1. Introduction

Understanding the environmental regulations and mechanisms of everyday processes, such as eating and talking, and the effect of parafunctional behaviors, can help dentists find the optimal methods for maintaining healthy teeth. [

1,

2] However, compromised teeth, as well as missed or hopeless teeth, must be restored.[

2,

3] Several available materials are used in dental practice today. Dental adhesives, metals, porcelains, polymers, and ceramics undergo in vitro testing to determine their long-term physical and mechanical properties.[

5]

The intricate landscape of dental materials and techniques continually evolves to address the challenges in maintaining oral health. Dental professionals navigate a spectrum of options, from testing materials like adhesives, metals, porcelains, polymers, and ceramics to the burgeoning advancements in dental implants. While implants represent a gold standard for rehabilitating compromised teeth, preserving viable teeth remains a priority. Modern approaches, such as guided surgery, harness digital technologies to meticulously plan implant placements, showcasing promising long-term success rates. However, challenges persist in achieving immediate function, prompting ongoing research into enhanced implant surfaces. The prevalent use of polymers, particularly polymethyl-methacrylate (PMMA), underscores the quest for durable interim restorations, albeit with concerns regarding fractures under masticatory forces. Efforts to innovate involve exploring novel composite polymers, seeking alternatives to reinforce PMMA interim restorations. This dynamic landscape calls for rigorous comparative studies to ascertain the efficacy and resilience of emerging materials in dental applications. In recent years, the use of dental implants has become the gold standard to rehabilitate hopeless or missed teeth, however, attempts should be made first to save maintainable teeth.6 Industries are focusing their effort to improve the protocols for immediate function. Within these, enhancement of implant surfaces allows better and faster osseointegration, even in compromised scenarios. However, immediate function remains a challenge in dentistry. [

7,

8]

Computer-assisted, template-based surgery, also known as guided surgery, takes advantages from modern digital technologies to guide implants in the optimal, virtually planned, prosthetically driven position. It has been demonstrated high long-term success and low incidence of peri-implantitis, over a period of 10 years, with the lower value of bone remodeling compared to a free-hand approach.[

9,

10,

11] The pros of guided surgery are the tridimensional view of bone, anatomical structures, and prosthetic plan. These allow the surgeon to plan the implant position and to prepare a fixed interim restoration, making implant placement and immediate function safer and quicker. For the latter, several materials have been proposed to fabricate implant fixed interim restorations. Within these, polymeric materials are commonly used as temporary materials on the basis of their enhanced clinical performance in comparison with alternative options.[

12,

13]

Polymethyl-methacrylate (PMMA) represents the most used polymeric material, since it has been used for several time in dentistry. In the last year, milled PMMA has replaced conventional processed PMMA in order to overcome its drawbacks. However, although interim restorations milled from high-density PMMA demonstrated 35% higher flexural strength, metal reinforcement is still recommended.[

14] Fractures are the main complication associated with PMMA, which gradually develop during the first period of function and typically result from exposure to high mastication forces.[

14,

15,

16] An option to strengthen the PMMA fixed interim restorations is to include a metallic bar, enhancing the mechanical properties of PMMA temporary restorations.[

17]

With the aim to simplify the workflow for immediate loading in complete edentulous or failing dentition cases, several materials and techniques have been proposed.[

18,

19] However, there has yet to be a consensus on the best material. Compression testing is one of the most fundamental types of mechanical testing, alongside tensile and flexion tests.[

20,

21] Compression tests are used to determine a material’s behavior under applied crushing loads, and are typically conducted by applying compressive pressure to a test specimen (usually of either a cuboid or cylindrical geometry) using platens or specialized fixtures on a universal testing machine. During the test, various properties of the material can be calculated and plotted as a stress-strain diagram which is used to determine qualities such as elastic limit, proportional limit, yield point, yield strength, and, for some materials, compressive strength.

Dynamic loads (fatigue tests) are an essential component of research and clinical practice in dental implantology, providing crucial information on the strength and durability of implants and dental prostheses, thereby contributing to the improvement of the quality and reliability of implant treatments [

3]. These tests are represented through stress-load diagrams, where the number of cycles to failure of the specimen is related to the magnitude of the cyclic stresses. By evaluating the material’s fatigue in this way, it is possible to understand the mechanical phenomenon of progressive degradation of a material subjected to variable loads over time (either regularly or randomly), which can lead to its failure. The fatigue limit corresponds to the maximum load level that a material can withstand without fracturing for a theoretically infinite number of load cycles. In laboratories, fatigue tests are conducted at high frequencies, typically between 1 Hz (1 cycle per second) and 10 Hz (10 cycles per second), to accelerate the process. At a frequency of 10 Hz, one year of mastication (365,000 cycles) can be simulated in about 10 hours.

The aim of the present in vitro, comparative research is to validate a novel composite polymer, developed to replace metal-reinforced, PMMA, interim restorations due to its advantages of easier manufacturing and handling. The null hypothesis is that there is no differences for load and displacement under compression test, as well as under dynamic (fatigue) test.

2. Materials and Methods

This study was designed as comparative, case-control, in vitro research and was performed at the Department of Medicine, Surgery, and Pharmacy, of the University of Sassari, Italy. Mechanical tests were performed at the Department of Engineering of the University of Ferrara (compressive test), and at the Faculty of Materials Science and Engineering, Warsaw University of Technology (dynamic test). Data were analyzed at the Department of Medicine, Surgery, and Pharmacy, of the University of Sassari.

