1. Introduction

Wastewater management is a critical challenge in modern societies, particularly in the context of urban areas and industrialized regions, with the increasing volume and complexity of waste generation posing a threat to the environment and human health. Effective management of wastewater is essential for maintaining environmental health, conserving water resources, and mitigating the impact of pollutants. Understanding waste streams and their composition is key to optimise wastewater management strategies. In this context, the accurate prediction of waste streams composition is crucial for the development of targeted interventions to divert materials from landfill disposal [

1].

Conventional waste management techniques have proven inadequate, leading researchers to explore innovative solutions to address this pressing issue.

In the quest to address the global challenge of food waste and its environmental impact, researchers have increasingly turned to AI-based approaches to automate and optimize waste management processes.

Previous studies have explored the application of artificial intelligence and machine learning techniques in the context of waste and wastewater management.

Researchers have demonstrated the ability of neural networks to assess the reuse potential of wastewater [

2,

3,

4] highlighting the ability of these models to capture the non-linear, uncertain, and time-varying nature of wastewater treatment systems [

5,

6,

7]. Furthermore, comparative studies have revealed the superior performance of decision tree algorithms and gradient boosting machines in predicting total nitrogen levels in wastewater, a critical parameter in nutrient removal and treatment plant optimization [

8].

The application of machine learning algorithms, including neural networks, has shown promise in improving municipal solid waste management [

9]. Furthermore, the use of advanced sensing and monitoring technologies, such as wireless sensor networks, can provide valuable data for optimizing waste management strategies [

10]. Additionally, efforts are being made to improve the robot’s structure, sensors, waste classification algorithms, and robotic arms to make them more effective and efficient. Sensor-based waste monitoring is a technology that utilizes sensors to track the amount of waste generated, identify the sources of waste, and measure the effectiveness of waste management strategies in a specific area. Sensor-based waste monitoring and classification systems have been developed to enhance the efficiency of waste management in smart cities [

10]. Recent studies have explored the use of deep learning and neural networks for various waste management applications, including waste segregation, classification [

11] and prediction [

4].

Deep learning techniques have also been employed to classify and quantify food waste, a significant component of municipal solid waste [

12]. Several models were proposed and assessed for their high accuracy and precision rates in waste classification, including RWNet [

13], Garbage Classification Net [

14], Faster Region-Based Convolutional Neural Network [

15], and ConvoWaste [

16]. Some studies also incorporate IoT [

17] and waste grid segmentation mechanisms [

18] to classify and segregate waste in real-time.

In this context, vermicomposting, a process that utilizes earthworms to convert organic waste into nutrient-rich compost, has gained increasing attention as an eco-friendly and viable solution for managing municipal solid waste and wastewater sludge but also as an extensive approach for restoring the environment, producing nutrient-rich bio-fertilizers, and growing crops in a sustainable manner [

19].

The potential of vermicomposting as a solution for sustainable waste management has been well-documented [

20,

21]. Vermicomposting utilizes earthworms as a natural bioreactor to transform organic waste, such as household and kitchen waste, into a valuable soil amendment [

21]. Feeding, stocking density, pH, C/N ratio, temperature, and moisture are critical factors that influence the vermicomposting process [

22]. To enhance the efficiency of vermicomposting, it is essential to accurately predict the optimal time for harvesting the vermicompost. Chromatographic analysis of vermicompost can indicate the mature condition of the compost materials [

20]. However, the complex interactions between the various environmental factors make it challenging to precisely determine the optimal harvesting time [

23].

Neural networks, with their ability to model non-linear relationships, have the potential to address this challenge. Recent advancements in artificial intelligence and machine learning have opened up new possibilities to assist in predicting waste generation from vermicomposting processes and to enhance its efficiency [

24].

The first step in developing the neural network model is to establish a robust dataset for training and validation. The work of [

25] on improving the deployment of recycling classification through efficient hyper-parameter analysis provides a valuable benchmark for the model’s performance.

According to Sim & Wu [

21], the study of the neural network structure within vermicomposted waste can provide valuable insights into the decomposition and transformation processes occurring during this sustainable waste treatment method.

Senthil Kumar et al. [

20] integrated deep learning algorithms and scanning electron microscopy analysis to investigate the structural changes and compositional dynamics of vermicomposted waste.

Embalzado et al. [

26] developed an Automated Vermicomposting System (of Proper Waste Ratio + MCU Vermicomposting Bed) and concluded that the produced Vermicompost had a high content of Nitrogen, medium content of Phosphorus, and sufficient content of Potassium and that the prototype has faster processing of Vermicomposting due to the Waste Ratio input.

To address the issue of accurately predicting the optimal time for harvesting the vermicompost, the primary objective of this study is to develop a robust and accurate model for predicting waste generation and composition in the vermicomposting process, thereby enhancing the overall efficiency and sustainability of this waste management technique.

In this paper, we propose a novel paradigm for waste prediction in the vermicomposting process, leveraging the power of neural networks and a unique processing schema based on gallium arsenide technology. The proposed approach combines the benefits of neural network-assisted waste prediction with the advantages of the Gallium Arsenide Processing Schema. The Neural Network Skeleton is used to predict the composition of waste, with a particular focus on fine separation and destructive processes. Gallium Arsenide is a semiconductor material known for its high efficiency and performance, making it an attractive choice for various applications, including waste management systems.

By leveraging the power of neural networks, this study seeks to contribute to the understanding of the intricate relationships between the microstructural changes, decomposition patterns, and the overall effectiveness of the vermicomposting process; it also aims to accurately predict the composition of the waste stream, enabling more efficient resource recovery and reducing the environmental impact of the process.

The main contributions of this study are as follows.

1. A Neural Network-assisted novel paradigm is proposed to predict waste from vermicomposting. The proposed Neural Network Skeleton is based on a Gallium Arsenide Processing Schema, used to separate wastes

2. Classification and separation processes are performed based on chemical liability reactions.

In summary, this comprehensive analysis provides valuable insights for the advancement of efficient and sustainable waste management practices in the context of vermicomposting and beyond.

2. Materials and Methods

2.1. Vermicomposting Process and Its Relative Components

Vermicomposting is a special process that uses the combined activity of earthworms and microorganisms in their stomach to turn organic wastes into vermicompost or organic fertilizer. Vermicompost is a nutrient, microbes and plant growth promoting rich organic substance that enhances crop yield and maintains soil heath [

27]. Similar to traditional composting, vermicomposting necessitates the presence of oxygen as it is an aerobic process [

28].

Decomposable organic wastes such as animal excreta, kitchen waste, farm residues and forest litter are commonly used as composting materials. In general, animal dung mostly cow dung and dried chopped crop residues are the key raw materials. Mixture of leguminous and non-leguminous crop residues enriches the quality of vermicompost. Raw materials are utilized by earthworms to aid in their decomposition, where they can only be consumed under conditions of prolonged moisture. Moisture content during the bio conversion process must be maintained between 45-75% for optimal reproduction and activity of the earthworms [

29]. Optimum temperature for suitable earthworm species used in vermicomposting ranges from 15 to 30 °C. At temperature below 10 °C, feeding and other developmental activities get reduced and further below 4 °C, cocoon production and growth rate of earthworm stops [

30]. When raw material is completely decomposed it appears black and granular. Watering should be stopped as compost gets ready. The compost shout be kept over a heap of partially decomposed cow dung so that earthworms could migrate to cow dung from compost. After two days compost can be separated and sieved for use.

