Submitted:

03 August 2024

Posted:

05 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

- RQ1:

- What is the current state of the literature on digital twin use in transportation systems operation and maintenance between 2012 and 2024?

- RQ2:

- What are the main research and knowledge gaps in DT use in transportation systems operation and maintenance, especially in the context of in-house logistics?

- RQ3:

- What are the future research directions and perspectives in DT modeling in the context of the operation and maintenance of transportation systems?

- RQ4:

- What scope should the framework for digital twin for maintenance management of transportation systems have?

2. Theory Background

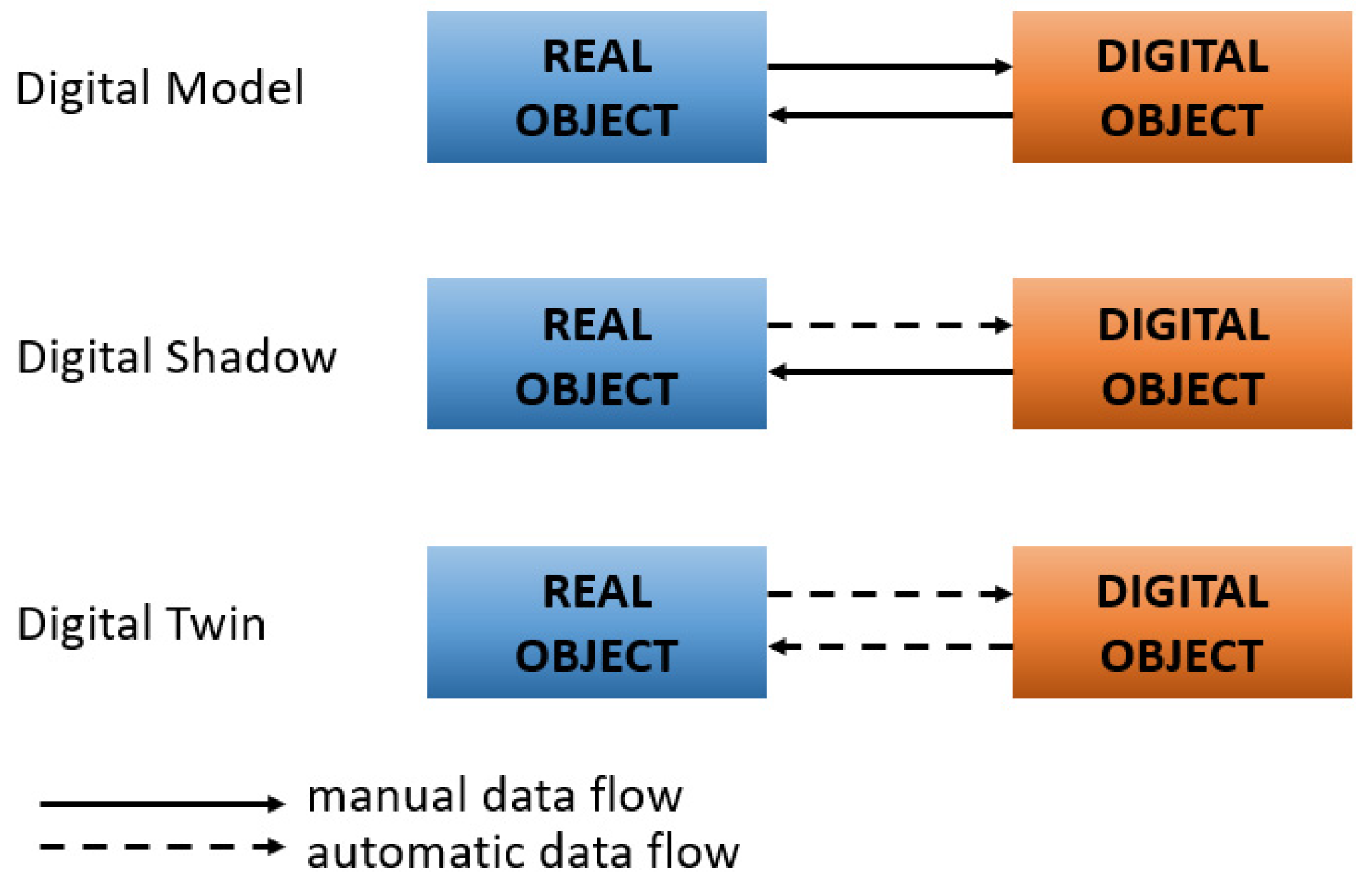

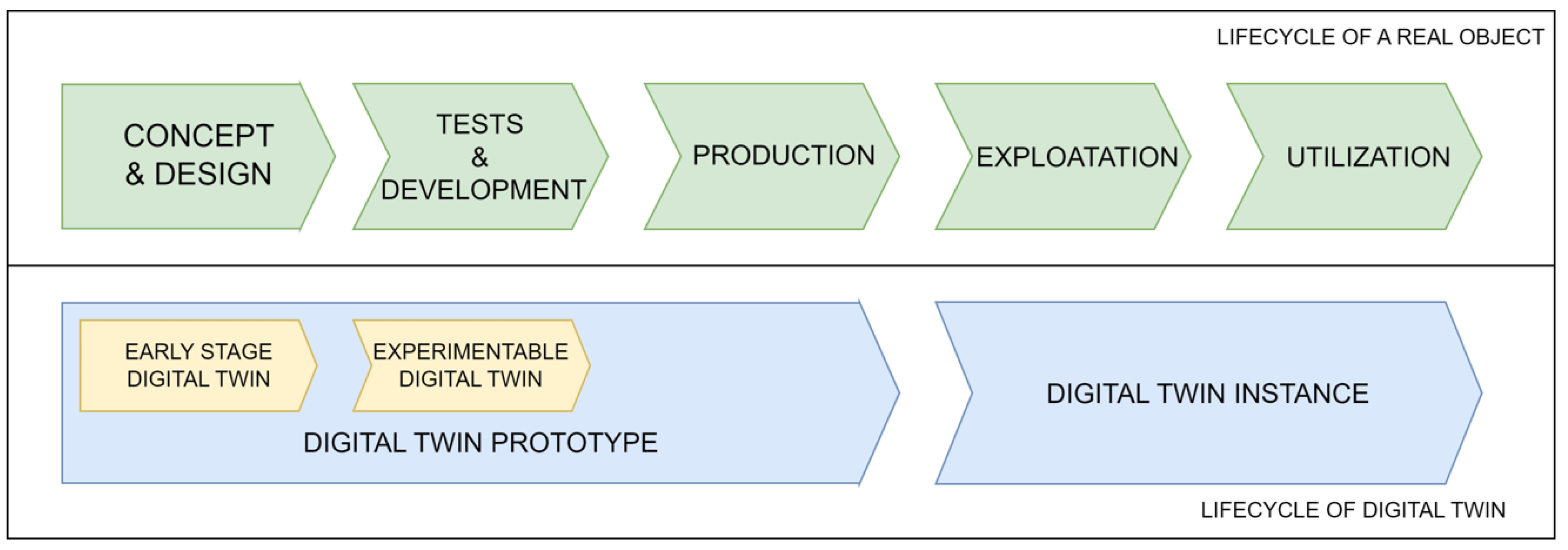

2.1. Digital Twin Concept - Introduction

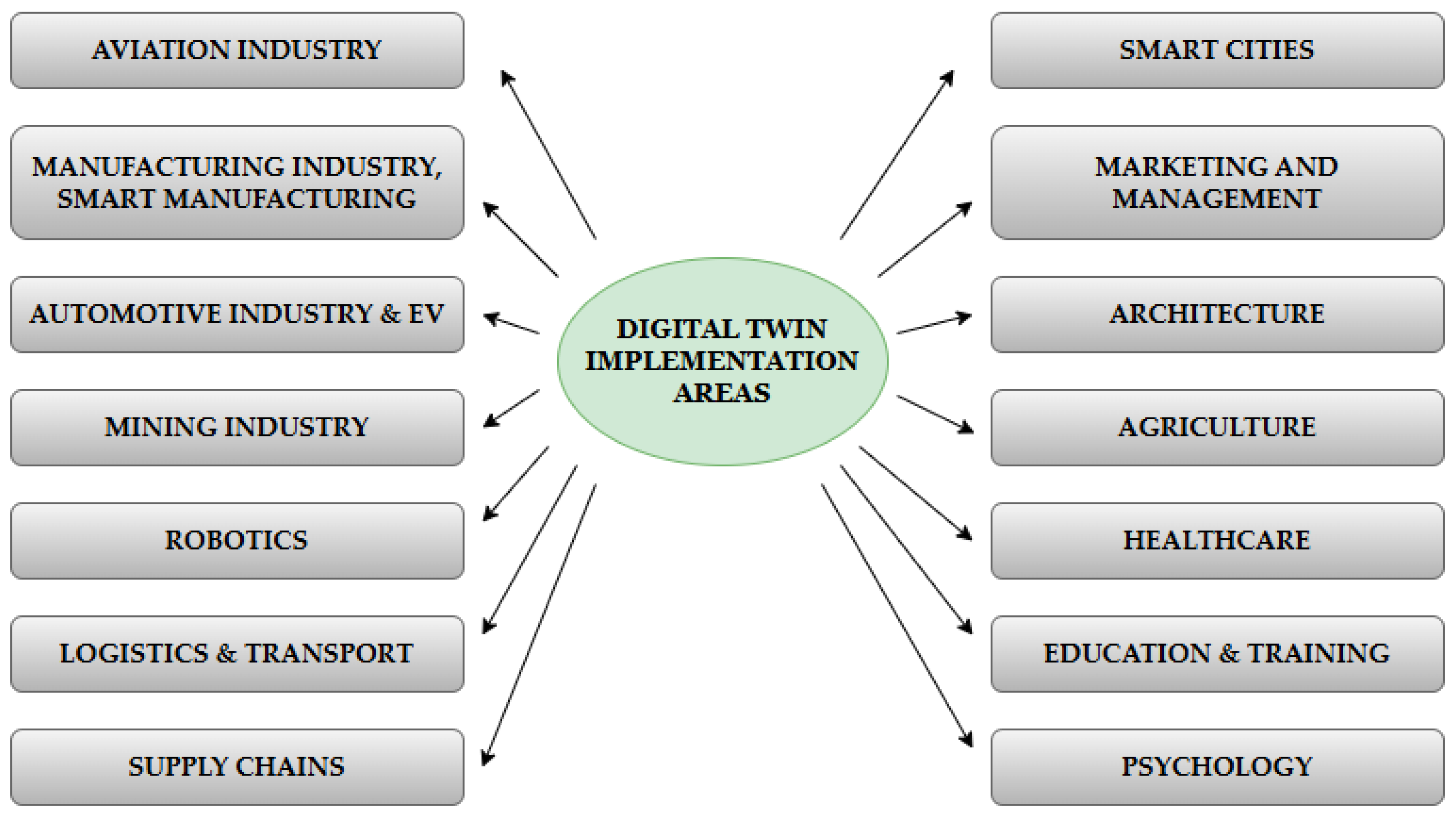

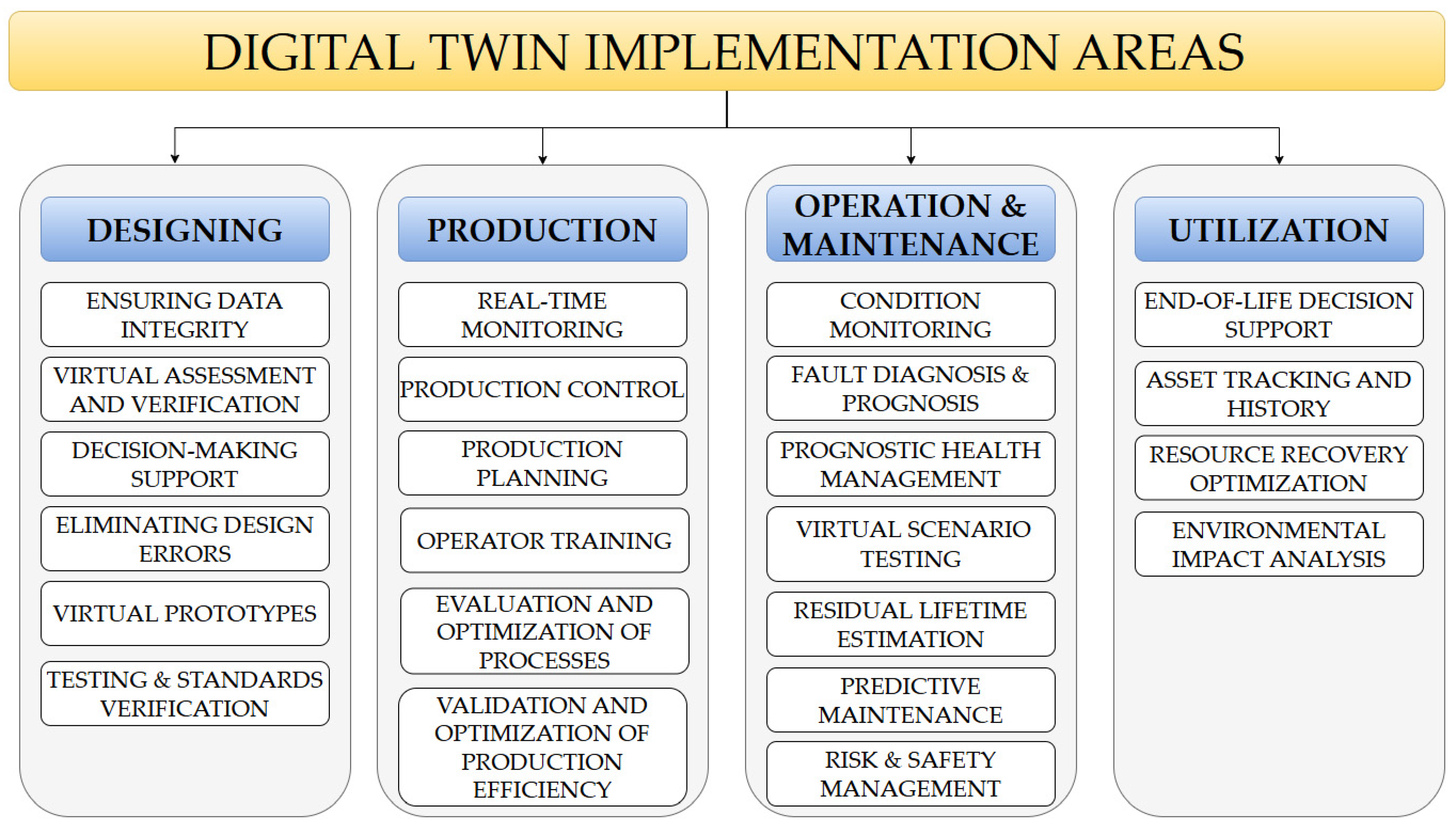

2.2. Digital Twin Concept – Implementation Areas

2.3. Digital Twin in Transportation Systems

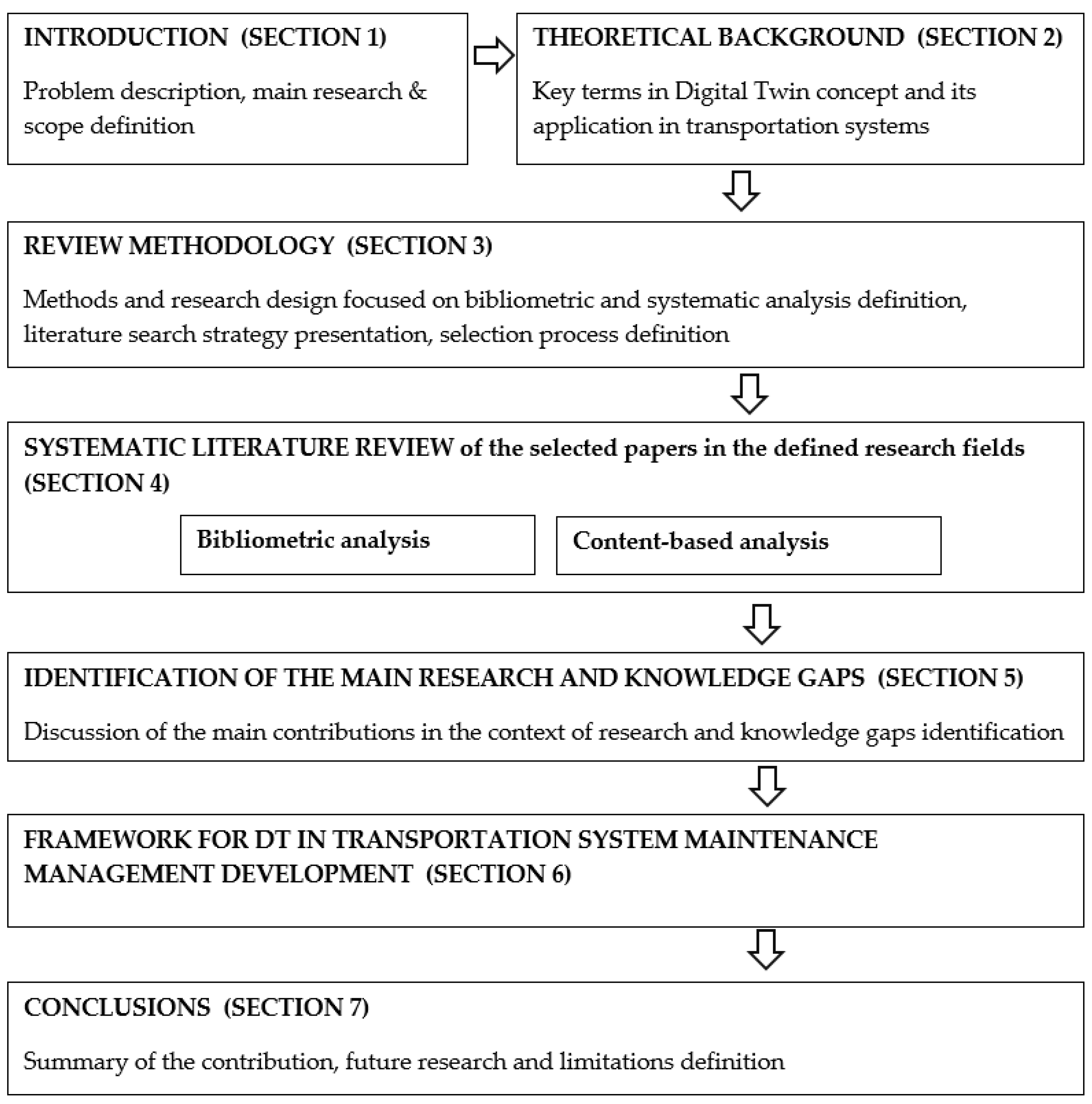

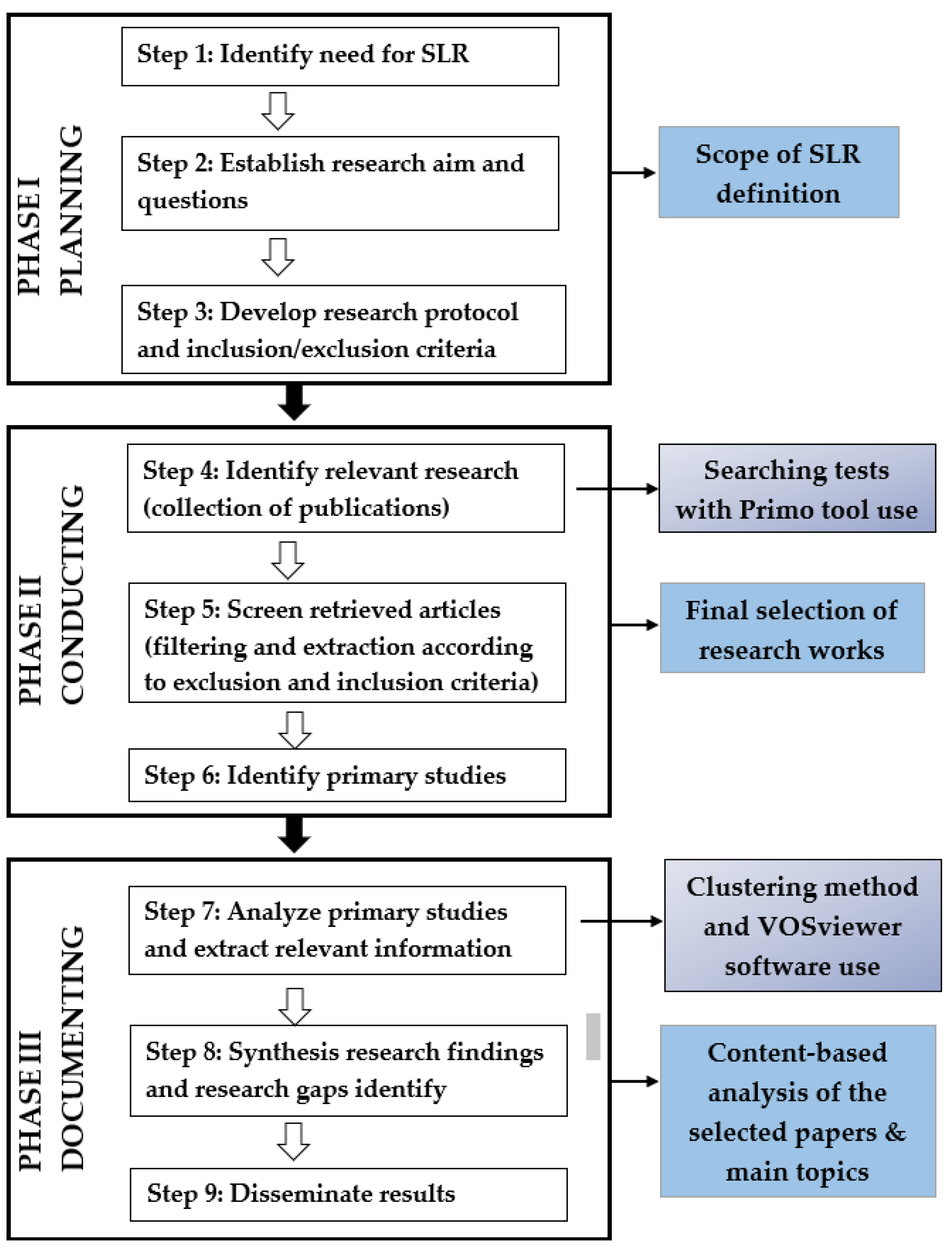

3. Review Methodology

3.1. Planning of the SLR Study

- RQ1:

- What is the current state of the literature on digital twin use in transportation systems operation and maintenance between 2012 and 2024?

