Submitted:

06 August 2024

Posted:

07 August 2024

Read the latest preprint version here

Abstract

Keywords:

Introduction

Experimental Procedures

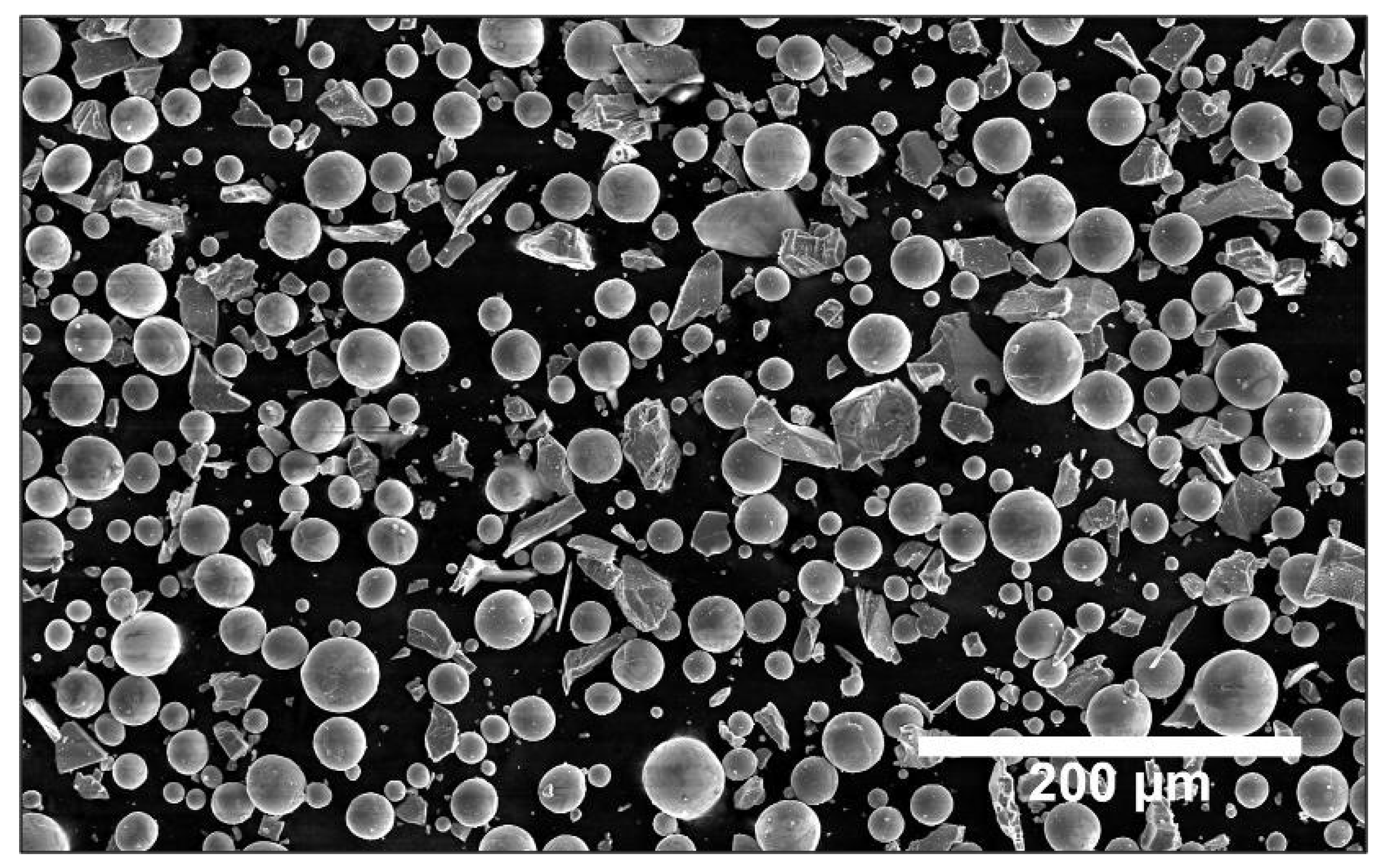

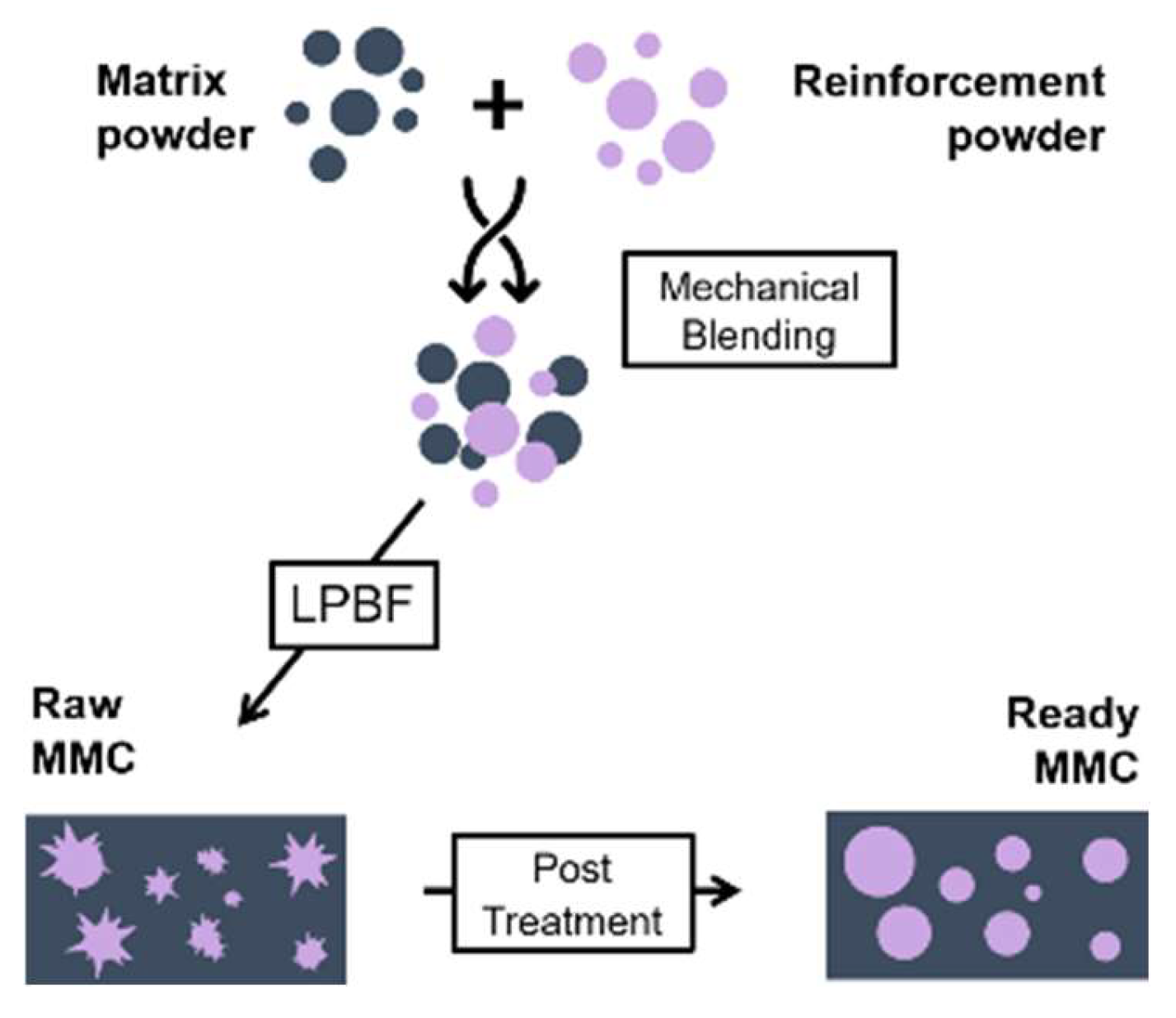