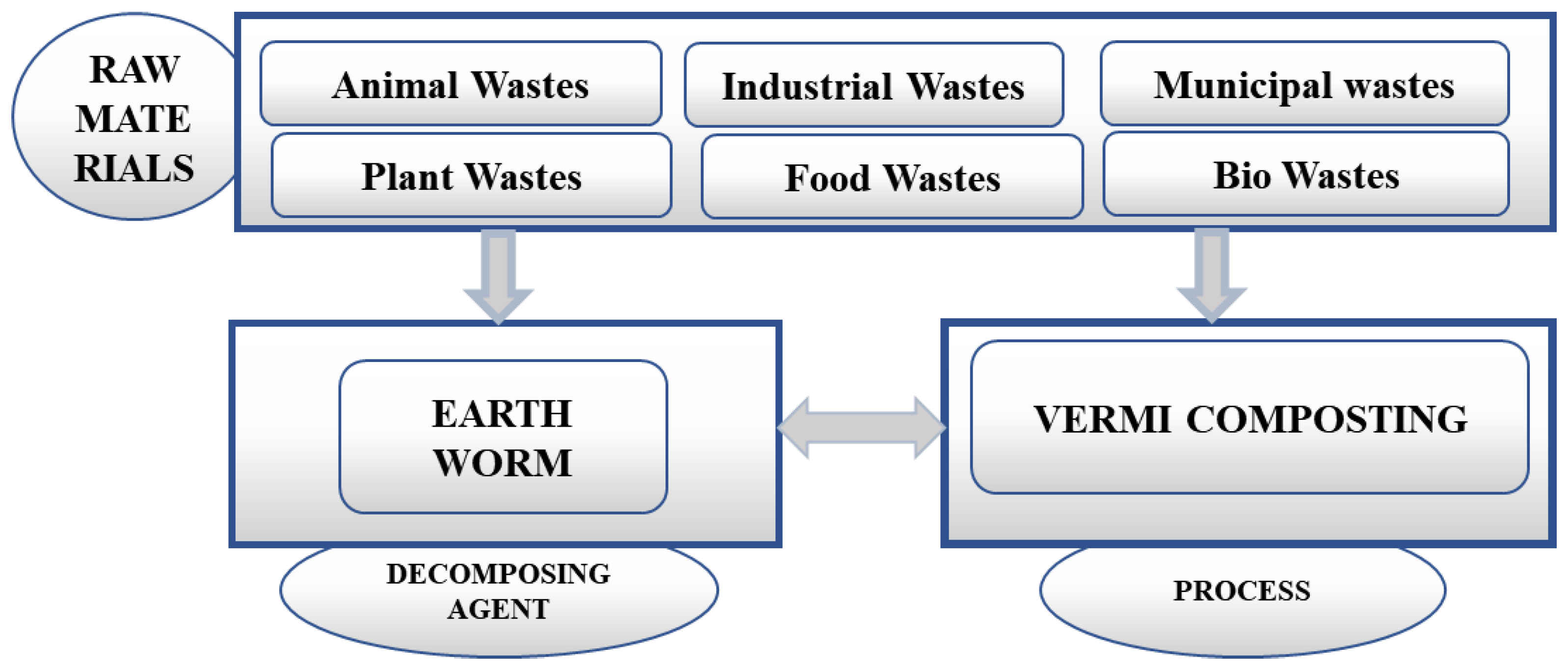

A flow chart for the vermicomposting procedure, depicted in

Figure 1, was developed for this study.

2.2. Vermicomposting Layers

In addition, different methods of soil extraction for soil composting are also studied, culminating in the effective organic layers of the soil composting form for the vermiculture bed or vermi bed.

A layer of fine sand (3 cm) should be spread over the culture bed followed by a layer of garden soil (3 cm). All layers must be moistened with water. Shredded paper or cardboard, straw, and leaves makes an excellent bedding, particularly when combined with typical on-farm organic resources such as straw and hay.

This makes an ideal environment for earthworms to live in and complete their composting tasks. A first layer of sawdust, newspaper, straw, coir waste, sugarcane trash, etc. can be placed at the bottom of the tub or container to prepare the vermi bed. Newspaper is one bedding material with a high absorbency level, while sawdust has a poor to medium absorbency level.

The vermi beds may have several layers. Earthworms can use this to break down waste. Layer 1 can be processed using rapidly decomposing materials like wood shavings, coconut shells, and shed leaves. The next layer of decomposing leaves for layer 2 was made up of particles with rice straw and cow dung, as well as any other materials with layer 1 of the vermicomposting process.

Layers can be filled with solid cow dung, and materials that can be partially moisturized can be covered with layers of vermi beds that can be moistened over a period and can be used with vermi beds [

31]. For earthworms, layers can be used in moist environments. Waste materials can be slowly decayed by covering them with jute fibers for a period of 60 to 70 days.

The leachate derived from vermicomposting units is called vermiwash. It is a naturally occurring product with a brown color that is rich in plant nutrients and can be used as liquid fertilizer. Furthermore, the composition of its humic acid aids in the development of plants. Earthworms can be very effective in digestion and waste excretion as layers of the vegetable compost process. This process is used in the neural network approach to predict waste layers and determine which specific waste materials to use as bedding for an effective waste management procedure.

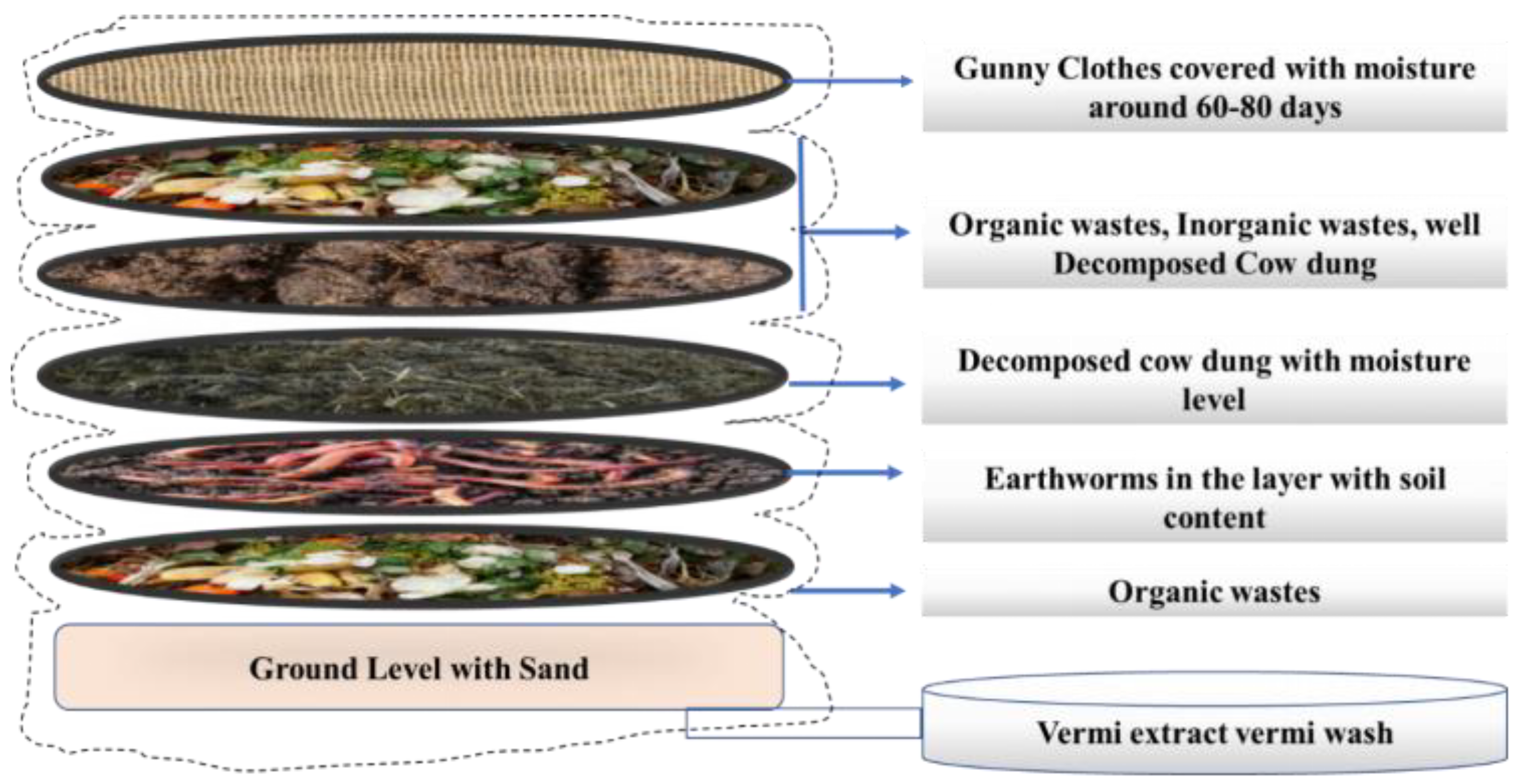

Figure 2 illustrates how vermi bed layers are used in the vermicomposting process. These layers are primarily made up of organic wastes, which have a significant impact on the entire soil to vermicomposting process [

32]. Wastes can be found in layers that can be transformed into waste found in soil by earthworm digestion components, nutrients, and mineral-enriched soil.

Jutes and gunny sack components help keep the soil balanced and moist, allowing these layers to be preserved in a closed environment [

33].

