1. Introduction

The wood panel industry is characterized by an ever-increasing scarcity of resources and raw materials, resulting in the need for suitable alternatives [

1]. An excellent way to solve this problem is to use traditionally used sources combined with newly discovered ones. Researchers often rely on recycled additives. This is an added advantage when we can use the waste in production. It is sometimes found that additives positively affect the tested material’s physical and mechanical properties. For example, Kilani et al. [

2] found that banana and orange peels hold substantial potential for reinforcing concrete. Another study where recycled waste was used is described by Borysiewicz and Kowaluk [

3], where the addition of HDPE can benefit MDF panel parameters. In this way, highly innovative solutions can be invented.

The textile industry ranks among the world’s top polluters [

4]. It is responsible for approximately 8% of the global carbon emissions and 20% of the pollution in industrial water [

5]. Almost 85% of textile waste is incinerated in landfills, leading to significant environmental pollution and substantial resource wastage, highlighting the need for alternative fabric production methods [

6]. The entire lifecycle of textiles, from fiber production to disposal, poses numerous environmental challenges. Textile manufacturing relies heavily on chemicals and uses large amounts of water at various stages [

7]. This results in a significant impact not only on the environment but also on the economy. Each year,

$500 billion is lost due to clothing needing more utilized and the lack of recycling [

8]. In the past twenty years, the textile industry has doubled its production, and the average global annual consumption of textiles has increased from 7 to 13 kg per person, reaching 100 million tonnes [

9]. Artificial fiber woven products, such as those made from nylon and polyester, are known for their durability but present significant environmental challenges due to their slow decomposition rates [

10]. Polyester, a widely used synthetic fiber, can decompose anywhere from 20 to 200 years [

11]. Reusing and recycling textile waste are the most effective disposal methods, offering the lowest environmental impacts [

12]. European Union regulations [

13] mandate that by January 2025, the textile waste recycling rate in Europe should be increased [

14]. Increasing the textile recycling rate can reduce the negative environmental impact caused by landfill use and the production of new textiles. Recycled textile fibers can be a valuable secondary material. In their study, Zach et al. [

15] obtained a raw material to produce medium, higher, and high-density acoustic insulators from used filters and edges from carpet manufacturing. An essential aspect of using textile waste in producing fiberboards is its impact on the bonding process of these boards. Some methods allow for assessing the chemical effects on gelation, such as the Acid Buffering Capacity (ABC) coefficient. In the development of technology for producing such boards, especially when there is significant variability in the properties of textile waste, ABC can be utilized in the manufacturing process [

16].

This research aimed to assess the feasibility of incorporating textile fibers from artificial leather waste originating from the upholstered furniture industry into the structure of high-density fibreboards and to verify if the tested alternative raw material of recycled origin would have a positive impact on physical and mechanical properties of the produced panels. This is also an attempt to extend the period of carbon fixation in the textile and produced HDF boards, positively contributing to CCS policy instead of energetic recycling and carbon emission.

2. Materials and Methods

2.1. Materials

The following raw materials were used to create the test material:

virgin pine (Pinus sylvestris L.) debarked round wood from Polish State Forests (Podlaskie voivodeship, Orla, Poland) was used to produce the fibers;

commercial urea-formaldehyde (UF) resin (Silekol Sp. z o.o., Kędzierzyn-Koźle, Poland) of about 66.5% of dry content with formaldehyde to urea (F:U) molar ratio of 0.89, pH of 9.6 and viscosity of 470 mPa s was used;

3.0% of ammonium nitrate hardener, calculated regarding the dry resin content;

distilled water;

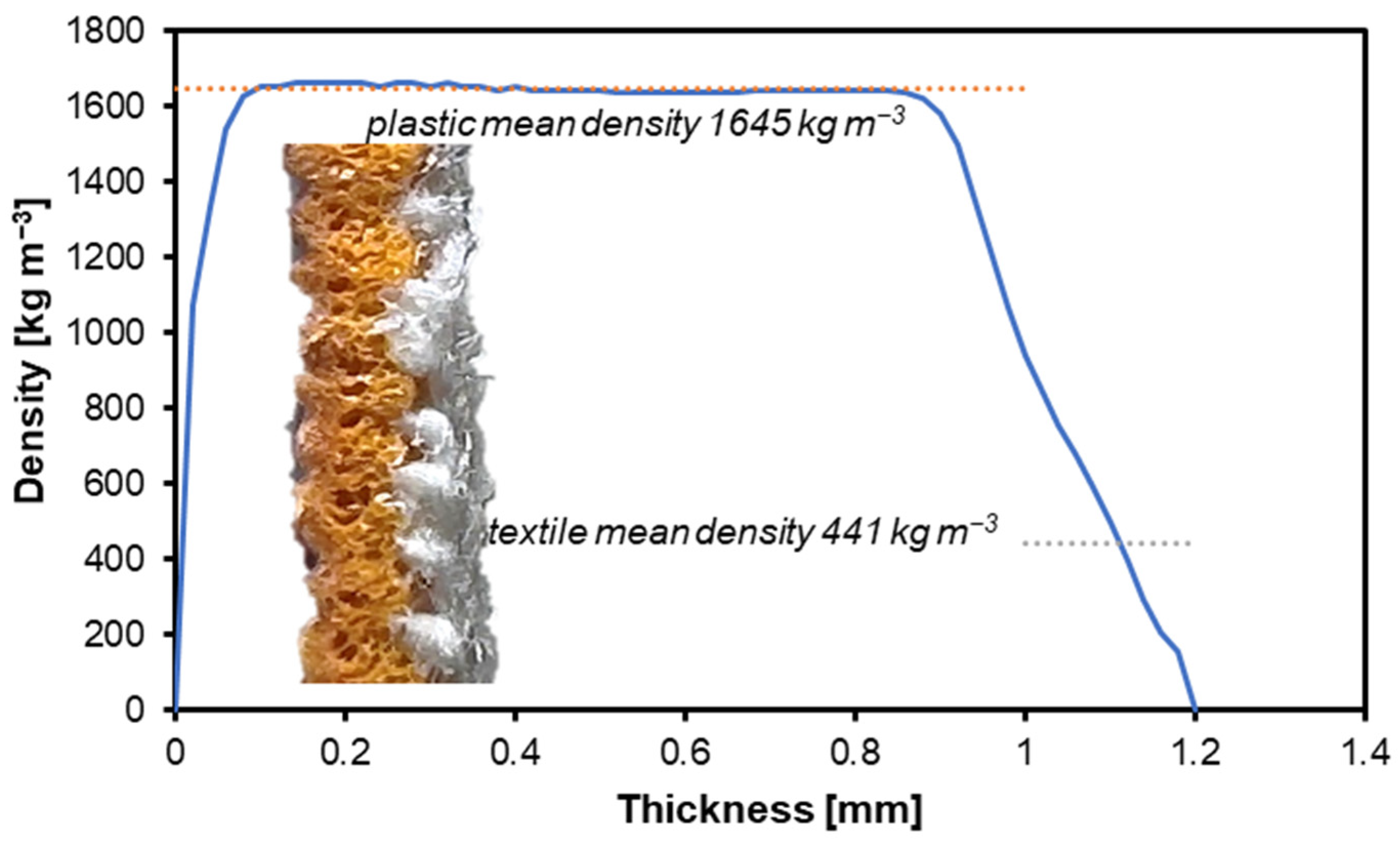

the textile fibers mixture containing 75% polyester and 25% cotton (w/w) coming from the mechanical recycling of eco-leather upholstery fabric particles about 30 mm × 30 mm (thickness 1.2 mm, grammage 400 g m−2) covered by polyurethane surface layer (foamy brown zone in

Figure 1), that has been removed during milling.

