1. Introduction

Underground gas storage(UGS) is a key component of the system of natural gas that include "production, transportation, supply, storage and sales", it plays an extremely important role in peak regulation and supply protection of natural gas. By the end of 2022, China has built 24 underground gas storage units (groups), forming a gas storage capacity of about 192×10

8m

3 [

1]. The target areas for building these gas storage has poor geological conditions, such as the burial depth generally greater than 3000m, complex structure, rapid sedimentary phase transformation, and strong heterogeneity [

2], and most of UGS are gas reservoir type gas reservoirs with relatively developed faults. In addition, periodically strong injection and production of gas storage will lead to alternating changes in regional geostress field, resulting in stress concentration in the fracture section [

3], while the rock in the fault is generally weak and broken. Therefore, alternating stress is easy to cause fault resistance reduction and relative dislocation, which may lead to fault sealing failure. Therefore, it is particularly important to study fault slipping characteristics during the preliminary study and program design of gas storage construction. Numerous studies have shown that fault slipping often affects the reservoir and distribution of underground resources and the sealing of the oil and gas traps[

4,

5,

6], faults also play an important role in controlling the development and distribution of reservoirs, and fault slipping may cause deformation, fracture or folding of reservoirs [

7,

8,

9]. For the caprock, fault slipping may cause the caprock to stretch or squeeze, which has a serious impact on the integrity and sealing of the caprock [

10,

11]. As one of the occurrence of faults, fault inclination has an impact on many aspects, such as shear stress [

12], normal stress variation trendency [

13] and oil and gas migration direction [

14]. As a component of faults, fault gouge is the part with the worst mechanical properties in the fault zone, and it is also the geological unit with the largest deformation and the first to be destroyed after disturbance [

15]. Many scholars have carried out a large number of studies on fault gouge. Ma et al. [

16] concluded through two-dimensional simulation tests that the greater the fault inclination, the more favorable the upward movement and accumulation of oil and gas;Jia et al. [

17] focused on the propagation law of acoustic emission signals in faults, and relevant tests showed that the propagation speed and maximum value of acoustic signals were positively correlated with fault inclination;Li et al. [

18] introduced the distance coefficient to establish the weighted gouge ratio method to verify the sealing of oil and gas systems. It is concluded that when the weighted gouge ratio is greater than 0.6, the fault has a good sealing ability;Xie et al. [

19] used kaolin, montmorillonite and quartz to make fault gouges with water content of 30% of different components for direct shear experiments, found that the cohesion and internal friction Angle changed with the change of different components.

In summary, fault inclination and gouge mechanical properties can affect fault slipping. Therefore, the orthogonal combination experiment is carried out to study the fault slip characteristics under alternating stress based on these two factors in order to deeper understand the fault slip mechanism of gas storage.

2. Materials and Methods

2.1. Preparation of Test Samples

The fault sample is the essential condition for experiments, and the high degree of fracturing at the fault, along with the strong softness of the rock mass, results in the occurrence of drilling core blockages and the detachment of the drill bit when drilling the fault core [

20,

21], and it is impossible to obtain the fault sample that can be used for the test. In this study, cylindrical fault samples were prepared using materials similar to sandstone and cement mortar, which exhibit strong homogeneity, for testing purposes.

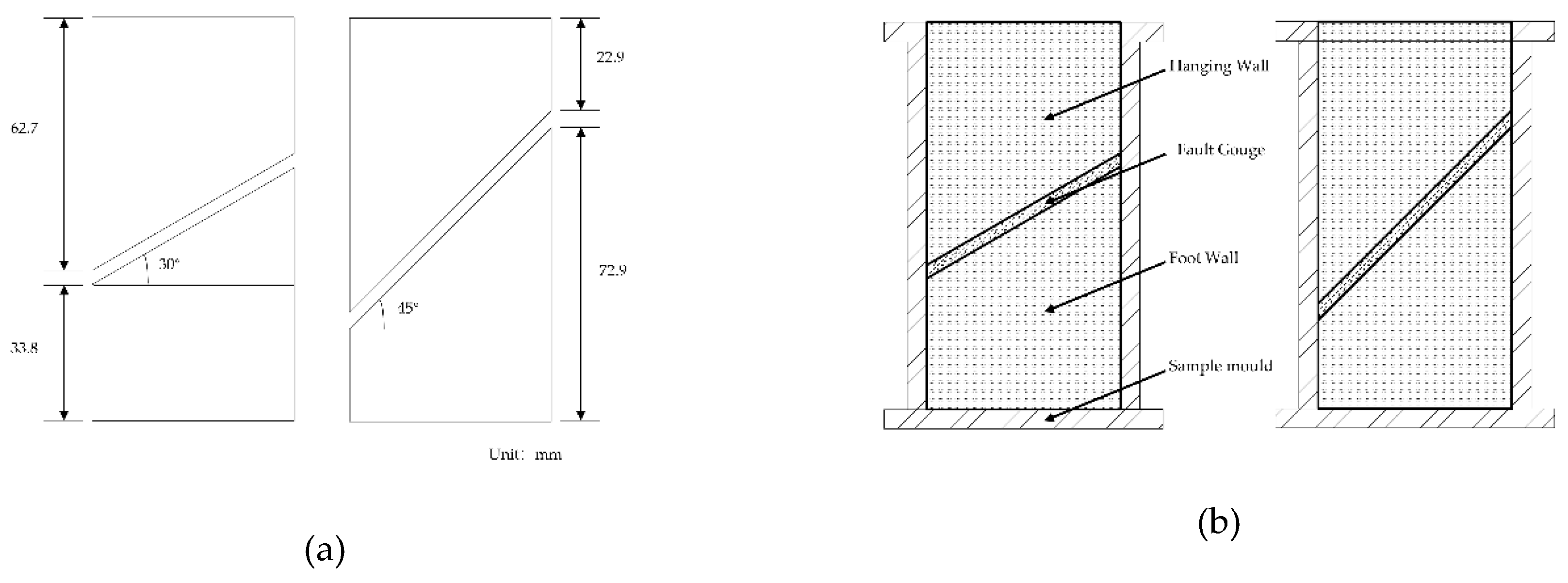

Initially, rock sections with consistent dip angles were machined to 30° and 45° for hanging and foot walls respectively, as shown in

