1. Introduction

Livestock production and meat consumption are growing rapidly, especially in low and middle-income countries [

1,

2]. Red meat from ruminants (e.g., cattle, sheep, goats) accounts for more than 50% of average global meat consumption, equating to 100 g per capita per day [

2]. Animal by-products (ABP) generated at the European Union (EU) level are estimated at 20 million tons per year, consisting 70% low-risk and 30% high-risk material (European Food Safety Authority,

www.efsa.europa.eu). ABP classification and appropriate treatment technologies (rendering and incineration) are detailed in Regulation (EC) No 1069/2009 of the European Parliament and Commission Regulation (EC) No 142/2011. Currently, incineration is primarily conducted in centralized facilities. Consequently, the long-distance transportation of ABP often raises health (biosecurity) and environmental concerns [

3]. Decentralized and on-farm incineration facilities are also available, which enhance the efficiency of emergency responses during infectious disease outbreaks.

Incineration is recognized as a safe ABP treatment process capable of destroying infectious zoonotic and animal pathogens due to the implementation of high temperatures (>850

oC) [

3,

4]. Wastes can be rapidly disposed of, and the resultant residue is easily managed without attracting scavengers or insects [

5]. Other advantages include the reduction of waste volume and weight, as well as the recovery of materials (calcium, phosphorus) and energy [

6,

7,

8,

9]. In compliance with regulatory requirements, these facilities are equipped with afterburners to minimize gaseous emissions. Afterburners significantly decrease noxious compounds such as dioxins and furans [

3]. Cummins et al. [

10] showed that the concentrations of NO

2, CO, HCl and ground level SO

2 were significantly lower than the legislative thresholds when peat and meat and bone meal (MBM) were co-incinerated.

The ABP ashes generated during incineration may vary between 1 and 5% of the initial carcass weight [

3,

11]. In some cases, however, higher ash production percentages (up to 30% of ABP weight) have been reported [

12]. Factors affecting the quantity of ash generated during incineration include kiln technology, operating conditions, and the type of ABP treated [

3,

13]. Animal by-products, such as sludges, animal tissue waste, materials unsuitable for consumption or processing, feces, and manure, whether from primary production or from the preparation and processing of meat and other foods of animal origin, are considered non-hazardous as per European Commission Directive 2014/955/EU. However, ABP such as whole animals, mortalities, and wastes whose collection and disposal are subject to special requirements for infection prevention may be categorized as hazardous (see

Table 1). The ashes (such as bottom ash, fly ash, pyrolysis waste) generated by ABP incineration facilities may also be categorized as hazardous depending on the concentration of dangerous substances.

Most incineration facilities consider ash a by-product, and this material often ends up in landfills [

14]. However, ABP ash contains nutrients (e.g., calcium and phosphorus) that can be used as a soil improver or fertilizer, enabling further valorization within the context of the circular economy [

8,

15,

16,

17,

18]. The nutrients present, however, exhibit low bioavailability [

19]. Cohen [

20] tested phosphorus dissolution from incinerated animal carcasses using sulphuric acid, while Bujak [

7] designed a phosphorus fertilizer production process from bone ash.

Limited data is available in the literature regarding the capital (CAPEX) and operational expenses (OPEX) for ABP incineration facilities. Blake [

5] reported an OPEX of

$77.2 to incinerate 1 ton of poultry carcasses, based on a propane cost of

$0.16 per liter. A similar OPEX (74 € per ton) was provided by Zagklis et al. [

11], which considered natural gas, electricity consumption, maintenance, and labor. The costs of ABP incineration in Germany to control bovine spongiform encephalopathy were reported between 50 and 150 € per ton, although a detailed breakdown is missing [

21].

The aim of this study was to assess the performance and costs involved in a full-scale decentralized incineration facility treating animal carcasses and by-products. Field data were collected over a three-year period and evaluated for performance (burning rate, ash production, fuel and electricity consumption), and capital and operational expenses. Additionally, samples of bottom ash were obtained and characterized for the concentration of dangerous substances (heavy metals) and macronutrients, while their leaching behavior was studied as a function of pH. The results of the study were ultimately used to propose a circular incineration facility designed for maximum resource recovery.

2. Materials and Methods

2.1. Incinerator Design

The incinerator used in this study was a top-loaded system manufactured by Waste Spectrum Incineration Systems (UK). It had overall dimensions of 11.1 × 5.8 × 2.8 m (L × W × H), a chamber load capacity of 3,580 kg, and a nominal burning rate capacity of 1000 kg per hour. The incinerator was equipped with an integral secondary chamber (afterburner). The main chamber had a total volume of 10.9 m