2.2. Production of the Panels

The material tested was high-density dry-formed panels with dimensions 320 mm × 320 mm, 3 mm thick, and a target density of 900 kg m−3. Boards were made with artificial leather fibers at 1%, 5%, 10%, and 25% w/w, or board weight. The synthetic fibers were only added to the core layer, constituting 68% w/w of the panel weight. The face layers, 2 × 16% w/w, have been created without artificial fiber addition. The reference variants were produced without incorporating artificial leather fibers. The adhesive compound had a curing time of approximately 88 seconds at 100 °C. The resination was set at 12% of dry resin calculated on dry fibers. The wood fibers were placed in a drum mixer. Artificial leather fibers were gradually added during mixing, and the glue mixture was sprayed with an air gun. The hot pressing parameters (hydraulic press AKE, Mariannelund, Sweden) were the temperature of 200 ºC, the maximum unit pressure of 2.5 MPa, and the pressing factor of 20 s mm−1 of the nominal board thickness. No hydrophobic agent was used to produce the boards. Before testing, all samples were conditioned in atmospheric air pressure at 20 °C and 65% relative humidity to achieve constant weight.

2.3. Methods

The bulk density of the fibers used in the research was tested [

17]. At least three individual measurements were carried out for each listed type. The bending elasticity (modulus of elasticity, MOE) and bending strength (modulus of rupture, MOR) tests were carried out using a computer-controlled universal testing machine in accordance with the EN 310 (1993) [

18] standard. Screw withdrawal resistance (SWR) was tested according to EN 320 [

19]. At least eight samples from each board variant were used for testing. Tensile strength perpendicular to the plane of the board (internal bond, IB) was tested according to EN 319 [

20]. Water absorption (WA) and thickness swelling (TS) tests were conducted following EN 317 [

21] guidelines after 2 hours and 24 hours of water immersion, using at least eight samples per variant. Surface water absorption (SWA) was measured according to EN 382-2 [

22] after 2 hours on two samples from each variant. The density profile of the samples was analyzed using a DA-X measuring instrument (GreCon in Alfeld, Germany). The measurement was carried out with a speed of 0.05 mm/s across the panel thickness with a sampling step of 0.02 mm. Samples were cut into 50 mm × 50 mm nominal dimensions. Three samples of each composite type were tested to determine the density profile. Then, the representative profile per every tested variant has been selected for further evaluation and presentation in the plot. The density has been tested in accordance with EN 323 [

23] standards.

Analysis of variance (ANOVA) and t-test calculations were conducted to identify significant differences (α = 0.05) between factors and levels when applicable, using the IBM SPSS statistic base (IBM, SPSS20, Armonk, NY, USA). The homogenous groups are indicated in

Table 1. The results shown in the graphs represent mean values and standard deviation as error bars.

3. Results and Discussion

3.1. Bulk Density

The bulk density of the samples made with the addition of wood fiber was 28.30 kg m

−3. This is marginally higher than the bulk density of the samples with textile fibers as an additive (25.77 kg m

−3). Sala et al. [

24] validated that the density distribution in HDF surface layers changes after adding raw materials with different bulk densities. The low bulk density of hemp shavings (90 kg m

−3) in the Savov et al. [

25] study positively affected physical and mechanical strengths.

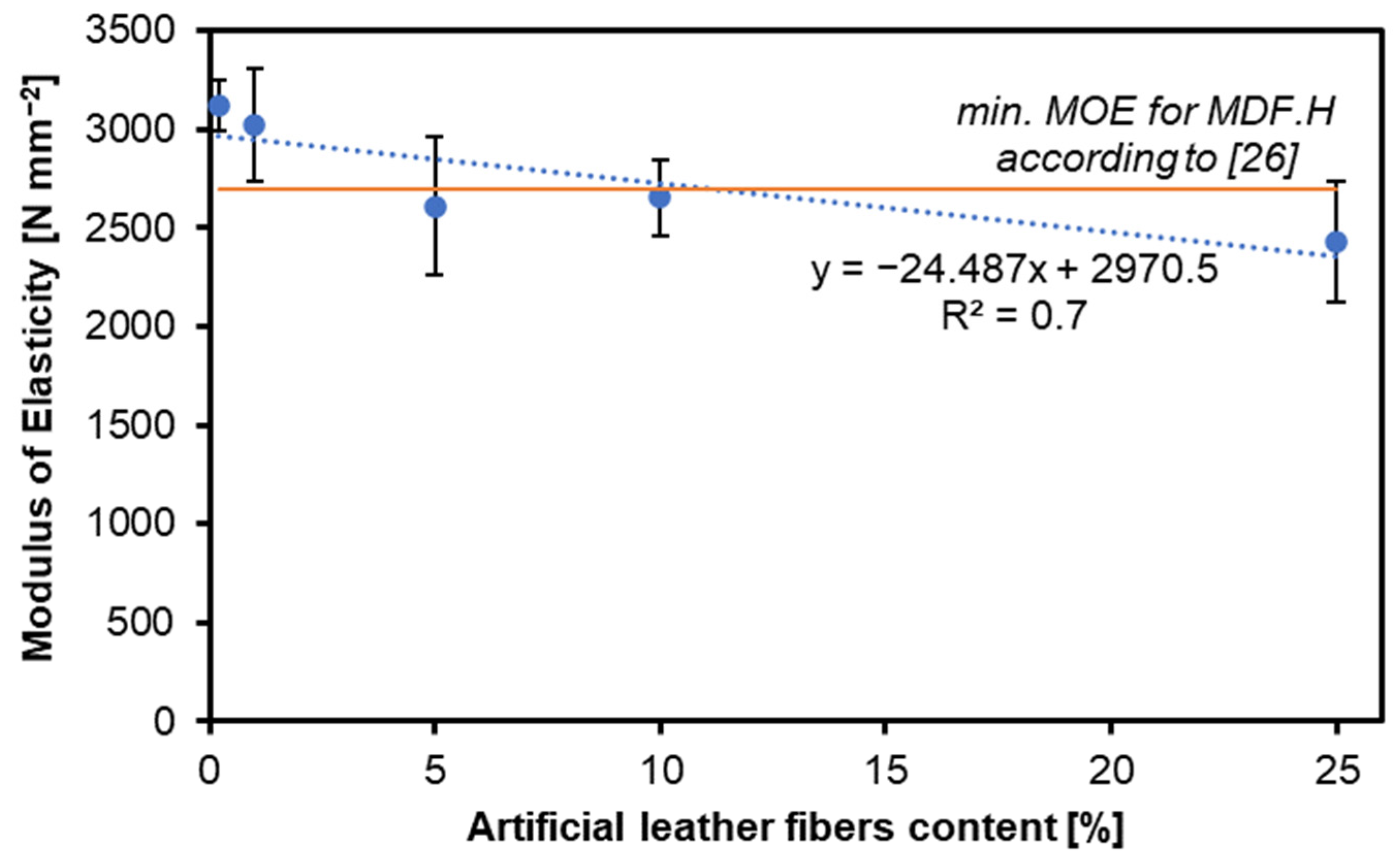

3.2. Modulus of Elasticity in Bending and of Bending Strength

The results of the measurement of the modulus of elasticity in bending are visualized in

Figure 2. The lowest result for the sample was 25% of the content of artificial leather fibers and was 2430 N mm

−2. As can be seen from the chart, no sample with artificial leather fibers for MOE has higher values than the reference sample, whose value is 3123 N mm

−2. The reference sample and the sample with a 1% addition of synthetic leather met the requirements of the European standards according to EN 622-5 [

26]. In a study on the production of eco-friendly, formaldehyde-free high-density fiberboard (HDF) panels from hardwood fibers bonded with urea-formaldehyde (UF) resin and ammonium lignosulfonate (ALS), Antov et al. [

27] obtained MOE values ranging from 3197 N mm

−2 to 4114 N mm

−2.

