Submitted:

29 July 2024

Posted:

30 July 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methodology

2.2.1. Electrochemical Etching

2.2.2. Coating Process

2.2.3. Field Ion Microscopy

3. Results and Discussion

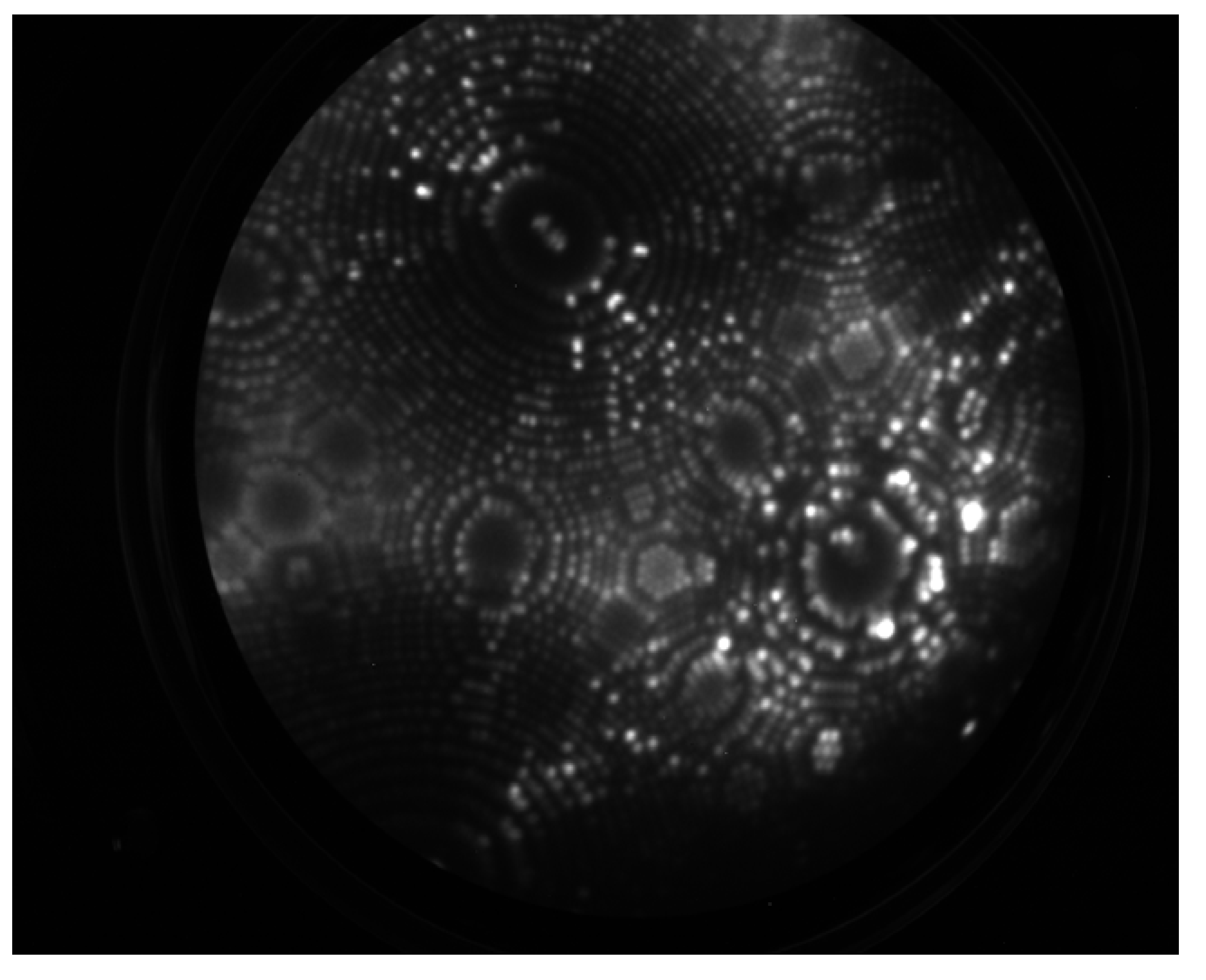

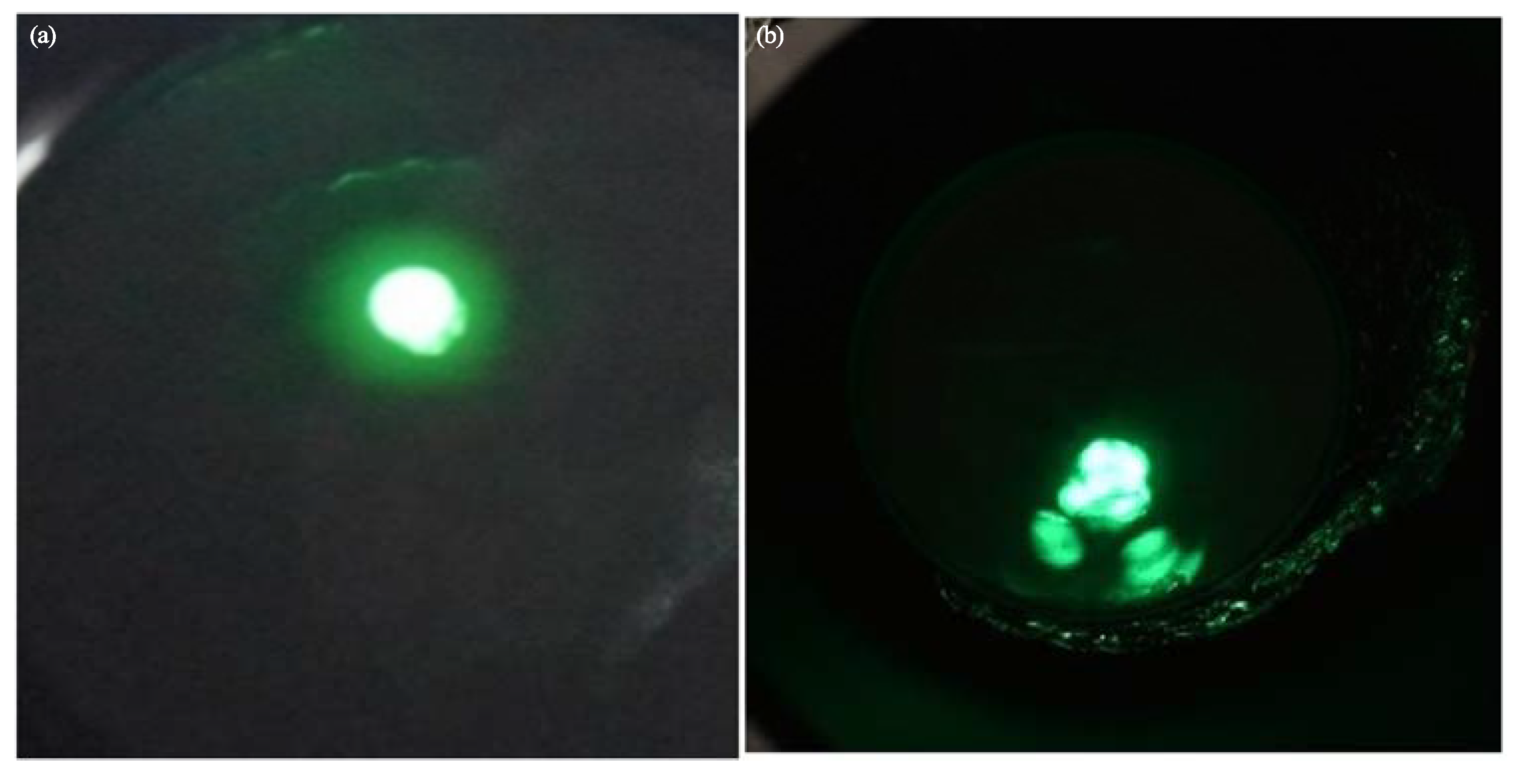

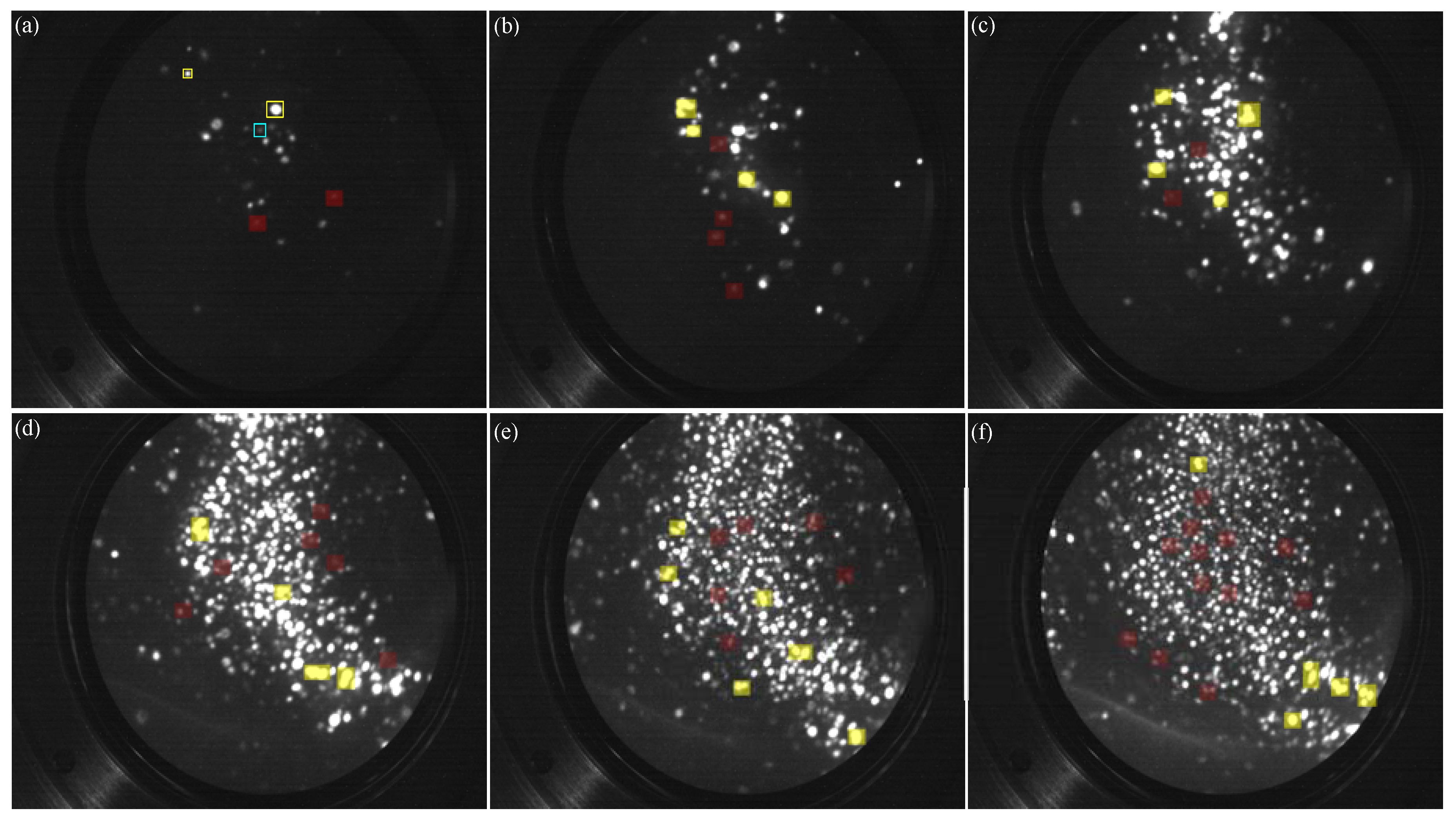

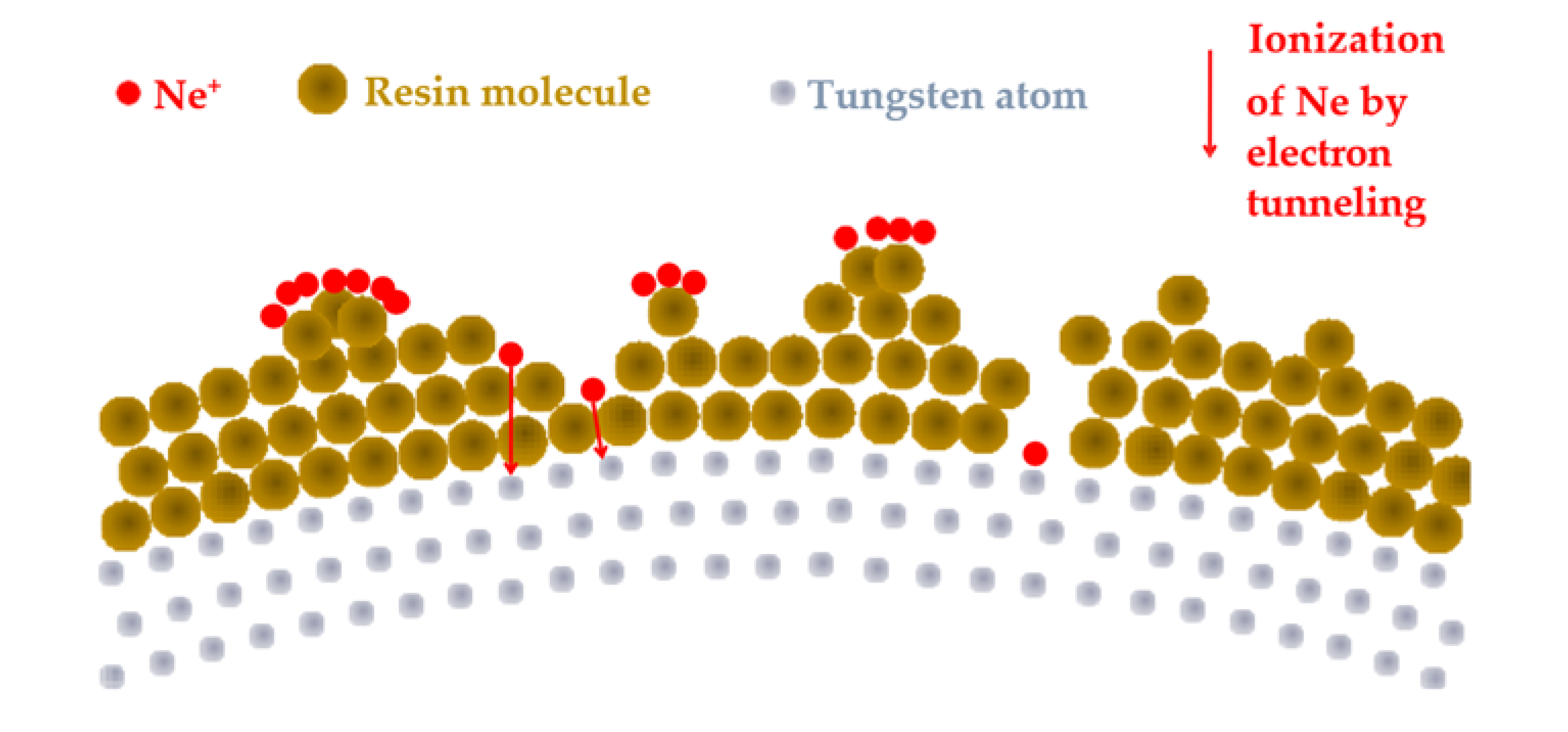

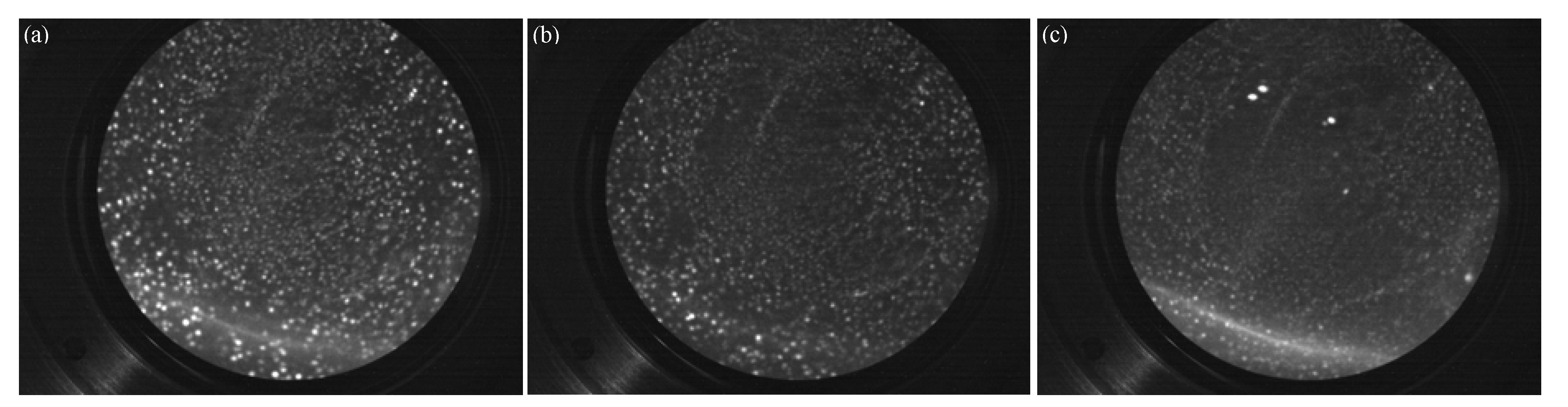