3 (with a load volume of 6.5 m

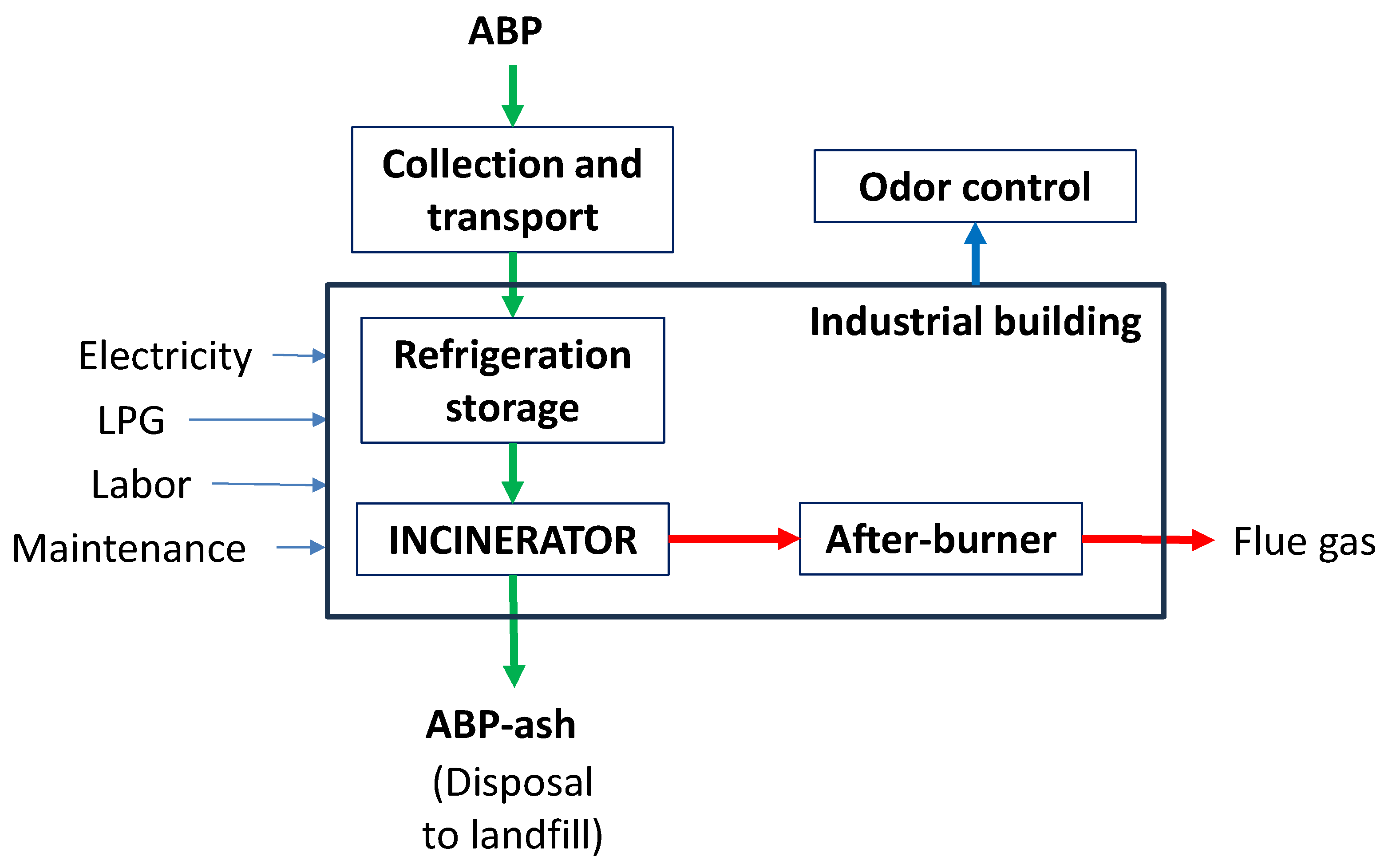

3) and was fitted with five burners (two above and three below). Two additional burners were installed in the secondary chamber. The system included a multiple-channel thermocouple data logger integrated with a programmable logic controller (PLC). The incineration plant (see

Figure 1) also featured refrigeration equipment for animal carcass storage (Bitzer Kuhlmaschinenbau Gmbh, 10 kW), propane gas tanks (two steel tanks with a total capacity of 50 m

3), carcass loading equipment (Manitou), and an industrial building (metal construction with a concrete base) equipped with odor control measures. The facility was located adjacent to a commercial slaughterhouse in northern Greece.

2.2. Incinerator Operation

The incinerator facility received approximately 600 tons of animal carcasses annual from nearby farms. During the study period, the majority of the incoming waste consisted of ruminants, with 74% being cattle and 20% sheep. Details on the composition of cattle and sheep carcasses, such as moisture content, elemental analysis, and calorific value, can be found in previous studies [

22,

23].

The incineration facility operated in fed-batch mode. During operation, the incinerator was loaded with ABP, and the burners were activated to increase the temperature inside the main chamber. Given that the main chamber had a capacity of 3 tons, a second batch was introduced after 3 hours. Ash removal occurred at the end of the process, requiring 6 to 12 hours for cooling and an additional 4 hours for removal and storage.

