Submitted:

09 August 2024

Posted:

12 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

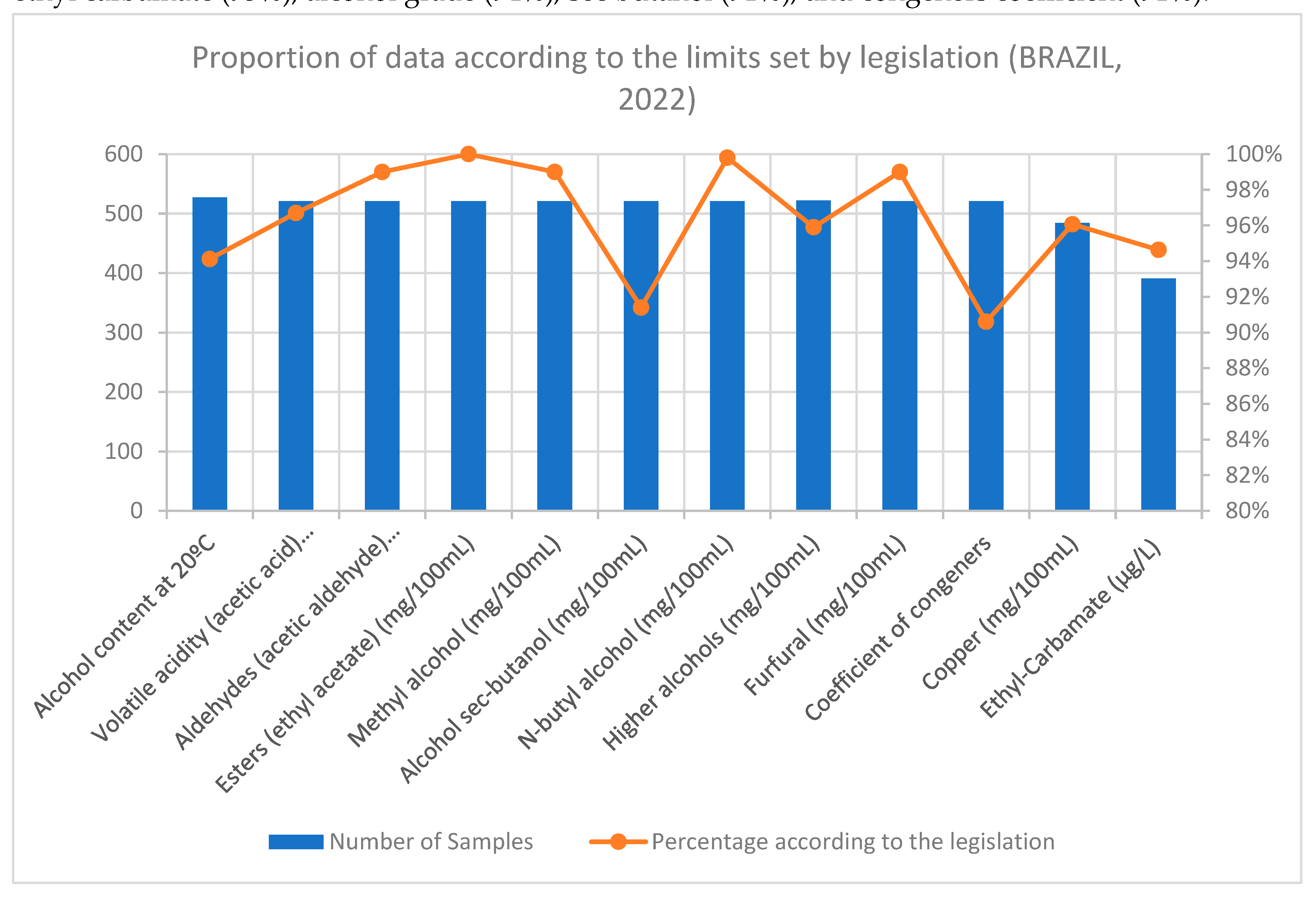

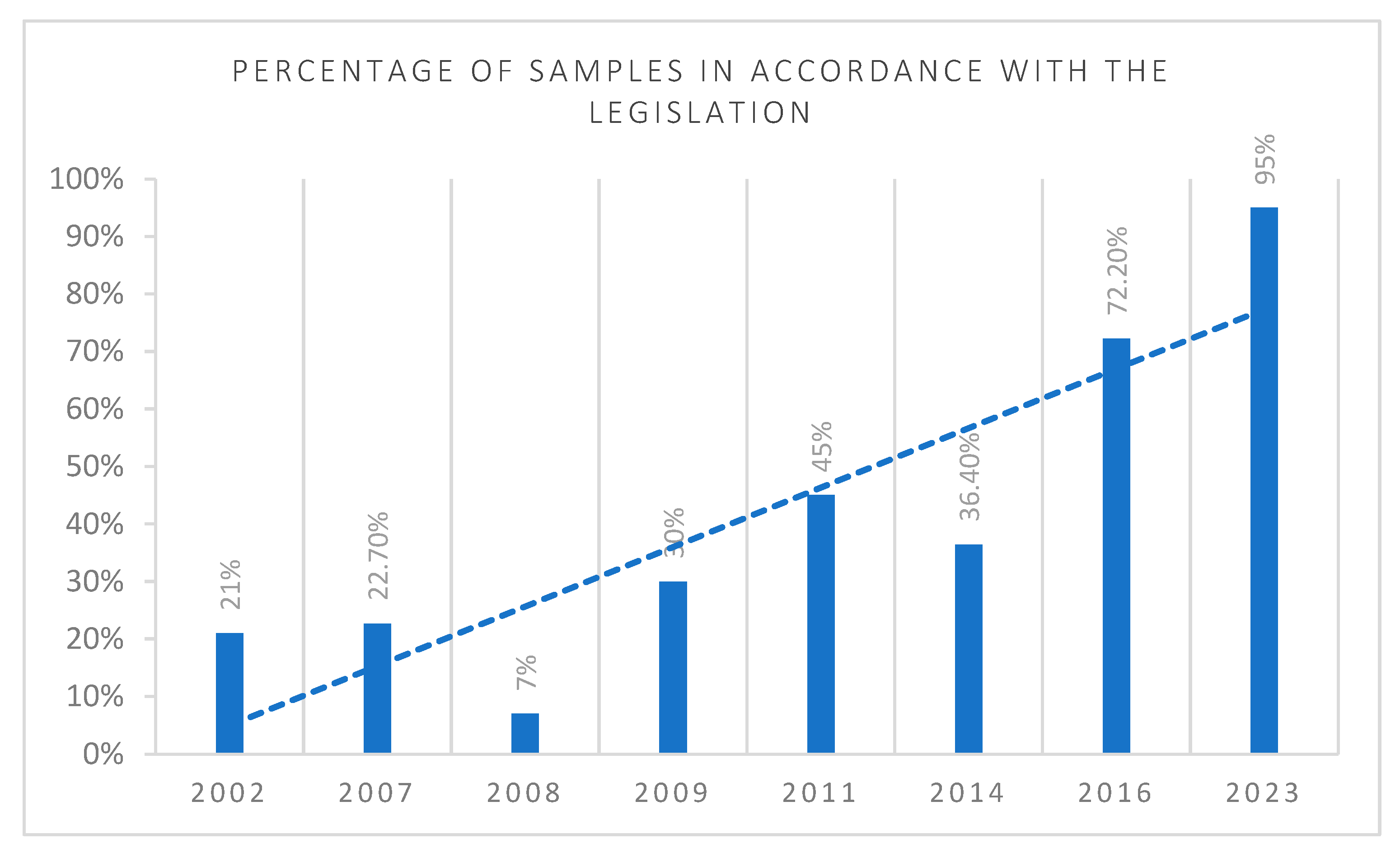

- 90% of the cachaças analyzed in the period are in accordance with Brazilian identity and quality standards;

- These results suggest that Brazilian producers have faced fewer difficulties related to the use of Good Manufacturing Practices;

- The improvement of the quality of cachaça may be one of the factors that increase the export of the distillate.