Figure 1(a). Subsequently, cylindrical molds were employed to fill cement mortar as fault gouge, maintaining a uniform 3mm thickness, and following prescribed standards for curing procedures. Upon completion of curing, the fault samples were prepared as depicted in

Figure 1(b). To investigate the influence of fault gouge strength on fault slip characteristics, four types of fault gouge were prepared with uniaxial compressive strengths of 20.1, 30.2, 42.4, and 51.4 MPa, achieved by varying the cement-to-river sand ratio.

As per experimental protocol, a cement-sand mortar mix trial was undertaken, In order to shorten the curing period and quickly improve the mechanical properties of fault gouge, high-strength cement ( Type 425 Portland cement), 50 mesh fine sand and cement mortar reinforcement agent are innovatively used as raw materials in the preparation of fault gouge. Employing fine sand ensured optimal consistency of the fault gouge, while the enhancer not only improved mortar workability but also bolstered its resistance to cracking and bond strength, expeditiously meeting test requisites. To ascertain genuine fault gouge strength, identical materials, mix proportions, and curing protocols were concurrently used to fashion validation specimens for uniaxial compressive strength tests alongside fault sample production. Uniaxial test outcomes for surrounding rock and fault gouge specimens are detailed in

Table 1 for reference.

2.2. Test Methods

The experiment was conducted using the fault mechanics testing apparatus developed by the PetroChina Key Laboratory of Underground Oil and Gas Storage, featuring a maximum axial load capacity of 2000 kN and a maximum confining pressure capability of 80 MPa. Prior to formal testing, the samples underwent preloading. Deformation sensors were strategically installed on the upper and lower indenters to monitor axial compression, while sensors on the fault were deployed to monitor fault compression and slip behavior. To prevent interference from the confining pressure oil during loading and ensure test accuracy, the samples were encapsulated with structural sealant, illustrated in

Figure 1(c).

During the experiment, the simulated slipping process of faults at a depth of 25 km under cyclic stress mimicked the operational pressure conditions of gas storage facilities, ranging from 8 to 26 MPa. Following the cessation of cyclic stress, deformation control was maintained until sample failure occurred, as depicted in

Figure 1(d).

