Submitted:

01 August 2024

Posted:

01 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results

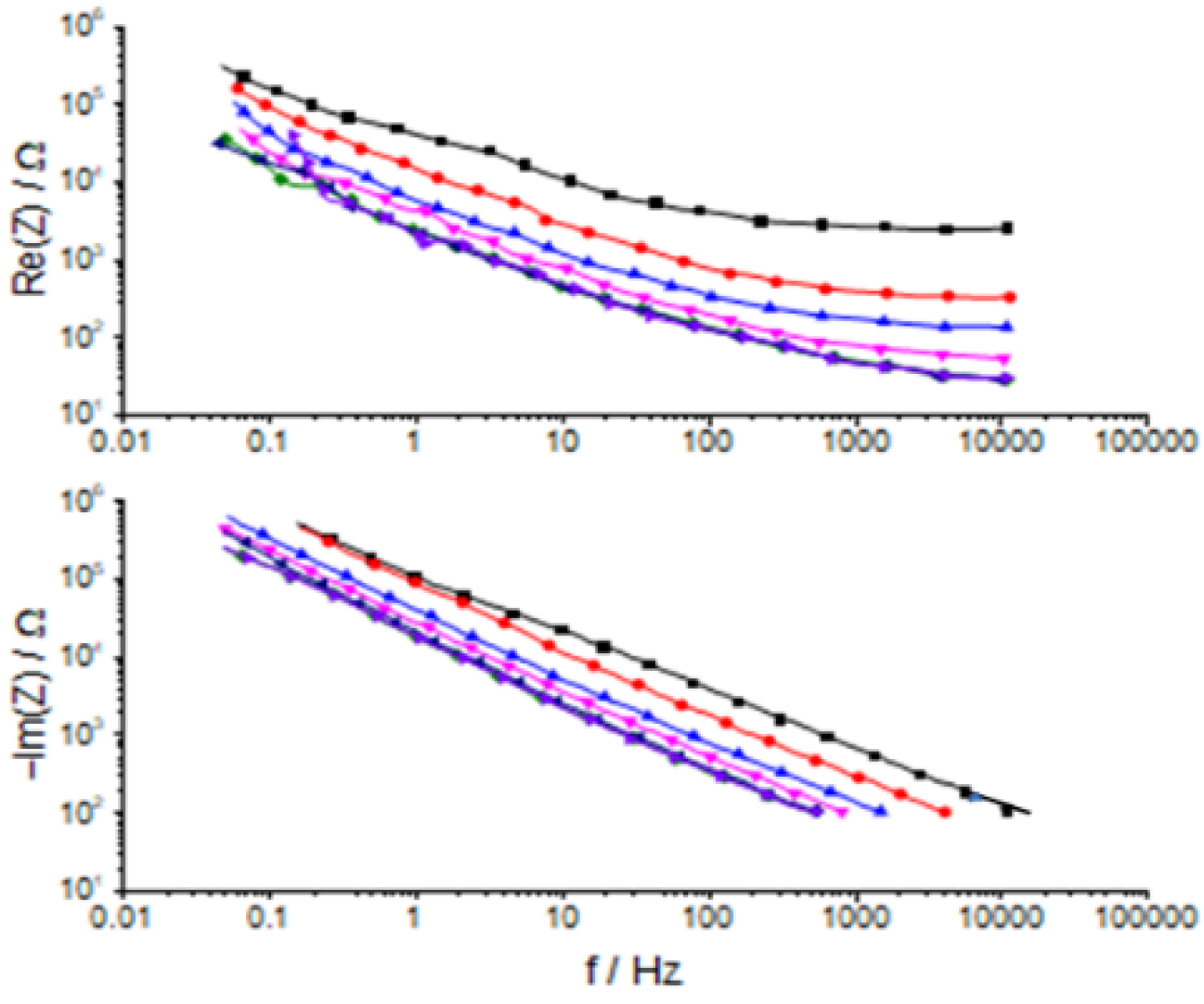

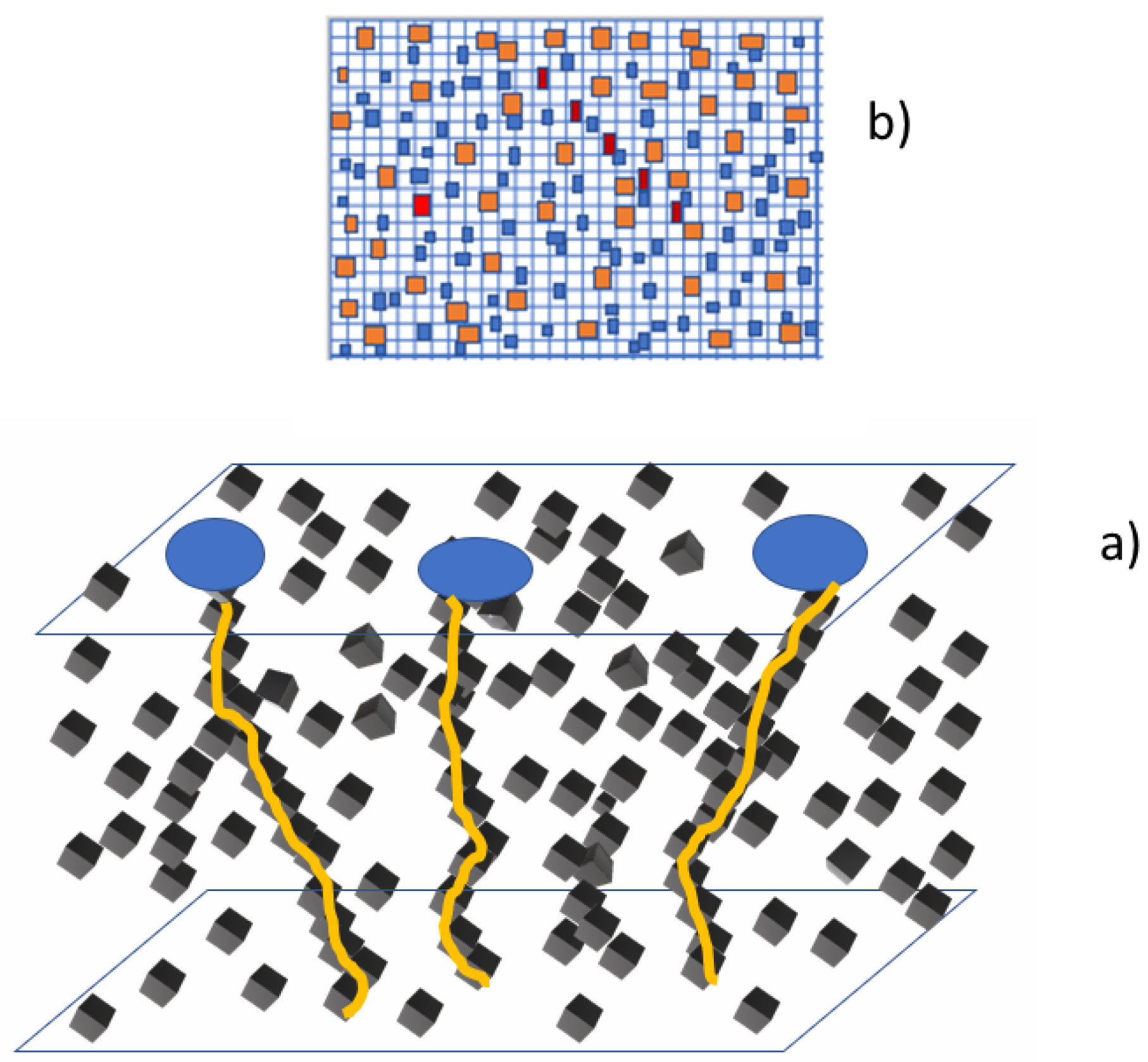

3.1. A Fractal Perspective of the EIS of GHDPE/ KCl Aqueous Solution Composite

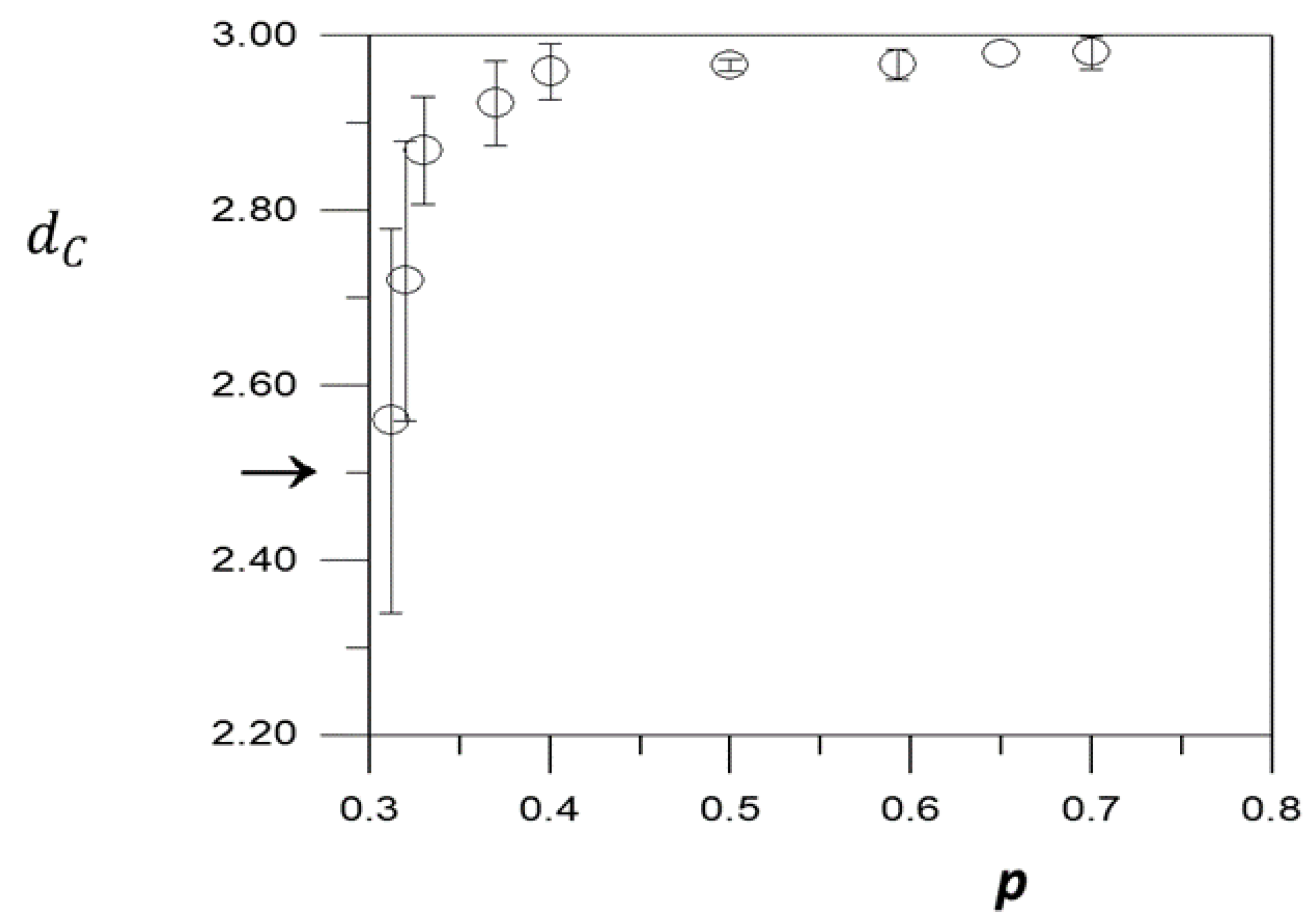

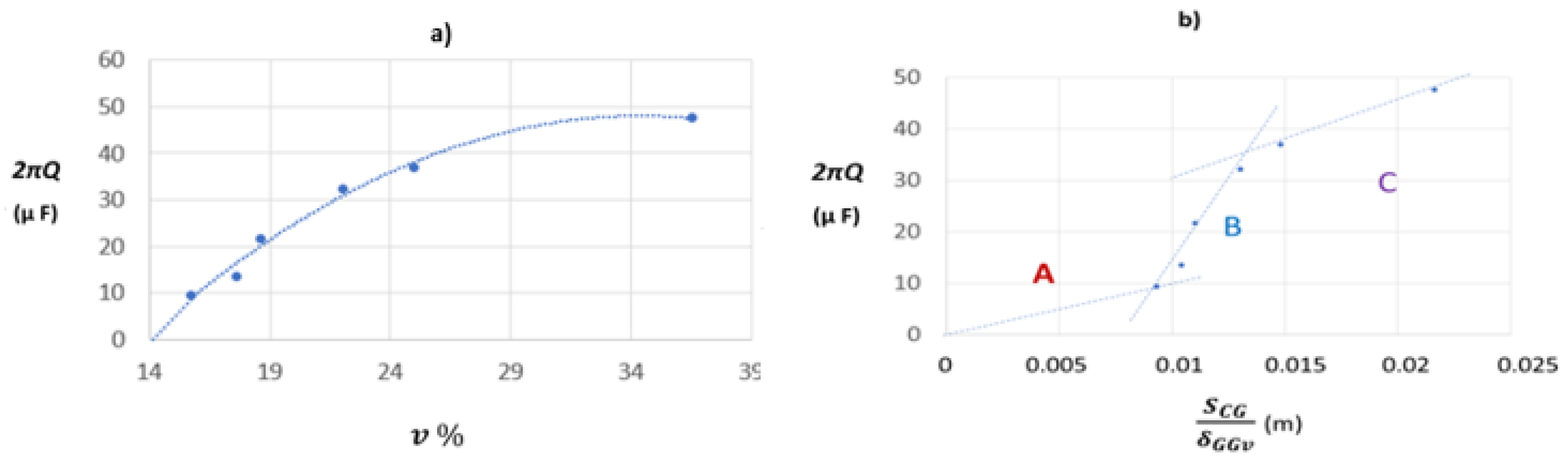

3.2. Relation between the Experimental Imaginary Part of the Impedance and the Fractal Dimensions

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lin, L.; Ning, H.; Song, S.; Xu, C.; Hu, N. Flexible Electrochemical Energy Storage: The Role of Composite Materials. Compos. Sci. Technol. 2020, 192, 108102. [CrossRef]

- Islam, J.; Chowdhury, F.; Uddin, J.; Amin, R.; Uddin, J. Review on Carbonaceous Materials and Metal Composites in Deformable Electrodes for Flexible Lithium-Ion Batteries. RSC Adv. 2021, 11, 5958–5992. [CrossRef]

- Navarro-Laboulais, J.; Trijueque, J.; García-Jareño, J.J.; Vicente, F. Impedance Analysis of Graphite + Polyethylene and Graphite + Epoxy Composite Electrodes. Journal of Electroanalytical Chemistry 1995, 399, 115–120. [CrossRef]

