1. Introduction

Lost foam casting, recognized as a prominent casting process of the 21st century, has a history spanning over thirty years. This technology is widely applicable, capable of producing castings with precise dimensions and smooth surfaces, facilitating mechanization of the production process, and reducing production costs [

1,

2,

3]. It offers significant design flexibility, thereby enhancing production efficiency and enabling clean production to achieve environmentally friendly casting [

4,

5]. Currently, many domestic companies have adopted advanced processes and equipment to meet the requirements for producing castings of various materials. Lost foam casting, also known as evaporative pattern casting, involves the use of a foam pattern that evaporates when in contact with molten metal, leaving behind a precisely shaped casting [

6,

7,

8,

9,

10]. The process eliminates the need for traditional cores and parting lines, which can reduce defects and improve the overall quality of the castings. This method is particularly beneficial for producing complex geometries that would be challenging to achieve with conventional casting techniques.

In the lost foam casting process, the coating is a crucial technology. Reviewing the development of this process reveals the increasingly prominent role of lost foam casting coatings. In recent years, numerous scholars have identified lost foam casting coatings as one of the three main research focuses for the further development and application of this technology [

11,

12,

13,

14,

15,

16]. Additionally, scholars have emphasized the importance of coatings in process control. The functions of lost foam coatings include supporting and protecting the foam model, preventing liquid metal from infiltrating the sand and adhering to the sand, absorbing decomposition products, and allowing decomposition gases to pass through the coating [

17,

18]. When the foam mold breaks, it helps maintain the integrity of the cavity's air while preventing the rapid loss of heat from the liquid metal. Therefore, lost foam coatings must have sufficient refractoriness, appropriate mechanical strength, suitable thermal insulation and conductivity, appropriate permeability and absorption capacity for liquid decomposition products, a smooth surface, adequate brushing performance, and must not chemically react with the foam model [

19,

20,

21]. These properties are essential to ensure that the coating performs its protective and supportive roles effectively during the casting process. Advances in materials science have facilitated the development of coatings with enhanced properties, enabling better performance and wider application of lost foam casting.

In recent years, casting technology has developed rapidly, leading to further improvements in coating performance, expanded coating functionalities, and an increase in coating varieties. Correct selection and reasonable use of coatings are crucial for producing high-quality casting products. Due to the complexity of coating compositions and their critical role in the casting process, the selection of coatings and the success of the EPC (Expendable Pattern Casting) process are vital, necessitating ongoing performance analysis and measurement of the coatings, particularly their viscosity, coating weight, and surface morphology. These parameters significantly impact the final quality of the castings and the efficiency of the production process [

22,

23]. Undoubtedly, coatings are key to obtaining high-quality castings. Research and production have proven that improving coating performance significantly increases the probability of successful castings in the lost foam casting process [

24,

25,

26]. The mixing of coating powders and liquid carriers is the primary process for most coatings. To ensure the effectiveness of the coating, the performance of the mixed coating must be uniform and thoroughly mixed. Thus, the mixing process parameters, such as mixing time, blade shape, and mixing speed, are crucial for coating performance, with the shape of the blade being particularly important. Studies have shown that variations in these parameters can lead to significant differences in the coating's viscosity, application consistency, and final surface quality of the castings [

27,

28,

29,

30,

31,

32]. For example, improper mixing can result in non-uniform coatings, which can cause defects such as uneven surfaces, poor adherence, and inadequate protection of the foam pattern during casting. Consequently, optimizing the mixing parameters is essential to enhance the performance of lost foam coatings.

This paper focuses on lost foam coatings, discussing the effects of blade shape on coating viscosity, coating weight, and surface morphology after drying. It aims to provide technical support and theoretical reference for the proper use of lost foam coatings. By investigating the influence of blade geometry on the mixing efficiency and the resulting coating properties, this study seeks to offer insights that can lead to more consistent and high-quality castings. The findings are expected to contribute to the broader field of casting technology, offering practical solutions for industrial applications and advancing the overall understanding of lost foam casting processes.

2. Materials and Methods

2.1. Experimental Materials

The materials used in this study are commercial lost foam casting coatings. These coatings are characterized by high layer strength and excellent permeability, allowing for multiple applications. The final product is easy to apply and has high coverage. The refractory aggregate of the coating primarily consists of zircon sand, while the binder is mainly phenolic resin, and the suspending agent is Na-based bentonite.

Figure 1 shows the powder of the coating used in this study.

For the preparation of the coating solution, a ratio of 1.25:1 was used, i.e., 250g of coating powder to 200g of water. The mixture was then blended using a high-speed disperser to ensure thorough mixing. The high-speed disperser ensures that the coating powder is evenly distributed within the solution, which is critical for achieving uniform application and optimal performance during the casting process. The choice of blade shapes was intended to evaluate their impact on the mixing efficiency, viscosity, and final coating properties.To analyze the effects of different blade shapes on the performance of the coatings, this study selected several blade shapes: straight, tri-blade, quad-blade, and serrated, as shown in

Figure 2.

The experimental setup involved preparing multiple batches of the coating solution using the different blade shapes mentioned. Each batch was subjected to the same mixing conditions, including mixing time, speed, and temperature, to ensure comparability of results. The performance of each coating mixture was then evaluated based on key parameters such as viscosity, coating weight, drying behavior, and surface morphology.

2.2. Viscosity Measurement

Measuring the viscosity of casting coatings is crucial for effectively predicting and controlling their application performance. In this study, a rotational viscometer, which is manufactured by Shanghai Fangriu Instrument Co., Ltd., as depicted in

Figure 3,was used to measure the viscosity of the casting coatings. When the rotor rotates in the liquid, the liquid generates a viscous torque on the rotor. The higher the viscosity of the liquid, the greater the viscous torque; conversely, the lower the viscosity, the smaller the viscous torque. This viscous torque acting on the rotor is detected by a sensor, and the viscosity of the tested liquid is calculated and processed by a computer.

To ensure the accuracy of the experimental data, the viscosity is measured at three different positions at the same rotational speed, and the average value is taken as the viscosity of the casting coating. To precisely characterize the changes in coating viscosity, the rotational speed of the rotor during measurement is set to 6 rpm, 12 rpm, 30 rpm, and 60 rpm, respectively. Since the viscosity of the coating increases gradually once the stirred coating is left to stand, it is essential to minimize the time interval between sampling and measurement to ensure data consistency across samples.All testing processes were conducted at room temperature, which was approximately 20°C. In addition to measuring viscosity at different rotational speeds, the study also considered the thixotropic behavior of the coatings. Thixotropy refers to the property of certain fluids to exhibit a decrease in viscosity over time when subjected to shear, followed by a gradual recovery of viscosity when the shear is removed. This property is particularly important for casting coatings, as it affects their application and settling behavior.

2.3. Coating Weight Measurement

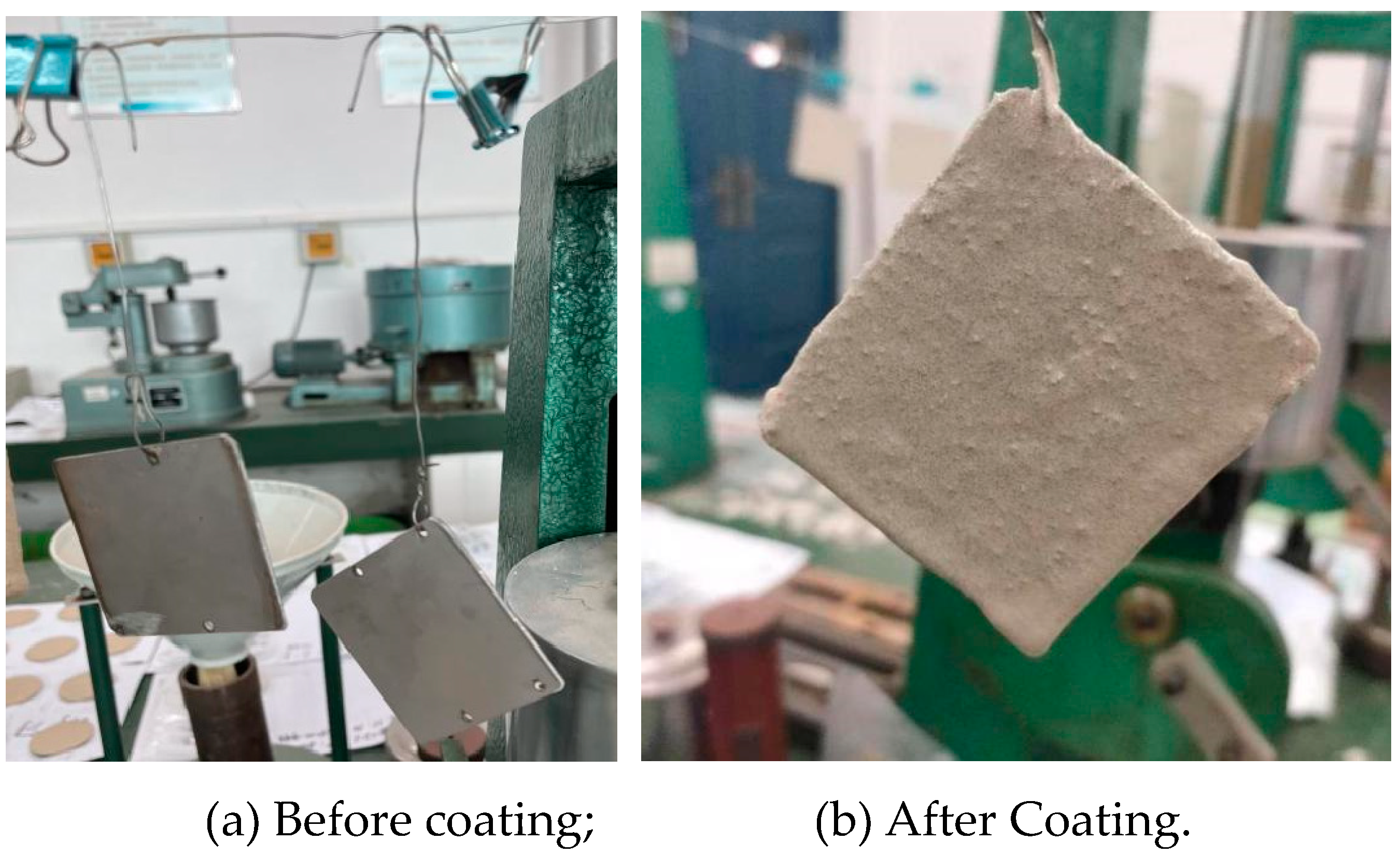

The measurement of the coating weight was conducted using metal sheets, as shown in

Figure 4. The specific method involved ensuring that the surface of the metal sheet was smooth and dry before the experiment. Initially, the metal sheet was tared and weighed using an electronic balance. The metal sheet was then fully immersed in the coating solution. After two minutes, the sheet was removed and clamped onto a test rack for observation.