2. Materials and Methods

2.1. Sample Collection

2.2. Analytical Methods

2.2.1. Gas Chromatography with Flame Ionization Detection (FID)

2.2.2. Gas Chromatography with Mass Spectrophotometer (GC-MS)

2.2.3. Copper

2.2.4. Alcohol Content

3. Results and Discussion

4. Conclusion

Author Contributions

Acknowledgments

References

- BRASIL. Ministério da Agricultura, P. e A. do M. Portaria no 539. https://www.in.gov.br/en/web/dou/-/portaria-mapa-n-539-de-26-de-dezembro-de-2022-453828778 (accessed 2023-04-06).

- Lima, C. M. G.; Benoso, P.; Pierezan, M. D.; Santana, R. F.; Hassemer, G. de S.; da Rocha, R. A.; Dalla Nora, F. M.; Verruck, S.; Caetano, D.; Simal-Gandara, J. A State-of-the-Art Review of the Chemical Composition of Sugarcane Spirits and Current Advances in Quality Control. J. Food Compos. Anal. 2022, 106, 104338. [Google Scholar] [CrossRef]

- Diário Oficial da União - Seção 1 - 4/1/2002, P. 1. DECRETO No 4.072, DE 3 DE JANEIRO DE 2002. 2002. https://www2.camara.leg.br/legin/fed/decret/2002/decreto-4072-3-janeiro-2002-430418-norma-pe.html#:~:text=DECRETO No 4.072%2C DE 3 DE JANEIRO DE,inspeção%2C a produção e a fiscalização de bebidas.

- Ministry of Agriculture, L. and S. B. Approves the Technical Regulation for Establishing Identity and Quality Standards for Sugarcane Spirit and Cachaça. Official Gazette of the Union: Section 1, Edition: 124:3-4.

- Medeiros, A. B. P.; de Matos, M. E.; de Pinho Monteiro, A.; de Carvalho, J. C.; Soccol, C. R. Cachaça and Rum. In Current Developments in Biotechnology and Bioengineering; Elsevier, 2017; pp 451–468. [CrossRef]

- Da Silva, V. P.; De Souza, J. B.; De Queiroz, A. L. M.; Ribeiro-Filho, N.; Bezerra, T. K. A. Cachaça Production: From Sugar Cane to Spirit. J. Inst. Brew. 2023, 129. [Google Scholar] [CrossRef]

- Bortoletto, A. M.; Silvello, G. C.; Alcarde, A. R. Good Manufacturing Practices, Hazard Analysis and Critical Control Point Plan Proposal for Distilleries of Cachaça. Sci. Agric. 2018. [Google Scholar] [CrossRef]

- Bortoletto, A. M.; Silvello, G. C.; Alcarde, A. R. Chemical and Microbiological Quality of Sugar Cane Juice Influences the Concentration of Ethyl Carbamate and Volatile Congeners in Cachaça. J. Inst. Brew. 2015, 121, 251–256. [Google Scholar] [CrossRef]

- Duarte, F.; Cardoso, M.; Santiago, W.; Machado, A. M.; Nelson, D. Brazilian Organic Sugarcane Spirits: Physicochemical and Chromatographic Profile. Rev. Ciência Agronômica 2017, 48. [Google Scholar] [CrossRef]

- Cardoso, M. das G. Produção de Aguardente de Cana, 3rd ed.; UFLA, 2013.

- Bortoletto, A. M.; Alcarde, A. R. Congeners in Sugar Cane Spirits Aged in Casks of Different Woods. Food Chem. 2013, 139, 695–701. [Google Scholar] [CrossRef] [PubMed]

- Alcarde, A. R.; Souza, L. M.; Bortoletto, A. M. Ethyl Carbamate Kinetics in Double Distillation of Sugar Cane Spirit. Part 2: Influence of Type of Pot Still. J. Inst. Brew. 2012, 118, 352–355. [Google Scholar] [CrossRef]

- lloyd Currie. International Recommendations Offered on Analytical Detection and Quantification Concepts and Nomenclature: Preamble, in Validation of Analytical Methods. Anal. Chim. Acta 1999, 391. [Google Scholar]