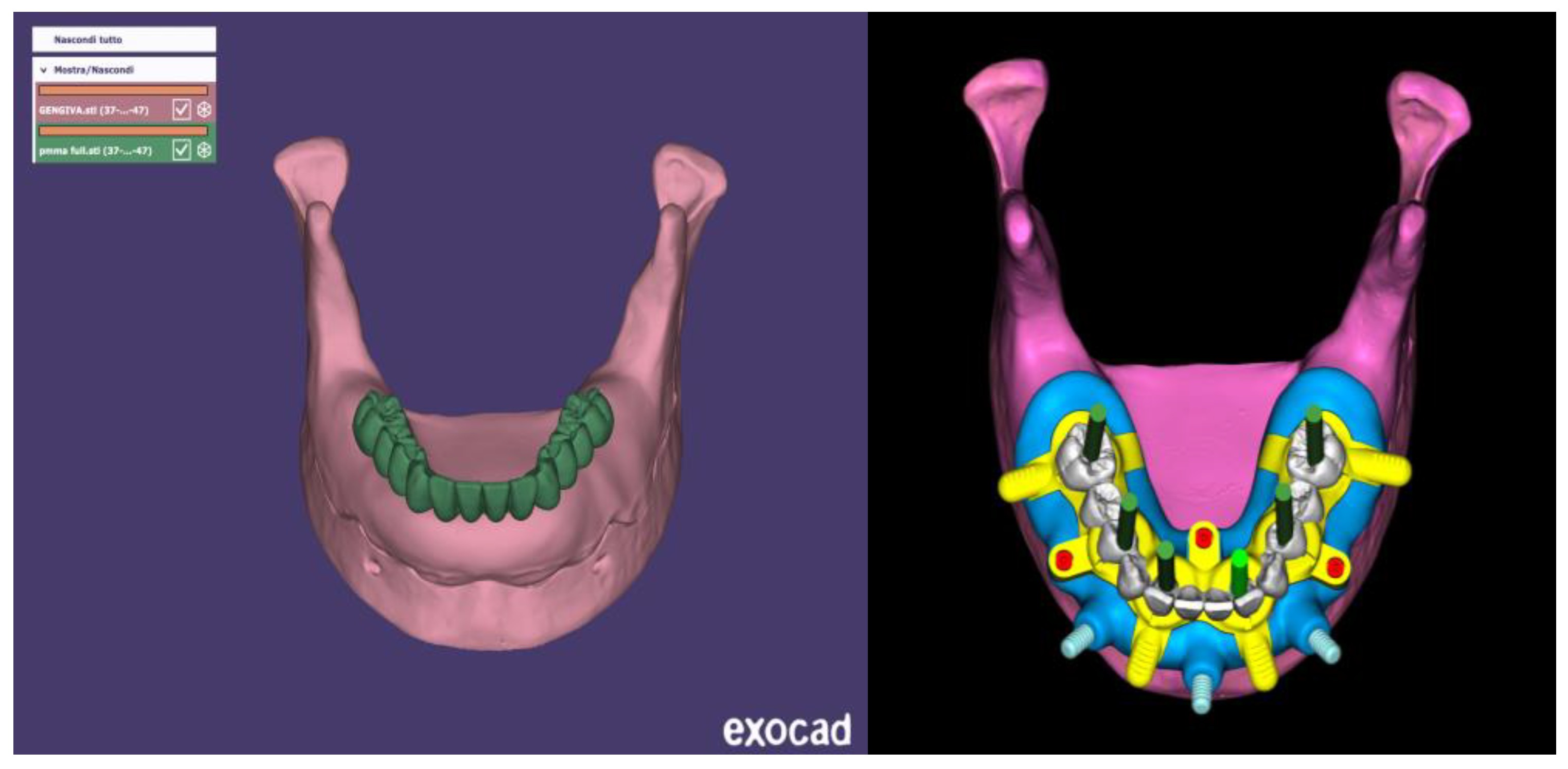

A prosthetically driven, virtual implant planning of a training model simulating a complete edentulous mandible (Dentalstore & Edizioni Lucisano SRL, Milan, Italy), to be rehabilitated with six implants, was considered for this in vitro research. The model was digitalized using an intra-oral scanner (Medit i700, Medit Corp., Seoul, Republic of Korea). After that, a cone beam computer tomography of the same model was taken (Cranex 3Dx, Soredex, Globatech srl, Italy). Two medical-certified software were used to design the virtual wax-up (DentalCAD 3.1 Rijeka, Exocad GmbH) and then to virtually plan the implants position (RealGUIDE 5.1, 3DIEMME, Cantù, Italy). The DICOM (Digital Imaging and Communications in Medicine) and STL (Standard Triangle Language) files were matched using common reference points. Then, six Osstem TSIII implants (Osstem Implants, Seoul, South Korea) of 4 mm in diameter and 10 mm in length were planned in laterals, first premolars, and first molars position. Implants were virtually planned fairly perpendicular to the occlusal plane, with a discrepancy of 6° (lateral incisors), 4.5° (premolars), and 0° (molars). In addition, three anchor pins were planned in the buccal position.

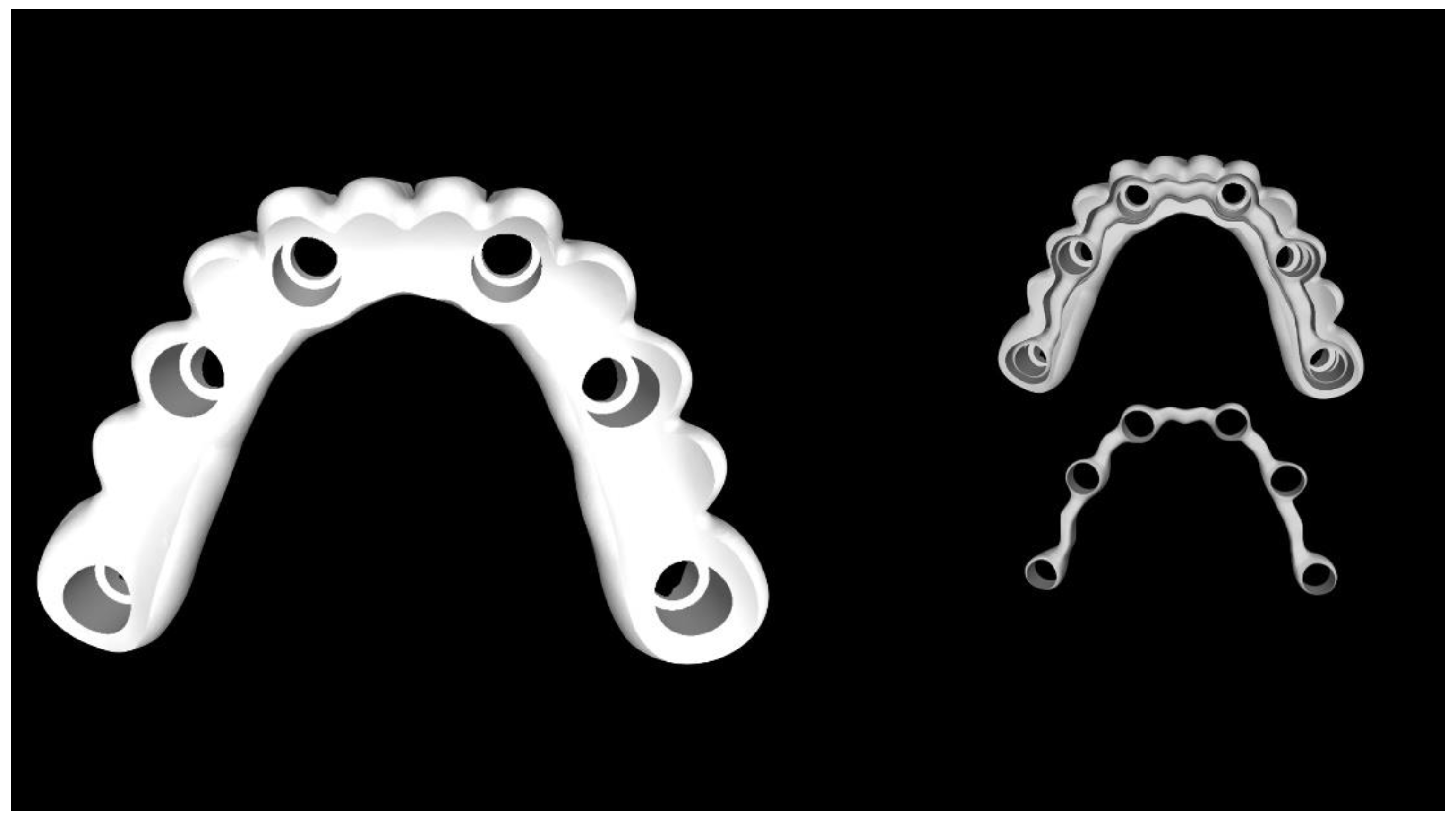

Figure 1.

Virtual wax-up (left) and virtual implant planning (right).

Figure 1.

Virtual wax-up (left) and virtual implant planning (right).

After virtual implant planning was completed and approved, the virtual implant positions were exported in a dental CAD software (DentalCAD 3.1 Rijeka, exocad GmbH). According to the protocol of the present research, a one-piece restoration, composed by 12 dental units, was designed with two different configurations, respectively named groups 1 and 2. In group 1 (test group), a solid (monolithic) restoration was designed, while, in group 2 (control group), a cutback was performed to allow the placement of a metal reinforcement (

Figure 2).

