1. Introduction

Modifying coatings deposited by the Physical Vapor Deposition (PVD) method are actively used to improve the performance properties of various modern industrial objects. Among the areas of application of coatings are cutting and stamping tools, medicine, engine building, energy and a few other applications. Preparation of the substrate surface before coating deposition is a key operation that ensures the strength of adhesion of the coating to the substrate and, accordingly, the durability and reliability of the coated part [1–8]. Among the main tasks of surface preparation is its cleaning from residual microcontaminants (including chemical, for example, oxide films), as well as thermal activation. The main method of such preparation is ion bombardment, although in some cases chemical desorption is also used [2,4,9]. Ion bombardment (cleaning, etching) involves bombarding a surface with accelerated ions. Various schemes of ion bombardment are used, among which we can highlight etching with a beam of gas ions (usually argon ions), which is formed during the operation of a special source [10–13].

Treatment with ions accelerated by the negative potential of the substrate from plasma created by a vacuum discharge is also used [6,14–21]. This method is based on the ability to regulate ion energy by changing the negative bias potential on the substrate [18,20].

An alternative method is etching in a glow discharge plasma [22–24]. This method consists in accelerating gas plasma ions (usually argon is also used) on the surface of the product, which is either the cathode of the glow discharge itself or an additional electrode negative relative to the plasma [1,3,26–28]. If nitrogen is used instead of argon, using this method it is possible to ensure nitriding of the surface layer of parts [29–31]. Other gas media are also used (acetylene, nitrogen, argon, hydrogen and their mixtures) [32]. This method is used less frequently due to the fact that the etching rate in this case is quite low due to the low plasma density. An additional disadvantage of this method, also associated with the relatively low speed of the process, is the possibility of introducing insoluble atoms of an inert gas into the surface layer and thereby reducing the properties of this layer [28,33]. To eliminate these disadvantages of etching in gas discharge plasma, various methods are used. For example, a mesh cylinder is placed inside a rotating fixture, to which a negative voltage is applied to increase the density of the gas plasma [34]. Other ways to increase the intensity of the etching process with glow discharge plasma include etching with dual capacitive coupled radio frequency (CCRF) glow discharge plasma (CCRF) [35], atmosphere pressure glow discharges (APGD) [36], high-pressure glow discharges (HPG) [37] and Arc-enhanced glow discharge (AEGD) [24,38,39]. Glow discharge plasma etching affects the surface layer of carbide substrates (for example, cutting tools). It was found that such etching has a greater effect on the surface layer of WC and a much smaller effect on the surface layer of TiC [41]. Pre-treatment in glow discharge plasma can significantly increase the adhesion of the coating and substrate, as well as improve the properties of the coating itself [23,24,38,39].

All ion etching (cleaning) methods discussed above are associated with the removal of surface layers of the substrate due to sputtering of atoms under the influence of bombardment with ions of gases or metals accelerated to high energy. During ion etching process various chemical and physical processes take place on the surface of the substrate, including interdependent processes of condensation, penetration and sputtering. When ions crash into the surface of a substrate, they transfer their kinetic energy to surface atoms [1,40]. As a result, those atoms that have acquired kinetic energy exceeding the chemical bond energy in the crystal lattice can be knocked out (emitted) from the surface of the substrate. First, those atoms that have the lowest binding energy with the surface are sputtered (for example, atoms of contaminants or chemical films).

Ion etching helps to reduce the number of macro and microdefects, residual internal stresses, create a favorable microrelief, clean up to the atomic level (obtaining an almost juvenile clean surface), enhance diffusion processes and surface activation by increasing the surface bond energy [5,9,41,42]. This treatment creates favorable conditions for the subsequent deposition of coatings with high adhesive bonds [6,7,15].

The efficiency of ion etching depends on the placement of samples in a vacuum chamber [26–28,43]. Under certain placement conditions, there may be a high likelihood of repeated cross-contamination of substrates. In areas where the intensity of ion bombardment is low, contaminants can accumulate due to the repeated redeposition of sputtered material from areas where the intensity is high.

This work compares two methods of cleaning and heating samples before coating deposition:

• ion bombardment with the generation of metal plasma by arc evaporators,

• ion bombardment with generation of gas plasma by a glow discharge.

2. Materials and Methods

To deposit coatings on the samples, a special research installation VIT-2 was used (IDTI RAS – MSUT “STANKIN”, Russia) [44–49]. At the same time, two types of evaporators were installed: one filtered cathodic vacuum arc deposition (FCVAD) system [50–52], which allows for up to 98 % phase separation of microparticles in combination with providing a high degree of focusing of the plasma flow. Two Controlled Accelerated Arc (CAA-PVD) system evaporators were also installed [19,53,54], which are characterized by high energy efficiency and a reduced number of microparticles compared to traditional arc-type evaporators. The Al cathode (99.8%) was installed on the FCVAD evaporator, since the Al cathode under normal conditions forms many microparticles during evaporation, which reduce the quality of the coating. Ti (99.6 %) and Cr (99.9 %) cathodes were installed on evaporators of the CAA-PVD system. Before installation on specialized equipment and placement in the chamber, the samples underwent a preparation procedure. This procedure included washing in a special solution at high temperature with ultrasonic stimulation, washing in specially purified water, and drying in a stream of purified air.

The working gas pressure in the chamber was maintained at different stages within the range of 1–10 Pa. The voltage on the substrate is from 300 to 1500 V.

In this work, we compare the properties of coatings using two different methods of surface cleaning and thermal activation: ion bombardment with an ion flow (hereinafter denoted as IB) and ion etching with a glow discharge (hereinafter denoted as GD).

Metal Ion Etching of Plasma Generated by Vacuum Evaporators (IB)

Upon completion of loading, the vacuum chamber was evacuated. Ion cleaning and heating of products was carried out at a pressure of no higher than 1.0 × 10-2 Pa in plasma generated by arc evaporators with titanium and chromium cathodes installed on them. At the beginning of the process, in order to avoid the appearance of micro-arcs, a negative potential of 100V was applied to the turntable. As the parts were cleaned and heated to achieve the required temperature of 650–700 °C, the negative potential gradually increased to 1000 V or more. When the specified temperature of the parts was reached, an adhesive titanium sublayer was deposited by an arc evaporator within 3 minutes. The arc current of the titanium cathode was 80 A, and the negative voltage on the parts decreased to 160 V. Then process gas (nitrogen) was supplied to the vacuum chamber to a pressure of 0.6 Pa and a layer of titanium nitride was applied for 15 minutes. For subsequent deposition of the (Ti,Cr,Al)N layer, arc evaporators with a chromium cathode and an aluminum cathode located in the separator were additionally turned on. The arc current of the evaporator with a chromium cathode was 80A, and that of the evaporator with an aluminum cathode was 160A. Precipitation was carried out for 30 minutes. at a temperature of about 480 °C. The temperature of the products was regulated by the value of the reference voltage of the turntable.

Etching by Gas Ions of a Self-Sustained Glow Discharge Plasma (GD)

This technological process differs from the one described above in that ion cleaning and heating of products was carried out by ion bombardment only with gas ions of a glow discharge plasma. All other stages and parameters of both technological cycles were identical. The stage of ion cleaning of products was carried out in a glow discharge in an argon environment at a pressure of 2.5 Pa. The process began with applying a negative bias potential of -100 V to the sprayed parts, then the potential gradually rose to –1500 V, the pressure in the chamber increased to 8 Pa, the negative bias potential on the products was fixed at –1500 V and the parts were heated to a temperature of 650 °C.

The temperature of the parts during the heating process was measured using a non-contact method using an Infrared Thermometer IRCON Module3.

To study the hardness and elastic modulus, an automated mechanical tester SV-500 (Nanovea, USA) was used with a nanomodule equipped with a precision piezo drive and a highly sensitive, drive-independent load sensor. The measurement method is instrumental indentation using a Berkovich pyramidal indenter. Measurement modes: maximum load – 200 mN, loading speed – 400 mN/min.