3. Results

3.1. Failure Characteristic Analysis

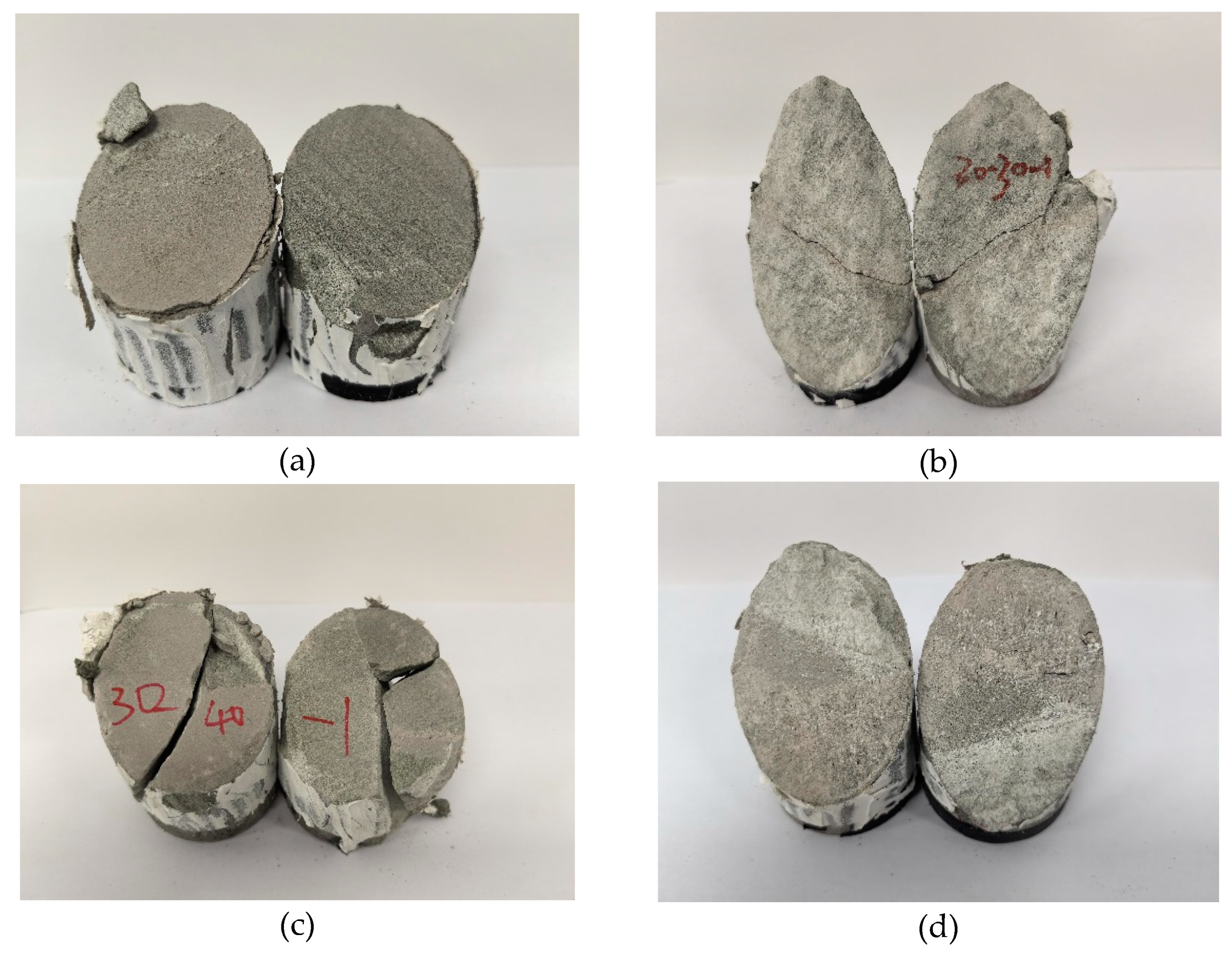

The variations in failure strength and the evolution of internal micro-cracks under distinct fault dip angles and fault gouge compositions manifest in diverse macro-fracture patterns exhibited by fault rocks.

At the fault dip angle of 30°, the complexity of the crack penetration network near the fault zone evolves with the strength of the gouge. At lower gouge strengths, such as 20.1 and 30.2 MPa, shear failure predominantly transpires along the contact plane between the gouge and surrounding rock, resulting in a single macroscopic shear crack on the sample surface, as depicted in

Figure 2(a). Upon reaching the gouge strength of 42.4 MPa, the sample exhibits not only shear cracks along the primary fracture surface, but also oblique shear cracks, forming an "X" type conjugate shear failure pattern, with the macroscopic failure intersecting the gouge midpoint, as illustrated in

Figure 2(b). Advancing to the gouge strength of 51.4 MPa, multiple secondary shear cracks emerge proximate to the primary sample section, accompanied by one or two oblique shear cracks, manifesting in multiple instances of "X" type conjugate shear failure, as depicted in

Figure 2(c).The escalation in gouge strength enhances both the shear and compressive resistance of the gouge, augmenting its cementation with the surrounding rock while diminishing the influence of weaker interfaces. Concurrently, heightened gouge strength elevates internal stress concentration within the sample, expanding the space for micro-crack development and fostering the generation of multiple secondary shear cracks in the vicinity of the primary fracture. This intricate interplay engenders a complex network of cracks within the sample, reflecting the interplay of mechanical properties and failure mechanisms in fault rocks under varying gouge strengths.

At the fault dip angle of 45°, the failure behavior of samples with gouge strengths of 21.1 and 30.2 MPa was similar to that observed at the 30° dip angle, characterized by shear failure predominantly along the gouge-bedrock interface. This results in macroscopic shear cracks visible on the sample surface, indicative of initial failure mechanisms. In contrast, at a gouge strength of 42.4 MPa, a distinct mode of failure emerges where shear failure initiates directly within the central region of the gouge. Notably, there is a reduced occurrence of oblique shear fractures intersecting the main fault section, indicative of a transition away from the "X" type conjugate shear failure observed at lower strengths. Upon reaching a gouge strength of 51.4 MPa, the failure mode exhibits shear cracks aligned with the fault inclination, accompanied by fewer oblique shear fractures along the fault plane. The characteristic "X" type conjugate shear failure pattern becomes less pronounced, and secondary shear cracks proximal to the fault diminish in number, as depicted in

Figure 2(d). The transition in failure modes between 30° and 45° fault dip angles underscores the conversion of axial stress into shear stress along the fault plane with increasing dip angle. This shift intensifies shear failure along the main fault section, influencing fracture characteristics within the samples. Such observations are pivotal for understanding how fault geometry interacts with material properties to govern the mechanical behavior of fault rocks under varying geological conditions.