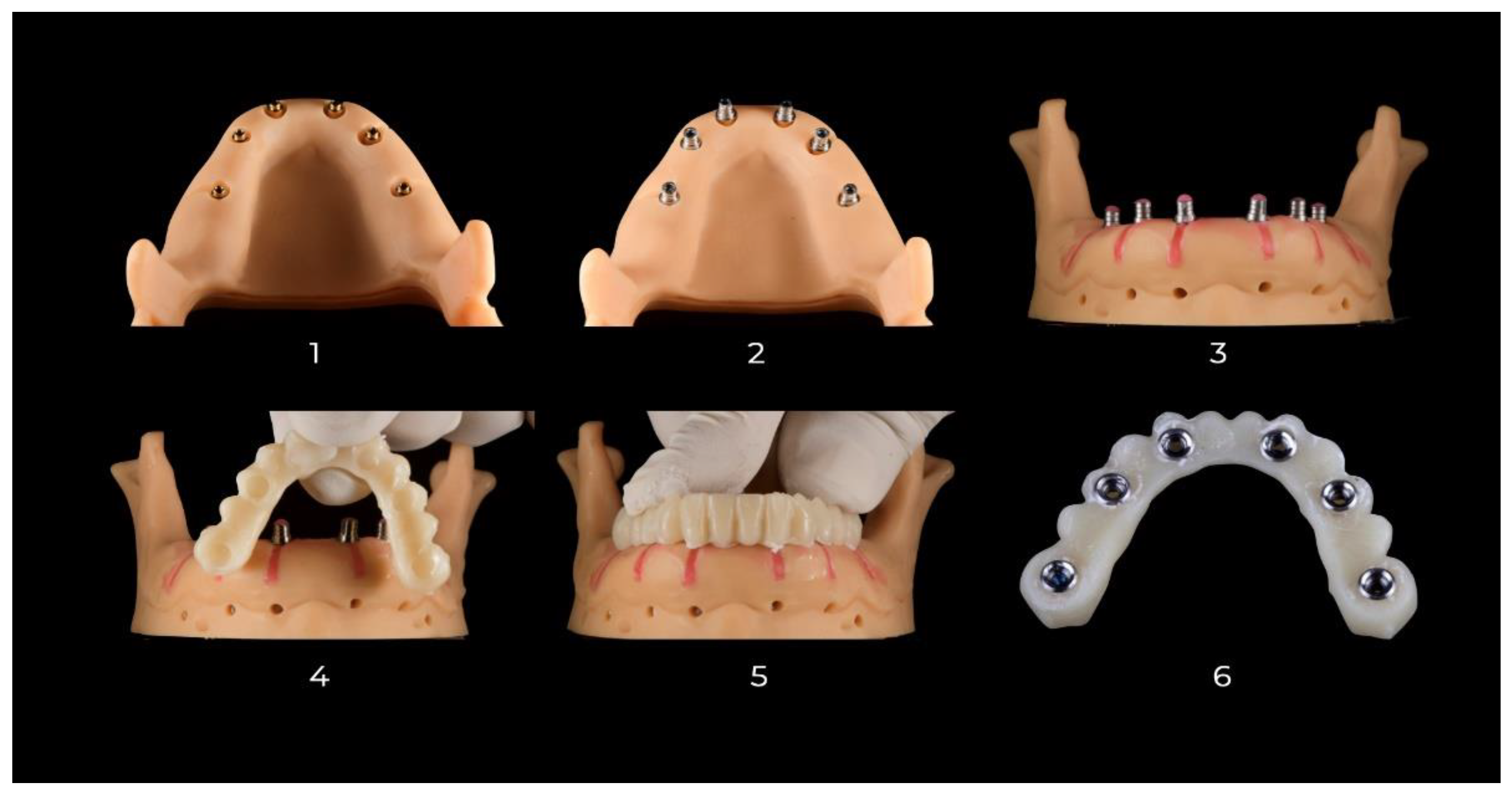

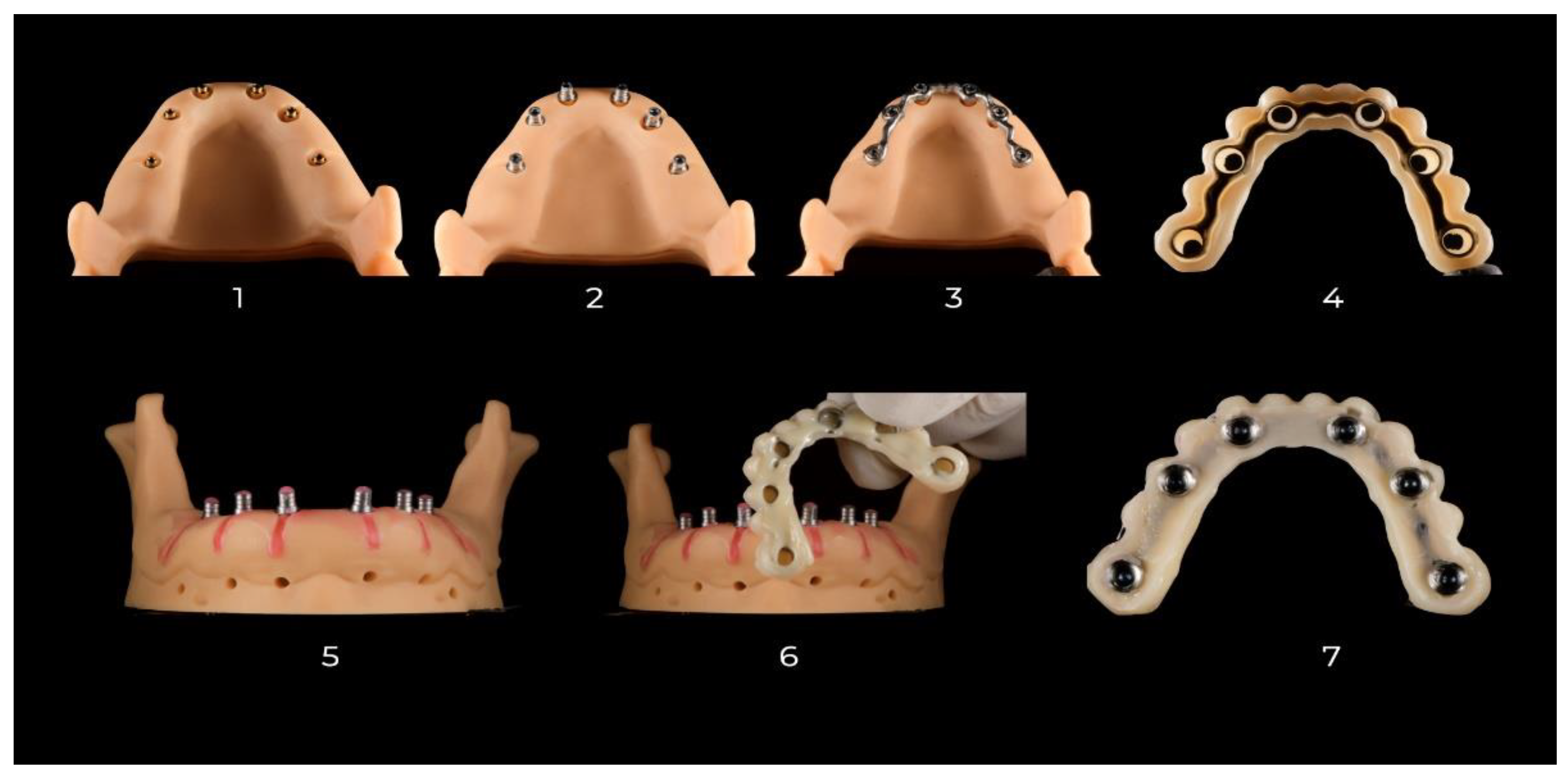

After CAD process was completed, the two prototype models were printed (CAM, computer aided manufacturing) in a qualified milling center (New Ancorvis SRL, Bologna, Italy) using a certified resin material (VisiJet M2R-TN [3D System Inc., Rock Hill, South Carolina]). Six digital lab analog (Osstem Europe s.r.o., Prague, Czech Republic) were screwed in each prototyped model. Finally, six Ot Equator (Rhein’83, Bologna, Italy) were screwed onto the digital analog at 25 N/cm, according to the company’s guidelines. All the temporary restorations and the metal reinforcements were milled in a private center (Just Dental Polymers, Vigonza PD, Italy). In the test group (composite ONLY), a patented composite material, made in polymethyl methacrylate (PMMA), leucite, and alumina was used (ONLY, Just Dental Polymers). The inorganic percentage is about 10-12%. Ratio between alumni and leucite depends by color. In the control group, conventional titanium reinforced PMMA was used (PMMA group).

All the materials were assembled by an expert dentist and dental technician (MT) as following. Temporary cylinders were shortened and screwed onto the OT Equator attachments at 15 N/cm. Then, the screw-hole was closed with teflon. The temporary restorations and metal reinforcements were tested and adapted if needed. Finally, the temporary restorations of both groups were bonded onto the titanium temporary cylinders as suggested by the manufacturer. In brief, in both groups, the temporary cylinders were shortened and the fit of the temporary restorations was tested accordingly. Metal reinforcements were adapted to fit into the PMMA restorations, while, in the test group, metal reinforcement was not used. After that, All the restorations and temporary cylinders were steam cleaned. In the test group, the temporary restorations were bonded to the temporary cylinders using dedicated cement (Just Dental Polymers, Vigonza PD, Italy). In the control group, conventional PMMA were used to assemble the metal reinforcements inside the temporary restorations, and to fix the metal-reinforced restorations to the temporary cylinders. In both groups, after polymerization process was completed, the restorations were finished. All the sequences in both gourds were reported in

Figure 3 and

Figure 4.