- Agrisuelas, J.; García-Jareño, J.J.; Guillén, E.; Vicente, F. RGB Video Electrochemistry of Copper Electrodeposition/Electrodissolution in Acid Media on a Ternary Graphite:Copper:Polypropylene Composite Electrode. Electrochim. Acta 2019, 305, 72–80. [CrossRef]

- Li, G.; Xia, Y.; Tian, Y.; Wu, Y.; Liu, J.; He, Q.; Chen, D. Review—Recent Developments on Graphene-Based Electrochemical Sensors toward Nitrite. J. Electrochem. Soc. 2019, 166, B881. [CrossRef]

- Li, G.; Xia, Y.; Tian, Y.; Wu, Y.; Liu, J.; He, Q.; Chen, D. Review—Recent Developments on Graphene-Based Electrochemical Sensors toward Nitrite. J. Electrochem. Soc. 2019, 166, B881–B895. [CrossRef]

- Himadri Reddy, P.C.; Amalraj, J.; Ranganatha, S.; Patil, S.S.; Chandrasekaran, S. A Review on Effect of Conducting Polymers on Carbon-Based Electrode Materials for Electrochemical Supercapacitors. Synthetic Metals 2023, 298, 117447. [CrossRef]

- Gao, X.; Li, W.; Wang, P.; Lu, Y.; Zhou, J.; Wang, X.Q. Advancing Energy Solutions: Carbon-Based Cementitious Composites in Energy Storage and Harvesting. Journal of Building Engineering 2024, 91, 109720. [CrossRef]

- Peinado, F.; Roig, A.; Vicente, F.; Vilaplana, J.; López, J. Electrochemical Characterization of Cement/Graphite and Cement/Aluminium Materials. J Mater Sci Lett 1994, 13, 609–612. [CrossRef]

- Das, N.C.; Maiti, S. Electromagnetic Interference Shielding of Carbon Nanotube/Ethylene Vinyl Acetate Composites. J Mater Sci 2008, 43, 1920–1925. [CrossRef]

- Miller, E.E.; Hua, Y.; Tezel, F.H. Materials for Energy Storage: Review of Electrode Materials and Methods of Increasing Capacitance for Supercapacitors. Journal of Energy Storage 2018, 20, 30–40. [CrossRef]

- Faga, M.; Duraccio, D.; Di Maro, M.; Pedraza, R.; Bartoli, M.; d’Ayala, G.; Torsello, D.; Ghigo, G.; Malucelli, G. Ethylene-Vinyl Acetate (EVA) Containing Waste Hemp-Derived Biochar Fibers: Mechanical, Electrical, Thermal and Tribological Behavior. Polymers 2022, 14, 4171. [CrossRef]