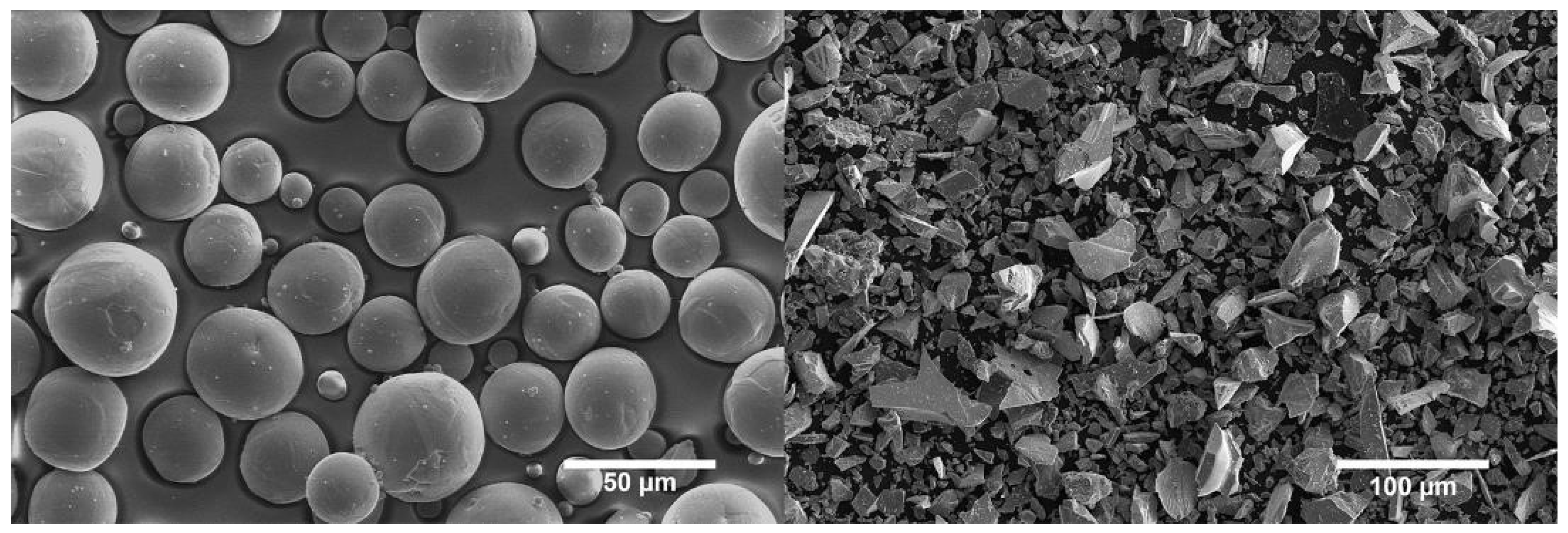

Powder Preparation

Laser Powder Bed Fusion Processing

Heat-Treatment

Microstructural and Mechanical Characterization

Results and Discussion

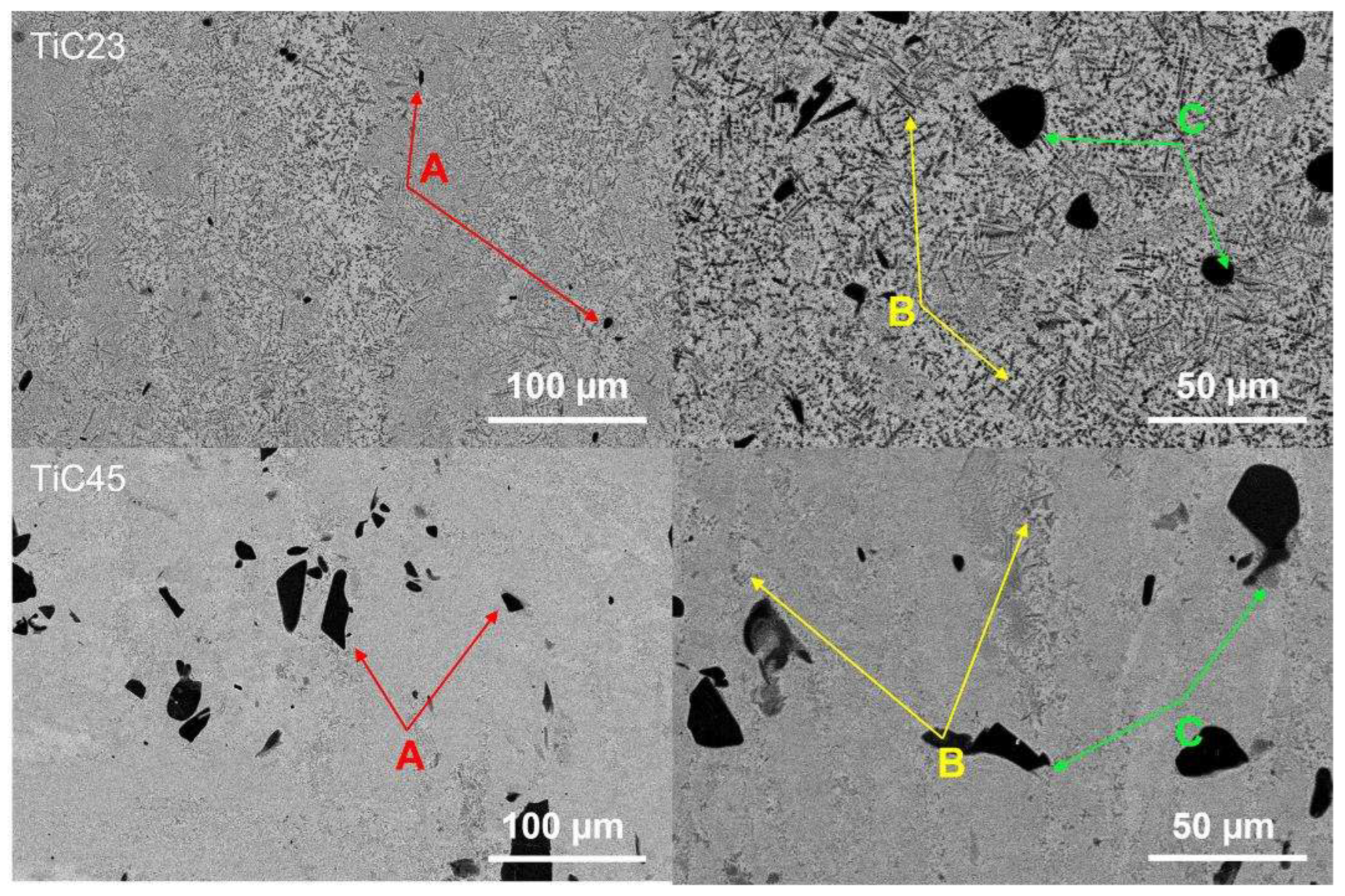