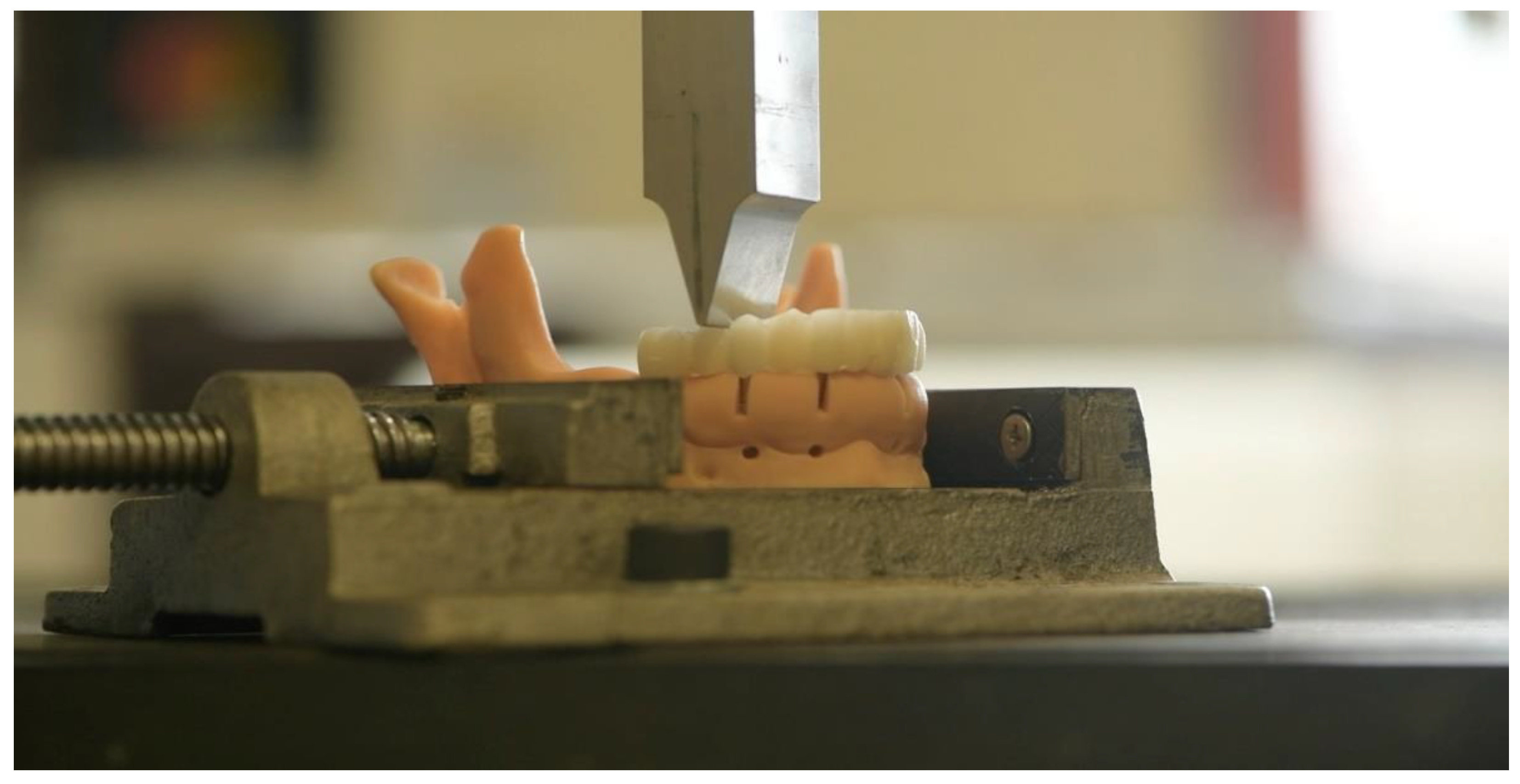

Primary outcome measures were peak break point (N) and displacement (mm) established by using the Instron 4467 Tensile Compression Test Machine 30kN 6750LBS 1kN Static Load Cell. The temporary restorations were screwed at 25 Ncm onto the training model simulating a complete edentulous mandible according to the manufacturer’s instruction. After that, all the samples were gripped with a vice under the INSTRON 4467 machine, as in the

Figure 5, immediately before the static loading tests.

Data of the load and displacement were repeated at least 5 samples in each combination. Loading test was conducted with a 1 mm/min of loading rate. The data were recorded from unloading until fracture of the samples. The data gives information about the highest load (N) and the behavior of load-displacement in axial loading (mm). Displacement (mm) is defined as the distance in millimeters moved by a particle or body in a specific direction. Breaking Load is defined as the load expressed in newton which causes fracture and the outcome measures were peak break point and deflection.

Figure 5.

Model gripped onto the INSTRON 4467 machine during test.

Figure 5.

Model gripped onto the INSTRON 4467 machine during test.

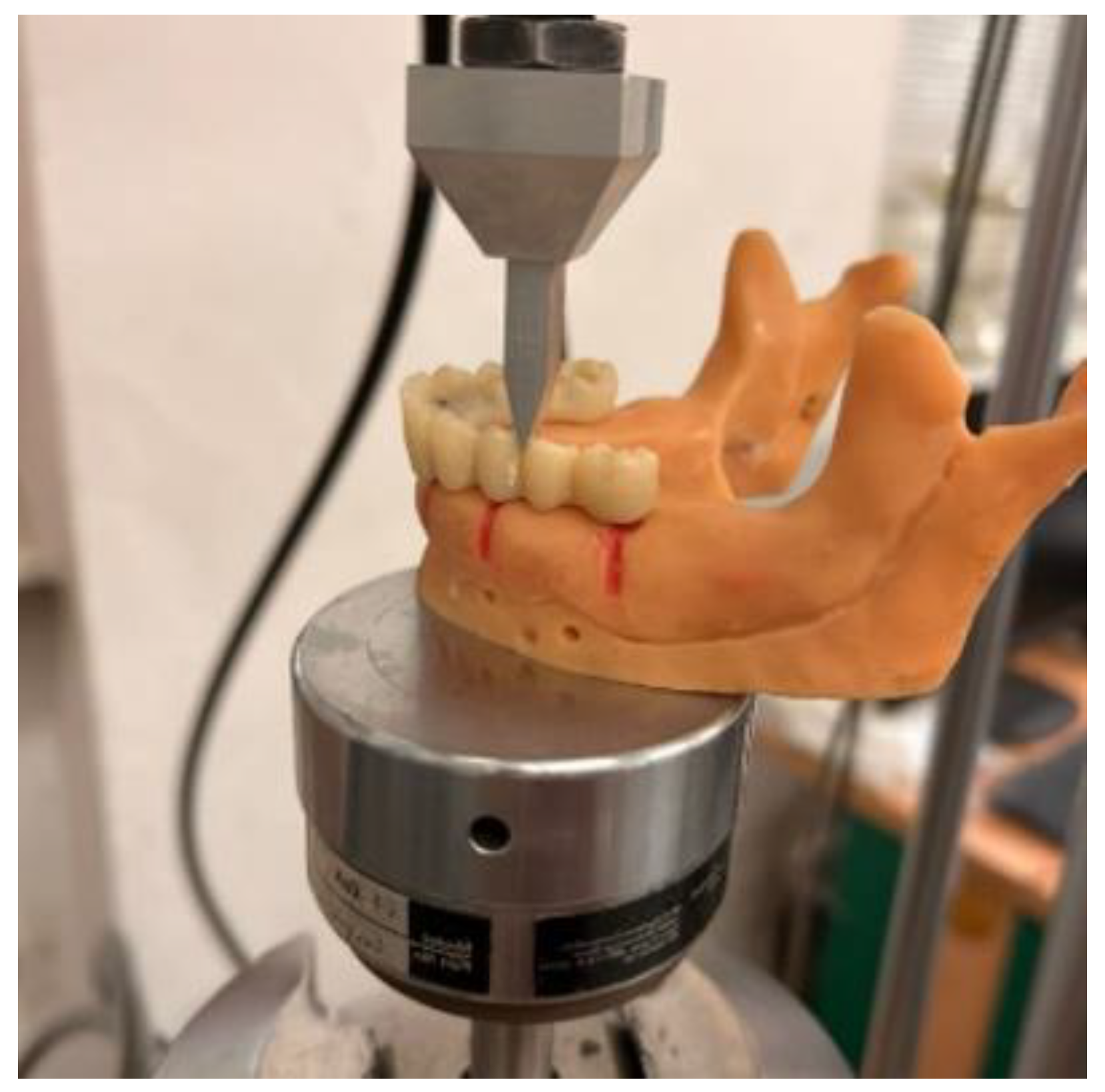

Secondary outcome measure were to evaluate behavior under fatigue tests, all the samples were placed under the MTS 858 (Materials Test System, Minnesota, USA) machine. This machine was equipped with a force sensor with a maximum range of ±2.6 kN.

Figure 6.

Model gripped onto the MTS 858 machine during cyclic tests.

Figure 6.

Model gripped onto the MTS 858 machine during cyclic tests.