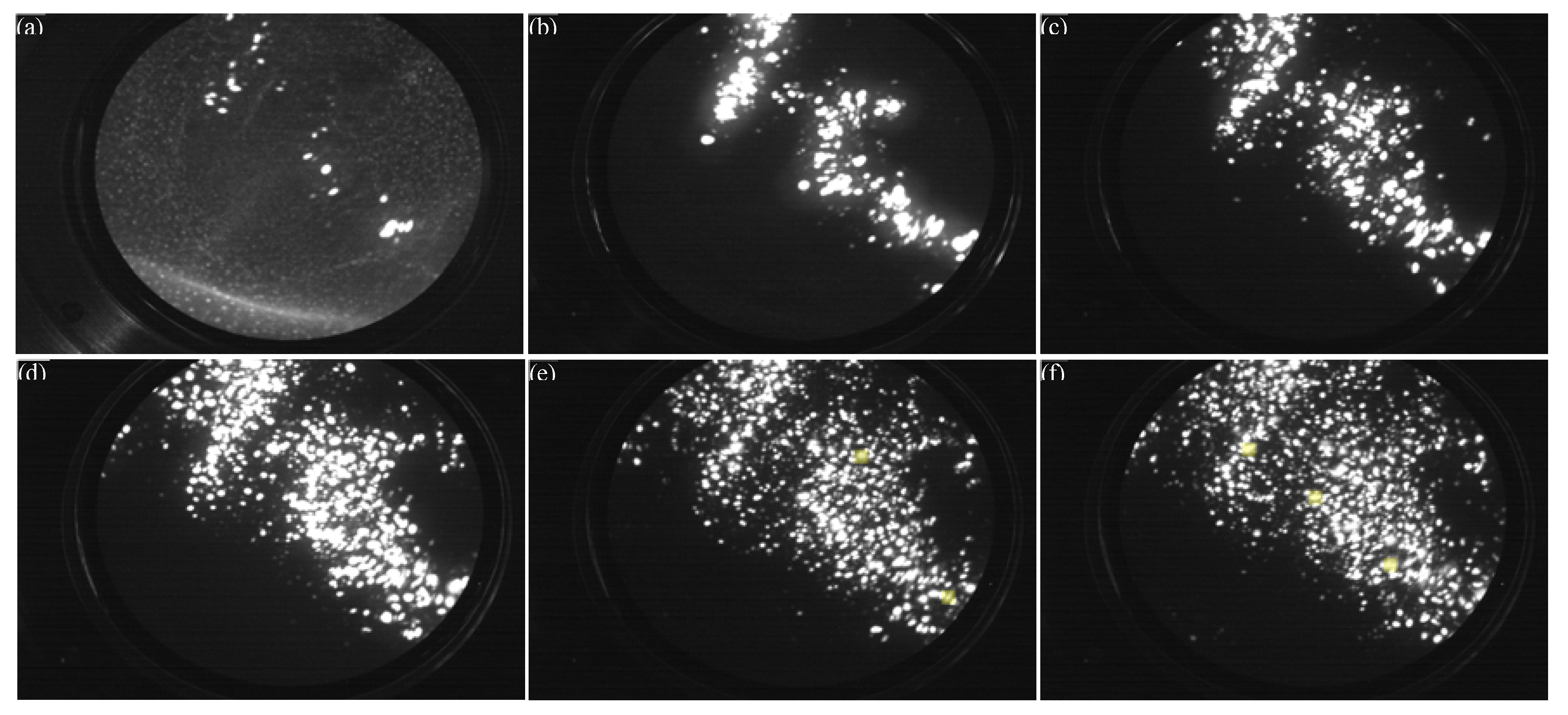

3.1. Field Ion Microscopy

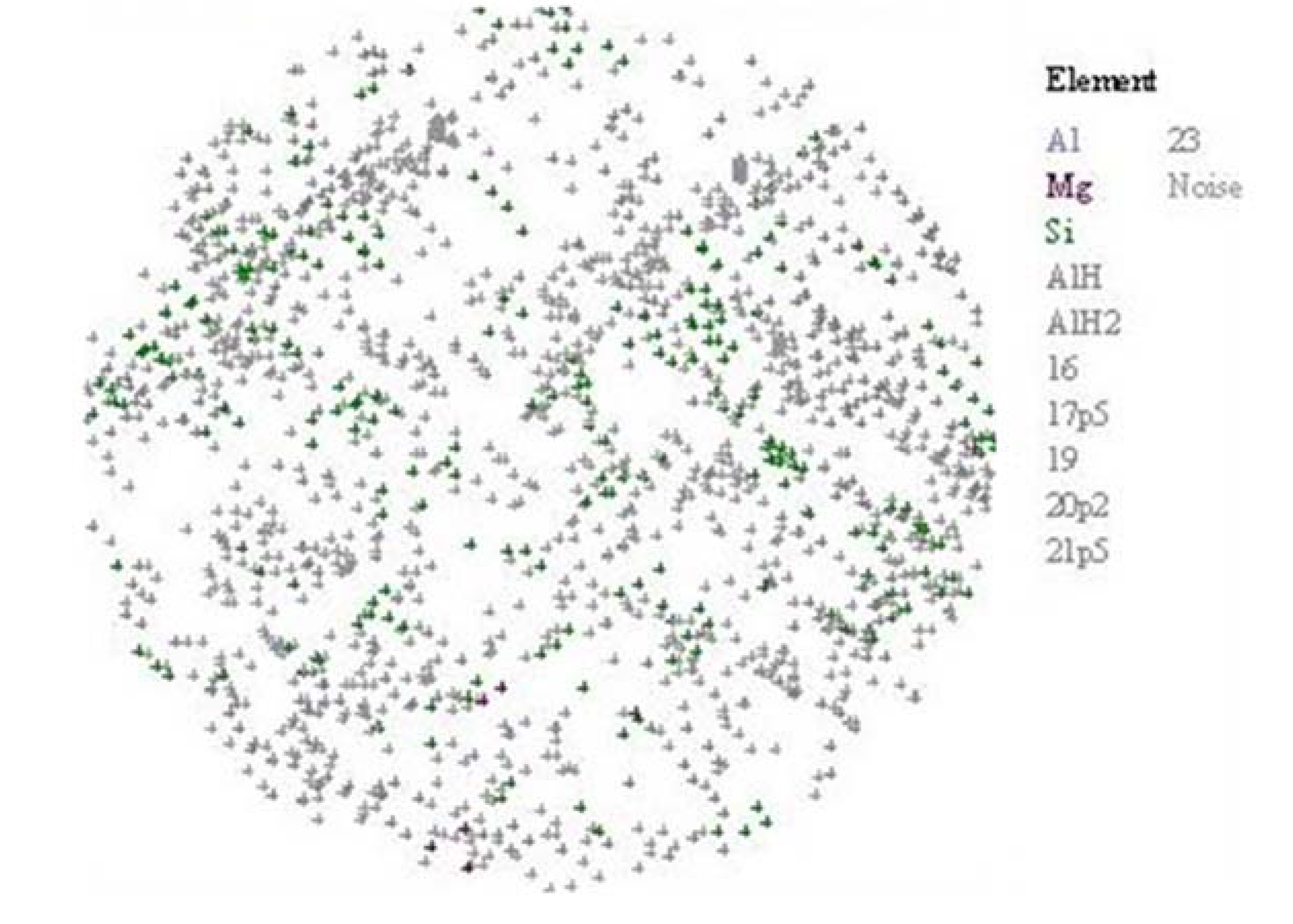

3.2. Atom Probe Tomography Analysis

5. Conclusions

Author Contributions

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- R. G. Forbes, Field electron and ion emission from charged sur- faces: a strategic historical review of theoretical concepts, Ultramicroscopy 95 (2003) 1–18. [CrossRef]