To study micro and nanostructures, a transmission electron microscope (TEM) JEM 2100 (JEOL, Japan) at an accelerating voltage of 200 kV was used. To analyze the composition of the coatings, TEM with the EDX system INCA Energy (OXFORD Instruments, UK) was used. Lamellas were manufactured using Strata focused ion beam (FIB) 205 (FEI, USA). A comparison of the wear resistance of samples with coatings was carried out when turning 1045 steel on an ACU 500 MRD lathe (Sliven) with a ZMM CU500MRD variable-speed drive, without the use of cutting fluid (dry cutting) tool (carbide inserts SNUN ISO 1832:2012 (WC + 15 % TiC + 6 % Co) with the studied coatings. The following cutting geometry and conditions were used: γ = –7°, α = 7°, λ = 0, r = 0.4 mm; feed f = 0.1 rpm, cutting depth ap = 0.5 mm, and cutting speed vc = 300 and 350 m/min. The maximum applicable rational cutting speed was selected, ensuring maximum productivity while maintaining sufficient tool life. Wear on the flank surface VBmax = 0.35 mm was considered as a criterion for tool wear. 5 experiments were carried out for the tool. with every coating.

3. Results

3.1. Scratch Test Hardness

The coatings have identical hardness (28.3 ± 1.2 and 29.7 ± 0.9 GPa, respectively, for IB and GD).

Coating IB begins to fail (peeling of coating fragments, critical failure load LC1) at 36 N (

Figure 1a). When the maximum load of 40 N is reached, no signs of destruction of the GD coating (visual or acoustic emission) are observed (

Figure 1b).

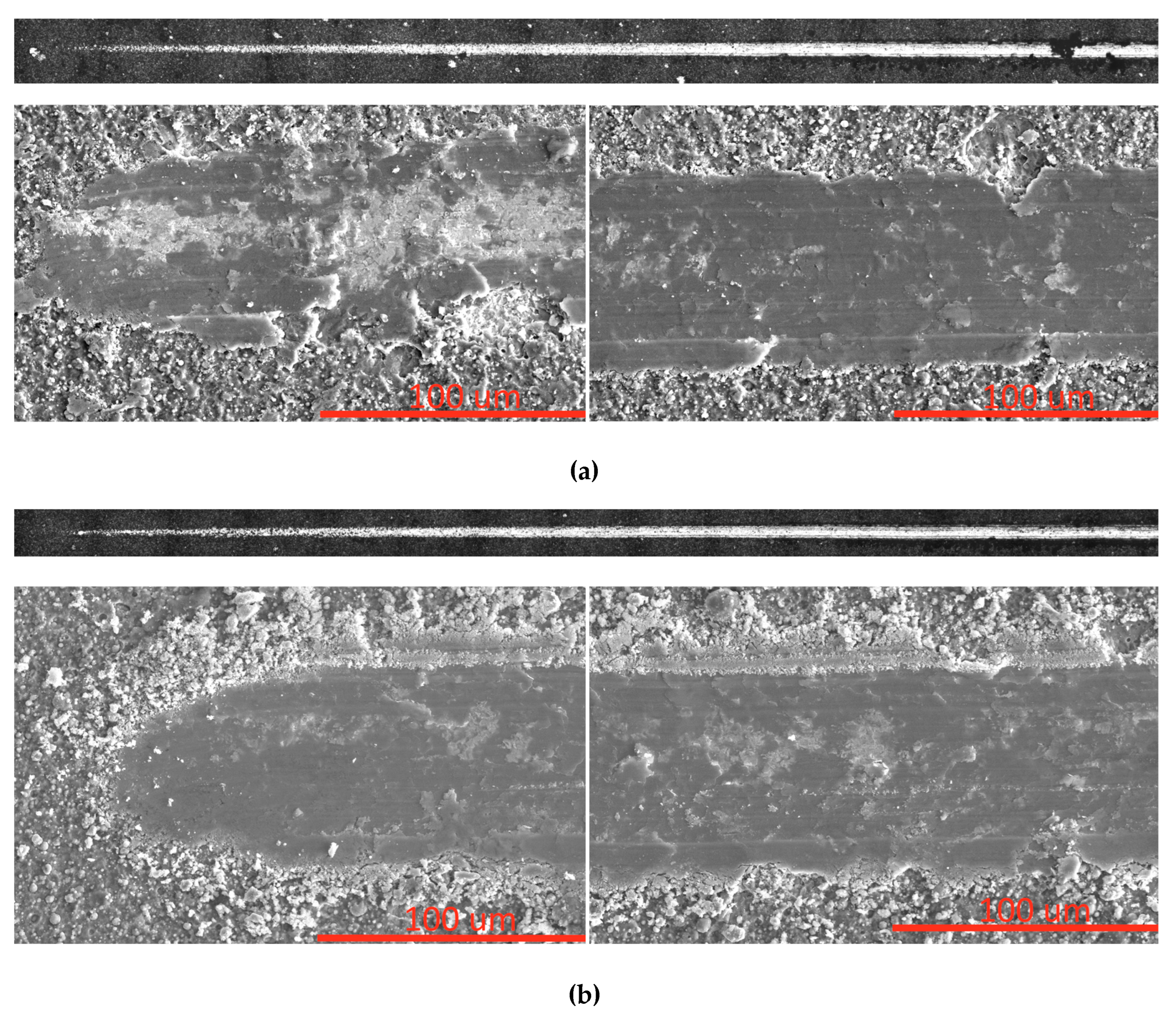

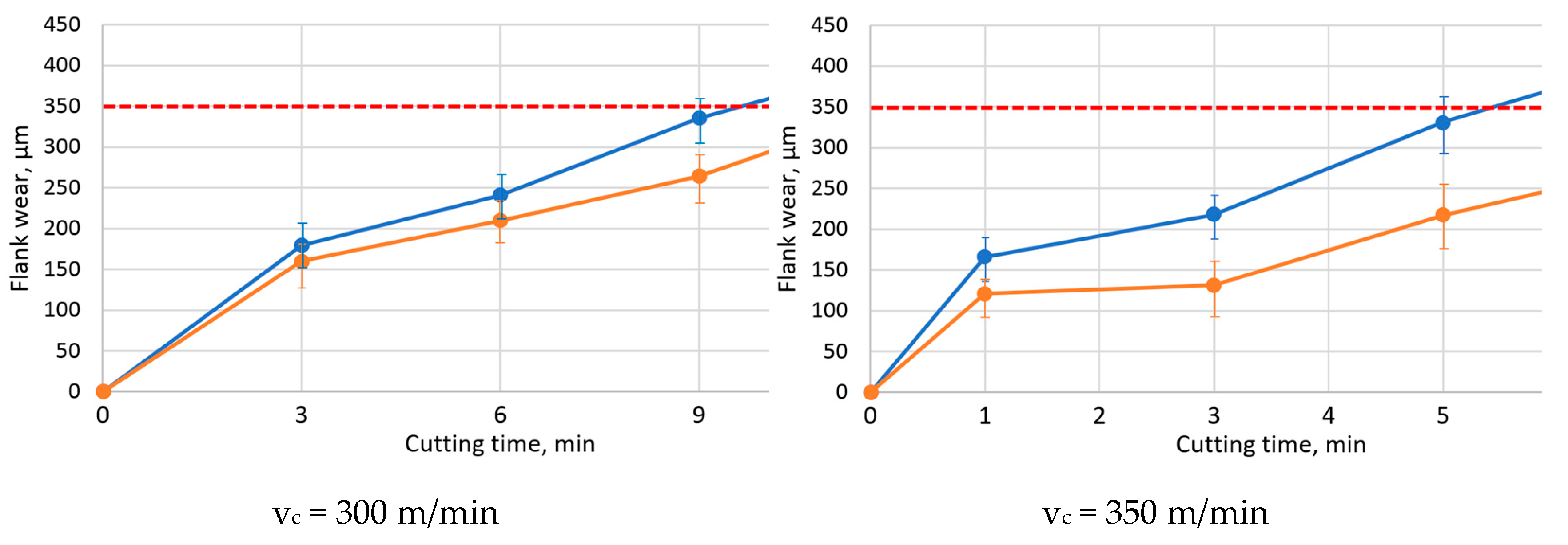

3.2. Cutting Test when Turning Steel 1045 (Cutting Speed vc = 300 and 350 m/min)

The results of the cutting test when turning steel 1045 show that at a cutting speed v

c = 300 m/min, a tool with an GD coating shows slightly less active wear dynamics compared to a tool with an IB coating, however, these differences are insignificant and can partly be offset by scatter values (

Figure 2). When the cutting speed increases to v

c = 350 m/min, the difference in wear dynamics becomes more noticeable and obvious. After 7 minutes of cutting, the tool coated with IB technology reached the wear limit criterion (VB

max = 350 μm), while the tool coated with GD technology remains operational and has not reached the wear limit. Since the temperature increases first when the cutting speed increases, it can be assumed that the GD coating has better heat resistance compared to the IB coating. But since the deposition parameters of the coatings are completely identical, except for the stage of cleaning and thermal activation, it can be assumed that the coating better maintains adhesion to the substrate under high temperature conditions.