The control variable was a sinusoidal force signal applied at a frequency of 2 Hz. The samples were loaded into the space between teeth 4 and 5 (premolars) using a pin with a radius of R=1 mm. Fatigue tests were conducted using the so-called "staircase methodology," where, after a predetermined number of load cycles (1 load step = 1000 cycles), the maximum load interval was increased by 250 N. Since the tests began with a load interval of 25-250 N, the subsequent load intervals were respectively 25-500 N, 25-750 N, 25-1000 N, and so on.

Statistical analyses were performed using NUMBERS, version 11.2 (Apple Inc., Cupertino, CA, USA). Mean values and standard deviations (SD) were calculated. Comparisons between groups for continuous outcomes (loading and displacement) were made by unpaired tests, in order to detect any changes. Correlation between loading and displacement was calculated to evaluate possible relationship between both variabilities. For the fatigue tests results, comparisons between groups were made by One Way ANOVA test, effect size 0.4 and significance level 0.05.

3. Results

A total of 20 samples were tested, 10 for each test. Within these, five samples were used in each group (test and control). All the specimens completed the mechanical tests, as planned. There was no statistically significant difference between groups for both, breakpoint and displacement. Break point in the test group was 1953.19±543.73 N, while, it was 2031.10±716.68 N in the control group. The difference was 77.90±504.56, and it was no statistically significant different (P=0.775). The displacement was 1.89±0.34 mm in the test group and 1.98±0.75 mm in the control group. The difference was 0.09±0.68, and it was no statistically significant different (P=0.763). Correlation between loading and displacement was found higher in the test group (0.842 versus 0.486). All the data are summarized in

Table 1.

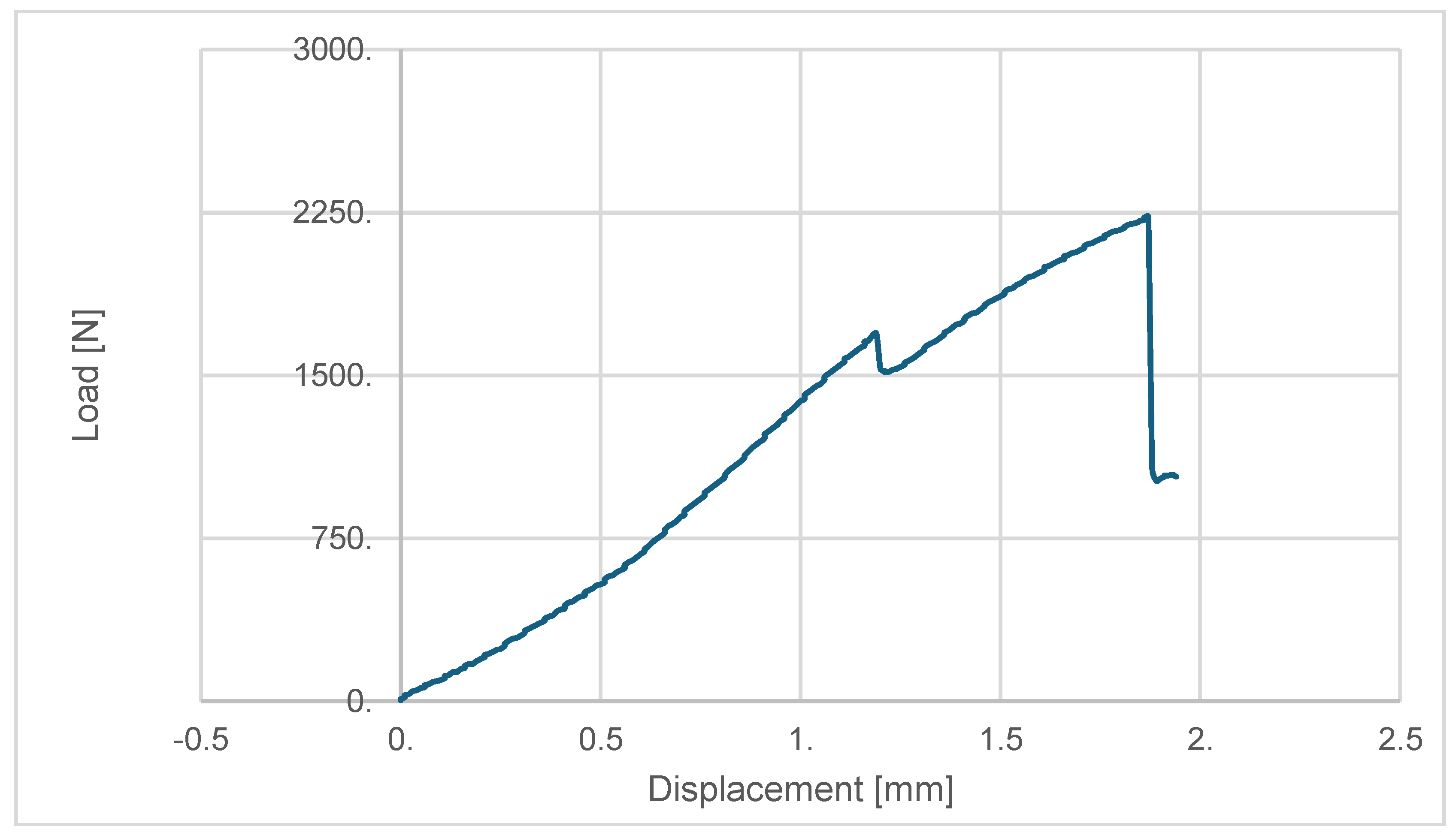

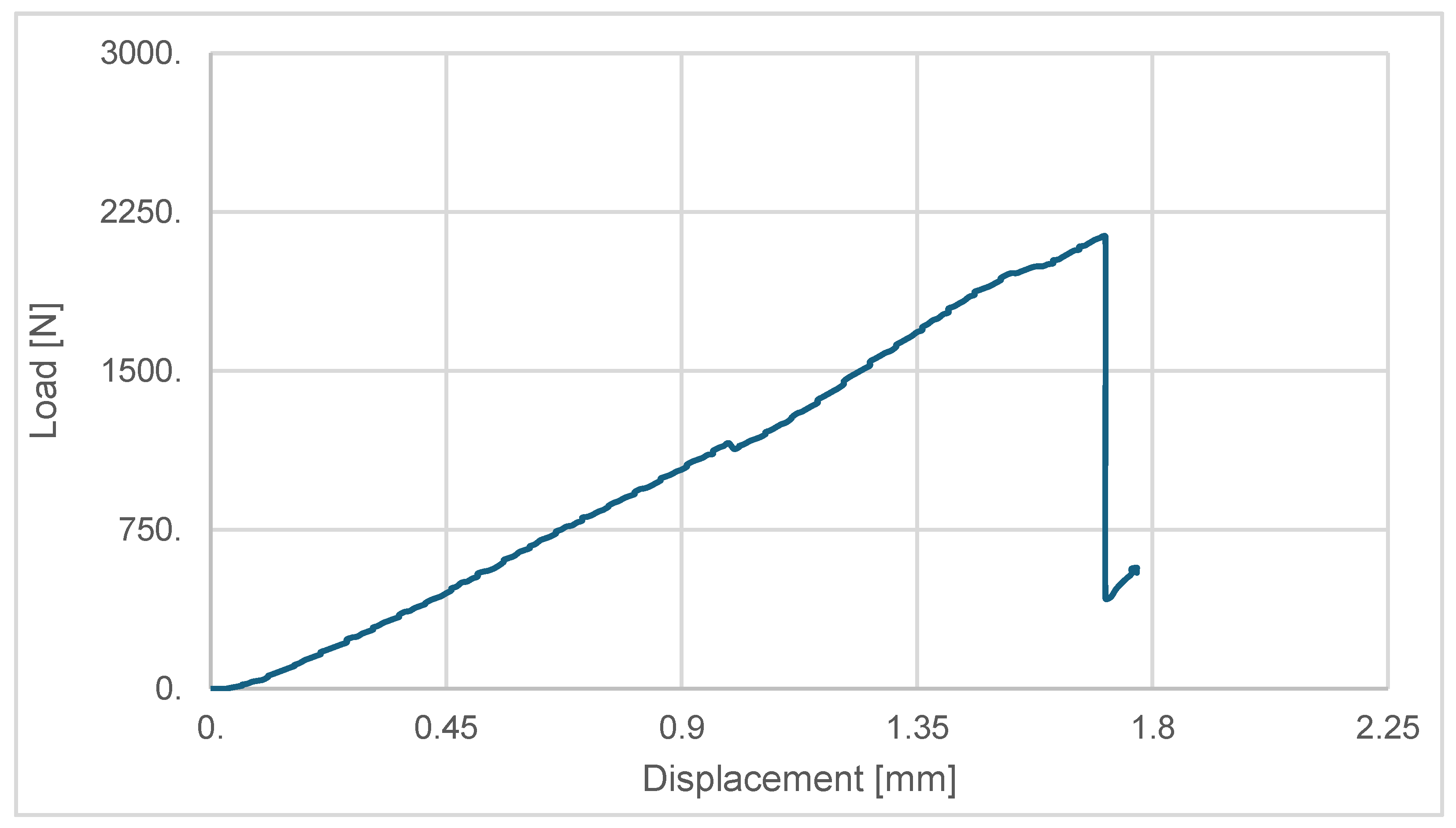

When analyzing the break points (

Figure 7 and

Figure 8), In the test group was noted a first minor crack at a mean loading value of 1400±274 N and displacement of 1.21±0.13. On the other hands, In the control group, the trend of the graph "load-displacement" was less consistent probably due to minor cracks in the PMMA material, supported by the metal reinforcement.

