1. Introduction

As the concept of "sustainable design" gains increasing recognition among consumers and designers, more consideration is being given to sustainable and ecological materials in the selection of raw materials for furniture production [

1]. Increasingly, raw materials for furniture production have shifted from scarce and expensive timbers like mahogany to sustainable materials such as laminated bamboo lumber. These bamboo materials are lightweight, artistic, possess excellent physical properties, are easy to process, and reduce transportation and processing costs [

2]. Laminated bamboo lumber is made by processing fast-growing, short-cycle bamboo into wide and thick bamboo sheets, drying them to a moisture content of 8-12%, and then glueing the sheets together with an adhesive to form a profile [

3]. The high strength of laminated bamboo lumber can meet the demands of different structures in terms of the physical and mechanical properties of the material [

4]. Laminated bamboo lumber has been widely used in building formwork, carriages, flooring, furniture and other products [

5]. The current production process of laminated bamboo lumber can flexibly control the size and length of its components and has a good prospect for promotion and application [

6].

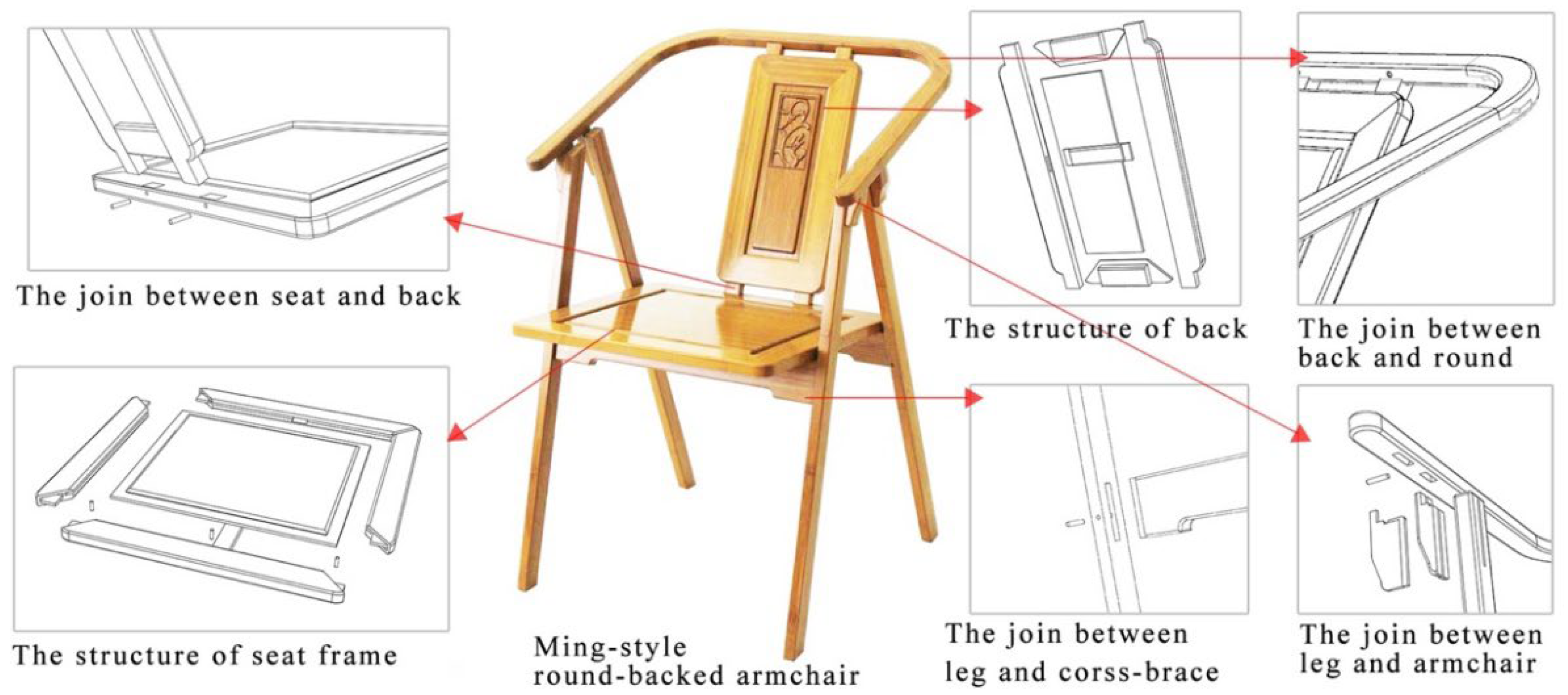

As a bestselling and classic piece of Chinese furniture, the round-backed armchair originated in the Tang Dynasty and became popular during the Ming Dynasty [

7]. The round-backed armchair is one of the representative pieces of Ming-style Chinese furniture as

Figure 1 depicted [

8]. The armrest seamlessly connects to the back of the chair, creating a natural resting place for the arms [

9]. This design is not only ergonomic but also practical and aesthetically pleasing. The round-backed armchair features a rounded upper armrest and a square seat cushion, symbolizing the traditional Chinese cultural concept of a round heaven and a square earth [

10]. Beyond its elegant and grand appearance, the round-backed armchair is also notable for its exquisite craftsmanship and ingenious design. The chair’s structure is assembled using traditional mortise and tenon joinery, including techniques such as the dark falcon and interspersed tenon, which connect various component structures [

11]. This traditional method ensures that the connections are both strong and durable [

8].

Traditionally, designers rely on furniture design manuals and past experiences to determine initial component dimensions [

12]. Subsequently, they conduct mechanical safety and destructive tests to refine these dimensions, a process both time-consuming and prone to material wastage [

13]. This method, though common, lacks efficiency and precision. It involves multiple tests and a lengthy cycle, often resulting in oversized or undersized components, failing to balance material conservation and structural strength [

14].

The Finite Element Method (FEM) in chair design is a sophisticated computational technique used for structural analysis and optimization [

15]. It enables designers to virtually test and analyze a chair's structural integrity, predict stress and strain points, and ensure durability and ergonomic comfort [

16]. By simulating various materials and loads, FEM assists in material selection and design refinement, allowing for the creation of chairs that are both aesthetically pleasing and structurally sound [

17]. This method accelerates the design process through virtual prototyping, reduces physical testing costs, and promotes sustainable practices by optimizing material usage [

18]. FEM's integration with CAD/CAM systems further streamlines the workflow, making it an indispensable tool in modern chair design for achieving a balance between functionality, comfort, and style [

4].