To test this assumption, the nature of wear and destruction of samples with the resulting coatings was studied in more detail. For further study, coated tool samples worn after cutting 1045 steel at vc = 350 m/min were selected.

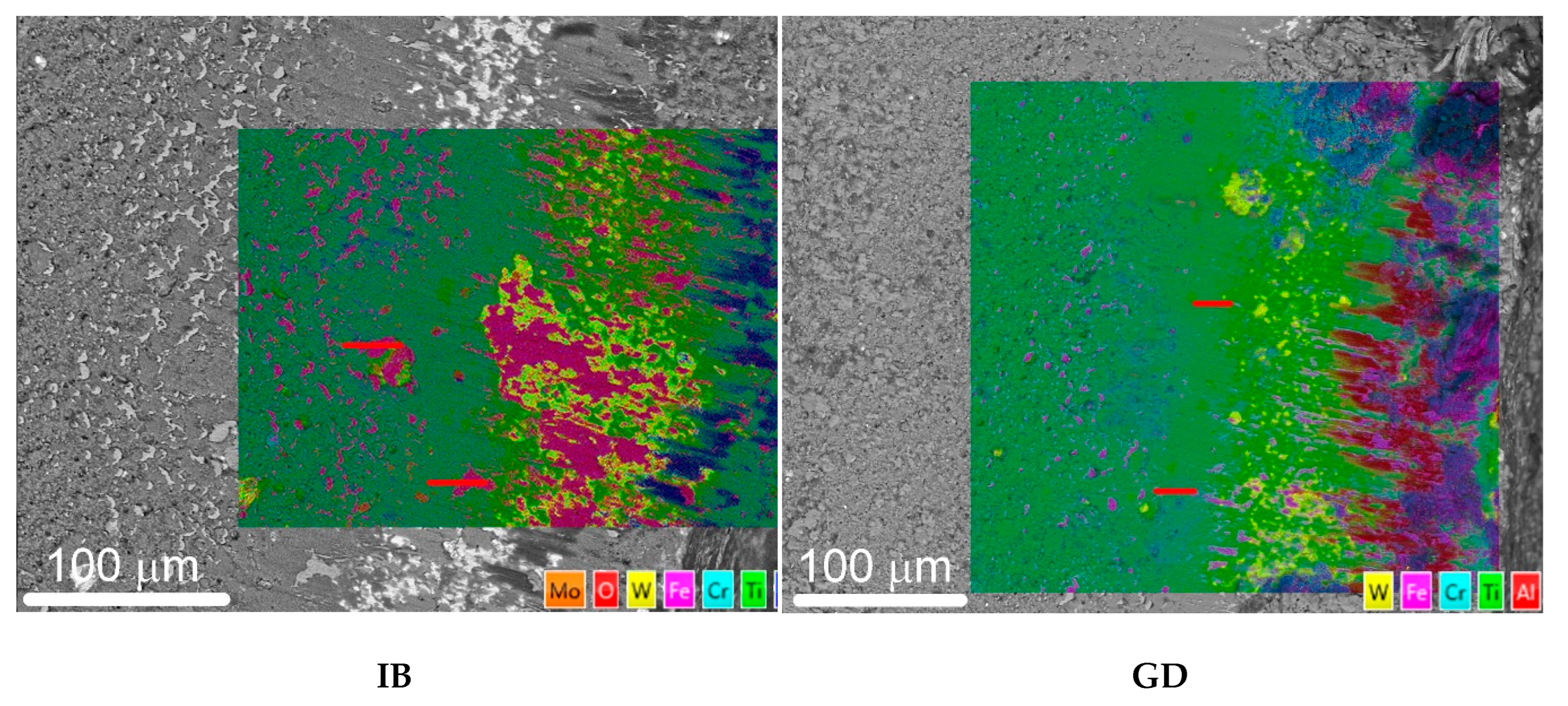

3.3. Character of Wear of Cutting Tools with the Studied Coatings

The worn rake face of an IB-coated tool shows signs of delamination of the coating from the substrate (this can be seen, in particular, based on the distribution of tungsten). In tools coated with GD, signs of delamination from the substrate are also present, but to a slightly lesser extent, appearing in several small areas of delamination. To study the reasons for this nature of coating destruction, we will study transverse sections (lamellae) cut from the wear boundary of the coatings (indicated by red lines in

Figure 3).