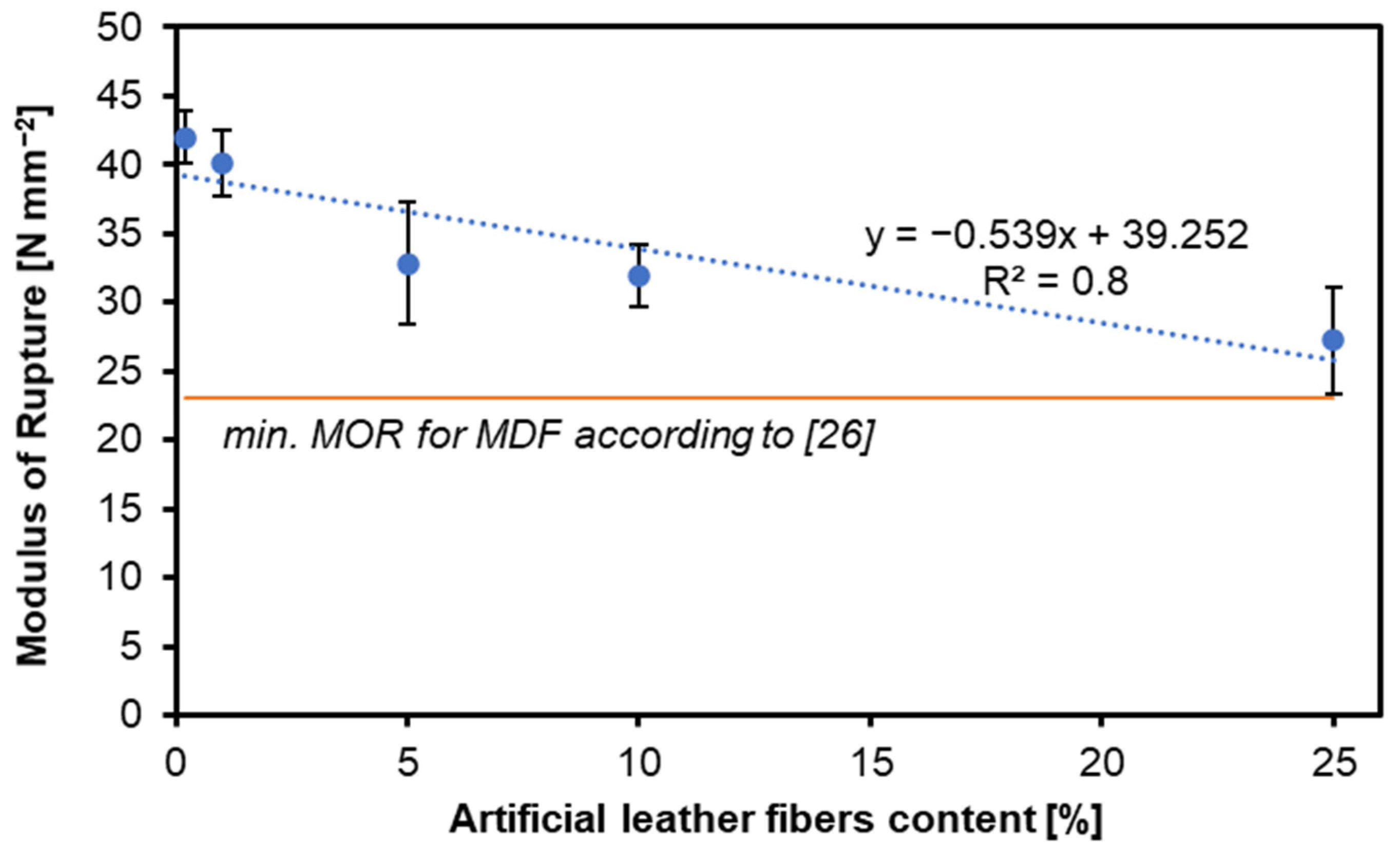

The following graph (

Figure 3) shows the test samples’ rupture modulus. As with the modulus of elasticity, the MOR decreases as the addition of artificial leather fibers increases. The reference sample had the highest bending strength, 42 N mm

−2. 27.2 N mm

−2 was the lowest result obtained from the sample with the highest synthetic leather content. As far as MOR is concerned, all samples obtained results conformance with European standards according to EN 622-5 [

26]. Very similar results were obtained in their research by Nicewicz and Monder [

28], where the highest modulus of rupture value was 41 N mm

−2 and the lowest 29 N mm

−2. In their study, Barbu et al. [

29] also observed decreased MOR and MOE values by adding waste skin. The same relationship was observed by Pásztory et al. [

30] in their study in which MOE and MOR values decrease linearly with poplar bark content. Research confirms that the mechanical strength of artificial leather can depend on the material from which it is made or the conditions under which it is produced. Therefore, depending on the type of synthetic leather, it may or may not affect the mechanical properties of wood-based materials [

31]. Nemli et al. [

32] found that 10% textile dust content in particleboard resulted in MOR and MOE of 13.0 and 1814 N mm

−2, respectively, while 20% textile dust content resulted in MOR and MOE values of 12.9 and 1755 N mm

−2, respectively.

Increasing additive content leads to a notable drop in mechanical characteristics. The size of the wood and synthetic leather fibers also influences strength properties. [

33] and replacing traditional wood raw materials with different sources can impact the mechanical resistance and water interaction of wood composites [

24]. Artificial leather scraps, as well as the leather itself, exhibit insulating properties. Therefore, one should not only view the results negatively but also look for potential applications of the produced composites as insulating materials, such as for sound insulation [

34]; for this purpose, bamboo fibers and leather fibers [

35] and denim shoddy and waste jute fibers were used [

36].