Therefore, this paper aims to: 1) Optimize the structure of classic Ming-style round-backed armchairs using finite element software to create a structurally sound design, uses less material, and maintains high strength; 2) Test the mechanical properties of laminated bamboo lumber, the material used in these armchairs, and input the data into the ANSYS Workbench material library to inform material selection for future designs; and 3) Use ANSYS Workbench to assess the mechanical strength and stability of the armchairs' Chinese connection structure, providing a reference for future designs. Achieving a lightweight design by reducing the overall mass of the frame offers several benefits, including enhanced market competitiveness, lower production costs, and shorter product development timelines. Additionally, this approach leads to a decrease in energy consumption, carbon emissions, and resource use, thereby minimising environmental impact and contributing to the product's overall sustainability.

2. Materials and Methods

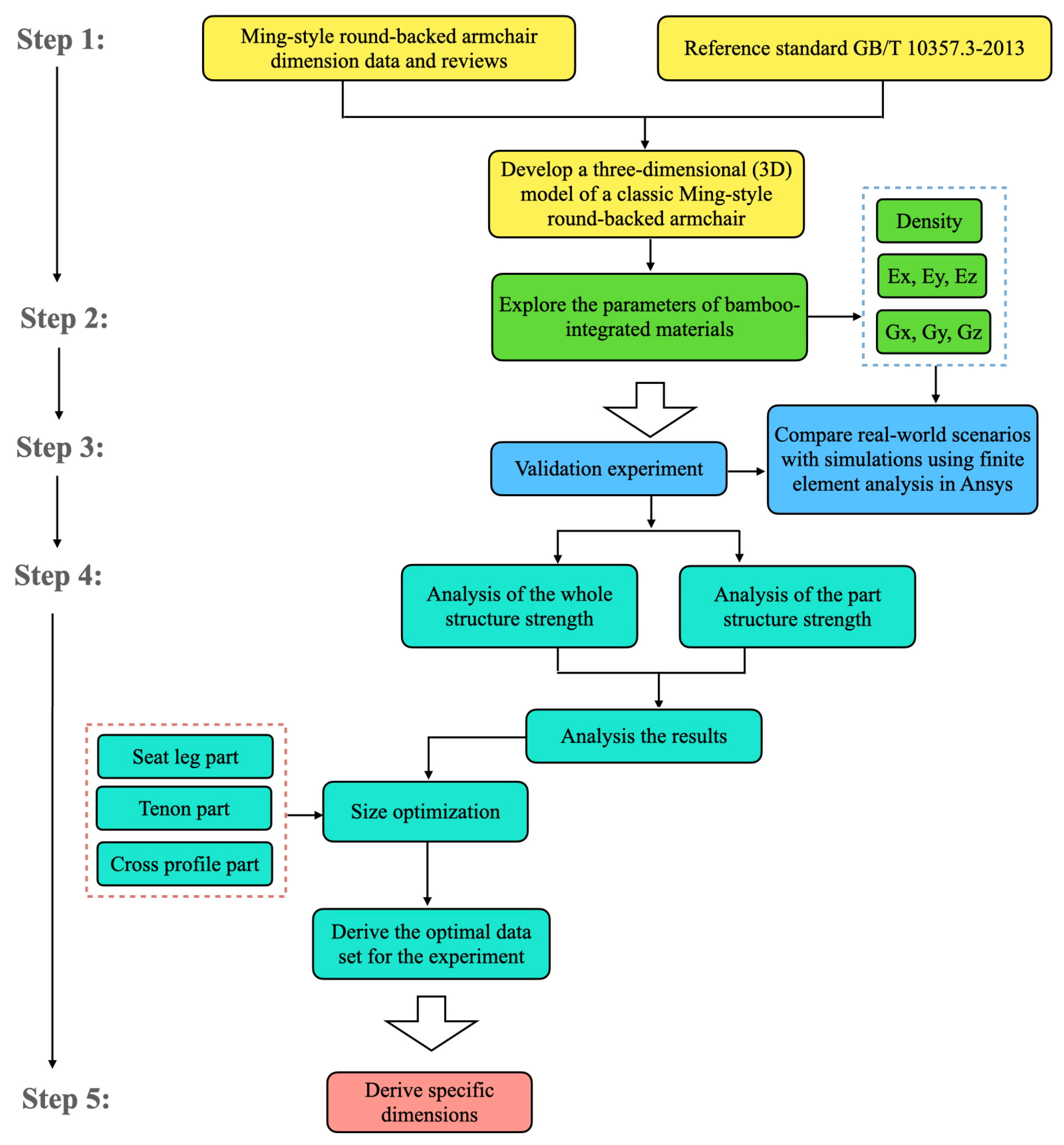

This research investigates the feasibility and application of laminated bamboo lumber materials in furniture design. As the design flow chart shows in

Figure 2. First, empirical research was conducted to comprehensively record the structure data of Ming-style round-backed armchairs, followed by developing a three-dimensional (3D) model of a classic Ming-style round-backed armchair. An experimental research method was then employed to explore the parameters of laminated bamboo lumber for future analysis. Additionally, a validation experiment was conducted to compare real-world scenarios with simulations using finite element analysis in Ansys. Finally, finite element analysis was used to test the feasibility and application of laminated bamboo lumber materials in furniture design, and optimization design, focusing on the material’s mechanical properties [

19].

3. Mechanical Testing and Analysis

3.1. Three-Dimensional Model of Ming-Style Round-Backed Armchair

In this paper, the author selected a classic single-person Ming-style round-backed armchair as the main object of finite element method optimisation analysis which was manufactured by designer Fang Hai in 1998 at Avanta Company in Finland as shown in

Figure 1 [

8]. The first generation of Ming-style round-backed armchairs made of rosewood are heavy overall and cannot be easily carried and placed as a work chair [

20]. To make the Ming-style round-backed armchair suitable for more occasions, new sustainable, high-strength and lightweight laminated bamboo lumber materials are considered as the base material to design a new generation of Ming-style round-backed armchair [

21]. After contacting with designer. A detail of the connection methods between the components of Ming-style round-backed Armchair furniture during the structural design process. The components of Ming-style round-backed Armchair furniture mainly include chair legs, backrest, seat, armrest, and crossbeam [