3.2. Analysis of Strength-Deformation Characteristics

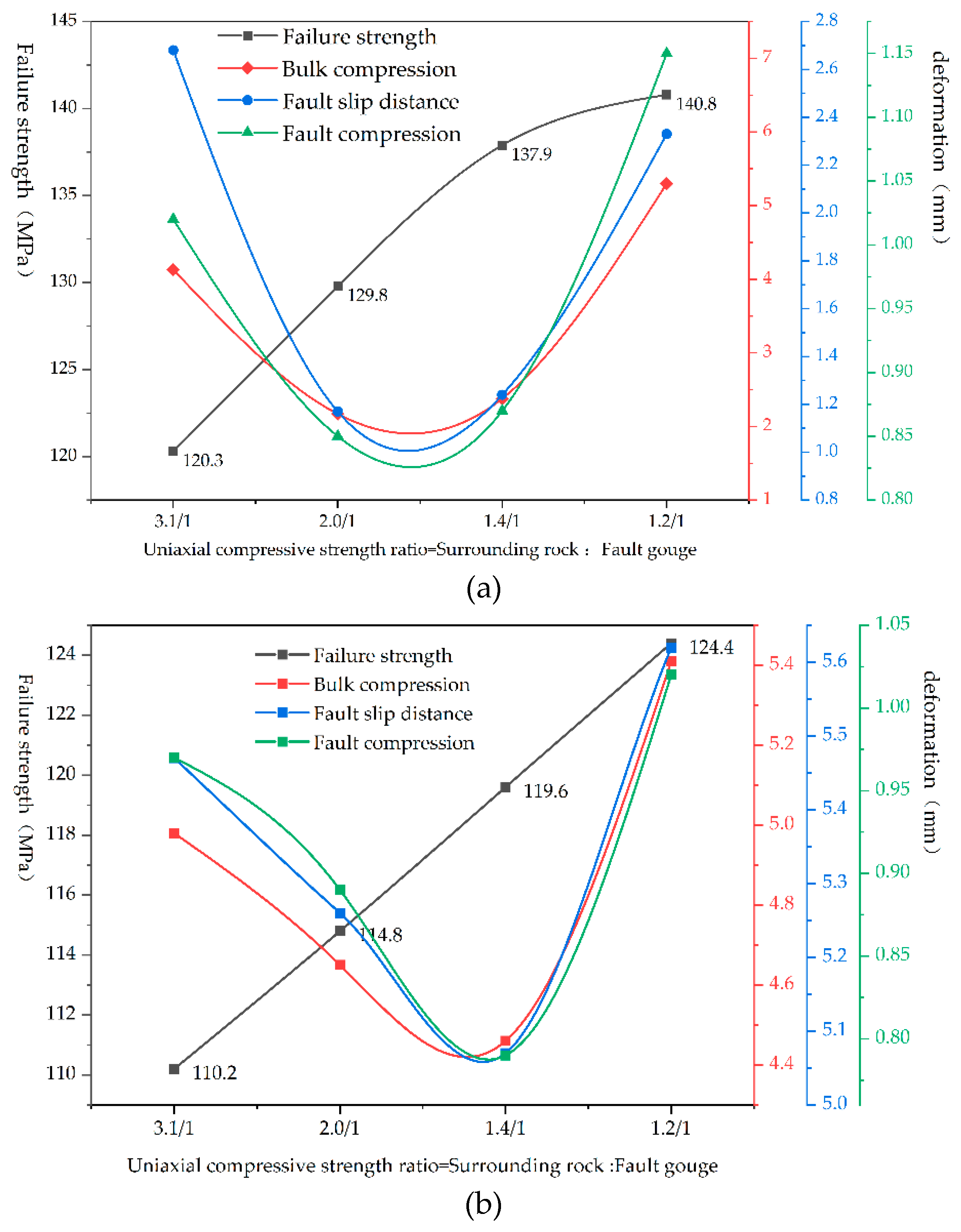

The compressive strength and deformation characteristics at failure of fault samples containing varying strengths of fault gouge at different dip angles are illustrated in

Figure 3. The figure depicts the ratio of uniaxial compressive strength between surrounding rock and fault gouge, where a lower ratio signifies higher strength in the fault gouge material. Observations from the figure reveal that as the strength ratio decreases, the failure strength of the samples consistently increases. Under equivalent strength ratios, the failure strength of 45° dip angle faults is consistently lower compared to those at 30°. Furthermore, the slip displacement of faults at 30° is less than that at 45°, whereas compressive deformation is greater at the latter angle.

This behavior is attributed to the larger normal stress ratio factor in the direction perpendicular to the 30° fault plane compared to the 45° fault, resulting in greater compressive deformation of the intermediate fault gouge section under equivalent stress conditions. Despite the higher compressive deformation, the 30° faults exhibit greater failure strength due to their higher resistance to failure compared to the 45° faults. As the fault dip angle increases, the increment in resolved shear stress along the fault plane alters, facilitating easier overcoming of frictional resistance. Consequently, the compressive strength of fault gouge material is not fully realized, necessitating deformation through fault slip to relieve stress. Thus, while the failure strength of 45° fault samples is lower than that of 30° faults, the former consistently exhibit greater slip displacement.

Additionally, experimental observations reveal that deformation of both 30° and 45° faults initially decreases and subsequently increases as the strength ratio between bedrock and fault gouge diminishes. The inflection point for deformation in the 30° fault occurs around a strength ratio of 1.7/1, whereas for the 45° fault, it occurs around 1.4/1. This trend is attributed to the insufficient deformation resistance of fault gouge with lower strength ratios, resulting in significant deformation occurring at a strength ratio of 3.1/1. As the strength of the fault gouge increases, its overall mechanical properties improve, leading to a declining trend in deformation. However, nearing parity with bedrock strength, increased deformation occurs as the sample accumulates energy pre-failure, predominantly released through slip displacement, causing a sudden surge in deformation. Furthermore, aside from shear failure along the fault plane, oblique shear failure across the fault plane also contributes significantly to slip displacement.

3.3. Fault Damage Analysis

Under the influence of alternating stress, processes within fault specimens such as crack closure, propagation, connectivity, and ultimate failure lead to energy dissipation, rendering the damage irreversible [

22]. The calculation of fault dissipated energy density during alternating processes using energy density methods has been established [