When the coating stopped dripping or dripped very slowly, the metal sheet was weighed again using the electronic balance. The difference in weight before and after immersion represents the relative coating weight. This process was repeated three times for each sample to ensure accuracy, and the average value was recorded.

To ensure consistency and accuracy, the coating process was standardized across all samples. The immersion time was carefully controlled to be exactly two minutes for each measurement. This time frame was chosen to allow sufficient coating absorption while avoiding excessive dripping, which could affect the weight measurement. Understanding the coating weight is essential for optimizing the application process, as it directly influences the thickness and uniformity of the coating layer. These factors are critical for achieving high-quality castings with the desired surface properties and structural integrity.

2.4. Observation of Coating Surface Morphology

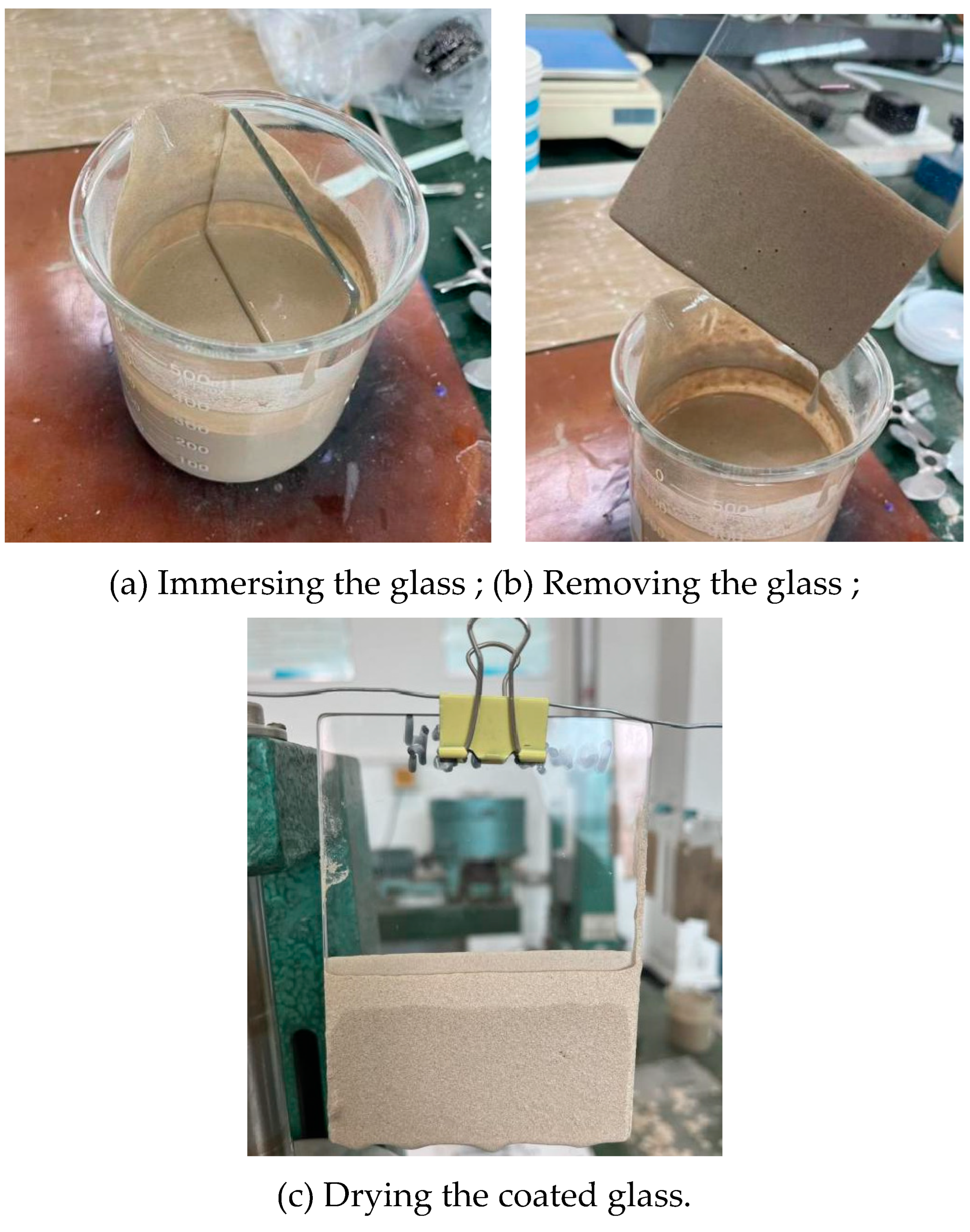

To observe the surface morphology of the coating, glass slides were prepared as specimens. The preparation process involved immersing the glass slides into the thoroughly mixed coating solution, as shown in

Figure 5. After a two-minute immersion, the slides were removed and allowed to air dry naturally. The surface morphology of the dried coating was then observed using a stereomicroscope.

During the immersion process, it is crucial to slowly submerge the glass slides to avoid entraining air bubbles, which could lead to defects in the coating layer. Once the glass slides were immersed, they were gently vibrated to ensure the uniformity of the coating and to remove any excess coating material.

Once dried, the coated glass slides were examined under a stereomicroscope with high magnification capabilities. This allowed for a detailed analysis of the coating's surface features, including uniformity, texture, and the presence of any defects or irregularities. The stereomicroscope was equipped with a digital camera to capture high-resolution images of the coating surfaces for further analysis and documentation.

