3.1. Results of Experimental Studies

The possibility of application of diatom sediments of Aktobe region of Zhalpak deposit of the Republic of Kazakhstan as a filler in water-dispersion paint and varnish composition has been investigated. Diatomite raw material samples are characterized by significant variation in chemical composition. The SiO

2 content varies from 73.087 % in white varieties of raw materials to 25.845 % in yellow (ochre-like). The Fe

2O

3 content varies from 2.356 % to 30.405 %. The change in the content of minor components (Na

2O, MgO, Al

2O

3, K

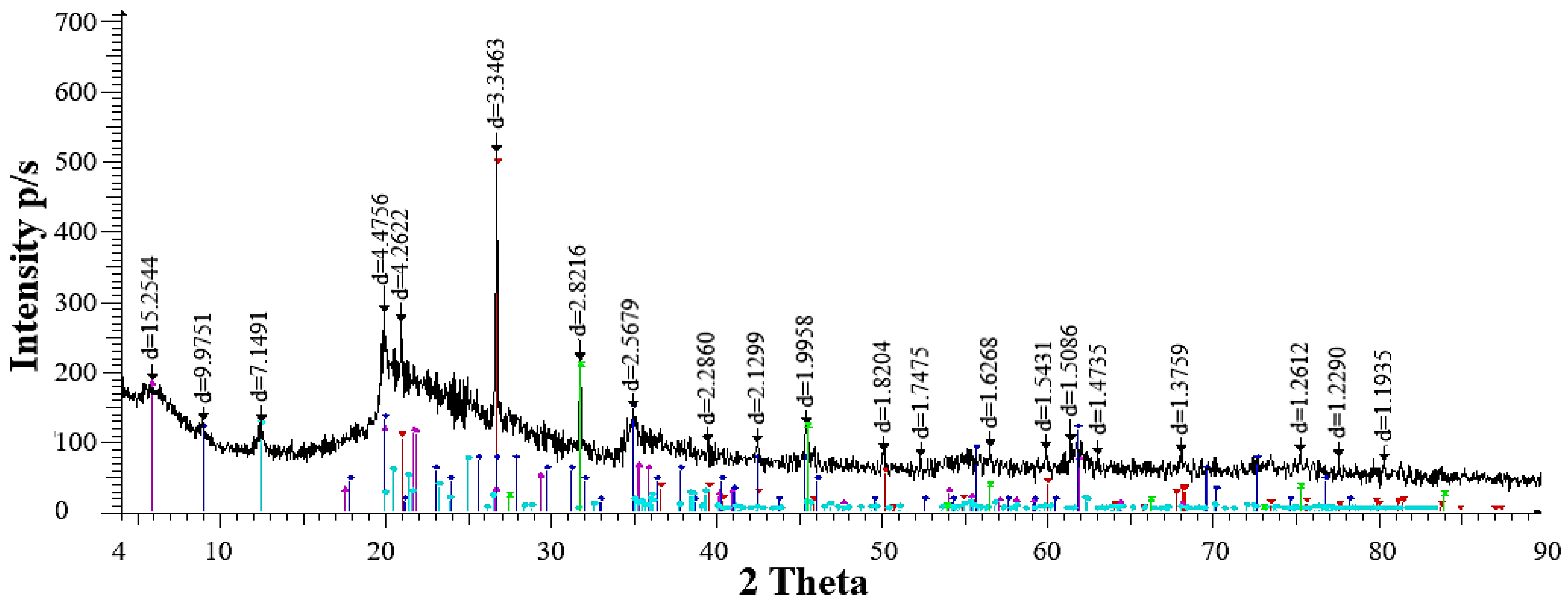

2O, CaO) is not as significant. Slightly elevated contents of vanadium, rubidium and strontium compounds were noted in quantities exceeding relative clark values, but not of interest for their targeted recovery as concentrates. To study the mineral composition of diatomite raw materials, X-ray phase analysis was performed on a D8 Advance diffract meter (BRUKER), a-Cu emission. Quartz and muscovite were found to be the major phase in all diatomite raw material samples (

Figure 1).

The obtained results of physical and chemical analysis of diatomite indicate the possibility of its use as a raw material for paint and varnish products.

Table 1 summarizes the physical and mechanical characteristics of natural diatomite.