- RQ2:

- What are the main research and knowledge gaps in DT use in transportation systems operation and maintenance, especially in the context of in-house logistics?

- RQ3:

- What are the future research directions and perspectives in DT modeling in the context of the operation and maintenance of transportation systems?

- RQ4:

- What scope should the framework for digital twin for maintenance management of transportation systems have?

3.2. Conducting the SLR Study

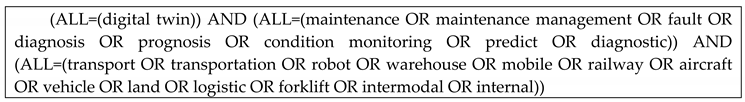

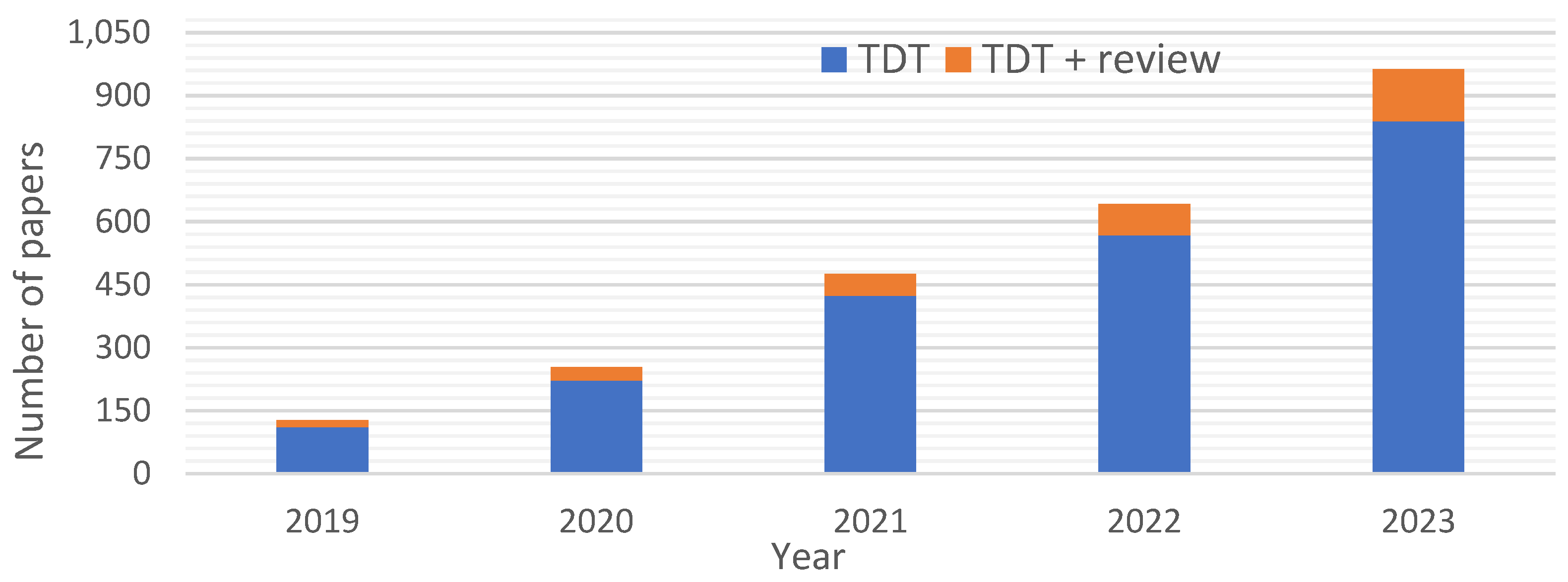

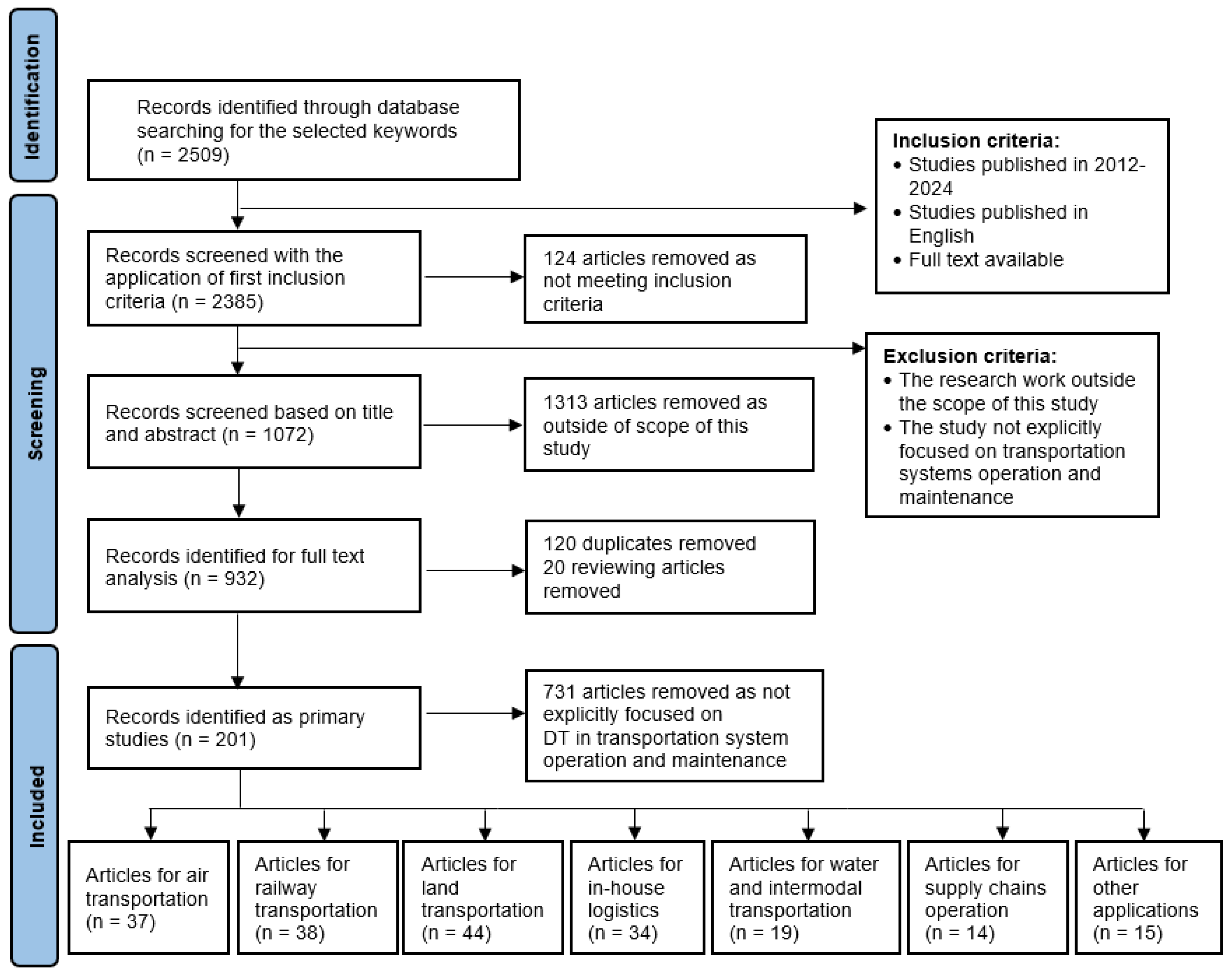

3.2.1. Collection of Publications for Review

3.2.2. Screening of Collected Publications

3.2.3. Primary Studies Identification

3.3. Documenting of the SLR Study

4. Systematic Review Analysis Results

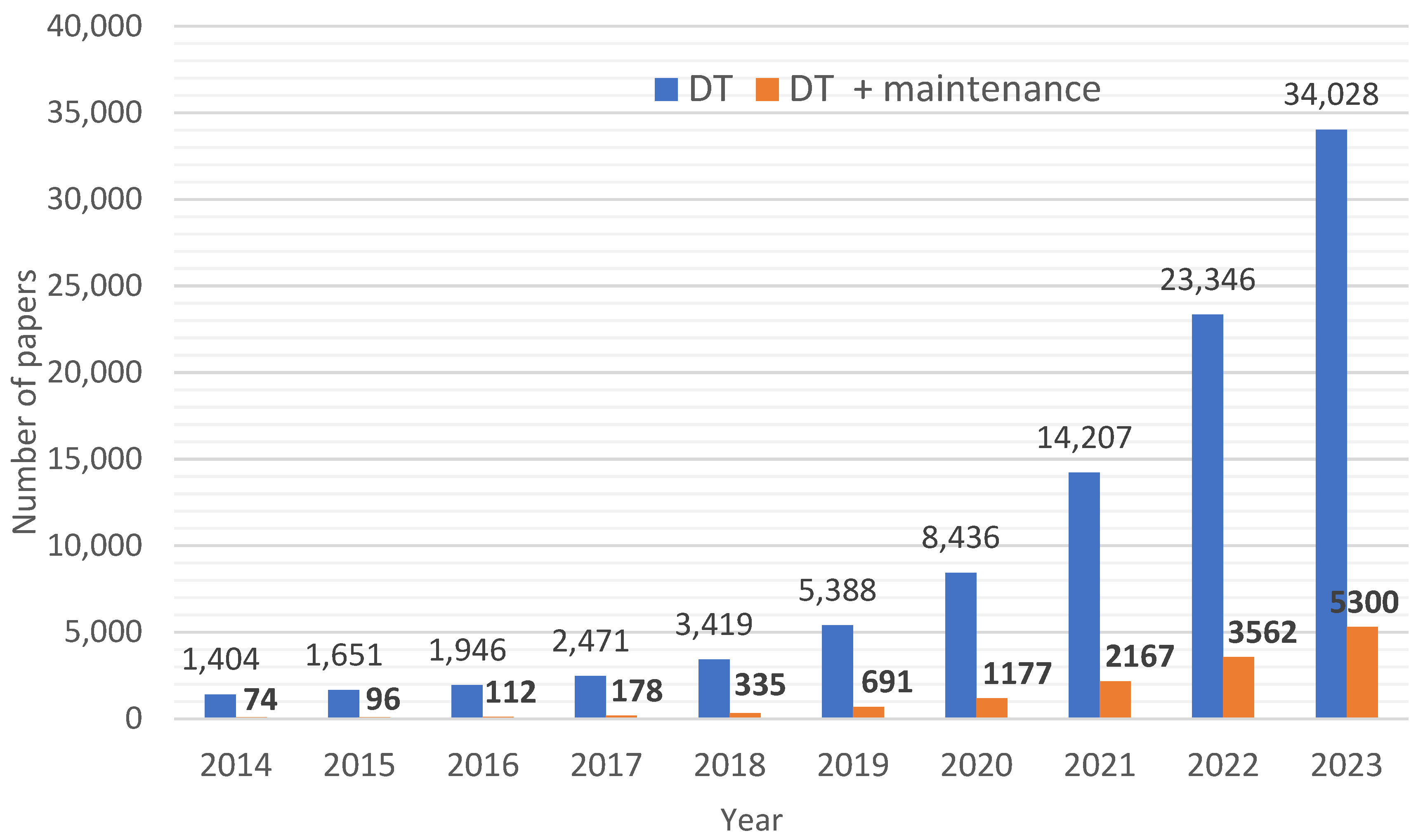

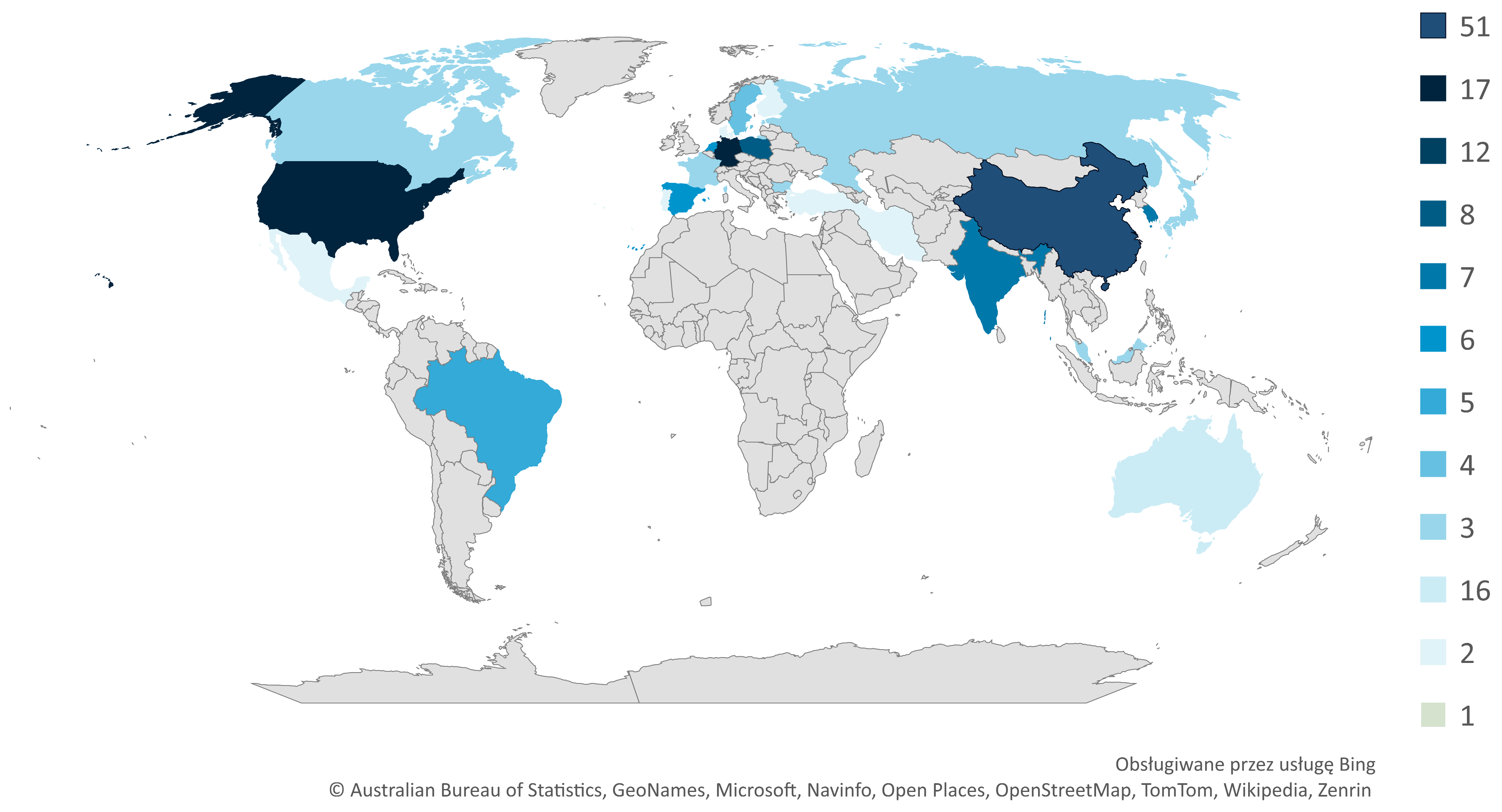

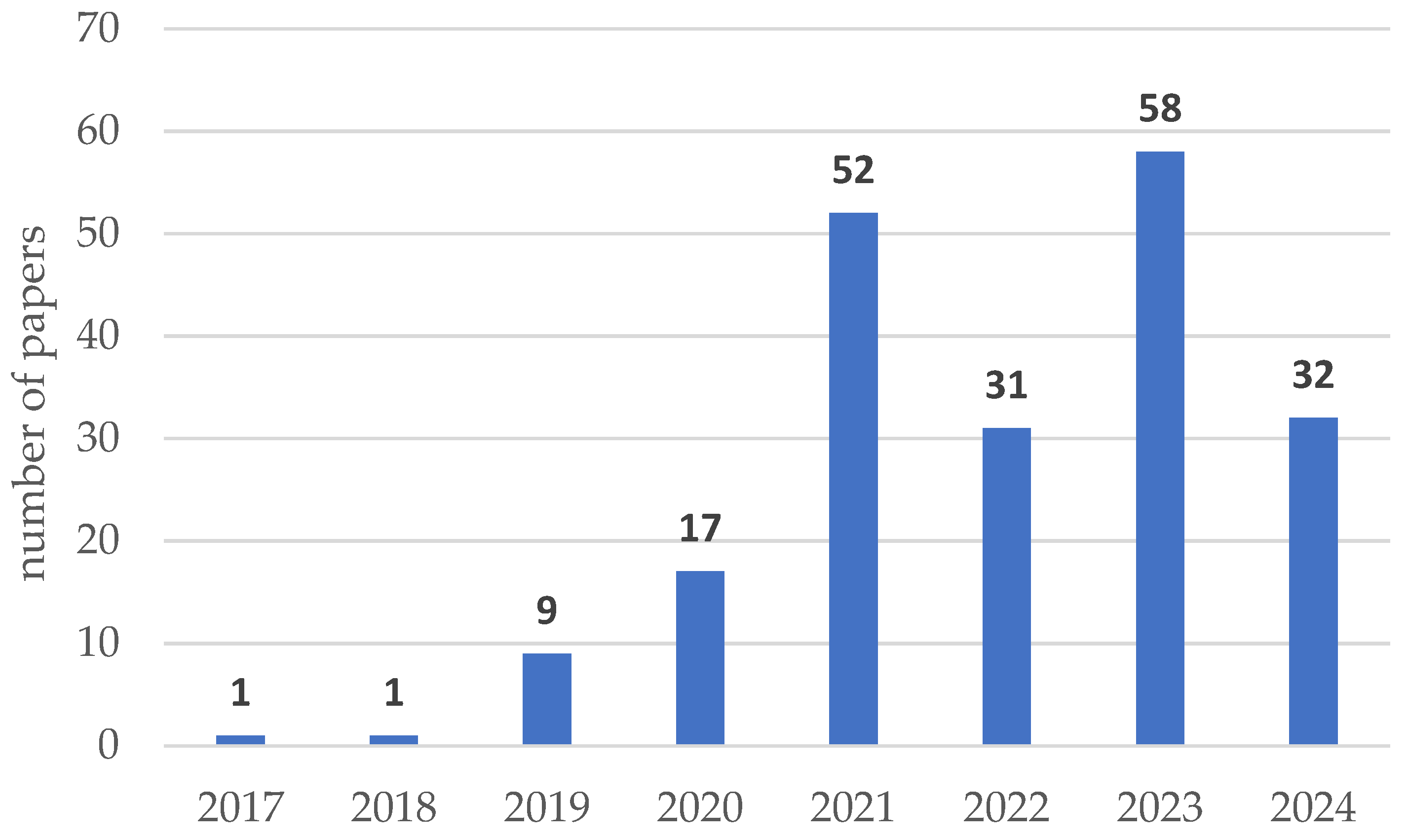

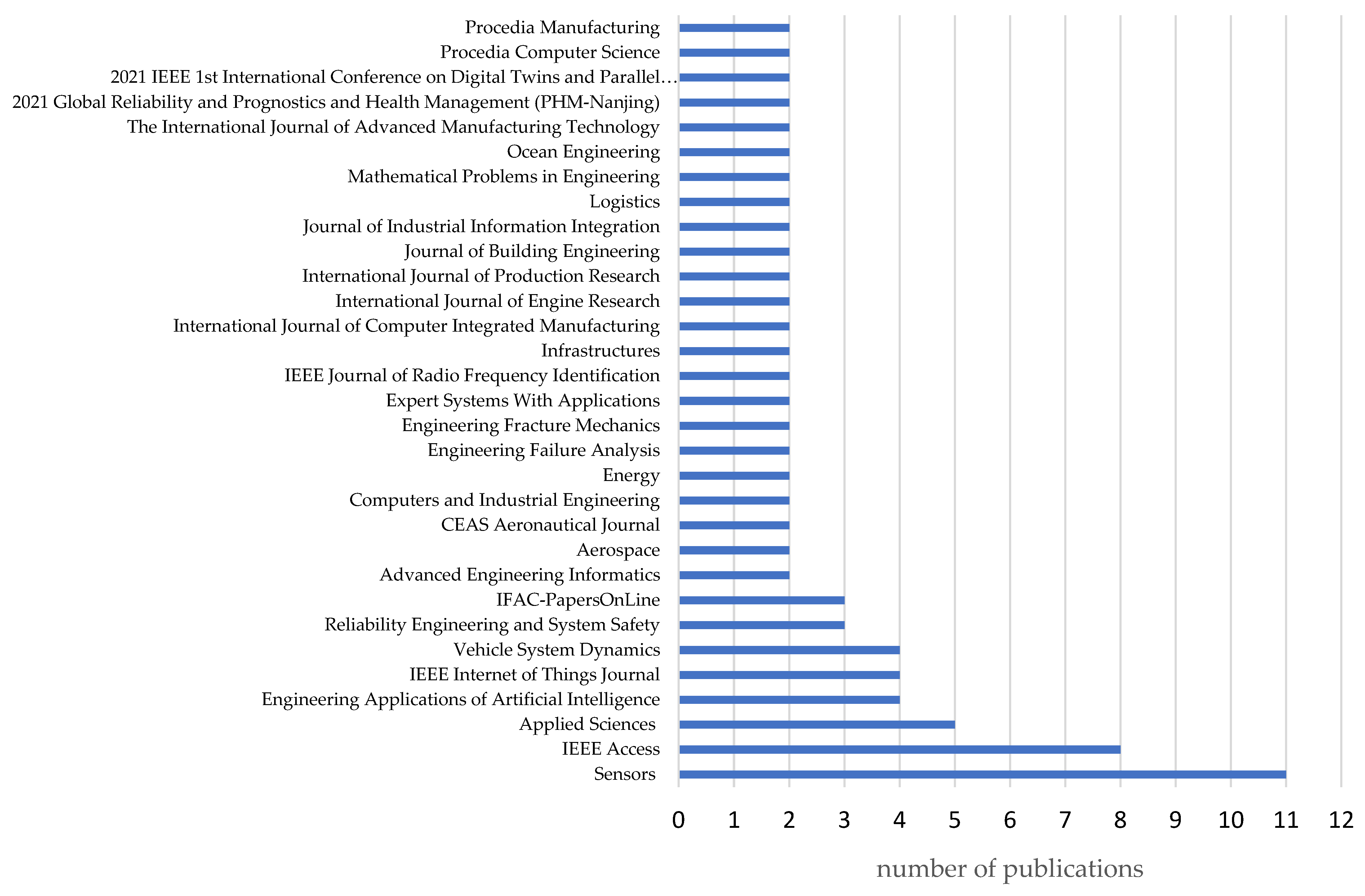

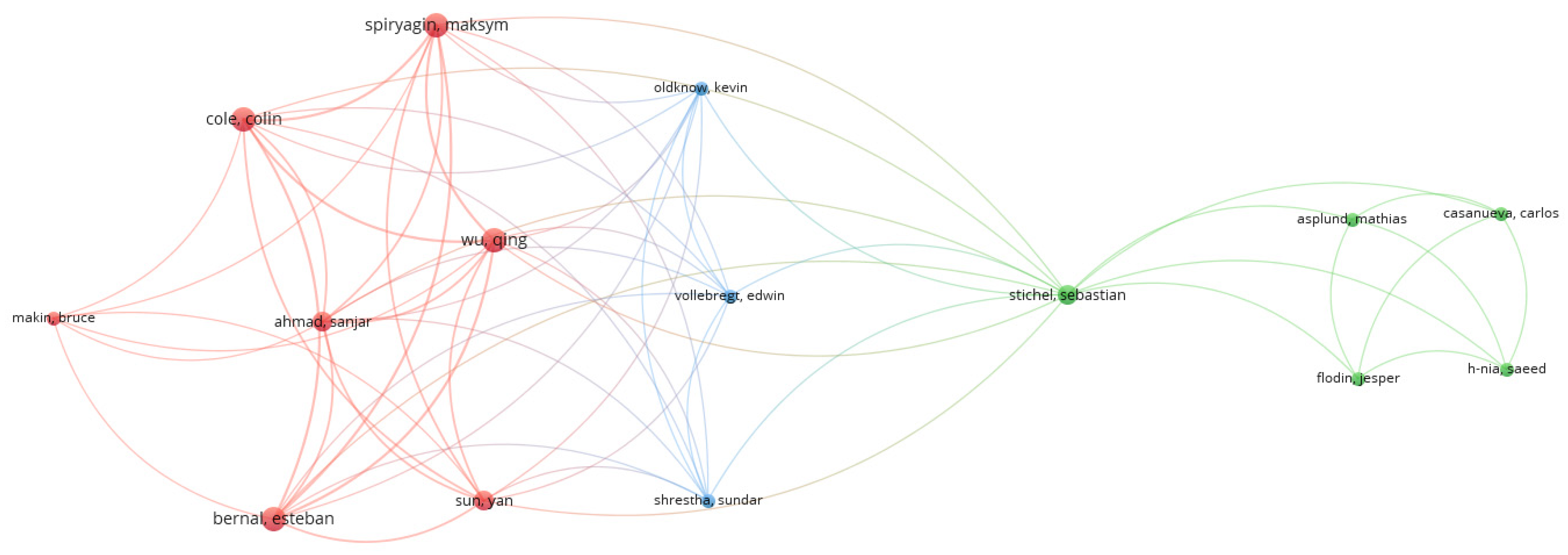

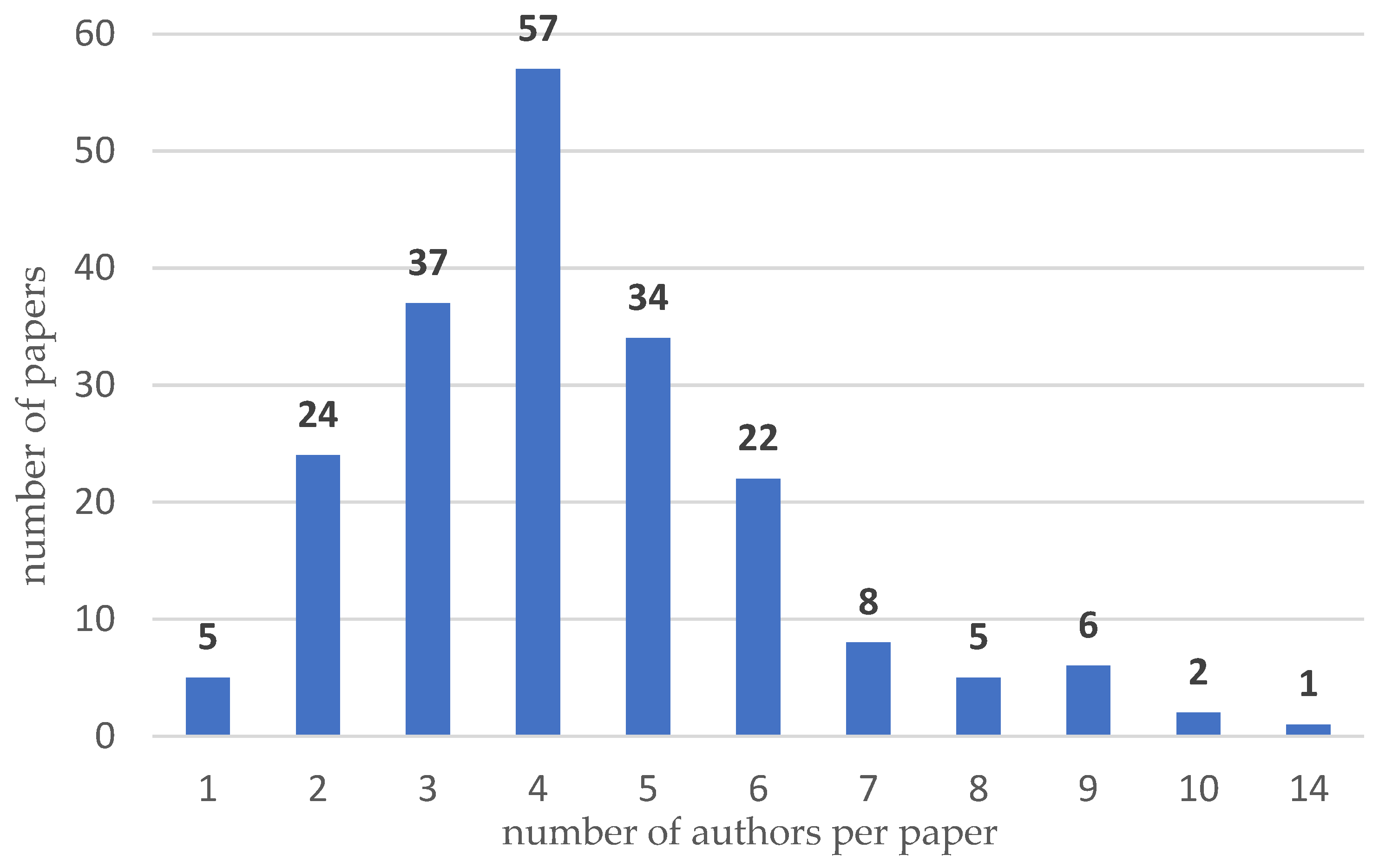

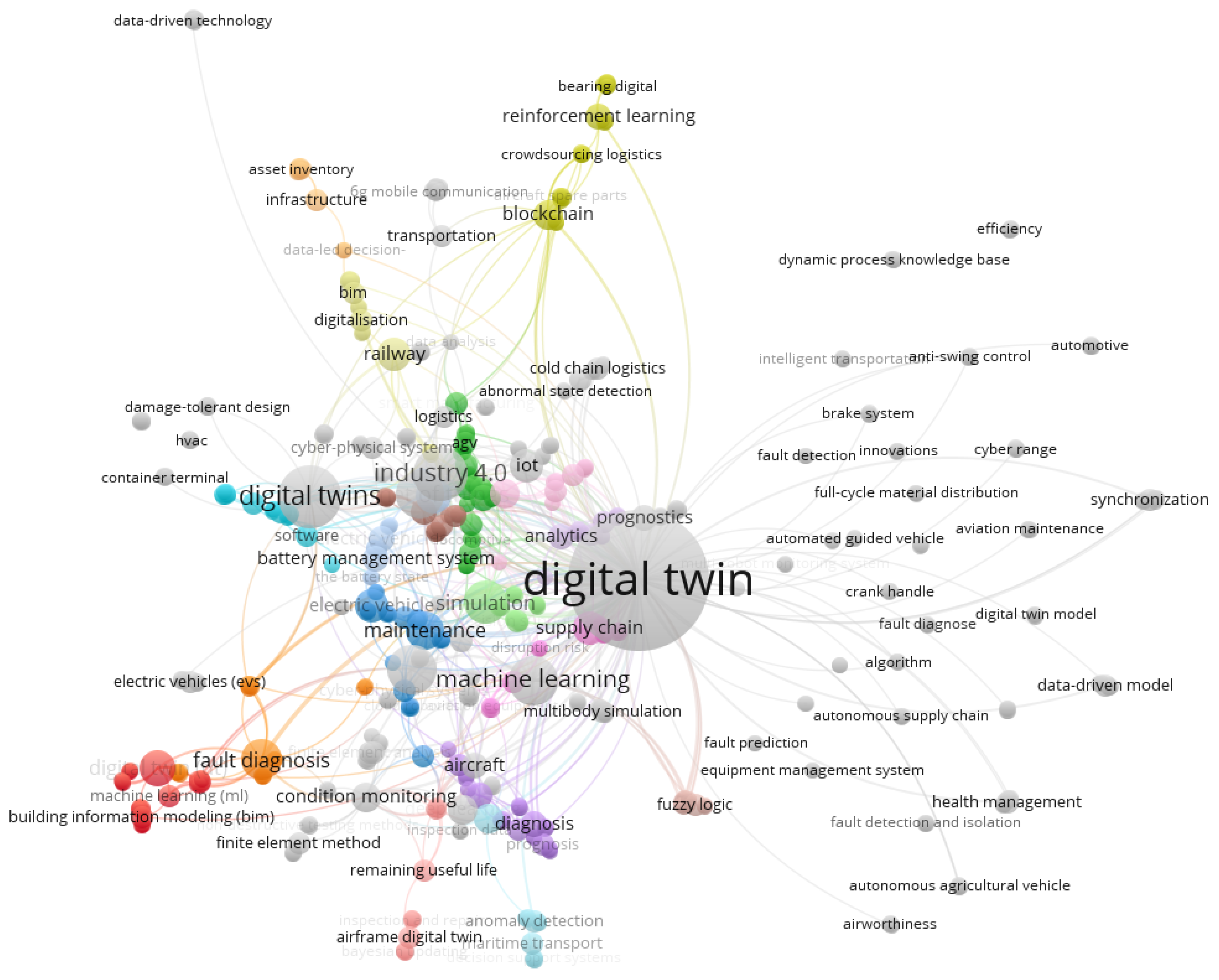

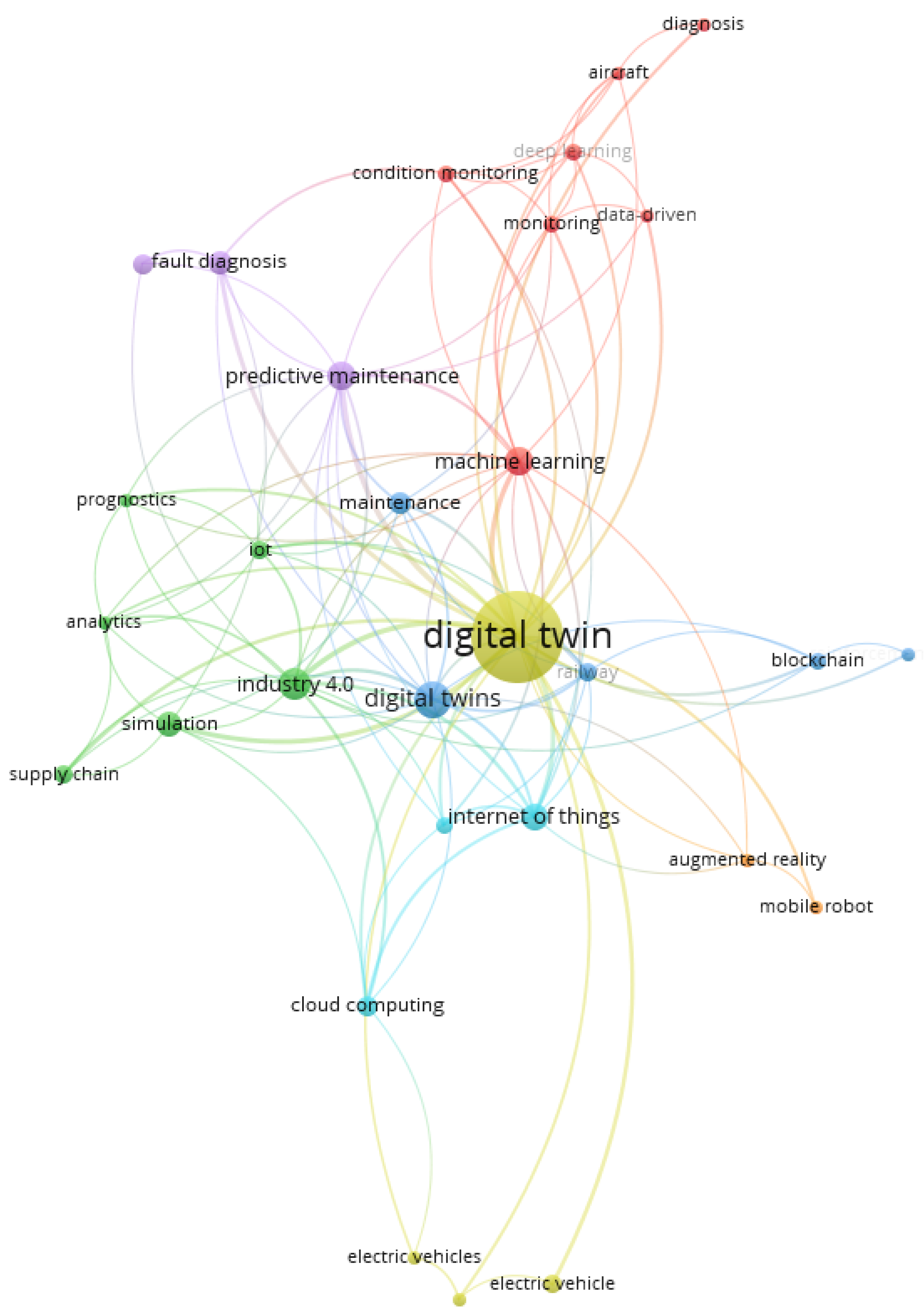

4.1. Bibliometric Analysis

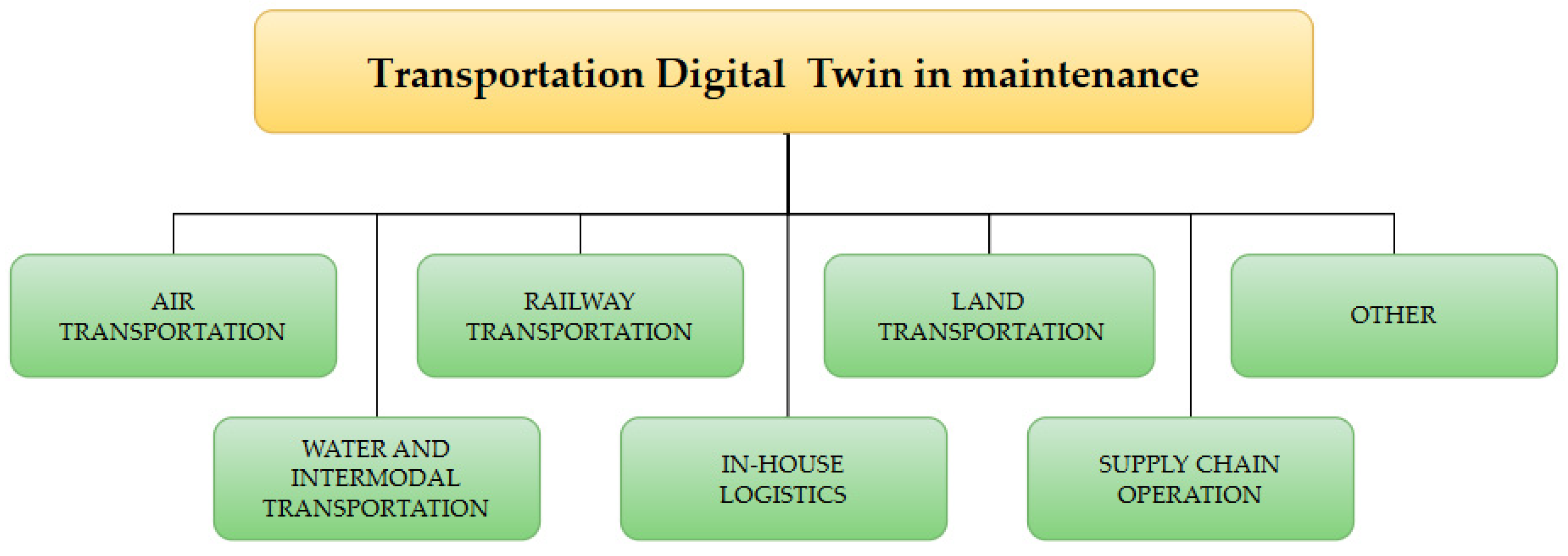

4.2. Content-Based Analysis

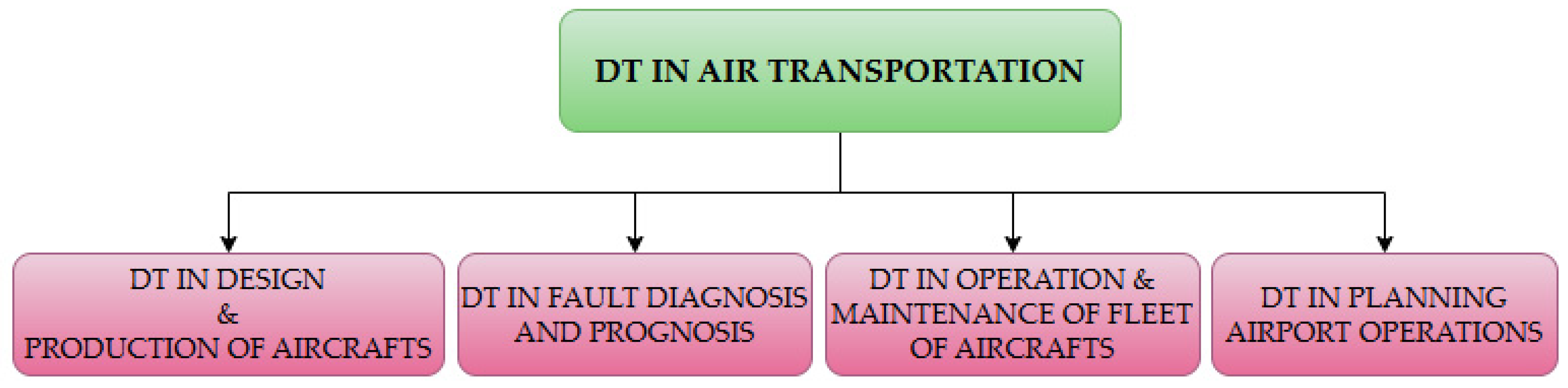

4.2.1. DT in Air Transportation

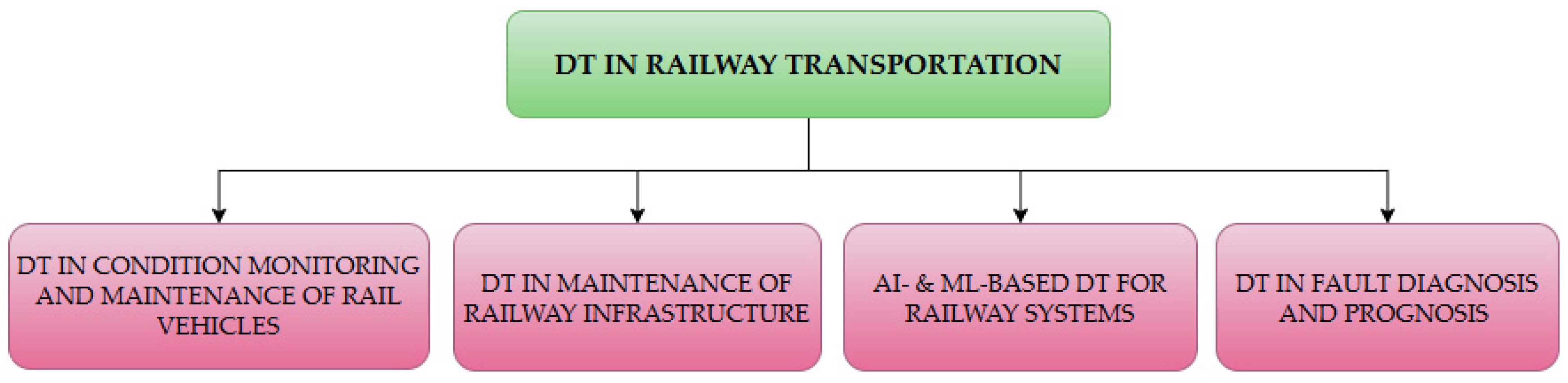

4.2.2. DT in Railway Transportation

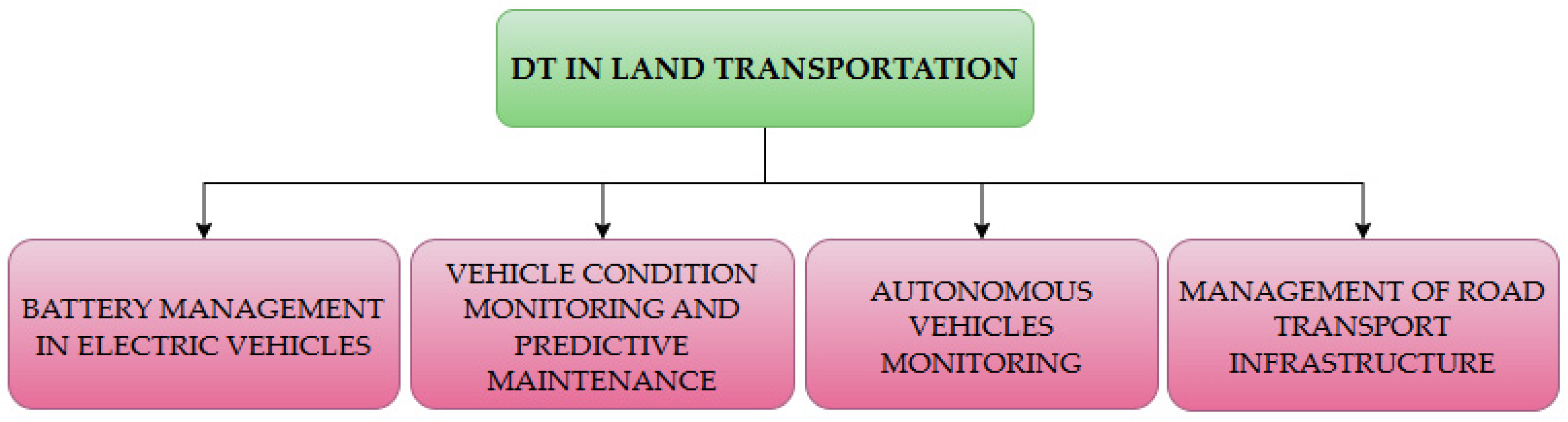

4.2.3. DT in Land Trasportation

4.2.4. DT in Supply Chain Operation

4.2.5. DT in Water and Intermodal Transportation

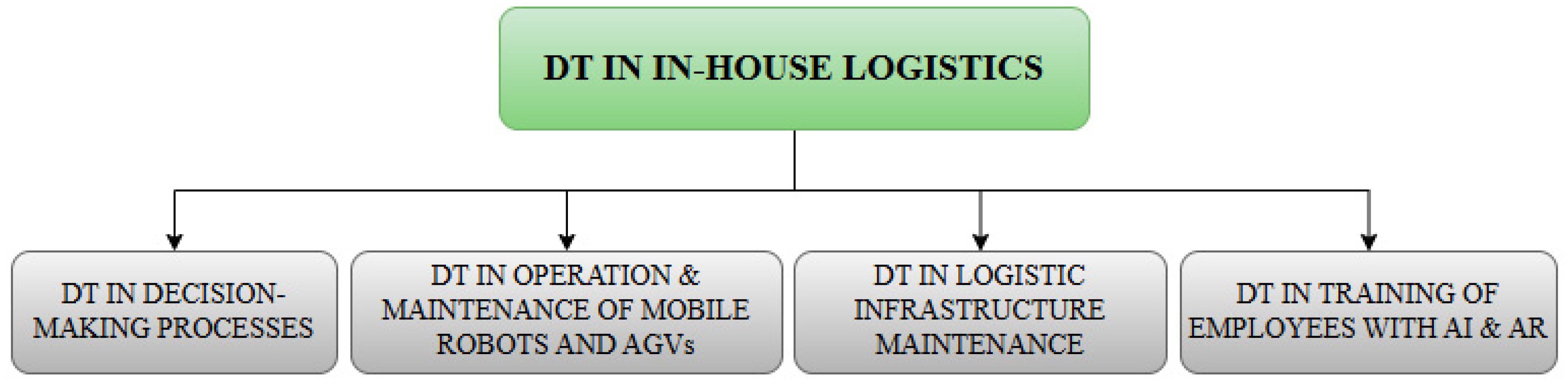

4.2.6. DT in In-House Logistics

4.2.7. Other Applications

5. Discussion

- technical condition monitoring: The digital twin enables continuous monitoring of the technical condition of vehicles and transportation infrastructure. Thanks to advanced sensors and IoT technologies, the DT can collect data on part wear, engine operating parameters, and even road conditions. This allows for the quick identification of potential technical problems and failures (see, e.g., [8,220]),

- optimization of maintenance plans and schedules: Utilizing data from the digital twin, more effective maintenance plans can be developed (maintenance scheduling). The DT allows for the individual adjustment of inspection and repair schedules to the actual technical condition of vehicles, which helps reduce the maintenance costs of the transport fleet (see, e.g., [306,329]).

- simulation and testing of new solutions: The digital twin enables the simulation of various operational scenarios and the testing of new technological solutions before their implementation in real conditions. This allows for the assessment of potential benefits and risks associated with the introduction of technological innovations in the operational activities of the transport fleet (see, e.g., [286,311]),

- optimization of fuel consumption and operational efficiency: The DT can be used to analyze and optimize fuel consumption and improve the operational efficiency of vehicles. By monitoring engine operating parameters, driver behavior, and road conditions, the DT helps identify areas needing improvement and implement effective fuel-saving strategies (e.g., [291,296]),