23,

24,

25,

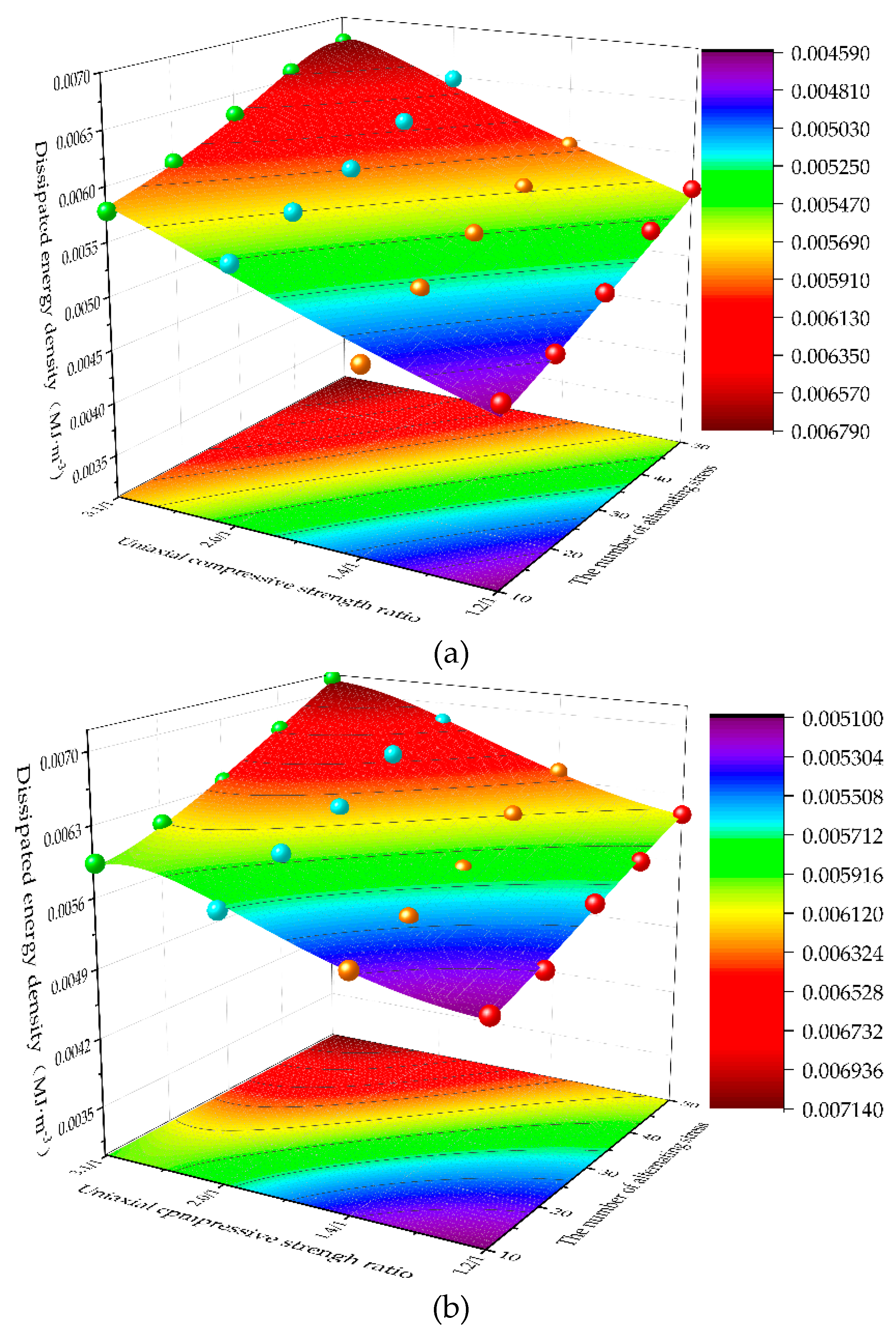

26], Three-dimensional visualization of damage data enhances the discernibility of dissipated energy trends, where elevated dissipated energy density signifies more severe fault damage, as illustrated in

Figure 4.

The analysis reveals a negative correlation between fault damage under alternating stress and fault gouge strength, while a positive correlation is observed with fault dip angle. As expounded, higher fault gouge strength results in enhanced stability and resistance to damage, thereby reducing the susceptibility to the impact of alternating stress. Conversely, greater fault dip angles increase the propensity for fault slip and shear failure under equivalent stress conditions, amplifying the influence of alternating stress on high-angle faults.

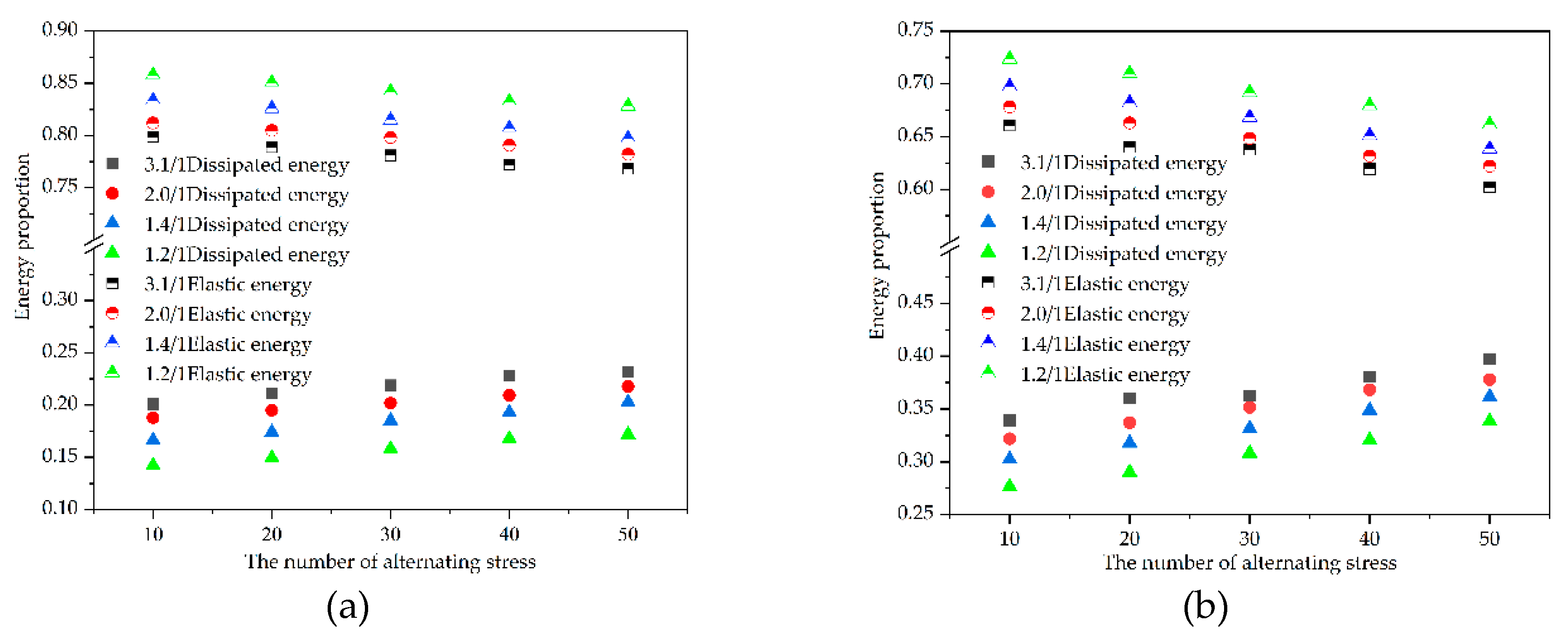

From the analysis above, it is evident that comparing the energy density distributions of fault gouge samples at different angles and strengths does not accurately assess the extent of fault damage and rupture. Therefore, non-dimensional parameters are introduced [

27]:

is Elastic energy ratio (the proportion of elastic energy in input energy) and

is dissipative energy ratio (the proportion of dissipative energy in input energy) were used to analyze the distribution law of elastic energy density and dissipative energy density at different stages.

where

is the input energy,

is the elastic energy during a particular cycle of alternation,

is the dissipative energy during a particular cycle of alternation.