- Subiela, J.R.; López, J.; Balart, R.; García-Jareño, J.J.; Vicente, F. Electrical Properties of EVA Filled by Zinc Powder. J Mater Sci 2006, 41, 6396–6402. [CrossRef]

- Fang, H.; Yang, D.; Su, Z.; Sun, X.; Ren, J.; Li, L.; Wang, K. Preparation and Application of Graphene and Derived Carbon Materials in Supercapacitors: A Review. Coatings 2022, 12, 1312. [CrossRef]

- Wang, P.; Song, T.; Abo-Dief, H.M.; Song, J.; Alanazi, A.K.; Fan, B.; Huang, M.; Lin, Z.; Altalhi, A.A.; Gao, S.; et al. Effect of Carbon Nanotubes on the Interface Evolution and Dielectric Properties of Polylactic Acid/Ethylene–Vinyl Acetate Copolymer Nanocomposites. Adv Compos Hybrid Mater 2022, 5, 1100–1110. [CrossRef]

- Agrisuelas, J.; Balart, R.; García-Jareño, J.J.; López-Martínez, J.; Vicente, F. A Macroscopic Interpretation of the Correlation between Electrical Percolation and Mechanical Properties of Poly-(Ethylene Vinyl Acetate)/Zn Composites. Materials 2024, 17, 2527. [CrossRef]

- Vovchenko, L.; Perets, Yu.; Ovsienko, I.; Matzui, L.; Oliynyk, V.; Launetz, V. Shielding Coatings Based on Carbon–Polymer Composites. Surface and Coatings Technology 2012, 211, 196–199. [CrossRef]

- Peng, Y.; Burtovyy, R.; Bordia, R.; Luzinov, I. Fabrication of Porous Carbon Films and Their Impact on Carbon/Polypropylene Interfacial Bonding. J. Compos. Sci. 2021, 5, 108. [CrossRef]

- Kratofil Krehula, L.; Peršić, A.; Popov, N.; Krehula, S. Polymer Composites of Low-Density Polyethylene (LDPE) with Elongated Hematite (α-Fe2O3) Particles of Different Shapes. J. Compos. Sci. 2024, 8, 73. [CrossRef]

- Sadeghi, P.; Goli, A.; Fini, E. Carbon Sequestration via Bituminous Composites Containing Recycled High-Density Polyethylene. J. Compos. Sci. 2024, 8, 100. [CrossRef]

- Kou, Y.; Cheng, X.; Macosko, C.W. Degradation and Breakdown of Polymer/Graphene Composites under Strong Electric Field. J. Compos. Sci. 2022, 6, 139. [CrossRef]

- Kahanda, G.L.M.K.S.; Tomkiewicz, M. Fractality and Impedance of Electrochemically Grown Silver Deposits. J. Electrochem. Soc. 1990, 137, 3423. [CrossRef]

- Sunde, S. Calculation of Conductivity and Polarization Resistance of Composite SOFC Electrodes from Random Resistor Networks. J. Electrochem. Soc. 1995, 142, L50. [CrossRef]

- De Arcangelis, L.; Redner, S.; Coniglio, A. Anomalous Voltage Distribution of Random Resistor Networks and a New Model for the Backbone at the Percolation-Threshold. Phys. Rev. B 1985, 31, 4725–4727. [CrossRef]

- De Arcangelis, L.; Redner, S.; Coniglio, A. Multiscaling Approach in Random Resistor and Random Superconducting Networks. Phys. Rev. B 1986, 34, 4656–4673. [CrossRef]

- Angulo, R.; Medina, E. Conductance Distributions in Random Resistor Networks - Self-Averaging and Disorder Lengths. J. Stat. Phys. 1994, 75, 135–151. [CrossRef]

- Koch, D.L.; Sangani, A.S. The AC Electrical Impedance of a Fractal Boundary to an Electrolytic Solution. J. Electrochem. Soc. 1991, 138, 475. [CrossRef]

- Lust, L.; Kakalios, J. Computer-Simulations of Conductance Noise in a Dynamical Percolation Resistor Network. Phys. Rev. E 1994, 50, 3431–3435. [CrossRef]

- Babalievski, F. Algorithm to Extract the Spanning Clusters and Calculate Conductivity in Strip Geometries. Phys. Rev. E 1995, 51, 6230–6234. [CrossRef]

- Kolek, A. Voltage Distribution in a Two-Component Random System. Phys. Rev. B 1996, 53, 14185–14195. [CrossRef]

- Batrouni, G.G.; Hansen, A.; Larson, B. Current Distribution in the Three-Dimensional Random Resistor Network at the Percolation Threshold. Phys. Rev. E 1996, 53, 2292–2297. [CrossRef]

- Barta, S.; Dieska, P. A Computer-Simulation Study of Anomalous Diffusion on Percolating Clusters Near to the Critical-Point. Physica A 1995, 215, 251–260.