- remote technical support: Using remote connections and digital interfaces, the DT allows for providing technical support by experts from anywhere in the world. This enables quick problem diagnosis and provides real-time repair instructions and guidance (see, e.g., [265]),

- operational data analysis of the monitored fleet: The DT allows for the analysis of data collected from the entire fleet of vehicles, which helps identify trends and patterns related to failure rates, fuel consumption, and driver behavior. This information can be used to implement improvements and optimize fleet management processes (see, e.g., [183]),

- integration with management systems: The digital twin can be integrated with existing fleet and maintenance management systems, enabling automatic data transfer and collaboration between different platforms and applications. This helps streamline operations and improve data consistency and accessibility (see, e.g., [326]),

- safety and regulatory compliance: Implementing the DT in technical maintenance management requires addressing issues related to data security and compliance with regulatory requirements, such as data protection and occupational safety standards. Ensuring appropriate data protection measures and regulation compliance is crucial for successfully implementing the DT (e.g., [279,326]).

- technological innovations – transport companies will introduce new technologies, such as AI, robotics, the Internet of Things, AR, and VR, with a DT approach to improve the efficiency and reliability of maintenance processes,

- organizational innovations – aimed at introducing new management methods, work procedures, or business models (e.g., Robot as a Service), which enable more efficient resource utilization and enhance the effectiveness of maintenance activities,

- process innovations – focused on optimizing existing maintenance processes and introducing new strategies and tools that allow for quicker responses to changes in operational conditions and minimize the risk of failures.

- technical diagnostic issues: the necessity of monitoring and collecting significant amounts of information and processing this information for proper reporting.

- investment costs: implementing modern technologies requires substantial financial investment, which will become evident through minimized repair and vehicle downtime costs due to better planning and resource utilization. The issue of investment profitability may limit companies.

- data security in collection and transmission processes: ensuring the security of transmitted data and minimizing the risk of cyberattacks are key aspects to consider when implementing Industry 4.0 technologies.

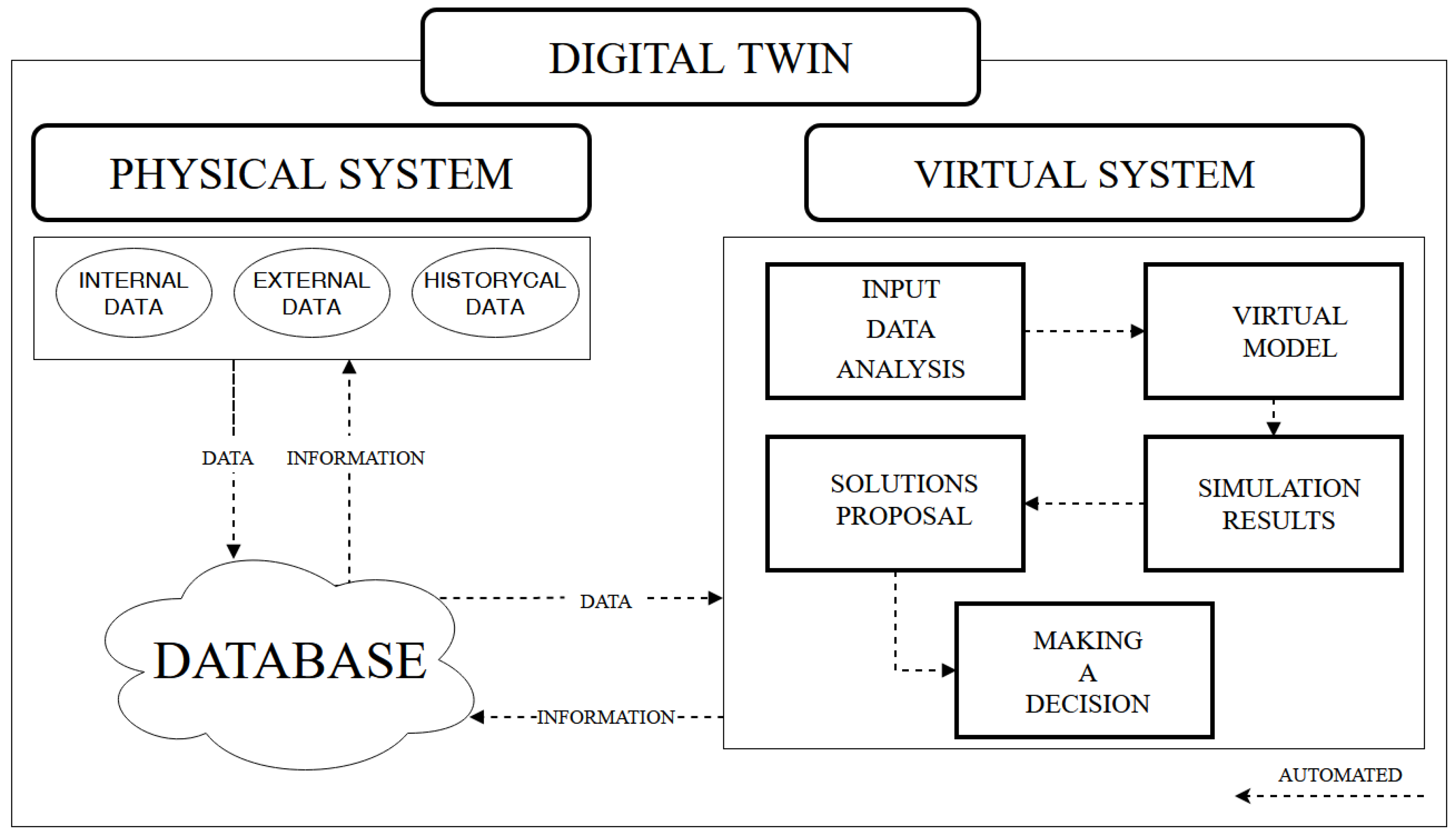