Figure 5 portrays the temporal evolution of elastic and dissipative energy fractions across fault samples subjected to cyclic loading, considering various dip angles and strength ratios. Throughout 50 loading cycles, elastic energy predominates over dissipative energy, indicating the samples’ primarily elastic response. The dissipative energy fraction for samples with 30° and 45° dip angles exhibits a distinct three-stage evolution: an initial rapid rise, a subsequent plateau, and a late-stage gradual increase.

During the rapid rise phase (cycles 10-20), external energy input consolidates existing microcracks, leading to a significant increase in dissipative energy. Notably, samples with lower strength ratios (indicative of higher fault gouge strength) exhibit less pronounced compaction due to their enhanced elastic properties, which resist microcrack closure. As loading progresses into the elastic phase (cycles 20-40), high-strength samples maintain a stable dissipative energy fraction, while low-strength samples stabilize, indicating effective microcrack compaction during the initial stages.

In the later stages of cyclic loading, some samples experience new microcrack formation or propagation, resulting in a gradual rise in dissipative energy fractions. This nuanced analysis underscores the complex interplay between microcrack compaction, elastic behavior, and dissipative energy distribution in fault samples under cyclic loading conditions.

3.4. Analysis of Critical Slip Points of Gas Storage Faults under the Alternating Stress

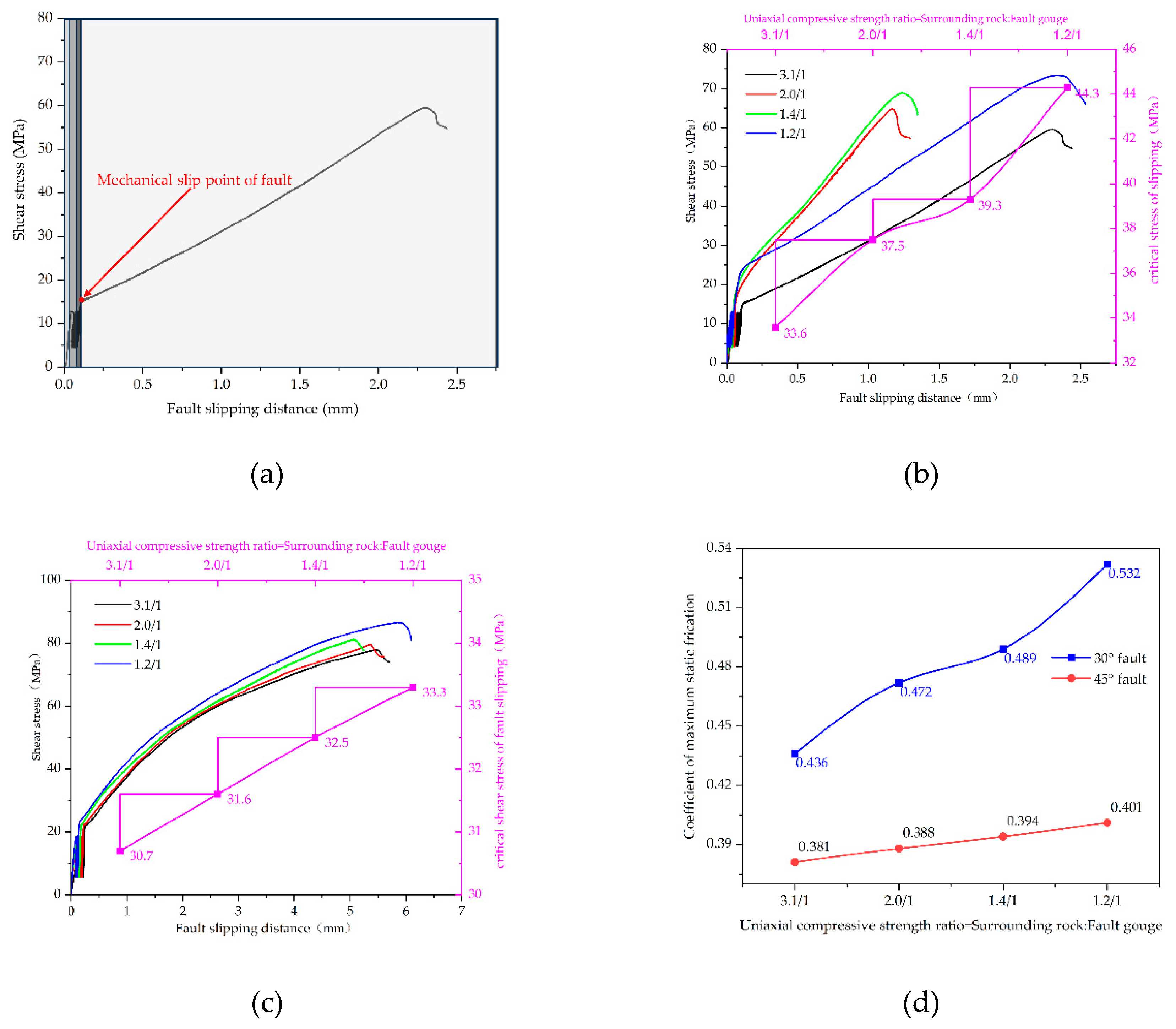

By systematically monitoring fault slip deformation during the loading process and analyzing its temporal progression, the complex behavior can be delineated into distinct phases: initial pore compaction, subsequent elastic deformation, ensuing plastic shear, and eventual shear instability, as elucidated in

Figure 6(a). Throughout the initial three phases, the fault exhibits negligible slip until reaching a critical shear stress threshold, where significant relative displacement occurs, posing potential gas leakage risks for storage facilities.

