 671–681. [Google Scholar] [CrossRef]

- Guo, C.; Liu, X.; Liu, G. Surface Finishing of FDM-Fabricated Amorphous Polyetheretherketone and Its Carbon-Fiber-Reinforced Composite by Dry Milling. Polymers 2021, 13, 2175. [Google Scholar] [CrossRef] [PubMed]

- Holzknecht, E. Everything you need to know about mechanical/mass finishing. Metal Finishing 2009, 107, 27–31. [Google Scholar] [CrossRef]

- Bartsch, A.; Burger, M.; Grad, M.; Esper, L.; Schultheiß, U.; Noster, U.; Schratzenstaller, T. Enhancement of laser cut edge quality of ultra-thin titanium grade 2 sheets by applying an in-process approach using modulated Yb:YAG continuous wave fiber laser. Discover Mechanical Engineering 2023, 2, 10. [Google Scholar] [CrossRef]

- Kopp, M.; Uhlmann, E. Prediction of the Roughness Reduction in Centrifugal Disc Finishing of Additive Manufactured Parts Based on Discrete Element Method. Machines 2022, 10, 1151. [Google Scholar] [CrossRef]

- Djender, K.; Hamouda, K.; Keddam, M.; Amrou, M. Statistical modelling and optimisation of the factors affecting the surface roughness of C45 steel treated by the centrifugal disk mass finishing process. International Journal of Materials Engineering Innovation 2020, 11, 70. [Google Scholar] [CrossRef]

- Pike-Wilson, E.; Karayiannis, T. Flow boiling of R245fa in 1.1 mm diameter stainless steel, brass and copper tubes. Experimental Thermal and Fluid Science 2014, 59, 166–183. [Google Scholar] [CrossRef]

- Kleppmann, W. Versuchsplanung: Produkte und Prozesse optimieren, 9., überarbeitete auflage ed.; Praxisreihe Qualitätswissen, Hanser: München Wien, 2016. [Google Scholar]

- Jones, B.; Nachtsheim, C.J. A Class of Three-Level Designs for Definitive Screening in the Presence of Second-Order Effects. Journal of Quality Technology 2011, 43, 1–15. [Google Scholar] [CrossRef]

- Jones, B.; Nachtsheim, C.J. Definitive Screening Designs with Added Two-Level Categorical Factors. Journal of Quality Technology 2013, 45, 121–129. [Google Scholar] [CrossRef]

- Alhelali, M.H.; Georgiou, S.D.; Stylianou, S. Screening designs based on weighing matrices with added two-level categorical factors. Journal of Quality Technology 2020, 52, 168–181. [Google Scholar] [CrossRef]

- Vera Candioti, L.; De Zan, M.M.; Cámara, M.S.; Goicoechea, H.C. Experimental design and multiple response optimization. Using the desirability function in analytical methods development. Talanta 2014, 124, 123–138. [Google Scholar] [CrossRef] [PubMed]

- Kraber, S. Improving Your DOE - Analysis with Response Transformations. Journal of Plastic Film & Sheeting 2022, 38, 15–20. [Google Scholar] [CrossRef]

- Vijayaraghavan, V.; Castagne, S. Measurement of surface characteristics of Ti6Al4V aerospace engineering components in mass finishing process. Measurement 2018, 115, 279–287. [Google Scholar] [CrossRef]

| Treatment | Type of media1 | Speed [rpm] | Time [min] | Amount of Water2 | Use of compound | Amount of media [dm3] |

|---|---|---|---|---|---|---|

| D1 | P | 354 | 240 | max | Yes | 1.50 |

| D2 | C | 200 | 30 | min | No | 1.00 |

| D3 | C | 277 | 240 | min | No | 1.50 |

| D4 | P | 277 | 30 | max | Yes | 1.00 |

| D5 | C | 354 | 135 | max | No | 1.00 |

| D6 | P | 200 | 135 | min | Yes | 1.50 |

| D7 | C | 200 | 240 | min | Yes | 1.00 |

| D8 | P | 354 | 30 | max | No | 1.50 |

| D9 | C | 200 | 30 | max | No | 1.50 |

| D10 | P | 354 | 240 | min | Yes | 1.00 |

| D11 | C | 354 | 30 | min | Yes | 1.25 |

| D12 | P | 200 | 240 | max | No | 1.25 |

| D13 | P | 277 | 135 | min | No | 1.25 |

| D14 | C | 277 | 135 | max | Yes | 1.25 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-value |