- Lopez, J.; Rodriguez, M.; Pesquera, L. Analysis of Self-Averaging Properties in the Transport of Particles Through Random-Media. Phys. Rev. E 1995, 51, R1637–R1640. [CrossRef]

- Bunde, A.; Havlin, S.; Porto, M. Are Branched Polymers in the Universality Class of Percolation. Phys. Rev. Lett. 1995, 74, 2714–2716. [CrossRef]

- Scher, H.; Zallen, R. Critical Density in Percolation Processes. J. Chem. Phys. 1970, 53, 3759-. [CrossRef]

- Gupta, R.; Malik, A.; Kumari, K.; Singh, S.K.; Vivier, V.; Mondal, P.C. Metal-Free Platforms for Molecular Thin Films as High-Performance Supercapacitors. Chem. Sci. 2024, 10.1039.D4SC00611A. [CrossRef]

- Navarro-Laboulais, J.; Garcı́a-Jareño, J.J.; Vicente, F. Kramers–Kronig Transformation, Dc Behaviour and Steady State Response of the Warburg Impedance for a Disk Electrode Inlaid in an Insulating Surface. Journal of Electroanalytical Chemistry 2002, 536, 11–18. [CrossRef]

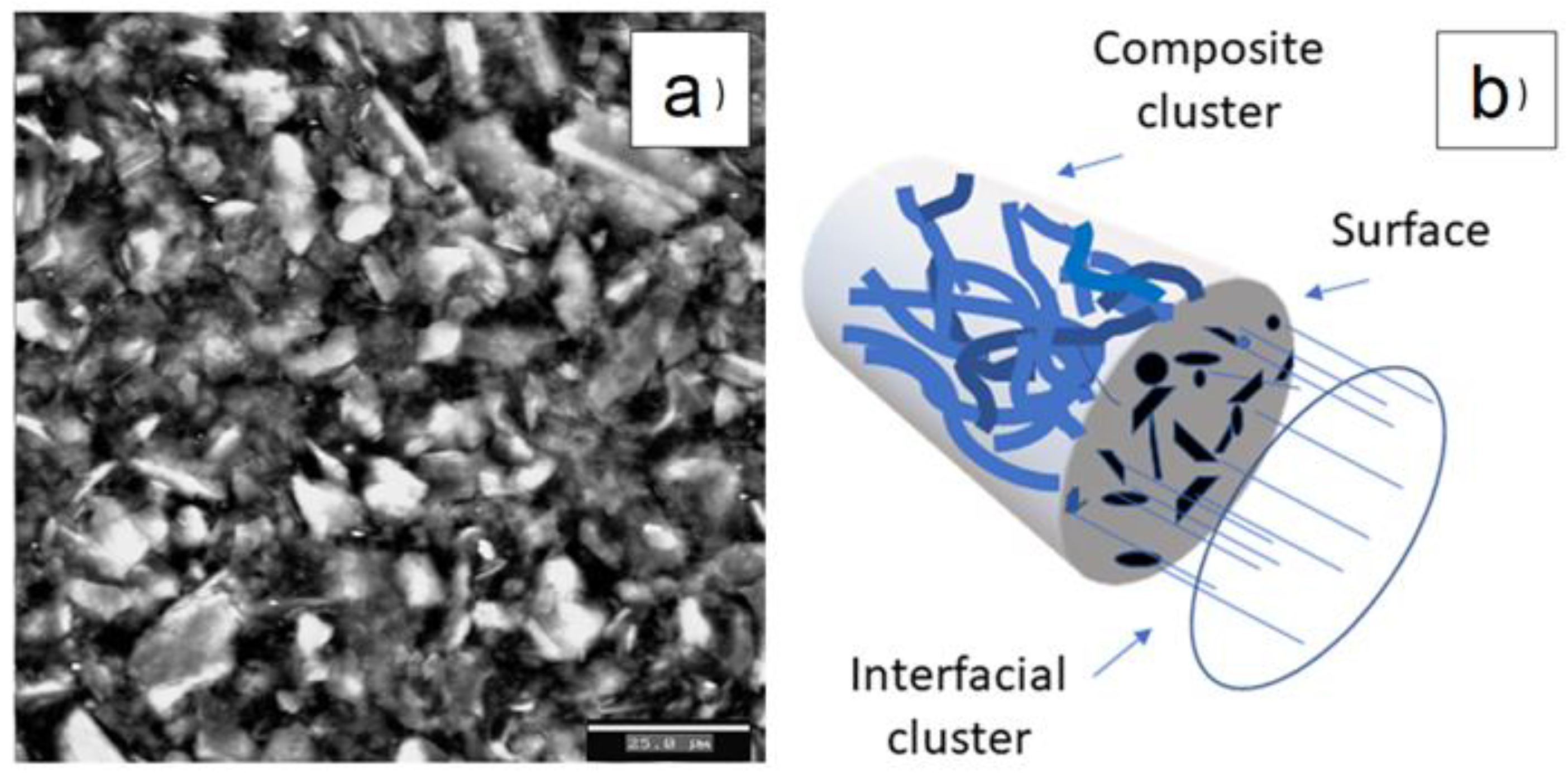

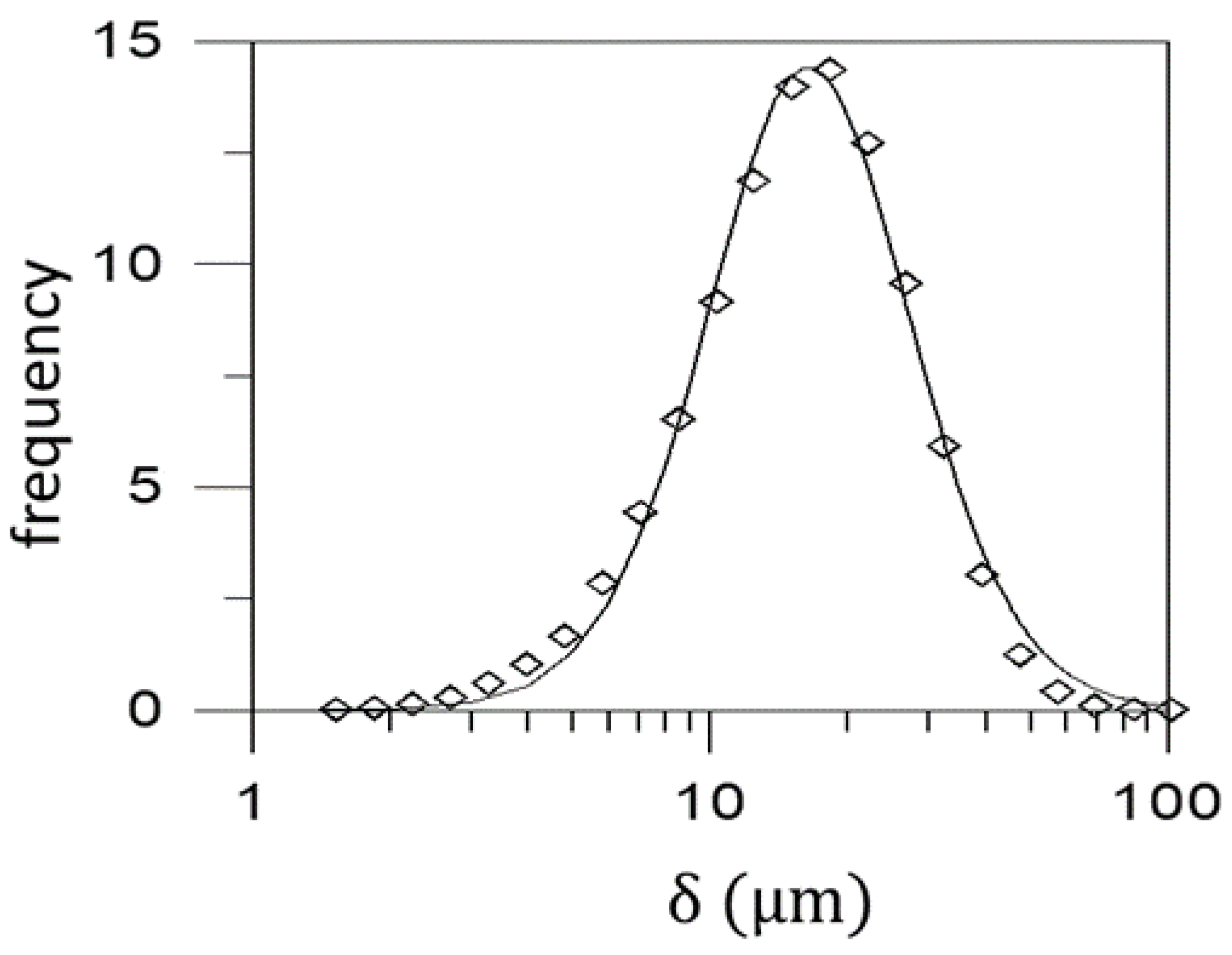

- Beaunier, L.; Keddam, M.; Garcia-Jareno, J.J.; Vicente, F.; Navarro-Laboulais, J. Surface Structure Determination by SEM Image Processing and Electrochemical Impedance of Graphite plus Polyethylene Composite Electrodes. J. Electroanal. Chem. 2004, 566, 159–167. [CrossRef]

- Navarro-Laboulais, J.; Trijueque, J.; García-Jareño, J.J.; Vicente, F. Ohmic Drop Effect on the Voltammetric Behaviour of Graphite + Polyethylene Composite Electrodes. Journal of Electroanalytical Chemistry 1997, 422, 91–97. [CrossRef]

- Navarro-Laboulais, J.; Trijueque, J.; Garcı́a-Jareño, J.J.; Benito, D.; Vicente, F. Determination of the Electroactive Area of Graphite+polyethylene Composite Electrodes. Uncompensated Resistance Effects and Convolution Analysis of Chronoamperograms. Journal of Electroanalytical Chemistry 1998, 443, 41–48. [CrossRef]