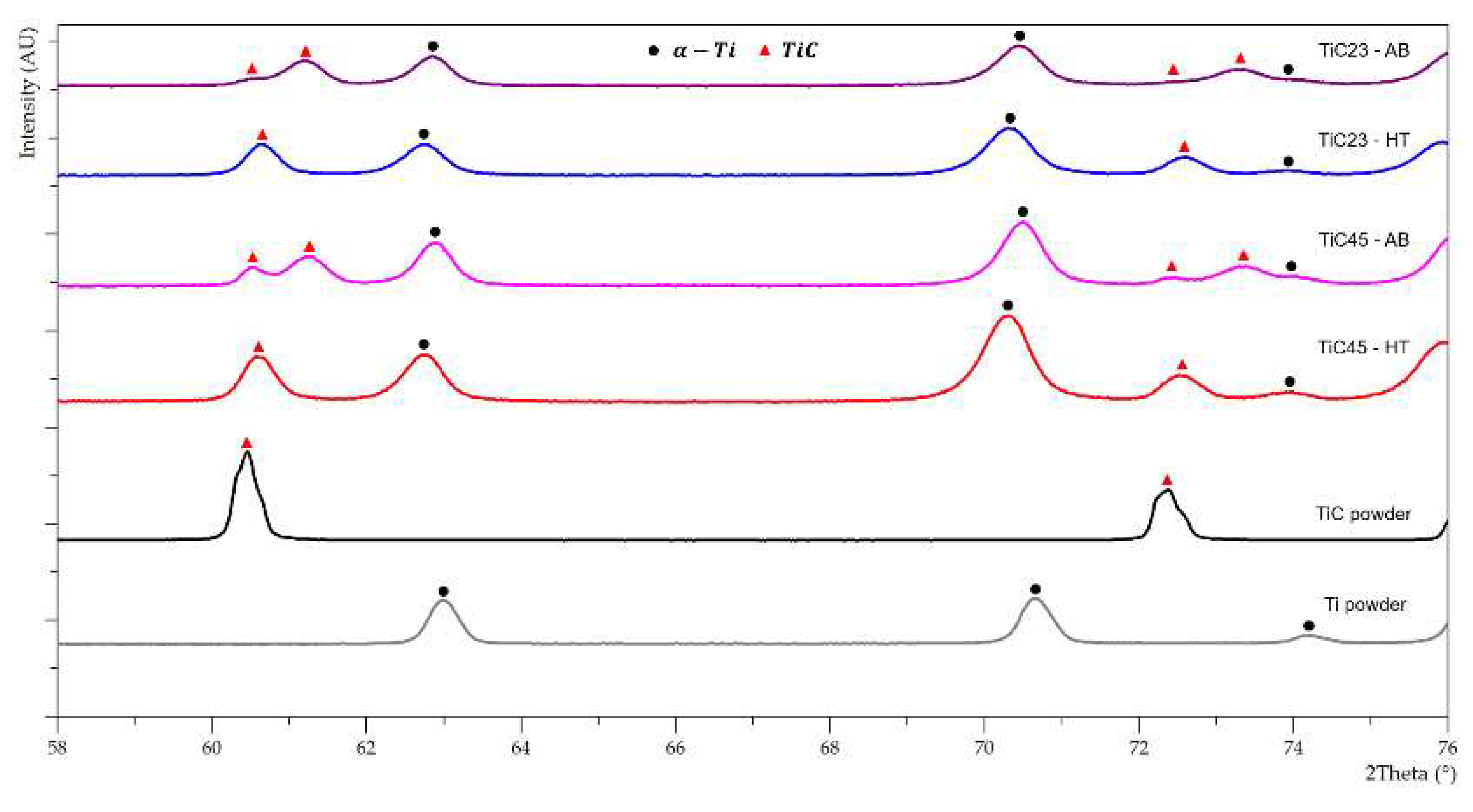

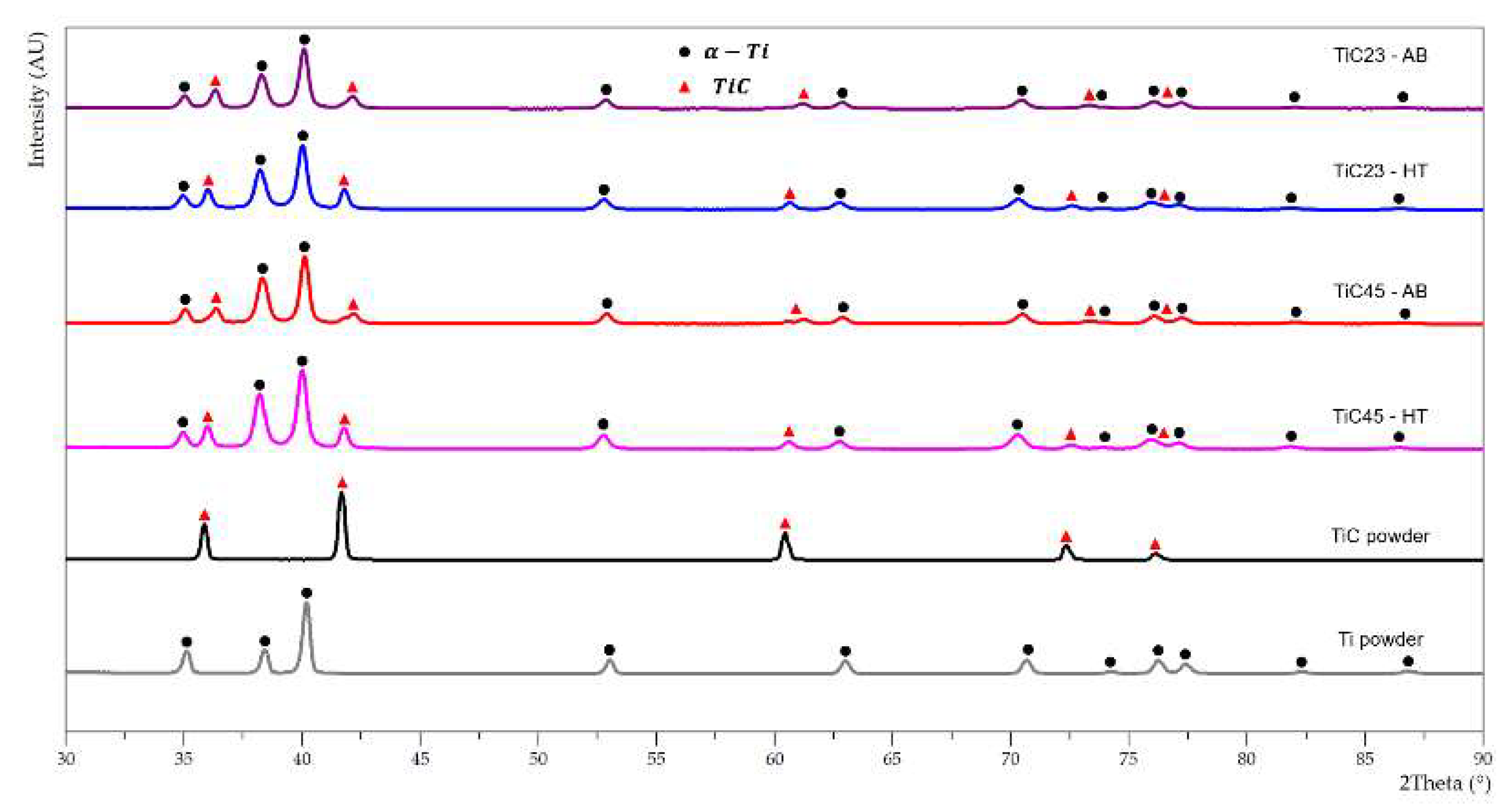

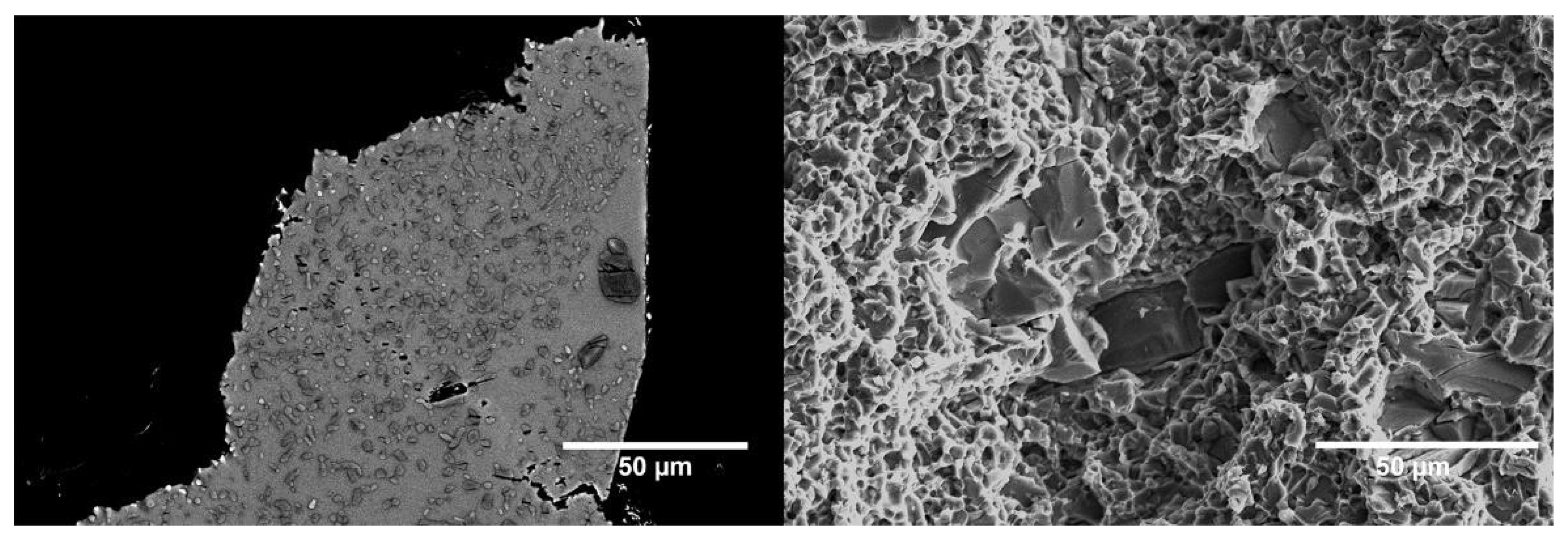

As-Built Microstructure

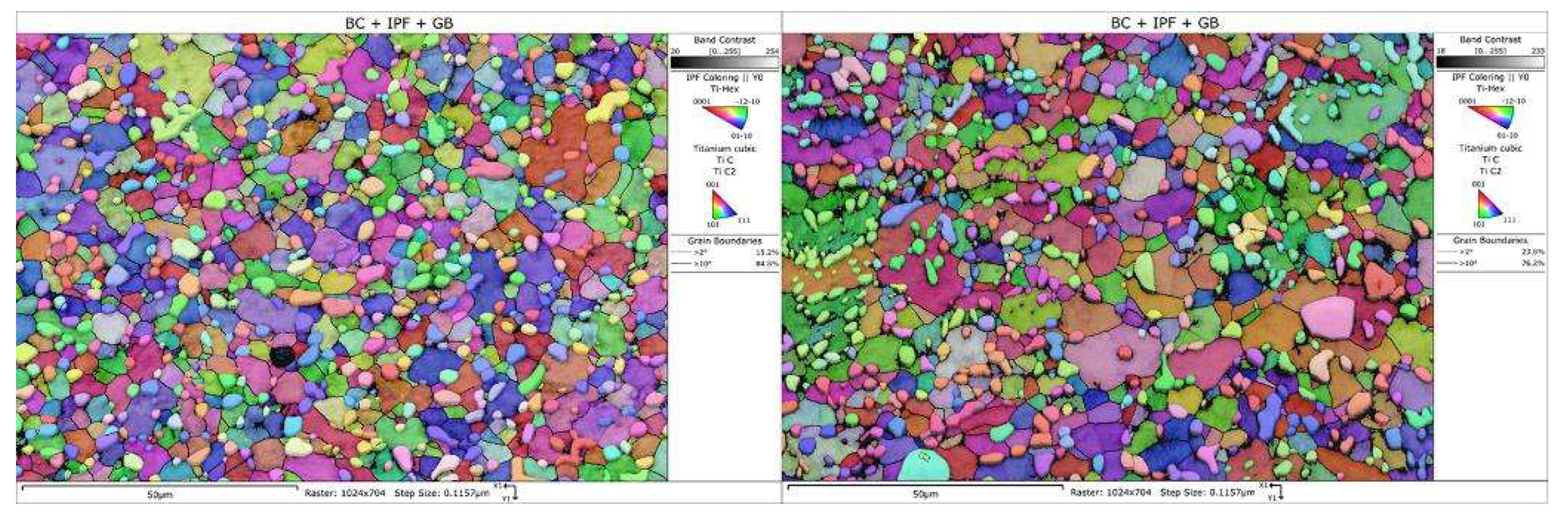

Heat-Treated Microstructure

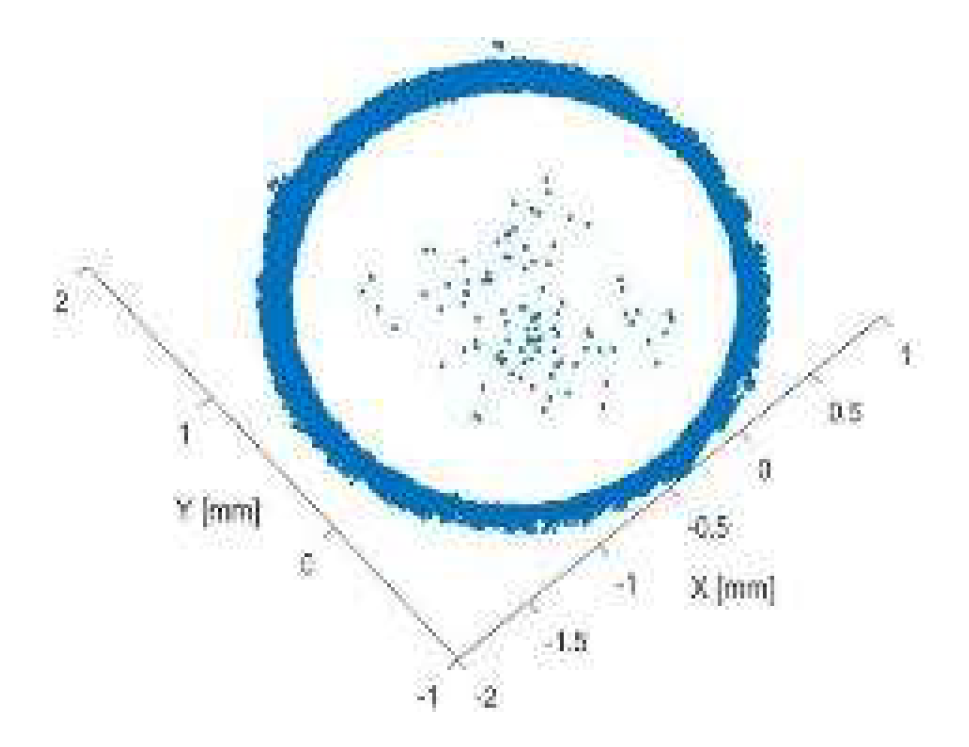