- R. H. Fowler, L. R. H. Fowler, L. Nordheim, Electron emission in intense electric fields, Proc. R. Soc. Lond. A 119 (1928) 173–181. [CrossRef]

- ERev. 102 (1956)1464- 1473. [CrossRef]

- M. M. Allaham, R. G. M. M. Allaham, R. G. Forbes, A. Kn´apek, D. Sobola, D. Burda, P. Sedl´ak, M. S. Mousa, Interpretation of field emission cur- rent–voltage data: Background theory and detailed simulation testing of a user-friendly webtool, Mater. Today Commun. 31 (2022) 103654. [CrossRef]

- C. Oshima, R. C. Oshima, R. Souda, M. Aono, Y. Ishizawa, Stable field electron emission from a tungsten tip under the ultrahigh vac- uum of 10−10 pa, Appl. Phys. Lett. 43 (1983) 611. [CrossRef]

- P. S. Mikhailov, I. L. P. S. Mikhailov, I. L. Muzyukin, Field electron emission from a nanostructured tungsten surface, J. Phys.: Conf. Ser. 2064 (1) (2021) 012059. [CrossRef]

- Z. Xu, L. Z. Xu, L. Zeng, Y. Zhao, R. Cheng, X. Zhang, J. Ren, X. Zhou, X. Wang, Y. Lei, Y. Li, Y. Yu, X. Liu, G. Xiao, F. Li, Electron emission from tungsten surface induced by neon ions, J. Phys.: Conf. Ser. 488 (13) (2014) 132032. [CrossRef]

- M. A. Madanat, M. S. M. A. Madanat, M. S. Mousa, A. N. Al-Rabadi, A. Fischer, Electron microscopy-based performance evaluation of various tungsten field-emitter tips apex radii, Jordan J. Phys. 8 (2) (2015) 79–85.

- Kna´pek, R. Dallaev, D. Burda, D. Sobola, M. M. Allaham, M. Hora´ˇcek, P. Kaspar, M. Matˇejka, M. S. Mousa, Field emission properties of polymer graphite tips prepared by mem- brane electrochemical etching, Nanomaterials 10 (2020) 1–12. [CrossRef]

- T. Boll, K. T. Boll, K. A, Unocic, B. A. Pint, K. Stiller, Interfaces in oxides formed on nialcr doped with y, hf, ti, and b, Microsc. Microana 173 (2017) 396–403. [CrossRef]

- E. W. Mu¨ller, Field ion microscopy, Science 149 (3684) (1965) 591–601.

- E. Mu¨ller, T. E. Mu¨ller, T. Tsong, Field ion microscopy, field ionization and field evaporation, Prog. Surf. Sci. 4 (1974) 1–139. [CrossRef]

- R. G. Forbes, Field evaporation theory: The atomic-jug for- malism, Surface Science 70 (1) (1978) 239–254. [CrossRef]

- E. Mu¨ller, Field ion microscopy of the platinum metals, Plat- inum Metals Rev. 9 (3) (1965) 84–89.