- Bortoletto, A. M.; Alcarde, A. R. Assessment of Chemical Quality of Brazilian Sugar Cane Spirits and Cachaças. Food Control 2015, 54, 1–6. [Google Scholar] [CrossRef]

- Borges, G. B. V.; de Cássia Oliveira Gomes, F.; Badotti, F.; Silva, A. L. D.; de Resende Machado, A. M. Selected Saccharomyces Cerevisiae Yeast Strains and Accurate Separation of Distillate Fractions Reduce the Ethyl Carbamate Levels in Alembic Cachaças. Food Control 2014, 37, 380–384. [Google Scholar] [CrossRef]

- Peixoto, C.; Rosa, G.; Silva, C.; Santos, B.; Engelmann, T. Mini-Project on Fermentation of Sugarcane Juice for Practical General Chemistry Courses. Quim. Nova 2011, 35, 1686–1691. [Google Scholar] [CrossRef]

- Martini, C.; Margarido, L. A. C.; Ceccato-Antonini, S. R. Microbiological and Physicochemical Evaluations of Juice Extracted from Different Parts of Sugar Cane Stalks from Three Varieties Cultivated under Organic Management. Ciência e Tecnol. Aliment. 2010, 30, 808–813. [Google Scholar] [CrossRef]

- Briggs DE, Boulton CA, Brookes PA, S. R. Brewing: Science and Practice.; Woodhead Publishing: Cambridge, UK, 2004. [Google Scholar]

- Alcarde, A. R. Cachaça: CIência, Tecnologia e Arte.; Edgar Blucher: São Paulo, 2017. [Google Scholar]

- Rosa CA, Soares AM, F. J. Chapter 34: Cachaça Production. In The Alcohol Textbook.; Nottingham University press., Ed.; 2009; pp 481-490.

- Paredes, R. de S.; Vieira, I. P. V.; Mello, V. M. de; Vilela, L. de F.; Schwan, R. F.; Eleutherio, E. C. A. Identification of Three Robust and Efficient Saccharomyces Cerevisiae Strains Isolated from Brazilian’s Cachaça Distilleries. Biotechnol. Res. Innov. 2018, 2, 22–29. [Google Scholar] [CrossRef]

- de Araújo Vicente, M.; Fietto, L. G.; de Miranda Castro, I.; Gonçalves dos Santos, A. N.; Coutrim, M. X.; Brandão, R. L. Isolation of Saccharomyces Cerevisiae Strains Producing Higher Levels of Flavoring Compounds for Production of “Cachaça” the Brazilian Sugarcane Spirit. Int. J. Food Microbiol. 2006, 108, 51–59. [Google Scholar] [CrossRef] [PubMed]

- Nova, M. X. V.; Schuler, A. R. P.; Brasileiro, B. T. R. V.; Morais, M. A. Yeast Species Involved in Artisanal Cachaça Fermentation in Three Stills with Different Technological Levels in Pernambuco, Brazil. Food Microbiol. 2009, 26, 460–466. [Google Scholar] [CrossRef] [PubMed]

- Duarte, W. F.; Amorim, J. C.; Schwan, R. F. The Effects of Co-Culturing Non-Saccharomyces Yeasts with S. Cerevisiae on the Sugar Cane Spirit (Cachaça) Fermentation Process. Antonie Van Leeuwenhoek 2013, 103, 175–194. [Google Scholar] [CrossRef] [PubMed]

- Amorim, J. C.; Schwan, R. F.; Duarte, W. F. Sugar Cane Spirit (Cachaça): Effects of Mixed Inoculum of Yeasts on the Sensory and Chemical Characteristics. Food Res. Int. 2016, 85, 76–83. [Google Scholar] [CrossRef] [PubMed]

- Melo, T. dos S.; Magalhães, A. E. de M.; Da Silva, A. P. G.; Da Silva, E. L.; Lins, H. T. S.; Ferreira, M. C.; Melo, T. dos S.; De Oliveira, M. M. B. Processo de Produção Da Aguardente e Cachaça: Uma Revisão / Process of Production of the Brandy and Cachaça: A Review. Brazilian J. Dev. 2021, 7, 95981–96001. [Google Scholar] [CrossRef]