During the study period, the incinerator was operated 77 times with the following total durations: 24 and 36 hours (33 instances), 36 to 48 hours (12 instances), 48 to 60 hours (17 instances), 60 to 72 hours (6 instances), 72 to 84 hours (6 instances), and 84 to 96 hours (3 instances). During operation, the temperature inside the main chamber was maintained at 850 oC, while the afterburner operated at 1,100 oC. The fuel used for incinerator operation was liquefied petroleum gas (LPG), and an LPG flow meter (Samtech) was installed between the tanks and the incinerator to monitor fuel consumption. Electricity consumption was due to the continuous operation of the fan (2 kW) and the refrigerators (10 kW) used for ABP storage. Maintenance costs for the incinerator ranged between 10 and 20 € per working hour and included grate replacement, cover and insulation refurbishment, and burner maintenance. The plant required two full-time workers and a supervisor for its operation.

2.3. ABP Ash Leaching and Characterization

ABP-ash leaching was conducted following the European Standard CEN/TS 14429, using batch reactors with a 0.6 L working volume, stirred at 190 rpm for 24 h. The tests were performed at room temperature (22±2

oC), with a liquid-to-solid ratio (L/S) of 10, under various pH conditions (3, 7, and 12). Three replicate samples were treated at pH 3, four at pH 7 and six at pH 12. At the end of the leaching process, liquid samples were filtered (0.45 μm) and analyzed chemically. The total content of macronutrients and trace elements in the ABP ash was determined after acid digestion according to EPA Method 3050Β. Concentrations of calcium (Ca), sodium (Na), potassium (K), magnesium (Mg), aluminum (Al), zinc (Zn), iron (Fe), manganese (Mn), copper (Cu), lead (Pb), chromium (Cr), nickel (Ni) and cadmium (Cd) were measured using atomic absorption spectroscopy (AAS) with a Varian 220 S. pH, total phosphorus (TP), total kjeldahl nitrogen (TKN), and ammonia nitrogen (NH

4-N) were measured according to standard methods for the examination of water and wastewater [

24] (Clesceri et al. 1998).