Figure 6(b,c) depict slip curves for faults inclined at 30° and 45°, respectively. Notably, the highest clay strength sample within the 45° fault exhibits a lower shear stress at slip initiation than the lowest strength sample in the 30° fault. Moreover, the variability in shear stress during slip is more pronounced for the 30° fault compared to the 45° fault, underscoring the substantial influence of clay strength on slip behavior in shallow-angle faults, while steep-angle faults consistently pose elevated slip risks.In the context of gas storage facilities, fault slip implies potential natural gas leakage, necessitating rigorous assessment through introduction of the friction coefficient. The maximum static friction coefficient serves as a pivotal parameter in evaluating the fault’s resistance to slip under activation conditions. Statistical analysis of the maximum static friction coefficients for 30° and 45° faults (

Figure 6(d)) reveals that, for faults of equivalent strength, the coefficient is higher for 30° faults than for 45° faults. Specifically, the maximum static friction coefficient for 30° faults escalates with increasing clay strength: 0.436, 0.472, 0.489, 0.532, contrasting with the range of 0.381 to 0.401 observed for 45° faults. This indicates that 30° faults manifest superior resistance to slip relative to their 45° counterparts, thereby mitigating the risk of natural gas leakage. Furthermore, heightened clay strength correlates positively with increased maximum static friction coefficients, substantiating enhanced resistance to slip and reduced likelihood of slip occurrence.

In conclusion, through meticulous observation and rigorous analysis of fault slip dynamics and associated mechanical properties, a comprehensive understanding of potential risks associated with natural gas leakage in critical infrastructure such as gas storage facilities can be attained. This scientific foundation informs robust strategies for risk mitigation and operational safety protocols.

4. Conclusions and Discussion

This article investigates the influence mechanisms of fault inclination and fault clay strength on the mechanical slip behavior of faults in gas storage facilities through triaxial compression tests under cyclic loading conditions on fault samples with different characteristics (varying angles and strengths of fault clay). Four key conclusions are drawn as follows:

(1) During fault failure, the strength of fault clay and fault inclination significantly affect the mode and intensity of failure. Higher fault clay strength correlates with increased failure intensity, leading to more extensive crack propagation upon fault failure, gradual convergence of the failure location towards the fault core from the periphery, and the development of shear cracks oblique to the fault plane. As fault inclination increases, the failure intensity tends to decrease, resulting in reduced sample damage.

(2) With increasing fault clay strength, the overall compression, fault slip, and fault compression of fault samples exhibit a trend of initial decrease followed by an increase. The inflection point for 30° faults occurs at a ratio of around 1.7/1 between rock strength and fault clay strength, while for 45° faults, the inflection point is near 1.2/1.

(3) Fault clay strength plays a decisive role in the damage to faults under cyclic loading conditions. Higher fault strength leads to lower dissipated energy and higher elastic energy proportions at the same number of loading cycles. Furthermore, for the same number of loading cycles and fault clay, greater fault inclination results in more severe fault damage.

(4) The maximum static friction coefficient represents the fault’s resistance to slip. Overall, the static friction coefficient of 30° faults is higher than that of 45° faults. The static friction coefficient of 30° faults demonstrates nonlinear growth with increasing fault clay strength, while that of 45° faults shows nearly linear growth.

Author Contributions

Conceptualization, Songlin Cheng and Zhide Wu ; methodology, Xiaosong Qiu; validation, Haitao Xu, Guosheng Ding and Bingbing Liu.; formal analysis, Songlin Cheng.; investigation, Songlin Cheng.; data curation, Zhide Wu ; writing—original draft preparation, Songlin Cheng; writing—review and editing, Haitao Xu; supervision, Guosheng Ding. All authors have read and agreed to the published version of the manuscript.

Funding

The authors declare that this study received funding from Fundamental and Prosp-ective Research Project (Number:2022DJ8304) and the Technology Special Projects (Number:2023YCQ01) from PetroChina Co.Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

The authors acknowledge the technical support provided by Research Institute of Petroleum Exploration & Development,and the experimental help of tester in CNPC Key Laboratory of Oil & Gas Underground Storage Engineering.

Conflicts of Interest

Author Songlin Cheng was employed by PetroChina Co.Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ding, G.; Wang, Y.; Wanyan, Q.; Wang, J.; Xu, H.; Li, K.; Xia, Y.; Li, L.; Zeng, D.; Liu, Z. Construction difficulties and research directions of various complex UGSs. Natural Gas Industry 2023, 43, 14-23.

- Ma, X.; Zheng, D.; Ding, G.; Wang, J. “Extreme utilization” theory and practice in gas storageswith complex geological conditions Petroleum Exploration and Development 2023, 50, 373-383. [CrossRef]

- Wang, C.; Gao, G.; Jia, J.; Chang, C.; Wu, Z. Variation of stress field and fault slip tendency induced byinjection and production in the H underground gas storage. Natural Gas Industry 2020, 40, 76-85.