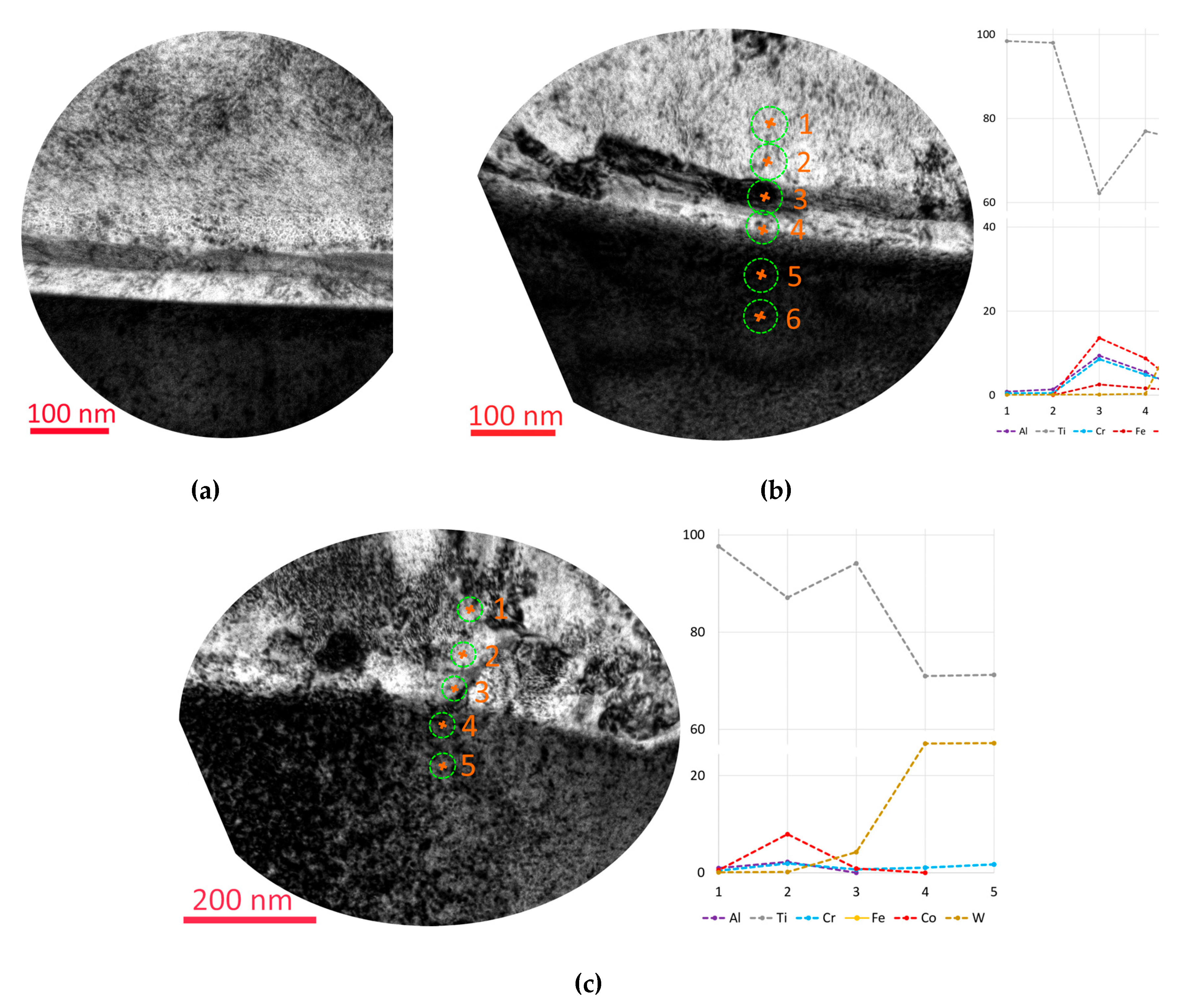

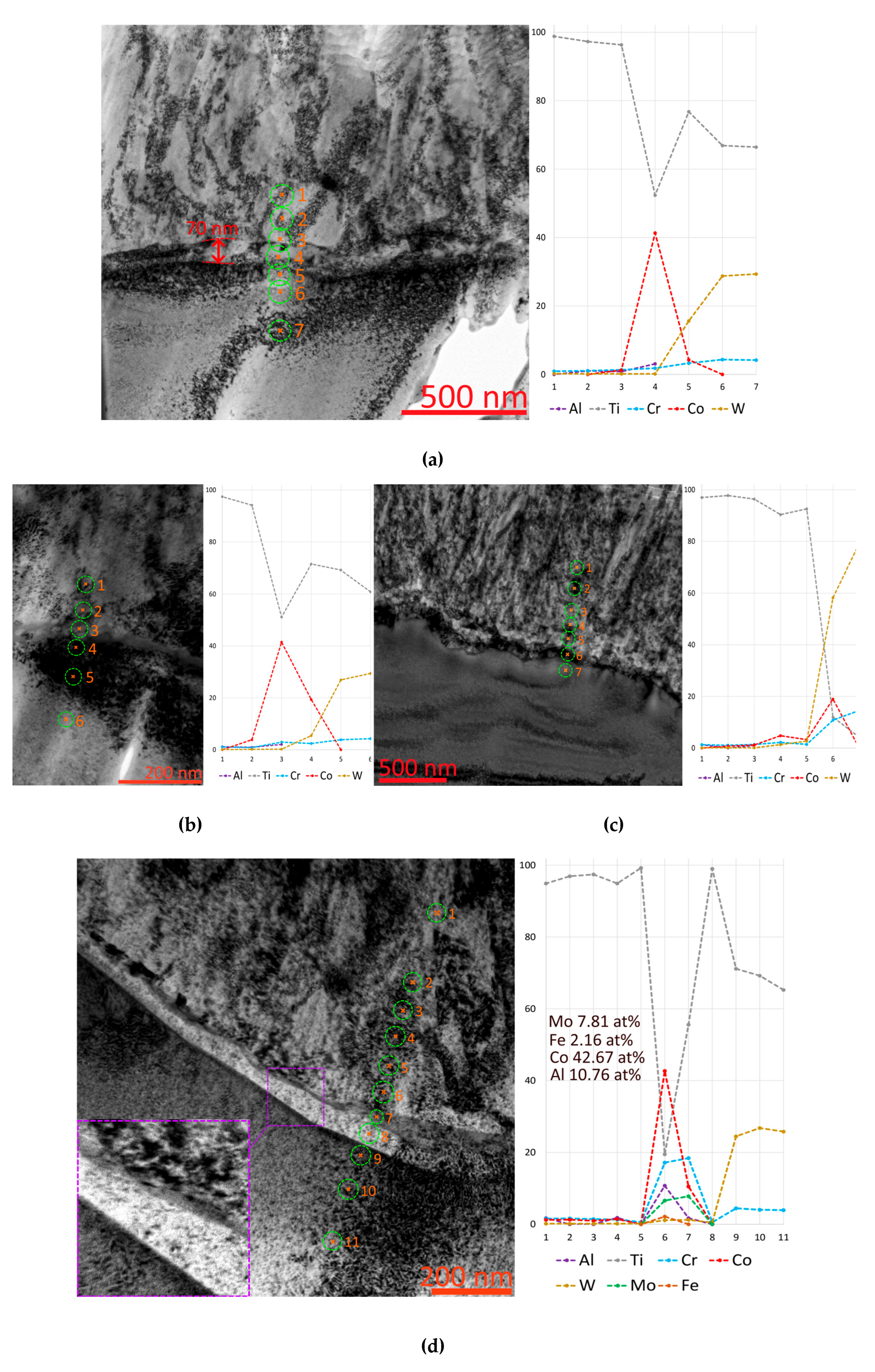

3.3.1. Heating by Ion Bombardment with Plasma Generation by Arc Evaporators (IB)

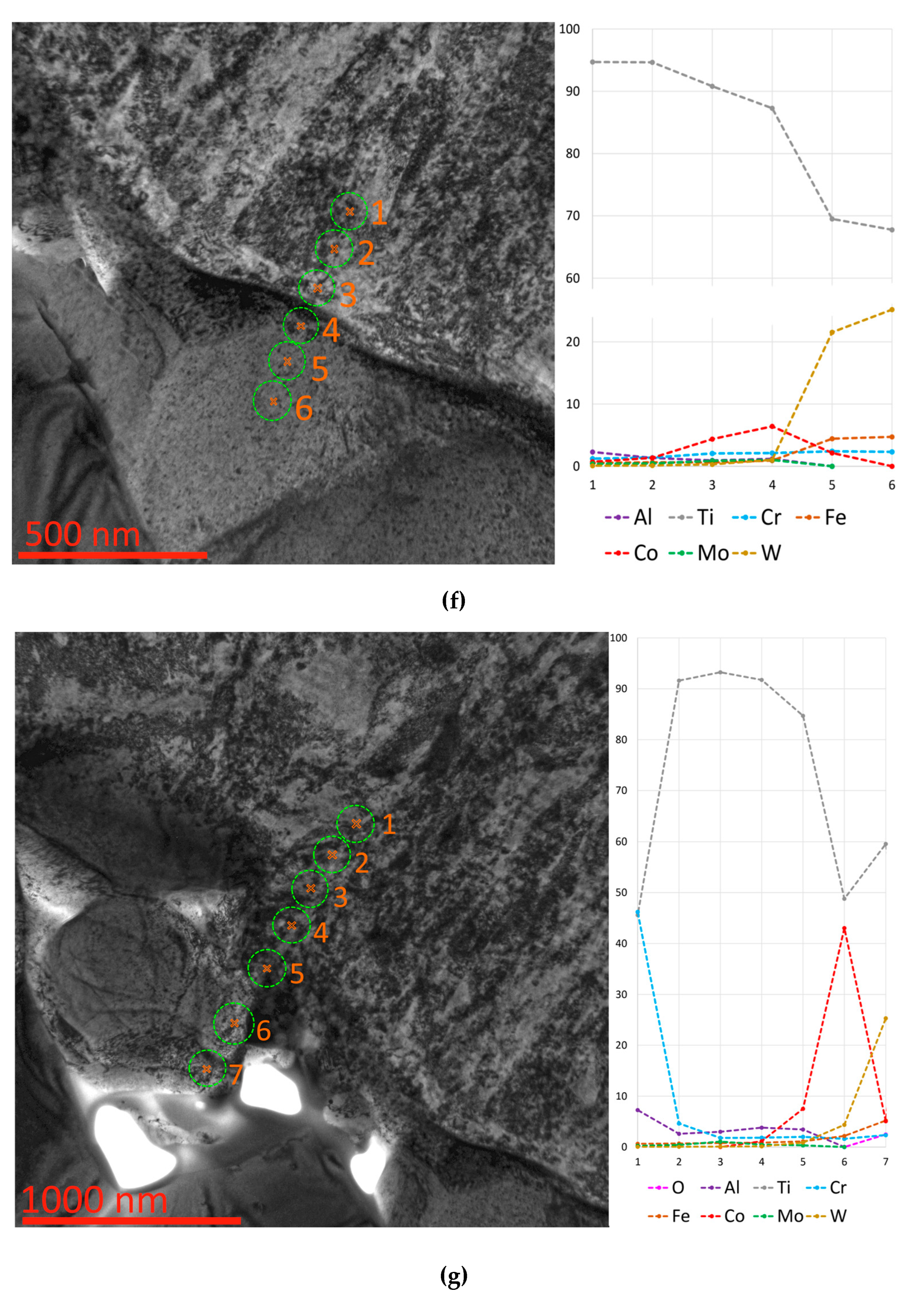

The interface between the coating and the substrate has a rather complex layered structure (

Figure 4a). A study of the distribution of elements in these layers shows that the layer, dark in contrast (point 3 in

Figure 4b), with a thickness of about 20 nm, has a high cobalt content. This layer also contains the presence of iron and a high content of chromium and aluminum, with a lower titanium content relative to neighboring layers. Directly adjacent to the substrate is a light-colored layer with a high titanium content, also containing cobalt, chromium and aluminum. Examination of another interface region (

Figure 4c) also shows alternating layers with high cobalt and titanium content, but in this case, they are less differentiated in contrast. In the layer adjacent to the substrate (point 3 in

Figure 4c), noticeable diffusion of tungsten is also observed. In both cases under consideration, chromium diffuses into the substrate to a depth of up to 200 nm.