2.5. Analysis of the Coating Drying Process

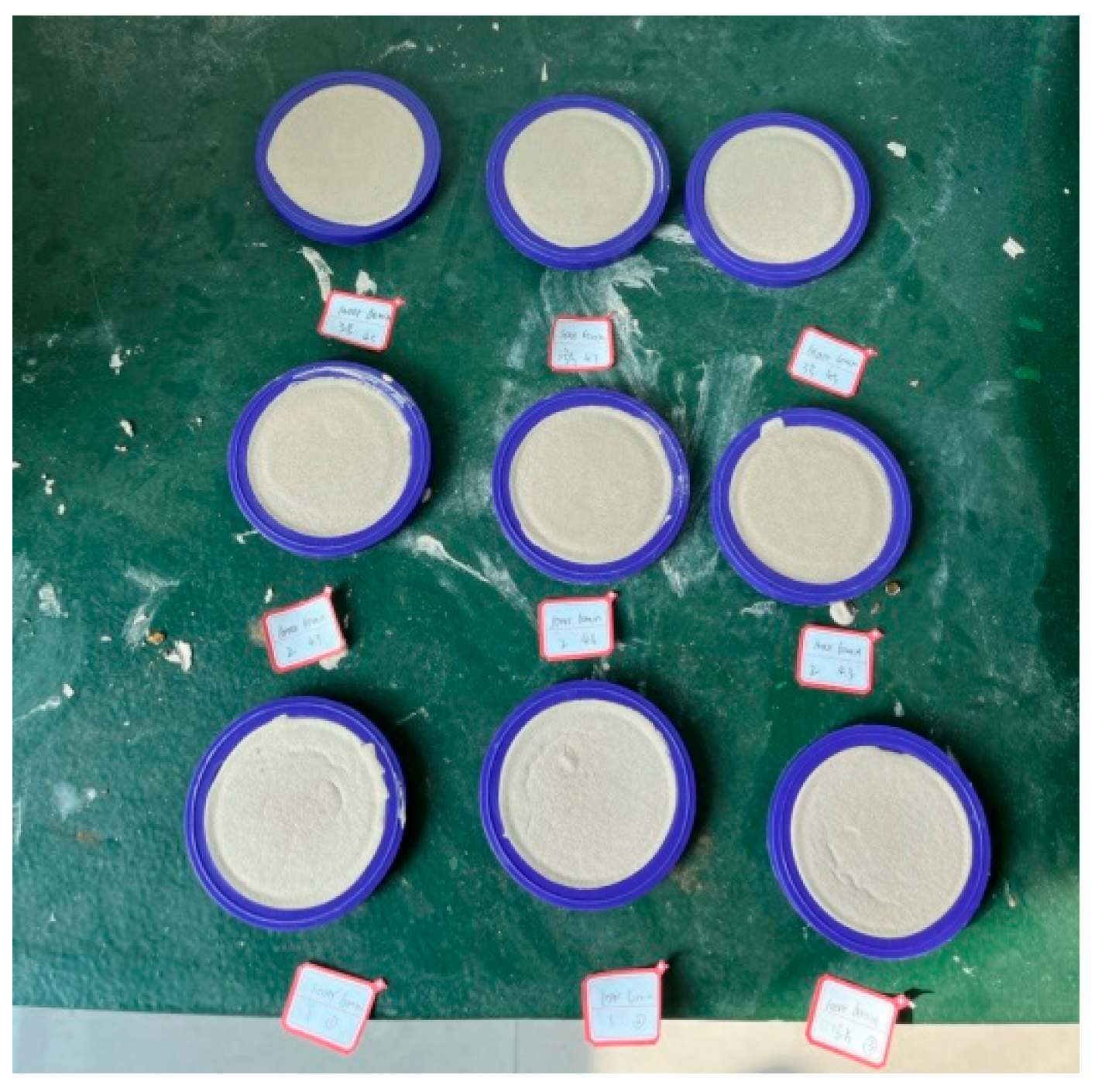

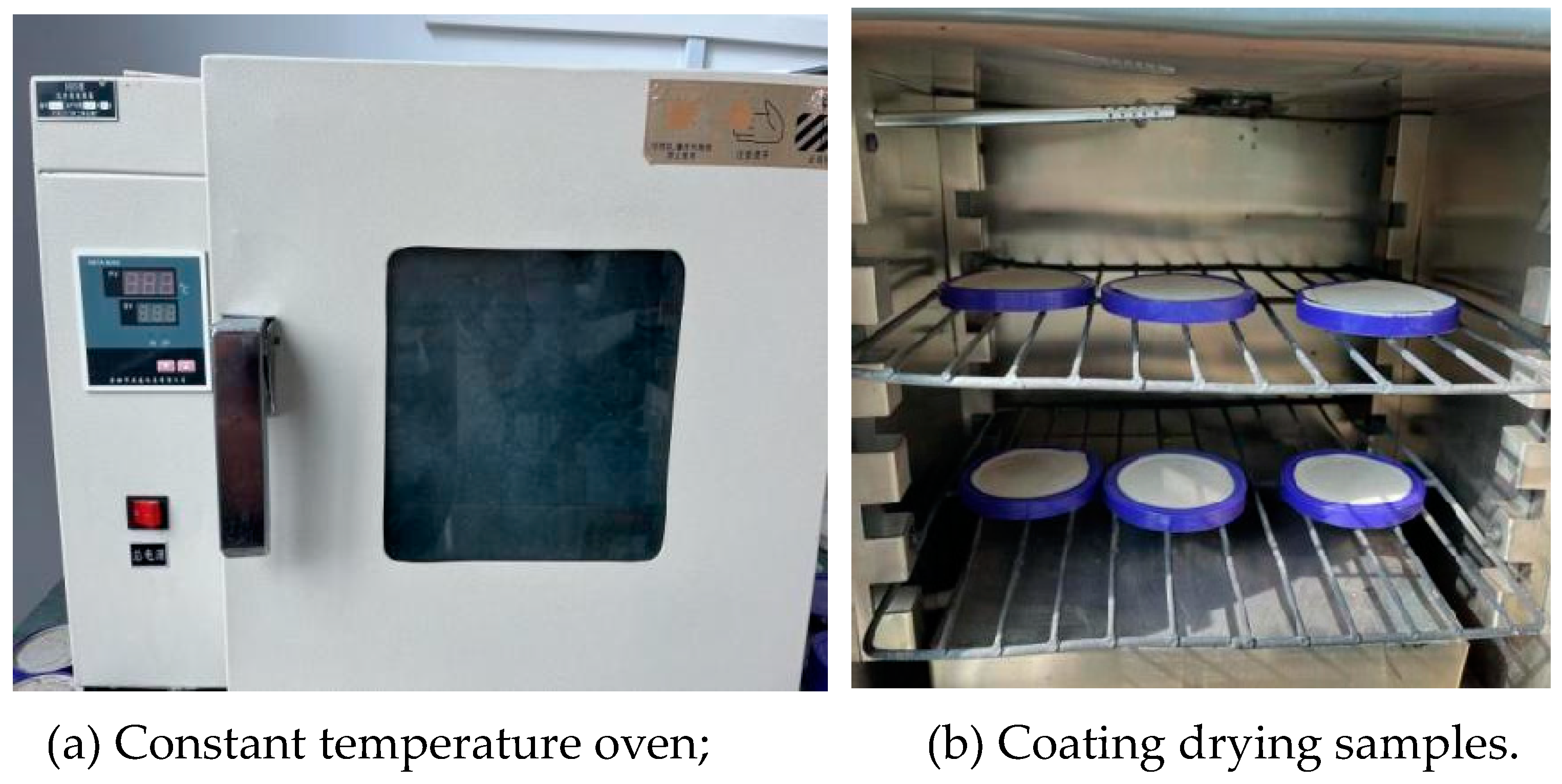

To analyze the drying process of the coatings, the stirred coating mixture was slowly poured into molds with a diameter of approximately 40 mm and a depth of about 2 mm, as shown in

Figure 6. The coatings were then placed in a constant temperature oven for drying. The weight of the coatings was measured at regular intervals to analyze the drying process under different conditions. The constant temperature oven used in this experiment was the XMTA-6000 model.

During the drying process analysis, the samples were dried at constant temperatures of 30°C, 40°C, and 50°C. Before each drying cycle, the oven was preheated to the required temperature to ensure consistent drying conditions. The samples were placed in the center of the oven to achieve uniform drying, as illustrated in

Figure 7. Each sample was carefully prepared to ensure uniform thickness and volume, minimizing variability in the drying process.

3. Results and Discussion

3.1. Influence of Blade Shape on Coating Performance

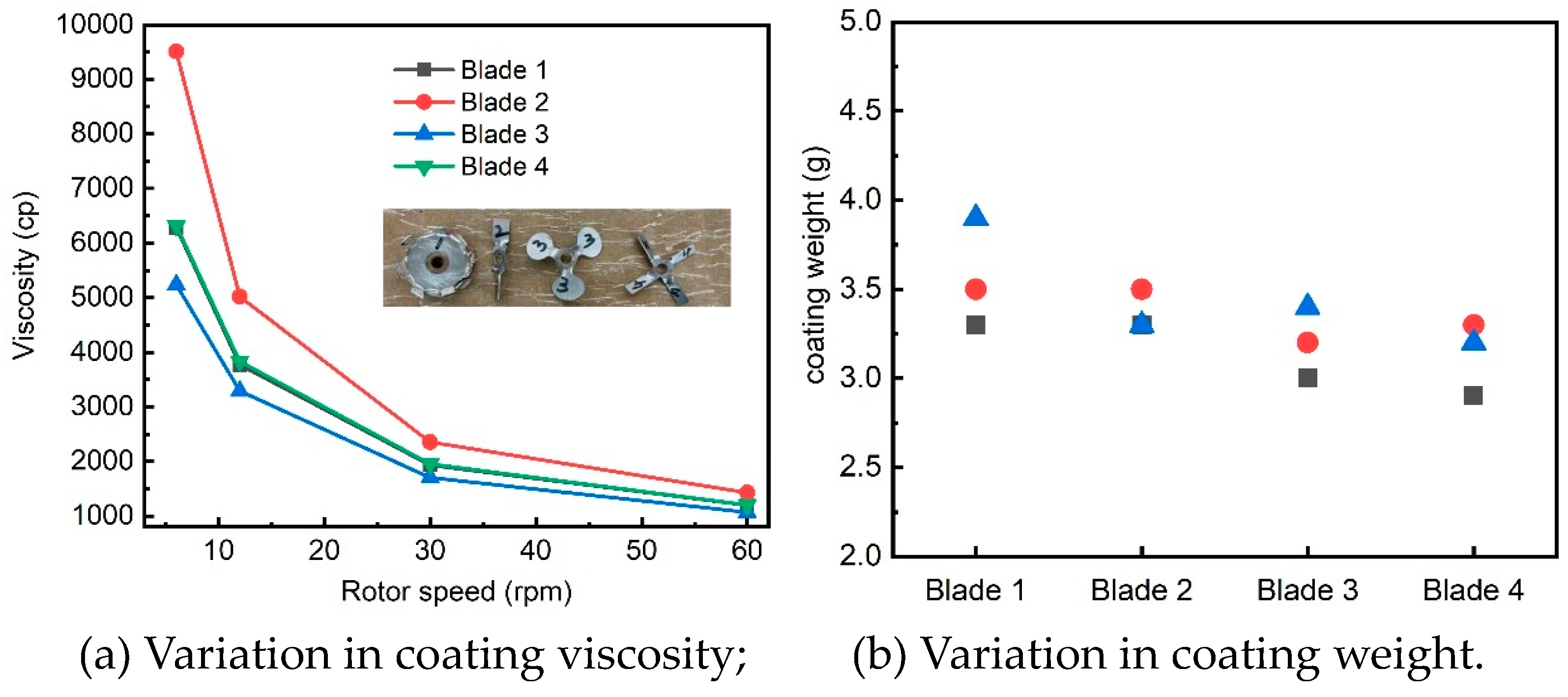

Different blade shapes used for stirring the coating can result in varying degrees of uniformity, thereby affecting the performance of the coating. The stirring speed was fixed at 1000 rpm, and the stirring time was set to 30 minutes to analyze the influence of blade shape on the performance of the coating after stirring. The results are shown in

Figure 8.

As seen in

Figure 8a, changing the blade shape leads to different coating viscosities under the same stirring speed and time. At a constant rotor speed, the viscosity of the solution stirred by Blade 2 is the highest, while the viscosities of the solutions stirred by Blades 1 and 4 are similar, both being lower than that stirred by Blade 2. The solution stirred by Blade 3 has the lowest viscosity. This can be attributed to the shear thinning characteristic of the lost foam coating, where the viscosity decreases with increased stirring intensity. The viscosity measurements in

Figure 8 indicate that Blade 2 has the weakest stirring ability; achieving the same mixing effect would require a longer stirring time or higher stirring speed. Blade 4 shows the strongest stirring ability, quickly achieving uniform mixing. The coating weight also varies with different blade shapes, with Blade 4 resulting in the lowest coating weight and Blade 1 the highest, consistent with the viscosity results. Overall, Blade 3 demonstrates the strongest mixing ability, making it the preferred choice for efficient and thorough mixing.