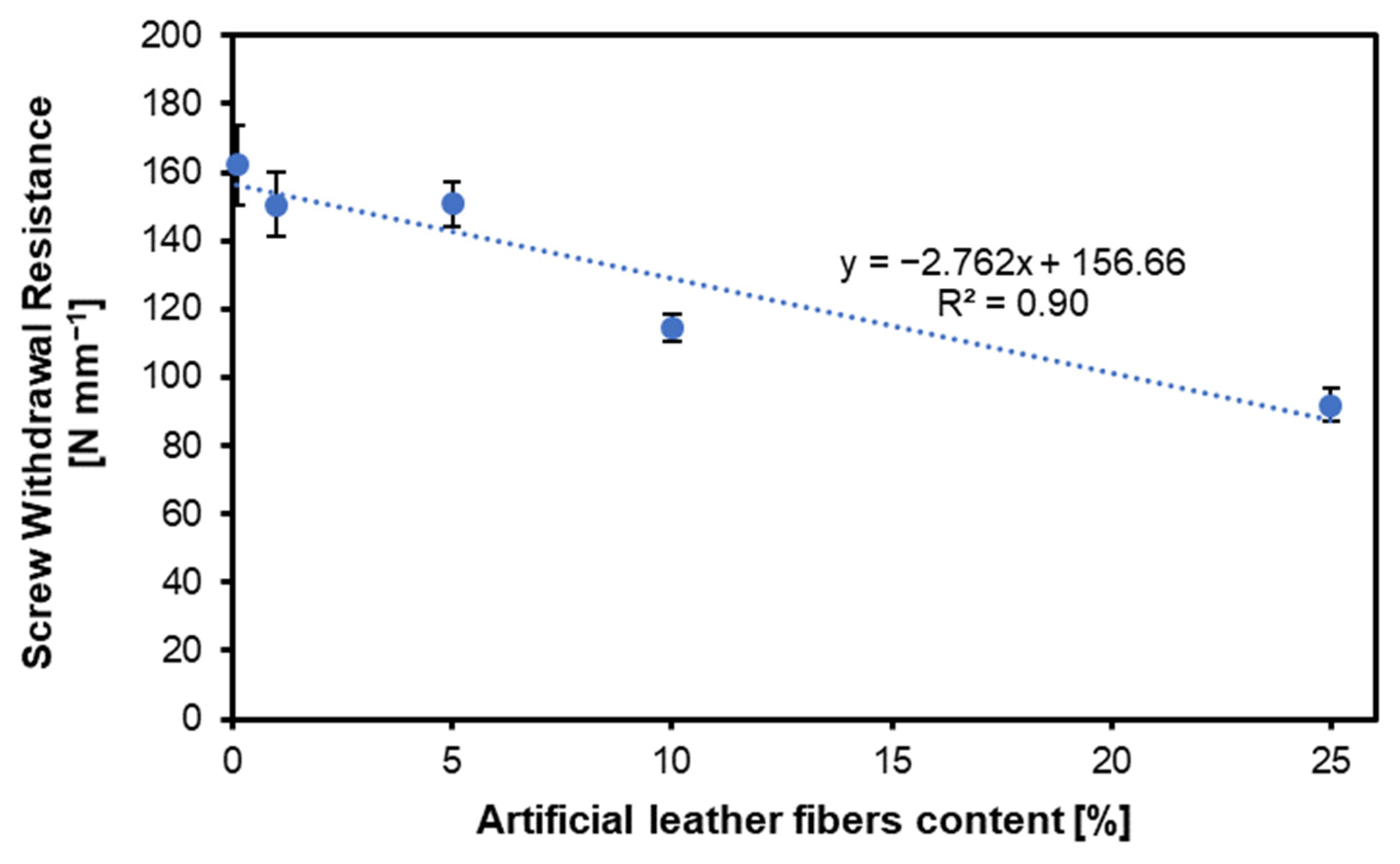

3.3. Screw Withdrawal Resistance and Internal Bonding

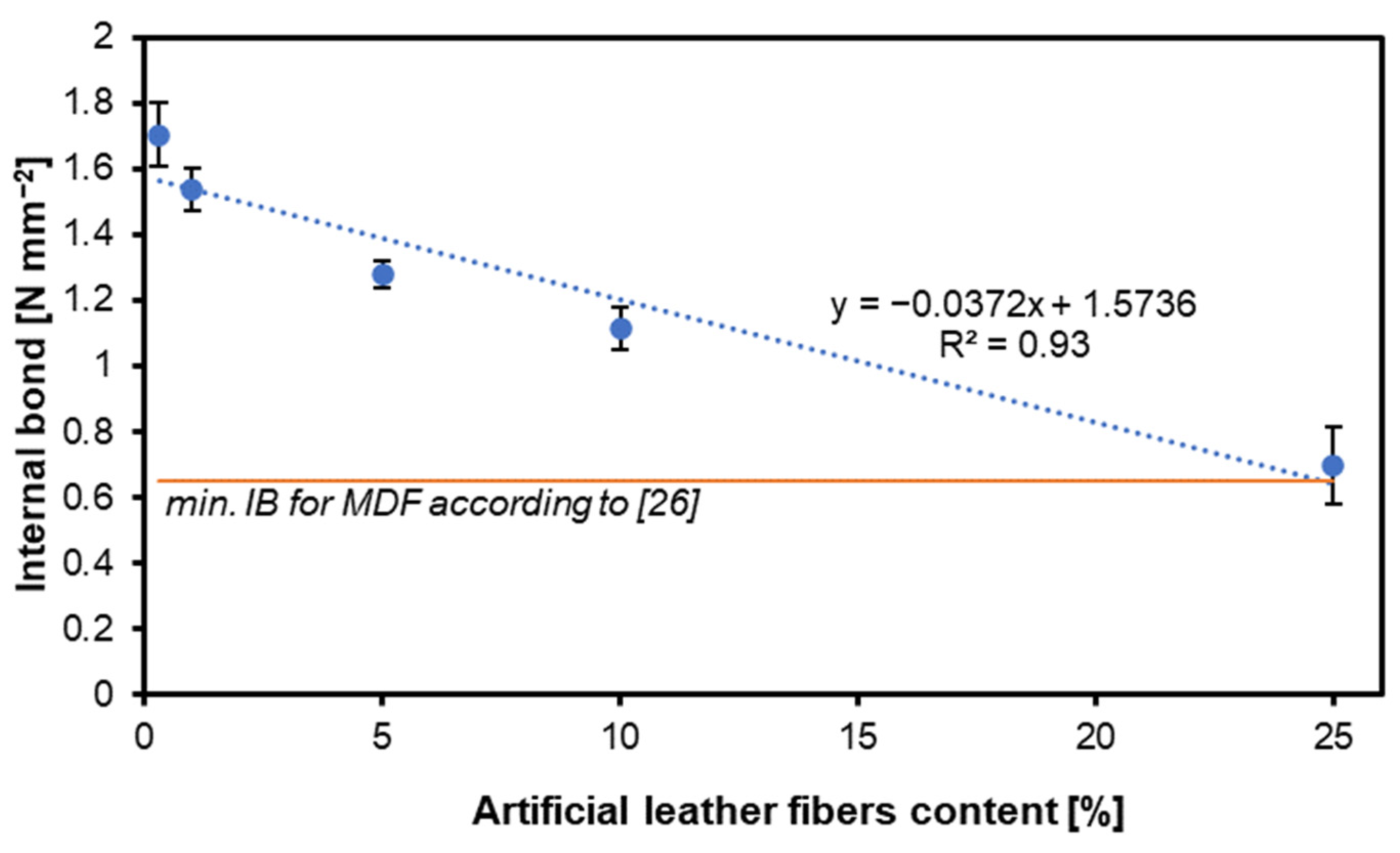

The results of the measurement of internal bonding and screw withdrawal resistance are presented in

Figure 4. For screw withdrawal resistance, the average values show a decreasing trend as the leather particle content increases. Upon analyzing the values, it is evident that the reference variant samples exhibited the highest resistance (162 N mm

−1). The sample with 25% artificial leather fiber content revealed a resistance of 92 N mm

−1, representing the lowest result in the test. A similar study was conducted by Bartoszuk and Kowaluk [

37], describing the effect of adding natural leather fibers on the production of HDF. Despite the comparable material used for the study, their results were surprisingly different. For example, screw withdrawal resistance showed an increasing trend with the addition of fibers. In their test, a sample with 10% added natural leather fibers achieved a result of 156 N mm

−1. In our test, a sample with the same fiber content achieved a result of 115 N mm

−1. Similar studies on HDF panels with the addition of upholstery fabrics have shown that the internal bond (IB) decreases as the amount of fibers increases. It was estimated that the maximum content of upholstery fabrics can be approximately 15.6% to meet the standard requirements for IB [

38].

Figure 5 shows the results of tensile strength perpendicular to the plane of the board. The graph shows that all samples have a lower tensile strength perpendicular to the surface than the reference sample. The highest internal bond strength is 1.70 N mm

−2, as shown in the reference sample. The sample with 25% artificial leather fibers as an additive revealed a tensile strength of 0.70 N mm

−2, representing the lowest internal bond strength test result. According to the requirements of EN 622-5 [

26], for MDF-type boards with a thickness of 2.5 mm to 4 mm, the minimum IB value is 0.65 N mm

−2. All tested samples achieved values in accordance with the European standard. Wood damage was observed in most of the samples examined. In the case of Kryńska and Kowaluk’s [

39] study about using soy starch as a binder in HDF technology, internal bond values decrease as the proportion of soy starch increases. This is similar to the relationship obtained in this study, but in the case of artificial leather fibers, all samples obtained results per European norms. Savov et al. [

40] described that replacing UF resin with PF resin resulted in an increase in IB strength values from 0.75 to 1.16 N mm

−2, i.e., the overall improvement of that property was by 1.56 times.