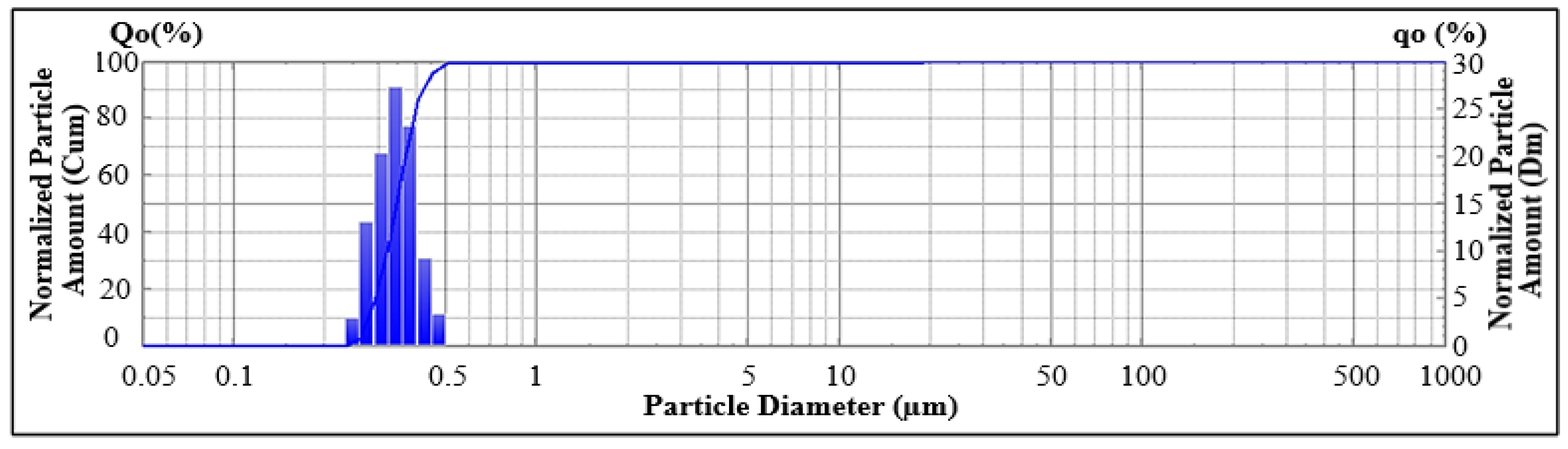

The samples of diatomites under study were are finely dispersed powders of grayish-yellowish color, obtained by milling slightly cemented rocks of the respective deposits. The particle size distribution of the dispersed material prepared in this way is shown in

Figure 2.