- Data acquisition and integration: this component involves collecting real-time data from various sources, including sensors, IoT devices, and existing management systems. It is crucial for creating a comprehensive digital representation of physical assets, as it enables aggregating relevant data such as operational conditions, maintenance history, and environmental factors. Effective integration of these diverse data streams ensures that the Digital Twin remains accurate and reflects the system’s status.

- Data analytics and visualization: once the data is collected, advanced analytics techniques, including machine learning and statistical analysis, are employed to derive insights. This component helps identify data patterns, trends, and anomalies, facilitating predictive maintenance and decision-making. Visualization tools play a critical role in presenting complex data in a user-friendly manner, enabling stakeholders to interpret findings and make informed decisions easily.

- Simulation and modeling: this aspect of the framework allows for creating of virtual models that replicate the behavior of physical assets under various conditions. Through simulation, organizations can test different maintenance scenarios, evaluate the impact of potential changes, and optimize maintenance schedules. This capability not only aids in risk assessment but also supports strategic planning and resource allocation.

- Communication and collaboration tools: effective communication among stakeholders is essential for successfully implementing the Digital Twin framework. Collaborative tools enable seamless information sharing, ensuring that all team members, from maintenance personnel to management, are aligned and informed about asset status and maintenance activities.

- Feedback mechanisms: a vital component of the Digital Twin framework is the establishment of feedback loops that facilitate continuous improvement. By analyzing the outcomes of maintenance actions and comparing them with the predictions made by the Digital Twin, organizations can refine their models and improve their predictive capabilities, leading to more effective maintenance strategies over time.

- condition monitoring – providing dashboards and alerts that reflect the real-time health status of assets, allowing for immediate action when anomalies are detected,

- failure prediction – implementing predictive algorithms that analyze historical and real-time data to forecast potential failures and recommend maintenance actions accordingly,

- maintenance scheduling – automatically generating and optimizing maintenance schedules based on predicted failure points, historical maintenance data, and operational requirements,

- resource management – helping manage spare parts inventory and resource allocation by predicting the demand for parts based on the analysis of maintenance schedules,

- reporting and compliance – facilitating reporting functionalities to ensure compliance with regulatory requirements and standards in maintenance practices,

- feedback loop – establishing a feedback mechanism to continuously improve the digital twin models and algorithms based on actual maintenance outcomes and operational experiences.