Density Characterization

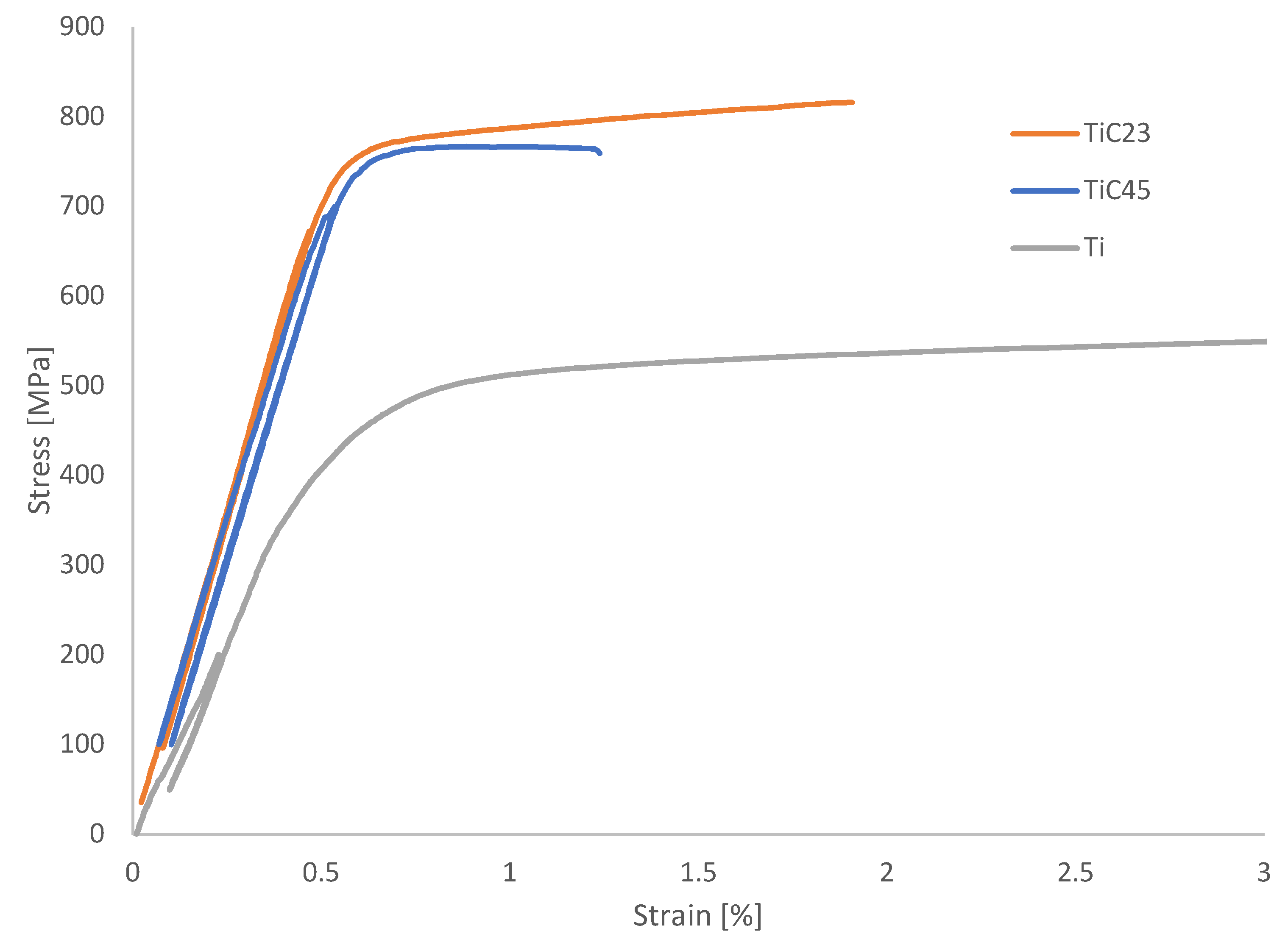

Mechanical Properties in Heat Treated Condition

Conclusions

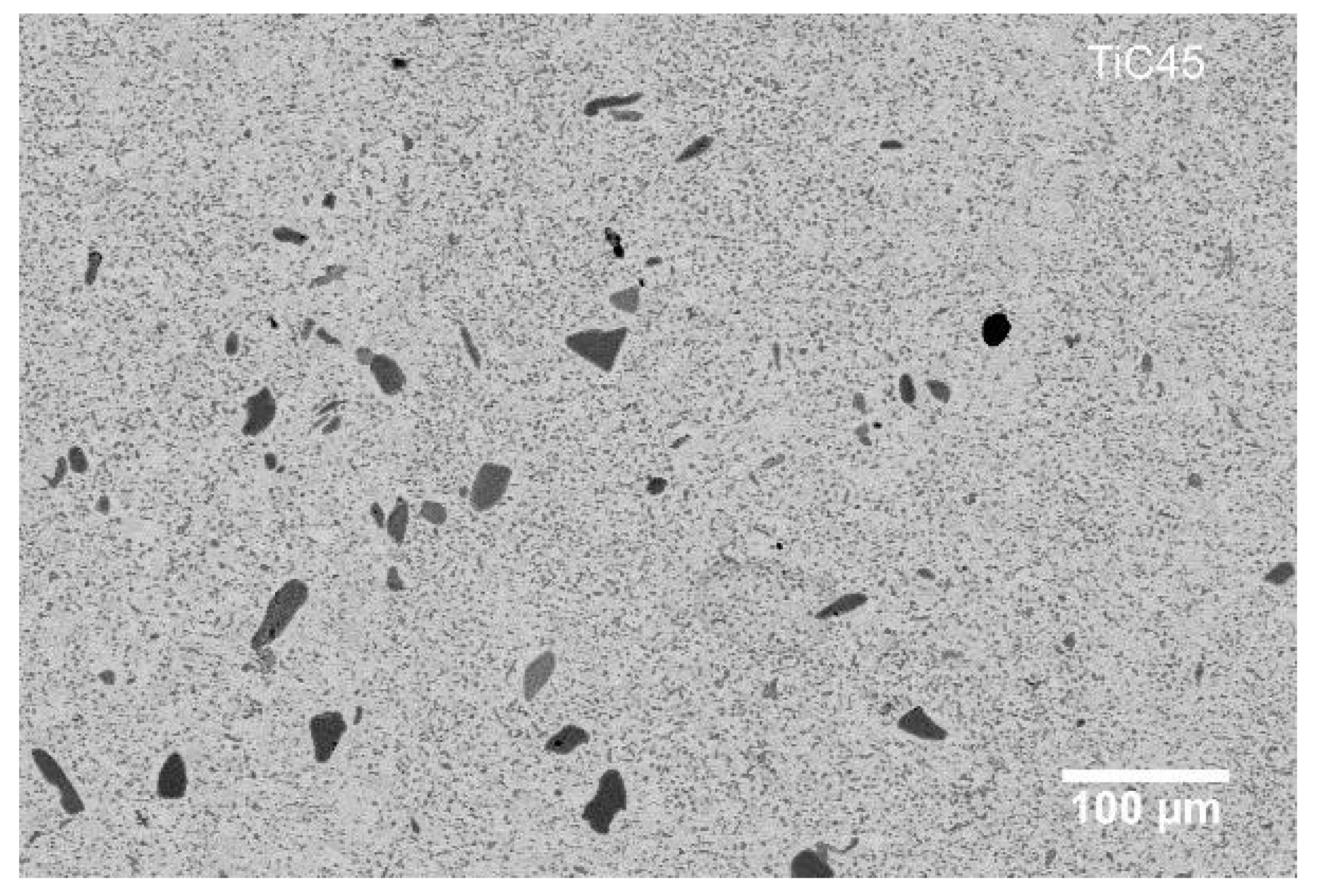

- Density >99% was achieved with the lowest reinforcement particle sizes, while a density >98% was achieved with the other one. The remaining porosities were located between the contour and hatching regions. Removal of those porosities could lead to >99.9% density with the lowest particle sizes.