|---|---|---|---|---|---|---|---|

| Waviness reduction | 9 | 0.822052 | 98.32% | 0.822052 | 0.091339 | 26.08 | 0.003 |

| Linear | 6 | 0.815685 | 97.56% | 0.815685 | 0.135948 | 38.82 | 0.002 |

| Type of media ★ | 1 | 0.696120 | 83.26% | 0.732762 | 0.732762 | 209.26 | 0.000 |

| Speed ★ | 1 | 0.063718 | 7.62% | 0.060971 | 0.060971 | 17.41 | 0.014 |

| Time ★ | 1 | 0.044375 | 5.31% | 0.033081 | 0.033081 | 9.45 | 0.037 |

| Amount of Water | 1 | 0.004870 | 0.58% | 0.002864 | 0.002864 | 0.82 | 0.417 |

| Use of compound | 1 | 0.006485 | 0.78% | 0.005998 | 0.005998 | 1.71 | 0.261 |

| Amount of media | 1 | 0.000118 | 0.01% | 0.000118 | 0.000118 | 0.03 | 0.864 |

| Square | 3 | 0.006367 | 0.76% | 0.006367 | 0.002122 | 0.61 | 0.645 |

| Speed*Speed | 1 | 0.003988 | 0.48% | 0.002623 | 0.002623 | 0.75 | 0.436 |

| Time*Time | 1 | 0.001868 | 0.22% | 0.002234 | 0.002234 | 0.64 | 0.469 |

| Amount of media*Amount of media | 1 | 0.000512 | 0.06% | 0.000512 | 0.000512 | 0.15 | 0.722 |

| Error | 4 | 0.014007 | 1.68% | 0.014007 | 0.003502 | ||

| Total | 13 | 0.836059 | 100.00% | ||||

| Weight loss | 9 | 0.332640 | 99.21% | 0.332640 | 0.036960 | 55.70 | 0.001 |

| Linear | 6 | 0.324430 | 96.76% | 0.324430 | 0.054072 | 81.49 | 0.000 |

| Type of media ★ | 1 | 0.238061 | 71.00% | 0.261453 | 0.261453 | 394.02 | 0.000 |

| Speed ★ | 1 | 0.022923 | 6.84% | 0.025191 | 0.025191 | 37.96 | 0.004 |

| Time ★ | 1 | 0.060929 | 18.17% | 0.056329 | 0.056329 | 84.89 | 0.001 |

| Amount of water | 1 | 0.000636 | 0.19% | 0.000441 | 0.000441 | 0.66 | 0.461 |

| Use of compound | 1 | 0.000087 | 0.03% | 0.000272 | 0.000272 | 0.41 | 0.557 |

| Amount of media | 1 | 0.001795 | 0.54% | 0.001795 | 0.001795 | 2.70 | 0.175 |

| Square | 3 | 0.008210 | 2.45% | 0.008210 | 0.002737 | 4.12 | 0.102 |

| Speed*Speed | 1 | 0.002786 | 0.83% | 0.000502 | 0.000502 | 0.76 | 0.434 |

| Time*Time | 1 | 0.004508 | 1.34% | 0.003404 | 0.003404 | 5.13 | 0.086 |

| Amount of media*Amount of media | 1 | 0.000916 | 0.27% | 0.000916 | 0.000916 | 1.38 | 0.305 |

| Error | 4 | 0.002654 | 0.79% | 0.002654 | 0.000664 | ||

| Total | 13 | 0.335294 | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).