2.3. Prediction of Wastes on Vermi Bed Layers

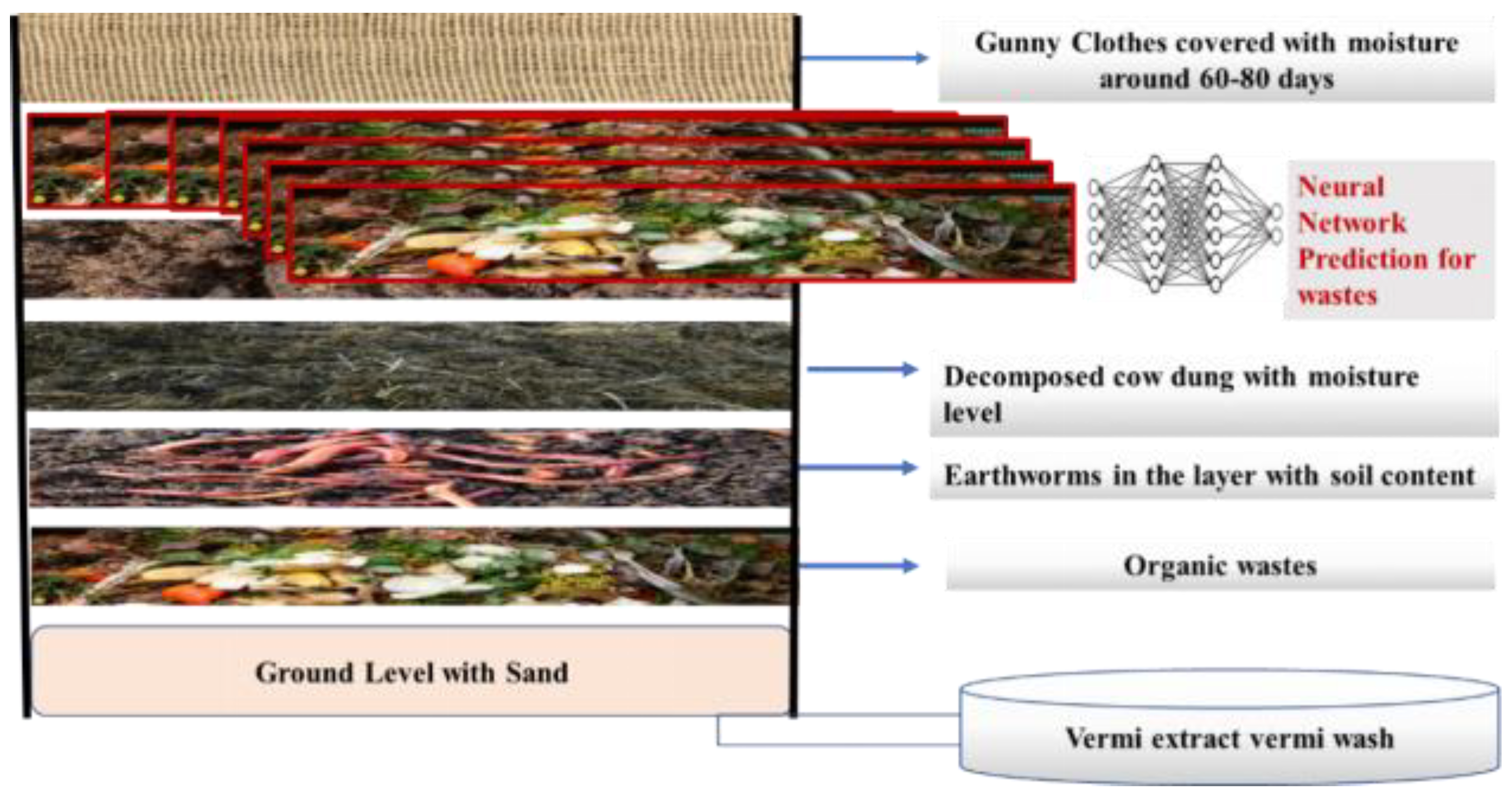

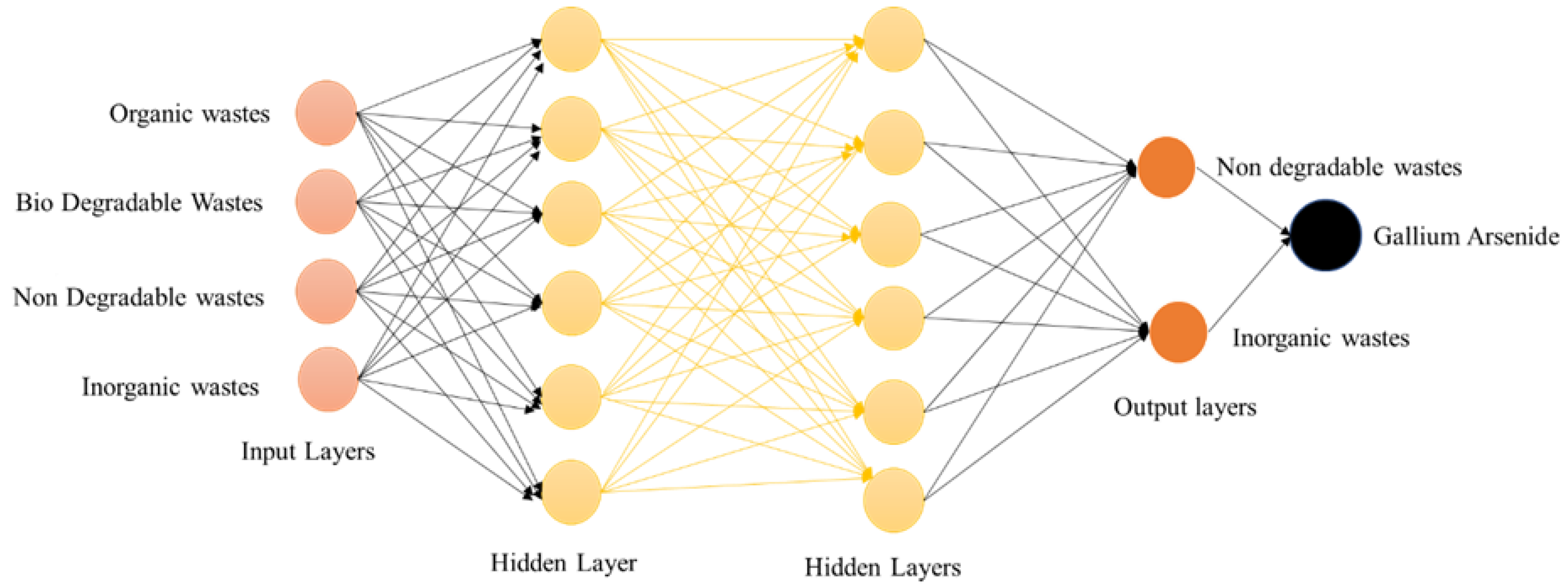

Neural networks are used for prediction of wastes in vermi beds by using the processed layer illustrated in

Figure 3.

As layers in the vermicomposting process, earthworms can use it very effectively for the digestion and excretion of waste.

The processes described in the previous paragraph are used in the neural network approach to predict waste layers and determine which specific waste materials to use as bedding for an effective waste management procedure.

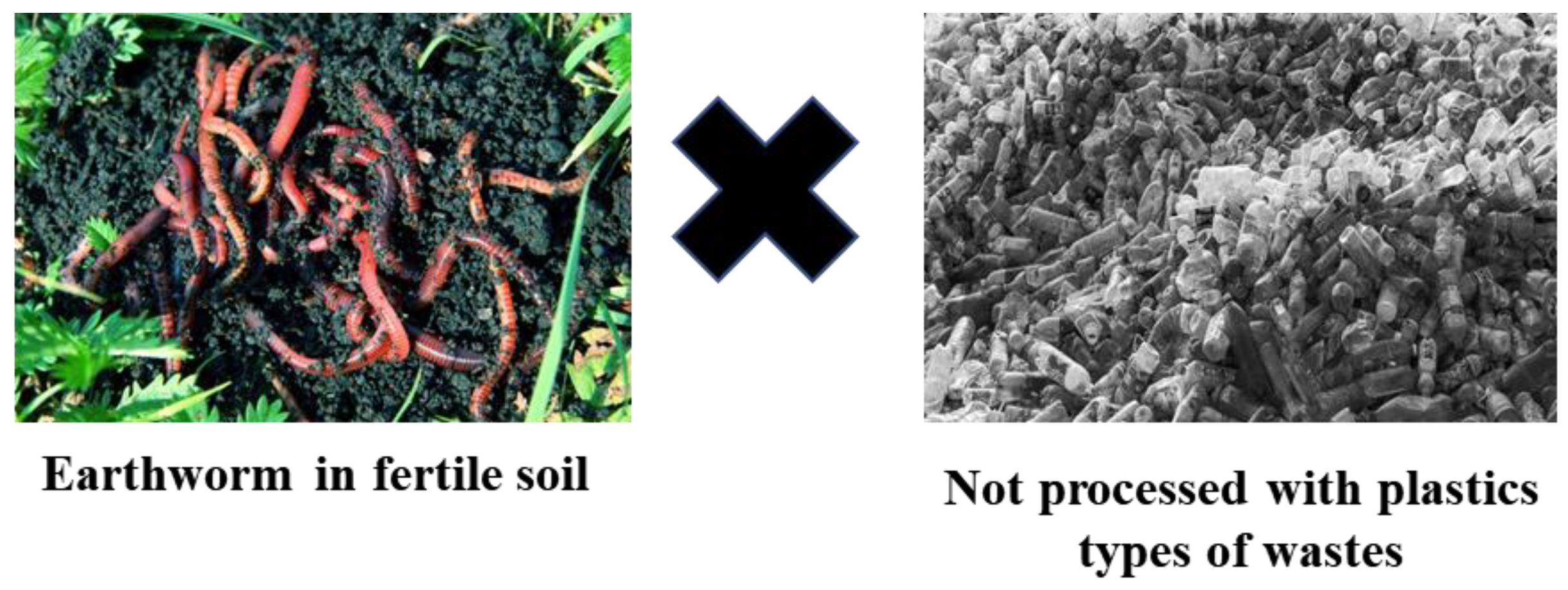

Figure 4 shows the earthworm types of digestive particles with biodegradable, not non-biodegradable, plastic wastes. Thus, it can be separated using a neural network approach [

34].

As different forms of waste can be processed with neural network processes to the pool,

Figure 5 demonstrates how the process of vermicomposting to layers can be defined by neural network processing of input layers. In order to specify a way of removing waste particles for various gallium arsenide separation schemes for chemical processing with a balanced waste management process, hidden layers can be used in conjunction with the output process [

35]. The prediction algorithm can be applied to time series of bio- and non-bio-waste prediction using a Shallow Neural Network (SNN).