- T. Boll, T. T. Boll, T. Al-Kassab, Y. Yuan, Z. Liu, Investigation of the site occupation of atoms in pure and doped tial/ti3al inter- metallic, Ultramicroscopy 107 (2007) 796–801. [CrossRef]

- W. H. Escovitz, T. R. W. H. Escovitz, T. R. Fox, R. Levi-Setti, Scanning transmission ion microscope with a field ion source., Proc. Natl. Acad. Sci. 72 (5) (1975) 1826–1828. [CrossRef]

- R. V. Latham, M. S. R. V. Latham, M. S. Mousa, Hot electron emission from com- posite metal-insulator micropoint cathodes, J. Phys. D: Appl. Phys. 19 (1986) 699. [CrossRef]

- M. S. Mousa, Field electron emission studies on zinc oxide coated tungsten microemitters, Surf. Sci. 266 (1992) 110–120. [CrossRef]

- F. Yunyun, L. F. Yunyun, L. Xu, Z. Wankun, Z. Yuxuan, Y. Yunhan, Q. Honglin, X. X. W. Fan, Spinel comn2o4 nanosheet ar- rays grown on nickel foam for high-performance supercapaci- tor electrode, Surf. Sci. 357, Part B (2015) 2013–2021. [CrossRef]

- K. H. Bayliss, R. V. K. H. Bayliss, R. V. Latham, An analysis of field-induced hot-electron emission from metal-insulator microstructures on broad-area high-voltage electrodes, A. Math. Phys. Sci 403 (1986) 285–311. [CrossRef]

- Alsoud, A. Kna´pek, M. S. Mousa, Analysis of the various effects of coating w tips with dielectric epoxylite 478 resin or upr-4 resin coatings under similar operational conditions, Jor- dan J. Phys 19 (2020) 191–199.

- M. S. Mousa, A. S. M. S. Mousa, A. S. M, Study of the mgo-coated w emitters by field emission microscopy, Ultramicroscopy 79 (1999) 195–202. [CrossRef]

- Alsoud, R. AlBuqain, M. S. Mousa, Composite metallic nano emitters coated with a layer of insulator covered by au layer, Jordan J. Phys 13 (2020) 253–262. [CrossRef]

- M. Madanat, M. A. M. Madanat, M. A. Share, M. M. Allaham, M. S. Mousa, In- formation extraction from murphy–good plots of tungsten field electron emitters, J. Vac Sci. Technol. B 39 (2) (2021) 024001. [CrossRef]

- J. Li, Y. J. Li, Y. Wang, Z. Ran, H. Yao, B. Du, T. Takada, Molecular structure modulated trap distribution and carrier migration in fluorinated epoxy resin, Molecules 25 (2020) 1–8. [CrossRef]

- 26. S. Yu, S. Wang, M. T. Nazir, W. Wang, S. Li, T. Phung, T. Takada, Surface trap effects on flashover voltages of epoxy/al2o3 nanocomposites for high voltage insulation, Mater. Sci. Mater. Electron 30 (2019) 18135–18143. [CrossRef]

- M. S. Mousa, A. M. S. Mousa, A. Karpowicz, S. Surma, ’switch-on’ phenom-ena in field-electron and field-ion microscopy, Vacuum 45 (1994) 249–254. [CrossRef]

- V. N. Bliznyuk, D. V. N. Bliznyuk, D. LaJeunesse, A. Boseman, Application of helium ion microscopy to nanostructured polymer materials, Nanotechnol. Rev. 3 (4) (2014) 361–387. [CrossRef]

- R. Morgan, Field-ion microscopy of uranium dioxide, J. Mater. Sci. 5 (1970) 445–452. [CrossRef]

- C. Oberdorfer, G. C. Oberdorfer, G. Schmitz, On the field evaporation behavior of dielectric materials in three-dimensional atom probe: A numeric simulation, Microsc. Microanal. 17 (2011) 12–25. [CrossRef]

- W. A. Brainard, D. H. W. A. Brainard, D. H. Buckley, Adhesion of polymers to tung- sten as studied by field ion microscopy, Tech. rep., University of Zurich, Department of Informatics (71). 19 October.

- F. Cardarelli, Materials Handbook: A Concise Desktop Reference. Second edition, Springer, 2008.

- M. M. Allaham, Comprehensive analysis of e478 single- component epoxy resin and tungsten-e478 interface for metallic- polymer composite electron source applications, ACS Omega 9 (28) (2024) 30975–30985. [CrossRef]

- M. Mousa, K. M. Mousa, K. Lorenz, N. S. Xu, In situ observation of the transition process from cold to hot electron emission during field emission assisted vacuum deposition of polymer on w tips, Ultramicroscopy 79 (1999) 43–49. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).