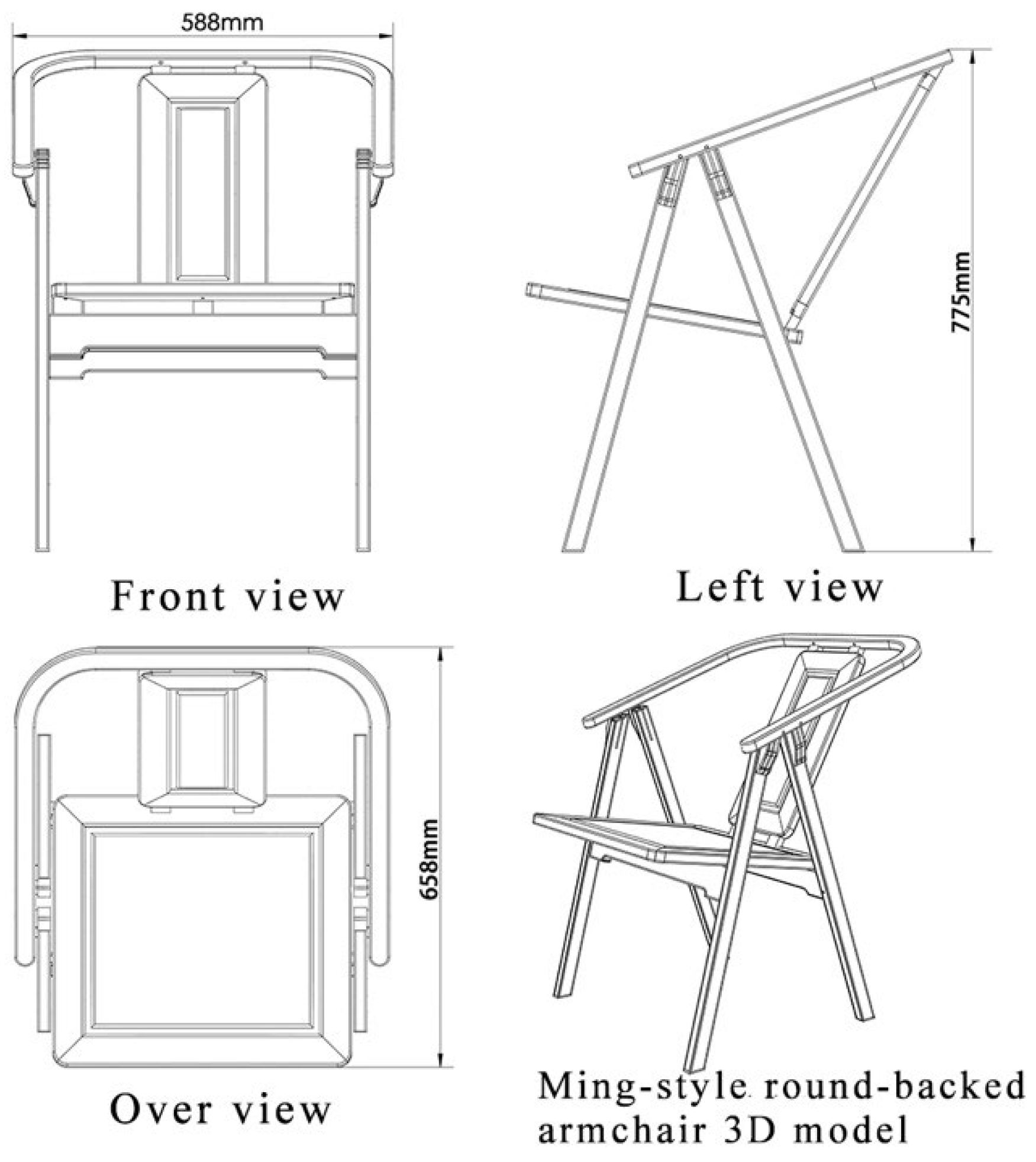

22]. The components are mainly connected through Chinese-style structures, including mortise and tenon joints, bamboo nail joints, glue and paint joints, and connector joints. By contacting the classic round-backed armchair’ designer, Fang Hai to measure the initial dimensions of the chair, the geometric model of the chair was built with UG modelling software using the collected data as shown in

Figure 3. The three-view and three-dimensional diagram of the Ming-style round-backed Armchair furniture [

23].