- Caine, J.S.; Evans, J.P.; Forster, C.B. Fault zone architecture and permeability structure. Geology 1996, 24, 1025-1028. [CrossRef]

- Cello, G.; Tondi, E.; Micarelli, L.; Invernizzi, C. Fault zone fabrics and geofluid properties as indicators of rock deformation modes. Journal of Geodynamics 2001, 32, 543-565. [CrossRef]

- Brogi, A. Fault zone architecture and permeability features in siliceous sedimentary rocks: Insights from the Rapolano geothermal area (Northern Apennines, Italy). Journal of Structural Geology 2008, 30, 237-256. [CrossRef]

- Zhang, X.; Sun, Z.; Zhao, J.; Pan, Y.; Wu, M. Study on the Influence of Strike-slip Fault Displacement on Reservoir in Northern Slope,Tazhong Area. Geoscience 2014, 28, 1017-1022.

- Zheng, H.; Hu, Z.; Yun, L.; Lin, H.; Deng, S.; Jia, H.; Pu, Y. Strike-slip faults in marine cratonic basins in China:Development characteristics and controls on hydrocarbon accumulation. Earth Science Frontiers 2022, 29, 224-238.

- Wu, M.; Liu, Y.; Peng, P.; Chai, X.; Yan, N. Characteristics of strike-slip faults in Lunnan buried hill and its influence on hydrocarbon accumulation. Fault Block Oil & Gas Field 2021, 28, 456-462.

- Wu, Y.; Sun, C.; Wang, D.; Jiang, T.; Huang, Y.; Gong, J. Hydrocarbon distribution characteristics and main controlling factors of accumulation in South Konys Oilfield in South Turgay Basin,Kazakhstan. Natural Gas Geoscience 2016, 27, 2013-2022. [CrossRef]

- Lan, X.; Lv, X.; Zhu, Y.; Li, S.; Xie, E. Hydrocarbon accumulation pattern jointly controlled by strike-slip faults and cap rocks:a case from Yingshan Formation in ZG-51 wellblock of eastern Tazhong area,Tarim Basin. Oil & Gas Geology 2014, 35, 107-115.

- Jia, X. Numerical simulation of the effect of fault inclination on faultactivation and water inrush from floor. Coal Engineering 2017, 49, 90-93.

- Piao, W.; Mao, X. Research on effect of fault dip on fault activation andwater inrush of coal floor. Chinese Journal of Rock Mechanics and Engineering 2009, 28, 386-394.

- Ma, Z.; Zeng, J.; Zhao, L.; Wu, Y.; Xu, X.; Li, D. Experimental simulation for the influence of fault property and dip angle onpetroleum migr ation and accumulation in Jiyang Depr ession. Lithologic Reservoirs 2008, 109-113.

- Li, Z.; Zhou, M.; Huang, H.; Tong, Y.; Zhang, W. Mechanical and constitutive characterization of gouge considering cementation. Journal of Basic Science and Engineering, 1-20.

- Ma, Z.; Zeng, J.; Zhao, L.; Wu, Y.; Xu, X.; Li, D. Experimental simulation for the influence of fault property and dip angle on petroleum migration and accumulation in Jiyang Depression. Lithologic Reservoirs 2008, 109-113.

- Jia, B.; Li, B.; Zhou, L.; Chen, H. Experimental study on the influence of fault dip angle on acoustic emission sinalpropagation. Coal Science and Technology, 1-16.

- Li, C.; Yu, W.; Ding, J. Quantitative evaluation of fault sealing by Weighted Shale Gouge Ratio(WSGR) : a case study of Yongan area in Gaoyou Sag,Subei Basin. Petroleum Geology & Expriment 2024, 46, 158-165. [CrossRef]

- Xie, L.; Liu, H.; Ban, S.; Mao, H.; Xia, D.; Song, Y.; Tong, R.; Ying, Q. Experimental study on shear properties of fault gouge withdifferent mineral compositions Rock and Soil Mechanics 2023, 44, 2545-2554. [CrossRef]

- Zhang, J. Study on causes and preventive measures of coring and plugging in complex formation. China Mine Engineering 2021, 50, 52-55. [CrossRef]

- Li, X.; Li, K.; Liang, J.; Yin, H.; Wang, Z.; Sun, J.; Zhang, Y. Analysis of core-blocking causes in complex formation core drilling and its preventive measures. Exploration Engineering (Rock & Soil Drilling and Tunneling) 2018, 45, 12-15.

- Chen, X.; Xiao, Y.; Tang, M.; Jiao, T.; Zhang, F. Experimental study on deformation,permeability and AE characteristics ofsandstone under multi-stage cyclic loading with a constant amplitude Chinese Journal of Rock Mechanics and Engineering, 1-13. [CrossRef]

- Duyi, Y.; Zhenlin, W. A new approach to low-cycle fatigue damage based on exhaustion of static toughness and dissipation of cyclic plastic strain energy during fatigue. International Journal of Fatigue 2001, 23, 679-687. [CrossRef]

- Xiao, J.-Q.; Ding, D.-X.; Jiang, F.-L.; Xu, G. Fatigue damage variable and evolution of rock subjected to cyclic loading. International Journal of Rock Mechanics and Mining Sciences 2009, 47, 461-468. [CrossRef]

- Zhou, H.; Hou, W.; Zhang, L.; Xie, S.; Jia, W.; Shi, B. Constitutive model of coal considering temperature under cyclic loading andunloading conditions. Journal Of China Coal Society 2024, 49, 442-453. [CrossRef]

- Li, X.; Yao, Z.; Huang, X.; Liu, Z.; Zhao, X.; Mu, K. Investigation of deformation and failure characteristics and energy evolution ofsandstone under cyclic loading and unloading. Rock and Soil Mechanics 2021, 42, 1693-1704. [CrossRef]

- Yang, L.; Gao, F.; Wang, X.; Li, J. Energy evolution law and failure mechanism of coal-rockcombined specimen. Journal of China Coal Society 2019, 44, 3894-3902. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).