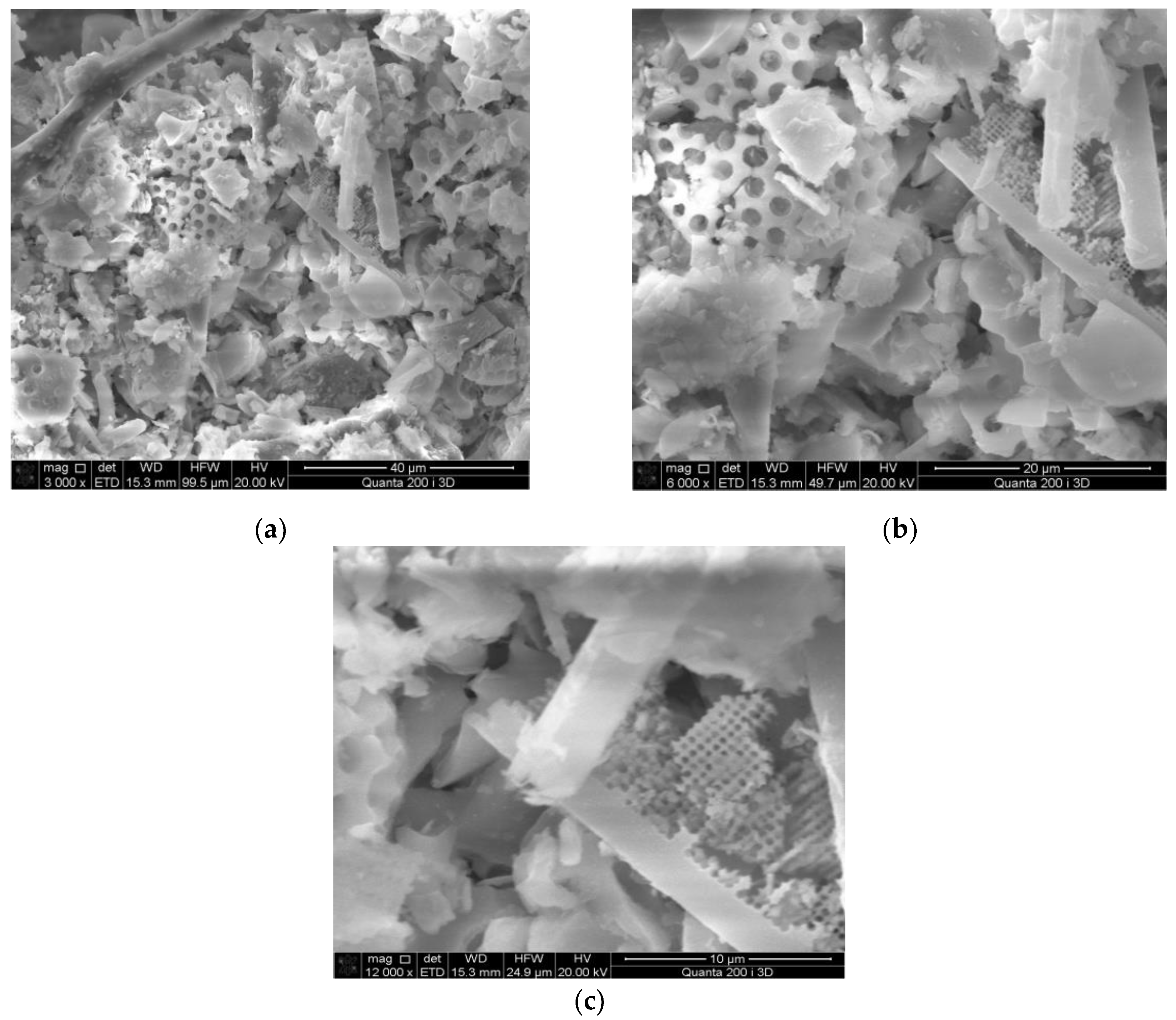

Figure 3 shows the structure images obtained by electron microscopy of natural diatomite powders at magnification (a) 3000x, (b) 6000x, (c) 12000x multiples. Remains of shell flaps of diatom algae with regular channels ~ 100-500 nm in diameter, which constitute the life-support system of unicellular algae, as well as various in shape and size fragments of dispersed material, are clearly visible. A characteristic feature of granular systems is their significant porosity, reaching even for natural fossil rocks, 70% and more. Free space between particles, as well as inhomogeneities of amorphous silica particles themselves in the form of pores, channels, cracks of nano- and submicrometre sizes form a developed pore structure of different scale levels, which determines many properties of mineral powders.

Studies on chemical activation of diatomite’s, determination of optimal parameters of the processes were carried out. The interaction of different forms of diatomite raw materials with calcium oxide to improve the quality parameters of building products has been investigated.

To activate the diatomite, mechanical grinding in the VG-3 vibro-grinder for 60 min and thermal activation in a laboratory furnace at 650 0C for 1 hour followed by grinding in the VG-3 grinder for 60 min were carried out. Mechanical grinding in the abrasion machine achieved an average effective particle size of 70-80 μm. The abrasion of annealed ferruginous diatomite produced particles of 5-10 nm in size, which subsequently favored the formation of high-strength compounds such as hedenbergite - Ca(Fe,Mg)Si2O6 and chloritoid -А - FeAl2SiO5(OH)2. Thermal activation of ferruginous forms of diatomite allowed achieving compressive strength of 25.2 MPa and water absorption of 4.3 %.

The processes occurring during heating of diatomite’s were investigated by thermo gravimetric analysis. The results of thermal analysis of diatomite samples from the thermo gravimetric analysis curve showed three stages of mass loss of the samples during the heating process. The first one starts immediately after the start of heating and lasts until about 350 0C. This partially dehydrates the natural diatomite’s and reduces the mass of the samples by about 6%. At further heating in the temperature range of 400-600 0C along with continuing dehydration of small-scale pores and pore channels of amorphous silica particles, intensive burning of organic material residues in flaps and shell fragments of diatom algae, as well as other impurities of organogenic origin is observed. These processes are recorded on the thermo gravimetric analysis diagram as an endothermic peak around 500 0C, with a mass loss of approximately 2.5 %. Heating the dispersed material from 600 to 1000 0C also results in a decrease in the mass of the diatomite sample, amounting to ~ 9% of the original mass.

The water-dispersible paint composition is prepared as follows.

Lightly mix the components by sequentially adding one component to the others. In this case, as a pigment use, for example, titanium dioxide grade TiO2 P-02; as a filler - for example, activated diatomite Aktobe deposit, burnt at a temperature of 650 0C; lime fluff - 1-2 grades; water - for example, drinking water.

Then place the obtained mixture in the vortex layer apparatus and stir in it for 3-5 minutes at the frequency of electric current in the windings of the apparatus 50 Hz.

At performance of the given work the main task of research was a question of studying of influence of a mineral natural filler on characteristics of water-dispersion composite on a polymeric basis.

Table 2 presents a comprehensive study of the effect of the mineral additive diatomite in water-dispersion composite, designed for interior finishing works, on some standardised indicators of paint quality.

The addition of diatomite to the composite was carried out directly during the mixing of the components in the dispersing unit. At the same time, the study of composite properties was carried out in two stages: immediately after mixing and preparation of the composite, as well as after 2 months of composite storage. The latter study is due to the need to evaluate the influence of the degree of diatomite coagulation on the composite properties. The results of the research are presented in

Table 3.

The introduction of activated diatomite into the water-dispersion composite did not particularly change the regulatory quality parameters such as density and dry residue. When diatomite is added, a significant increase in viscosity and hiding power of the composite is observed. At the same time, the influence of diatomite on these indicators is significantly higher, which is probably due to the different values of the wetting edge angle of these materials. The covering power as one of the main indicators of composite quality at introduction of diatomite increases very insignificantly and is practically within the normative limits. It should be noted that a slight increase in the viscosity of water-dispersion composites in the process of production while maintaining the other parameters is positive, because it allows to reduce the viscosity of the composite to dilute it with water to ensure the standardized quality, which, in turn, contributes to cheaper production and increased efficiency.

The addition of diatomite during the composite production process significantly increases its viscosity. However, after prolonged storage, the viscosity of the paint decreases to almost standard values. This effect can be favorably utilized when the composite is stored for long periods of time or transported long distances.