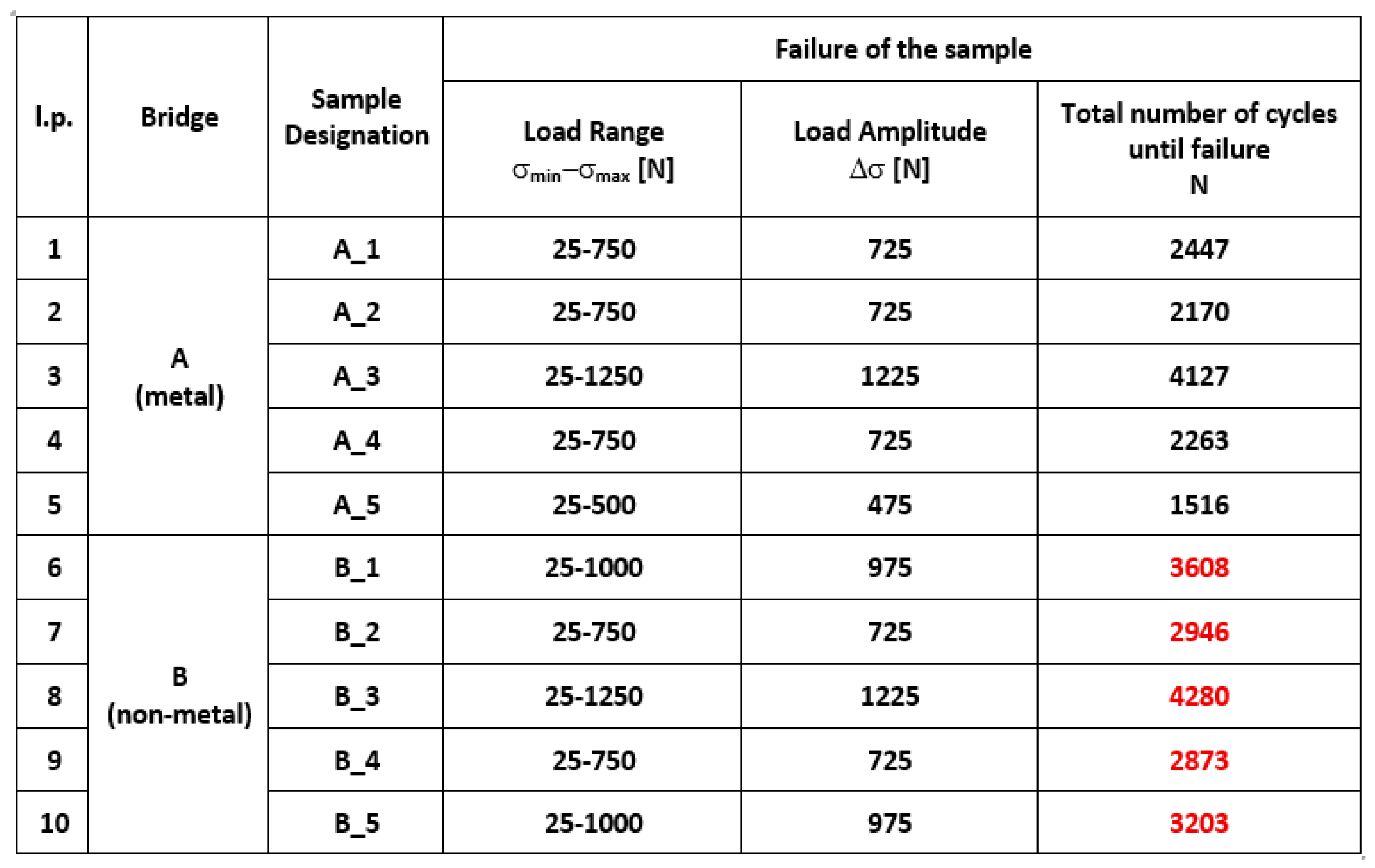

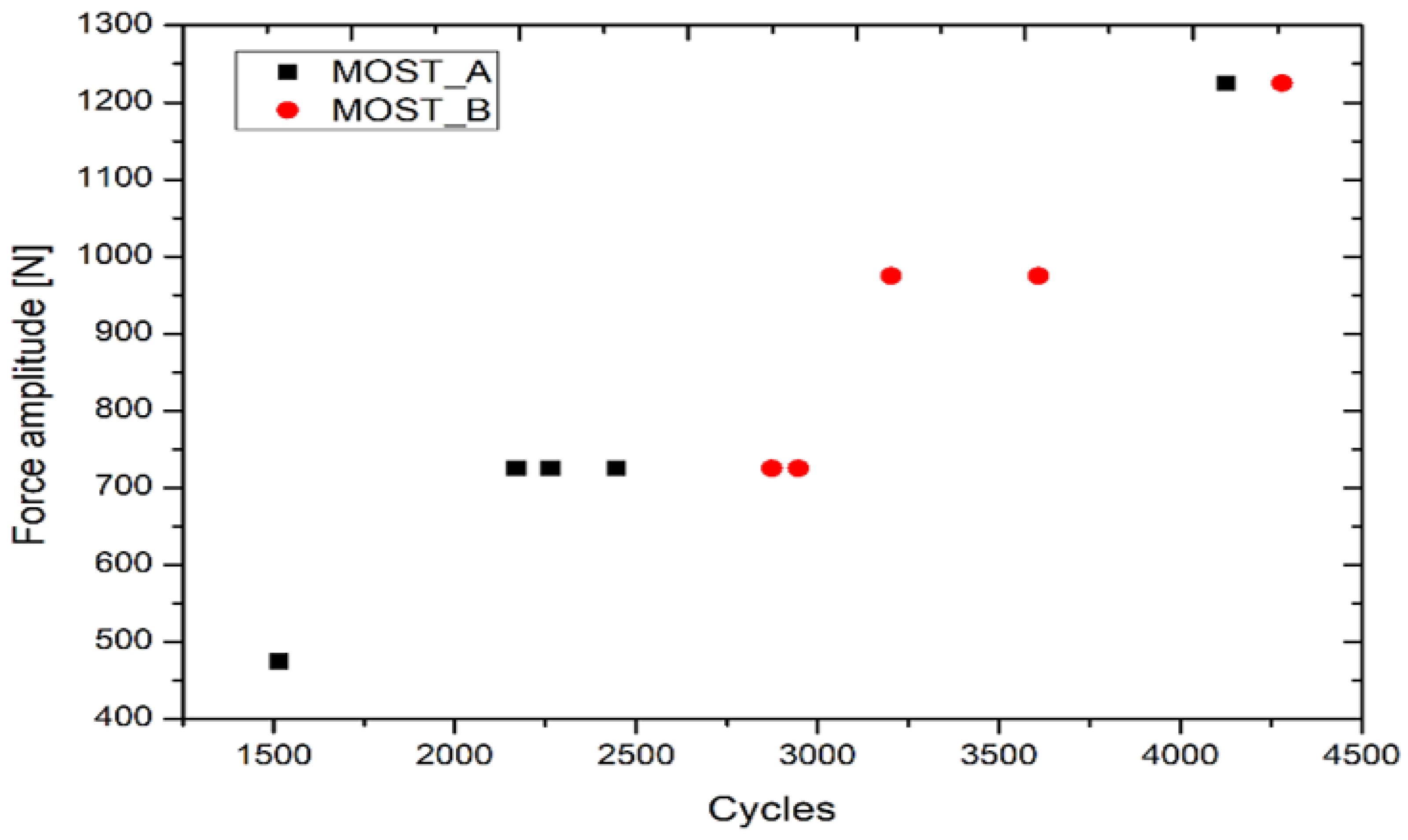

After successfully completing all the static load tests, the very same protocol was followed for the dynamic cyclic test; 10 samples were tested, and all the specimens completed the fatigue tests as planned. Based on the obtained data, the new polymer-based restorative material (ONLY) endured a greater number of load cycles before being damaged in any test. The threshold of each load at which the artifact failed (usually a fracture), along with the total number of cycles until failure, is reported in

Table 2 and

Figure 9.