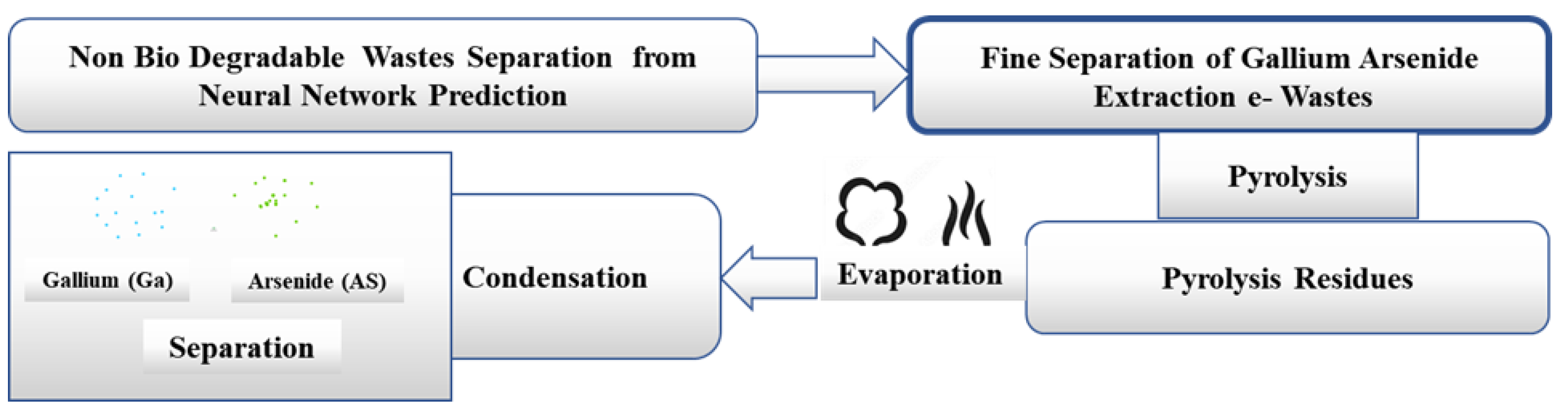

2.4. Gallium Arsenide Processing Schema from GaAs Wastewater Separation Wastes

Gallium is a material composed of metals, which can be soft, silvery-white metals like aluminum, as silicon-like arsenide can be mixed with it. It is useful as a replacement for items made by the electronic industry, such as integrated circuit chips and radio-and microwave particles, which are mostly employed in the production of electronic devices and gadgets for the electronic industry.

Neural networks can be used to separate gallium arsenide, and different solid waste management systems can be used to process it. Only biodegradable wastes that are primarily used for vermicomposting earthworm digestive tracts can be categorized as waste products. Only bioproducts that are suitable for vermicomposting are secreted by these earthworms [

36]. In addition to affecting earthworm fertility toward vermicomposting, this approach cannot replicate proper digestion and excretion of waste management to the vermicomposting process if waste particles are to be implemented for the operation of the entire vermicomposting ecosystem.

Figure 6 illustrates the approach used to extract waste products for non-biodegradable waste materials. The process of using non-biodegradable waste materials for the careful separation of the pyrolysis method—which can be used to find pyrolysis residues—for the study’s conclusion is covered in [

37]. It can be applied as a vaporization method for managing wastewater as well as a chemical separation method for removing gallium and arsenide materials from the wastewater management system. Balz-Schiemann reaction can be used to process the finalization by-products of resultants with chemical balancing, as well as proof of chemical equilibrium, in order to further move to the operation of technological implementation.

Chemical formulas for this approach can be expressed as follows: benzene diazonium chloride or diazonium salt with fluoric acid can be balanced, and aryl fluoride and diazonium fluoroborate can be precipitated with heat precipitation of -N2 and -BF3 [

38]. The hybrid method of gallium arsenide (GaAs) and Balz-Schiemann can be used to apply the Balz-Schiemann reaction mechanism in chemical formulas. Gallium can be used in conjunction with wastewater separation to observe a reaction that will allow states to use it for the chemical equilibrium of liability in the process:

Chemical processing can make use of the above equation for the gallium arsenide process with N2 and BF4 sediment. Therefore, waste and chemical processing can be separated from the vermicomposting layers, and (GaAs) wastewater can be separated according to processed wastewater types. When combined with an artificial neural network, the system can be utilized for effective waste management. On the other hand, pyrolysis waste management techniques can be used to separate waste materials that are not used for vermicomposting [

39].

Therefore, waste management and wastewater separation through chemical processing are possible with the recently developed (GaAs) method.

3. Results and Discussion

A Neural Network Skeleton is used to estimate the suggested chemical processing for waste management in vermicomposting. This study uses a dataset of 24,705 solid household wastes that have been divided into two classes: recyclable (10,825) and organic (13,880). The initial dataset was created by Sashaank Sekar and is accessible via this link:

https://www.kaggle.com/techsash/waste-classification-data [

40].

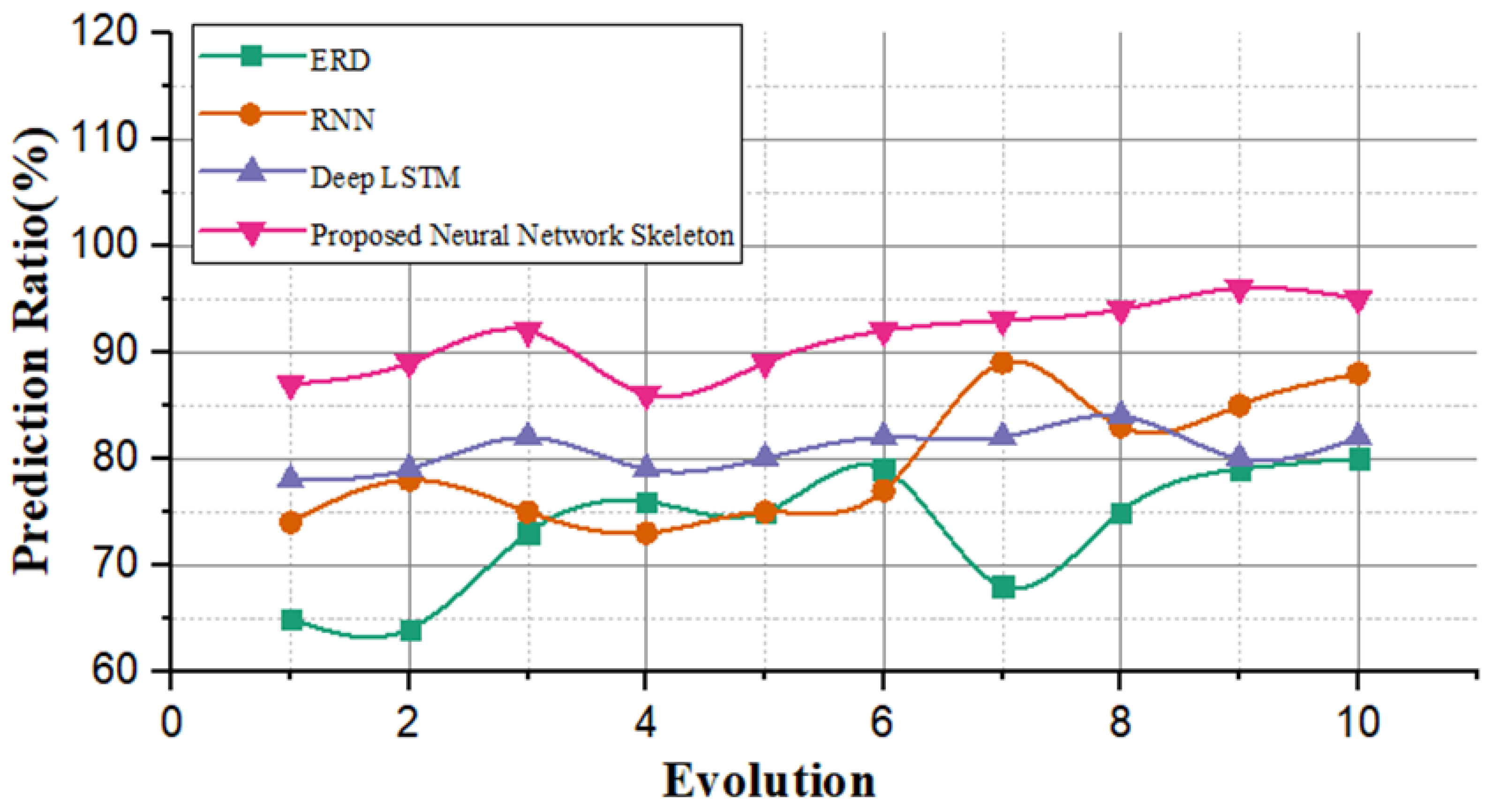

Then, based on a number of parameters, a performance comparison analysis was carried out between the proposed methods and the existing ones such as recurrent neural network (RNN), deep long short-term memory (Deep LSTM), and code-Recurrent decoder (ERD). The Prediction Ratio, Separation Ratio, Prediction Accuracy and Separation Accuracy are estimated.

Table 1 shows the percentage prediction ratio of the suggested method compared to our current procedure. Compared to ERD, RNN, and Deep LSTM, which have average prediction ratios of 73.4%, 79.7%, and 80.8, respectively, our suggested method has the highest average prediction ratio of 91.32%.

Figure 7 shows the prediction ratio of various classification techniques in vermicomposting based on an increasing evolution count.