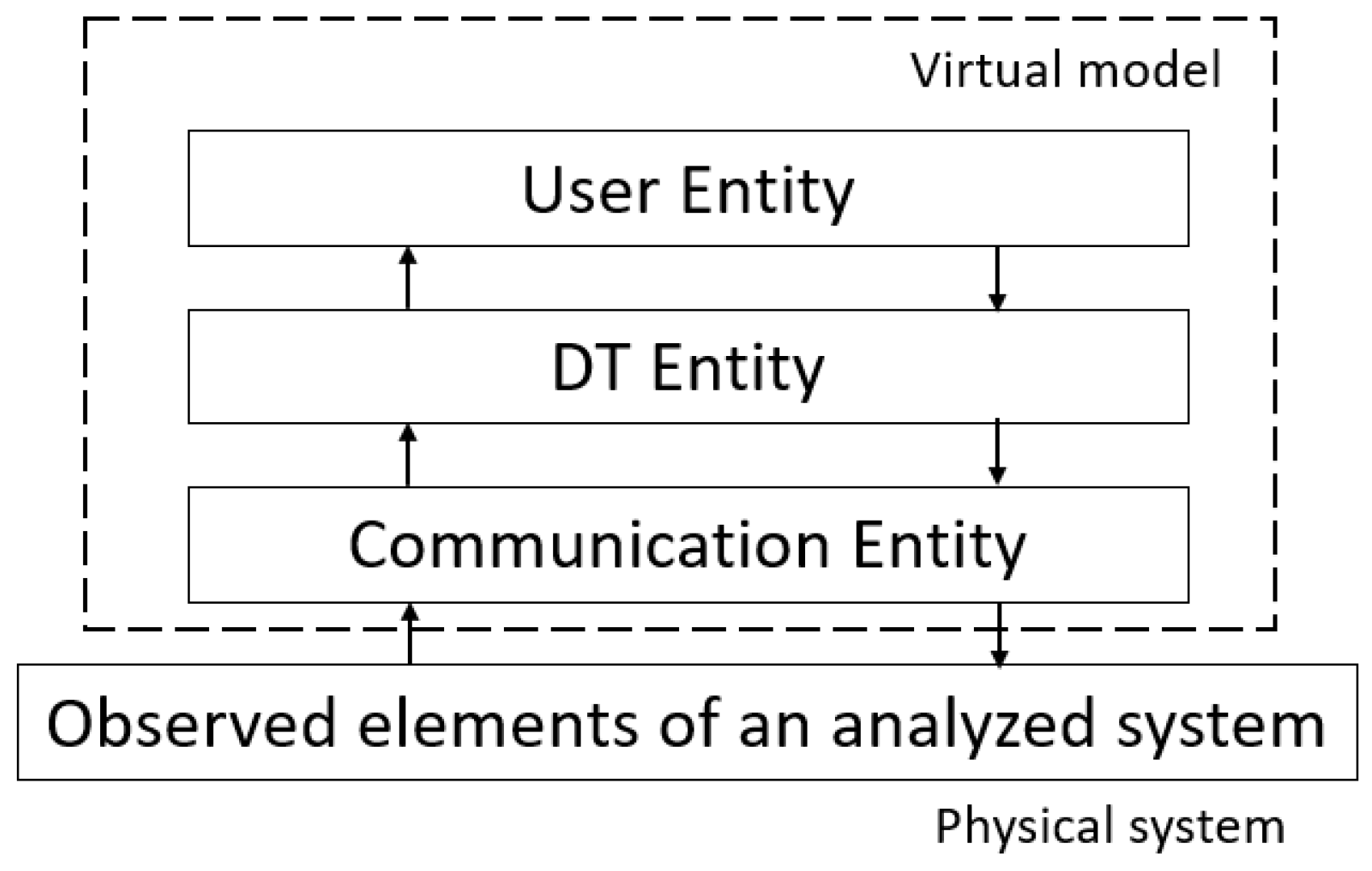

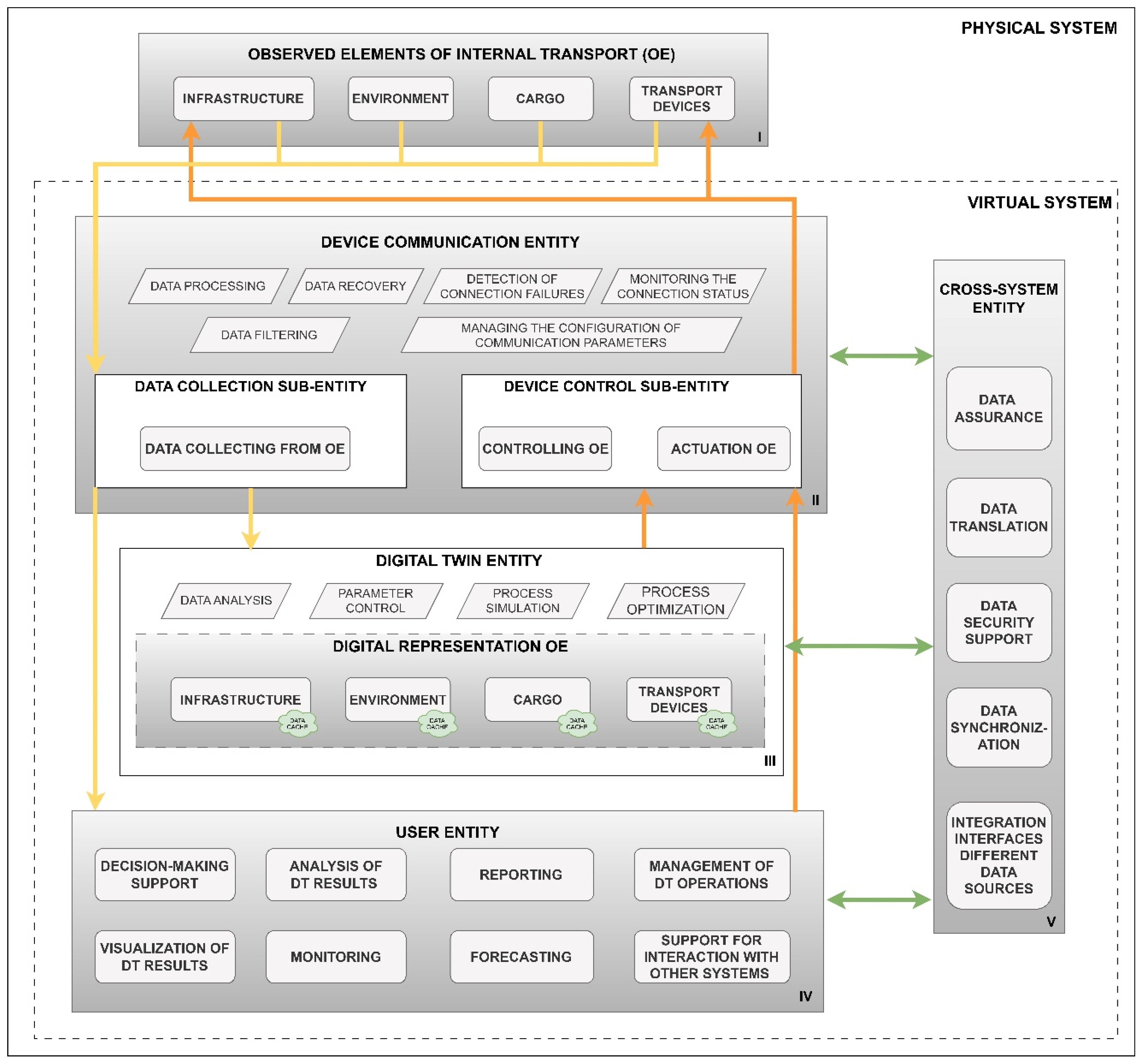

6. Framework for DT in Transportation System Maintenance Management

- -

- fully automated mode, where a closed-loop connection exists between the communication unit and the DT unit,

- -

- semi-automated mode, where feedback with instructions comes directly from the user unit.

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ABBREVIATION | FULL DESCRIPTION |

| AGV | Automated Guided Vehicles |

| AI | Artificial Intelligence |

| ASC | Automated Stacking Cranes |

| BIM | Building Information Modeling |

| DEVOTION | DEVelOping digital TwIn systems with autOmated model maNagement |

| DM | Digital Model |

| DRL | Deep Reinforcement Learning |

| DS | Digital Shadow |

| DT | Digital Twin |

| DTI | Digital Twin Instance |

| DTP | Digital Twin Prototype |

| EDT | Experimentable Digital Twin |

| ESDT | Early Stage Digital Twin |

| FMEA | Failure Mode and Effect Analysis |

| IoT | Internet of Things |

| MAS | Multi-Agent System |

| ML | Machine Learning |

| OE | Observed elements of internal transport |

| O&M | Operation and Maintenance |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyzes |

| RIS | Reconfigurable Intelligent Surface |

| SLR | Systematic Literature Review |

| TDT | Transportation Digital Twin |

| UAV | Unmanned Aerial Vehicle |

| UUV | Unmanned Underwater Vehicle |

| VR | Virtual Reality |

Appendix A

| SOURCE | NUMBER OF WORKS |

| CONFERENCE PROCEEDINGS | |

| 2019 IEEE 60th Annual International Scientific Conference on Power and Electrical Engineering of Riga Technical University, RTUCON 2019 | 1 |

| 2019 IEEE Aerospace Conference | 1 |

| 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC) | 1 |

| 2020 IEEE International Conference on Big Data (Big Data) | 1 |

| 2021 13th Electrical Engineering Faculty Conference (BulEF) | 1 |

| 2021 28th International Workshop on Electric Drives: Improving Reliability of Electric Drives, IWED2021 | 1 |

| 2021 Global Reliability and Prognostics and Health Management (PHM-Nanjing) | 2 |

| 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI) | 2 |

| 2021 IEEE 23rd Conference on Business Informatics, CBI | 1 |

| 2021 IEEE 23rd International Conference on High Performance Computing and Communications, 7th International Conference on Data Science and Systems, 19th International Conference on Smart City and 7th International Conference on Dependability in Sensor, Cl | 1 |

| 2021 IEEE International Power and Renewable Energy Conference, IPRECON 2021 | 1 |

| 2021 International Conference on ICT for Smart Society (ICISS) | 1 |

| 2021 International Symposium on Computer Science and Intelligent Controls (ISCSIC) IoT | 1 |

| 2022 IEEE 23rd International Symposium on a World of Wireless, Mobile and Multimedia Networks, WoWMoM | 1 |

| 2023 20th Technical Scientific Conference on Aviation Dedicated to the Memory of N.E. Zhukovsky, TSCZh 2023 | 1 |

| 2023 25th European Conference on Power Electronics and Applications, EPE 2023 ECCE Europe | 1 |

| 2023 European Control Conference, ECC 2023 | 1 |

| 2023 IEEE International Conference on Omni-Layer Intelligent Systems, COINS 2023 | 1 |

| 2023 IEEE International Electric Machines and Drives Conference, IEMDC 2023 | 1 |

| 25th AIAA/AHS Adaptive Structures Conference | 1 |

| 30th National Conference with International Participation “Telecom 2022” | 1 |

| 4th International Conference on Smart Grid and Renewable Energy, SGRE 2024 - Proceedings | 1 |

| 7th International Conference on Inventive Computation Technologies, ICICT 2024 | 1 |

| Advances in Production, Logistics and Traffic. ICPLT 2019. Lecture Notes in Logistics | 1 |

| AIP Conference Proceedings | 1 |

| Bridge Safety, Maintenance, Management, Life-Cycle, Resilience and Sustainability - Proceedings of the 11th International Conference on Bridge Maintenance, Safety and Management, IABMAS 2022 | 1 |

| Case Studies on Transport Policy | 1 |

| Ce/Papers | 1 |

| Congress in Computer Science, Computer Engineering, and Applied Computing | 1 |

| Global Power, Energy and Communication Conference, | 1 |

| IEEE International Conference on Automation Science and Engineering | 1 |

| IEEE International Conference on Industrial Engineering and Engineering Management | 1 |

| IEEE International Conference on Industrial Informatics (INDIN) | 1 |

| IEEE International Symposium on Industrial Electronics | 1 |

| IFAC-PapersOnLine | 3 |

| International Conference on Electronic Engineering | 1 |

| International Multi-Conference on Systems, Signals & Devices | 1 |

| IOP Conference Series: Materials Science and Engineering | 1 |

| Journal of Physics: Conference Series | 1 |

| Materials Today: Proceedings | 1 |

| PHM Society Asia-Pacific Conference | 1 |

| Procedia CIRP | 1 |

| Procedia Computer Science | 2 |

| Procedia Manufacturing | 2 |

| Proceedings - 2020 IEEE International Conference on Engineering, Technology and Innovation, ICE/ITMC 2020 | 1 |

| Proceedings - 2022 CPSSI 4th International Symposium on Real-Time and Embedded Systems and Technologies, RTEST 2022 | 1 |

| Proceedings - 2023 ACM/IEEE International Conference on Model Driven Engineering Languages and Systems Companion, MODELS-C 2023 | 1 |

| Proceedings - 2023 IEEE SmartWorld, Ubiquitous Intelligence and Computing, Autonomous and Trusted Vehicles, Scalable Computing and Communications, Digital Twin, Privacy Computing and Data Security, Metaverse, SmartWorld/UIC/ATC/ScalCom/DigitalTwin/PCDS/Me | 1 |

| Proceedings - 2023 IEEE/ACM Symposium on Edge Computing, SEC 2023 | 1 |

| Proceedings - 2024 5th International Conference on Mobile Computing and Sustainable Informatics, ICMCSI 2024 | 1 |

| Proceedings of the 2020 Winter Simulation Conference | 1 |

| Proceedings of the 2022 Winter Simulation Conference | 1 |

| Proceedings of the ASME Turbo Expo American Society of Mechanical Engineers (ASME) | 1 |

| Transportation Research Procedia | 1 |

| JOURNALS | |

| Academy of Strategic Management Journal | 1 |

| Advanced Engineering Informatics | 2 |

| Advances in Civil Engineering | 1 |

| Advances in Transdisciplinary Engineering | 1 |

| Aerospace | 2 |

| Aerospace Systems | 1 |

| Aircraft Engineering and Aerospace Technology | 1 |

| Alphanumeric Journal | 1 |

| Applied Sciences | 5 |

| Applied System Innovation | 1 |

| Batteries | 1 |

| CEAS Aeronautical Journal | 2 |

| China Communications | 1 |

| Computers | 1 |

| Computers and Electrical Engineering | 1 |

| Computers and Industrial Engineering | 2 |

| Computers and Operations Research | 1 |

| Computers in Industry | 1 |

| Decision Support Systems | 1 |

| Designs | 1 |

| Energy | 2 |

| Energy Storage | 1 |

| Engineering Applications of Artificial Intelligence | 4 |

| Engineering Failure Analysis | 2 |

| Engineering Fracture Mechanics | 2 |

| Eurasip Journal on Wireless Communications and Networking | 1 |

| Expert Systems With Applications | 2 |

| Frontiers in Bioengineering and Biotechnology | 1 |

| Frontiers of Engineering Management | 1 |

| Fusion Engineering and Design | 1 |

| Future Internet | 1 |

| High-speed Railway | 1 |

| IEEE Access | 8 |

| IEEE Communications Magazine | 1 |

| IEEE Intelligent Transportation Systems Magazine | 1 |

| IEEE Internet of Things Journal | 4 |

| IEEE Journal of Radio Frequency Identification | 2 |

| IEEE Transactions on Intelligent Transportation Systems | 1 |

| IEEE Transactions on Wireless Communications | 1 |

| IET Cyber-Systems and Robotics | 1 |

| IET Electric Power Applications | 1 |

| Indonesian Journal of Electrical Engineering and Computer Science | 1 |

| Information | 1 |

| Infrastructures | 2 |

| International Journal of Agricultural and Biological Engineering | 1 |

| International Journal of Computer Integrated Manufacturing | 2 |

| International Journal of Digital Earth | 1 |

| International Journal of Engine Research | 2 |

| International Journal of Green Energy | 1 |

| International Journal of Logistics Management | 1 |

| International Journal of Production Economics | 1 |

| International Journal of Production Research | 2 |

| Journal of Advanced Transportation | 1 |

| Journal of Airport Management | 1 |

| Journal of Building Engineering | 2 |

| Journal of Computational Design and Engineering | 1 |

| Journal of Industrial Information Integration | 2 |

| Journal of Intelligent Manufacturing | 1 |

| Journal of Manufacturing Systems | 1 |

| Journal of Reliable Intelligent Environments | 1 |

| Logistics | 2 |

| Lubricants | 1 |

| Machines | 1 |

| Materials | 1 |

| Mathematical and Computational Applications | 1 |

| Mathematical Problems in Engineering | 2 |

| Mathematics | 1 |

| Mechanical Systems and Signal Processing | 1 |

| Mobile Networks and Applications | 1 |

| Ocean Engineering | 2 |

| Operational Research | 1 |

| Platforms | 1 |

| Processes | 1 |

| Production Planning and Control | 1 |

| Quarterly Report of RTRI | 1 |

| R&D Journal | 1 |

| Reliability Engineering and System Safety | 3 |

| Renewable and Sustainable Energy Reviews | 1 |

| Scientific Reports | 1 |

| Sensors | 11 |

| SNE Technical Note | 1 |

| Technologies | 1 |

| The International Journal of Advanced Manufacturing Technology | 2 |

| Transactions on Transportation Electrification | 1 |

| Transportation Research Record | 1 |

| Vehicle System Dynamics | 4 |

| Vehicles | 1 |

| World Electric Vehicle Journal | 1 |

References

- Cockerell, B.S.; Systems, B. Is the Transportation Industry Ready for Digital Twins ? 2022.

- Kartsan, P.; Mavrin, S. The Digital Revolution of the Transportation Industry. Transp. Res. Procedia 2023, 68, 116–119. [CrossRef]

- Ammar, A.; Maier, F.; Pratt, W.S.; Richard, E.; Dadi, G. Practical Application of Digital Twins for Transportation Asset Data Management: Case Example of a Safety Hardware Asset. Transp. Res. Rec. 2024. [CrossRef]

- Astarita, V.; Guido, G.; Haghshenas, S.S.; Haghshenas, S.S. Risk Reduction in Transportation Systems: The Role of Digital Twins According to a Bibliometric-Based Literature Review. Sustain. 2024, 16. [CrossRef]

- Ersöz, O.Ö.; İnal, A.F.; Aktepe, A.; Türker, A.K.; Ersöz, S. A Systematic Literature Review of the Predictive Maintenance from Transportation Systems Aspect. Sustain. 2022, 14. [CrossRef]

- Alawaysheh, I.; Alsyouf, I. Environmental Sustainability in Maintenance Management of Public Transport Systems: Literature Review. IEEE Int. Conf. Ind. Eng. Eng. Manag. 2018, 2019-Decem, 1125–1129. [CrossRef]

- Bernal, E.; Spiryagin, M.; Cole, C. Onboard Condition Monitoring Sensors, Systems and Techniques for Freight Railway Vehicles: A Review. IEEE Sens. J. 2019, 19, 4–24. [CrossRef]

- Brant, J.; Liang, B. Condition Monitoring Systems in the Railway Industry BT - Advances in Asset Management and Condition Monitoring. In Advances in Asset Management and Condition Monitoring. Smart Innovation, Systems and Technologies, vol. 166; Ball, A., Gelman, L., Rao, B.K.N., Eds.; Springer International Publishing: Cham, 2020; pp. 671–683 ISBN 978-3-030-57745-2.

- Donato, L. De; Flammini, F.; Marrone, S.; Mazzariello, C.; Nardone, R.; Sansone, C.; Vittorini, V. A Survey on Audio-Video Based Defect Detection Through Deep Learning in Railway Maintenance. IEEE Access 2022, 10, 65376–65400. [CrossRef]

- Entezami, M.; Roberts, C.; Weston, P.; Stewart, E.; Amini, A.; Papaelias, M. Perspectives on Railway Axle Bearing Condition Monitoring. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 234, 17–31. [CrossRef]

- Fraga-Lamas, P.; Fernández-Caramés, T.M.; Castedo, L. Towards the Internet of Smart Trains: A Review on Industrial IoT-Connected Railways. Sensors (Switzerland) 2017, 17, 1457. [CrossRef]

- Sitarz, M.; Chruzik, K. An Approach to the Legal Requirements Regarding Railway Transport Safety Monitoring in the European Union. Transport 2019, 34, 163–174. [CrossRef]

- Chen, Y.; Li, Y.; Niu, G.; Zuo, M. Offline and Online Measurement of the Geometries of Train Wheelsets: A Review. IEEE Trans. Instrum. Meas. 2022, 71, 1–15. [CrossRef]

- Gogu, C. Prognostics and Health Management: Current State-of-the-Art for Optimizing Aircraft Structural Maintenance. 2018 19th Int. Conf. Therm. Mech. Multi-Physics Simul. Exp. Microelectron. Microsystems, EuroSimE 2018 2018, 1–4. [CrossRef]

- Meijer, M. Preventive Maintenance of Transport Vehicles Is It Improving Production Stability of a Smelter? BT - Light Metals 2013. In Light Metals 2013. The Minerals, Metals & Materials Series; Sadler, B.A., Ed.; Springer International Publishing, 2016; pp. 669–671 ISBN 978-3-319-65136-1.

- Hou, Y.; Li, Q.; Zhang, C.; Lu, G.; Ye, Z.; Chen, Y.; Wang, L.; Cao, D. The State-of-the-Art Review on Applications of Intrusive Sensing, Image Processing Techniques, and Machine Learning Methods in Pavement Monitoring and Analysis. Engineering 2021, 7, 845–856. [CrossRef]

- Wieczorek, A.; Stecuła, K.; Wes Grebski, W. Methods and Techniques Supporting Energy and Media Savings in Maintenance of Public Transport Buses—State of the Art and Recommendations. Energies 2024, 17, 2051. [CrossRef]

- Choudhary, A.; Fatima, S.; Panigrahi, B.K. State-of-the-Art Technologies in Fault Diagnosis of Electric Vehicles: A Component-Based Review. IEEE Trans. Transp. Electrif. 2023, 9, 2324–2347. [CrossRef]

- Knowles, M.; Ren, Q.; Baglee, D. The State of the Art in Fuel Cell Condition Monitoring and Maintenance. In Proceedings of the EVS 2010 - Sustainable Mobility Revolution: 25th World Battery, Hybrid and Fuel Cell Electric Vehicle Symposium and Exhibition; 2010; Vol. 4, pp. 487–494.

- Gbako, S.; Paraskevadakis, D.; Ren, J.; Wang, J.; Radmilovic, Z. A Systematic Literature Review of Technological Developments and Challenges for Inland Waterways Freight Transport in Intermodal Supply Chain Management. Benchmarking 2024. [CrossRef]

- Negi, P.; Kromanis, R.; Dorée, A.G.; Wijnberg, K.M. Structural Health Monitoring of Inland Navigation Structures and Ports: A Review on Developments and Challenges. Struct. Heal. Monit. 2024, 23, 605–645. [CrossRef]

- Allaix, D.L.; Bigaj-Van Vliet, A.; Cerar, B. Review of the Current State of Standardisation on Monitoring, Data-Informed Safety Assessment and Decision-Making Regarding Maintenance of the Transport Infrastructure; 2022; ISBN 9783857481833.

- Cepa, J.J.; Pavón, R.M.; Alberti, M.G.; Ciccone, A.; Asprone, D. A Review on the Implementation of the BIM Methodology in the Operation Maintenance and Transport Infrastructure. Appl. Sci. 2023, 13. [CrossRef]

- Hoelzl, C.; Dertimanis, V.; Landgraf, M.; Ancu, L.; Zurkirchen, M.; Chatzi, E. On-Board Monitoring for Smart Assessment of Railway Infrastructure: A Systematic Review. Rise Smart Cities Adv. Struct. Sens. Monit. Syst. 2022, 223–259. [CrossRef]

- Komalan, N. Aggregation and Fault Detection Techniques for Tracks Using Wireless Sensor Network. In Proceedings of the International Conference on Innovative Mechanisms for Industry Applications (ICIMIA 2017); 2017; pp. 116–123.

- Ngamkhanong, C.; Kaewunruen, S.; Afonso Costa, B.J. State-of-the-Art Review of Railway Track Resilience Monitoring. Infrastructures 2018, 3, 1–18. [CrossRef]

- Taheri, A.; Sobanjo, J. Civil Integrated Management (CIM) for Advanced Level Applications to Transportation Infrastructure: A State-of-the-Art Review. Infrastructures 2024, 9, 90. [CrossRef]

- Zinno, R.; Haghshenas, S.S.; Guido, G.; Vitale, A. Artificial Intelligence and Structural Health Monitoring of Bridges: A Review of the State-of-the-Art. IEEE Access 2022, 10, 88058–88078. [CrossRef]

- Tubis, A.A.; Rohman, J. Intelligent Warehouse in Industry 4.0—Systematic Literature Review. Sensors 2023, 23. [CrossRef] [PubMed]

- Selvam, K.; Dhiman, H.S.; Pandya, D.; Sahoo, S. Synergizing Digital Twins for Enhanced Maintenance of Integrated Chargers in Electric Vehicles: A State-of-the-Art Analysis and Future Implications. 2023 Int. Conf. Integr. Comput. Intell. Syst. ICICIS 2023 2023, 1–6. [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372. [CrossRef]

- Vohra, M. Overview of Digital Twin. In Digital Twin Technology: Fundamentals and Applications; Vohra, M., Ed.; Scrivener Publishing LLC, 2023; pp. 1–18.