3. Results and Discussion

3.1. Incinerator Operating Conditions

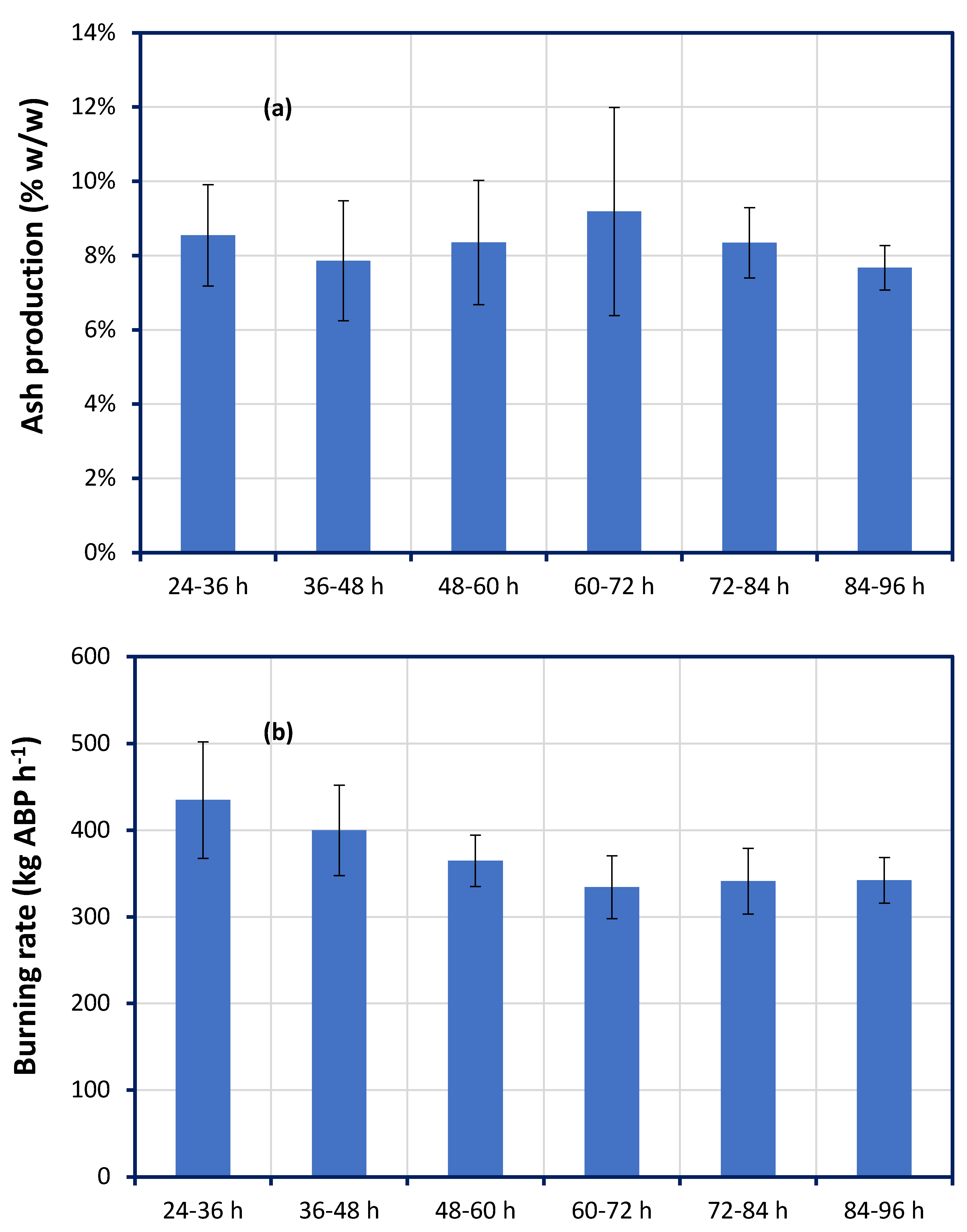

The burning rate of the examined incineration facility ranged between 300 and 500 kg of ABP per hour (

Figure 2a). This rate includes the processes of loading, cooling, and ash removal. When the incinerator processes more than 20 tn of ABP (equivalent to over 60 h of operation), the burning rate stabilized at 360 kg per hour. In contrast, for ABP quantities around 12 tons (data not shown), the burning rate increased to 900 kg per hour, approaching the plant’s nominal capacity of 1000 kg per hour. The amount of ash generated was not influenced by the quantity of ABP incinerated and consistently ranged between 7 and 10% (w/w) of the incoming ABP (see

Figure 2b).