- Navarro-Laboulais, J.; Trijueque, J.; García-Jareño, J.J.; Benito, D.; Vicente, F. Electrochemical Impedance Spectroscopy of Conductor—Insulator Composite Electrodes: Properties in the Blocking and Diffusive Regimes. Journal of Electroanalytical Chemistry 1998, 444, 173–186. [CrossRef]

- Bhattacharya, S.; Tandon, R.P.; Sachdev, V.K. Electrical Conduction of Graphite Filled High Density Polyethylene Composites; Experiment and Theory. J Mater Sci 2009, 44, 2430–2433. [CrossRef]

- Panwar, V.; Mehra, R. m. Analysis of Electrical, Dielectric, and Electromagnetic Interference Shielding Behavior of Graphite Filled High Density Polyethylene Composites. Polymer Engineering & Science 2008, 48, 2178–2187. [CrossRef]

- Luo, W.; Cheng, C.; Zhou, S.; Zou, H.; Liang, M. Thermal, Electrical and Rheological Behavior of High-Density Polyethylene/Graphite Composites. Iran Polym J 2015, 24, 573–581. [CrossRef]

- Krupa, I.; Novák, I.; Chodák, I. Electrically and Thermally Conductive Polyethylene/Graphite Composites and Their Mechanical Properties. Synthetic Metals 2004, 145, 245–252. [CrossRef]

- Agrisuelas, J.; García-Jareño, J.J.; Gimenez-Romero, D.; Negrete, F.; Vicente, F. The Fractal Dimension as Estimator of the Fractional Content of Metal Matrix Composite Materials. J. Solid State Electrochem. 2009, 13, 1599–1603. [CrossRef]

- Ghanbari, K.; Mousavi, M.F.; Shamsipur, M.; Rahmanifar, M.S.; Heli, H. Change in Morphology of Polyaniline/Graphite Composite: A Fractal Dimension Approach. Synth. Met. 2006, 156, 911–916. [CrossRef]

- Lee, S.-B.; Pyun, S.-I. Determination of the Morphology of Surface Groups Formed and PVDF-Binder Materials Dispersed on Graphite Composite Electrodes in Terms of Fractal Geometry. Journal of Electroanalytical Chemistry 2003, 556, 75–82. [CrossRef]

- Nyikos, L.; Pajkossy, T. Fractal Dimension and Fractional Power Frequency-Dependent Impedance of Blocking Electrodes. Electrochim. Acta 1985, 30, 1533–1540. [CrossRef]