- Singh, M.; Fuenmayor, E.; Hinchy, E.P.; Qiao, Y.; Murray, N.; Devine, D. Digital Twin: Origin to Future. Appl. Syst. Innov. 2021, 4, 1–19. [CrossRef]

- Boyes, H.; Watson, T. Digital Twins: An Analysis Framework and Open Issues. Comput. Ind. 2022, 143, 103763. [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the Art Theory and Practice, Challenges, and Open Research Questions. J. Ind. Inf. Integr. 2022, 30, 1–18. [CrossRef]

- Matyi, H.; Tamás, P. Application of Digital Twin Technology in the Development of Logistics Process. Adv. Logist. Syst. - Theory Pract. 2021, 15, 12–19. [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [CrossRef]

- Digital Twin: Definition & Value; 2020.

- Fang, X.; Wang, H.; Liu, G.; Tian, X.; Ding, G.; Zhang, H. Industry Application of Digital Twin: From Concept to Implementation. Int. J. Adv. Manuf. Technol. 2022, 121, 4289–4312. [CrossRef]

- van Beek, A.; Nevile Karkaria, V.; Chen, W. Digital Twins for the Designs of Systems: A Perspective. Struct. Multidiscip. Optim. 2023, 66, 1–17. [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A Systematic Literature Review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [CrossRef]

- Schwartz, S.M.; Wildenhaus, K.; Bucher, A.; Byrd, B. Digital Twins and the Emerging Science of Self: Implications for Digital Health Experience Design and “Small” Data. Front. Comput. Sci. 2020, 2, 1–16. [CrossRef]

- Rasheed, A.; San, O.; Kvamsdal, T. Digital Twin: Values, Challenges and Enablers from a Modeling Perspective. IEEE Access 2020, 8, 21980–22012. [CrossRef]

- Sharma, A.; Kosasih, E.; Zhang, J.; Brintrup, A.; Calinescu, A. Digital Twins: State of the Art Theory and Practice, Challenges, and Open Research Questions. J. Ind. Inf. Integr. 2022, 100383. [CrossRef]

- Harper, K.E.; Ganz, C.; Harper, K.E. Digital Twin Architecture and Standards. IIC J. Innov. 2019, 1–12.

- van der Valk, H.; Haße, H.; Möller, F.; Otto, B. Archetypes of Digital Twins. Bus. Inf. Syst. Eng. 2022, 64, 375–391. [CrossRef]

- Rathore, M.M.; Shah, S.A.; Shukla, D.; Bentafat, E.; Bakiras, S. The Role of AI, Machine Learning, and Big Data in Digital Twinning: A Systematic Literature Review, Challenges, and Opportunities. IEEE Access 2021, 9, 32030–32052. [CrossRef]

- Minerva, R.; Lee, G.M.; Crespi, N. Digital Twin in the IoT Context: A Survey on Technical Features, Scenarios, and Architectural Models. In Proceedings of the Proceedings of the IEEE; 2020; Vol. 108, pp. 1785–1824.

- Lv, Z. Digital Twins in Industry 5.0. Research 2023, 6, 1–16. [CrossRef]

- Tao, F.; Qi, Q.; Wang, L.; Nee, A.Y.C. Digital Twins and Cyber–Physical Systems toward Smart Manufacturing and Industry 4.0: Correlation and Comparison. Engineering 2019, 5, 653–661. [CrossRef]

- Fett, M.; Turner, E.; Breimann, R.; Kirchner, E. Extension of the System Boundary of the Digital Twin onto the Sensors of the Physical Twin through the Introduction of Redundant Soft Sensors. Forsch. im Ingenieurwesen/Engineering Res. 2023, 479–488. [CrossRef]

- Xu, Y.; Kohtz, S.; Boakye, J.; Gardoni, P.; Wang, P. Physics-Informed Machine Learning for Reliability and Systems Safety Applications: State of the Art and Challenges. Reliab. Eng. Syst. Saf. 2023, 230, 108900. [CrossRef]

- Röhm, B.; Emich, B.; Anderl, R. Approach of Simulation Data Management for the Application of the Digital Simulation Twin. Procedia CIRP 2021, 100, 421–426. [CrossRef]

- Bestjak, L.; Lindqvist, C. Assessment of How Digital Twin Can Be Utilized in Manufacturing Companies to Create Business Value. 2020.

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Kahlen, F.J., Flumerfelt, S., Alves, A., Eds.; Springer International Publishing Switzerland, 2017; pp. 85–113 ISBN 9783319387567.

- Jones, D.E.; Snider, C.; Kent, L.; Hicks, B. Early Stage Digital Twins for Early Stage Engineering Design. Proc. Int. Conf. Eng. Des. ICED 2019, 2019-Augus, 2557–2566. [CrossRef]

- Schluse, M.; Rossmann, J. From Simulation to Experimentable Digital Twins: Simulation-Based Development and Operation of Complex Technical Systems. ISSE 2016 - 2016 Int. Symp. Syst. Eng. - Proc. Pap. 2016, 1–6. [CrossRef]

- Wang, K.; Wang, Y.; Li, Y.; Fan, X.; Xiao, S.; Hu, L. A Review of the Technology Standards for Enabling Digital Twin. Digit. Twin 2022, 2, 4. [CrossRef]

- Botín-Sanabria, D.M.; Mihaita, S.; Peimbert-García, R.E.; Ramírez-Moreno, M.A.; Ramírez-Mendoza, R.A.; Lozoya-Santos, J. de J. Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sens. 2022, 14, 1–25. [CrossRef]

- Ozkaya, I. Architectural Concerns of Digital Twins. IEEE Softw. 2022, 39, 3–6. [CrossRef]

- Radanliev, P.; De Roure, D.; Nicolescu, R.; Huth, M.; Santos, O. Digital Twins: Artificial Intelligence and the IoT Cyber-Physical Systems in Industry 4.0. Int. J. Intell. Robot. Appl. 2022, 6, 171–185. [CrossRef]

- Balogh, M.; Földvári, A.; Varga, P. Digital Twins in Industry 5.0: Challenges in Modeling and Communication. In Proceedings of the Proceedings of IEEE/IFIP Network Operations and Management Symposium 2023, NOMS 2023; 2023; Vol. 0, pp. 0–5.

- Wang, B.; Zhou, H.; Li, X.; Yang, G.; Zheng, P.; Song, C.; Yuan, Y.; Wuest, T.; Yang, H.; Wang, L. Human Digital Twin in the Context of Industry 5.0. Robot. Comput. Integr. Manuf. 2024, 85, 102626. [CrossRef]

- Eleftheriou, O.T.; Anagnostopoulos, C.-N. Digital Twins: A Brief Overview of Applications, Challenges and Enabling Technologies in the Last Decade. Digit. Twin 2022, 2, 2. [CrossRef]

- Alnowaiser, K.K.; Ahmed, M.A. Digital Twin: Current Research Trends and Future Directions. Arab. J. Sci. Eng. 2023, 48, 1075–1095. [CrossRef]

- Hribernik, K.; Cabri, G.; Mandreoli, F.; Mentzas, G. Autonomous, Context-Aware, Adaptive Digital Twins—State of the Art and Roadmap. Comput. Ind. 2021, 133, 103508. [CrossRef]

- Hu, W.; Zhang, T.; Deng, X.; Liu, Z.; Tan, J. Digital Twin: A State-of-the-Art Review of Its Enabling Technologies, Applications and Challenges. J. Intell. Manuf. Spec. Equip. 2021, 2, 1–34. [CrossRef]

- Kuehner, K.J.; Scheer, R.; Strassburger, S. Digital Twin: Finding Common Ground - A Meta-Review. Procedia CIRP 2021, 104, 1227–1232. [CrossRef]

- Alcaraz, C.; Lopez, J. Digital Twin: A Comprehensive Survey of Security Threats. IEEE Commun. Surv. Tutorials 2022, 24, 1475–1503. [CrossRef]

- Ji, T.; Huang, H.; Xu, X. Digital Twin Technology — A Bibliometric Study of Top Research Articles Based on Local Citation Score. J. Manuf. Syst. 2022, 64, 390–408. [CrossRef]

- Mihai, S.; Yaqoob, M.; Hung, D. V.; Davis, W.; Towakel, P.; Raza, M.; Karamanoglu, M.; Barn, B.; Shetve, D.; Prasad, R. V.; et al. Digital Twins: A Survey on Enabling Technologies, Challenges, Trends and Future Prospects. IEEE Commun. Surv. Tutorials 2022, 24, 2255–2291. [CrossRef]

- Rossmann, A.; Hertweck, D. Digital Twins: A Meta-Review on Their Conceptualization, Application, and Reference Architecture. In Proceedings of the Proceedings of the 55th Hawaii International Conference on System Sciences; 2022; Vol. 7, pp. 4518–4527.

- Kitchenham, B. Procedures for Performing Systematic Reviews; 2004.

- Attaran, M.; Celik, B.G. Digital Twin: Benefits, Use Cases, Challenges, and Opportunities. Decis. Anal. J. 2023, 6, 100165. [CrossRef]

- Correia, J.B.; Abel, M.; Becker, K. Data Management in Digital Twins: A Systematic Literature Review. Knowl. Inf. Syst. 2023. [CrossRef]

- Melesse, T.Y.; Di Pasquale, V.; Riemma, S. Digital Twin Models in Industrial Operations: A Systematic Literature Review. Procedia Manuf. 2020, 42, 267–272. [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of Digital Twin Applications in Manufacturing. Comput. Ind. 2019, 113, 103130. [CrossRef]

- Liu, Y.K.; Ong, S.K.; Nee, A.Y.C. State-of-the-Art Survey on Digital Twin Implementations. Adv. Manuf. 2022, 10, 1–23. [CrossRef]

- Segovia, M.; Garcia-Alfaro, J. Design, Modeling and Implementation of Digital Twins. Sensors 2022, 22. [CrossRef] [PubMed]

- Perno, M.; Hvam, L.; Haug, A. Implementation of Digital Twins in the Process Industry: A Systematic Literature Review of Enablers and Barriers. Comput. Ind. 2022, 134, 103558. [CrossRef]

- Xiong, M.; Wang, H. Digital Twin Applications in Aviation Industry: A Review. Int. J. Adv. Manuf. Technol. 2022, 121, 5677–5692. [CrossRef]

- Moenck, K.; Rath, J.E.; Koch, J.; Wendt, A.; Kalscheuer, F.; Schüppstuhl, T.; Schoepflin, D. Digital Twins in Aircraft Production and MRO: Challenges and Opportunities. CEAS Aeronaut. J. 2024. [CrossRef]

- Oliveira, P.P. Digital Twin Development for Airport Management. J. Airpt. Manag. 2020, 14, 246–259.

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Informatics 2019, 15, 2405–2415. [CrossRef]

- Fu, Y.; Zhu, G.; Zhu, M.; Xuan, F. Digital Twin for Integration of Design-Manufacturing-Maintenance: An Overview. Chinese J. Mech. Eng. (English Ed. 2022, 35. [CrossRef]

- Cimino, C.; Negri, E.; Fumagalli, L. Review of Digital Twin Applications in Manufacturing. Comput. Ind. 2019, 113. [CrossRef]

- Singh, M.; Srivastava, R.; Fuenmayor, E.; Kuts, V.; Qiao, Y.; Murray, N.; Devine, D. Applications of Digital Twin across Industries: A Review. Appl. Sci. 2022, 12. [CrossRef]

- Wang, Y.; Kang, X.; Chen, Z. A Survey of Digital Twin Techniques in Smart Manufacturing and Management of Energy Applications. Green Energy Intell. Transp. 2022, 100014. [CrossRef]

- Rjabtšikov, V.; Rassõlkin, A.; Kudelina, K.; Kallaste, A.; Vaimann, T. Review of Electric Vehicle Testing Procedures for Digital Twin Development: A Comprehensive Analysis. Energies 2023, 16. [CrossRef]

- Piromalis, D.; Kantaros, A. Digital Twins in the Automotive Industry: The Road toward Physical-Digital Convergence. Appl. Syst. Innov. 2022, 5, 1–12. [CrossRef]

- Sharma, M.; George, J.P. Digital Twin in the Automotive Industry : Driving Physical-Digital Convergence. White Pap. (TATA Consult. Serv. 2018, 8.

- Vandana; Garg, A.; Panigrahi, B.K. Multi-dimensional Digital Twin of Energy Storage System for Electric Vehicles: A Brief Review. Energy Storage 2021, 3. [CrossRef]

- Naseri, F.; Gil, S.; Barbu, C.; Cetkin, E.; Yarimca, G.; Jensen, A.C.; Larsen, P.G.; Gomes, C. Digital Twin of Electric Vehicle Battery Systems: Comprehensive Review of the Use Cases, Requirements, and Platforms. Renew. Sustain. Energy Rev. 2023, 179, 113280. [CrossRef]

- Elbazi, N.; Tigami, A.; Laayati, O.; Maghraoui, A. El; Chebak, A.; Mabrouki, M. Digital Twin-Enabled Monitoring of Mining Haul Trucks with Expert System Integration: A Case Study in an Experimental Open-Pit Mine. In Proceedings of the Proceedings - 2023 IEEE 5th Global Power, Energy and Communication Conference, GPECOM 2023; IEEE, 2023; pp. 168–174.

- Phanden, R.K.; Sharma, P.; Dubey, A. A Review on Simulation in Digital Twin for Aerospace, Manufacturing and Robotics. Mater. Today Proc. 2020, 38, 174–178. [CrossRef]

- Baidya, S.; Das, S.K.; Uddin, M.H.; Kosek, C.; Summers, C. Digital Twin in Safety-Critical Robotics Applications: Opportunities and Challenges. In Proceedings of the 41st IEEE International Performance Computing and Communications Conference (IPCCC); 2022; pp. 101–107.

- Le, T. V.; Fan, R. Digital Twins for Logistics and Supply Chain Systems: Literature Review, Conceptual Framework, Research Potential, and Practical Challenges. Comput. Ind. Eng. 2024, 187, 109768. [CrossRef]

- Moshood, T.D.; Nawanir, G.; Sorooshian, S.; Okfalisa, O. Digital Twins Driven Supply Chain Visibility within Logistics: A New Paradigm for Future Logistics. Appl. Syst. Innov. 2021, 4. [CrossRef]

- Kosacka-Olejnik, M.; Kostrzewski, M.; Marczewska, M.; Mrówczyńska, B.; Pawlewski, P. How Digital Twin Concept Supports Internal Transport Systems?—Literature Review. Energies 2021, 14. [CrossRef]

- Nguyen, T.; Duong, Q.H.; Nguyen, T. Van; Zhu, Y.; Zhou, L. Knowledge Mapping of Digital Twin and Physical Internet in Supply Chain Management: A Systematic Literature Review. Int. J. Prod. Econ. 2022, 244, 108381. [CrossRef]

- Ivanova, T.; Shkrobot, M. Digitalization in the Reverse Supply Chain: A Bibliometric Analysis. Logforum 2023, 19, 683–702. [CrossRef]

- Liu, Ji.; Yeoh, W.; Qu, Y.; Gao, L. Blockchain-Based Digital Twin for Supply Chain Management: State-of-The-Art Review and Future Research Directions. SSRN Electron. J. 2022, 1–34. [CrossRef]

- Bhandal, R.; Meriton, R.; Kavanagh, R.E.; Brown, A. The Application of Digital Twin Technology in Operations and Supply Chain Management: A Bibliometric Review. Supply Chain Manag. 2022, 27, 182–206. [CrossRef]

- Waqar, A.; Othman, I.; Almujibah, H.; Khan, M.B.; Alotaibi, S.; Elhassan, A.A.M. Factors Influencing Adoption of Digital Twin Advanced Technologies for Smart City Development: Evidence from Malaysia. Buildings 2023, 13. [CrossRef]

- Cooke, P. Image and Reality: ‘Digital Twins’ in Smart Factory Automotive Process Innovation – Critical Issues. Reg. Stud. 2021, 55, 1630–1641. [CrossRef]

- Slioa, A.E. Evaluation of Digital Twin Implementations in Facility Management-A Systematic Review, Jonkoping University, School of Engineering, 2022.

- Azeez, N.A.; Adjekpiyede, O.O. Digital Twin Technology: A Review of Its Applications and Prominent Challenges. Covenant J. Informatics Commun. Technol. 2022, 10, 1–15.

- Bado, M.F.; Tonelli, D.; Poli, F.; Zonta, D.; Casas, J.R. Digital Twin for Civil Engineering Systems: An Exploratory Review for Distributed Sensing Updating. Sensors 2022, 22. [CrossRef]

- Kim, H.J.; Lee, M.H.; Yoe, H. Research on the Design and Application of Digital Twin-Based Smart Agricultural Systems. In Proceedings of the Proceedings - 2023 Congress in Computer Science, Computer Engineering, and Applied Computing, CSCE 2023; IEEE, 2023; pp. 1770–1773.

- Popa, E.O.; van Hilten, M.; Oosterkamp, E.; Bogaardt, M.J. The Use of Digital Twins in Healthcare: Socio-Ethical Benefits and Socio-Ethical Risks. Life Sci. Soc. Policy 2021, 17, 1–25. [CrossRef]

- Primo Egoavil, X.; Sucaticona Araujo, F.; De La Torre Salazar, J. Viability of the Digital Twin in the Inventory of Educational Assets to Improve Maintenance Control. 2022 Congr. Int. Innov. y Tendencias en Ing. CONIITI 2022 - Conf. Proc. 2022, 1–6. [CrossRef]

- Rassudov, L.; Akmurzin, E.; Korunets, A.; Osipov, D. Engineering Education and Cloud-Based Digital Twins for Electric Power Drive System Diagnostics. In Proceedings of the 2021 28th International Workshop on Electric Drives: Improving Reliability of Electric Drives, IWED 2021; 2021; pp. 2021–2023.

- Kairat, K.; Ildar, P.; Karygash, A.; Saule, B.; Indira, K.; Markhaba, K.; Aizhan, B. Digital Twins Technology in the Educational Process of the Aviation Equipment Repair. Indones. J. Electr. Eng. Comput. Sci. 2023, 32, 752–762. [CrossRef]

- Schneider, G.; Wendl, M.; Kucek, S.; Leitner, M. A Training Concept Based on a Digital Twin for a Wafer Transportation System. In Proceedings of the 2021 IEEE 23rd Conference on Business Informatics, CBI; IEEE, 2021; Vol. 2, pp. 20–28.

- Gray, A. Body as Voice: Restorative Dance/Movement Psychotherapy with Survivors of Relational Trauma. Routledge Int. Handb. Embodied Perspect. Psychother. Approaches from Danc. Mov. Body Psychother. 2019, 147–160. [CrossRef]

- Dąbrowska, A.; Giel, R.; Winiarska, K. Sequencing and Planning of Packaging Lines With Reliability and Digital Twin Concept Considerations – a Case Study of a Sugar Production Plant. Logforum 2022, 18, 321–334. [CrossRef]

- You, Y.; Chen, C.; Hu, F.; Liu, Y.; Ji, Z. Advances of Digital Twins for Predictive Maintenance. Procedia Comput. Sci. 2022, 200, 1471–1480. [CrossRef]

- van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive Maintenance Using Digital Twins: A Systematic Literature Review. Inf. Softw. Technol. 2022, 151, 107008. [CrossRef]

- Zhong, D.; Xia, Z.; Zhu, Y.; Duan, J. Overview of Predictive Maintenance Based on Digital Twin Technology. Heliyon 2023, 9, e14534. [CrossRef] [PubMed]

- Booyse, W.; Wilke, D.N.; Heyns, S. Deep Digital Twins for Detection, Diagnostics and Prognostics. Mech. Syst. Signal Process. 2020, 140, 106612. [CrossRef]

- Okeagu, F.N.; Mgbemena, C.E. A Systematic Review of Digital Twin Systems for Improved Predictive Maintenance of Equipment in Smart Factories. Int. J. Ind. Prod. Eng. 2022, 1, 1–20.

- Gosavi, A.; Le, V.K. Maintenance Optimization in a Digital Twin for Industry 4.0. Ann. Oper. Res. 2022. [CrossRef]

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. A Classification Proposal of Digital Twin Applications in the Safety Domain. Comput. Ind. Eng. 2021, 154, 107137. [CrossRef]

- Thorn, A.C.; Technology, P.H.M.; Conroy, P.; Technology, P.H.M.; Chan, D.; Technology, P.H.M.; Stecki, C.; Technology, P.H.M. The Digital Risk Twin – Enabling Model-Based RAMS. In Proceedings of the 2023 Annual Reliability and Maintainability Symposium (RAMS); IEEE, 2023; pp. 1–6.

- Mohanraj, E.; Eniyavan, N.; Sidarth, S.; Sridharan, S. Digital Twins for Automotive Predictive Maintenance. In Proceedings of the 7th International Conference on Inventive Computation Technologies, ICICT 2024; 2024; pp. 1579–1584.