As the prediction ratio increased in percentage terms, the evolution counts also increased. Prediction ratios for the ERD, RNN, Deep LSTM, and Proposed Neural Network skeleton approaches were 65%, 74%, 78%, and 87% for the first 1 evolution, respectively. Our proposed neural network skeleton achieves a prediction ratio of 92% after more than five evolutions, which is 13% better than ERD, 15% better than RNN, and 10% more efficient than Deep LSTM methods. Compared to the other approaches, our suggested system produced a 95% prediction ratio of waste in the tenth and final evolution process. According to the aforementioned assertion, our suggested approach is more efficient than the other methods in terms of prediction ratios. After that, the proposed Gallium Arsenide Processing methods are used to separate wastes.

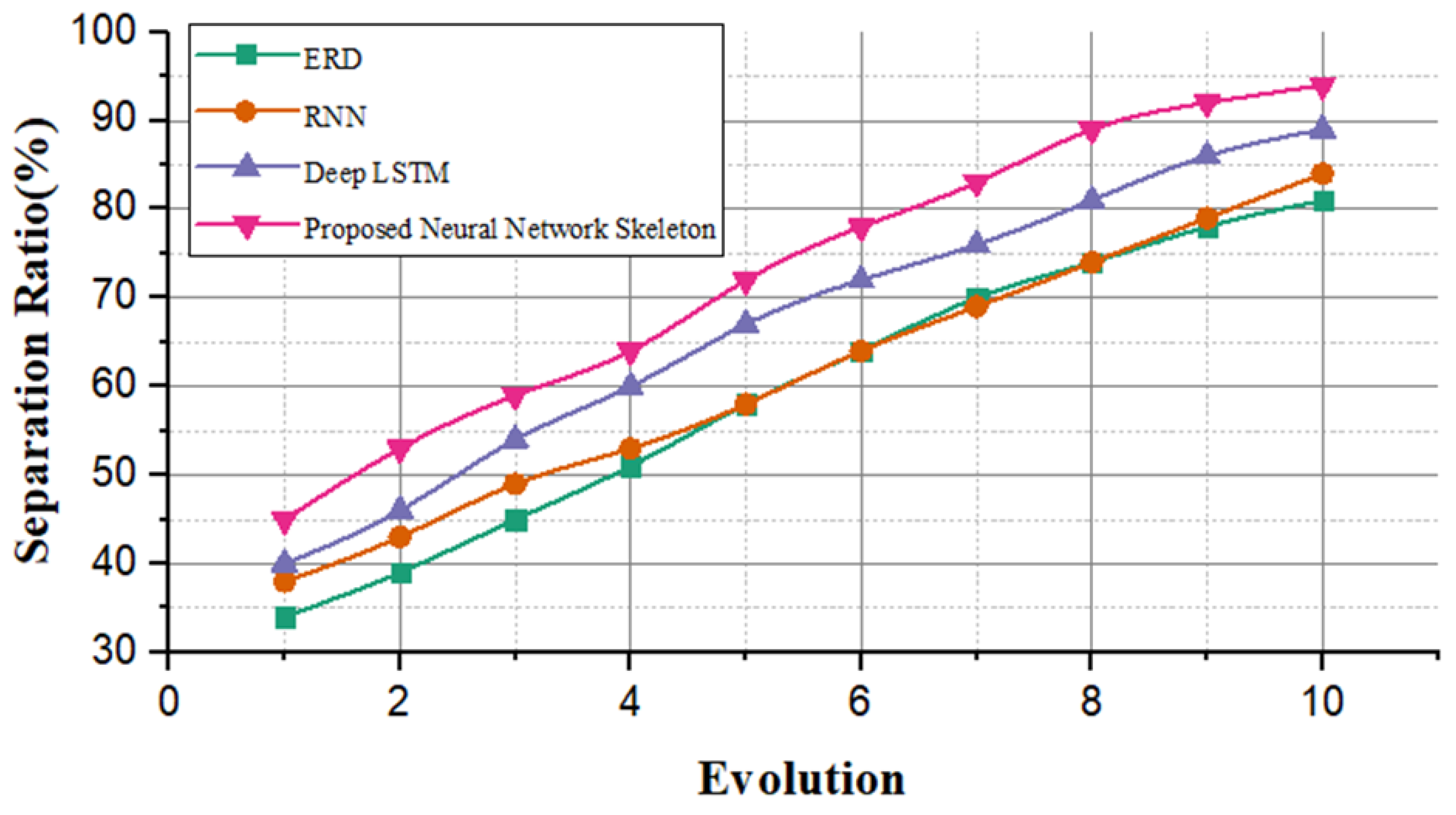

The separation ratio is the amount of material reduction that shows how the removed materials impact the measurement precision in percentage.

Table 2 compares the suggested approach with current techniques for the separation of waste.

Figure 8 illustrates the separation ratio of wastes during vermicomposting using four different methods.

The RNN spans from 38% to 845, while the ERD ranges from 34% to 81%. The deep LSTM’s accuracy varied from 40% to 89%. On the other hand, the separation ratio of our proposed method was 45–94%. As can be seen from the graph, separation ratios are derived by increasing count evaluation from 10 to 100. A higher separation ratio denotes better system performance, a lower value denotes lower performance and operation to reach the optimum value. Therefore, for each evolution, the suggested method offers a wider range of separation ratios for waste from vermicomposting.

Also, the chemical processing of waste management is analysed. When reactants and products are present in a chemical reaction at concentrations that do not seem to change over time, the system’s properties remain unchanged. This is known as chemical equilibrium. The Prediction accuracy can be defined as the difference between the observed value and the predicted value:

Prediction accuracy= Observed value -Predicted value

The prediction accuracy for waste was determined by subtracting the observed and predicted values.

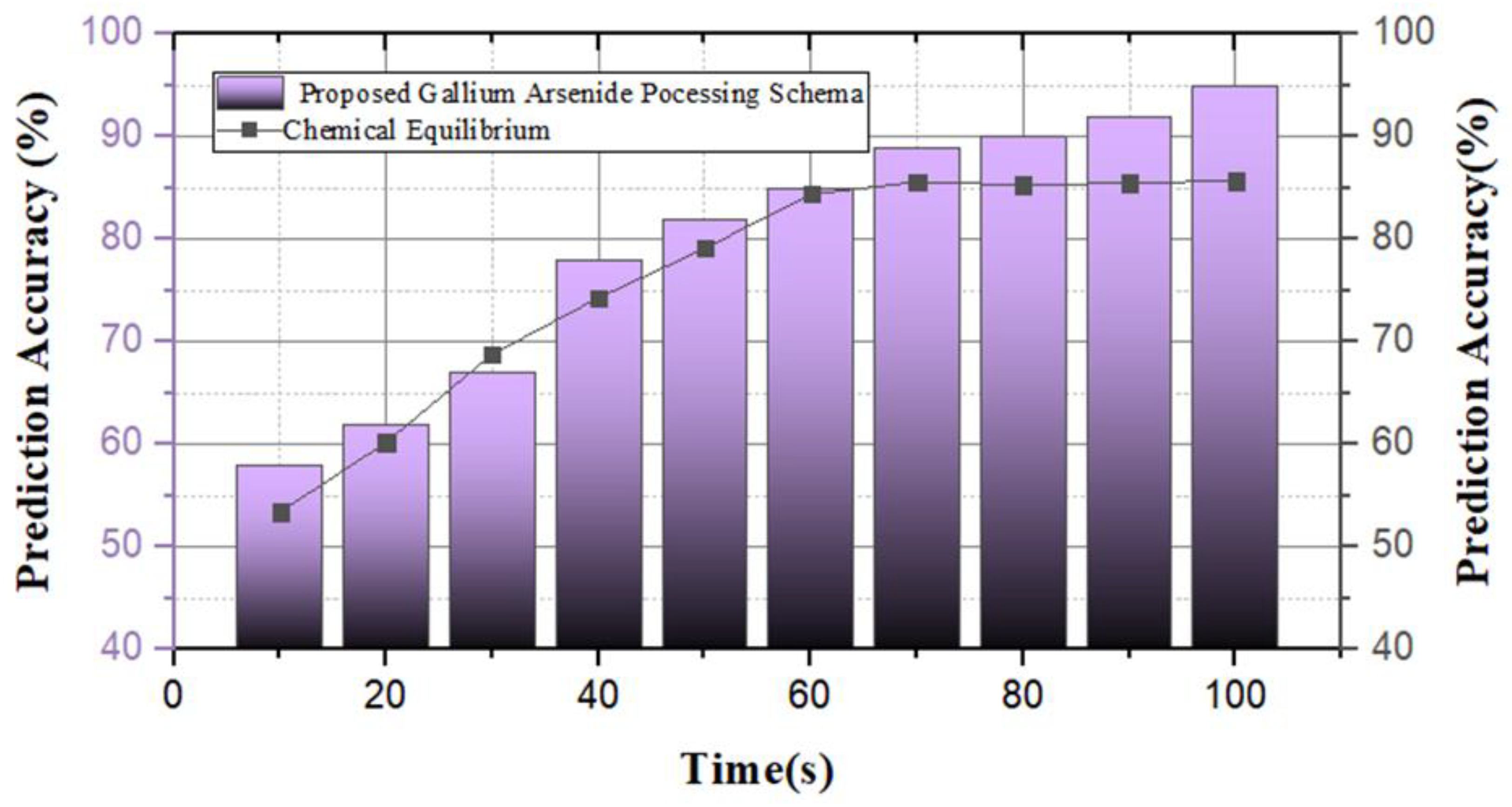

Table 3 shows the prediction accuracy of our proposed gallium arsenide processing scheme using the existing methods.