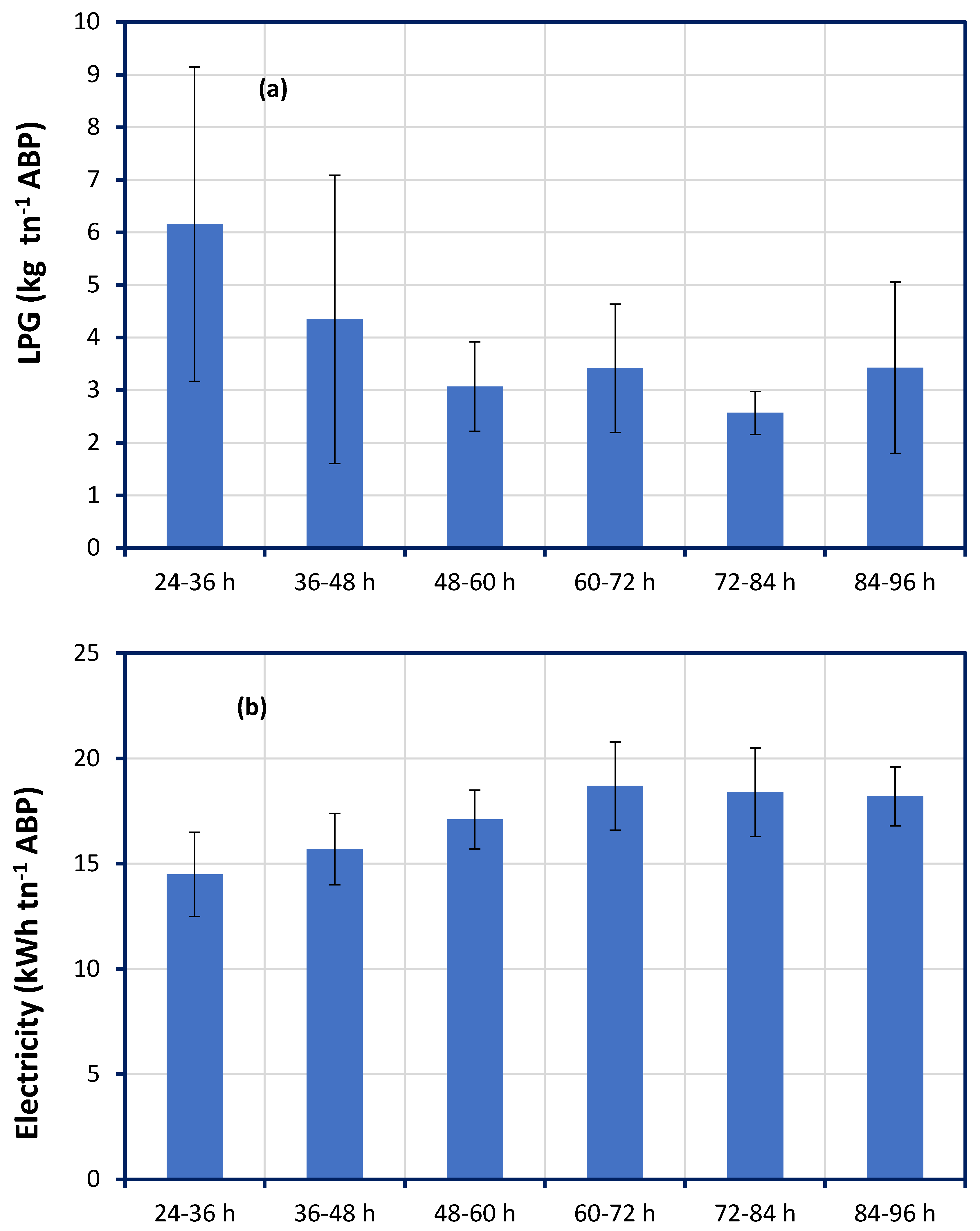

Figure 3 illustrates the quantity of LPG and electricity consumed per ton of ABP incinerated over different operating periods. LPG consumption was significantly higher during short incineration cycles (between 24 and 36 hours). As the quantity of ABP processed increased, LPG consumption stabilized at approximately 3 kg per ton of ABP. The LPG consumption during animal carcass incineration was relatively low compared to values reported by Zagklis et al. [

11], which indicated 1,135 kWh-th per ton of ABP, equivalent to 110 m

3 of natural gas per ton of ABP. However, the data from Zagklis et al. [

11] were theoretical, based on the nominal capacity of the burners and did not account for the calorific value of ABP. Since the calorific value of ABP ranges from 13 to 30 MJ kg

−1, the actual fuel consumption can be significantly lower [

8,

12]. Electricity consumption increased with incineration time, reaching 18 kWh per ton of ABP for incineration durations exceeding 60 hours (

Figure 3). The higher electricity consumption compared to the study of Zagklis et al. [

11] (which reported 6 kWh per ton of ABP) was attributed to the energy required for ABP storage (refrigeration).

Table 2 shows the chemical composition of the ABP ash generated by the incineration facility studied. The data reveal that calcium is the predominant component (30% by weight), followed by phosphorus (15% by weight), sodium (3% by weight), and potassium (2% by weight). The concentrations of trace elements in the ABP ash were low, consistent with results from previous studies (see

Table 3). According to the data presented in

Table 3, the concentrations of calcium and phosphorus in the ABP ash were consistently 300±53 and 152±30 g kg

−1, respectively. According to Leng et al. [

15] and Staron et al. [

13] the phosphorus in meat and bone meal (MBM) ash is primarily in the form of hydroxyapatite, which results in low phosphorus leachability and bioavailability.

Leaching ABP ash with a liquid-to-solid ratio (L/S) of 10 resulted in a highly alkaline supernatant with a pH of 11.6±0.1. Under these conditions, the solubilization of calcium and magnesium remained low (see

Table 2). In contrast, leaching under acidic conditions (pH = 3) led to significant solubilization of both macronutrients and trace elements. Maximum leachability was observed for sodium (91.0%), potassium (79.7%), magnesium (64.4%), phosphorus (11.5%) and calcium (8.8%). These findings are consistent with the study from Leng et al. [

15], which reported that the leachability of inorganic compounds in MBM ash is pH-depended, with substantial increases at pH levels below 6. In our study, sodium and potassium exhibited high leachability (45 and 65%, respectively) under both neutral and alkaline pH conditions. Ammonia and total Kjeldahl nitrogen (TKN) concentrations in the leachates remained low (28±9 mg kg

−1), regardless of the pH conditions applied. Based on the results from the leaching tests (

Table 2), the ABP ash was classified as non-hazardous and can be disposed of in sanitary landfills according to the European Commission Directive 2000/945/EC.

3.2. Techno-Economic Assessment

The capital expenses (CAPEX) of the examined facility totaled 385,000 €. This included the costs of the incinerator (200,000 €), the industrial building and concrete structures (60,000 €), refrigerators (40,000 €), LPG tanks and accesories (15,000 €), lifting equipment (30,000 €) and engineering/supervision/licencing expenditures (40,000 €). Assuming a lifespan of 15 years and an interest rate of 6%, the annual equivalent CAPEX was calculated to be 40,000 € per year using the following equation:

where, R = annual equivalent cost (€), P = present value or worth (€), I = interest rate (%) and n = number of years

Given the quantity of ABP processed at the examined decentralized facility (600 tons per year), the specific CAPEX was calculated to be 67 € per ton of ABP. According to the data provided by the facility operator, maintenance costs were 15 € per working hour, and labor costs were 10 € per working hour. Transportation expenses for ABP from nearby farms were 15 € per ton [

26]. Costs for electricity and LPG consumption were calculated at 0.16 € per kWh and 1.3 € per kg of LPG, based on current market prices.

Table 4 summarizes the capital and operational expenses of the examined incineration facility. The total cost per ton of ABP incinerated was 159 € tn

−1.