- Granato, D.; de Oliveira, C. C.; Caruso, M. S. F.; Nagato, L. A. F.; Alaburda, J. Feasibility of Different Chemometric Techniques to Differentiate Commercial Brazilian Sugarcane Spirits Based on Chemical Markers. Food Res. Int. 2014, 60, 212–217. [Google Scholar] [CrossRef]

- Silva, J.; Regina Verruma-Bernardi, M.; Oliveira, A. Cachaça Production in Brazil and Its Main Contaminant (Ethyl Carbamate). Sci. Agric. 2020, 77. [Google Scholar] [CrossRef]

- Rodrigues, L. M. A. Uma Dose de História: A Cachaça de Alambique e Aguardente de Coluna. Perspect. e Diálogos Rev. História Soc. e Práticas Ensino 2019, 2. [Google Scholar]

- Reche, R. V.; Franco, D. W. Distinção Entre Cachaças Destiladas Em Alambiques e Em Colunas Usando Quimiometria. Quim. Nova 2009, 32, 332–336. [Google Scholar] [CrossRef]

- Bruno, S.; Vaitsman, D.; Kunigami, C.; Brasil, M. Influence of the Distillation Processes from Rio de Janeiro in the Ethyl Carbamate Formation in Brazilian Sugar Cane Spirits. Food Chem. 2007, pp 1345–1352. [CrossRef]

- Moreira, R.; Netto, C.; Maria, C. A. B. The Volatile Fraction of Sugar Cane Spirits Produced in Brazil. Quim. Nova 2012, 35, 1819–1826. [Google Scholar] [CrossRef]

- Böck, F. C.; Helfer, G. A.; da Costa, A. B.; Dessuy, M. B.; Ferrão, M. F. Low Cost Method for Copper Determination in Sugarcane Spirits Using Photometrix UVC® Embedded in Smartphone. Food Chem. 2022, 367, 130669. [Google Scholar] [CrossRef] [PubMed]

- De Freitas, J.; Wintz, H.; Hyoun Kim, J.; Poynton, H.; Fox, T.; Vulpe, C. Yeast, a Model Organism for Iron and Copper Metabolism Studies. Biometals 2003, 16, 185–197. [Google Scholar] [CrossRef] [PubMed]

- Bortoletto, A. M.; Silvello, G. C.; Alcarde, A. R. Aromatic Profiling of Flavor Active Compounds in Sugarcane Spirits Aged in Tropical Wooden Barrels. Brazilian J. Food Technol. 2021, 24. [Google Scholar] [CrossRef]

- Labanca, R.; Gloria, M. B. A.; Pinto, G.; Afonso, R. Determinação Dos Teores de Cobre e Grau Alcoólico Em Aguardentes de Cana Produzidas No Estado de Minas Gerais. Quim. Nova 2006, 29. [Google Scholar] [CrossRef]

- Ohe, T.; Da Silva, A.; Rocha, T.; Godoy, F.; Franco, D. A Fluorescence-Based Method for Cyanate Analysis in Ethanol/Water Media: Correlation between Cyanate Presence and Ethyl Carbamate Formation in Sugar Cane Spirit. J. Food Sci. 2014, 79. [Google Scholar] [CrossRef] [PubMed]

- Resende Machado, A. M.; Cardoso, M. das G.; Saczk, A. A.; dos Anjos, J. P.; Zacaroni, L. M.; Dórea, H. S.; Nelson, D. L. Determination of Ethyl Carbamate in Cachaça Produced from Copper Stills by HPLC. Food Chem. 2013, 138, (2–3). [Google Scholar] [CrossRef]

- Mendonça, J. G. P.; Cardoso, M. D. G.; Santiago, W. D.; Rodrigues, L. M. A.; Nelson, D. L.; Brandão, R. M.; da Silva, B. L. Determination of Ethyl Carbamate in Cachaças Produced by Selected Yeast and Spontaneous Fermentation. J. Inst. Brew. 2016, 122, 63–68. [Google Scholar] [CrossRef]