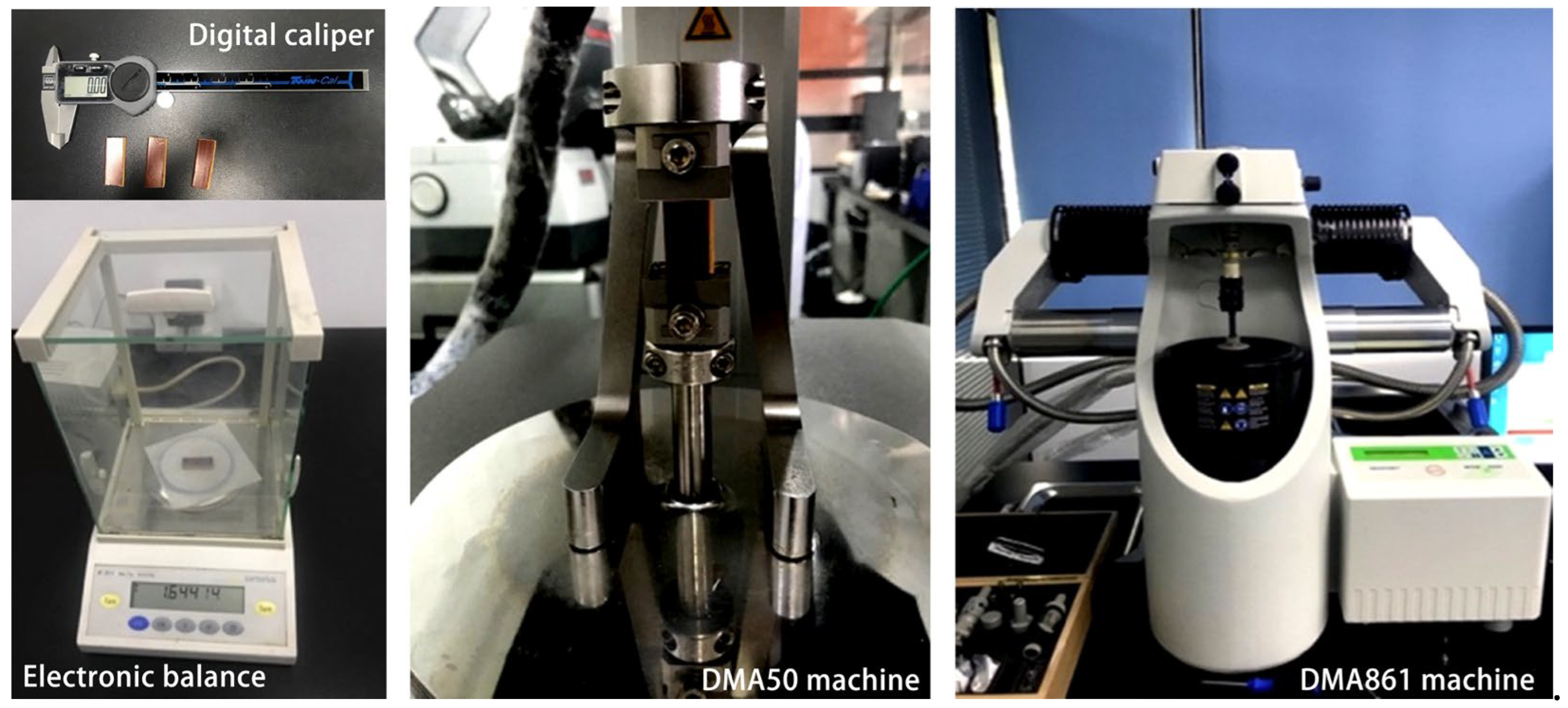

2.2. Parameters of Laminated Bamboo Lumber

The material used to design the round-backed armchair is laminated bamboo lumbers, which is a sustainable material with low density, high strength and high stiffness, and is an ideal raw material for making furniture. The experiment involved testing the density, modulus of elasticity, and shear modulus of bamboo lumber and integrals. For density testing, bamboo panels were obtained, and small specimens were prepared, with an average density of 0.69 g/cm³ determined according to the GB/T17657-2013 standard. The modulus of elasticity was measured in three directions (x, y, z) using a DMA50 machine, yielding values of 26,938 MPa, 6,640 MPa, and 3,870 MPa, respectively. Shear modulus testing was performed using a DMA861 machine, with values of 574 MPa, 283 MPa, and 122 MPa obtained for the x, y, and z directions, respectively. The instruments used included digital vernier calipers and an electronic balance for density testing, a DMA50 machine for modulus of elasticity testing, and a DMA861 machine for shear modulus testing.

Figure 4.

The experiment instruments.

Figure 4.

The experiment instruments.

The parameters of laminated bamboo lumber obtained by consulting the relevant test standards [

24] for parameter testing results are shown in

Table 1.

2.3. Validation Tests

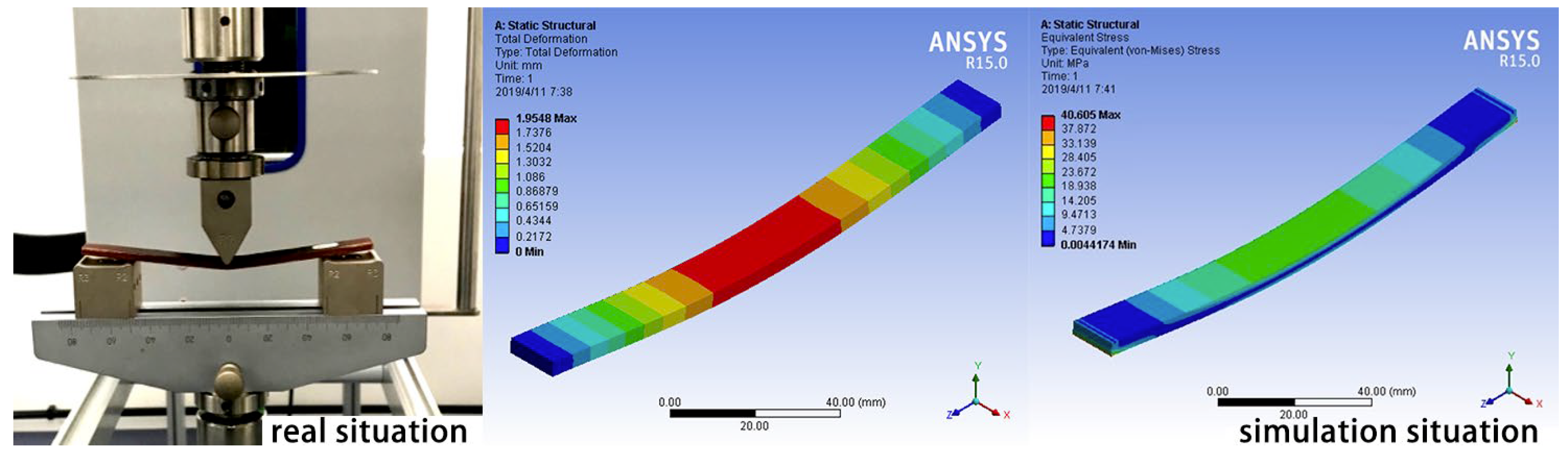

This study used a universal electronic testing machine to perform a three-point compression test on laminated bamboo lumber samples as

Figure 5 shows. The sample, with dimensions 100mm × 14.08mm × 3.97mm, was loaded at a uniform speed of 1mm/min up to 1000N, measuring the bending angle and displacement without causing the sample to break. The results, including load, compressive strength, and displacement, were recorded, and the test was followed by a finite element analysis using ANSYS Workbench. The simulated results showed a maximum displacement of 1.95mm and stress of 40.605MPa under a 175N load, closely matching the real test values, as results shown in

Figure 6. Validating the reliability of the finite element method for analyzing laminated bamboo lumber materials.