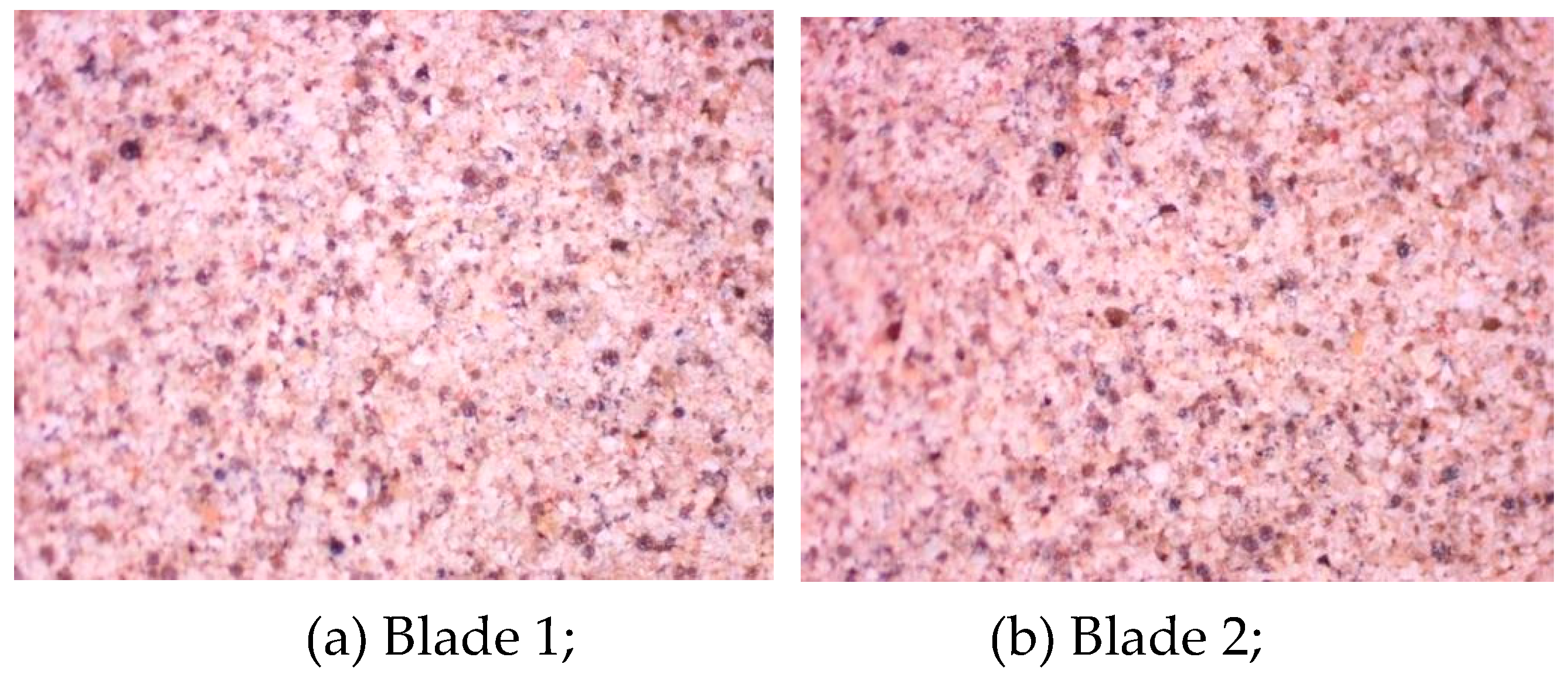

The surface morphology of the dried coatings after stirring with different blades was observed, and the results are shown in

Figure 9.

Figure 9 shows that the surface morphology of the coatings stirred by different blades does not exhibit significant differences. However, localized areas of uneven particle distribution and aggregation were observed in the coatings stirred by Blades 2 and 4. The coatings stirred by Blades 1 and 3 were more uniform. The poorer uniformity and larger particles in the coatings stirred by Blades 2 and 4 suggest insufficient mixing. The particle distribution is directly related to the viscosity of the stirred coating; Blade 2 produces a higher viscosity coating, resulting in greater shear resistance and less uniform particle distribution during application. Conversely, Blade 3 produces the lowest viscosity coating, facilitating more uniform particle dispersion.

The observed differences in viscosity and surface morphology indicate that blade shape significantly influences the mixing efficiency and coating quality. Blade 3, with its superior mixing capability, ensures a more uniform and consistent coating, which is crucial for achieving high-quality castings with minimal defects. The findings highlight the importance of selecting the appropriate blade shape to optimize the coating process and improve the performance and quality of the final cast products. The insights gained from this analysis provide valuable guidelines for improving the efficiency and quality of the coating process in industrial applications, contributing to advancements in casting technology.

3.2. Influence of Stirring Speed on Coating Performance

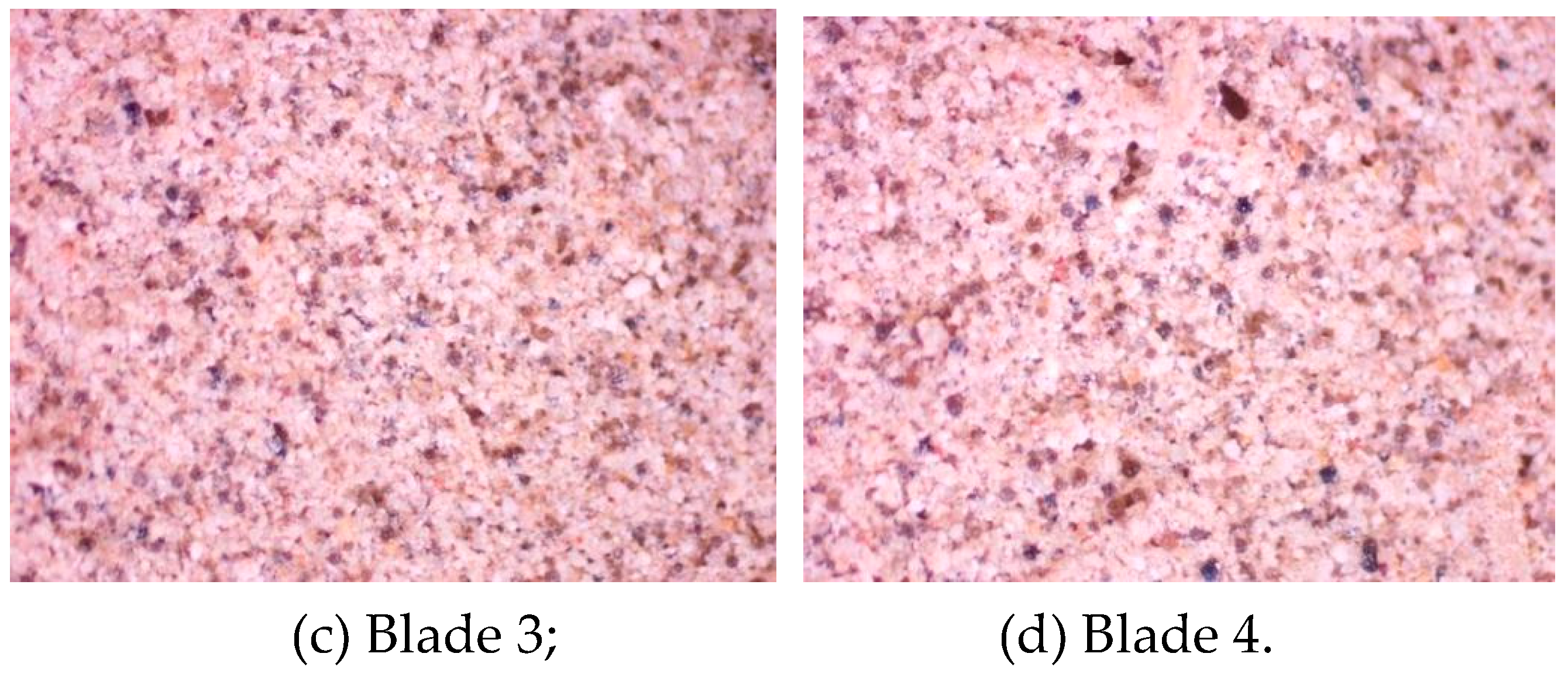

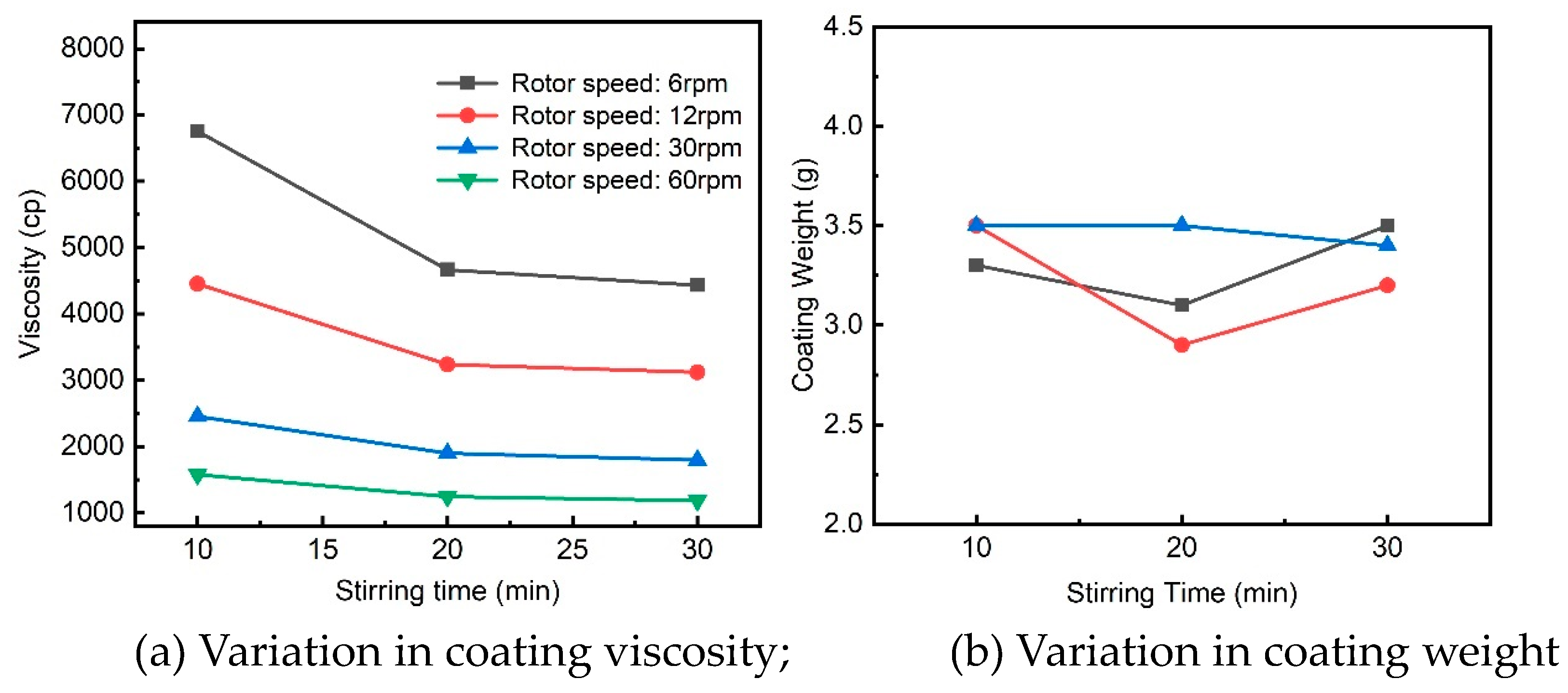

Understanding the effect of stirring speed on coating properties is crucial for ensuring the optimal performance of the coating. In this study, Blade 3 was chosen, and the stirring time was fixed at 30 minutes to analyze the influence of stirring speed on coating performance. The effect of stirring speed on coating viscosity and coating weight are shown in

Figure 10.