- Hilton, S.; Technology, P.H.M.; Langton, J.; Technology, P.H.M.; Conroy, P.; Technology, P.H.M.; Stecki, C.; Technology, P.H.M. Digital Availability Twin – Targeted Risk Mitigation from Design to Operation. In Proceedings of the 2023 Annual Reliability and Maintainability Symposium (RAMS); IEEE, 2023; pp. 1–6.

- Aivaliotis, P.; Georgoulias, K.; Alexopoulos, K. Using Digital Twin for Maintenance Applications in Manufacturing: State of the Art and Gap Analysis. Proc. - 2019 IEEE Int. Conf. Eng. Technol. Innov. ICE/ITMC 2019 2019. [CrossRef]

- Errandonea, I.; Beltrán, S.; Arrizabalaga, S. Digital Twin for Maintenance: A Literature Review. Comput. Ind. 2020, 123. [CrossRef]

- Ali, W.A.; Roccotelli, M.; Fanti, M.P. Digital Twin in Intelligent Transportation Systems: A Review. In Proceedings of the 2022 8th International Conference on Control, Decision and Information Technologies, CoDIT 2022; 2022; pp. 576–581.

- Irfan, M.S.; Dasgupta, S.; Rahman, M. Towards Transportation Digital Twin Systems for Traffic Safety and Mobility Applications: A Review. arXiv 2022.

- Munkeby, S.K. On Application of Digital Twin in Ship Operation and Performance, Norvegian University of Science and Technology, 2022.

- Digitization in Ports: Application of Digital Twins to Complex Logistics. FAL Bull. 2022, 393.

- Saifutdinov, F.; Tolujevs, J. Time and Space Discretization in the Digital Twin of the Airport Transport Network. Transp. Telecommun. 2021, 22, 257–265. [CrossRef]

- Errandonea, I.; Goya, J.; Alvarado, U.; Beltron, S.; Arrizabalaga, S. IoT Approach for Intelligent Data Acquisition for Enabling Digital Twins in the Railway Sector. Proc. - 2021 Int. Symp. Comput. Sci. Intell. Control. ISCSIC 2021 2021, 164–168. [CrossRef]

- Kampczyk, A.; Dybeł, K. The Fundamental Approach of the Digital Twin Application in Railway Turnouts with Innovative Monitoring of Weather Conditions. Sensors 2021, 21. [CrossRef] [PubMed]

- Pool, A. Digital Twins in Rail Freight-The Foundations of a Future Innovation, University of Twente, 2021.

- Dasgupta, S.; Rahman, M.; Lidbe, A.D.; Lu, W.; Jones, S. A Transportation Digital-Twin Approach for Adaptive Traffic Control Systems. arXiv Prepr. arXiv2109.10863 2021.

- Guo, Y.; Zou, K.; Chen, S.; Yuan, F.; Yu, F. 3D Digital Twin of Intelligent Transportation System Based on Road-Side Sensing. J. Phys. Conf. Ser. 2021, 2083. [CrossRef]

- Kušić, K.; Schumann, R.; Ivanjko, E. A Digital Twin in Transportation: Real-Time Synergy of Traffic Data Streams and Simulation for Virtualizing Motorway Dynamics. Adv. Eng. Informatics 2023, 55. [CrossRef]

- Marcucci, E.; Gatta, V.; Le Pira, M.; Hansson, L.; Bråthen, S. Digital Twins: A Critical Discussion on Their Potential for Supporting Policy-making and Planning in Urban Logistics. Sustain. 2020, 12, 1–15. [CrossRef]

- Rudskoy, A.; Ilin, I.; Prokhorov, A. Digital Twins in the Intelligent Transport Systems. Transp. Res. Procedia 2021, 54, 927–935. [CrossRef]

- Felix-Cigalat, J.S.; Domingo, R. Towards a Digital Twin Warehouse through the Optimization of Internal Transport. Appl. Acoust. 2023, 13. [CrossRef]

- Ganesh, M.; Rizvi, A.M.; Anbu, A. Digital Twin Framework for Material Handling and Logistics in Manufacturing: Part 1. In Proceedings of the 2022 International Conference on Connected Systems & Intelligence (CSI); IEEE, 2022.

- Martínez-Gutiérrez, A.; Díez-González, J.; Ferrero-Guillén, R.; Verde, P.; Álvarez, R.; Perez, H. Digital Twin for Automatic Transportation in Industry 4.0. Sensors 2021, 21. [CrossRef]

- Cruz, H. Digital Twin Technology Applications For Transportation Infrastructure - A Survey-Based Study. Open Access Theses Diss. 2021, 3234, https://scholarworks.utep.edu/open_etd/3234.

- Vieira, J.; Martins, J.P.; de Almeida, N.M.; Patricio, H. Towards Resilient and Sustainable Rail and Road Networks: A Systematic Literature Review on Digital Twins. Sustain. 2022, 14. [CrossRef]

- Assani, N.; Matić, P.; Katalinić, M. Ship’s Digital Twin—A Review of Modelling Challenges and Applications. Appl. Sci. 2022, 12. [CrossRef]

- Kaiblinger, A.; Woschank, M. State of the Art and Future Directions of Digital Twins for Production Logistics: A Systematic Literature Review. Appl. Sci. 2022, 12. [CrossRef]

- Gao, C.; Wang, J.; Dong, S.; Liu, Z.; Cui, Z.; Ma, N.; Zhao, X. Application of Digital Twins and Building Information Modeling in the Digitization of Transportation: A Bibliometric Review. Appl. Sci. 2022, 12. [CrossRef]

- Budgen, D.; Brereton, P. Performing Systematic Literature Reviews in Software Engineering. Proc. - Int. Conf. Softw. Eng. 2006, 2006, 1051–1052. [CrossRef]

- Madhukar, P.; McCulloch, M.; Gorman, J.; Pai, N.P.; Enanoria, W.T.A.; Kennedy, G.E.; Tharyan, P.; Colford, J.M. Systematic Reviews and Meta-Analyses: An Illustrated, Step-by-Step Guide. Natl. Med. J. India 2004, 17, 86–95.

- Zamani, E.D.; Smyth, C.; Gupta, S.; Dennehy, D. Artificial Intelligence and Big Data Analytics for Supply Chain Resilience: A Systematic Literature Review. Ann. Oper. Res. 2022. [CrossRef]

- Aromataris, E.; Pearson, A. The Systematic Review: An Overview. Am. J. Nurs. 2014, 114, 53–58. [CrossRef]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. Int. J. Surg. 2010, 8, 336–341. [CrossRef] [PubMed]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. BMJ 2009, 339, 332–336. [CrossRef] [PubMed]

- Https://Omnis-Pwr.Primo.Exlibrisgroup.Com/Discovery/Search?Vid=48OMNIS_TUR:48TUR&lang=pl&mode=advanced.

- Liu, H.; Xia, M.; Williams, D.; Sun, J.; Yan, H. Digital Twin-Driven Machine Condition Monitoring: A Literature Review. J. Sensors 2022, 2022. [CrossRef]

- Werbińska-Wojciechowska, S.; Winiarska, K. Maintenance Performance in the Age of Industry 4.0: A Bibliometric Performance Analysis and a Systematic Literature Review. Sensors 2023, 23, 1409. [CrossRef] [PubMed]

- van Dinter, R.; Tekinerdogan, B.; Catal, C. Predictive Maintenance Using Digital Twins: A Systematic Literature Review. Inf. Softw. Technol. 2022, 151, 107008. [CrossRef]

- Prikler, L.M.; Wotawa, F. A Systematic Mapping Study of Digital Twins for Diagnosis in Transportation. In Proceedings of the Proceedings - 2023 10th International Conference on Dependable Systems and Their Applications, DSA 2023; 2023; pp. 431–442.

- Yan, B.; Yang, F.; Qiu, S.; Wang, J.; Cai, B.; Wang, S.; Zaheer, Q.; Wang, W.; Chen, Y.; Hu, W. Digital Twin in Transportation Infrastructure Management: A Systematic Review. Intell. Transp. Infrastruct. 2023, 2, 1–18. [CrossRef]

- Watson, R.T.; Webster, J. Analysing the Past to Prepare for the Future: Writing a Literature Review a Roadmap for Release 2.0. J. Decis. Syst. 2020, 29, 129–147. [CrossRef]

- Wang, J.; Li, X.; Wang, P.; Liu, Q. Bibliometric Analysis of Digital Twin Literature: A Review of Influencing Factors and Conceptual Structure. Technol. Anal. Strateg. Manag. 2024, 36, 166–180. [CrossRef]

- Krüger, S.; Borsato, M. Developing Knowledge on Digital Manufacturing to Digital Twin: A Bibliometric and Systemic Analysis. Procedia Manuf. 2019, 38, 1174–1180. [CrossRef]

- Agnusdei, G.P.; Elia, V.; Gnoni, M.G. Is Digital Twin Technology Supporting Safety Management? A Bibliometric and Systematic Review. Appl. Sci. 2021, 11, 1–17. [CrossRef]

- Lorenzetti, D.L.; Ghali, W.A. Reference Management Software for Systematic Reviews and Meta-Analyses: An Exploration of Usage and Usability. BMC Med. Res. Methodol. 2013, 13. [CrossRef] [PubMed]

- Silva, A.A. da; Pedrosa, M.R. Using Reference Manager ( Mendeley ) in Systematic Reviews 2018.

- VOSviewer, Https://Www.Vosviewer.Com/.

- van Eck, N.J.; Waltman, L. Software Survey: VOSviewer, a Computer Program for Bibliometric Mapping. Scientometrics 2010, 84, 523–538. [CrossRef] [PubMed]

- Bernal, E.; Wu, Q.; Spiryagin, M.; Cole, C. Augmented Digital Twin for Railway Systems Augmented Digital Twin for Railway Systems. Veh. Syst. Dyn. 2023. [CrossRef]

- Bernal, E.; Spiryagin, M.; Vollebregt, E.; Oldknow, K.; Stichel, S.; Shrestha, S.; Ahmad, S.; Wu, Q.; Sun, Y.; Cole, C. Prediction of Rail Surface Damage in Locomotive Traction Operations Using Laboratory-Field Measured and Calibrated Data. Eng. Fail. Anal. 2022, 135, 106165. [CrossRef]

- Ahmad, S.; Spiryagin, M.; Wu, Q.; Bernal, E.; Sun, Y.; Cole, C.; Makin, B. Development of a Digital Twin for Prediction of Rail Surface Damage in Heavy Haul Railway Operations. Veh. Syst. Dyn. 2023, 62, 41–66. [CrossRef]

- Spiryagin, M.; Edelmann, J.; Klinger, F.; Cole, C. Vehicle System Dynamics in Digital Twin Studies in Rail and Road Domains. Veh. Syst. Dyn. 2023. [CrossRef]

- Guo, Y.; Zhu, Q.; Ding, Y.; Li, Y.; Wu, H.; He, Y.; Li, Z.; Li, H.; Zhang, L.; Zhao, Y.; et al. Efficient Distributed Association Management Method of Data, Model, and Knowledge for Digital Twin Railway. Int. J. Digit. Earth 2024, 17. [CrossRef]

- Li, L.; Aslam, S.; Wileman, A.; Perinpanayagam, S. Digital Twin in Aerospace Industry : A Gentle Introduction. IEEE Access 2022, 10, 9543–9562.

- Liao, M.; Renaud, G.; Bombardier, Y. Airframe Digital Twin Technology Adaptability Assessment and Technology Demonstration. Eng. Fract. Mech. 2020, 225, 106793. [CrossRef]

- Li, J.; Zhou, G.; Zhang, C. A Twin Data and Knowledge-Driven Intelligent Process Planning Framework of Aviation Parts. Int. J. Prod. Res. 2022, 60, 5217–5234. [CrossRef]

- Borgo, M.D.; Elliott, S.J.; Ghandchi, M.; Ian, T. Virtual Sensing of Wheel Direction from Redundant Sensors in Aircraft Ground - Steering Systems. CEAS Aeronaut. J. 2022, 13, 199–213. [CrossRef]

- Mhenni, F.; Vitolo, F.; Rega, A.; Plateaux, R.; Hehenberger, P.; Patalano, S.; Choley, J. Heterogeneous Models Integration for Safety Critical Mechatronic Systems and Related Digital Twin Definition : Application to a Collaborative Workplace for Aircraft Assembly. Appl. Sci. 2022, 12. [CrossRef]

- Apostolidis, A.; Stamoulis, K.P. An AI-Based Digital Twin Case Study in the MRO Sector. Transp. Res. Procedia 2021, 56, 55–62. [CrossRef]

- Smagin, D.I.; Grachev, S. V.; Suchkov, M. V.; Vereikin, A.A. Method for Predictive Analysis of Failure and Pre-Failure Conditions of Aircraft Units Using Data Obtained during Their Operation. Aerosp. Syst. 2023, 6, 231–248. [CrossRef]

- Zaccaria, V.; Stenfelt, M.; Aslanidou, I.; Kyprianidis, K.G. Fleet Monitoring and Diagnostics Framework Based on Digital Twin of Aero-Engines. In Proceedings of the Proceedings of the ASME Turbo Expo American Society of Mechanical Engineers (ASME); 2018; pp. 1–10.

- Xiong, M.; Wang, H.; Fu, Q.; Xu, Y. Digital Twin – Driven Aero-Engine Intelligent Predictive Maintenance. Int. J. Adv. Manuf. Technol. 2021, 114, 3751–3761.

- Wu, Z.; Li, J. A Framework of Dynamic Data Driven Digital Twin for Complex Engineering Products: The Example of Aircraft Engine Health Management. Procedia Manuf. 2021, 55, 139–146. [CrossRef]

- Ren, J.; Cheng, Y.; Zhang, Y.; Tao, F. A Digital Twin-Enhanced Collaborative Maintenance Paradigm for Aero-Engine Fleet. Front. Eng. Manag. 2024, 11, 356–361. [CrossRef]

- Wang, Z.; Wang, Y.; Wang, X.; Yang, K.; Zhao, Y. A Novel Digital Twin Framework for Aeroengine Performance Diagnosis. Aerospace 2023, 10. [CrossRef]

- Kilic, U.; Yalin, G.; Cam, O. Digital Twin for Electronic Centralized Aircraft Monitoring by Machine Learning Algorithms. Energy 2023, 283, 129118. [CrossRef]

- Ezhilarasu, C.M.; Jennions, I.K. A System-Level Failure Propagation Detectability Using ANFIS for an Aircraft Electrical Power System. Appl. Sci. 2020, 10. [CrossRef]

- Starostin, I.E.; Khalyutin, S.P.; Druzhinin, A.A.; Gavrilenkov, S.I. Development of an Information System of Digital Twins of Aviation Electrical Equipment as a Software Module of the Local Load Control Center. In Proceedings of the 2023 20th Technical Scientific Conference on Aviation Dedicated to the Memory of N.E. Zhukovsky, TSCZh 2023; IEEE, 2023; pp. 26–31.

- Liu, W.; Li, X.; Shen, Z.; Ma, C. A Digital Twin Method for Civil Aircraft Power Distribution System Based on Unity3D and Simulink. J. Phys. Conf. Ser. 2023, 2615, 1–11. [CrossRef]

- Ren, B.; Gao, Y.; Gu, Z.; Liu, P.; Xiong, J. Intelligent Equipment Scenario for Aviation Maintenance VR System Based on Digital Twin Model. In Proceedings of the Proceedings - 2024 5th International Conference on Mobile Computing and Sustainable Informatics, ICMCSI 2024; IEEE, 2024; pp. 427–433.

- Utzig, S.; Kaps, R.; Azeem, S.M.; Gerndt, A. Augmented Reality for Remote Collaboration in Aircraft Maintenance Tasks. In Proceedings of the 2019 IEEE Aerospace Conference; IEEE, 2019; pp. 1–10.

- Wei, R.; Yang, R.; Liu, S.; Fan, C.; Zhou, R.; Wu, Z.; Wang, H.; Cai, Y.; Jiang, Z. Towards an Extensible Model-Based Digital Twin Framework for Space Launch Vehicles. J. Ind. Inf. Integr. 2024, 100641. [CrossRef]

- Wu, M.; Xiao, Y.; Gao, Y.; Xiao, M. Digital Twin for UAV-RIS Assisted Vehicular Communication Systems. IEEE Trans. Wirel. Commun. 2023, 23, 7638–7651. [CrossRef]

- Tavares, S.M.O.; Ribeiro, J.A.; Ribeiro, B.A.; de Castro, P.M.S.T. Aircraft Structural Design and Life-Cycle Assessment through Digital Twins. Designs 2024, 8, 1–17. [CrossRef]

- Sadeghi, A.; Bellavista, P.; Song, W.; Yazdani-Asrami, M. Digital Twins for Condition and Fleet Monitoring of Aircraft: Towards More-Intelligent Electrified Aviation Systems. IEEE Access 2024, PP, 1. [CrossRef]

- Bisanti, G.M.; Mainetti, L.; Montanaro, T.; Patrono, L.; Sergi, I. Digital Twins for Aircraft Maintenance and Operation: A Systematic Literature Review and an IoT-Enabled Modular Architecture. Internet of Things (Netherlands) 2023, 24. [CrossRef]

- Goraj, R. Digital Twin of the Rotor-Shaft of a Lightweight Electric Motor during Aerobatics Loads. Aircr. Eng. Aerosp. Technol. 2020, 92, 1319–1326. [CrossRef]

- Oyekan, J.; Farnsworth, M.; Hutabarat, W.; Miller, D. Applying a 6 DoF Robotic Arm and Digital Twin to Automate Fan-Blade Reconditioning for Aerospace. 2020.

- Millwater, H.; Ocampo, J.; Crosby, N. Probabilistic Methods for Risk Assessment of Airframe Digital Twin Structures. Eng. Fract. Mech. 2019, 221, 106674. [CrossRef]

- Pinello, L.; Hassan, O.; Giglio, M.; Sbarufatti, C. Preliminary Nose Landing Gear Digital Twin for Damage Detection. Aerospace 2024, 11. [CrossRef]

- Ezhilarasu, C.M.; Skaf, Z.; Jennions, I.A.N.K. A Generalised Methodology for the Diagnosis of Aircraft Systems. IEEE Access 2021, 9, 11437–11454. [CrossRef]

- Dong, Y.; Jiang, H.; Wu, Z.; Yang, Q.; Liu, Y. Digital Twin-Assisted Multiscale Residual-Self-Attention Feature Fusion Network for Hypersonic Flight Vehicle Fault Diagnosis. Reliab. Eng. Syst. Saf. 2023, 235, 109253. [CrossRef]

- Seshadri, B.R.; Krishnamurthy, T. Structural Health Management of Damaged Aircraft Structures Using the Digital Twin Concept. In Proceedings of the 25th AIAA/AHS Adaptive Structures Conference; 2017; pp. 1–13.

- Heim, S.; Clemens, J.; Steck, J.E.; Basic, C. Predictive Maintenance on Aircraft and Applications with Digital Twin. In Proceedings of the 2020 IEEE International Conference on Big Data (Big Data); 2020; pp. 4122–4127.

- Ho, G.T.S.; Ming, Y.; Yat, K.; Tang, V.; Yin, K. A Blockchain-Based System to Enhance Aircraft Parts Traceability and Trackability for Inventory Management. 2021, 179. [CrossRef]

- Winkler, P.; Gallego-Garcia, S.; Groten, M. Design and Simulation of a Digital Twin Mobility Concept: An Electric Aviation System Dynamics Case Study with Capacity Constraints. Appl. Sci. 2022, 12, 1–18. [CrossRef]

- Shen, G.; Lei, L.; Li, Z.; Cai, S.; Zhang, L.; Cao, P.; Liu, X. Deep Reinforcement Learning for Flocking Motion of Multi-UAV Systems: Learn From a Digital Twin. IEEE Internet Things J. 2022, 9, 11141–11153.

- Dimitrova, E.; Tomov, S. Digital Twins: An Advanced Technology for Railways Maintenance Transformation. In Proceedings of the 2021 13th Electrical Engineering Faculty Conference (BulEF); IEEE, 2021; pp. 1–5.

- Ikeda, M. Recent Research and Development Activities in Maintenance Technologies for Electric Railway Power Supply Systems. Q. Rep. RTRI 2020, 61, 1–5. [CrossRef] [PubMed]

- Vatakov, V.; Pencheva, E.; Dimitrova, E. Recent Advances in Artificial Intelligence for Improving Railway Operations. In Proceedings of the 30th National Conference with International Participation “Telecom 2022”; IEEE, 2022; pp. 7–10.

- Dirnfeld, R.; De Donato, L.; Somma, A.; Azari, M.S.; Marrone, S.; Flammini, F.; Vittorini, V. Integrating AI and DTs: Challenges and Opportunities in Railway Maintenance Application and Beyond. Simulation 2024. [CrossRef]

- Ghaboura, S.; Ferdousi, R.; Laamarti, F.; Yang, C.; Saddik, A. El Digital Twin for Railway: A Comprehensive Survey. IEEE Access 2023, 11, 120237–120257. [CrossRef]

- Zhang, T.; Du, W.; Zhang, G.; Wang, J. PHM of Rail Vehicle Based on Digital Twin. In Proceedings of the 2021 Global Reliability and Prognostics and Health Management (PHM-Nanjing); 2021; pp. 1–5.