The carried out complex of researches has allowed to define the character of influence of the activated mineral natural filler introduced into water-dispersion composites on change of standard indicators of composites that gives the possibility of formation of a new complex of properties of water-dispersion paint and varnish composition with simultaneous increase of efficiency of process of their industrial production.

Coatings and free films were obtained from the developed aqueous dispersion materials. Drying time of coatings up to degree 3 at temperature (20±2) °C is 1 h and does not change with the introduction of modified diatomite. The characteristics of the samples are summarized in

Table 4.

From the data in

Table 4 it is evident that modification with activated diatomite provides a significant increase in the elastic modulus of composite films without reducing the tensile strength. This indicates high adhesive strength at the polymer-modified diatomite interphase boundary and, accordingly, good compatibility of the modified diatomite and the polymer matrix (acrylate binder). Adhesive strengthening is ensured both without pigment and with pigment of the developed coatings. The introduction of modified diatomite into a sample with pigment does not lead to a decrease in the hiding power of the paint and varnish material. In combination with the ability to regulate the rheological properties of the dispersion during modification, this can help reduce the consumption of paint and varnish material during painting. Coatings modified with modified diatomite are characterized by increased hardness, this is presumably due to the ordering of polymer chains near the aluminosilicate surface, which is often observed in the case of good compatibility of the polymer and highly dispersed filler [

23], the resulting boundary layer of the polymer is characterized by increased physical and mechanical properties compared to the polymer in the volume. Modification of coatings with diatomite allows for a significant reduction in water absorption of coatings (2.6 times with the introduction of 20% modified diatomite). This may also be due to the compaction of the supramolecular structure of the polymer matrix; in addition, when introducing ultradispersed nanoparticles, the diffusion coefficient of water molecules in the composite decreases [

24]. A sharp decrease in water absorption of the coating with an increase in the content of modified diatomite from 10 to 20% by weight may be associated with a change in the nanostructure of the composite; in work [

25], in this range of concentrations of modified diatomite in the polymer dispersion, a transition from the exfoliated morphology of the nanocomposite to the intercalated morphology, characterized by a higher degree of ordering of the particles, is observed.

Thus, modification of aqueous dispersions with silica activated diatomite by mixing the components in a vortex layer apparatus helps to eliminate the main disadvantages of materials and coatings based on an acrylate binder - low water resistance and low physical and mechanical characteristics. The low cost of modified diatomite, ease of introduction into water-dispersed materials, the possibility of regulating the rheological properties of the dispersion and the achieved improvement in the characteristics of modified coatings determine the prospects for the practical application of water-dispersed materials modified with activated diatomite in a vortex layer apparatus, including paints and varnishes based on acrylate polymer.

Water-based paints based on modified fillers are of particular interest to consumers and manufacturers of paints and varnishes. Having a large specific surface area, granules of dispersed modified fillers create strong bonds between components and fill the voids between them, forming a homogeneous and durable coating.

It is known that dispersed granules of silicon dioxide are hollow balls that form the porous structure of paint.

In this regard, we conducted a series of experiments:

determination of porosity, adhesion, elasticity, hiding power of the control composition;

porosity, adhesion, elasticity, hiding power obtained using a modified filler.

The prescribed amount of the additive was introduced into a 200 ml glass beaker and stirred at room temperature using a magnetic stirrer for 5 min.

It has been established that the introduction of modified diatomite into water-based acrylate paint does not lead to deterioration of the main performance characteristics of paint and varnish coatings – porosity, adhesion, elasticity and hiding power. The influence of the filler – modified diatomite – on the performance characteristics of paint and varnish coatings is insignificant, at the level of experimental error.

An insignificant influence of the time of full-scale tests in the studied small range, regardless of the quantitative composition of the modified diatomite, on the performance characteristics of paint and varnish coatings is shown.

The appearance of the coatings obtained without and with the addition of the modifier was assessed before and after full-scale tests for compliance with regulatory requirements and was found to be satisfactory.

The covering power of the dried film of paint and varnish material was 100 g/m2 (in accordance with the standard). The elasticity of all the studied coatings had a “flexibility of 10” (corresponds to the standard).

As can be seen from the experimental results presented in

Table 6,

Table 7,

Table 8,

Table 9 and Table 10, the adhesion and porosity of the obtained coatings from paint and varnish material with modified diatomite coincide with these characteristics for the base material at the level of experimental error and correspond to the norm.