- Dassas, Y.; Duby, P. Diffusion toward Fractal, Interfaces Potentiostatic, Galvanostatic, and Linear Sweep Voltammetric Techniques. J. Electrochem. Soc. 1995, 142, 4175–4180. [CrossRef]

- Navarro-Laboulais, J.; Vilaplana, J.; López, J.; García-Jareño, J.J.; Benito, D.; Vicente, F. Prussian Blue Films Deposited on Graphite+epoxy Composite Electrodes: Electrochemical Detection of the Second Percolation Threshold. Journal of Electroanalytical Chemistry 2000, 484, 33–40. [CrossRef]

- Trijueque, J.; Garcı́a-Jareño, J.J.; Navarro-Laboulais, J.; Sanmatı́as, A.; Vicente, F. Ohmic Drop of Prussian-Blue/Graphite+epoxy Electrodes. Electrochimica Acta 1999, 45, 789–795. [CrossRef]

- Garcı́a-Jareño, J.J.; Sanmatı́as, A.; Navarro-Laboulais, J.; Vicente, F. Chronoamperometry of Prussian Blue Films on ITO Electrodes: Ohmic Drop and Film Thickness Effect. Electrochim. Acta 1999, 44, 4753–4762. [CrossRef]

- Pajkossy, T.; Nyikos, L. Scaling-Law Analysis to Describe the Impedance Behavior of Fractal Electrodes. Phys. Rev. B 1990, 42, 709–719. [CrossRef]

- Sapoval, B.; Gutfraind, R.; Meakin, P.; Keddam, M.; Takenouti, H. Equivalent-Circuit, Scaling, Random-Walk Simulation, and an Experimental-Study of Self-Similar Fractal Electrodes and Interfaces. Phys. Rev. E 1993, 48, 3333–3344. [CrossRef]

- Dobrescu, G.; Georgescu-State, R.; Papa, F.; Staden, J. (Koos) F.V.; State, R.N. Fractal Properties of Composite-Modified Carbon Paste Electrodes—A Comparison between SEM and CV Fractal Analysis. Fractal Fract 2024, 8, 205. [CrossRef]

- Gimenezromero, D. Correlation between the Fractal Dimension of the Electrode Surface and the EIS of the Zinc Anodic Dissolution for Different Kinds of Galvanized Steel. Electrochemistry Communications 2004, 6, 148–152. [CrossRef]

- Aoki, K.J. Frequency-Dependence of Electric Double Layer Capacitance without Faradaic Reactions. Journal of Electroanalytical Chemistry 2016, 779, 117–125. [CrossRef]

- Isichenko, M.B. Percolation, Statistical Topography, and Transport in Random Media. Rev. Mod. Phys. 1992, 64, 961–1043. [CrossRef]

- Alexander, C.L.; Tribollet, B.; Orazem, M.E. Contribution of Surface Distributions to Constant-Phase-Element (CPE) Behavior: 2. Capacitance. Electrochimica Acta 2016, 188, 566–573. [CrossRef]

- Orazem, M.E.; Tribollet, B.; Vivier, V.; Riemer, D.P.; White, E.; Bunge, A. On the Use of the Power-Law Model for Interpreting Constant-Phase-Element Parameters. J. Braz. Chem. Soc. 2014, 25, 532–539. [CrossRef]

- Gateman, S.M.; Gharbi, O.; Gomes De Melo, H.; Ngo, K.; Turmine, M.; Vivier, V. On the Use of a Constant Phase Element (CPE) in Electrochemistry. Current Opinion in Electrochemistry 2022, 36, 101133. [CrossRef]

- Jaroniec, M. The Fractal Approach to Heterogeneous Chemistry: Surfaces, Colloids, Polymers. Edited by David Avnir, Wiley, New York. 1989, 460 Pp., $75.00. AIChE Journal 1990, 36, 1456–1456. [CrossRef]

- Meakin, P.; Sapoval, B. Random-Walk Simulation of the Response of Irregular or Fractal Interfaces and Membranes. Phys. Rev. A 1991, 43, 2993–3004. [CrossRef]

- Kaplan, T.; Liu, S.; Gray, L. Inverse-Cantor-Bar Model for the Ac Response of a Rough Interface. Phys. Rev. B 1986, 34, 4870–4873. [CrossRef]

- Liu, S.; Kaplan, T.; Gray, L. Ac Response of Fractal Interfaces. Solid State Ion. 1986, 18–9, 65–71. [CrossRef]

- Nyikos, L.; Pajkossy, T. Diffusion to Fractal Surfaces. Electrochim. Acta 1986, 31, 1347–1350. [CrossRef]

- Pajkossy, T.; Nyikos, L. Impedance of Fractal Blocking Electrodes. J. Electrochem. Soc. 1986, 133, 2061–2064. [CrossRef]

- Nyikos, L.; Pajkossy, T.; Martemyanov, S. Diffusion to a Rotating-Disk Electrode with Fractal Surface. Soviet Electrochemistry 1989, 25, 1381–1384.

- Nyikos, L.; Pajkossy, T. Electrochemistry at Fractal Electrodes. In Proceedings of the Instationary Processes and Dynamic Experimental Methods in Catalysis, Electrochemistry and Corrosion; Sandstede, G., Kreysa, G., Eds.; V C H Verlagsgesellschaft: Weinheim, 1989; Vol. 120, pp. 361–371.