To confirm the discovered patterns, we will analyze a lamella cut from another sample (

Figure 5). The general pattern is the presence of a layer with a high cobalt content (in some cases, above 40 at.%, see

Figure 5d). In most cases, there is a layer directly adjacent to the surface of the substrate with a high titanium content (80–98 at.%, see

Figure 5a,d,e). In two cases (

Figure 5b,c) such a layer is not observed; a layer with a high cobalt content is directly adjacent to the substrate. In one case (

Figure 5d), between layers with a high titanium and cobalt content, a layer with a high (up to 19 at.%) chromium content is formed. This layer also contains a high content of aluminum and molybdenum. The presence of iron in minor quantities in the cobalt-rich layer is observed in

Figure 5d (point 6) and 5e (point 5).

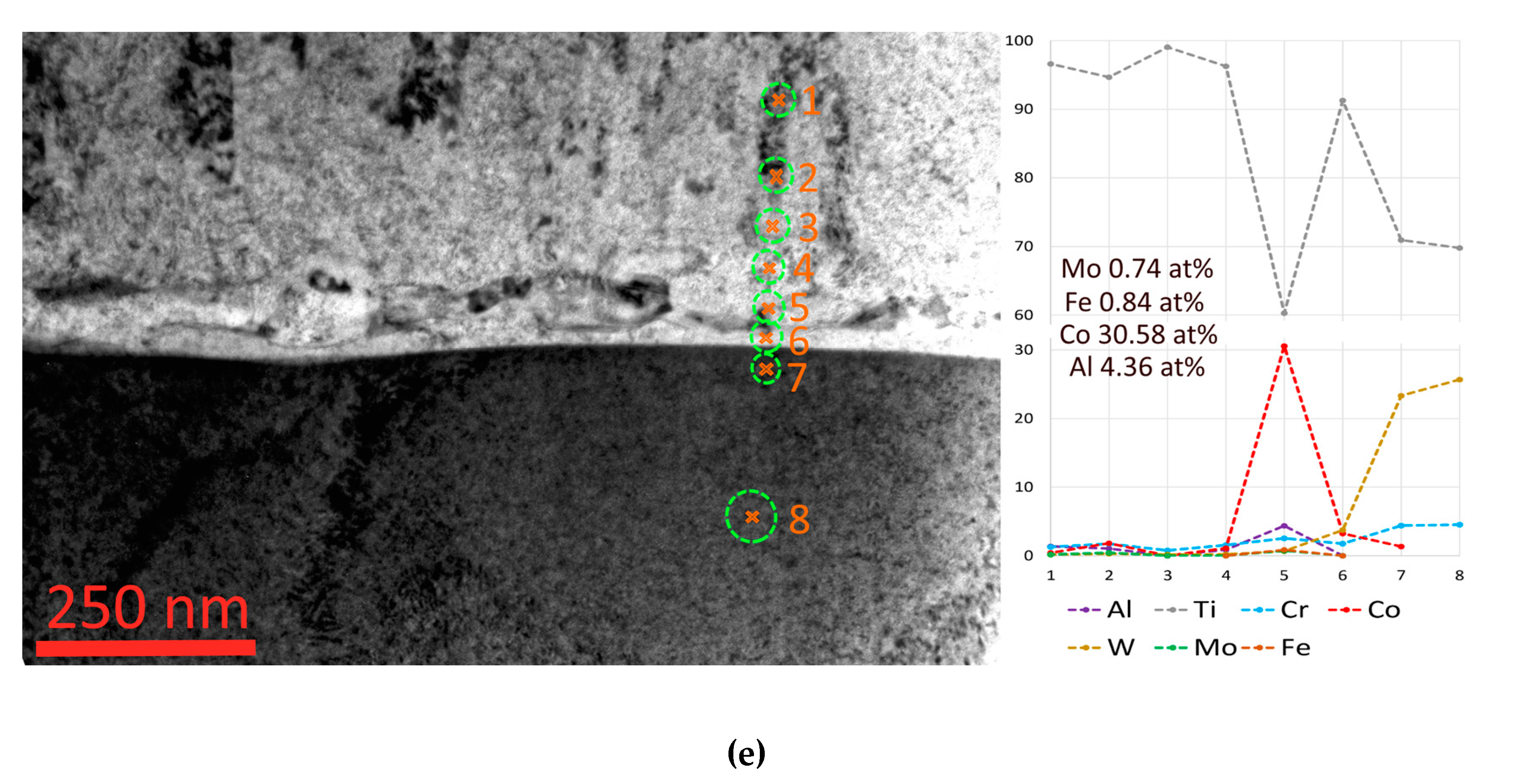

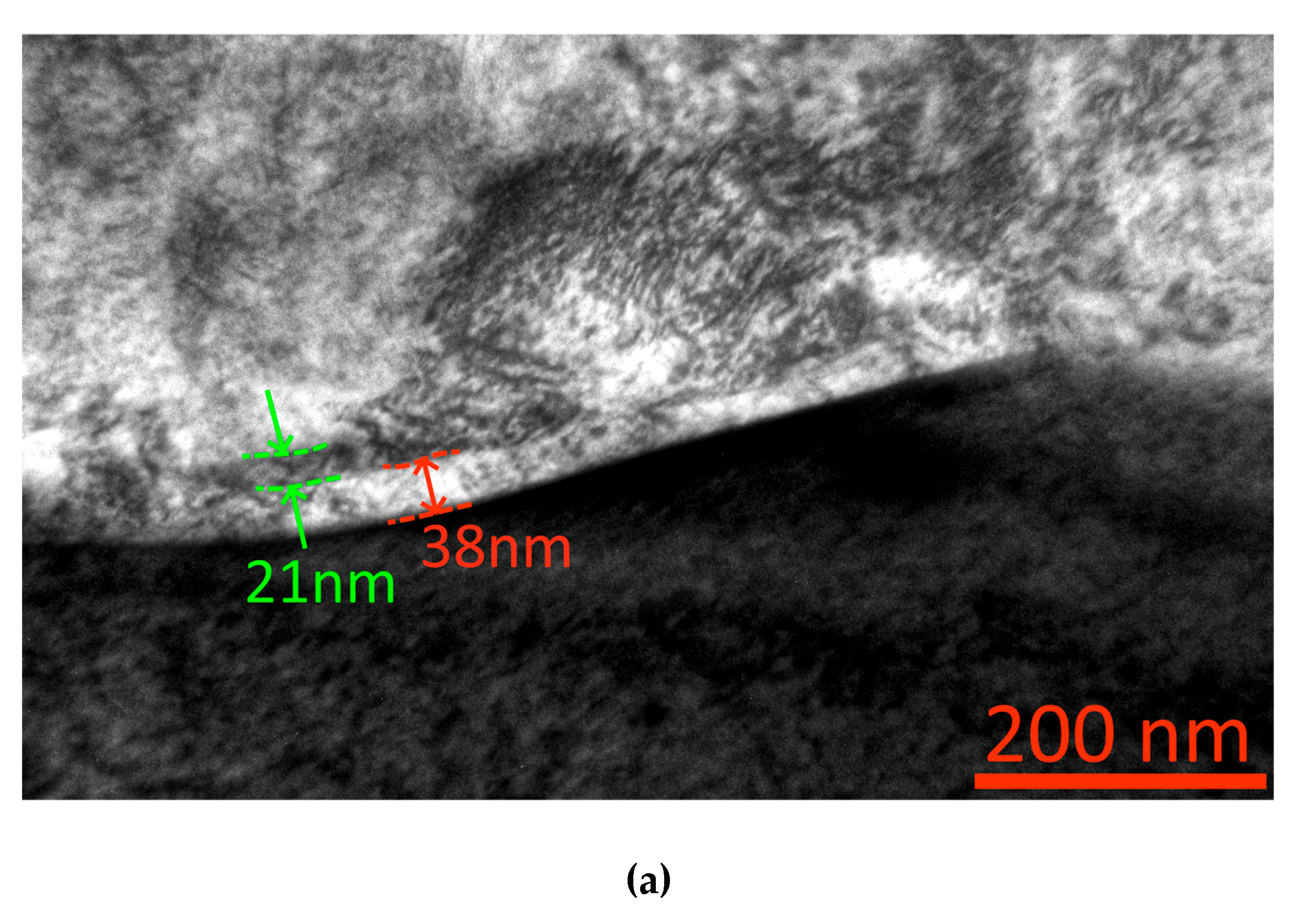

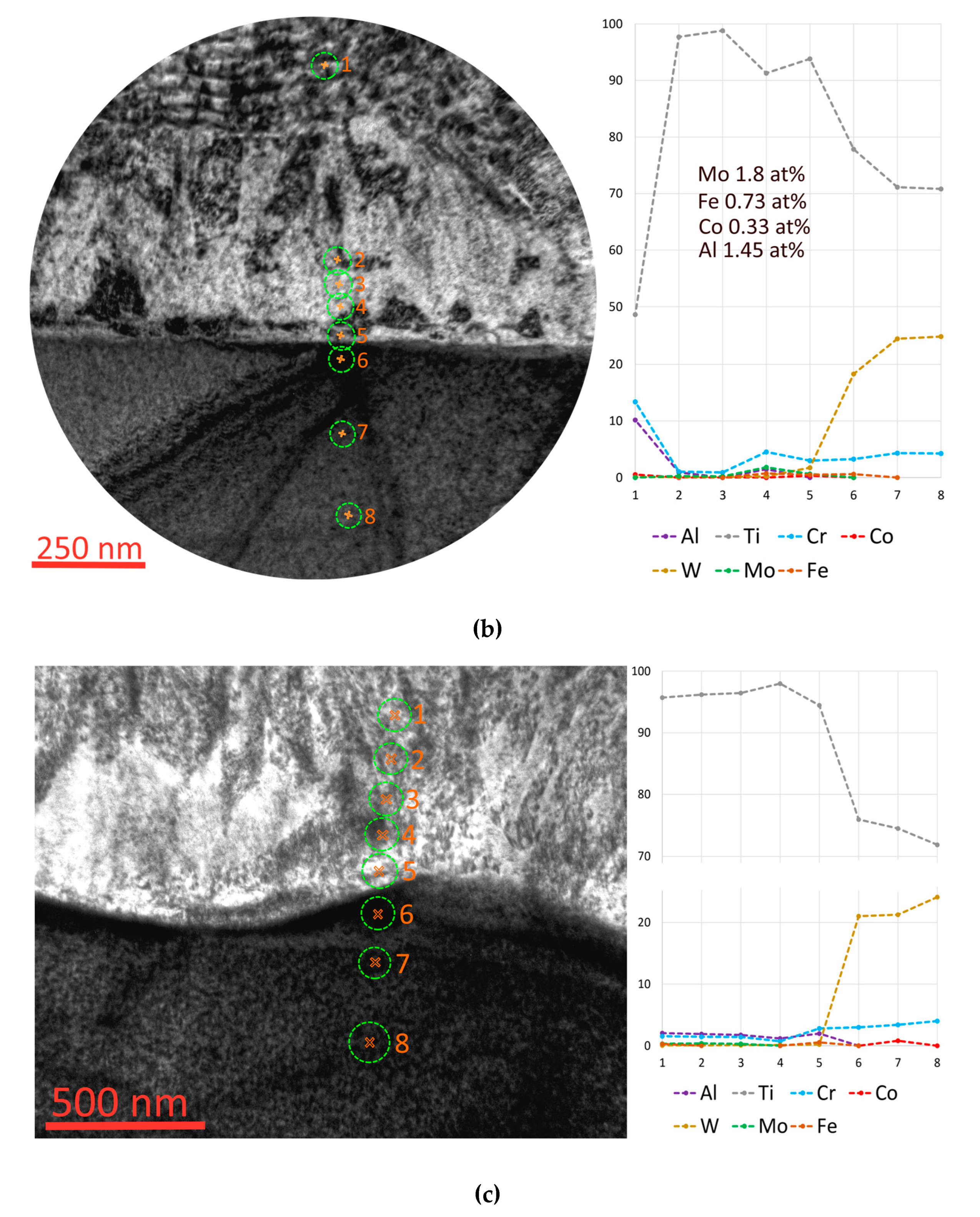

3.3.2. Heating of the Substrate Surface by a Glow Discharge (GD)

Let us consider the structure and composition of the layer formed when the substrate surface is heated by the GD method. The coating-substrate interface also has a layered structure (

Figure 6a). In this case, there is no layer with a high cobalt content; in some areas the presence of cobalt is observed in extremely small quantities. There is also a slight presence of iron and molybdenum, their content being significantly lower than that observed in the study of IB coatings. In some cases (

Figure 6b,d), tungsten diffuses into the titanium-rich layer adjacent to the substrate.

4. Discussion

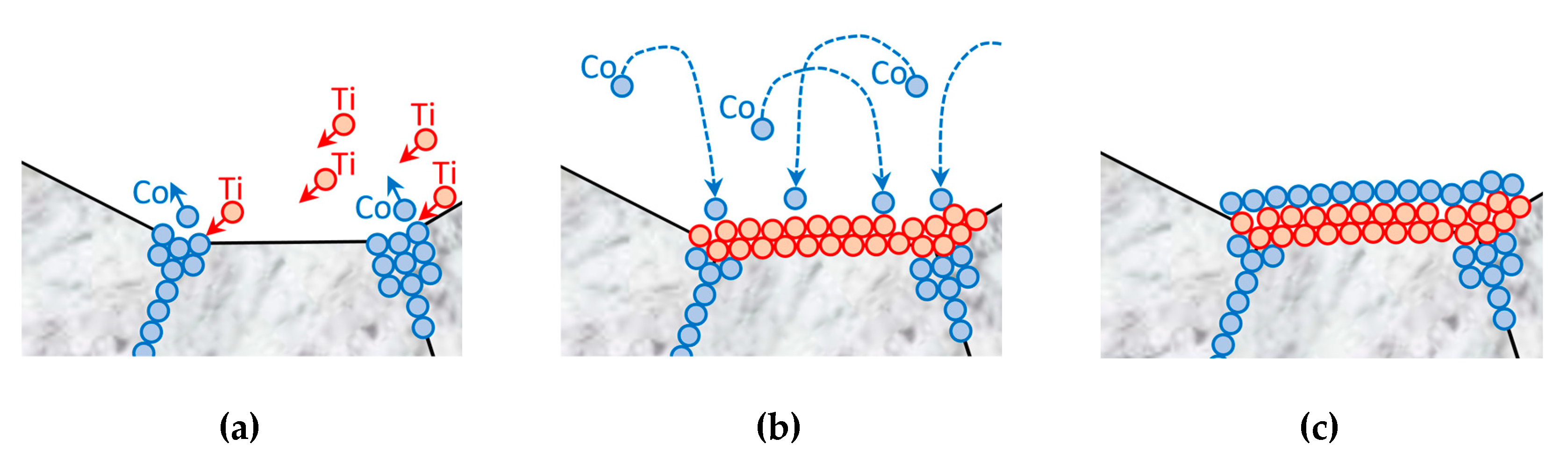

The formation of a layered structure, including a layer of almost pure titanium and a layer with a high cobalt content and the possible inclusion of some additional elements (for example, iron), which are absent both in the composition of the coating and in the composition of the substrate, requires some discussion. It was previously established [5] that ion etching with an inert gas leads to faster removal of carbides than of the cobalt matrix. On the