3.4. Thickness Swelling, Water Absorption, and Surface Water Absorption

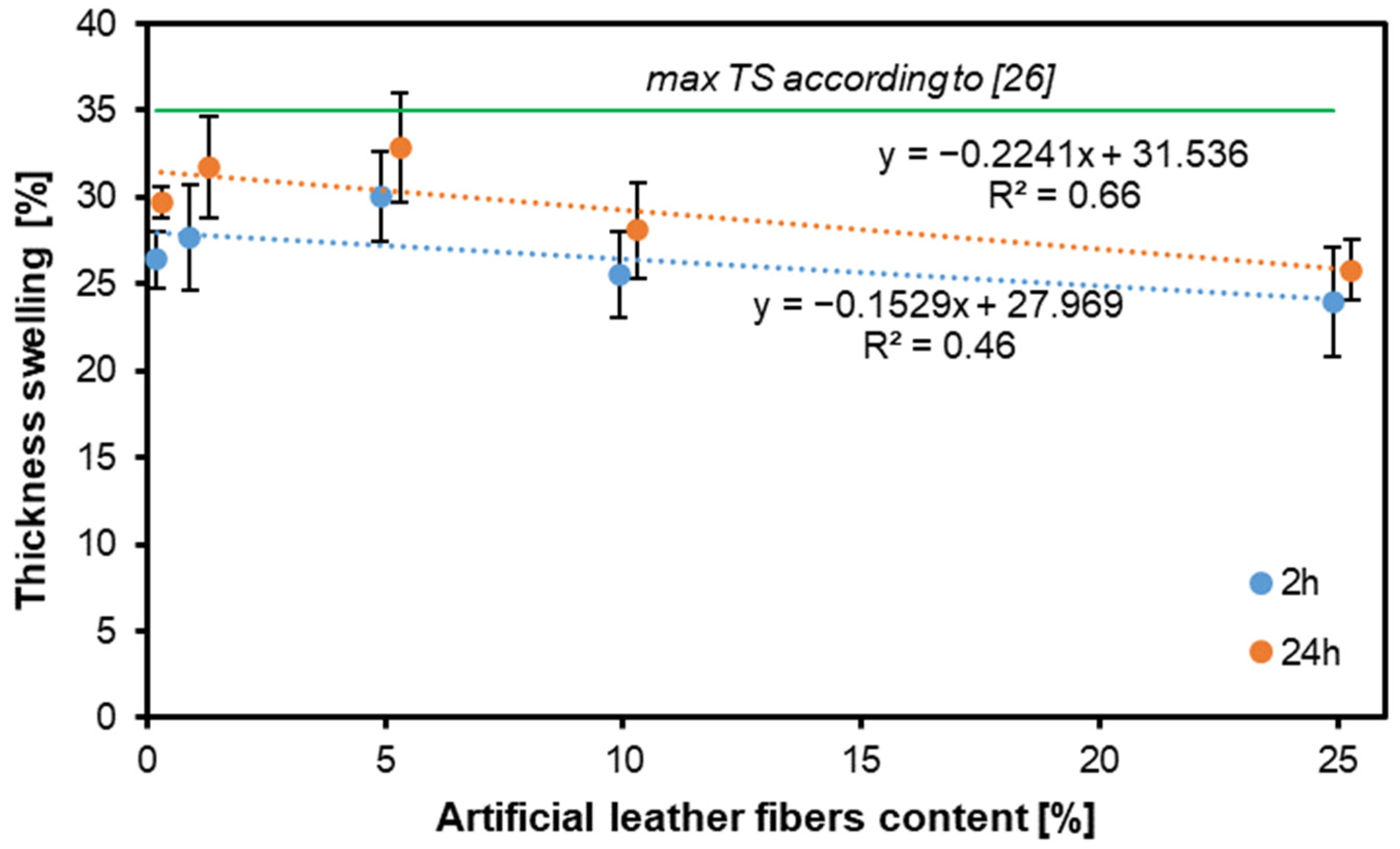

The graph shown in

Figure 6 displays the influence of artificial leather fibers on the thickness swelling. Samples soaked in water for 2 hours and 24 hours exhibit a gradual reduction in swelling with increased leather addition. The swelling decreases with higher artificial leather fiber content from the sample with 1% leather after two h 27.7% and after 24h 31.7% to sample with 25% leather after two h 24% and 24h 25.8%. The reference sample achieved 26.4% after two h soaking and 29.7% after 24h. In accordance with EN 622-5 [

26], MDF boards with a thickness ranging from 2.5 mm to 4 mm should have a maximum TS value of 35%. Research confirms that depending on the type of fiber, a given material may react differently to water [

38]. Polypropylene fibers, for example, are lightweight, dry (because of low water retention), and have high strength properties [

41]. On the other hand, natural materials are often more prone to water absorption [

42]. The hygroscopic nature of natural fibers has a negative impact on the mechanical properties of composites. Hence, it is vital to understand and control water absorption in these materials [

43]. All tested samples obtained results that were in accordance with European standards. In a study by Antov et al. [

44] aimed at reducing formaldehyde emissions, the addition of ammonium lignosulphonate (ALS) as an eco-friendly additive to urea-formaldehyde resin for manufacturing HDF panels had a positive effect on TS results. Values ranged from 33.4% to 23.3%, with only the reference sample failing to achieve a result compliant with EU regulations.

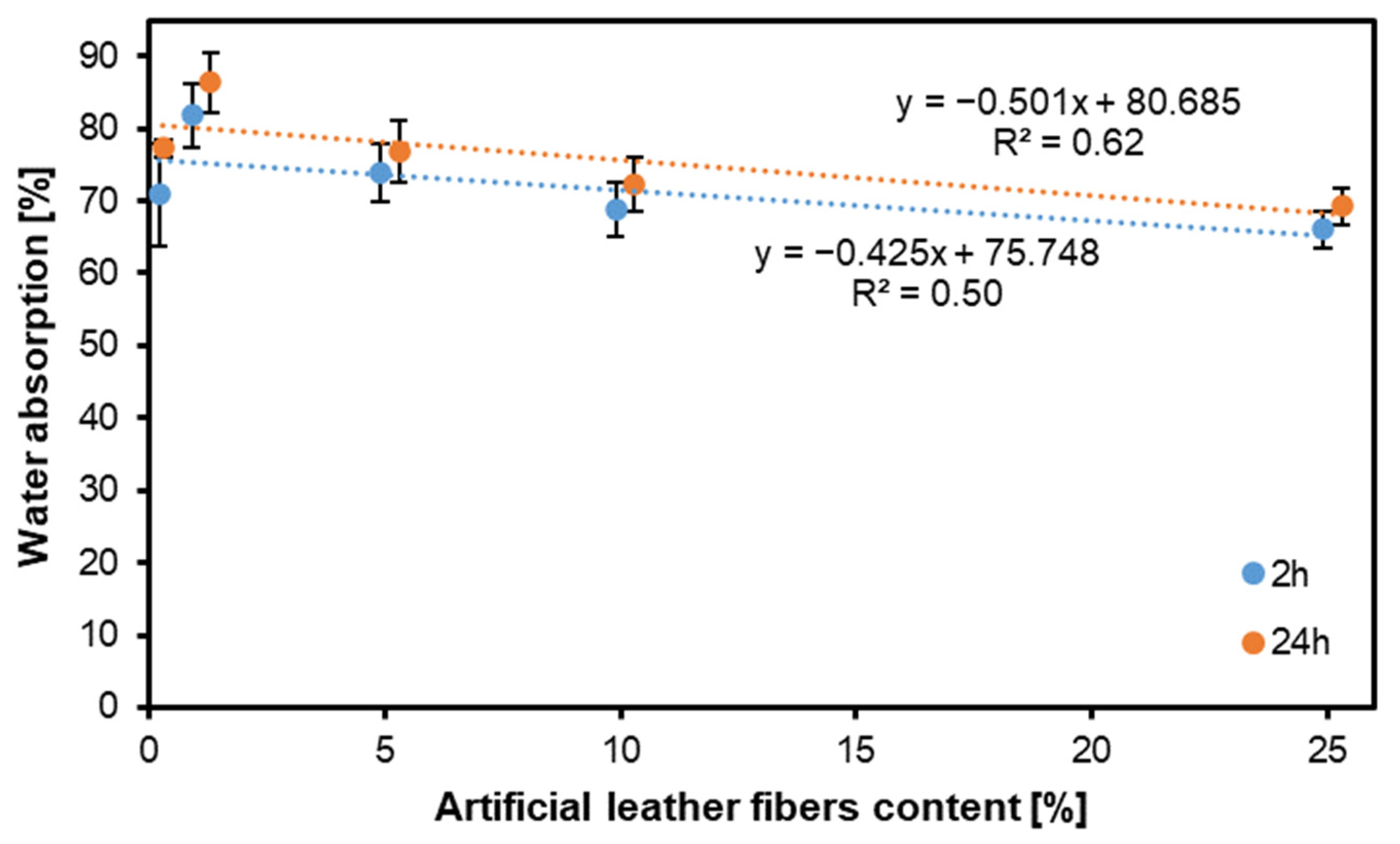

The results of the measurement of water absorption are displayed in

Figure 7. Similar to TS, absorption decreases with higher artificial leather fiber content. The sample obtained the highest result with 1% artificial leather fibers. After two hours, this sample achieved a score of 81.8%; after 24 hours, it gained 86.3%. The lowest result obtained in the test was 66% after two hours and 69.2% after 24 hours, soaking the sample with 25% leather. The reference sample scored 70.9% after two hours and 77.3% after 24 hours. A downward trend in thickness swelling and water absorption was obtained by Dasiewicz and Kowaluk [

45] in their study on the manufacture of HDF using rice starch as a binder. Similar to our study, their research found that the samples with the highest filler content had the lowest value (not including reference samples).