- Pajkossy, T.; Nyikos, L. Diffusion to Fractal Surfaces .2. Verification of Theory. Electrochim. Acta 1989, 34, 171–179. [CrossRef]

- Pajkossy, T.; Borosy, A.; Imre, A.; Martemyanov, S.; Nagy, G.; Schiller, R.; Nyikos, L. Diffusion Kinetics at Fractal Electrodes. J. Electroanal. Chem. 1994, 366, 69–73. [CrossRef]

- Gouyet, J.; Rosso, M.; Sapoval, B. Fractal Structure of Diffusion and Invasion Fronts in 3-Dimensional Lattices Through the Gradient Percolation Approach. Phys. Rev. B 1988, 37, 1832–1838. [CrossRef]

- Rosso, M.; Sapoval, B.; Gouyet, J. Fractal Nature of Diffusion, Invasion and Corrosion Fronts. Solid State Ion. 1988, 26, 172–173. [CrossRef]

- Sapoval, B.; Chazalviel, J.; Peyriere, J. Electrical Response of Fractal and Porous Interfaces. Phys. Rev. A 1988, 38, 5867–5887. [CrossRef]

- Sapoval, B.; Chazalviel, J.; Peyriere, J. Effective Impedance of a Non-Blocking Fractal Electrode. Solid State Ion. 1988, 28, 1441–1444. [CrossRef]

- Maritan, A.; Stella, A.; Toigo, F. Anomalous Warburg Impedance and Universal Surface Magnetic Exponent for Gaussian Models in the Presence of Fractal Boundaries. Phys. Rev. B 1989, 40, 9269–9273. [CrossRef]

- Borosy, A.; Nyikos, L.; Pajkossy, T. Diffusion to Fractal Surfaces .5. Quasi-Random Interfaces. Electrochim. Acta 1991, 36, 163–165. [CrossRef]

- Arvia, A.; Salvarezza, R. Progress in the Knowledge of Irregular Solid Electrode Surfaces. Electrochim. Acta 1994, 39, 1481–1494. [CrossRef]

- Garcia, M.; Gomez, M.; Salvarezza, R.; Arvia, A. Kinetics of Roughness Relaxation at Gold Electrodes. J. Electrochem. Soc. 1994, 141, 2291–2296. [CrossRef]

- Galam, S.; Mauger, A. Universal Formulas for Percolation Thresholds. Phys. Rev. E 1996, 53, 2177–2181. [CrossRef]

- van der Marck, S.C. sComment on ``Universal Formulas for Percolation Thresholds’’. Phys. Rev. E 1997, 55, 1228–1229. [CrossRef]

- Singh, M.B.; Kant, R. Debye–Falkenhagen Dynamics of Electric Double Layer in Presence of Electrode Heterogeneities. Journal of Electroanalytical Chemistry 2013, 704, 197–207. [CrossRef]

- Jeanmairet, G.; Rotenberg, B.; Salanne, M. Microscopic Simulations of Electrochemical Double-Layer Capacitors. Chem. Rev. 2022, 122, 10860–10898. [CrossRef]

- AL-Bazali, T. Insight into Debye Hückel Length (Κ−1): Smart Gravimetric and Swelling Techniques Reveals Discrepancy of Diffuse Double Layer Theory at High Ionic Concentrations. J Petrol Explor Prod Technol 2022, 12, 461–471. [CrossRef]

- Córdoba-Torres, P. Relationship between Constant-Phase Element (CPE) Parameters and Physical Properties of Films with a Distributed Resistivity. Electrochimica Acta 2017, 225, 592–604. [CrossRef]

- Orazem, M.E.; Frateur, I.; Tribollet, B.; Vivier, V.; Marcelin, S.; Pébère, N.; Bunge, A.L.; White, E.A.; Riemer, D.P.; Musiani, M. Dielectric Properties of Materials Showing Constant-Phase-Element (CPE) Impedance Response. J. Electrochem. Soc. 2013, 160, C215. [CrossRef]

- Gharbi, O.; Dizon, A.; Orazem, M.E.; Tran, M.T.T.; Tribollet, B.; Vivier, V. From Frequency Dispersion to Ohmic Impedance: A New Insight on the High-Frequency Impedance Analysis of Electrochemical Systems. Electrochimica Acta 2019, 320, 134609. [CrossRef]

- García-Jareño, J.J.; Agrisuelas, J.; Vicente, F. Overview and Recent Advances in Hyphenated Electrochemical Techniques for the Characterization of Electroactive Materials. Materials 2023, 16, 4226. [CrossRef]

| Equations | Conditions | References |

|---|---|---|

| Capacitor | ||

| Warburg | ||

| Resistance | ||

| = - 1 | Inductor | |

| 2 < < 3 Porous or roughhouse electrodes |

[49] | |

| Koch curve porous/dendritic electrodes |

[22,55,63,64] | |

| 3D Cantor-bar model | [65,66] | |

| EIS in diffusive control | [50,67,68,69,70,71,72,73,74,75,76,77,78,79,80] | |

| Plane ensemble of micro electrodes | This work |

|

Ω |

µ F |

|||||

|---|---|---|---|---|---|---|

| 0.38 | 0.157 | 70000 | 1.50 | 0.68 | 1.68 | 2.68 |

| 0.41 | 0.176 | 8400 | 2.10 | 0.85 | 1.85 | 2.85 |

| 0.45 | 0.186 | 1900 | 3.46 | 0.86 | 1.86 | 2.86 |

| 0.50 | 0.220 | 520 | 5.13 | 0.87 | 1.87 | 2.87 |

| 0.52 | 0.250 | 180 | 5.90 | 0.88 | 1.88 | 2.88 |

| 0.65 | 0.365 | 25 | 7.58 | 0.90 | 1.90 | 2.90 |

|

… |

µ F |

SCG m2 |

µ m |

mm2 |

τ µ s |

|

|---|---|---|---|---|---|---|

| 0.157 | 1.50 | 0.010 | 27 | 0.029 | 0.211 | 105 |

| 0.176 | 2.10 | 0.011 | 26 | 0.041 | 0.234 | 18 |

| 0.186 | 3.46 | 0.014 | 24 | 0.067 | 0.240 | 6 |

| 0.220 | 5.13 | 0.015 | 23 | 0.092 | 0.246 | 3 |

| 0.250 | 5.90 | 0.021 | 20 | 0.114 | 0.250 | 5 |

| 0.365 | 7.58 | 0.024 | 18 | 0.147 | 0.274 | 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).