contrary, etching with metal ions provides the effect of active sputtering of the cobalt binder. Thus, we can propose the following hypothesis for the formation of a layered structure including a cobalt layer. Titanium ions, when cutting into the surface of a substrate due to collisions, transfer their kinetic energy to surface atoms [1,40]. Since the atomic mass of cobalt (58.93) is comparable to the mass of titanium (47.86) and significantly less than the mass of tungsten (183.84), cobalt atoms are more likely to be knocked out from the surface of the substrate (

Figure 7a). Thus, a rarefied cloud of cobalt atoms knocked out from the surface is formed, and titanium atoms form a layer of nanometric thickness on the surface of the substrate (

Figure 7b). In this case, cobalt atoms are attracted to the surface of the substrate and at some point, they are re-deposited to form a corresponding layer saturated with cobalt (

Figure 7c). Regarding the content of iron and some other elements in the nanolayer under consideration, it can be assumed that during the process of ion etching, the flow of ions can also knock out atoms of iron and some other elements from the fastening equipment elements (made of stainless steel). Similar to cobalt atoms, atoms of these elements (in particular, iron) can settle on the surface of the substrate during the process of thermal activation before deposition of the adhesive sublayer.

Thus, in the process of ion bombardment with plasma generation by arc evaporators, a layer of complex structure and composition is formed at the boundary of the coating and substrate, which may include:

diffusion layer in the substrate (up to 200 nm thick). Diffusion of chromium and, possibly, titanium is observed (identification of titanium diffusion is difficult due to its presence also in the composition of the substrate – TiC),

layer with a dominant titanium content (30–50 nm thick),

a layer with a high cobalt content and the possible presence of elements from the equipment (in particular, iron and molybdenum). The composition of this layer is almost impossible to control.