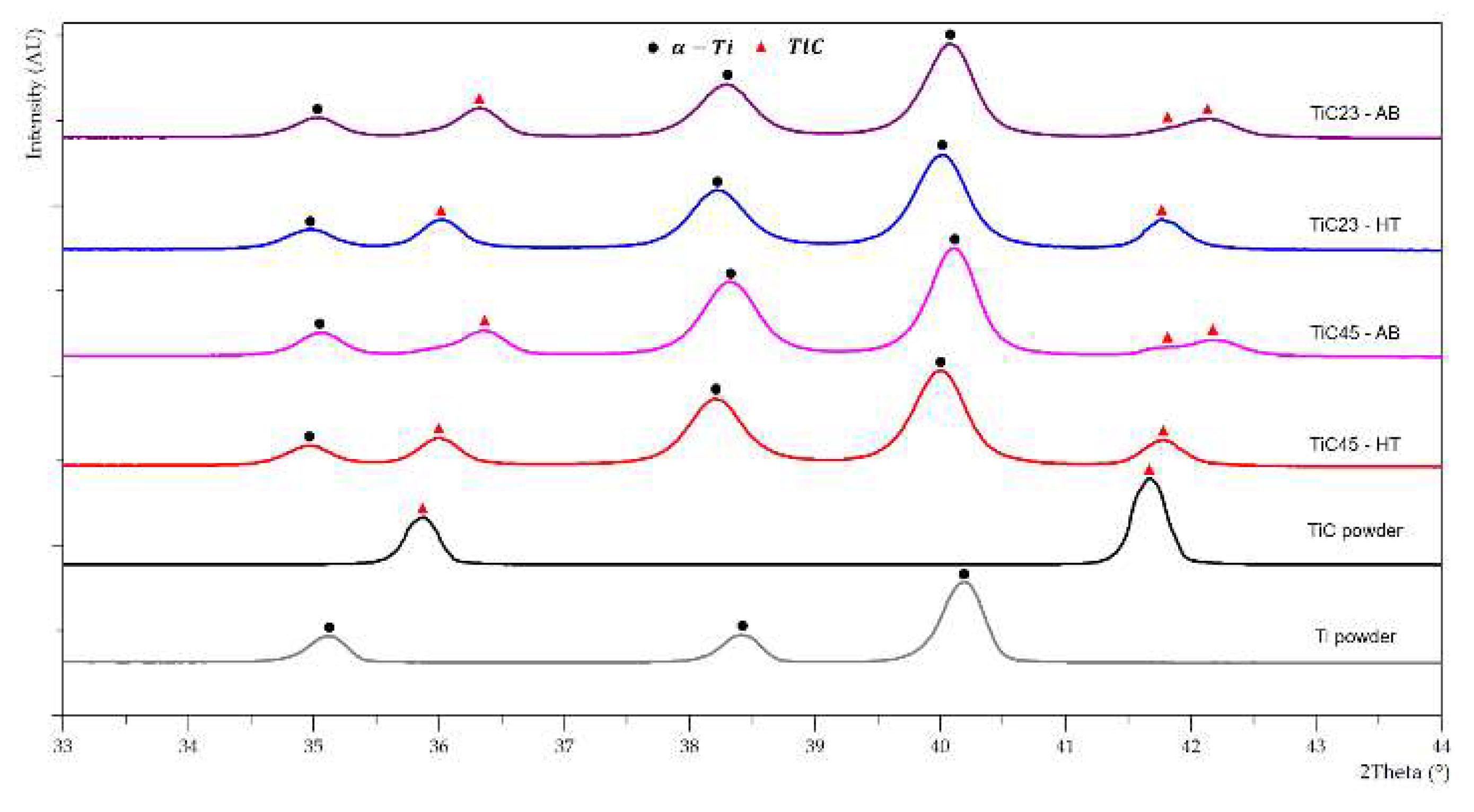

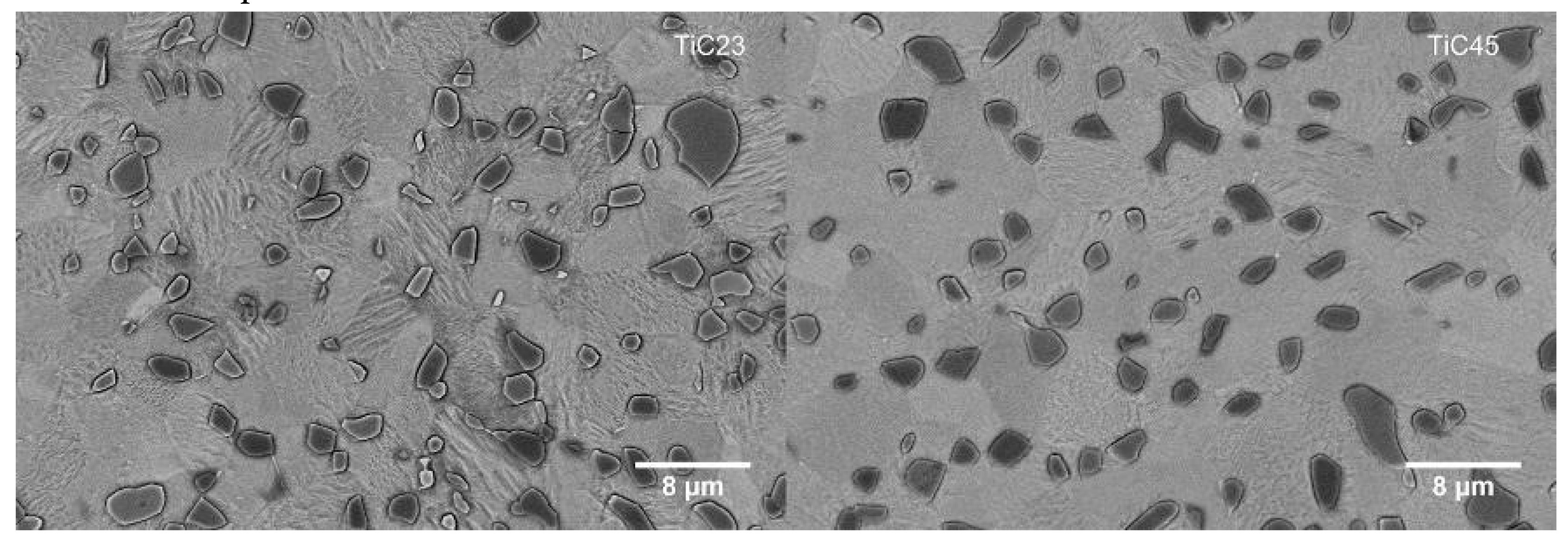

- Microstructural analysis showed a homogeneous distribution of TiC dendrites as well as un-melted TiC particles in the as-built condition, and a full conversion of dendritic into equiaxed grains after heat treatment. Grain size analysis showed a tight control of the Ti and TiC grain size after heat treatment, with an average Ti grain size <1.5 µm and an average TiC grain size ≤3 µm. The significant differences between the MMC produced with the two powder size distributions of reinforcement relate to the size of the un-melted particles, and the associated stochastic defects.