Figure 9 illustrates the waste management prediction accuracy based on time(s) increases of up to 100 (s)

In a GaAs waste management system, the technique of interruption of operation is utilized to preserve chemical equilibrium throughout a chemical reaction. After a period of time, the chemical equilibrium of this chemical reaction and forward action is reached at 70s with an 85% prediction accuracy, starting at 53% at 10 s. Our suggested method’s chemical equilibrium keeps an accuracy of 85%–85.9%. According to

Figure 10, the suggested gallium arsenide processing schema has a prediction observance that rises linearly with time. Using the suggested gallium arsenide processing schema, the waste management prediction accuracy begins at 58% at 10s.

At 100s, it grows and reaches 95% prediction accuracy. The chemical equilibrium and gallium arsenide processing schematic of our suggested method are more accurately predicted in

Figure 10. Consequently, an analysis of the suggested system method’s separation accuracy is performed.

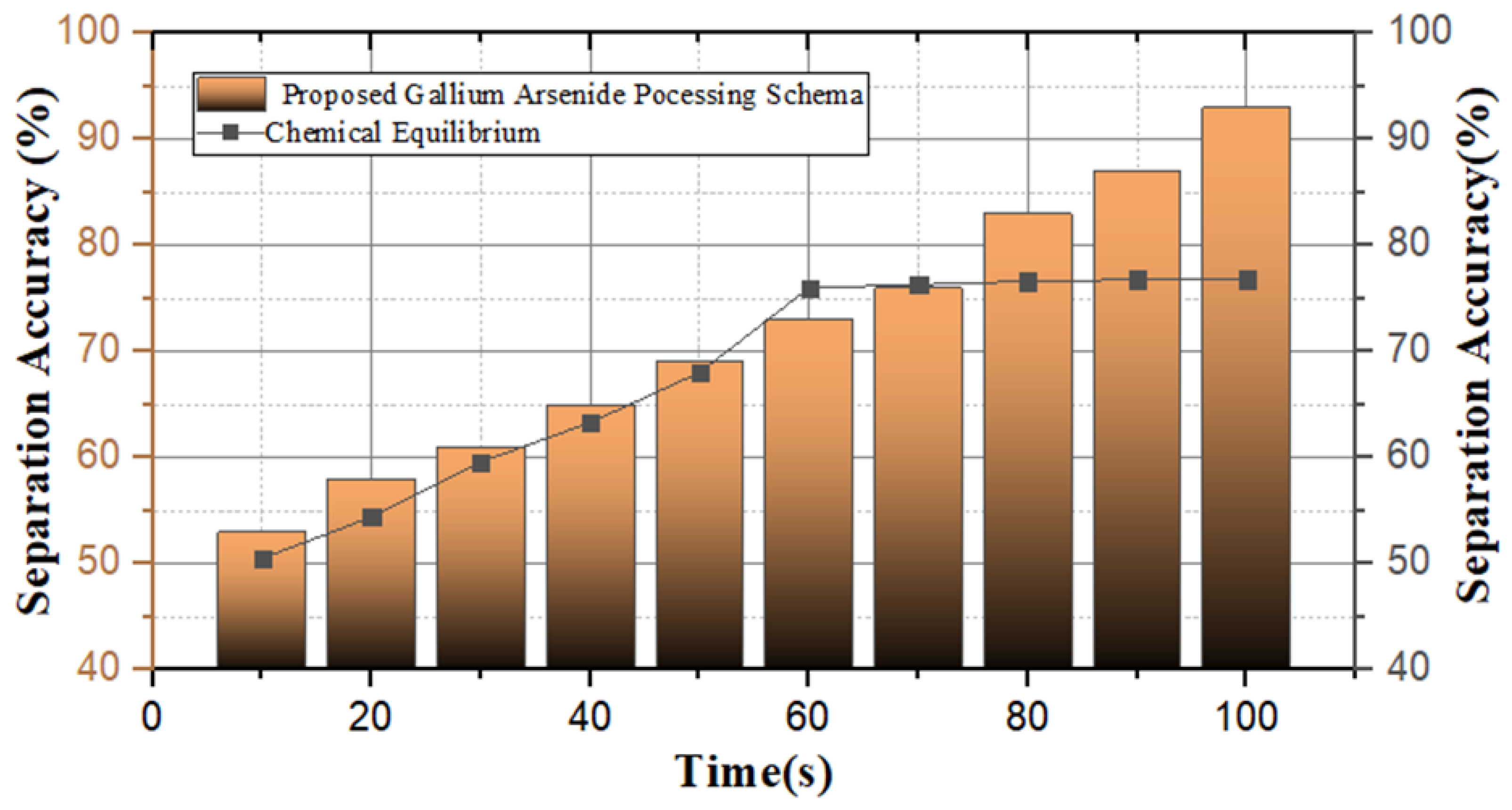

Table 4 compares the separation accuracy of our proposed Gallium Arsenide Processing Schema with existing methods.

Figure 10 illustrates how waste management’s separation accuracy varies with time, expressed in seconds. Waste prediction is important, but waste separation plays a more important role. In order to achieve a satisfactory level of waste separation, the froth flotation technique is applied in the GaAs wastewater separation method. Then, chemical equilibrium is followed by operation cessation, and the Balz-Schiemann reaction is used to support chemical liability. Chemical compensation for waste management separation accuracy increases linearly and is maintained at a particular time, with an approximate separation accuracy of 76%. This study demonstrates that the analysis of wastewater separation using our suggested gallium arsenide processing schema increases with time.

The waste separation accuracy was 53% at the beginning, rising to 93% at the end of the 10-second time interval. This leads us to the conclusion that our method provides a significant separation accuracy percentage.

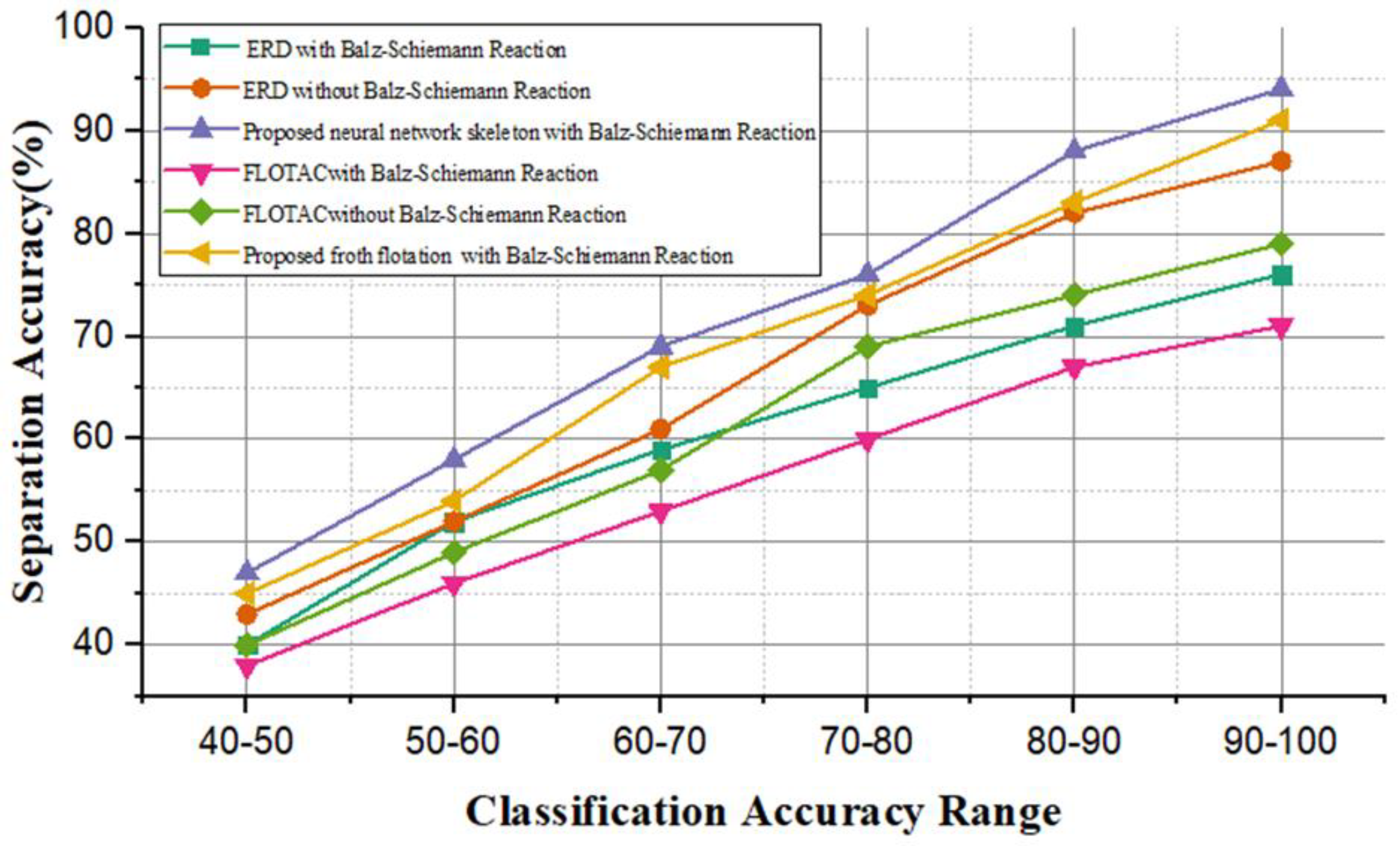

The relationship between the separation accuracy and classification accuracy of the proposed method and the methods currently used will be further investigated in this study.