5. Conclusions

The properties of coatings obtained using two surface preparation methods were compared: heating and etching by ion bombardment with plasma generation by arc evaporators (IB) and heating and etching by a glow discharge (GD). A Ti-TiN-(Ti,Cr,Al)N coating was deposited. It was found that:

the use of heating when exposed to gas ions of a glow discharge provides a smaller spread in the temperature of the samples throughout the chamber volume compared to heating by ion bombardment with plasma generation by arc evaporators;

the IB coating begins to fail at 36 N. When the maximum load of 40 N is reached, there are no signs of failure of the GD coating;

the cutting test results for turning 1045 steel show that at a cutting speed vc = 300 m/min, the GD coated tool shows slightly less active wear dynamics compared to the IB coated tool. When the cutting speed increases to vc = 350 m/min, the difference in wear dynamics becomes more noticeable and obvious. After 7 minutes of cutting, the IB coated tool reached the wear limit criterion (VBmax = 350 μm), while the GD coated tool remains functional and has not reached the wear limit value;

-

in the process of ion bombardment, a layer of complex structure and composition is formed at the boundary of the coating and substrate, which may include:

- ○

diffusion layer in the substrate (up to 200 nm thick). Diffusion of chromium and possibly titanium is observed,

- ○

layer with a dominant titanium content (30–50 nm thick),

- ○

layer with a high cobalt content and the possible presence of elements of other elements (in particular iron and molybdenum). This layer is formed only when using heating and etching by ion bombardment with plasma generation by arc evaporators;

the formation of a layer with a high molybdenum content may be associated with sputtering of cobalt atoms from the substrate by a flow of metal ions, followed by reverse deposition of cobalt;

a layer with a high cobalt content and the presence of other (contaminant) elements can negatively affect the overall adhesion strength of the coating and the substrate. This issue requires additional study.

Thus, the method of heating and etching by a glow discharge (GD) can be effectively used in the process of deposition of coatings using the PVD method.

Author Contributions

Conceptualization, J.B. and A.V.; Methodology, J.B., A.V., C.S. and F.M.; Resources, S.G.; Data curation, C.S. and I.S.; investigation, C.S., N.S., and I.S.; Writing—original draft preparation, A.V. and J.B.; Writing—review and editing, A.V., C.S., S.G. and M.V.; Project administration, C.S. and M.V. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the state assignment of the Ministry of Science and Higher Education of the Russian Federation, Project No. FSFS-2023-0003.

Data Availability Statement

Not applicable.

Acknowledgments

The study used the equipment from the Center for Collective Use of Moscow State Technological University STANKIN (agreement no. 075-15-2021-695, 26/07/2021).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Frey, H.; Khan, H.R. Handbook of Thin Film Technology; Publisher: Springer-Verlag Berlin Heidelberg, 2015. [Google Scholar]

- Ilyin, A.A.; Plihunov, V.V.; Petrov, L.M.; Zelenkov, V.V.; Ivanchuk, S.B.; Sokolov, I.V. Cleaning and Activation of the Surface of Products from Structural Metallic Materials in the Process of Vacuum Ion-Plasma Treatment. Technology of light alloys 2009, 2, 111–117. [Google Scholar]

- Luchkin, A.G.; Luchkin, G.S. Cleaning the Surface of Substrates for Coating by Vacuum-Plasma Methods. Bulletin of the Kazan Technological University 2012, 15, 208–210. [Google Scholar]

- Oura, K.; Lifshitz, V.G.; Saranin, A.A.; Zotov, A.V.; Katayama, M. Introduction to surface physics; Publisher: Nauka, Moscow, Russia, 2006. [Google Scholar]

- Tillmann, W.; Hagen, L.; Stangier, D.; Krabiell, M.; Elbers, M. Influence of etching-pretreatment on nano-grained WC-Co surfaces and properties of PVD/HVOF duplex coatings. Surf Coat Tech 2019, 374, 32–43. [Google Scholar] [CrossRef]

- Pemmasani, S.P.; Valleti, K.; Gundakaram, R.C.; Rajulapati, K.V.; Mantripragada, R.; Koppoju, S.; Joshi, S.V. Effect of microstructure and phase constitution on mechanical properties of Ti1−xAlxN coatings. Appl Surf Sci 2014, 313, 936–946. [Google Scholar] [CrossRef]

- Yang, J.; Odén, M.; Johansson-Jõesaar, M.P.; Esteve, J.; Llanes, L. Mechanical strength of ground WC-Co cemented carbides after coating deposition. Mater Sci Eng A 2017, 689, 72–77. [Google Scholar] [CrossRef]

- Barshilia, H.C.; Ananth, A.; Khan, J.; Srinivas, G. Ar + H2 plasma etching for improved adhesion of PVD coatings on steel substrates. Vacuum 2012, 86(8), 1165–1173. [Google Scholar] [CrossRef]

- Buchwalder, A.; Zenker, R. Pre- and post-surface treatments using electron beam technology for load-related application of thermochemical and PVD hard coatings on soft substrate materials. Surf Coat Tech 2019, 375(6), 920–932. [Google Scholar] [CrossRef]

- Komarovskaya, V.M.; Ivashchenko, S.A. Optimization of modes of ion treatment of the surface of non-metallic materials. Uprochnyayuscie technologii I pokrytiya (Russ.) 2013, 3, 23–27. [Google Scholar]

- Zabrodin, I.G.; Zorina, M.V.; Kaskov, I.A.; Malyshev, I.V.; Mikhailenko, M.S.; Pestov, A.E.; Salashchenko, N.N.; Chernyshev, A.K.; Chkhalo, N.I. Ion-Beam Methods for High-Precision Processing of Optical Surfaces. Tech Phys 2020, 65(11), 1837–1845. [Google Scholar] [CrossRef]

- Kaufman, H.R.; Harper, J.M.E. Ion-assist applications of broad-beam ion sources. Proceedings of SPIE – The International Society for Optical Engineering, 2004, 5527(07), 50–68.

- Talipov, N.Kh.; Voitsekhovsky, A.V. Influence of ion-beam etching modes on the process of radiation heating of CdxHg1-xTe. J Appl Phys 2018, 4, 61–66. [Google Scholar]

- Stepanovsky, A.S. Ionic Processing of Materials. Ogaryov-online. Mashinostroenie: nauka i technika 2013, 14, 1–3. [Google Scholar]

- Hovsepian, P.; Reinhard, C.; Ehiasarian, A.P. CrAlYN/CrN superlattice coatings deposited by the combined high power impulse magnetron sputtering/unbalanced magnetron sputtering technique. Surf Coat Technol 2006, 201, 4105–4110. [Google Scholar] [CrossRef]

- Abdullin, I.Sh.; Khubathuzin, A.A. The use of low-pressure high-frequency plasma to obtain the isotropic properties of the metal. Kazan, Bulletin of KSTU 2010, 11, 625–627.

- Kablov, E.N.; Muboyadzhyan, S.A. Ion etching and surface modification of critical machine parts in vacuum-arc plasma. Bulletin of MSTU im. N.E. Bauman 2011, 149–162. [Google Scholar]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Sotova, C. Investigation of the influence of the features of the deposition process on the structural features of microparticles in PVD coatings. Vacuum, 2022, 202, 111144. [Google Scholar] [CrossRef]

- Lattemann, M.; Ehiasarian, A.P.; Bohlmark, J.; Persson, P.; Helmersson, U. Investigation of high power impulse magnetron sputtering pretreated interfaces for adhesion enhancement of hard coatings on steel. Surf Coat Technol 2006, 200, 6495–6499. [Google Scholar] [CrossRef]

- Mattox, M.D. A Short History of In Situ Cleaning in Vacuum for Physical Vapor Deposition (PVD). SVC Bull Fall, 2014, 50–52.

- Broitman, E.; Hultman, L. Adhesion improvement of carbon-based coatings through a high ionization deposition technique. J Phys Conf Ser 2012, 370, 012009. [Google Scholar] [CrossRef]

- Yurshev, V.I.; Serdyuk, A.I.; Mukatdarov, R.I.; Yurshev, I.V. Deposition of Coatings Under Pulsed Action of Glow Discharge. Met Sci Heat Treat 2018, 59(9–10), 637–640. [CrossRef]

- Zadorozhnyi, V.G.; Rafalovich, D.M.; Roikh, I.L. Effect of Surface Treatment of Steel with a Glow Discharge on the Adhesion and Porosity of Vacuum Coatings of Polyfluorotrichloroethylene. Elektronnaya Obrabotka Materialov 1977, 1, 43–45. [Google Scholar]

- Vetter, J.; Burgmer, W.; Perry, A.J. Arc-enhanced glow discharge in vacuum arc machines. Surf Coat Technol 1993, 59(1–3), 152–155. [CrossRef]

- Berlin, E.; Dvinin, S.; Seidman, L. World of Materials and Technologies. Vacuum technology and equipment for deposition and etching of thin films; Publisher: Technosphere, Moscow, Russia, 2007.