- Guillén López, A.J.; Gómez Fernández, J.F.; Urda, P.; Escalona, J.L.; Crespo Márquez, A.; Olivencia, F. Digital Twin for Condition Based Maintenance within a Railway Infrastructure Testing Lab. In Proceedings of the PHM Society Asia-Pacific Conference; 2023; Vol. 4, pp. 1–7.

- Putra, H.G.P.; Supangkat, S.H.; Nugraha, I.G.B.B.; Hidayat, F. Designing Machine Learning Model for Predictive Maintenance of Railway Vehicle. In Proceedings of the 2021 International Conference on ICT for Smart Society (ICISS); IEEE, 2021; pp. 0–4.

- Jung, C.; Toguyeni, A.K.A.; Bouamama, B.O. Supervised Machine Learning from Digital Twin Data for Railway Switch Fault Diagnosis. In Proceedings of the 2023 European Control Conference, ECC 2023; EUCA, 2023; pp. 1–7.

- Bosso, N.; Magelli, M.; Trinchero, R.; Zampieri, N. Application of Machine Learning Techniques to Build Digital Twins for Long Train Dynamics Simulations. Veh. Syst. Dyn. 2023, 62, 21–40. [CrossRef]

- Gálvez, A.; Rubio, J.; Seneviratne, D.; Gonzalez, A.; Jimenez, A.; Martinez-de-estarrona, U.; Galar, D.; Juuso, E. Hybrid Models and Digital Twins for Condition Monitoring: HVAC System for Railway. SNE Tech. Note 2021, 31, 121–126. [CrossRef]

- Bustos, A.; Rubio, HiHeras, E.; Castejon, C. Methodology for the Integration of a High-Speed Train in Maintenance 4.0. J. ofComputational Des. Eng. 2021, 8, 1605–1621. [CrossRef]

- Franzen, J.; Stecken, J.; Pfaff, R.; Kuhlenkötter, B. Using the Digital Shadow for a Prescriptive Optimization of Maintenance and Operation. In Advances in Production, Logistics and Traffic. ICPLT 2019. Lecture Notes in Logistics; Clausen, U., Langkau, S., Kreuz, F. (eds), Ed.; Springer, Cham, 2019; Vol. 1, pp. 265–276 ISBN 9783030135355.

- Guan, K.; Guo, X.; He, D.; Svoboda, P.; Berbineau, M.; Wang, S.; Ai, B.; Zhong, Z.; Rupp, M. Key Technologies for Wireless Network Digital Twin towards Smart Railways. High-speed Railw. 2024, 2, 1–10. [CrossRef]

- Galvez, A.; Seneviratne, D.; Galar, D. Hybrid Model Development for HVAC System in Transportation. Technologies 2021, 9. [CrossRef]

- H-nia, S.; Flodin, J.; Casanueva, C.; Asplund, M.; Stichel, S. Predictive Maintenance in Railway Systems: MBS- Based Wheel and Rail Life Prediction Exemplified for the Swedish Iron-Ore Line. Veh. Syst. Dyn. 2023. [CrossRef]

- Granzner, M.; Strauss, A.; Reiterer, M.; Cao, M.; Novák, D. Data-Driven Condition Assessment and Life Cycle Analysis Methods for Dynamically and Fatigue-Loaded Railway Infrastructure Components. Infrastructures 2023, 8. [CrossRef]

- Rahman, M.; Liu, H.; Masri, M.; Durazo-cardenas, I.; Starr, A. Computers in Industry A Railway Track Reconstruction Method Using Robotic Vision on a Mobile Manipulator: A Proposed Strategy. Comput. Ind. 2023, 148, 103900. [CrossRef]

- Pillai, N.; Shih, J.-Y.; Roberts, C. Evaluation of Numerical Simulation Approaches for Simulating Train – Track Interactions and Predicting Rail Damage in Railway Switches and Crossings (S&Cs). Infrastructures 2021, 6. [CrossRef]

- Ramatlo, D.A.; Wilke, D.N.; Loveday, P.W. Digital Twin Hybrid Modeling for Enhancing Guided Wave Ultrasound Inspection Signals in Welded Rails. Math. Comput. Appl. 2023, 28, 58. [CrossRef]

- Zhang, S.; Dong, H.; Maschek, U.; Song, H. A Digital-Twin-Assisted Fault Diagnosis of Railway Point Machine. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI); IEEE, 2021; pp. 2021–2024.

- Yang, J.; Sun, Y.; Cao, Y.; Hu, X. Predictive Maintenance for Switch Machine Based on Digital Twins. Information 2021, 12. [CrossRef]

- Kaewunruen, S.; Lian, Q. Digital Twin Aided Sustainability-Based Lifecycle Management for Railway Turnout Systems. J. Clean. Prod. 2019, 228, 1537–1551. [CrossRef]

- Sresakoolchai, J.; Kaewunruen, S. Railway Infrastructure Maintenance Efficiency Improvement Using Deep Reinforcement Learning Integrated with Digital Twin Based on Track Geometry and Component Defects. Sci. Rep. 2023, 13. [CrossRef]

- Du, W.; Zhang, T.; Zhang, G.; Wang, J. A Digital Twin Framework and an Implementaion Method for Urban Rail Transit. In Proceedings of the 2021 Global Reliability and Prognostics and Health Management (PHM-Nanjing); 2021; pp. 2021–2024.

- Doubell, G.D.; Basson, A.H.; Kruger, K.; Conradie, P.D.F. A Digital Twin System for Railway Infrastructure. R&D J. 2023, 23–34. [CrossRef]

- Kim, M.; Hwang, D.; Park, D. Analysis of Maintenance Techniques for a Three-Dimensional Digital Twin-Based Railway Facility with Tunnels. Platforms 2023, 1, 5–17. [CrossRef]

- De Donato, L.; Dirnfeld, R.; Somma, A.; De Benedictis, A.; Flammini, F.; Marrone, S.; Saman Azari, M.; Vittorini, V. Towards AI-Assisted Digital Twins for Smart Railways: Preliminary Guideline and Reference Architecture. J. Reliab. Intell. Environ. 2023, 9, 303–317. [CrossRef]

- Chen, R.; Jin, C.; Zhang, Y.; Dai, J.; Lv, X. Digital Twin for Equipment Management of Intelligent Railway Station. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI); IEEE, 2021; pp. 2021–2024.

- Chandaluri, R.; Nelakuditi, U.R. Performance Evaluation of Electro-Mechanical Railway Interlocking System for Digital Twin Application. Comput. Electr. Eng. 2024, 116, 109225. [CrossRef]

- Armijo, A.; Zamora-Sánchez, D. Integration of Railway Bridge Structural Health Monitoring into the Internet of Things with a Digital Twin: A Case Study. Sensors 2024, 24. [CrossRef] [PubMed]

- Chacón, R.; Posada, H.; Ramonell, C.; Sierra, P.; Rodríguez, A.; Koulalis, I.; Ioannidis, K.; Vrochidis, S.; Tomar, R.; Freitag, S.; et al. On the Digital Twinning of Load Tests in Railway Bridges. Case Study: High Speed Railway Network, Extremadura, Spain. Bridg. Safety, Maintenance, Manag. Life-Cycle, Resil. Sustain. - Proc. 11th Int. Conf. Bridg. Maintenance, Saf. Manag. IABMAS 2022 2023, 819–827. [CrossRef]

- Naraniecki, H.; Lazoglu, A.; Marx, S.; Zaidman, I. Concept for a Digital Twin of Railway Bridges on the Example of the New Filstal Bridges. Ce/Papers 2023, 6, 711–717. [CrossRef]

- Padovano, A.; Longo, F.; Manca, L.; Grugni, R. Improving Safety Management in Railway Stations through a Simulation-Based Digital Twin Approach. Comput. Ind. Eng. 2024, 187, 109839. [CrossRef]

- Ibrahim, M.; Rjabtšikov, V.; Gilbert, R. Overview of Digital Twin Platforms for EV Applications. Sensors 2023, 23. [CrossRef]

- Zhang, Z.; Zou, Y.; Zhou, T.; Zhang, X.; Xu, Z. Energy Consumption Prediction of Electric Vehicles Based on Digital Twin Technology. World Electr. Veh. J. 2021, 12, 1–13. [CrossRef]

- Eaty, N.D.K.M.; Bagade, P. Digital Twin for Electric Vehicle Battery Management with Incremental Learning. Expert Syst. Appl. 2023, 229. [CrossRef]

- Karnehm, D.; Samanta, A.; Neve, A.; Williamson, S. Five-Layer IoT and Fog Computing Framework Towards Digital Twinning of Battery Management Systems for e-Transportation. In Proceedings of the 4th International Conference on Smart Grid and Renewable Energy, SGRE 2024 - Proceedings; IEEE, 2024; pp. 1–7.

- Zhang, T.; Liu, X.; Luo, Z.; Dong, F.; Jiang, Y. Time Series Behavior Modeling with Digital Twin for Internet of Vehicles. Eurasip J. Wirel. Commun. Netw. 2019, 271, 1–12. [CrossRef]

- Jafari, S.; Byun, Y.C. Prediction of the Battery State Using the Digital Twin Framework Based on the Battery Management System. IEEE Access 2022, 10, 124685–124696. [CrossRef]

- Merkle, L.; Pöthig, M.; Schmid, F. Estimate E-Golf Battery State Using Diagnostic Data and a Digital Twin. Batteries 2021, 7, 1–22. [CrossRef]

- Li, H.; Kaleem, M. Bin; Chiu, I.J.; Gao, D.; Peng, J.; Huang, Z. An Intelligent Digital Twin Model for the Battery Management Systems of Electric Vehicles. Int. J. Green Energy 2023, 1–15. [CrossRef]

- Li, H.; Bin Kaleem, M.; Chiu, I.J.; Gao, D.; Peng, J. A Digital Twin Model for the Battery Management Systems of Electric Vehicles. In Proceedings of the 2021 IEEE 23rd International Conference on High Performance Computing and Communications, 7th International Conference on Data Science and Systems, 19th International Conference on Smart City and 7th International Conference on Dependability in Sensor, Cl; IEEE, 2022; pp. 1100–1107.

- Venkatesan, S.; Manickavasagam, K.; Tengenkai, N.; Vijayalakshmi, N. Health Monitoring and Prognosis of Electric Vehicle Motor Using Intelligent-Digital Twin. IET Electr. Power Appl. 2019, 13, 1328–1335. [CrossRef]

- Kurukuru, V.S.B.; Khan, M.A.; Singh, R. Health Monitoring Framework for Electric Vehicle Drive Train in Digital Twin. In Proceedings of the 2023 25th European Conference on Power Electronics and Applications, EPE 2023 ECCE Europe; EPE Association, 2023; pp. 1–10.

- Suhaib Kamran, S.; Haleem, A.; Bahl, S.; Javaid, M.; Nandan, D.; Singh Verma, A. Role of Smart Materials and Digital Twin (DT) for the Adoption of Electric Vehicles in India. Mater. Today Proc. 2021, 52, 2295–2304. [CrossRef]

- Elbakry, M.S.; Mahmoud, A.M.; Hassan, S.E.; Ismail, T. Digital Twin Simulations for Connected and Automated Vehicles: A Comprehensive Study. In Proceedings of the ICEEM 2023 - 3rd IEEE International Conference on Electronic Engineering; IEEE, 2023; pp. 1–6.

- Gürses, A.; Reddy, G.; Masrur, S.; Özdemir, Ö.; Güvenç, İ.; Sichitiu, M.L.; Şahin, A.; Alkhateeb, A.; Dutta, R. Digital Twins for Supporting AI Research with Autonomous Vehicle Networks. IEEE Commun. Mag. 2024, 1–7.

- Schwarz, C.; Wang, Z. The Role of Digital Twins in Connected and Automated Vehicles. IEEE Intell. Transp. Syst. Mag. 2022, 14, 41–51. [CrossRef]

- Heithoff, M.; Konersmann, M.; Michael, J.; Rumpe, B.; Steinfurth, F. Challenges of Integrating Model-Based Digital Twins for Vehicle Diagnosis. In Proceedings of the Proceedings - 2023 ACM/IEEE International Conference on Model Driven Engineering Languages and Systems Companion, MODELS-C 2023; IEEE, 2023; pp. 470–478.

- Campolo, C.; Genovese, G.; Molinaro, A.; Pizzimenti, B.; Ruggeri, G.; Zappala, D.M. An Edge-Based Digital Twin Framework for Connected and Autonomous Vehicles: Design and Evaluation. IEEE Access 2024, 12, 46290–46303. [CrossRef]

- Rassolkin, A.; Vaimann, T.; Kallaste, A.; Kuts, V. Digital Twin for Propulsion Drive of Autonomous Electric Vehicle. In Proceedings of the 2019 IEEE 60th Annual International Scientific Conference on Power and Electrical Engineering of Riga Technical University, RTUCON 2019; 2019; pp. 1–4.

- Lei, T.; Sellers, T.; Luo, C.; Cao, L.; Bi, Z. Digital Twin-based Multi-objective Autonomous Vehicle Navigation Approach as Applied in Infrastructure Construction. IET Cyber-Systems Robot. 2024, e12110. [CrossRef]

- Wang, X.; Huang, Z.; Zheng, S.; Yu, R.; Pan, M. Unpredictability of Digital Twin for Connected Vehicles. China Commun. 2023, 20, 26–45. [CrossRef]

- Ezhilarasu, C.M.; Skaf, Z.; Jennions, I.K. Understanding the Role of a Digital Twin in Integrated Vehicle Health Management (IVHM). In Proceedings of the 2019 IEEE International Conference on Systems, Man and Cybernetics (SMC); IEEE, 2019; pp. 1484–1491.

- Moloudi, M.A.; Foshati, A.; Kalantari, H.; Ejlali, A. A Combination of FMEA and Digital Twinning for Rapid, Accurate, and Online Diagnosis in Vehicles Using COTS Embedded Computing Devices. In Proceedings of the Proceedings - 2022 CPSSI 4th International Symposium on Real-Time and Embedded Systems and Technologies, RTEST 2022; IEEE, 2022.

- Bondarenko, O.; Fukuda, T. Development of a Diesel Engine’s Digital Twin for Predicting Propulsion System Dynamics. Energy 2020, 196, 117126. [CrossRef]

- Bo, Y.; Wu, H.; Che, W.; Zhang, Z.; Li, X.; Myagkov, L. Methodology and Application of Digital Twin-Driven Diesel Engine Fault Diagnosis and Virtual Fault Model Acquisition. Eng. Appl. Artif. Intell. 2024, 131, 107853. [CrossRef]

- Rajesh, P.K.; Manikandan, N.; Ramshankar, C.S.; Vishwanathan, T.; Sathishkumar, C. Digital Twin of an Automotive Brake Pad for Predictive Maintenance. Procedia Comput. Sci. 2019, 165, 18–24. [CrossRef]

- Venturini, S.; Rosso, C.; Velardocchia, M. An Automotive Steel Wheel Digital Twin for Failure Identification under Accelerated Fatigue Tests. Eng. Fail. Anal. 2024, 158, 107979. [CrossRef]

- Tomanik, E.; Jimenez-Reyes, A.J.; Tomanik, V.; Tormos, B. Machine-Learning-Based Digital Twins for Transient Vehicle Cycles and Their Potential for Predicting Fuel Consumption. Vehicles 2023, 5, 583–604. [CrossRef]

- Pan, Y.H.; Wu, N.Q.; Qu, T.; Li, P.Z.; Zhang, K.; Guo, H.F. Digital-Twin-Driven Production Logistics Synchronization System for Vehicle Routing Problems with Pick-up and Delivery in Industrial Park. Int. J. Comput. Integr. Manuf. 2021, 34, 814–828. [CrossRef]

- Liu, Q.; Qi, X.; Liu, S.; Cheng, X.; Ke, X.; Wang, F. Application of Lightweight Digital Twin System in Intelligent Transportation. IEEE J. Radio Freq. Identif. 2022, 6, 729–732. [CrossRef]

- Kaytaz, U.; Ahmadian, S.; Sivrikaya, F.; Albayrak, S. Graph Neural Network for Digital Twin-Enabled Intelligent Transportation System Reliability. In Proceedings of the 2023 IEEE International Conference on Omni-Layer Intelligent Systems, COINS 2023; IEEE, 2023; pp. 1–7.

- Wang, Z.; Gupta, R.; Han, K.; Wang, H.; Ganlath, A.; Ammar, N.; Tiwari, P. Mobility Digital Twin: Concept, Architecture, Case Study, and Future Challenges. IEEE Internet Things J. 2022, 9, 17452–17467. [CrossRef]

- Duan, J.; Wang, Z.; Jing, X. Digital Twin Test Method With LTE-V2X for Autonomous Vehicle Safety Test. IEEE Internet Things J. 2024, 1–11. [CrossRef]

- Dorofeev, A.; Kurganov, V.; Filippova, N.; Petrov, A.; Zakharov, D.; Iarkov, S. Improving Transportation Management Systems (TMSs) Based on the Concept of Digital Twins of an Organization. Appl. Sci. 2024, 14. [CrossRef]

- Cisneros Lombera, D.; Soualmi, B.; Sentouh, C.; Popieul, J.C. Driver Model Using Fuzzy Logic for Virtual Validation. Adv. Transdiscipl. Eng. 2024, 50, 31–43. [CrossRef]

- Hasan Shuvo, M.N.; Zhu, Q.; Hossain, M. Empowering Digital Twin: Early Action Decision through GAN-Enhanced Predictive Frame Synthesis for Autonomous Vehicles. In Proceedings of the Proceedings - 2023 IEEE/ACM Symposium on Edge Computing, SEC 2023; ACM, 2023; pp. 330–335.

- Ertürk, M.A. Time Series Prediction with Digital Twins in Public Transportation Systems. Alphanumeric J. 2023, 11, 183–192. [CrossRef]

- Agavanakis, K.; Cassia, J.; Drombry, M.; Elkaim, E. Telemetry Transformation Towards Industry 4.0 Convergence - A Fuel Management Solution for the Transportation Sector Based on Digital Twins. In Proceedings of the AIP Conference Proceedings; 2022; Vol. 2437, pp. 0–23.

- Moshood, T.D.; Nawanir, G.; Sorooshian, S.; Okfalisa, O. Digital Twins Driven Supply Chain Visibility within Logistics: A New Paradigm for Future Logistics. Appl. Syst. Innov. 2021, 4. [CrossRef]

- Nguyen, T.; Duong, Q.H.; Nguyen, T. Van; Zhu, Y.; Zhou, L. Knowledge Mapping of Digital Twin and Physical Internet in Supply Chain Management: A Systematic Literature Review. Int. J. Prod. Econ. 2022, 244, 108381. [CrossRef]

- Abideen, A.Z.; Sundram, V.P.K.; Pyeman, J.; Othman, A.K.; Sorooshian, S. Digital Twin Integrated Reinforced Learning in Supply Chain and Logistics. Logistics 2021, 5. [CrossRef]

- Marmolejo-Saucedo, J.A. Design and Development of Digital Twins: A Case Study in Supply Chains. Mob. Networks Appl. 2020, 25, 2141–2160. [CrossRef]

- Park, K.T.; Son, Y.H.; Noh, S. Do The Architectural Framework of a Cyber Physical Logistics System for Digital-Twin-Based Supply Chain Control. Int. J. Prod. Res. 2020, 59, 1–22. [CrossRef]

- Busse, A.; Gerlach, B.; Lengeling, J.C.; Poschmann, P.; Werner, J.; Zarnitz, S. Towards Digital Twins of Multimodal Supply Chains. Logistics 2021, 5. [CrossRef]

- Yevu, S.K.; Owusu, E.K.; Chan, A.P.C.; Sepasgozar, S.M.E.; Kamat, V.R. Digital Twin-Enabled Prefabrication Supply Chain for Smart Construction and Carbon Emissions Evaluation in Building Projects. J. Build. Eng. 2023, 78, 107598. [CrossRef]

- Ashraf, M.; Eltawil, A.; Ali, I. Disruption Detection for a Cognitive Digital Supply Chain Twin Using Hybrid Deep Learning; Springer Berlin Heidelberg, 2024; Vol. 24; ISBN 0123456789.

- Lee, D.; Lee, S. Digital Twin for Supply Chain Coordination in Modular Construction. Appl. Sci. 2021, 11. [CrossRef]

- Ivanov, D.; Dolgui, A. A Digital Supply Chain Twin for Managing the Disruption Risks and Resilience in the Era of Industry 4.0. Prod. Plan. Control 2021, 32, 775–788. [CrossRef]

- Wu, W.; Shen, L.; Zhao, Z.; Harish, A.R.; Zhong, R.Y.; Huang, G.Q. Internet of Everything and Digital Twin Enabled Service Platform for Cold Chain Logistics. J. Ind. Inf. Integr. 2023, 33, 100443. [CrossRef]