Table 2.

Fatigue results for individual series of samples.

Table 2.

Fatigue results for individual series of samples.

Figure 9.

Load amplitude versus the number of cycles until failure for each sample series.

Figure 9.

Load amplitude versus the number of cycles until failure for each sample series.

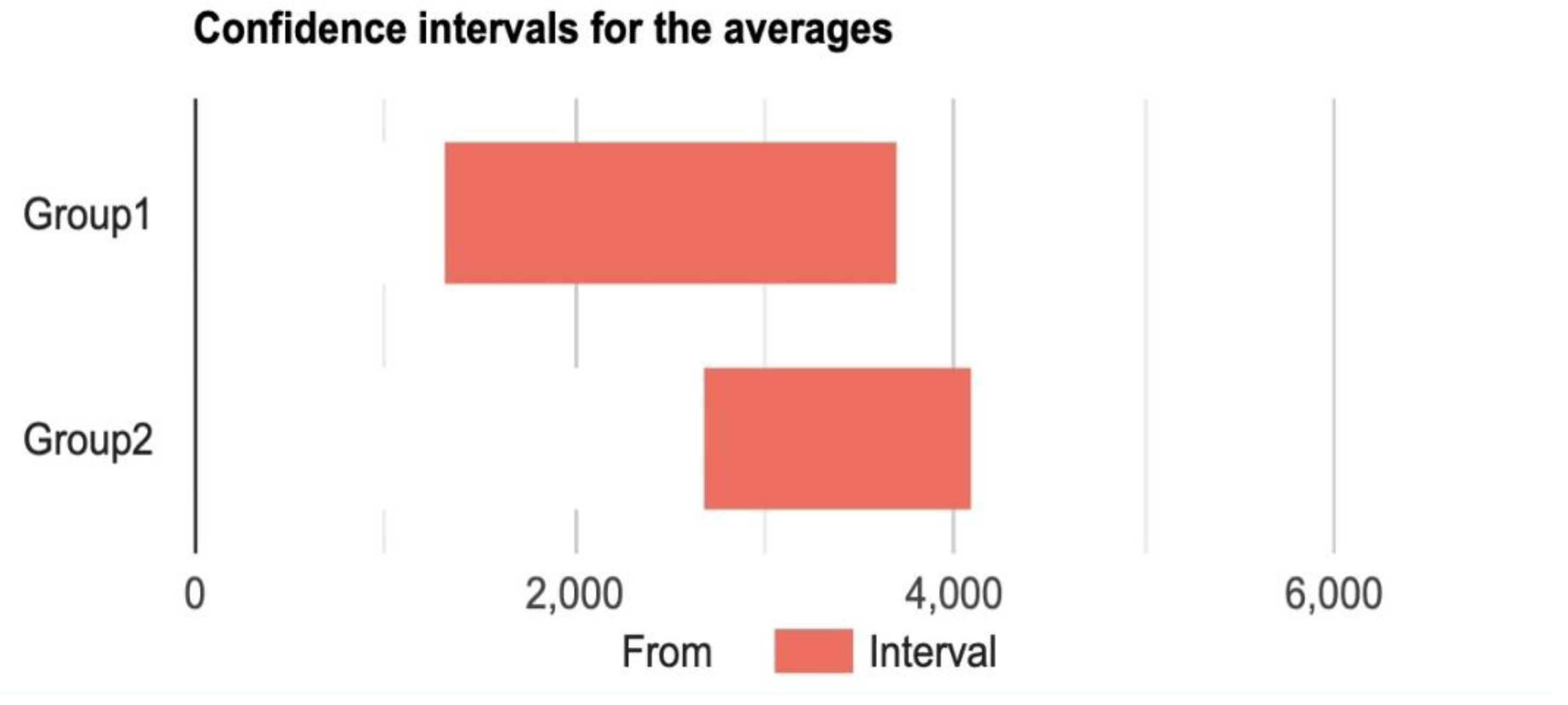

In the control group the mean value was 2504.6±972.15 N, while, in the test group the mean value was 3382±578.5 N. The averages of all groups assumed to be equal. The difference s between group was 877.4±579.3 (p value=0.121) N; p-value equals 0.121181, [p( x ≤ F ) = 0.878819]. It means that if we would reject H0, the chance of type1 error (rejecting a correct H0) would be too high: 0.1212 (12.12%). The bigger the p-value the stronger it supports H0. Since p-value > α, H0 is accepted. In other words, the difference between the sample averages of all groups is not big enough to be statistically significant.The test statistic F equals 3.006062, which is in the 95% region of acceptance: [0 : 5.3177]. The observed effect size f is large (0.61). That indicates that the magnitude of the difference between the averages is large. The η2 equals 0.27. It means that the group explains 27.3% of the variance from the average (similar to R2 in the linear regression). The normality assumption was checked based on the Shapiro-Wilk Test. (α=0.05). It is assumed that all the groups distribute normally or have a big sample size, at least 30.

The confidence intervals for the averages graphic shows that the ONLY composite has values that are more concentrated within the mean value, therefore more predictable, while the reinforced-PMMA displays a broader range of values on the graph (

Figure 10).

4. Discussion

This in vitro study was designed to evaluate a novel composite polymer, to load dental implants immediately. At today, the gold standard is to fabricate a metal-reinforced, PMMA, interim restoration. However, due to its advantages of easier manufacturing and handling, this new composite polymer, named ONLY, could replace the metal-reinforced PMMA. In the present research, the null hypothesis of no differences for load and displacement under compression test was accepted. Both materials demonstrated successful results. However, the novel composite polymer was tested as a monolithic material without reinforcement. This allows to easier design and milled temporary restoration, with potential lower costs. Moreover, chairside time needed to adapt and fix the temporary restoration onto the metal cylinders could be potentially reduced.

In the present research, in the control group, for all the PMMA samples, the load has a linear behavior until the brittle fracture point as in the figure below. On the other hands, in the test group, for all the composite samples the load has a linear behavior but before the fracture the graphics show a cheeping point as in the graphic below which could be due to friction effect of the StenleySteal puncher of INSTRON 4467 (

Figure 11).

While the compression tests showed that the two materials exhibited different types of fractures with varying patterns (due to the presence of metal in PMMA, which inevitably makes it less brittle than the ONLY composite; in the PMMA and metal restoration, the fractured portion was only the coating), from the fatigue tests, it was highlighted that most fractures occur at the interface between the metallic abutment and the ONLY material (

Figure 12); proving this to be the weakest point of the whole restoration.

Several benefits may results from this study. Polymethyl Methacrylate is commonly used in implant dentistry for the fabrication of implant-supported interim prostheses and as milled or 3D printed prototypes. Metal-reinforced temporary restoration can be easily produced and assembled before surgery, using computer-assisted, template-based surgery. However, some discrepancy between virtual implant planning and real implant placement can occur, even with modern template without metallic sleeves.[

10,

11] For the latter, interim restoration should be adjusted to be fixed onto the metallic cylinders. Using the novel composite polymer without metal reinforcement, may allow the clinician to easily adapt the interim restoration even in case of higher discrepancy with the virtual plan. This benefits is especially needed in case of complete edentulous patients, where the accuracy of guided surgery is lower. compared with partially edentulous patients.[

22]

Traditionally, metal-reinforced acrylics have been the materials of choice for temporary fixed implant-supported rehabilitations. However, as in the present research, novel protocols to prosthetically restore a completely edentulous patient following a digital workflow, with fixed, screw-retained, implant-supported prostheses fabricated from CAD/CAM milled polymethyl methacrylate, with no metal substructure has been proposed.[

23] In a clinical trial with two years follow-up, esthetics, phonetics, function and biological tissue response remain functional and free of mechanical, or biological complications.[

23] In the present in vitro research, an interim restoration without metal reinforcement has been tested. However, a novel composite polymer, with higher mechanical resistance, has been used. Even if clinical, long-term study are needed, the test material could be used as definitive restoration. Moreover, while this study provides valuable insights into the mechanical performance of the novel composite polymer, its in vitro nature inherently limits the extrapolation of findings to clinical scenarios. Clinical trials are imperative to gauge the material’s performance in the dynamic oral environment, considering factors like cyclic loading, thermal changes, and long-term stability. Additionally, investigating the biological responses, such as tissue compatibility and inflammatory reactions, is pivotal for assessing the material’s biocompatibility and ensuring patient safety. Future research endeavors should encompass comprehensive clinical studies, evaluating not only the mechanical aspects but also the material’s clinical functionality and biological responses, ultimately substantiating its viability as a reliable alternative in dental applications.