- Santiago, W. D.; Cardoso, M. das G.; Nelson, D. L. Cachaça Stored in Casks Newly Constructed of Oak (Quercus Sp.), Amburana (Amburana Cearensis), Jatoba (Hymenaeae Carbouril), Balsam (Myroxylon Peruiferum) and Peroba (Paratecoma Peroba): Alcohol Content, Phenol Composition, Colour Intensity and Dry Extrac. J. Inst. Brew. 2017, 123, 232–241. [Google Scholar] [CrossRef]

- Ljungdahl, P. O.; Daignan-Fornier, B. Regulation of Amino Acid, Nucleotide, and Phosphate Metabolism in Saccharomyces Cerevisiae. Genetics 2012, 190, 885–929. [Google Scholar] [CrossRef] [PubMed]

- Lachenmeier, D. W.; Lima, M. C.; Nóbrega, I. C.; Pereira, J. A.; Kerr-Corrêa, F.; Kanteres, F.; Rehm, J. Cancer Risk Assessment of Ethyl Carbamate in Alcoholic Beverages from Brazil with Special Consideration to the Spirits Cachaça and Tiquira. BMC Cancer 2010, 10, 266. [Google Scholar] [CrossRef] [PubMed]

- Santiago, W. D.; Das Graças Cardoso, M.; Duarte, F. C.; Saczk, A. A.; Nelson, D. L. Ethyl Carbamate in the Production and Aging of Cachaça in Oak ( Quercus Sp.) and Amburana (Amburana Cearensis) Barrels. J. Inst. Brew.2014, n/a-n/a. [CrossRef]

- Ryu, D.; Choi, B.; Kim, E.; Park, S.; Paeng, H.; Kim, C.; Lee, J.-Y.; Yoon, H.; Koh, E. Determination of Ethyl Carbamate in Alcoholic Beverages and Fermented Foods Sold in Korea. Toxicol. Res. 2015, 31, 289–297. [Google Scholar] [CrossRef] [PubMed]

- (EFSA), E. F. S. A. Ethyl Carbamate and Hydrocyanic Acid in Food and Beverages - Scientific Opinion of the Panel on Contaminants. EFSA J. 2007, 5, 551. [Google Scholar] [CrossRef]

- Commission Recommendation of 2 March 2010 on the prevention and reduction of ethyl carbamate contamination in stone fruit spirits and stone fruit marc spirits and on the monitoring of ethyl carbamate levels in these beverages (Text with EEA relevance). http://data.europa.eu/eli/reco/2010/133/oj.

- Andrade Sobrinho, L.; Boscolo, M.; Lima-Neto, B.; Franco, D. Ethyl Carbamate in Alcoholic Beverages (Cachaça, Tiquira, Whisky and Grape). Quim. Nova 2002, 25, 1074–1077. [Google Scholar] [CrossRef]

- Baffa Júnior, J.; SOARES, N.; PEREIRA, J.; Melo, N. Ocorrência de Carbamato de Etila Em Cachaças Comerciais Da Região Da Zona Da Mata Mineira – MG. Aliment. e Nutr. 2008, 18. [Google Scholar]

- Labanca, R.; Gloria, M. B. A.; Afonso, R. Determinação de Carbamato de Etila Em Aguardentes de Cana Por CG-EM. Quim. Nov. - QUIM Nov. 2008, 31. [Google Scholar] [CrossRef]

- Nóbrega, I. C. C.; Pereira, J. A. P.; Paiva, J. E.; Lachenmeier, D. W. Ethyl Carbamate in Pot Still Cachaças (Brazilian Sugar Cane Spirits): Influence of Distillation and Storage Conditions. Food Chem. 2009, 117, 693–697. [Google Scholar] [CrossRef]

- Nóbrega, I. C. C.; Pereira, J. A. P.; Paiva, J. E.; Lachenmeier, D. W. Ethyl Carbamate in Cachaça (Brazilian Sugarcane Spirit): Extended Survey Confirms Simple Mitigation Approaches in Pot Still Distillation. Food Chem. 2011, 127, 1243–1247. [Google Scholar] [CrossRef]