From

Figure 10a it can be seen that, the viscosity of the coating shows a slight decrease with increasing stirring speed, although the overall change is not significant. This indicates that the coating achieves uniformity at the selected stirring speeds of 800-1200 rpm after 30 minutes of stirring. At a stirring speed of 1200 rpm, the coating weight is slightly lower than that at 800 rpm and 1000 rpm, as shown in

Figure 10b. This reduction in coating weight at 1200 rpm is due to shear thinning, where the viscosity of the coating decreases under higher shear rates, leading to lower coating thickness.

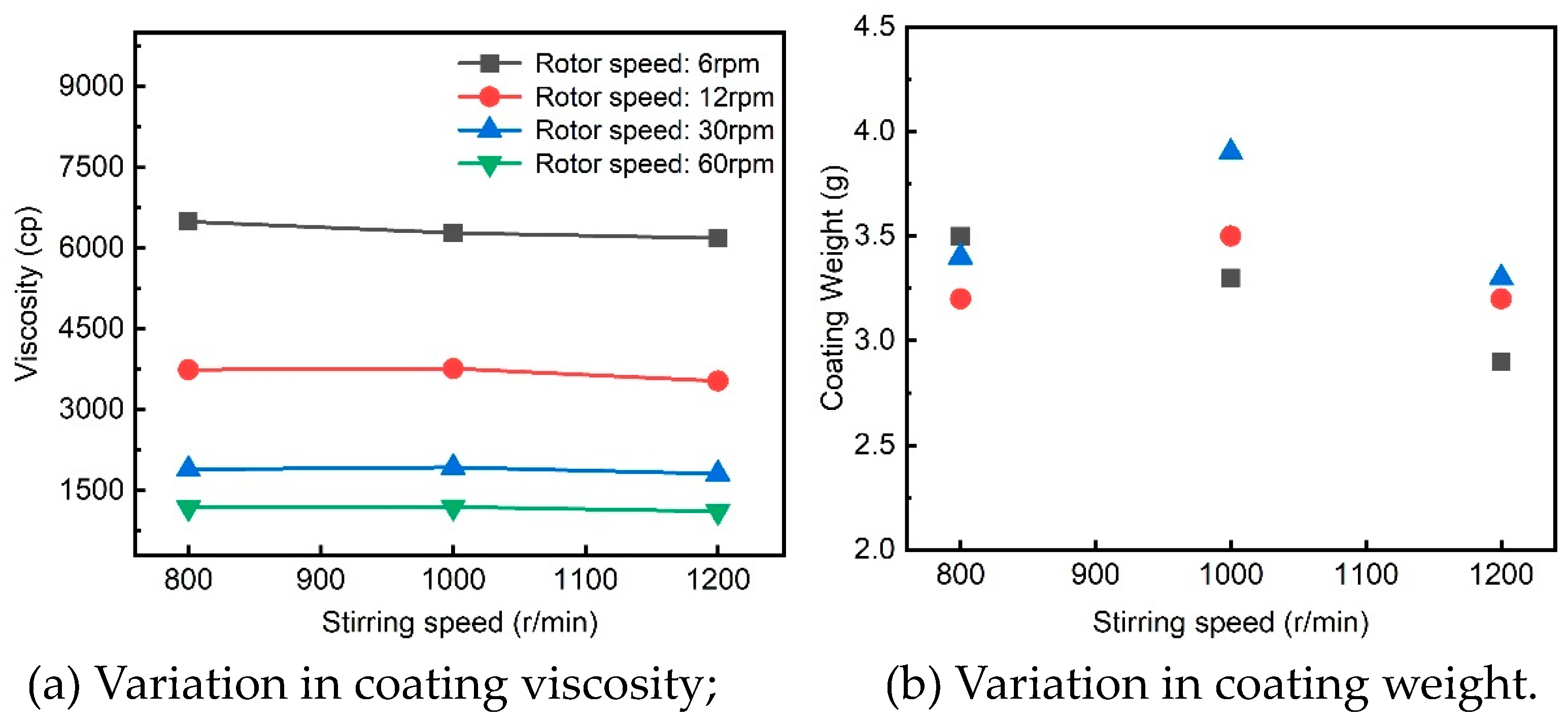

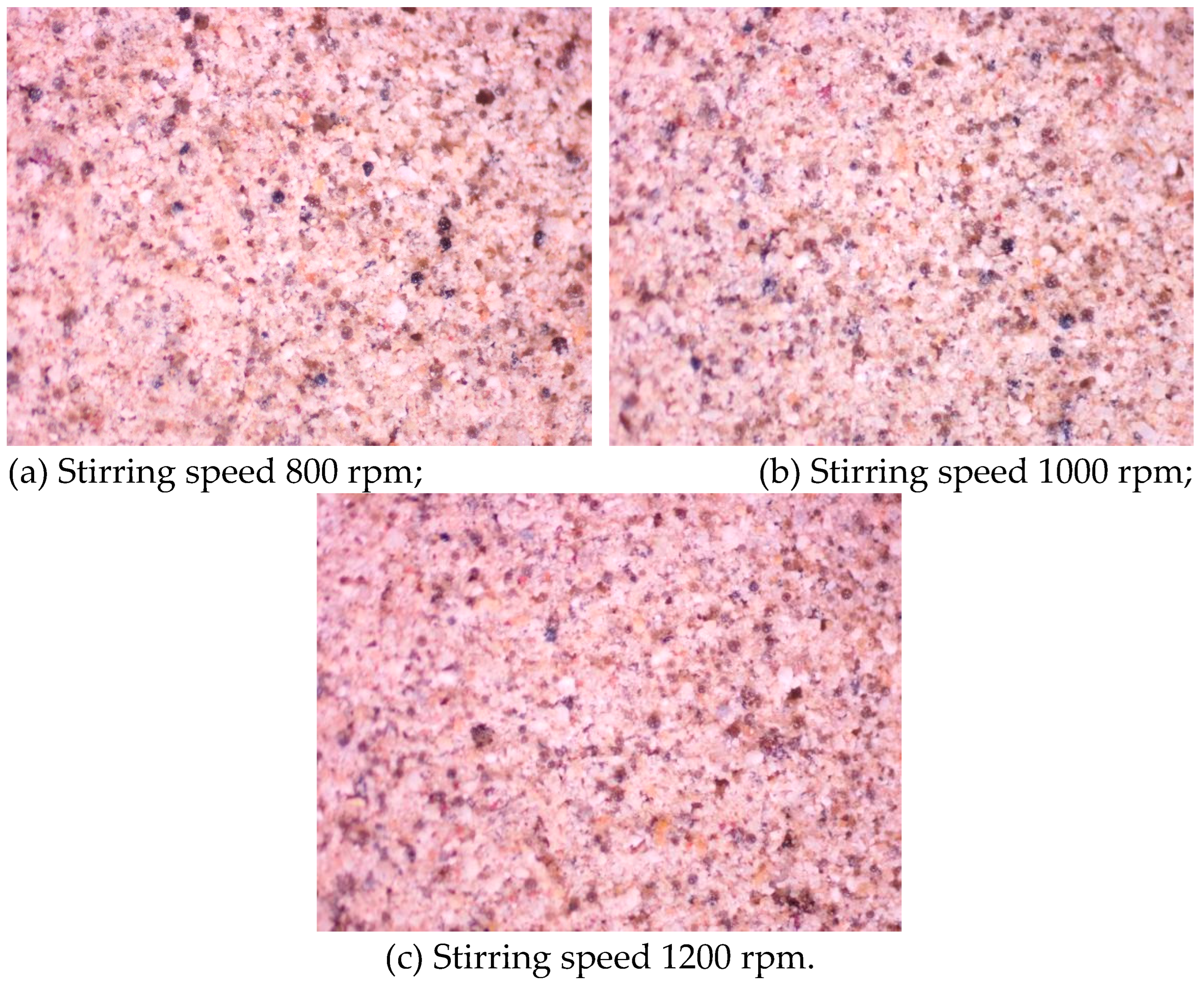

The surface morphology of the coatings after being fully air-dried was observed at different stirring speeds, as shown in

Figure 11. As the stirring speed increases, the coating mixture becomes more uniform within the same stirring time. The surface morphology of the coatings at stirring speeds of 800 rpm to 1200 rpm appears uniform with no significant differences.

The observations from

Figure 11 indicate that the coating's surface morphology remains relatively consistent across the different stirring speeds. This uniformity suggests that the coating mixture achieves a sufficient level of homogeneity within the tested speed range. The slight variations in surface texture are attributed to the differences in shear forces and mixing efficiency at different speeds. Higher stirring speeds can enhance the dispersion of particles within the coating, leading to a smoother and more uniform surface.

The results demonstrate that stirring speeds between 800 rpm and 1200 rpm are effective for achieving a homogeneous coating mixture. The slight decrease in viscosity and coating weight at higher speeds can be beneficial for specific applications requiring thinner coatings. These findings underscore the importance of optimizing stirring speed to enhance the coating performance, ensuring consistent quality and optimal properties for lost foam casting processes. The insights from this study provide valuable guidelines for industrial applications, aiding in the selection of appropriate stirring parameters to achieve desired coating characteristics.