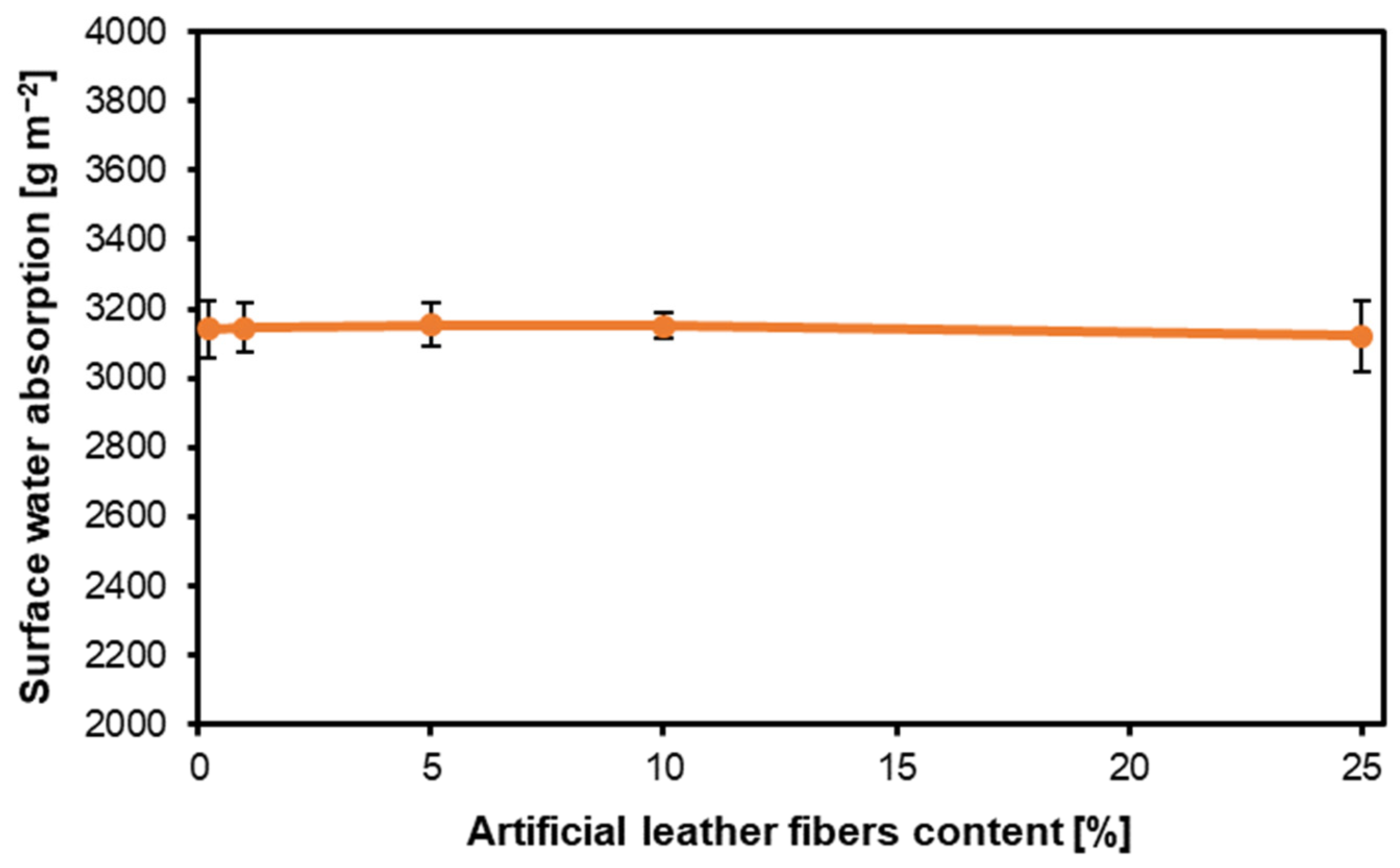

Figure 8 shows the results of surface water absorption for boards containing varying amounts of leather particles. As can be seen from the graph, the results for all samples tested are almost identical. Based on the results, it can be concluded that adding artificial leather fibers has no effect on water absorption on the surface. Averaging gives a result of 3142 g m

−2. This is also the result that the reference sample achieved. In their study, Gumowska and Kowaluk [

46] observed a decrease in SWA as the biopolymer binder content increased. In Rosa and Kowaluk’s [

47] study of MDF production using a plant binder, TS, WA, and SWA values decrease with increasing resination.

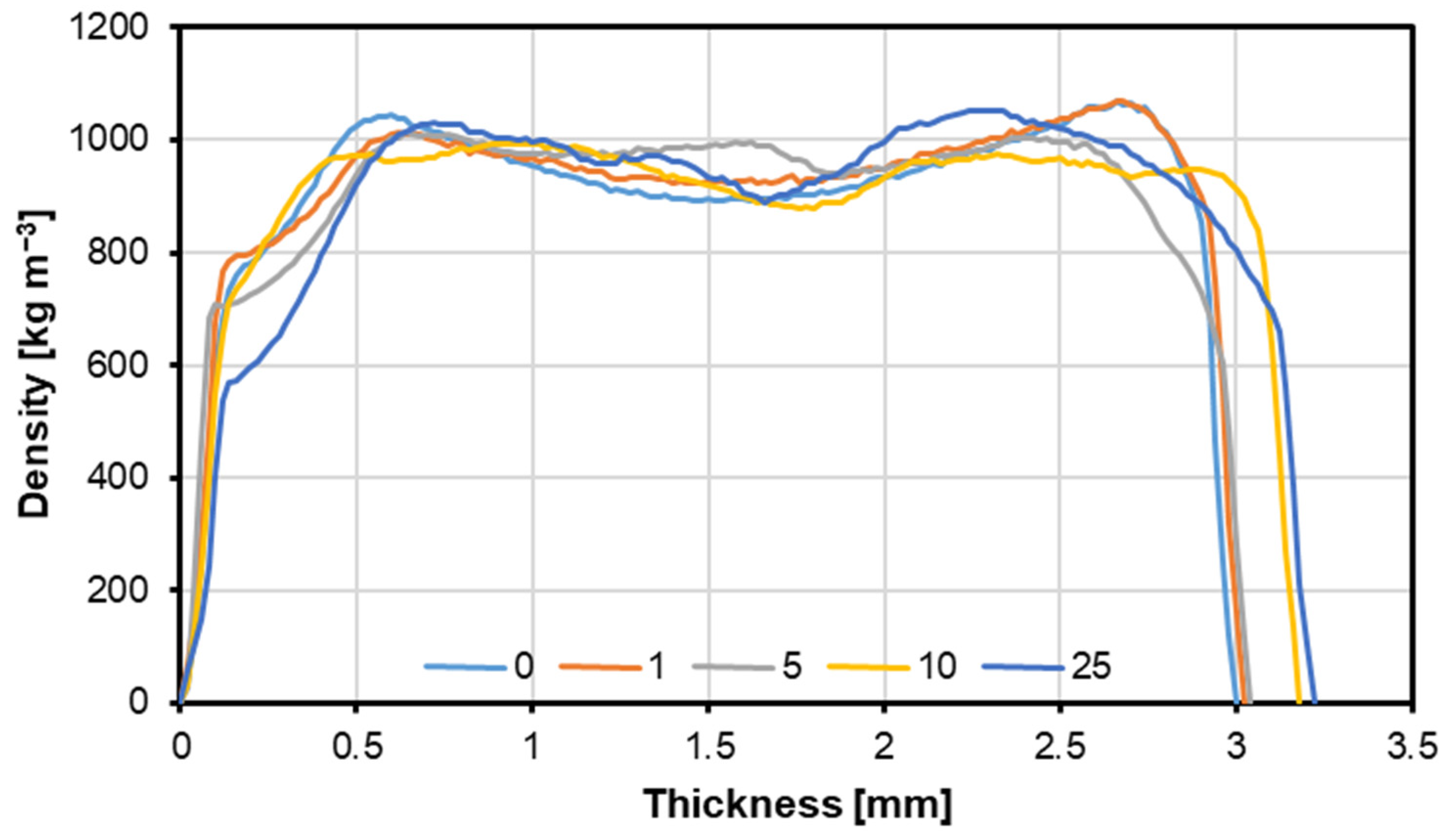

3.5. Density profile

The results of the density profile measurement are displayed in

Figure 9. The graph shows the results of one sample from each variant, as the analysis revealed that the values obtained across the series of tests were similar. All samples have a slightly higher density in the face layers than in the core layer. The most varied results were obtained for samples with 5% of the artificial leather fibers as an additive, as it has a slightly higher value in the middle layer. The sample obtained the lowest value in the inner layer with 10% of the artificial leather fibers as an additive (880 kg m