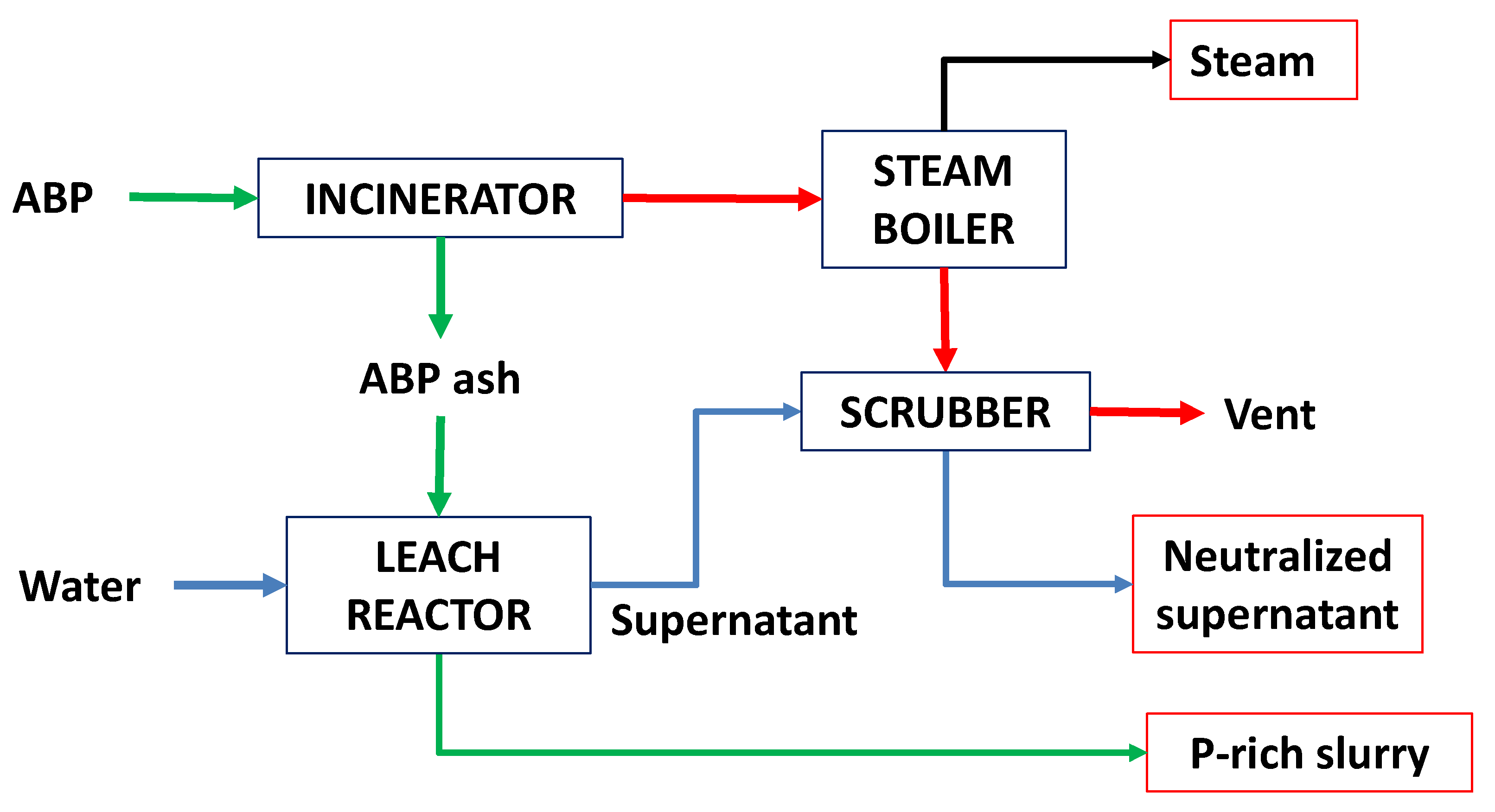

3.3. Perspectives for a Circular Incineration Facility

Figure 4 illustrates a proposed circular incineration process designed for maximum resource recovery. As depicted, ABP is received by the incineration facility and incinerated in the kiln. The incinerator is equipped with an afterburner where flue gases are thermally destroyed at high temperatures (900-1100

oC). The resulting ABP ash is then mixed with water in a mixing tank. Under the alkaline conditions in the mixing tank, phosphorus solubilization remains low (<3%) (see

Table 3), while sodium and potassium are separated from the solid fraction. The alkaline supernatant from the mixing tank can be used to scrub the incinerator flue gas [

27]. This process allows for the capture of CO

2 from the flue gas and the neutralization the supernatant [

28,

29].

The remaining slurry from the mixing tank, which is rich in calcium and phosphorus, can be further used for phosphorus recovery using state-of-the-art techniques. For example, Sharrock et al. [

12] employed sulfuric, phosphoric or nitric acid to solubilize bone residues into various phosphorus forms suitable for fertilization. Bujak [

7] produced monocalcium phosphate by adding phosphoric acid to bone ash. Cohen [

20] applied a pH range of 1.5-2.0 to maximize phosphorus dissolution from animal carcass ash, similar to the study from Leng et al. [

15] that solubilized 100 g of phosphorus per kg of MBM ash under low pH conditions (< 2.7).