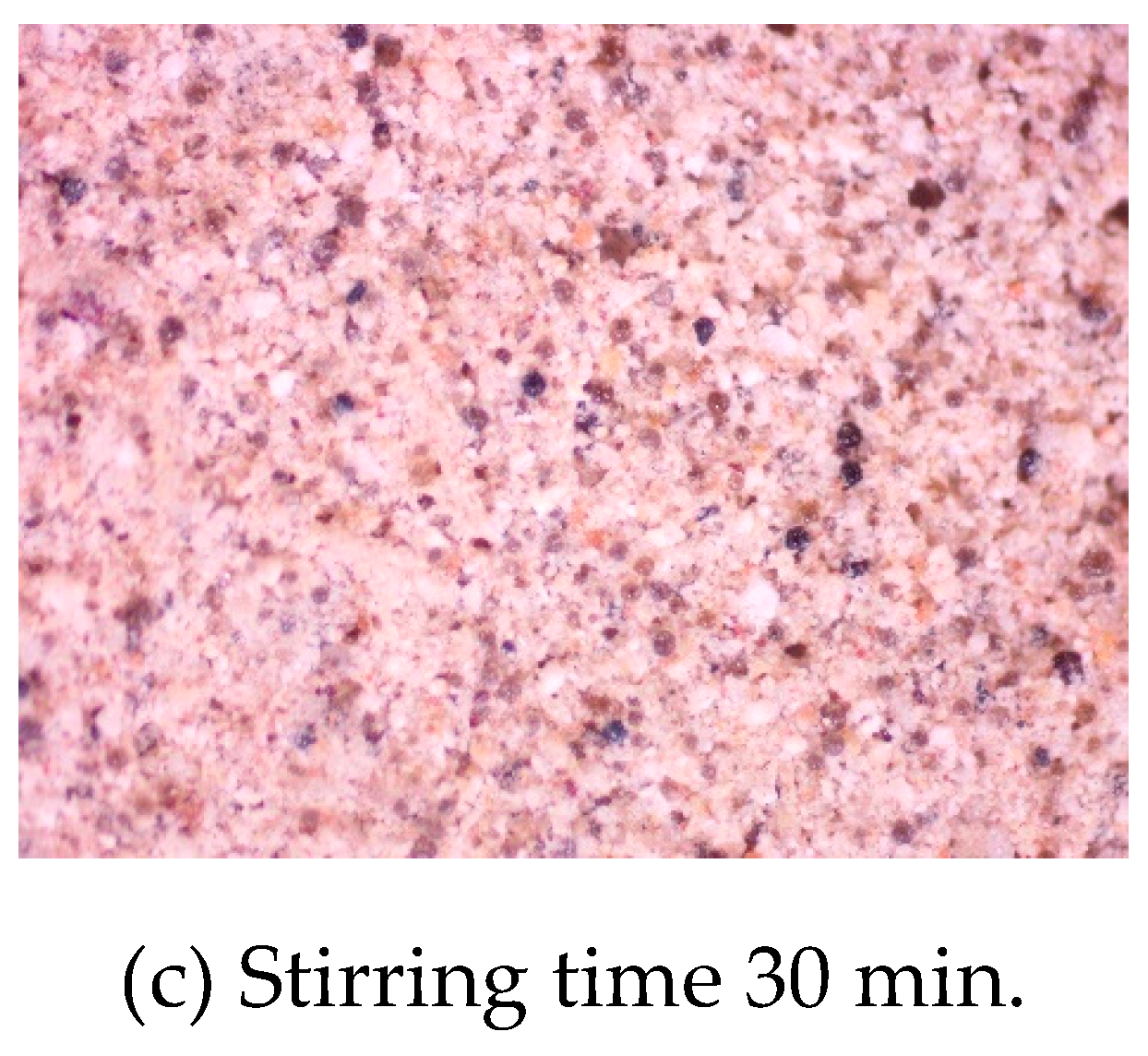

3.3. Influence of Stirring Time on Coating Performance

The duration of stirring during the preparation of lost foam coatings affects the performance of the coating. Typically, a short stirring time may lead to inadequate mixing, while excessively long stirring can lead to wastage and increased costs. This study investigates the impact of stirring time on coating performance, using a stirring speed of 800 rpm and Blade 3. The effects of stirring time on coating viscosity and coating weight are illustrated in

Figure 12.

As depicted in

Figure 12a, with a constant stirring speed of 800 rpm and blade shape, the viscosity of the coating exhibits a slight decreasing trend as the stirring time increases. The viscosity quickly stabilizes after a sufficient stirring period, indicating that further increases in stirring time have minimal impact on viscosity.

Figure 12b shows that at a stirring time of 10 minutes, the coating weight is slightly higher than the average value; at 20 minutes, the coating weight is lower than the average value; and at 30 minutes, the coating weight approaches the average value. However, the differences in stirring time do not result in significant changes in coating weight, which remains within a small range of fluctuation. Therefore, once the coating achieves a stable viscosity and coating weight after a certain stirring period, extending the stirring time further has minimal impact on coating performance.

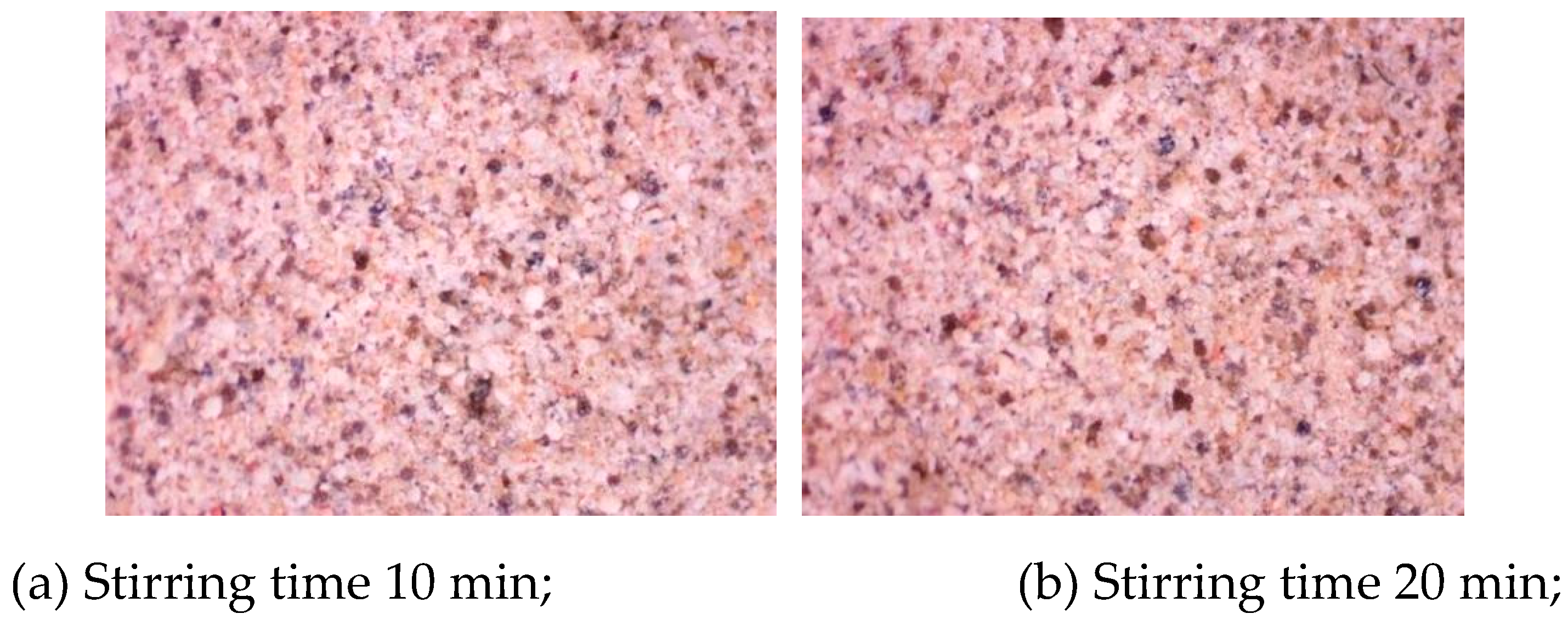

The surface morphology of the coatings, after being naturally air-dried for different stirring times, is shown in

Figure 13. As illustrated, there are no significant visual differences in the surface morphology of the coatings with varying stirring times. The theoretical analysis suggests that as the stirring time increases, the coating becomes progressively more uniform, although the observable changes are subtle.

In conclusion, extending the stirring time beyond a certain period does not significantly alter the coating's viscosity or weight. The surface morphology remains relatively consistent with increased stirring time, indicating that the coating achieves uniformity relatively quickly. This finding highlights that optimal stirring time is crucial for achieving consistent coating properties while avoiding unnecessary wastage and cost. These insights are valuable for optimizing the preparation process in industrial applications to ensure efficient and effective coating performance.