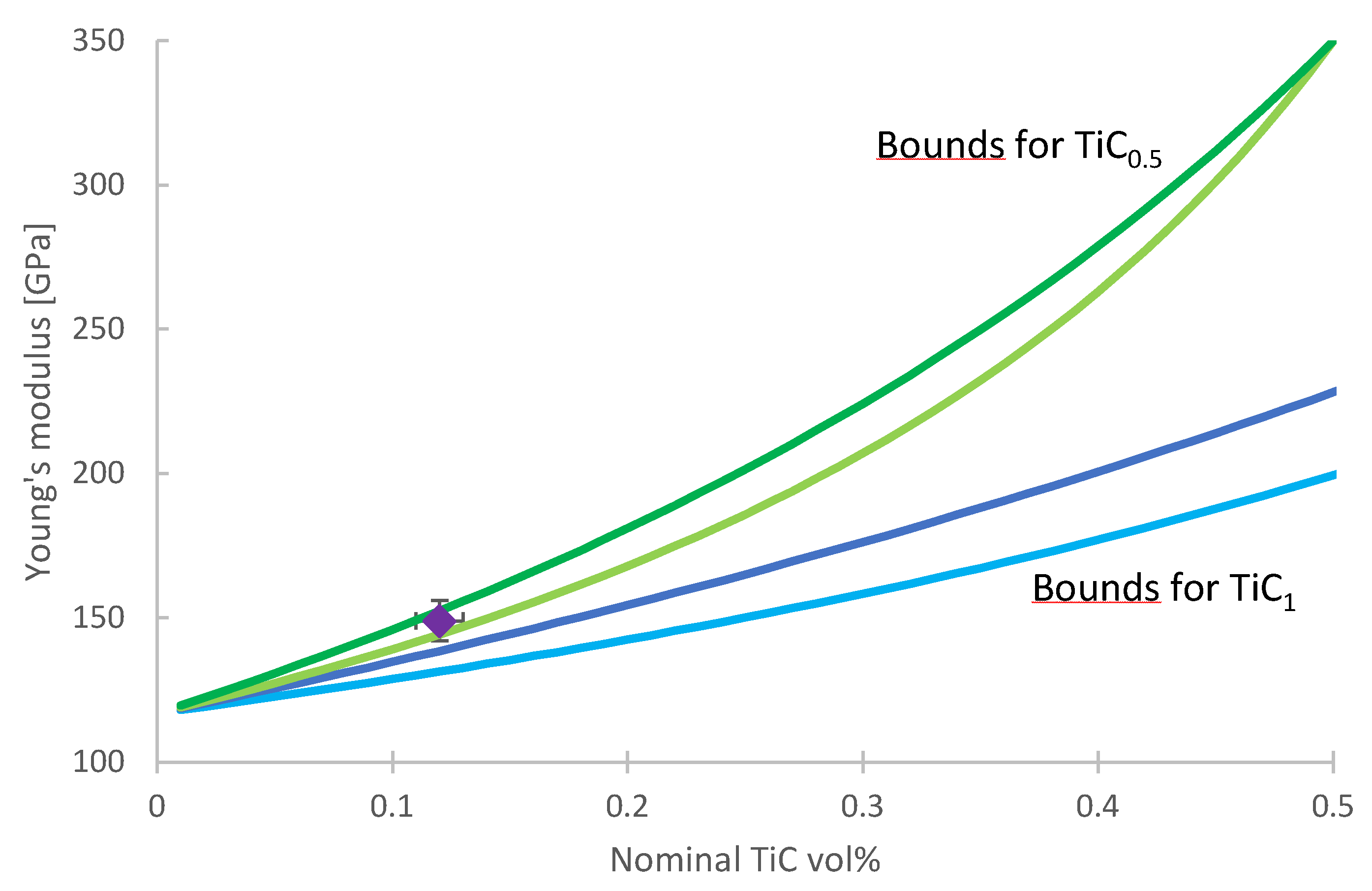

- Drastic evolution of the reinforcement content (12 vol% to 21 vol%) and C/Ti ratio (0.98 to 0.57) was observed following LPBF, introducing the important notion of effective reinforcement content in the MMC.

- Mechanical properties were remarkably enhanced for both reinforcement powder size distributions, and plastic ductile behaviour was shown for the first time in a highly reinforced Ti-TiC MMC produced by LPBF. Young’s modulus, yield strength, ultimate tensile strength, and fracture strain of 147 GPa, 806 MPa, 827 MPa and 1.7% were achieved for the lowest particle sizes, and 148 GPa, 700 MPa, 752 MPa and 1.3% were achieved for the other one.

- Lower particle sizes were shown to be beneficial for both density and mechanical properties. Further decrease of reinforcement size could lead to even higher performances.

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix

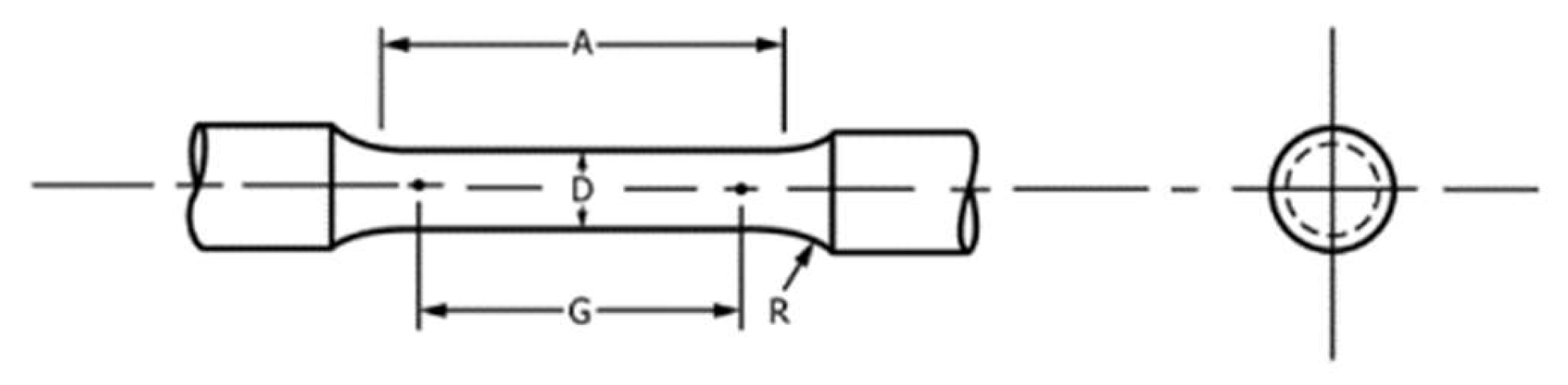

| ASTM E8 [mm] | Effective dimensions [mm] | |

| G- Gauge length | 10±0.1 | 10 |

| D- Diameter | 2.5±0.1 | 2.5 |

| R- Radius of filler, min | 2 | 2 |

| A- Length of reduced parallel section, min | 20 | 25 |

References

- Mohanraj, C.; Kumar, K.M.N.; PraveenKumar, K.; Mukesh, S. Development of AA6082 based metal matrix composite using Sic,Ti,Ni,Cr by conventional casting technique. Mater. Today Proc. May 2020, S2214785320333022. [Google Scholar] [CrossRef]

- Saito, T. A cost-effective P/M titanium matrix composite for automobile use. Adv Perform Mater 1995, 2, 121–144. [Google Scholar] [CrossRef]

- Soorya Prakash, K.; Gopal, P.M.; Anburose, D.; Kavimani, V. Mechanical, corrosion and wear characteristics of powder metallurgy processed Ti-6Al-4V/B4C metal matrix composites. Ain Shams Engineering Journal Dec. 2018, 9, 1489–1496. [Google Scholar] [CrossRef]

- Gofrey, T.M.T.; Goodwin, P.S.; Ward-Close, C.M. Titanium Particulate Metal Matrix Composites-Reinforcement, Production Methods, and Mechanical Properties. Adv. Eng. Mater Mar. 2000, 2, 85–91. [Google Scholar] [CrossRef]

- Cai, C.; He, S.; Li, L.; Teng, Q.; Song, B.; Yan, C.; Wei, Q.; Shi, Y. In-situ TiB/Ti-6Al-4V composites with a tailored architecture produced by hot isostatic pressing: Microstructure evolution, enhanced tensile properties and strengthening mechanisms. Composites Part B: Engineering May 2019, 164, 546–558. [Google Scholar] [CrossRef]

- Lagos, M.A.; Agote, I.; Atxaga, G.; Adarraga, O.; Pambaguian, L. Fabrication and characterisation of Titanium Matrix Composites obtained using a combination of Self propagating High temperature Synthesis and Spark Plasma Sintering. Materials Science and Engineering: A Feb. 2016, 655, 44–49. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Mertens, R.; Hao, L.; Van Humbeeck, J.; Kruth, J. Selective Laser Melting to Manufacture “In Situ” Metal Matrix Composites: A Review. Adv. Eng. Mater Mar. 2019, 21, 1801244. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Y. Development of metal matrix composites by laser-assisted additive manufacturing technologies: A review. J Mater Sci Aug. 2020, 55, 9883–9917. [Google Scholar] [CrossRef]

- Hu, Y.; Cong, W. A review on laser deposition-additive manufacturing of ceramics and ceramic reinforced metal matrix composites. Ceramics International Dec. 2018, 44, 20599–20612. [Google Scholar] [CrossRef]