−3). In comparison, the sample obtained the highest value in this layer, with 5% of the artificial leather fibers as an additive (998 kg m

−3). As for the outer layers, the highest density was obtained by a sample with 1% of the artificial leather fibers as an additive (1070 kg m

−3). In a study by Badin et al. [

48], adding bark and increasing the percentage of hardwood fibers while reducing the rate of softwood in the production of HDF had a negative effect on density. The study by Henke et al. [

49] shows that density is not a determining factor for the surface roughness of HDF boards. The appearance of the attached density profile is influenced by the size of the fibers used, both wood and artificial leather fibers [

50]. The pressing temperature also affects the final appearance of the density profile [

51].

4. Conclusions

Based on the conducted research and the analysis of the results obtained, the following conclusions and remarks can be made:

As the addition of artificial leather fibers increases, the bending strength and modulus of elasticity decrease.

Of all the tested samples, the variant with 5% artificial leather fibers as an additive differed most from the others.

The average values for screw withdrawal resistance indicate a downward trend as the content of artificial leather fibers increases.

In the case of thickness swelling and water absorption, a profitable decreasing trend can be observed with an increase in synthetic leather fibers. Even without adding any hydrophobic agent, the panels meet the requirements of the European standard in the case of thickness swelling.

The bulk density of textile fibers is slightly lower than that of wood fibers.

The study results show that adding synthetic leather fibers to produce HDF boards does not show properties that would improve the boards’ mechanical and physical quality. Despite this, most tested samples achieved results aligned with European standards. It can be concluded that the maximum content of the artificial leather fibers content in HDF boards produced, as described in the paper, should be at most 10% w/w due to the modulus of elasticity limitation.

Author Contributions

Formal analysis, investigation, methodology, resources, validation, visualization, writing—original draft, writing—review & editing, M.W.; conceptualization, data curation, formal analysis, funding acquisition, investigation, methodology, project administration, supervision, validation, writing—original draft, writing—review & editing, G.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no funding.

Data Availability Statement

Acknowledgments

The presented study was completed within the activity of the Student Furniture Scientific Group (Koło Naukowe Meblarstwa), Faculty of Wood Technology, Warsaw University of Life Sciences - SGGW, Warsaw, Poland. The authors kindly thank Mr. Janusz Bartoszuk from BHM Sp. z o.o. Dorohuska St. 32, Srebrzyszcze, 22-100 Chełm, Poland (

https://www.bhm-ui.com/en), for common care of upholstery textile waste valorization and providing some testing materials. The authors kindly thank M.Sc. eng. Anita Wronka, Institute of Wood Sciences and Furniture, Warsaw University of Life Sciences - SGGW, Warsaw, Poland, for technical support in manuscript preparation.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Neitzel, N.; Hosseinpourpia, R.; Walther, T.; Adamopoulos, S. Alternative Materials from Agro-Industry for Wood Panel Manufacturing—A Review. Materials (Basel). 2022, 15, 1–27. [Google Scholar] [CrossRef] [PubMed]

- Kilani, A.; Olubambi, A.; Ikotun, B.; Adeleke, O.; Adetayo, O. Structural Performance of Concrete Reinforced with Banana and Orange Peel Fibers—a Review. J. Sustain. Constr. Mater. Technol. 2022, 7, 339–357. [Google Scholar] [CrossRef]

- Borysiewicz, I.; Kowaluk, G. Selected Properties of MDF Boards Bonded with Various Fractions of Recycled HDPE Particles. Ann. WULS, For. Wood Technol. 2023, 123, 18–29. [Google Scholar] [CrossRef]

- Leal Filho, W.; Perry, P.; Heim, H.; Dinis, M.A.P.; Moda, H.; Ebhuoma, E.; Paço, A. An Overview of the Contribution of the Textiles Sector to Climate Change. Front. Environ. Sci. 2022, 10, 1–5. [Google Scholar] [CrossRef]

- Wagaw, T.; Babu, K.M. Textile Waste Recycling: A Need for a Stringent Paradigm Shift. AATCC J. Res. 2023, 10, 376–385. [Google Scholar] [CrossRef]

- Fan, W.; Wang, Y.; Liu, R.; Zou, J.; Yu, X.; Liu, Y.; Zhi, C.; Meng, J. Textile Production by Additive Manufacturing and Textile Waste Recycling: A Review. Environ. Chem. Lett. 2024, 22, 1929–1987. [Google Scholar] [CrossRef]

- Pensupa, N.; Leu, S.-Y.; Hu, Y.; Du, C.; Liu, H.; Jing, H.; Wang, H.; Lin, C.S.K. Recent Trends in Sustainable Textile Waste Recycling Methods: Current Situation and Future Prospects. Top. Curr. Chem. 2017, 375, 76. [Google Scholar] [CrossRef] [PubMed]

- Herold, P.I.; Prokop, D. Is Fast Fashion Finally out of Season? Rental Clothing Schemes as a Sustainable and Affordable Alternative to Fast Fashion. Geoforum 2023, 146, 103873. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Motamed, B.; Ramakrishna, S.; Naebe, M. Death by Waste: Fashion and Textile Circular Economy Case. Sci. Total Environ. 2020, 718. [Google Scholar] [CrossRef]

- Royer, S.J.; Wiggin, K.; Kogler, M.; Deheyn, D.D. Degradation of Synthetic and Wood-Based Cellulose Fabrics in the Marine Environment: Comparative Assessment of Field, Aquarium, and Bioreactor Experiments. Sci. Total Environ. 2021, 791, 148060. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, C.; Zhang, X.; Zeng, S. Research on Sustainable Furniture Design Based on Waste Textiles Recycling. Sustain. 2023, 15. [Google Scholar] [CrossRef]

- Bonifazi, G.; Gasbarrone, R.; Palmieri, R.; Serranti, S. End-of-Life Textile Recognition in a Circular Economy Perspective: A Methodological Approach Based on Near Infrared Spectroscopy. Sustain. 2022, 14. [Google Scholar] [CrossRef]

- EC Amending Directive 2008/98/EC on Waste. 2015, 0275, 1–5. [CrossRef]

- Wojnowska-Baryła, I.; Bernat, K.; Zaborowska, M.; Kulikowska, D. The Growing Problem of Textile Waste Generation—The Current State of Textile Waste Management. Energies 2024, 17. [Google Scholar] [CrossRef]

- Zach, J.; Bubenik, J.; Novak, V.; Trisko, P. Development of Acoustic Insulating Materials from Recycled Textile Fiber. IOP Conf. Ser. Mater. Sci. Eng. 2019, 583. [Google Scholar] [CrossRef]

- Król, P.; Borysiuk, P.; Mamiński, M. Comparison of Methodologies for Acid Buffering Capacity Determination-Empirical Verification of Models. Appl. Sci. 2019, 9, 2345. [Google Scholar] [CrossRef]

- TAPPI UM 23 Bulk Density of Wood Chips. Useful Method. 2015.

-

EN 310; Wood-Based Panels. Determination of Modulus of Elasticity in Bending and of Bending Strength. European Committee for Standardization: Brussels, Belgium, 1993.