Finally, the overall costs of the proposed facility could be significantly reduced if the production and utilization of saturated steam in a recovery boiler is incorporated [

30], or if electricity is generated using the saturated steam via a steam turbine [

9]. According to Bujak [

7], it is possible to recover up to 1,070 kWh of thermal energy per ton of ABP, which is equivalent to 100 m

3 of natural gas per ton of ABP. This substantial value highlights that energy recovery and valorization, such as for industrial processes, can help minimize costs and reduce greenhouse gas emissions by replacing fossil fuels [

7].

4. Conclusions

The incineration facility examined in the study was capable to process 600 tons of ABP annually, with a variable burning rate that stabilizes at 360 kg pr hour for larger quantities. The specific CAPEX was found to be 67 € per ton of ABP, while the annual OPEX equal to 92 € per ton of ABP. Major operational costs, included maintenance, labour and ABP transportation.

The ABP ash generated has a high calcium content and low concentrations of trace elements, making it a valuable resource. Leaching tests indicated that phosphorus solubilization is minimal under alkaline conditions but substantial under acidic conditions. This suggests potential for phosphorus recovery and valorisation in agricultural applications.

Incorporating energy recovery and resource valorisation techniques can minimize greenhouse gas emissions by reducing reliance on fossil fuels. This approach supports environmental sustainability and enhances the overall efficiency of the incineration process.

Author Contributions

Conceptualization, V.D.; methodology, P.C., E.V.; investigation, P.C., A.E.; data curation, V.D., E.V.; writing—original draft preparation, V.D.; writing—review and editing, E.V., P.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data included in this study are available to researchers upon request.

Acknowledgments

We acknowledge Ioannis Papaspyros for the assistance with the laboratory work.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Godfray, H.C.J.; Aveyard, P.; Garnett, T.; Hall, J.H.; Key, T.J.; Lorimer, J.; Pierrehumbert, R.T.; Scarborough, P.; Springmann, M.; Jebb, S.A. Meat consumption, health, and the environment. Science 2018, 361, eaam5324. [Google Scholar] [CrossRef] [PubMed]

- McMichael, A.J.; Powles, J.W.; Butler, C.D.; Uauy, R. Food, livestock production, energy, climate change, and health. Lancet 2007, 370, 1253–1263. [Google Scholar] [CrossRef] [PubMed]

- Gwyther, C.L.; Williams, A.P.; Golyshin, P.N.; Edward-Jones, G.; Jones, D.L. The environmental and biosecurity characteristics of livestock carcass disposal methods: a review. Waste Manage 2011, 31, 767–778. [Google Scholar] [CrossRef] [PubMed]

- Chowdhury, S.; Kim, G.H.; Bolan, N.; Longhurst, P. A critical review on risk evaluation and hazardous management in carcass burial. Process Saf Environ 2019, 123, 272–288. [Google Scholar] [CrossRef]

- Blake, J.P. Methods and technologies for handling mortality losses. World Poultry Sci J 2004, 60, 489–499. [Google Scholar] [CrossRef]

- Kowalski, Z.; Kulczycka, J.; Makara, A.; Harazin, P. Quantification of material recovery from meat waste incineration—an approach to an updated food waste hierarchy. J Hazard Mater 2021, 416, 126021. [Google Scholar] [CrossRef] [PubMed]

- Bujak, J.W. New insights into waste management—meat industry. Renew Energ 2015, 83, 1174–1186. [Google Scholar] [CrossRef]

- Cascarosa, E.; Gea, G.; Arauzo, J. Thermochemical processing of meat and bone meal: a review. Renew Sust Energ Rev 2012, 16, 942–957. [Google Scholar] [CrossRef]

- Paulides, J.J.H.; Post, E.; Post, J.; Encica, L.; Lomonova, E.A. Green turbine: a high speed double turbine solution for sustainable energy harvesting from waste heat. In: 10th International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 2015, pp. 1–7. [CrossRef]

- Cummins, E.J.; McDonnell, K.P.; Ward, S.M. Dispersion modelling and measurement of emissions from the co-combustion of meat and bone meal with peat in a fluidized bed. Bioresource Technol 2006, 97, 903–913. [Google Scholar] [CrossRef]

- Zagklis, D.; Konstantinidou, E.; Zafiri, C.; Kornaros, M. Assessing the economic viability of an animal byproduct rendering plant: case study of a slaughterhouse in Greece. Sustainability 2020, 12, 5870. [Google Scholar] [CrossRef]

- Sharrock, P.; Fiallo, M.; Nzihou, A.; Chkir, M. Hazardous animal waste carcasses transformation into slow release fertilizers. J Hazard Mater 2009, 167, 119–123. [Google Scholar] [CrossRef] [PubMed]

- Staron, P.; Kowalski, Z.; Staron, A.; Seidlerova, J.; Banach, M. Residues from the thermal conversion of waste from the meat industry as a source of valuable macro- and micronutrients. Waste Manage 2016, 49, 337–345. [Google Scholar] [CrossRef] [PubMed]