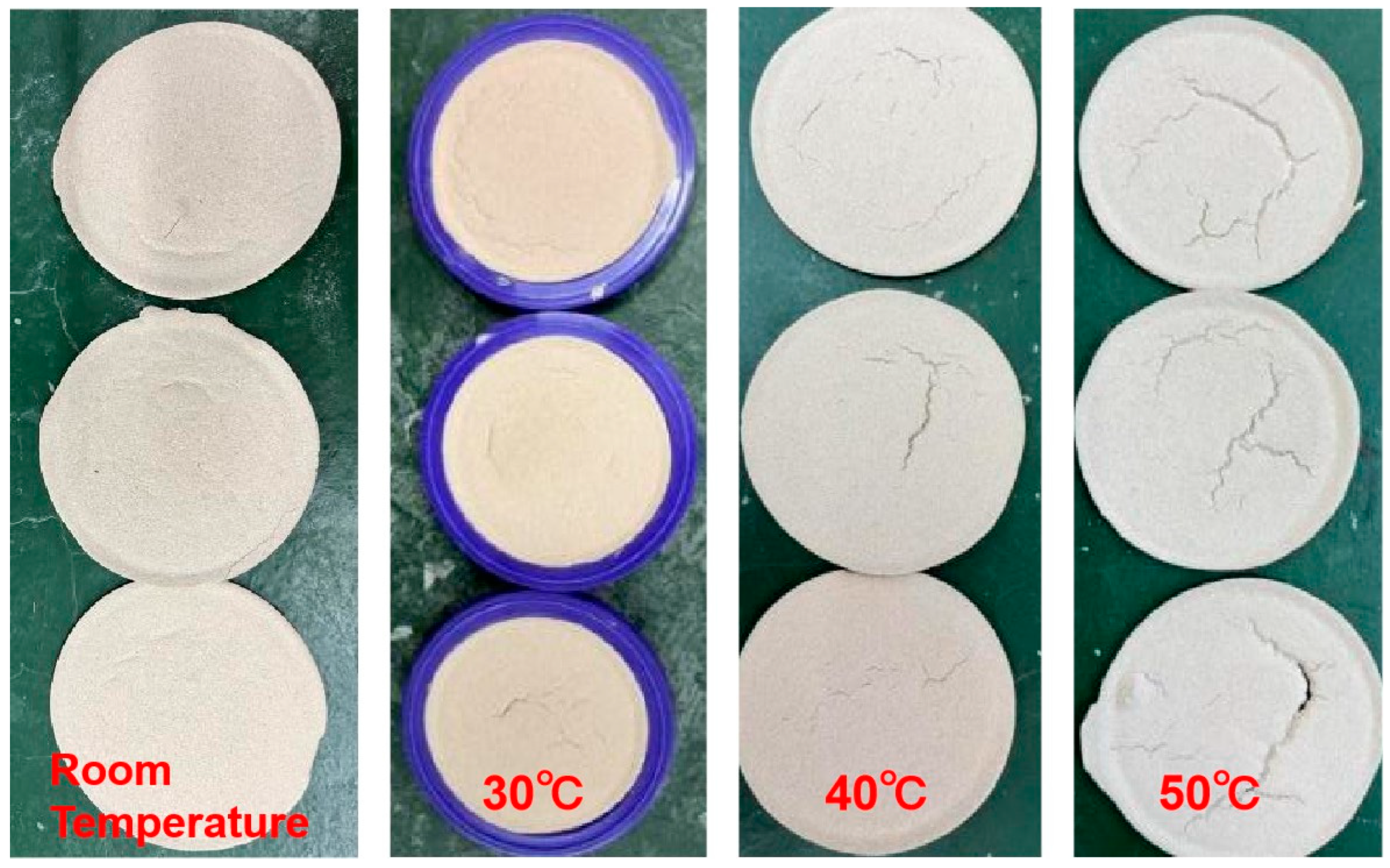

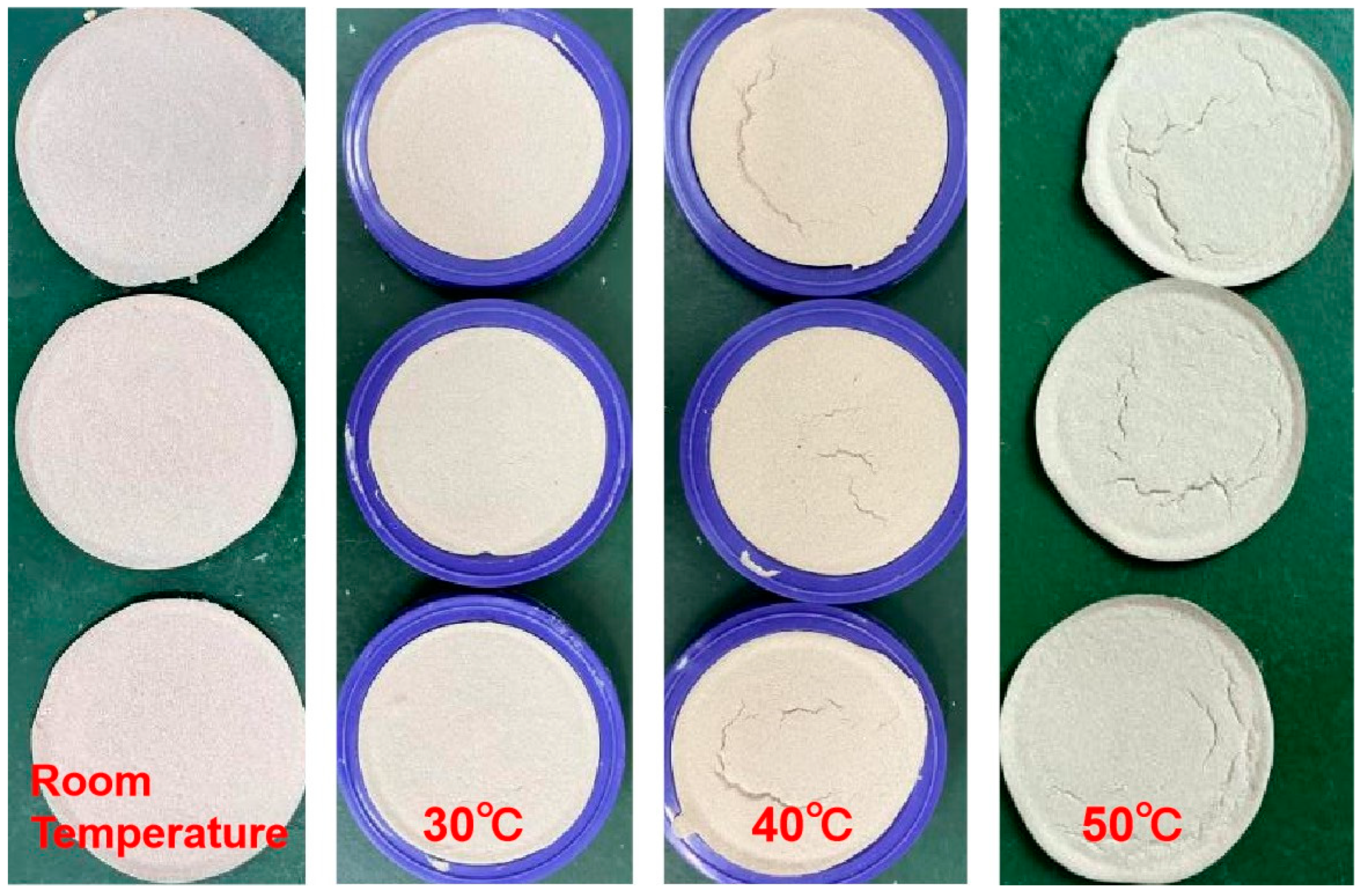

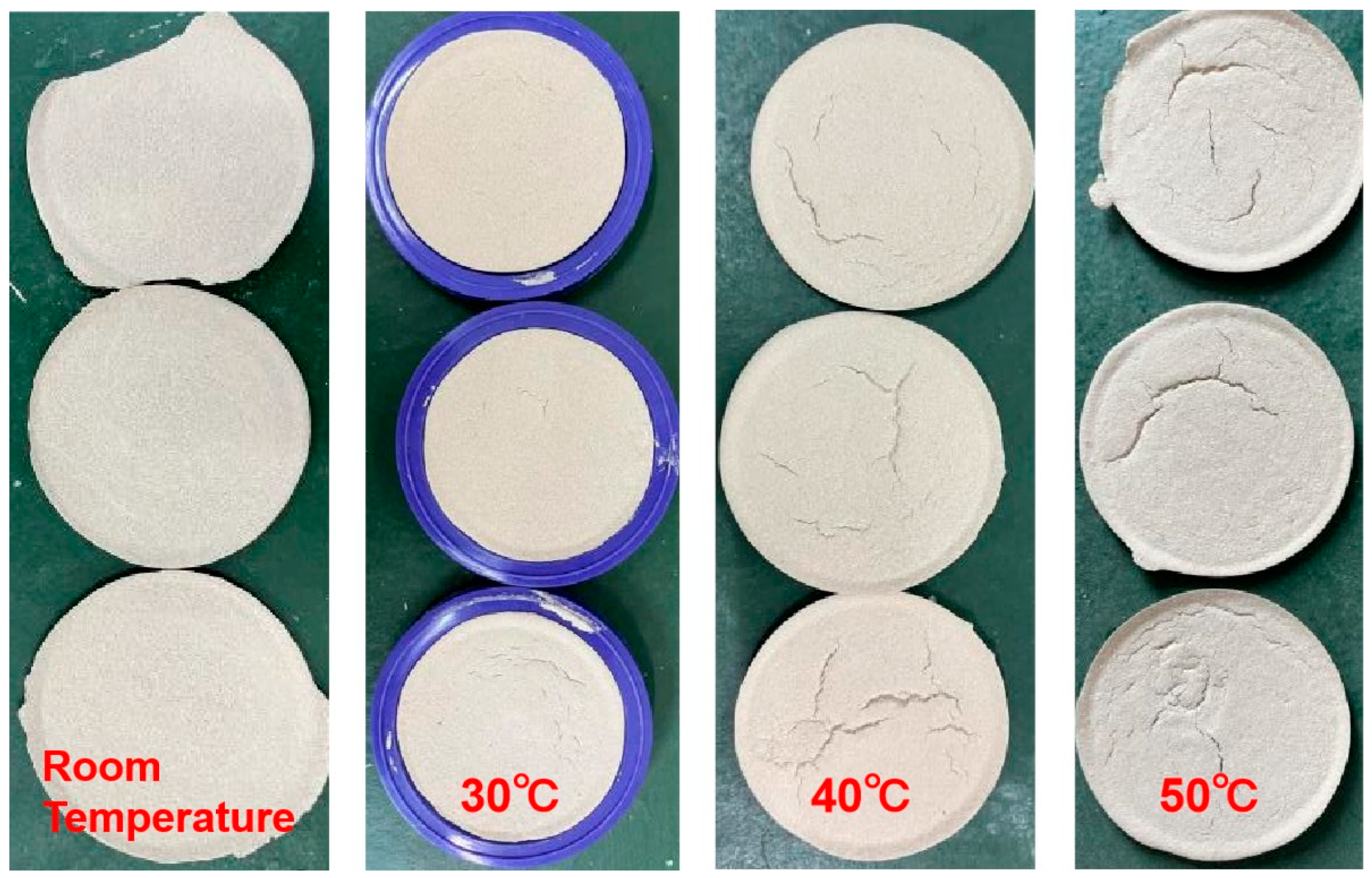

3.4. Analysis of Coating Drying Behavior

After the coating is prepared and mixed, it is applied to the model surface and subsequently dried to achieve a certain strength and maintain a specific shape. Inadequate selection of drying parameters can lead to defects such as cracking, deformation, and insufficient strength during the drying process, adversely affecting the performance of the coating. Coatings mixed with different blade shapes were subjected to drying at temperatures of 30°C, 40°C, and 50°C. The surface morphology of the fully dried coatings is shown in

Figure 14,

Figure 15,

Figure 16 and

Figure 17.