- Yu, W.H.; Sing, S.L.; Chua, C.K.; Kuo, C.N.; Tian, X.L. Particle-reinforced metal matrix nanocomposites fabricated by selective laser melting: A state of the art review. Progress in Materials Science Jul. 2019, 104, 330–379. [Google Scholar] [CrossRef]

- Mahmood, M.A.; Popescu, A.C.; Mihailescu, I.N. Metal Matrix Composites Synthesized by Laser-Melting Deposition: A Review. Materials Jun. 2020, 13, 2593–10. [Google Scholar] [CrossRef] [PubMed]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Dargusch, M.S. Recent developments and opportunities in additive manufacturing of titanium-based matrix composites: A review. International Journal of Machine Tools and Manufacture Oct. 2018, 133, 85–102. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Lin, P.; Wang, J. Effect of TiC particle size on the microstructure and tensile properties of TiCp/Ti6Al4V composites fabricated by laser melting deposition. Optics & Laser Technology Sept. 2018, 105, 195–206. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. The influences of melting degree of TiC reinforcements on microstructure and mechanical properties of laser direct deposited Ti6Al4V-TiC composites. Materials & Design Dec. 2017, 136, 185–195. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.Q.; Li, A.; Wang, H.M. Microstructure and tensile properties of laser melting deposited TiC/TA15 titanium matrix composites. Journal of Alloys and Compounds Oct. 2009, 485, 156–162. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.Q.; Li, A.; Wang, H.M. High temperature mechanical properties of a laser melting deposited TiC/TA15 titanium matrix composite. Journal of Alloys and Compounds Apr. 2010, 496, 189–195. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Wissenbach, K.; Poprawe, R. Selective Laser Melting of in-situ TiC/Ti5Si3 composites with novel reinforcement architecture and elevated performance. Surface and Coatings Technology Feb. 2011, 205, 3285–3292. [Google Scholar] [CrossRef]

- Pan, Y.; Li, W.; Lu, X.; Hayat, M.D.; Yin, L.; Song, W.; Qu, X.; Cao, P. Microstructure and tribological properties of titanium matrix composites reinforced with in situ synthesized TiC particles. Materials Characterization Dec. 2020, 170, 110633. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Mertens, R.; Ji, G.; Vrancken, B.; Vanmeensel, K.; Fan, H.; Addad, A.; Kruth, J.-P. Heat treatment possibilities for an in situ βTi-TiC composite made by laser powder bed fusion. Additive Manufacturing Sept. 2020, 10, 101577. [Google Scholar] [CrossRef]

- Zhang, C.; Guo, Z.; Yang, F.; Wang, H.; Shao, Y.; Lu, B. In situ formation of low interstitials Ti-TiC composites by gas-solid reaction. Journal of Alloys and Compounds Nov. 2018, 769, 37–44. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi, A.; Elbestawi, M. Unique opportunities for microstructure engineering via trace B4C addition to Ti-6Al-4V through laser powder bed fusion process: As-built and heat-treated scenarios. Additive Manufacturing Feb. 2022, 50, 102557. [Google Scholar] [CrossRef]

- Han, C.; Babicheva, R.; Chua, J.D.Q.; Ramamurty, U.; Tor, U.; Sun, C.-N.; Zhou, K. Microstructure and mechanical properties of (TiB+TiC)/Ti composites fabricated in situ via selective laser melting of Ti and B4C powders. Additive Manufacturing Dec. 2020, 36, 101466. [Google Scholar] [CrossRef]

- Xi, L.; Ding, K.; Gu, D.; Guo, S.; Cao, M.; Zhuang, J.; Lin, K.; Okulov, I.; Sarac, B.; Eckert, J.; Prashanth, K.G. Interfacial structure and wear properties of selective laser melted Ti/(TiC+TiN) composites with high content of reinforcements. Journal of Alloys and Compounds Jul. 2021, 870, 159436. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Li, J.S. Super-high-strength graphene/titanium composites fabricated by selective laser melting. Carbon Apr. 2021, 174, 451–462. [Google Scholar] [CrossRef]

- Liu, S.; Shin, Y.C. Simulation and experimental studies on microstructure evolution of resolidified dendritic TiC in laser direct deposited Ti-TiC composite. Materials & Design Dec. 2018, 159, 212–223. [Google Scholar] [CrossRef]

- Gu, D.; Meng, G.; Li, C.; Meiners, W.; Poprawe, R. Selective laser melting of TiC/Ti bulk nanocomposites: Influence of nanoscale reinforcement. Scripta Materialia Jul. 2012, 67, 185–188. [Google Scholar] [CrossRef]

- Gu, D.; Hagedorn, Y.-C.; Meiners, W.; Wissenbach, K.; Poprawe, R. Nanocrystalline TiC reinforced Ti matrix bulk-form nanocomposites by Selective Laser Melting (SLM): Densification, growth mechanism and wear behavior. Composites Science and Technology Sept. 2011, 71, 1612–1620. [Google Scholar] [CrossRef]

- Andrieux, J.; Gardiola, B.; Dezellus, O. Synthesis of Ti matrix composites reinforced with TiC particles: In situ synchrotron X-ray diffraction and modeling. J Mater Sci Jul. 2018, 53, 9533–9544. [Google Scholar] [CrossRef]

- Roger, J.; Gardiola, B.; Andrieux, J.; Viala, J.-C.; Dezellus, O. Synthesis of Ti matrix composites reinforced with TiC particles: Thermodynamic equilibrium and change in microstructure. J. Mater. Sci. Dec. 2016, 13, 4129–4141. [Google Scholar] [CrossRef]

- Lin, Y.; Zee, R.H.; Chin, B.A. In situ formation of three-dimensional TiC reinforcements in Ti-TiC composites. MTA Apr. 1991, 22, 859–865. [Google Scholar] [CrossRef]

- Guemmaz, M.; Mosser, A.; Ahujab, R.; Johansson, B. Elastic properties of sub-stoichiometric titanium carbides Comparison of FP-LMTO calculations and experimental results. Solid State Communications Feb. 1999, 5, 299–303. [Google Scholar] [CrossRef]

- Miracle, D.B.; Lipsitt, H.A. Mechanical Properties of Fine-Grained Substoichiometric Titanium Carbide. Journal of the American Ceramic Society Aug. 1983, 66, 592–597. [Google Scholar] [CrossRef]

- E28 Committee. Test Methods for Tension Testing of Metallic Materials. ASTM International. [CrossRef]

- Attar, H.; Ehtemam-Haghighi, S.; Kent, D.; Wu, X.; Dargusch, M.S. Comparative study of commercially pure titanium produced by laser engineered net shaping, selective laser melting and casting processes. Materials Science and Engineering: A Sept. 2017, 705, 385–393. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Krawczyńska, A.; Rożniatowski, K.; Zdunek, J.; Kurzydłowski, K.J.; Święszkowski, W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). Journal of Materials Processing Technology Mar. 2017, 241, 13–23. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. Journal of the Mechanics and Physics of Solids Mar. 1963, 11, 127–140. [Google Scholar] [CrossRef]

| Hatching parameters | Contour parameters | General parameters | |||||

| Power [W] | Speed [mm/s] | Power [W] | Speed [mm/s] | Hatching [µm] |

Layer thickness [µm] |

Contour distance [µm] |

Contour number [-] |

| 80 | 400 | 50 | 800 | 40 | 30 | 30 | 1 |

| Sample | Sample density [%] | Hatching density [%] |

|---|---|---|

| TiC23 | 99.5 | 99.9 |

| TiC45 | 98.8 | 99.1 |

| TiC45 | TiC23 | Ti | |

|---|---|---|---|

| E300 [GPa] | 148±7 | 147±4 | 117±7 |

| E700 [GPa] | 149±9 | 149±3 | - |

| YS [MPa] | 700±74 | 806±20 | 512±6 |

| UTS [MPa] | 752±11 | 827±9 | 576±4 |

| e [%] | 1.3±0.1 | 1.7±0.2 | 29.3±3.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).