- Valta, K.; Damala, P.; Orli, E.; Papadaskalopoulou, C.; Moustakas, K.; Malamis, D.; Loizidou, M. Valorisation opportunities related to wastewater and animal by-products exploitation by the Greek slaughterhouse industry: current status and future potentials. Waste Biomass Valori 2015, 6, 927–945. [Google Scholar] [CrossRef]

- Leng, L.; Bogush, A.A.; Roy, A.; Stegemann, J.A. Characterisation of ashes from waste biomass power plants and phosphorus recovery. Sci Total Environ 690, 573–583. [CrossRef]

- Darwish, M.; Aris, A.; Puteh, M.H.; Jusoh, M.N.H.; Kadir, A.A. Waste bones ash as an alternative source of P for struvite precipitation. J Environ Manage 2017, 203, 861–866. [Google Scholar] [CrossRef]

- Eftaxias, A.; Diamantis, A.; Aivasidis, A. Anaerobic digestion of thermal pre-treated emulsified slaughterhouse wastes (TESW): effect of trace element limitation on process efficiency and sludge metabolic properties. Waste Manage 2018, 76, 357–363. [Google Scholar] [CrossRef]

- Diamantis, V.; Eftaxias, A.; Stamatelatou, K.; Noutsopoulos, C.; Vlachokostas, C.; Aivasidis, A. Bioenergy in the era of circular economy: anaerobic digestion technological solutions to produce biogas from lipid-rich wastes. Renew Energ 2021, 168, 438–447. [Google Scholar] [CrossRef]

- Leng, L.; Zhang, J.; Xu, S.; Xiong, Q.; Xu, X.; Li, J.; Huang, H. Meat & bone meal (MBM) incineration ash for phosphate removal from wastewater and afterward phosphorus recovery. J Clean Prod 238, 117960. [CrossRef]

- Cohen, Y. Phosphorus dissolution from ash of incinerated sewage sludge and animal carcasses using sulphuric acid. Environ Technol 2009, 30, 1215–1226. [Google Scholar] [CrossRef] [PubMed]

- Probst, C.; Gethmann, L.M.; Heuser, R.; Niemann, H.; Conraths, F.J. Direct costs of bovine spongiform encephalopathy control measures in Germany. Zoonoses Public Hlth 2013, 60, 577–595. [Google Scholar] [CrossRef] [PubMed]

- Lambe, N.R.; Ross, D.W.; Navajas, E.A.; Hyslop, J.J.; Prieto, N.; Craigie, C.; Bunger, L.; Simm, G.; Roehe, R. The prediction of carcass composition and tissue distribution in beef cattle using ultrasound scanning at the start and/or end of the finishing period. Livest Sci 2010, 131, 193–202. [Google Scholar] [CrossRef]

- Sen, A.R.; Santra, A.; Karim, S.A. Carcass yield, composition and meat quality attributes of sheep and goat under semiarid conditions. Meat Sci 2004, 66, 757–763. [Google Scholar] [CrossRef] [PubMed]

- Clesceri, L.S.; Greenberg, A.E.; Eaton, A.D. Standard methods for the examination of water and wastewater. 20th Edition, American Public Health Association (APHA), Washington DC, USA, 1998.

- Deydier, E.; Guilet, R.; Sarda, S.; Sharrock, P. Physical and chemical characterization of crude meat and bone meal combustion residues: “waste or raw material?”. J Hazard Mater 2005, B121, 141–148. [Google Scholar] [CrossRef]

- Diamantis, V.; Erguder, T.H.; Aivasidis, A.; Verstaete, W.; Voudrias, E.A. Wastewater disposal to landfill-sites: a synergistic solution for centralized management of olive mill wastewater and enhanced production of landfill gas. J Environ Manage 2013, 128, 427–434. [Google Scholar] [CrossRef] [PubMed]

- Srivastava, R.K.; Jozewicz, W. Flue gas desulfurization: the state of the art. J Air Waste Manage 2001, 51, 1676–1688. [Google Scholar] [CrossRef] [PubMed]

- Psarras, S.; Pegkos, D.; Dimoka, P.; Eftaxias, A.; Charitidis, P.; Diamantis, V.; Kostopoulos, V. Performance, material degradation and durability of a biogas chemical scrubber operated under alkaline conditions. J Eng Sci Technol Rev 2022, 15, 117–122. [Google Scholar] [CrossRef]

- Yincheng, G.; Zhenqi, N.; Wenyi, L. Comparison of removal efficiencies of carbon dioxide between aqueous ammonia and NaOH solution in a fine spray column. Enrgy Proced 2011, 4, 512–518. [Google Scholar] [CrossRef]

- Bujak, J.; Sitarz, P. Incineration of animal by-products—The impact of selected parameters on the flux of flue gas enthalpy. Waste Manage 2016, 50, 309–323. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).