-

EN 320; Particleboards and Fibreboards—Determination of Resistance to Axial Withdrawal of Screws. CEN, European Committee for Standardization: Brussels, Belgium, 2011.

-

EN 319; Particleboards and Fibreboards. Determination of Tensile Strength Perpendicular to the Plane of the Board. European Committee for Standardization: Brussels, Belgium, 1993.

-

EN 317; Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersionin Water. CEN, European Committee for Standardization: Brussels, Belgium, 1993.

-

EN 382-2 Fibreboards—Determination of Surface Absorption—Part 2: Test Method for Hardboards; CEN, European Committee for Standardization: Brussels, Belgium, 1993.

-

EN 323; Wood-Based Panels—Determination of Density. CEN, European Committee for Standardization: Brussels, Belgium, 1993.

- Sala, C.M.; Robles, E.; Kowaluk, G. Influence of the Addition of Spruce Fibers to Industrial-Type High-Density Fiberboards Produced with Recycled Fibers. Waste and Biomass Valorization 2021, 12, 4033–4042. [Google Scholar] [CrossRef]

- Savov, V.; Hristodorova, D. Properties of Hemp Shive Panels With Different Resin Content. Bull. Transilv. Univ. Brasov, Ser. II For. Wood Ind. Agric. Food Eng. 2023, 16, 191–204. [Google Scholar] [CrossRef]

-

EN 622-5; Fiberboards. Specifications. Requirements for Dry Process Boards (MDF). European Committee for Standardization: Brussels, Belgium, 2009.

- Antov, P.; Savov, V.; Krišt’ák, L.; Réh, R.; Mantanis, G.I. Eco-Friendly, High-Density Fiberboards Bonded with Urea-Formaldehyde and Ammonium Lignosulfonate. Polymers (Basel). 2021, 13, 1–13. [Google Scholar] [CrossRef]

- Nicewicz, D.; Monder, S. Influence of Filling Mixtures on the Properties of HDF Surface. Ann. WULS, For. Wood Technol. 2015, 7, 112–116. [Google Scholar] [CrossRef]

- Solt-Rindler, A.; Solt-Rindler, P.; Barbu, M.C. Comparison between HB and HDF Made from Waste Leather. For. Prod. J. 2015, 65, S39–S47. [Google Scholar]

- Pásztory, Z.; Halász, K.; Börcsök, Z.; Srivaro, S. Properties of High Density Fiberboard Mixed with Poplar Bark. Walailak J. Sci. Technol. 2020, 17, 1286–1293. [Google Scholar] [CrossRef]

- Ratanawilai, T.; Taneerat, K. Alternative Polymeric Matrices for Wood-Plastic Composites: Effects on Mechanical Properties and Resistance to Natural Weathering. Constr. Build. Mater. 2018, 172, 349–357. [Google Scholar] [CrossRef]

- Nemli, G.; Odabaş-Serin, Z.; Özdemir, F.; Ayrılmış, N. Potential Use of Textile Dust in the Middle Layer of Three-Layered Particleboards as an Eco-Friendly Solution. BioResources 2019, 14, 120–127. [Google Scholar] [CrossRef]

- Valles-Rosales, D.J.; Méndez-Gonzdlez, L.C.; Rodríguez-Picon, L.A.; del Valle-Carrasco, A.; Alodan, H.A. Wood Chile Peppers Stalks-Plastic Composite Production. Maderas Cienc. y Tecnol. 2016, 18, 179–190. [Google Scholar] [CrossRef]

- Marconi, M.; Barbanera, M.; Calabrò, G.; Baffo, I. Reuse of Leather Scraps for Insulation Panels: Technical and Environmental Feasibility Evaluation. In Proceedings of the Procedia CIRP; 2020; Vol. 90; pp. 55–60. [Google Scholar]

- Pu, H.; Shu, C.; Dai, R.; Chen, H.; Shan, Z. Mechanical, Thermal and Acoustical Characteristics of Composite Board Kneaded by Leather Fiber and Semi-Liquefied Bamboo. Constr. Build. Mater. 2022, 340, 127702. [Google Scholar] [CrossRef]

- Raj, M.; Fatima, S.; Tandon, N. Recycled Materials as a Potential Replacement to Synthetic Sound Absorbers: A Study on Denim Shoddy and Waste Jute Fibers. Appl. Acoust. 2020, 159, 107070. [Google Scholar] [CrossRef]

- Bartoszuk, K.; Kowaluk, G. The Influence of the Content of Recycled Natural Leather Residue Particles on the Properties of High-Density Fiberboards. Materials (Basel). 2023, 16. [Google Scholar] [CrossRef] [PubMed]

- Suchorab, B.; Wronka, A.; Kowaluk, G. Towards Circular Economy by Valorization of Waste Upholstery Textile Fibers in Fibrous Wood-Based Composites Production. Eur. J. Wood Wood Prod. 2023, 1–7. [Google Scholar] [CrossRef]

- Kryńska, K.; Kowaluk, G. Application of Soy Starch as a Binder in HDF Technology. Ann. WULS, For. Wood Technol. 2023, 123, 41–50. [Google Scholar] [CrossRef]

- Savov, V.; Antov, P.; Trichkov, N. Properties of High-Density Fiberboards Bonded with Urea- Formaldehyde and Phenol-Formaldehyde Resins. Polymers (Basel). 2021. [Google Scholar] [CrossRef]

- Mukhopadhyay, S. Natural and Synthetic Fibres for Composite Nonwovens; Woodhead Publishing Limited, 2014; Vol. 20; ISBN 9780857097705.

- Célino, A.; Gonçalves, O.; Jacquemin, F.; Fréour, S. Quantitative Assessment of Water Sorption in Natural Fibres Using Infrared Spectroscopy. Rev. des Compos. des Mater. Av. 2014, 24, 81–95. [Google Scholar] [CrossRef]

- Ramesh Kumar, S.C.; Kaviti, R.V.P.; Mahesh, L.; Mohan Babu, B.M. Water Absorption Behavior of Hybrid Natural Fiber Reinforced Composites. Mater. Today Proc. 2022, 54, 187–190. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, Ľ.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea–Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers (Basel). 2021, 13. [Google Scholar] [CrossRef] [PubMed]

- Dasiewicz, J.; Kowaluk, G. Characteristics of High-Density Fibreboard Produced with the Use of Rice Starch as a Binder. Ann. Warsaw Univ. Life Sci. SGGW For. Wood Technol. 2023, 181, 169–181. [Google Scholar] [CrossRef]

- Gumowska, A.; Kowaluk, G. Physical and Mechanical Properties of High-Density Fiberboard Bonded with Bio-Based Adhesives. Forests 2023, 14. [Google Scholar] [CrossRef]

- Rosa, P.; Kowaluk, G. Selected Features of Medium Density Fiberboards Produced with the Use of Plant Binder. Ann. WULS, For. Wood Technol. 2022, 120, 27–36. [Google Scholar] [CrossRef]

- Badin, N.; Campean, M.; Lengyel, K.; Ispas, M.; Bedelean, B. Property Improvement of Thin High-Density Fiberboard Panels Used as Door-Skins. BioResources 2018, 13, 1042–1054. [Google Scholar] [CrossRef]

- Henke, M.; Lis, B.; Krystofiak, T. Evaluation of Surface Roughness Parameters of HDF for Finishing under Industrial Conditions. Materials (Basel). 2022, 15. [Google Scholar] [CrossRef]

- Siddikur Rahman, K.; Islam, M.N.; Ratul, S.B.; Dana, N.H.; Musa, S.M.; Hannan, M.O. Properties of Flat-Pressed Wood Plastic Composites as a Function of Particle Size and Mixing Ratio. J. Wood Sci. 2018, 64, 279–286. [Google Scholar] [CrossRef]

- Lee, S.H.; Lum, W.C.; Zaidon, A.; Fatin-Ruzanna, J.; Tan, L.P.; Mariusz, M.; Chin, K.L. Effect of Post-Thermal Treatment on the Density Profile of Rubberwood Particleboard and Its Relation to Mechanical Properties. J. Trop. For. Sci. 2017, 29, 93–104. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).