Table 5 shows the separation accuracy of wastes based on a classification accuracy range of 60-100.

We also calculate the separation accuracy in percentage of our proposed classification techniques with the Balz-Schiemann reaction and existing methods with or without the Balz-Schiemann reaction. A comparison between the separation accuracy value and the classification accuracy range is presented in

Figure 11. The accuracy of the current separation method is shown in

Figure 11 both with and without the Balz-Schiemann reaction. Our proposed separation and classification techniques using the Balz-Schiemann reaction continue to rank highest in

Figure 11.

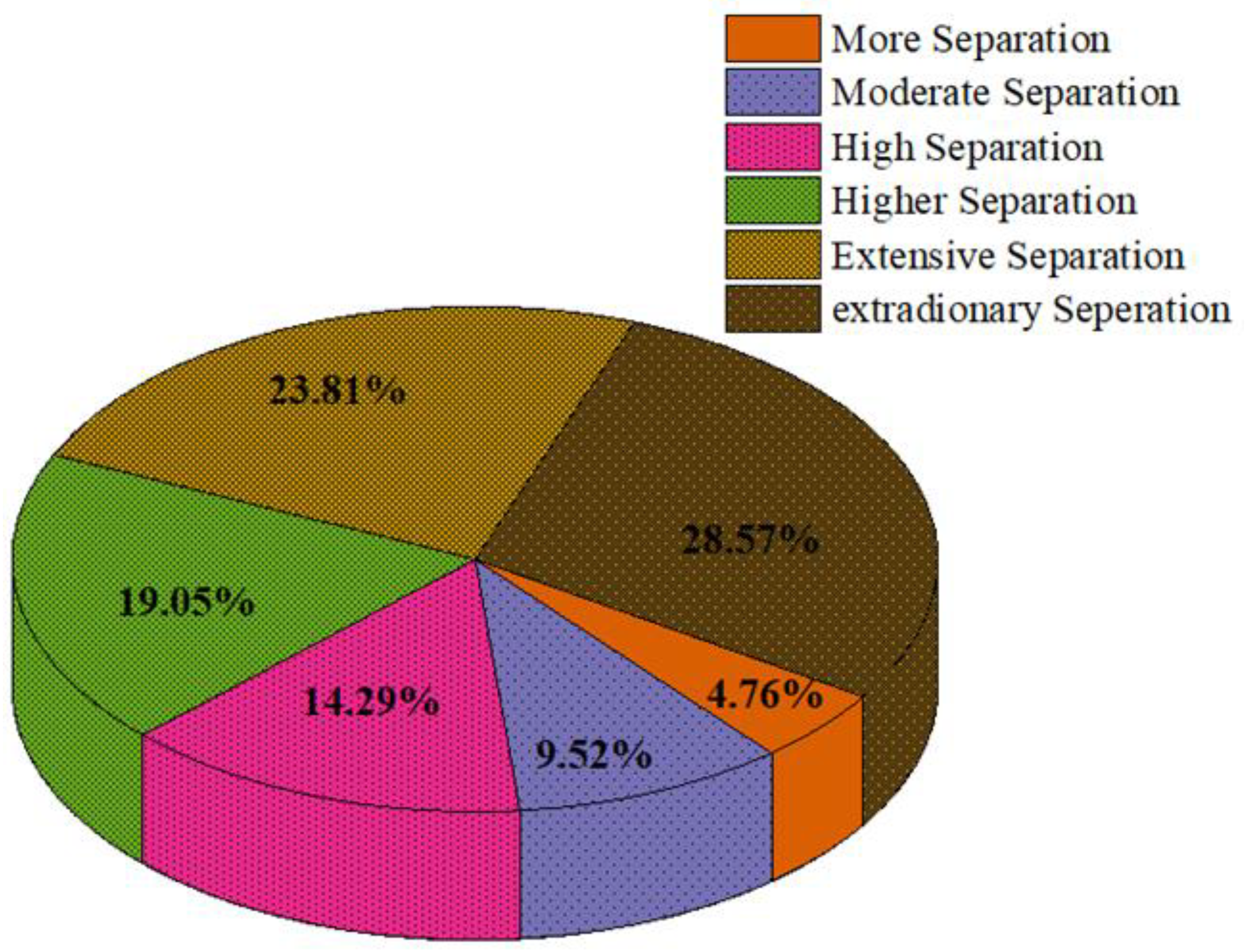

Table 6 illustrates the percentage of waste management that is separated using an exemplary separation mechanism. It also shows the separation level and its approximate percentage.

Finally, the percentage-based prediction of the process evolution stages is analysed. A pie chart representing the percentage separation stages of the prediction process is presented in

Figure 12 [

19]. The process of waste separation of waste processes is based on six levels: more separation, moderate separation, high Separation, Higher Separation, extensive separation, and extraordinary separation.

Each parameter has an estimated value expressed as a percentage. At level 1, this research mentions more separation of waste at 12%. Similarly, level 2 had a moderate separation of 45%, a high separation of 25% at level 3, 40% at level 4, and an extensive Separation of as 15% at level 5. Finally, a great separation occurs at level 6 at 28%.

4. Conclusions

Wastewater management is a critical challenge faced by municipalities and industrial facilities worldwide. The increasing volume and complexity of wastewater streams, coupled with the need to minimize environmental impact and maximize resource recovery, have necessitated the development of advanced treatment technologies. One promising approach is the integration of neural network-based models with traditional wastewater management practices, such as vermicomposting.

Vermicomposting, the process of using earthworms to convert organic waste into nutrient-rich compost, known as vermicompost, has gained significant attention as a sustainable waste management solution. The potential to utilize biodegradable municipal solid waste as feedstocks in vermicomposting offers an attractive alternative to conventional disposal methods, which often result in environmental degradation. However, the inherent complexity of the vermicomposting process, including the sensitivity of earthworms to environmental factors, has presented challenges in predicting the waste output and optimizing the system’s performance.

Neural network models have shown promise in addressing these challenges. By leveraging neural network-based models, researchers can develop more accurate predictions of waste generation from vermicomposting, enabling more effective planning and optimization of waste management systems.

This study focused on the estimation of a proposed chemical processing method for waste management in vermicomposting using a Neural Network Skeleton. An in-depth analysis was performed, comparing the proposed system with existing methods based on various parameters such as Prediction Ratio, Separation Ratio, Prediction Accuracy and Separation Accuracy.

The proposed Neural Network Skeleton demonstrated superior performance over existing methods, achieving an average prediction ratio of 91.32%, compared to the average prediction ratios of 73.4%, 79.7%, and 80.8% for ERD, RNN, and Deep LSTM, respectively. This superiority was further evident in the separation ratio and prediction accuracy, highlighting the efficiency and effectiveness of the proposed method.

Furthermore, the study delved into the chemical equilibrium and separation accuracy of waste, emphasizing the linear increase and maintenance of prediction accuracy and separation accuracy over time.

The findings showcased the significant potential of the proposed Gallium Arsenide Processing Schema, that shows high prediction and separation accuracy, underscoring its ability to optimize waste management and vermicomposting processes.

Lastly, the prediction of the process evolution stages was presented, indicating the efficiency of the proposed system in achieving various levels of waste separation.

The findings of this study underscore the potential of the proposed Neural Network Skeleton and Gallium-As-based processing schema in optimizing waste management strategies, improving the quality of vermicompost, and developing more efficient waste segregation systems.

These results highlight the need for further exploration and eventual implementation of these advanced techniques in real-world waste management scenarios. Further research and implementation of these methods could significantly contribute to environmental conservation and sustainable waste management practices.

Supplementary Materials

No supplementary materials.

Author Contributions

For research articles with several authors, a short paragraph specifying their individual contributions must be provided. The following statements should be used “Conceptualization, M. T. and G.A.; methodology, M.T., R.S., CC; software, M.T.; validation, G.A., R.S. and B.A.; formal analysis, C.C.; investigation, G.A.; resources, B.A.; data curation, B.A; writing—original draft preparation, M.T.; writing—review and editing, C.C.; supervision, C.C.; project administration, C.C. All authors have read and agreed to the published version of the manuscript.”.

Data Availability Statement

Conflicts of Interest

The authors declare no conflict of interest.

References

- Powell, J.T.; Chertow, M.R. Quantity, Components, and Value of Waste Materials Landfilled in the United States. J. Ind. Ecol. 2019, 23, 466–479. [Google Scholar] [CrossRef]

- Chen, J.; Chang, N.; Shieh, W. Assessing wastewater reclamation potential by neural network model. Eng. Appl. Artif. Intell. 2003, 16, 149–157. [Google Scholar] [CrossRef]

- Al-Ghazawi, Z.; Alawneh, R. Use of artificial neural network for predicting effluent quality parameters and enabling wastewater reuse for climate change resilience – A case from Jordan. J. Water Process. Eng. 2021, 44. [Google Scholar] [CrossRef]

- Gaudio, M.T.; Coppola, G.; Zangari, L.; Curcio, S.; Greco, S.; Chakraborty, S. Artificial Intelligence-Based Optimization of Industrial Membrane Processes. Earth Syst. Environ. 2021, 5, 385–398. [Google Scholar] [CrossRef]

- Petre, E., Selişteanu, D., Şendrescu, D., & Ionete, C. (2008). Nonlinear and neural networks based adaptive control for a wastewater treatment bioprocess. In Knowledge-Based Intelligent Information and Engineering Systems: 12th International Conference, KES 2008, Zagreb, Croatia, September 3-5, 2008, Proceedings, Part II 12 (pp. 273-280). Springer Berlin Heidelberg.