4. Finite Element Optimization

4.1. Finite Element Analysis

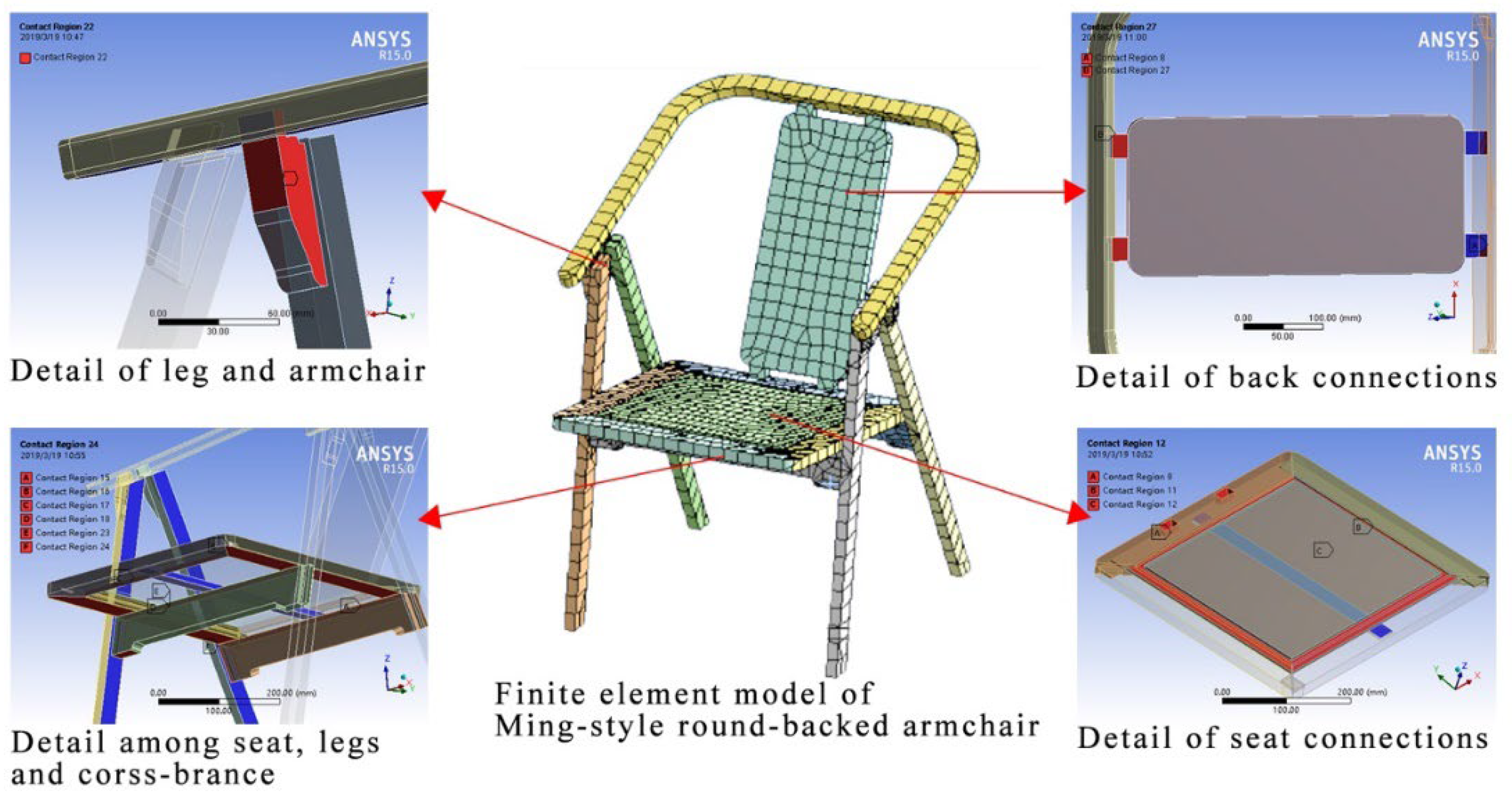

The modelled circle chair model is imported into the finite element software ANSYS for the structural strength simulation calculation of the chair.

The model imported into ANSYS software needs to be given the material parameter values, to realistically simulate the characteristics of each anisotropy of laminated bamboo lumber in the transverse, longitudinal and vertical directions, Solid 185 hexahedral unit body is selected as the basic composition of the model of the smallest finite element unit, and the parameters of bamboo integrals measured before are imported into the finite element software to define the material properties of the model, and the finite element model of the chair is obtained by mesh delineation through the importation of the 3D model into the finite element software. The 3D model of the chair is imported into the finite element software for meshing to obtain the finite element model of the chair, and the number of meshing determines the time and accuracy of the calculation. Therefore, this test refers to the usual furniture model of the accuracy of the mesh division of the cell size is set to 5mm, and the number of meshes of the final model of the chair is divided into a total of 143,842 solid cells, and after the mesh division of the overall finite element model of the chair. The finite element model of the chair after meshing is shown in

Figure 7.

The round-backed chair model consists of 19 component models connected by mortise and tenon joints, and the component models are in contact with each other, and the contact parts are fixed by glue. In order to accurately simulate the real deformation and stress diagrams of the chair model after stressing when the load is applied, the contact mode between the mortise and tenon component models is defined as bonded in the finite element software.