5. Conclusions

With the limitation of this in vitro study, the novel composite polymer can be safely used to immediately load dental implants as temporary restoration. However, further clinical researches are needed to confirm this preliminary results.

Author Contributions

Conceptualization, M.T. and S.C.; methodology, A.D.M. and I.K.; software, F.M.; validation, S.M.M. and A.I.L.; investigation, F.M., M.P., R.M.M.; resources, M.T. and G.C.; data curation, S.M.M.; writing—original draft preparation, M.T. and L.Z.; writing—review and editing, G.C. and M.P.; supervision, L.Z. and S.C.. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is available on request to Corresponding Author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leslie, P.; Broll, J. Eating, Drinking, and Swallowing Difficulties: The Impacts on, and of, Religious Beliefs. Geriatrics 2022, 7, 41. [CrossRef]

- Thorsteinsdottir, S.; Njardvik, U.; Bjarnason, R.; Olafsdottir, A.S. Changes in Eating Behaviors Following Taste Education Intervention: Focusing on Children with and without Neurodevelopmental Disorders and Their Families: A Randomized Controlled Trial. Nutrients 2022, 14, 4000. [CrossRef]

- Sasajima, M.; Yoshihara, A.; Odajima, A. Effects of Oral Function Training and Oral Health Status on Physical Performance in Potentially Dependent Older Adults. Int. J. Environ. Res. Public Health 2021, 18, 11348. [CrossRef]

- Ogino, Y. Oral Rehabilitation from Oral and Dental Diseases. Healthcare 2022, 10, 2065. [CrossRef]

- Lin, L.H.; Granatelli, J.; Alifui-Segbaya, F.; Drake, L.; Smith, D.; Ahmed, K.E. A Proposed In Vitro Methodology for Assessing the Accuracy of Three-Dimensionally Printed Dental Models and the Impact of Storage on Dimensional Stability. Appl. Sci. 2021, 11, 5994. [CrossRef]

- Sartoretto, S.C.; Shibli, J.A.; Javid, K.; Cotrim, K.; Canabarro, A.; Louro, R.S.; Lowenstein, A.; Mourão, C.F.; Moraschini, V. Comparing the Long-Term Success Rates of Tooth Preservation and Dental Implants: A Critical Review. J. Funct. Biomater. 2023, 14, 142. [CrossRef]

- Tallarico, M., Lumbau, A. M. I., Meloni, S. M., Ieria, I., Park, C. J., Zadrożny, L., Xhanari, E., & Pisano, M. (2022). Five-Year Prospective Study on Implant Failure and Marginal Bone Remodeling Expected Using Bone Level Implants with Sandblasted/Acid-Etched Surface and Conical Connection. European journal of dentistry, 16(4), 787–795. [CrossRef]

- Tallarico, M., & Meloni, S. M. (2017). Retrospective Analysis on Survival Rate, Template-Related Complications, and Prevalence of Peri-implantitis of 694 Anodized Implants Placed Using Computer-Guided Surgery: Results Between 1 and 10 Years of Follow-Up. The International journal of oral & maxillofacial implants, 32(5), 1162–1171. [CrossRef]

- Tallarico, M., Ceruso, F. M., Muzzi, L., Meloni, S. M., Kim, Y. J., Gargari, M., & Martinolli, M. (2019). Effect of Simultaneous Immediate Implant Placement and Guided Bone Reconstruction with Ultra-Fine Titanium Mesh Membranes on Radiographic and Clinical Parameters after 18 Months of Loading. Materials (Basel, Switzerland), 12(10), 1710. [CrossRef]

- Tallarico, M., Meloni, S. M., Canullo, L., Caneva, M., & Polizzi, G. (2016). Five-Year Results of a Randomized Controlled Trial Comparing Patients Rehabilitated with Immediately Loaded Maxillary Cross-Arch Fixed Dental Prosthesis Supported by Four or Six Implants Placed Using Guided Surgery. Clinical implant dentistry and related research, 18(5), 965–972. [CrossRef]

- Tallarico, M., Czajkowska, M., Cicciù, M., Giardina, F., Minciarelli, A., Zadrożny, Ł., Park, C. J., & Meloni, S. M. (2021). Accuracy of surgical templates with and without metallic sleeves in case of partial arch restorations: A systematic review. Journal of dentistry, 115, 103852. [CrossRef]

- Heboyan, A.; Zafar, M.S.; Karobari, M.I.; Tribst, J.P.M. Insights into Polymeric Materials for Prosthodontics and Dental Implantology. Materials 2022, 15, 5383. [CrossRef]

- Tigmeanu, C.V.; Ardelean, L.C.; Rusu, L.-C.; Negrutiu, M.-L. Additive Manufactured Polymers in Dentistry, Current State-of-the-Art and Future Perspectives-A Review. Polymers 2022, 14, 3658. [CrossRef]

- Estrin, N., Nam, K., Romanos, G. E., Saragossi, J., Iacono, V. J., & Bassir, S. H. (2023). Clinical Outcomes of Metal-Ceramic versus Metal-Acrylic Resin Implant-Supported Fixed Complete Dental Prostheses: A Systematic Review and Meta-analysis. The International journal of prosthodontics, 36(3), 354–365. [CrossRef]

- Tallarico, M., Canullo, L., Pisano, M., Peñarrocha-Oltra, D., Peñarrocha-Diago, M., & Meloni, S. M. (2016). An up to 7-Year Retrospective Analysis of Biologic and Technical Complication With the All-on-4 Concept. The Journal of oral implantology, 42(3), 265–271. [CrossRef]

- Papaspyridakos, P., Chen, C. J., Chuang, S. K., Weber, H. P., & Gallucci, G. O. (2012). A systematic review of biologic and technical complications with fixed implant rehabilitations for edentulous patients. The International journal of oral & maxillofacial implants, 27(1), 102–110.

- Chochlidakis, K., Einarsdottir, E., Tsigarida, A., Papaspyridakos, P., Romeo, D., Barmak, A. B., & Ercoli, C. (2020). Survival rates and prosthetic complications of implant fixed complete dental prostheses: An up to 5-year retrospective study. The Journal of prosthetic dentistry, 124(5), 539–546. [CrossRef]

- Jung, S. W., Fan, Y. Q., & Lee, C. (2022). Digital Workflow for Edentulous Patients with Implant-Supported Fixed Prostheses: A Fully Digital Technique. Dentistry journal, 10(9), 174. [CrossRef]

- Tallarico, M. et al. Digital Workflow for Prosthetically Driven Implants Placement and Digital Cross Mounting: A Retrospective Case Series. Prosthesis 4, 353–368 (2022).

- Paradowska-Stolarz, A.; Malysa, A.; Mikulewicz, M. Comparison of the Compression and Tensile Modulus of Two Chosen Resins Used in Dentistry for 3D Printing. Materials 2022, 15, 8956. [CrossRef]

- Pantea, M.; Ciocoiu, R.C.; Greabu, M.; Ripszky Totan, A.; Imre, M.; Țâncu, A.M.C.; Sfeatcu, R.; Spînu, T.C.; Ilinca, R.; Petre, A.E. Compressive and Flexural Strength of 3D-Printed and Conventional Resins Designated for Interim Fixed Dental Prostheses: An In Vitro Comparison. Materials 2022, 15, 3075. [CrossRef]

- Tahmaseb, A., Wu, V., Wismeijer, D., Coucke, W., & Evans, C. (2018). The accuracy of static computer-aided implant surgery: A systematic review and meta-analysis. Clinical oral implants research, 29 Suppl 16, 416–435. [CrossRef]

- Kotina, E., Hamilton, A., Lee, J.D., Lee, S.J., Grieco, P.C., Pedrinaci, I., Griseto, N.T., Gallucci, G.O. (2023). Milled PMMA, a Material for Long-Term Implant Supported Fixed Complete Dental Prostheses. International Journal of Prosthodontics, Epub ahead of print. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).