- Masson, J.; Cardoso, M.; Zacaroni, L.; Anjos, J.; Santiago, W.; Machado, A. M.; Saczk, A.; Nelson, D. GC-MS Analysis of Ethyl Carbamate in Distilled Sugar Cane Spirits from the Northern and Southern Regions of Minas Gerais. J. Inst. Brew. 2014, 120. [Google Scholar] [CrossRef]

- Bortoletto, A.; Alcarde, A. Assessment of Ethyl Carbamate Contamination in Cachaça (Brazilian Sugar Cane Spirit). Beverages 2016, 2, 28. [Google Scholar] [CrossRef]

- Baffa Júnior, J. C.; Mendonça, R. C. S.; de Assis Teixeira Kluge Pereira, J. M.; Marques Pereira, J. A.; de Fátima Ferreira Soares, N. Ethyl-Carbamate Determination by Gas Chromatography–Mass Spectrometry at Different Stages of Production of a Traditional Brazilian Spirit. Food Chem. 2011, 129, 1383–1387. [Google Scholar] [CrossRef]

| Temperature | Length of stay or gradual increase |

|---|---|

| 90 ºC | Permanence time for the first 2 minutes |

| 150 ºC | Increase at a rate of 10ºC/min until it reaches 150ºC |

| 220 ºC | Increase at a rate of 40ºC/min until it reaches 220ºC |

| 220 ºC | Permanence time during 2 minutes |

| Compound | RI (min) | LD* | QL* | Concentration range* | a | b | r2; |

|---|---|---|---|---|---|---|---|

|

Volatile Congeners |

|||||||

| Acetic aldehyde | 0.29 | 0.070 | 0.220 | 7.5 – 37.5 | 5.5900 | -1.0200 | 0.9957 |

| Ethyl acetate | 1.41 | 0.057 | 0.171 | 12.5 – 62.5 | 2.8792 | 0.9075 | 0.9996 |

| n-Propanol | 4.43 | 0.038 | 0.114 | 37.5 – 187.5 | 2.0471 | -0.2444 | 0.9999 |

| Isobutanol | 5.22 | 0.014 | 0.042 | 12.5 – 62.5 | 1.7260 | -0.1724 | 0.9998 |

| Isoamyl alcohol | 6.72 | 0.016 | 0.048 | 50 – 250 | 1.6748 | 9.1053 | 0.9999 |

| Acetic acid | 19.15 | 0.530 | 1.590 | 37.5 – 187.5 | 5.4259 | 4.1160 | 0.9997 |

| Contaminant congeners | |||||||

| Metanol | 1.62 | 0.092 | 0.276 | 5 – 25 | 4.1394 | -0.1620 | 0.9997 |

| sec-Butanol | 4.02 | 0.049 | 0.180 | 2.5 – 12.5 | 1.9168 | -5.1082 | 0.9998 |

| n-Butanol | 5.99 | 0.072 | 0.216 | 0.75 – 3.75 | 1.1168 | -1.8596 | 0.9997 |

| Ethyl carbamate | 10.15 | 0.180 | 0.550 | 50 – 500 | 64.714 | 1241.67 | 0.9984 |

|

Compounds |

Non-conforming samples Present Study |

Non-conforming samples |

Non-conforming samples |

Non-conforming simples |

|---|---|---|---|---|

| Esters | 0% | 1,5% | 6,4% | - |

| N-Butil Alcohol | 0,2% | 7,7% | - | - |

| Furfural | 1% | 2,1% | - | - |

| Aldehydes | 1% | 6,3% | 17% | - |

| Volatile acidity | 3,3% | 16,4% | 8,5% | - |

| Higher Alcohols | 4,1% | 25,7% | 4,3% | - |

| Copper | 3,9% | 26,2% | 14,9% | 7% |

| Ethyl carbamate | 5,4% | 39,1% | - | - |

| Sec-butanol alcohol | 8,6% | 12,5% | - | - |

| Coefficient of congeners | 9,4% | 6,1% | 8,5% | - |

| Alcohol Content | 5,8% | 4,9% | 9,6% | 21% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).