4.2. Finite Element Model of Ming-Style Round-Backed Armchair

4.2.1. Simulated Test Conditions for Armchair

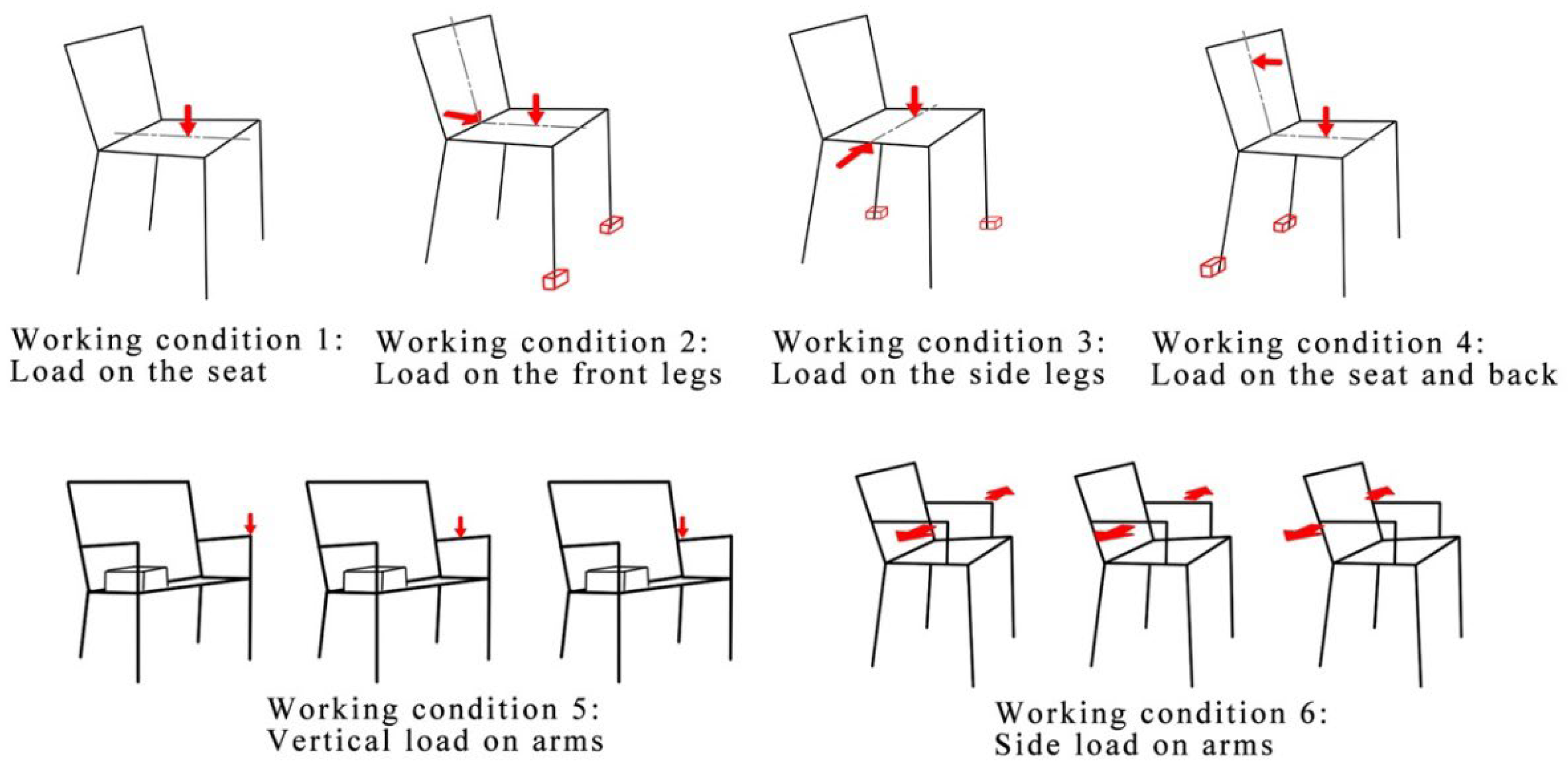

In order to ensure both compliance with industry standards and reliable assessment of the chair's safety and durability, a Chinese standard was adopted in this test. According to GBT 10357.3-2013 national chair mechanical strength test standards for structural strength testing of the armchair model, the test includes six working conditions [

26], each working condition corresponding to the chair test the location of the load applied to the test, the direction and constraints as shown in

Figure 8.

Working condition 1: The load on the chair surface is 1300N, the direction is vertically downward, and the ultimate load is 1600N considering the extreme use.

Working condition 2: the forward load is 500N, the vertical downward balance load of the chair is 800N, and the front two legs are fixed constraints.

Working condition 3: the lateral load is 500 N, the balance load of the chair surface vertically downward is 800 N, and the two legs on the right side choose fixed constraints.

Working condition 4: The vertical downward load is 800 N. Considering the ultimate use case, the ultimate load is 1600 N. The load of pushing the chair in the forward direction is 450 N. Fixed restraints are added to the rear two legs of the chair.

Working condition 5: The vertical downward load at the armrest is 500N, and the balanced load applied to the chair surface in the vertical direction is 800N.

Working condition 6: the load applied in both outward directions at the armrests is 500N, and the balanced load applied in the vertical direction at the chair surface is 800N.

4.2.2. Finite Element Software Simulation

To complete the meshing of the chair model, in accordance with the national standard of furniture strength testing six working conditions were developed in the static test module of the software to add loads and constraints and boundary conditions to the finite element model of the chair, with finite element software simulation of the working conditions in

Figure 9.