- Panjan, P.; Drnovšek, A.; Gselman, P.; Čekada, M.; Panjan, M. Review of Growth Defects in Thin Films Prepared by PVD Techniques. Coatings 2020, 10, 447. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Mahne, N.; Čekada, M.; Panjan, M. Surface Topography of PVD Hard Coatings. Coatings 2021, 11, 1387. [Google Scholar] [CrossRef]

- Schönjahn, C.; Lewis, D.B.; Münz, W.-D.; Petrov, I. Shortlisted substrate ion etching in combined steered cathodic arc–ubm deposition system: Effects on interface architecture, adhesion, and tool performance. Surf Eng 2000, 16, 176–180. [Google Scholar] [CrossRef]

- Gilman, V.N.; Fashutdinov, A.I.; Balabanov, I.P. Experience in the application of nitriding in a glow discharge to increase the efficiency of gear processing by the method of grinding. IOP Conference Series: Materials Science and Engineering 2020, 915(1), 012014. [CrossRef]

- Tsujikawa, M.; Sone, T.; Egawa, M.; Ueda, N.; Higashi, K. Hardness profile improvement of plasma nitrided high speed steel by glow discharge heating. Int Heat Treat Surf Eng 2011, 5(4), 171–174. [Google Scholar] [CrossRef]

- Kashaev, N.; Stock, H.-R.; Mayr, P. Nitriding of Ti - 6% Al - 4% v alloy in the plasma of an intensified glow discharge. Met Sci Heat Treat 2004, 46(7–8), 294–298. [CrossRef]

- Vetter, J.; Wallendorf, T. Plasma diagnostics of arc-enhanced glow discharge. Surf Coat Technol 1995, 76–77, 322–327. [Google Scholar] [CrossRef]

- Ehiasarian, A.P.; Wen, J.G.; Petrov, I. Interface microstructure engineering by high power impulse magnetron sputtering for the enhancement of adhesion. J Appl Phys 2007, 101, 054301. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Andreev, N.; Bublikov, J.; Kutina, N. Investigation of the properties of the Cr,Mo-(Cr,Mo,Zr,Nb)N-(Cr,Mo,Zr,Nb,Al)N multilayer composite multicomponent coating with nanostructured wear-resistant layer. Wear 2021, 468–469, 203597. [Google Scholar] [CrossRef]

- Bora, B. Studies on the effect of finite geometrical asymmetry in dual capacitively coupled radio frequency plasma. Plasma Sources Sci Technol 2015, 24(5), 054002. [Google Scholar] [CrossRef]

- So, S.-Y. Analysis on DC glow discharge properties of Ar gas at the atmosphere pressure. Trans Korean Inst Electr Eng 2010, 59(4P), 417–422. [Google Scholar]

- Yuan, X.; Raja, L.L. Computational study of capacitively coupled high-pressure glow discharges in helium. IEEE Trans Plasma Sci 2003, 31(4 II), 495–503. [Google Scholar] [CrossRef]

- Wang, Y.H.; Guo, F.; Ren, H.; Hu, S.Y.; Chen, Y.J.; Zhao, Y.H.; Gong, F.; Xie, Z.W. Enhancing wear resistance of TiN coating by gradient bias voltage and arc-enhanced glow discharge. Ceram Int 2022, 48(6), 8746–8750. [Google Scholar] [CrossRef]

- Xue, G.; Wang, Z.; Xiang, L.; Xiao, H.; Zhao, Y.; Wan, Y.; Ning, H.; Xie, Z. Enhancing hot corrosion performance of NiCoCrAlY/AlSiY coating by arc enhanced glow discharge. Materials Letters: X 2022, 13, 100130. [Google Scholar] [CrossRef]

- Berish, R. Problems of Applied Physics. Sputtering of solids by ion bombardment 1986, II, 482. [Google Scholar]

- Guo, X.; Liu, F.; Zhang, K.; Wang, C.; Piao, Z.; Sun, L. Controllable preparation of micro-textures on WC/Co substrate surface by an integrated laser-dry etching process for improving PVD coatings adhesion. Appl Surf Sci 2020, 534, 147580. [Google Scholar] [CrossRef]

- Zhang, K.D.; Deng, J.X.; Guo, X.H.; Sun, L.N.; Lei, S.T. Study on the adhesion and tribological behavior of PVD TiAlN coatings with a multi-scale textured substrate surface. Int J Refract Met H 2018, 72, 292–305. [Google Scholar] [CrossRef]

- Panjan, P.; Drnovšek, A.; Čekada, M.; Panjan, M. Contamination of Substrate-Coating Interface Caused by Ion Etching. Coatings 2022, 12(6), 846. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Bublikov, J.I.; Sitnikov, N.N.; Oganyan, G.V.; Sotova, C.S. Influence of nanolayer thickness on the performance properties of multilayer composite nano-structured modified coatings for metal-cutting tools. Int J Adv Manuf Technol 2018, 95(5–8), 2625–2640. [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Migranov, M.; Andreev, N.; Bublikov, J.; Sitnikov, N.; Oganyan, G. Investigation of the tribological properties of Ti-TiN-(Ti,Al,Nb,Zr)N composite coating and its efficiency in increasing wear resistance of metal cutting tools. Tribol Int 2021, 164, 107236. [Google Scholar] [CrossRef]

- Vereschaka, A.; Grigoriev, S.; Milovich, F.; Sitnikov, N.; Migranov, M.; Andreev, N.; Bublikov, J.; Sotova, C. Investigation of tribological and functional properties of Cr,Mo-(Cr,Mo)N-(Cr,Mo,Al)N multilayer composite coating. Tribol Int 2021, 155, 106804. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Vereschaka, A.A.; Sitnikov, N.N.; Milovich, F. Properties of (Cr,Al,Si)N-(DLC-Si) composite coatings deposited on a cutting ceramic substrate. Ceram. Int. 2020, 46, 18241–18255. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Bublikov, J. Investigation of wear mechanisms for the rake face of a cutting tool with a multilayer composite nanostructured Cr–CrN-(Ti,Cr,Al,Si)N coating in high-speed steel turning. Wear 2019, 438–439, 203069. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The Role of Thin-Film Vacuum-Plasma Coatings and Their Influence on the Efficiency of Ceramic Cutting Inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef]

- Vereschaka, A.A.; Grigoriev, S.N.; Volosova, M.A.; Batako, A.; Vereschaka, A.A.; Sitnikov, N.N.; Seleznev, A.E. Nano-scale multi-layered coatings for improved efficiency of ceramic cutting tools. Int J Adv Manuf Technol 2017, 90, 27–43. [Google Scholar] [CrossRef]

- Vereschaka, A.; Tabakov, V.; Grigoriev, S.; Sitnikov, N.; Milovich, F.; Andreev, N.; Sotova, C.; Kutina, N. Investigation of the influence of the thickness of nanolayers in wear-resistant layers of Ti-TiN-(Ti,Cr,Al)N coating on destruction in the cutting and wear of carbide cutting tools. Surf Coat Technol 2020, 385, 125402. [Google Scholar] [CrossRef]

- Vereschaka, A.S.; Grigoriev, S.N.; Sotova, E.S.; Vereschaka, A.A. Improving the efficiency of the cutting tools made of mixed ceramics by applying modifying nano-scale multilayered coatings. Adv Mat Res 2013, 712–715, 391–394. [Google Scholar]

- Grigoriev, S.; Vereschaka, A.; Zelenkov, V.; Sitnikov, N.; Bublikov, J.; Milovich, F.; Andreev, N.; Mustafaev, E. Specific features of the structure and properties of arc-PVD coatings depending on the spatial arrangement of the sample in the chamber. Vacuum 2022, 200, 111047. [Google Scholar] [CrossRef]

- Grigoriev, S.; Vereschaka, A.; Milovich, F.; Sitnikov, N.; Seleznev, A.; Sotova, C.; Bublikov, J. Influence of the yttrium cathode arc current on the yttrium content in the (Ti, Y, Al) N coating and the coating properties. Vacuum 2024, 222, 113028. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).