- Alvi, M.; Batstone, D.; Mbamba, C.K.; Keymer, P.; French, T.; Ward, A.; Dwyer, J.; Cardell-Oliver, R. Deep learning in wastewater treatment: a critical review. Water Res. 2023, 245, 120518. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Wang, D.; Zhao, M.; Qiao, J. Reinforcement learning control with n-step information for wastewater treatment systems. Eng. Appl. Artif. Intell. 2024, 133. [Google Scholar] [CrossRef]

- Bagherzadeh, F.; Mehrani, M.-J.; Basirifard, M.; Roostaei, J. Comparative study on total nitrogen prediction in wastewater treatment plant and effect of various feature selection methods on machine learning algorithms performance. J. Water Process. Eng. 2021, 41. [Google Scholar] [CrossRef]

- Xia, W.; Jiang, Y.; Chen, X.; Zhao, R. Application of machine learning algorithms in municipal solid waste management: A mini review. Waste Manag. Res. 2021, 40, 609–624. [Google Scholar] [CrossRef]

- Fang, B.; Yu, J.; Chen, Z.; Osman, A.I.; Farghali, M.; Ihara, I.; Hamza, E.H.; Rooney, D.W.; Yap, P.-S. Artificial intelligence for waste management in smart cities: a review. Environ. Chem. Lett. 2023, 21, 1959–1989. [Google Scholar] [CrossRef]

- Abdulmahmood, M.; Grammenos, R. Improving the Deployment of Recycling Classification through Efficient Hyper-Parameter Analysis. arXiv preprint 2021, arXiv:2110.11043. [Google Scholar]

- Mazloumian, A., Rosenthal, M., & Gelke, H. (2020). Deep learning for classifying food waste. arXiv preprint. arXiv:2002.03786.

- Lin, K.; Zhao, Y.; Gao, X.; Zhang, M.; Zhao, C.; Peng, L.; Zhang, Q.; Zhou, T. Applying a deep residual network coupling with transfer learning for recyclable waste sorting. Environ. Sci. Pollut. Res. 2022, 29, 91081–91095. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Ouyang, H.; Liu, Q.; Cai, S.; Wang, C.; Xie, J.; Hu, W. Image Recognition for Garbage Classification Based on Transfer Learning and Model Fusion. Math. Probl. Eng. 2022, 2022, 1–12. [Google Scholar] [CrossRef]

- J. Rashida, R. Hamzah, K. A. Fariza Abu Samah, and S. Ibrahim, “Implementation of faster region-based convolutional neural network for waste type classification,” in 2022 International Conference on Computer and Drone Applications (IConDA), 2022, pp. 125–130.

- M. S. Nafiz, S. S. Das, M. K. Morol, A. A. Juabir, and D. Nandi, “Convowaste: An automatic waste segregation machine using deep learning,” 2023 3rd International Conference on Robotics, Electrical and Signal Processing Techniques (ICREST), pp. 181–186, 2023.

- S. M. Cheema, A. Hannan, and I. M. Pires, “Smart waste management and classification systems using cutting edge approach,” Sustainability, 2022. https://github.com/sumn2u/deep-waste-app.

- S. M, N. V., J. Katyal, and R. R, “Technical solutions for waste classification and management: A mini-review.” Waste management & research : the journal of the International Solid Wastes and Public Cleansing Association, ISWA, p. 734242X221135262, 2022.

- Mohite, D.D.; Chavan, S.S.; Jadhav, V.S.; Kanase, T.; Kadam, M.A.; Singh, A.S. Vermicomposting: a holistic approach for sustainable crop production, nutrient-rich bio fertilizer, and environmental restoration. Discov. Sustain. 2024, 5, 1–13. [Google Scholar] [CrossRef]

- Kumar, D.S.; Kumar, P.S.; Rajendran, N.M.; Kumar, V.U.; Anbuganapathi, G. Evaluation of Vermicompost Maturity Using Scanning Electron Microscopy and Paper Chromatography Analysis. J. Agric. Food Chem. 2014, 62, 2738–2741. [Google Scholar] [CrossRef] [PubMed]

- Sim, E.Y.S.; Wu, T.Y. The potential reuse of biodegradable municipal solid wastes (MSW) as feedstocks in vermicomposting. J. Sci. Food Agric. 2010, 90, 2153–2162. [Google Scholar] [CrossRef] [PubMed]

- Usman Ali, Nida Sajid, Azeem Khalid, Luqman Riaz, Muhammad Muaz Rabbani, Jabir Hussain Syed, Riffat Naseem Malik Environmental progress & sustainable energy, 2015.

- Ana Vuković, Mirna Velki, Sandra Ečimović, Rosemary Vuković, Ivna Štolfa Čamagajevac, Zdenko Lončarić Agronomy, 2021.

- Zhu, S.; Gao, H.; Duan, L. Latest research progress on food waste management: a comprehensive review. IOP Conf. Series: Earth Environ. Sci. 2018, 153, 062043. [Google Scholar] [CrossRef]

- Abdulmahmood, M., & Grammenos, R. (2021). Improving the Deployment of Recycling Classification through Efficient Hyper-Parameter Analysis. arXiv:2110.11043.

- E. Embalzado, L. Samaniego, Z. Cortez, K. G. Justimbaste, J. M. L. Naidas and M. C. Polido, “Automated Vermicomposting System (of Proper Waste Ratio + MCU Vermicomposting Bed),” 2019 IEEE 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM ), Laoag, Philippines, 2019, pp. 1-5. [CrossRef]

- Enebe, M. C., & Erasmus, M. (2023). Vermicomposting technology-A perspective on vermicompost production technologies, limitations and prospects. Journal of Environmental Management, 345, 118585.

- Sulaiman, I. S. C., & Mohamad, A. (2020). The use of vermiwash and vermicompost extract in plant disease and pest control. In Natural remedies for pest, disease and weed control (pp. 187-201). Academic Press.

- J. Palsania, R Sharma, J. K Srivastava and D. Sharma, “Effect of moisture content variation over kinetic reaction rate during vermicomposting process”, J. Applied Ecology and Environmental Research, vol. 6(2) pp. 49-61, 2008.

- Garg, V.K.; Gupta, R. Effect of Temperature Variations on Vermicomposting of Household Solid Waste and Fecundity ofEisenia fetida. Bioremediation J. 2011, 15, 165–172. [Google Scholar] [CrossRef]

- Harris, E.; Yu, L.; Wang, Y.-P.; Mohn, J.; Henne, S.; Bai, E.; Barthel, M.; Bauters, M.; Boeckx, P.; Dorich, C.; et al. Warming and redistribution of nitrogen inputs drive an increase in terrestrial nitrous oxide emission factor. Nat. Commun. 2022, 13, 1–16. [Google Scholar] [CrossRef]

- Dehghani, M.H.; Salari, M.; Karri, R.R.; Hamidi, F.; Bahadori, R. Process modeling of municipal solid waste compost ash for reactive red 198 dye adsorption from wastewater using data driven approaches. Sci. Rep. 2021, 11, 1–20. [Google Scholar] [CrossRef]

- Dutt, C.; Krishna, S.R.; Reddy, A. Vermiculture Biotechnology for Promoting Sustainable Agriculture. Asia-Pacific J. Rural. Dev. 1998, 8, 105–117. [Google Scholar] [CrossRef]

- Marchettini, N.; Ridolfi, R.; Rustici, M. An environmental analysis for comparing waste management options and strategies. Waste Manag. 2007, 27, 562–571. [Google Scholar] [CrossRef] [PubMed]

- Staggs, H. (2021). Vermiculture: A Viable Solution for Sustainable Agriculture.

- Ramos-Ruiz, A.; Field, J.A.; Sun, W.; Sierra-Alvarez, R. Gallium arsenide (GaAs) leaching behavior and surface chemistry changes in response to pH and O-2. Waste Manag. 2018, 77, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Saber, W.I.A.; El-Naggar, N.E.-A.; El-Hersh, M.S.; El-Khateeb, A.Y.; Elsayed, A.; Eldadamony, N.M.; Ghoniem, A.A. Rotatable central composite design versus artificial neural network for modeling biosorption of Cr6+ by the immobilized Pseudomonas alcaliphila NEWG-2. Sci. Rep. 2021, 11, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Nathvani, R.; Clark, S.N.; Muller, E.; Alli, A.S.; Bennett, J.E.; Nimo, J.; Moses, J.B.; Baah, S.; Metzler, A.B.; Brauer, M.; et al. Characterisation of urban environment and activity across space and time using street images and deep learning in Accra. Sci. Rep. 2022, 12, 1–16. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, J.; Wang, Q.; Huang, D. Prediction of Filamentous Sludge Bulking using a State-based Gaussian Processes Regression Model. Sci. Rep. 2016, 6, 31303. [Google Scholar] [CrossRef]

- Finnveden, G.; Björklund, A.; Reich, M.C.; Eriksson, O.; Sörbom, A. Flexible and robust strategies for waste management in Sweden. Waste Manag. 2007, 27, S1–S8. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).