Based on the surface morphology of the fully dried coatings stirred by different blades, as shown in

Figure 14,

Figure 15,

Figure 16 and

Figure 17, it can be observed that, higher drying temperatures result in more pronounced surface cracks and rougher surface textures. At room temperature, coatings mixed with all four blade shapes exhibit relatively smooth surfaces. At 30°C, slight cracks are observed on the surfaces of all four coatings, with the coating mixed with Blade 3 being the smoothest. At 40°C, more noticeable cracks appear on the surfaces of all coatings. The coating mixed with Blade 1 and 3 shows relatively fewer cracks compared to those mixed with Blades 2 and 4. At 50°C, the surfaces of the coatings show very prominent cracks, with the coating mixed with Blade 2 and 3 exhibiting fewer cracks compared to those mixed with Blades 1 and 4. It is evident that temperature has a significant impact on the surface morphology of the dried coatings. Higher temperatures lead to more noticeable cracking and a shorter drying time. Initially, higher temperatures accelerate the drying process, but as drying progresses, the rate of change in the coating's properties becomes less pronounced regardless of the temperature.

Optimal drying conditions must be carefully selected to balance drying time and coating quality. Excessive temperatures can accelerate drying but may lead to surface defects, while lower temperatures may prolong drying but improve surface finish. Thus, understanding the interplay between drying temperature and coating performance is essential for optimizing the coating process in industrial applications.

4. Conclusions

This study investigates the effects of blade shape, stirring speed, stirring time, and drying temperature on the properties of lost foam coatings. The findings are summarized as follows:

(1) The shape of the stirring blade significantly impacts the uniformity, viscosity, and coating weight. The three-blade configuration achieved the highest mixing efficiency, resulting in consistent viscosity and optimal coating weight. In contrast, the two-blade and serrated blades produced less uniform mixtures, affecting the final coating quality.

(2) Increasing the stirring speed from 800 rpm to 1200 rpm slightly reduced the viscosity and coating weight due to shear thinning effects. However, the overall change was minimal, indicating effective mixing within this speed range.

(3) Extending the stirring time beyond 30 minutes did not significantly alter the coating’s viscosity or application weight. A stirring time of 30 minutes was sufficient to achieve stable properties, with prolonged stirring offering no substantial improvements.

(4) Higher drying temperatures increased surface cracking and roughness. Coatings dried at 50°C exhibited the most significant defects, while those dried at room temperature were smoother with fewer cracks. Thus, controlling the drying temperature is crucial for minimizing surface imperfections and ensuring high-quality coatings.

Author Contributions

Conceptualization, Guojin Sun; methodology, Guojin Sun, Zhenggui Li and Qi Wang; formal analysis, Guojin Sun, Qi Wang and Zhenggui Li; investigation, Guojin Sun, Qi Wang and Zhenggui Li; data curation, Guojin Sun and Qi Wang ; writing—original draft preparation, Guojin Sun; writing—review and editing, Guojin Sun and Zhenggui Li; supervision, Guojin Sun and Zhengui Li. All authors have read and agreed to the published version of the manuscript.

Acknowledgments

The authors acknowledge financial support from Kunlun Talent Project of Qinghai Province(2023-QLGKLYCZX-032).

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Kay A. Vacuum precision investment casting for clean metal castings. Foundry Trade Journal, 2006, 180, 280–282.

- Zhu H C, Zhang R, Li H B,et al.Evolution of Temperature Field of Slabs during the Feeding Strip Process in Continuous Casting. Steel Research International, 2023.

- Zailiang J, Zitian F, Wenming J,et al. Interfacial microstructures and mechanical properties of Mg/Al bimetal produced by a novel liquid-liquid compound casting process. Journal of Materials Processing Technology, 2018, 261, 149–158.

- Santa-Rosa W, Venet M, M'Peko J C,et al. Environmentally-friendly magnetoelectric ceramic multilayer composites by water-based tape casting. Elsevier, 2019(4).

- Schulz T, Janke D, Heller H P,et al. Development of environmentally friendly continuous casting fluxes. Stahl und Eisen 2008, 128, 65–78.

- Scarber P, Littleton H, Druschitz A.Preliminary Study of Compacted Graphite Iron Engine Blocks Produced by the Lost Foam Casting Process. Transactions of the American Foundry Society, 2009:117.

- Druschitz A, Littleton H, Dunlap W,et al.Advantages of pouring compacted graphite iron using the lost foam casting process. International Foundry Research, 2012(1):64.

- Kiran S, Krishna R, Bhanuprakashreddy D,et al. Structural analysis of grey iron nose leg component produced by lost foam casting. IWOSP 2021, International workshop on statistical physics, 2023.

- Bieniewicz K, Reich M, Soraruf N.Improving Metal Flow in LOST FOAM CASTING Through Use of Low Thermal Degradation Hot Melt Adhesives. Modern Casting, 2024, 114(3).

- Kavitha M, Raja V.Optimization of insert roughness and pouring conditions to maximize bond strength of (Cp)Al-SS304 bimetallic castings using RSM-GA coupled technique. Materials Today Communications, 2024, 39.

- Romazanov Z, Silayeva O, Tatieva M L M P A. The feasibility study for the creation of production based on technology of lost-foam casting. Metalurgija, 2023, 62, 103–106.

- LIU,Zi-li,(College,et al.Recent Development of Lost Foam Casting Technology Comment on the 7th Chinese Lost Foam Casting Symposium. China Foundry, 2006.

- Jiao C, Li G, Tian L,et al.Preparation and properties of magnesia porous ceramics by particle-stabilized foam casting. International journal of applied ceramic technology, 2023.

- Cibikci K C, Yaman M. Experimental investigation of compressive behavior and vibration properties of layered hybrid foam formed by aluminum foam/EPS-filled syntactic foam. Journal of Materials Science, 2024, 59, 3636–3651.

- Acar S, Gecu R, Kisasoz A,et al.A Study on Al/Cu Bimetal Production by Lost Foam Casting. Practical Metallography, 2018(11):55.

- Huang J, Lin Y X, Chen W P,et al. Numerical analysis of lost foam casting for large-caliber water meter shell. Advances in Mechanical Engineering, 2021, 13, 168781402110280.

- Griffiths W D, Davies P J. The permeability of Lost Foam pattern coatings for Al alloy castings. Journal of Materials Science, 2008, 43, 5441.

- Akbarzadeh Y, Rezaei M, Babaluo A A,et al. Microstructure, permeability and rheological behavior of lost foam refractory coatings. Surface and Coatings Technology, 2008, 202, 4636–4643.

- Karimian M, Idris M H, Ourdjini A,et al. Effect of flask vibration time on casting integrity, Surface Penetration and Coating Inclusion in lost foam casting of Al-Si Alloy. European Journal of Pharmacology, 2011, 1315, 633–638.

- Sands M, Shivkumar S. Influence of coating thickness and sand fineness on mold filling in the lost foam casting process. Journal of Materials Science, 2003, 38, 667–673.

- Opyd B, Granat K. Evaluation of Microwave Heating of Protective Coatings Used in the Lost Foam Technology. Archives of Foundry Engineering, 2015, 15, 65–70.

- Shivkumar S, Yao X, Makhlouf M.Polymer Melt Interactions During Casting Formation in the Lost Foam Process. Scripta Metallurgica et Materialia, 1995, 33(1).

- Shivkumar S, Yao X, Makhlouf M.Polymer Melt Interactions During Casting Formation in the Lost Foam Process. Scripta Metallurgica et Materialia, 1995, 33(1).

- Sun C, Cao Z. Effects of the Wettability Between the Coating and the Liquid EPS on the Filling Process of Lost Foam Casting. International Journal of Metalcasting, 2023, 18, 1318–1328.

- Pavlovi M, Nikolic J, Andric L,et al.Synthesis of the new lost foam refractory coatings based on talc. Journal of the Serbian Chemical Society, 2021.

- Sulaiman S, Ariffin M K A M, Tang S H,et al.Influence of Pattern Coating Thickness on Porosity and Mechanical Properties of Lost Foam Casting of Al-Si (LM6) Alloy. Applied Mechanics and Materials, 2013, 300-301, 1281-1284.

- Karimian M, Ourdjini A, Idris M H,et al.Process Control of Lost Foam Casting using Slurry Viscosity and Dipping Time. Journal of Applied Sciences, 2011, 11(21).

- Bambauer R A, Lee T, Delong T. Effect of Continuous Mixing on Viscosity and Permeability of an Iron Lost Foam Coating: A Joint Study. Transactions of the American Foundrymens Society, 1996, 104, 329–333.

- Hawley W B, Li J. Beneficial rheological properties of lithium-ion battery cathode slurries from elevated mixing and coating temperatures. Journal of Energy Storage, 2019, 26, 100994–1.

- Nwaogu, U.C. Poulsen, T.Stage, R.K.Bischoff, C.Tiedje, N.S.New sol-gel refractory coatings on chemically-bonded sand cores for foundry applications to improve casting surface quality. Surface & Coatings Technology, 2011, 205(16).

- Chen X, Penumadu D. Characterizing microstructure of refractory porous materials. Journal of Materials Science, 2006, 41, 3403–3415.

- Takatori N, Amano M, Miyachi R,et al. Viscosity properties prediction of semi-solid aluminum alloys using finite element analysis based on quenched solidified structure, and experimental validation. Journal of Japan Institute of Light Metals, 2020, 70, 187–193. [CrossRef]

- Gao Y X, Zhao C, Fang Z G,et al. Microstructures and Wear Properties of Micro-Nanostructure Coating on Cast Iron Rolls by Electro-Spark Deposition. Advanced Materials Research, 2011, 160-162, 176–181.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).