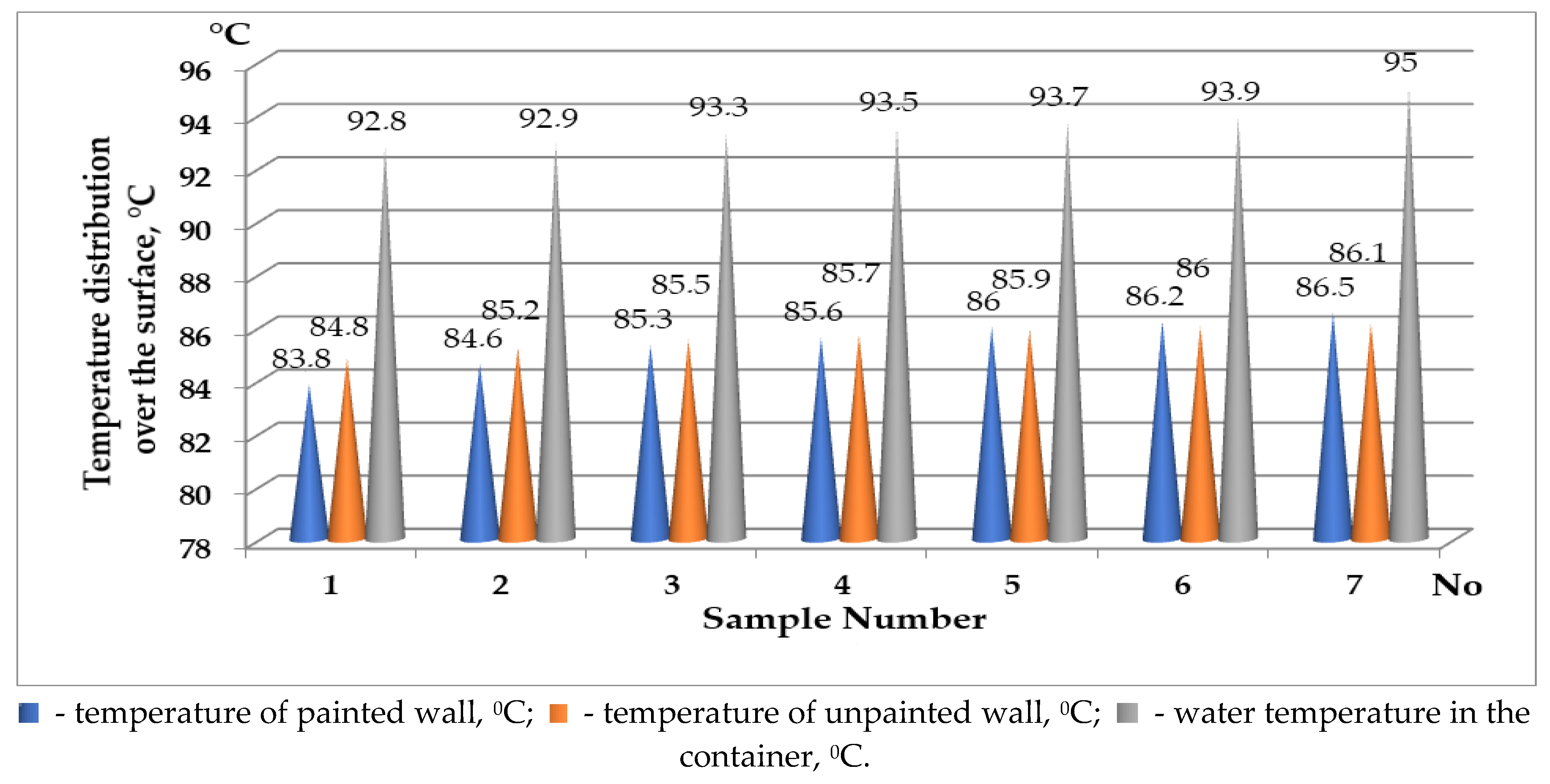

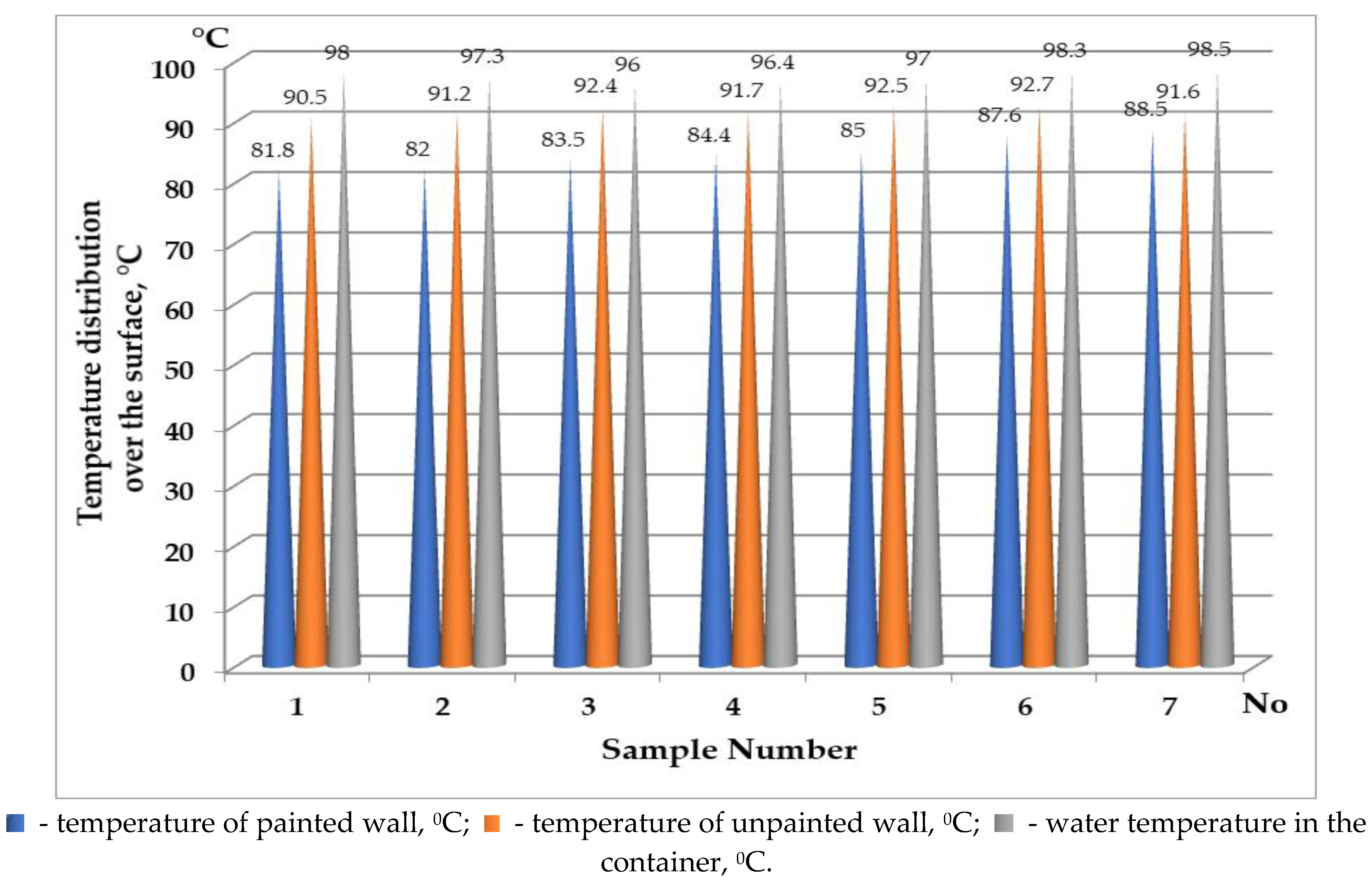

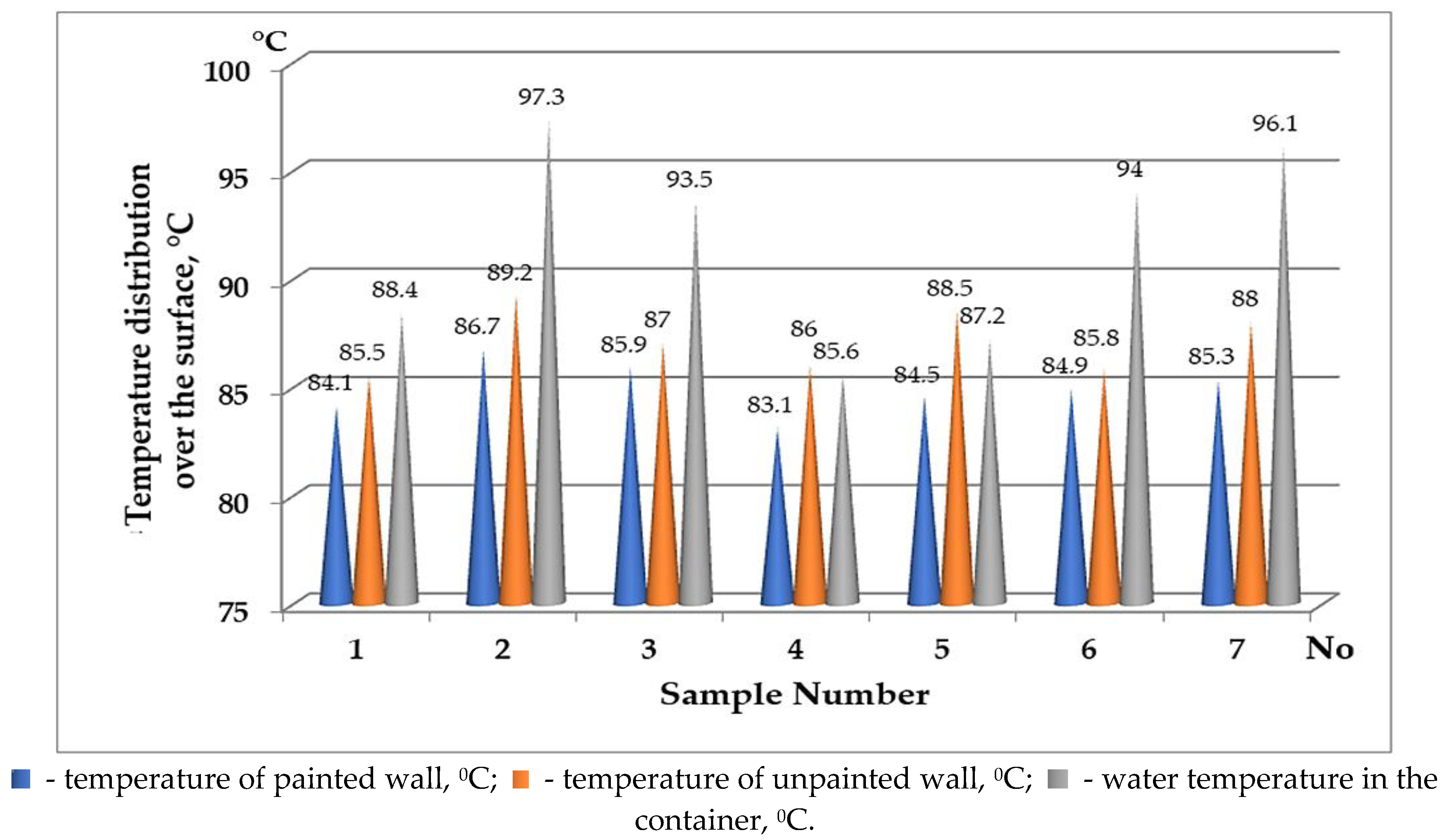

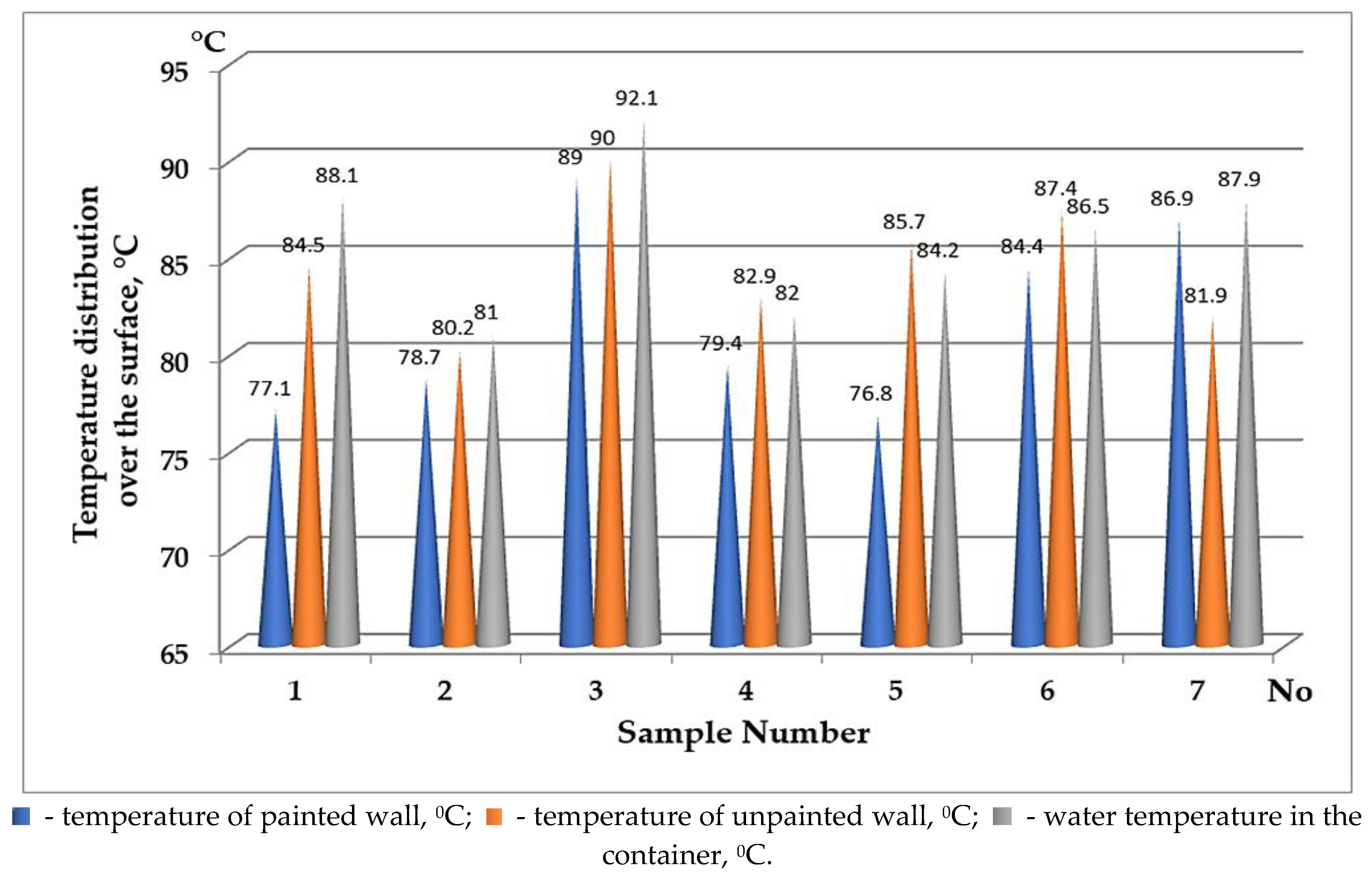

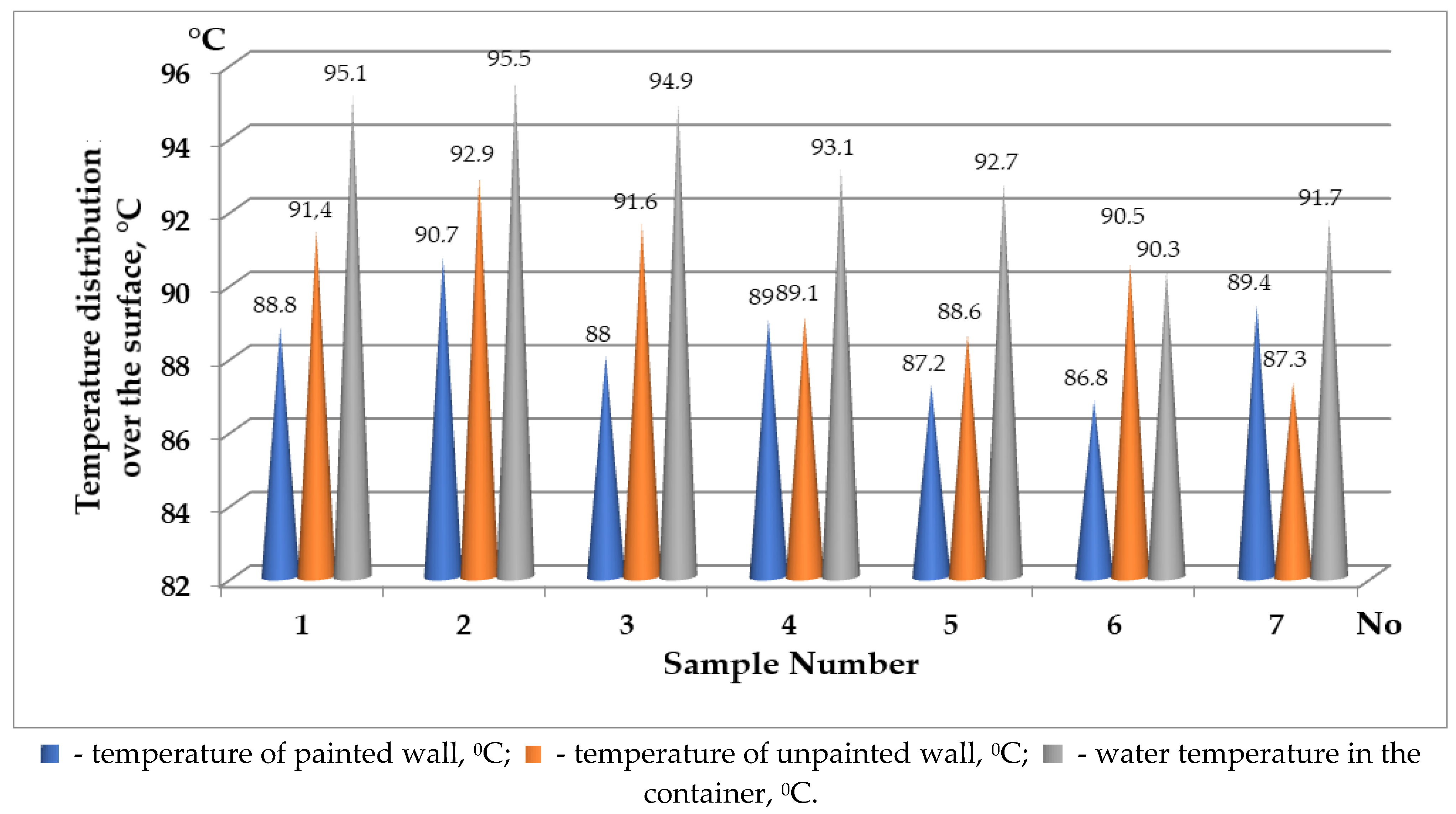

An experimental determination of the radiation in the IR region of the spectrum of the surface of modified water-dispersion paint and varnish composites based on activated diatomite was carried out.

The temperature of the surface areas of the containers in the IR spectrum and coated with paint and varnish material without the addition of modified diatomite and with the addition of modified diatomite and modified diatomite + lime was determined. The number of parallel dimensions is 7. Mathematical processing of the results was carried out. The estimate of the reproducibility variance was determined, and the hypothesis of the experiment’s reproducibility was confirmed. The results of the experiments were averaged and are presented in

Figure 4,

Figure 5,

Figure 6,

Figure 7 and

Figure 8.

Thus, when conducting experimental studies:

1. It has been established that the introduction of modifiers into a water-dispersion paint and varnish composition on an acrylate basis, selected as a base material, does not lead to a deterioration in the main performance characteristics of paint and varnish coatings - porosity, adhesion, elasticity and hiding power. The influence of modified diatomite on the performance characteristics of paint and varnish coatings is insignificant, at the level of experimental error.

2. An insignificant influence of the time of full-scale tests in the studied small range, regardless of the amount of modified diatomite, on the performance characteristics of paint and varnish coatings was shown.

3. A significant influence of the amount of modified diatomite on the reduction of the emissivity of paint and varnish coatings in the IR region of the spectrum was established.

4. It has been shown that a more significant effect of reducing the emissivity of paint and varnish coatings in the IR region of the spectrum is provided by the introduction of a mixture of additives of modified diatomite + lime.