5. Results

5.1. Simulation Results

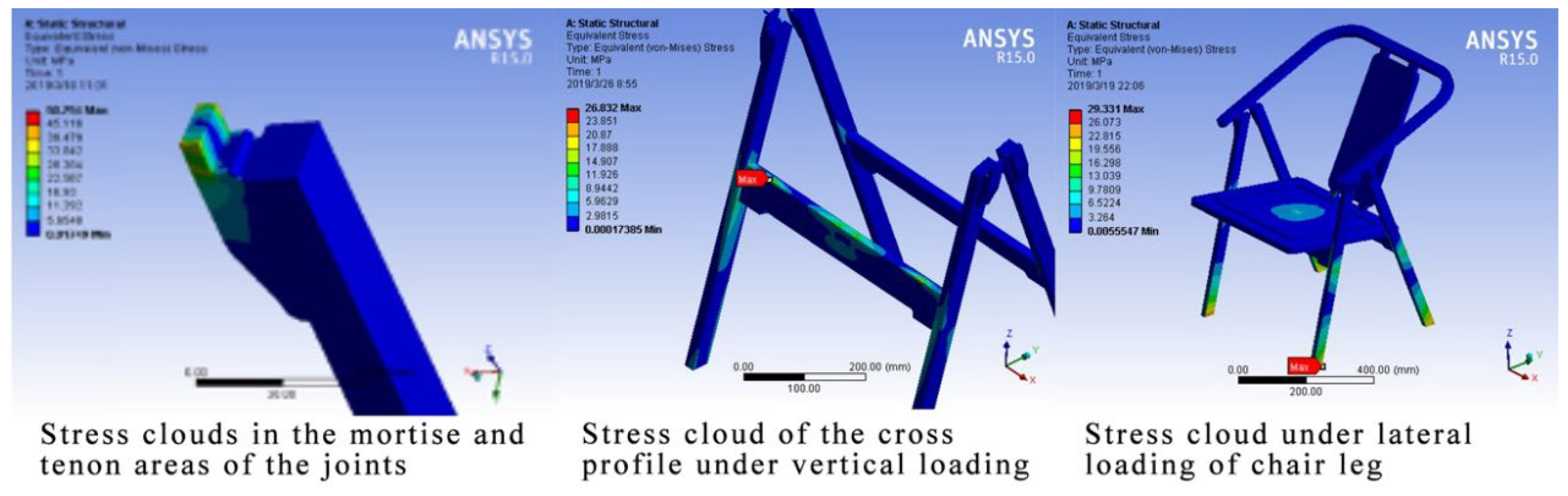

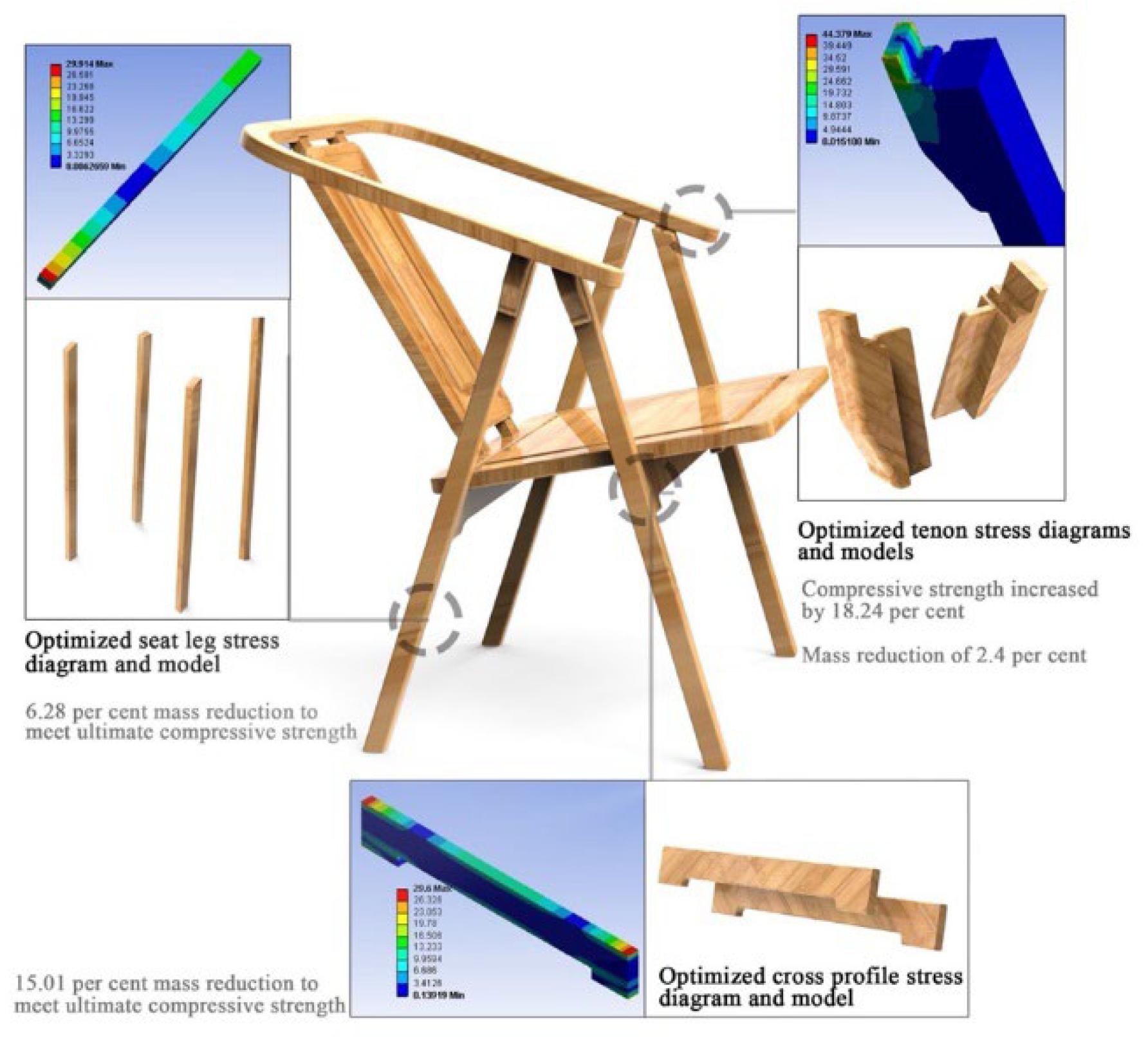

The simulation results after applying loads to the finite element model of the chair show that the mortise and tenon part of the connectors between the legs and the armrests, the cross-profile connectors between the bottoms of the legs, and the four legs of the chair are the parts that need to be optimized, as shown in

Figure 10.

In the finite element simulation test project of working conditions 5 and 6, the tenon part of the connecting part of the chair legs and armrests produces large stress (50.75Mpa), which exceeds the maximum stress that the bamboo integrals can withstand, 45Mpa, as shown on the left side of Figure 32, and it is necessary to carry out optimisation of the design in the later stage under the condition of meeting the maximum stress that the tenon can withstand;

In the finite element simulation test project of working condition 1, the profile part is subjected to a large amount of static load, as shown in the middle of Figure 32, the maximum stress generated at the top of the profile is 26.83Mpa, which is much smaller than the maximum stress of 45Mpa that the bamboo timber can withstand, so the optimized design can be carried out for the profile part by reducing the amount of the profile part;

In the finite element simulation test of working condition 6, as shown on the right side of Figure 32, the stress of lateral load transfer is mainly concentrated in the bottom of the four chair legs, with the size of 30Mpa, which is far smaller than the maximum stress of 45Mpa that laminated bamboo lumber can withstand, so the chair legs can be optimized by reducing the amount of design.

5.2. Optimal Design

According to the results of finite element software calculations were made on the chair legs and armrests of the joints mortise and tenon parts of the design to strengthen the chair, the bottom of the chair legs between the cross-post joints and the four legs for the design of weight reduction. The optimization module of finite element software ANSYS Workbench is used to optimize the design of these parts of the chair. The optimized dimensions and model of the chair are shown in

Figure 11.

(1) The width of the optimized joint tenon is 7.5mm, the height is 10mm, the length is unchanged, the optimized mass is 0.0178kg, which is 2.4% lighter than the pre-optimized mass, and the maximum stress of the load strength test under the new dimensions is 44.97Mpa, which is an improvement of 18.24% in compressive strength.

(2) The width of the optimized profile is 18mm, the height is 68mm, and the mass of the optimized profile is 0.337kg, which reduces the mass by 15% while maintaining the same compressive strength.

(3) The optimized single chair leg has a width of 28mm, a height of 21mm, a weight of 0.2771kg, and a mass of 0.2771kg, which reduces the mass of the optimized single chair leg by 6.28% under the condition of the same compressive strength.

6. Conclusion

In this paper, the finite element software ANSYS is used to scientifically and efficiently carry out the structural optimization design of the chair. Firstly, by collecting and measured the furniture dimensions of the chair, the structure of the internal parts and the connection mode, and through the experimental measurements, this research obtained the dimensions of each part of the chair to establish the model of the chair, calculated the density, modulus of elasticity, shear modulus, Poisson's ratio. Then imported them into the model of the chair, and finally, carried out the finite element model of the chair by mesh division. The finite element model of the chair. According to the GBT 10357.3-2013 national chair mechanical strength test standard in the six working conditions of the finite element model of the chair to add loads and constraints, through the finite element software simulation calculation of the chair model of the weak structure and the need to improve the structure, and finally use the finite element software ANSYS Workbench for the chair finite element model of the weak structure and the need to improve the structure of structural optimization design, the structural optimization of the chair finite element model, and the structural optimization of the chair finite element model, and the structural optimization of the classic round-backed chair finite element model. Finally, the finite element software ANSYS Workbench is used to optimize the design of the weak structure and the structure to be improved in the finite element model of the chair, to strengthen the design of the mortise and tenon joints, and to reduce the design of the legs and the door posts, so as to maximize the use of materials. The last part of the paper is to join the verification test for comparison, the real conditions of the chair furniture parts specimens in the universal mechanical testing machine under the loading test, the real loading of the displacement - load test results and finite element software ANSYS simulation of the chair model to get the displacement - stress function comparison, the two test data basically coincide with the data, so the use of finite element software to simulate the loading of the chair calculated data is reliable, can use the finite element software to simulate the loading of the chair. Therefore, the data calculated by using finite element software to simulate the loading of the chair are reliable, and the finite element software ANSYS can be used to guide the furniture of the chair and optimize the design of its components.

Author Contributions

Conceptualization, J.L.; Methodology, J.L.; Software, Q.Z.; Formal analysis, Q.Z.; Writing-original draft, J.L.; Writing-review & editing, R.C.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author Li and Rosalam, upon reasonable request.

Acknowledgements

The authors would like to express their sincere gratitude to supervisor committee whose contributions of time and expertise were invaluable to the success of this research.

Conflicts of Interest

No potential conflict of interest was reported by the author(s).

References

- Alkhursani, S.A.; et al. Application of Nano-Inspired Scaffolds-Based Biopolymer Hydrogel for Bone and Periodontal Tissue Regeneration. Polymers 2022, 14, 3791. [Google Scholar] [CrossRef] [PubMed]

- Azuwa, S.B. A review on experimental observation on structural performance of bamboo reinforced concrete beam. Heliyon 2024, 10, e24628. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Jin, X.; Li, J.; Qin, D. Mechanical and Fire Properties of Flame-Retardant Laminated Bamboo Lumber Glued with Phenol Formaldehyde and Melamine Urea Formaldehyde Adhesives. Polymers 2024, 16, 781. [Google Scholar] [CrossRef] [PubMed]

- Wen, Z.; Li, M. Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM. Materials 2021, 14, 4410. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Wang, G.; Chen, L.; Yu, Z.; Smith, L.M.; Chen, F. Hydrothermal Aging Properties of Three Typical Bamboo Engineering Composites. Materials 2019, 12, 1450. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.-F.; Cai, C.-J.; Zeng, X.-S.; Campbell, D.E.; Fan, S.-H.; Liu, G.-L. Bamboo vs. crops: An integrated emergy and economic evaluation of using bamboo to replace crops in south Sichuan Province, China. Journal of Cleaner Production 2018, 177, 464–473. [Google Scholar] [CrossRef] [PubMed]

- Zou, W.; Li, Z.; Sun, D. The teaching content of Shanghai style furniture design for Chinese art design speciality. Heliyon 2022, 8, e11627. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Wen, G. Structural optimisation design of Ming-style circle chair based on finite element method. Industrial Design, 2021.

- Ke, S.; Chunlei, C.; Haining, W. A Research on the Evolution Path of Ming-style Round-backed Armchair. 2009.

- Li, Z. Analysis of Humanistic Factors in the Design of Chinese Style Furnishings under the Background of National Culture. FSST 2021, 3. [Google Scholar] [CrossRef]

- Fang, H. Modern Design and the Future of Chinese FurnitureInterview with Master Designer Jorio Cucabolo. Furniture and interior decoration 2024. [Google Scholar] [CrossRef]

- Suarez, B.; Muneta, L.M.; Romero, G.; Sanz-Bobi, J.D. Efficient Design of Thin Wall Seating Made of a Single Piece of Heavy-Duty Corrugated Cardboard. Materials 2021, 14, 6645. [Google Scholar] [CrossRef] [PubMed]

- Jfm, M.; Ymt, K.-R.; Cj, S. Revision of the design of a standard for the dimensions of school furniture. Ergonomics 2003, 46, 681–694. [Google Scholar] [CrossRef] [PubMed]

- Suarez, B.; Muneta, L.M.; Romero, G.; Sanz-Bobi, J.D. Efficient Design of Thin Wall Seating Made of a Single Piece of Heavy-Duty Corrugated Cardboard. Materials 2021, 14, 6645. [Google Scholar] [CrossRef] [PubMed]

- Kalita, K.; Chakraborty, S.; Madhu, S.; Ramachandran, M.; Gao, X.-Z. Performance Analysis of Radial Basis Function Metamodels for Predictive Modelling of Laminated Composites. Materials 2021, 14, 3306. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Liao, W.; Hong, P. VISUAL IMAGE ANALYSIS IN FORM OF CHINESE MING DYNASTY ARMCHAIR. 2010.

- Çolakoğlu, M.H. Finite element analysis of wooden chair strength in free drop. Int. J. Phys. Sci. 2012; 7. [Google Scholar] [CrossRef]

- Weaver, E.; O’Hagan, C.; Lamprou, D.A. The sustainability of emerging technologies for use in pharmaceutical manufacturing. Expert Opinion on Drug Delivery 2022, 19, 861–872. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Xu, W.; Li, R.; Zhou, J.; Luo, Z. Study on Sustainable Lightweight Design of Airport Waiting Chair Frame Structure Based on ANSYS Workbench. Sustainability 2024, 16, 5350. [Google Scholar] [CrossRef]

- An, S.; Fang, H. The Influence of Chinese and Western Cultural Backgrounds on Qing Dynasty Guangzhou-made Furniture. PACKAGING ENGINEERING, 2021. [Google Scholar] [CrossRef]

- Fu, Y.; Fang, H. Parametric design of a reconfigured bamboo chair. China Forest Products Industry, 2016. [Google Scholar]

- Fu, Y.; Fang, H. Application of finite element method to validate recombinant bamboo materials for furniture applications. Journal of bamboo research, 2016. [Google Scholar]

- Fang, H. Chineseism in Modern Furniture Design" A Study of Chair Archetypes’. Decoration. [CrossRef]

- Colince, L.; Qian, J.; Zhang, J.; Wu, C.; Yu, L. Study on the Molding Factors of Preparing High-Strength Laminated Bamboo Composites. Materials 2024, 17, 2042. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; et al. Mechanical Performance of 3D Printed Concrete in Steam Curing Conditions. Materials 2022, 15, 2864. [Google Scholar] [CrossRef] [PubMed]

- Duan, Z.; Zu, Q.; Rao, F. Bamboo Scrimber as a Sustainable Material for Chairs: A Property Study Based on the Finite Element Method. Sustainability 2024, 16, 5357. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).