1. Introduction

Renewable energy technologies (RETs) are sustainable source of energy that operate without generating pollutants or particles associated with energy systems using fossil fuel [

1,

2]. Although RETs may not generate emissions during their operation stage, we have argued that a holistic view of the life cycle assessment of RETs, from cradle to grave, may reveal stages involving emissions or energy inefficiencies [

3]. For instance, before the operating stage of a RET, raw materials must have been obtained through local or global supply chains, subjected to various manufacturing processes, transported at different stages and subjected to an end-of-life management that may produce CO

2 and other pollutants.

Integrated photovoltaic-fuel cell (IPVFC) systems are RETs that include photovoltaic (PV) or photovoltaic-thermal (PV/T) module as prime mover; and a hydrogen generation module (electrolyser) and utilization module (fuel cell) as classified by Ogbonnaya et al. (2021). Functionally, a PV module generates electricity only while a PV/T module generates both electricity and hot air/hot water. Contextually, different configurations can be created from the modules to meet different use cases such as domestic, industrial, remote, transportation applications, thereby creating a family of IPVFC systems. These systems contributes to the decarbonisation of the energy infrastructure using solar energy, which is gaining serious traction particularly for producing blue solar hydrogen energy [

5,

6].

In Ogbonnaya [

7], domain-based systems thinking approach was shown to provide an opportunity for designers to create varieties of a system through permutations and combinations of parts. Domain-based thinking approach aligns with modularisation concept used in design and manufacturing of complex systems in several world-class organisations [

8]. Modularisation is a systematic decoupling of a system into modules that are independent of one another to enable customisation and mass production to meet variety of products demanded by customers [

9]. Modularisation can enable a company to achieve engineering economy, strategic flexibility, simplification of manufacturing processes and interchangeability of modules [

9]. Modularity in design is inherent in the composition of IPVFC systems because some functional modules can be manufactured by different companies across the globe whilst the final assembly can be done by a company leveraging global supply chains [

10]. Modularity in design is applied in software design but it is very relevant in the design of complex engineered systems and subsequent manufacturing management decisions to meet the requirements of customers [

11,

12].

The problem of study is, although applying modularisation in designing the family of IPVFC systems has benefits, a misalignment or mismanagement of the manufacturing strategy may create wasteful inventory management and cost inefficiencies. In lean manufacturing typified by Toyota production system, having excess inventory is gravely problematic because it will tie down cash thereby reducing the liquidity of the firm, prompt excess production of products that were not demanded and trigger a need for additional space to store excess products, and increase cost of labour without a significant contribution to profitability [

13]. Although these problems could be faced by manufacturers of the family of IPVFC systems, there are no previous studies that provided insights into how the multiple plausible configurations as well as the difficulty in determining demand can enable lean and agile manufacturing of the systems. Considering the concept of variety-volume relationships in characterizing products [

14], there is a need to determine if IPVFC systems will be better distributed based on make-to-order, assemble-to-order or other postponement strategies. Consequently, determining the customer order decoupling point (CODP) for members of the family of IPVFC systems could offer an alignment between engineering, manufacturing and supply chains; and ultimately provide a competitive advantage based on a combination of lean and agile manufacturing strategies. Jan [

15] proposed that using a dual design approach in which CODP can integrate production and supply chain could improve the overall effectiveness of operations.

Furthermore, based on Marshal Fisher’s matrix for matching supply chains of products in order to reduce demand uncertainties [

16], IPVFC systems can be classified under innovative products which require responsive supply chain strategy. Thus, by adopting lean and agile principles in manufacturing of IPVFC systems [

17], manufacturers and operators can achieve sustainable and profitable outcomes. A massive use of IPVFC systems for different applications is beneficial in achieving cleaner energy access which is very important in realising several goals within the Sustainable Development Goals (SDGs) [

1].

Therefore, the motivation of this study is to provide manufacturing perspectives on how to increase the contribution of the family of IPVFC systems to electrical, thermal and hydrogen energy. To determine whether modularity in design should be explored as the cornerstone for the manufacturing strategy of the family of IPVFC systems, the following null and alternate hypotheses were set forward.

Null hypothesis (H0): All customers prefer photovoltaic-battery-inverter system configuration (System 1).

Alternate hypothesis (HA): Not all customers prefer photovoltaic-battery-inverter system configuration (System 1).

The overarching aim of this research was to determine the manufacturing strategy that can be effective in serving customers who prefer certain configurations, consequent upon the outcome of the hypothesis testing. The specific objectives of this research were to:

Collect data to test the hypothesis.

Study the modularity in the design of IPVFC systems.

Analyse the implications of modularity in design for manufacturability.

Propose the optimal manufacturing strategy for the family of IPVFC systems.

The significance of this study is that it is the first study to explore the manufacturing strategy aspect of IPVFC systems as well as provide supply chain management insights for researchers, designers, manufacturers and investors. This study advanced our previous work on design methodologies, energy and exergy analysis, modelling and simulations of PV, PV/T and thermophotovoltaic systems [

18,

19,

20,

21] and IPVFC systems [

4,

10,

22,

23]. This paper contributes to knowledge on the design methodology to facilitate manufacturing as well as manufacturing strategy to guide the supply chain network design to deliver IPVFC systems to end-users.

The description of the IPVFC systems including potential applications is presented in the next section. This is followed by a presentation of the research methods adopted for realising the research objectives.

Section 4 presents the results and critical discussions on the survey results and model-based systems analysis. Conclusions from the study were presented in

Section 5.

2. Description of the Family of Integrated Photovoltaic-Fuel Cell (IPVFC) Systems

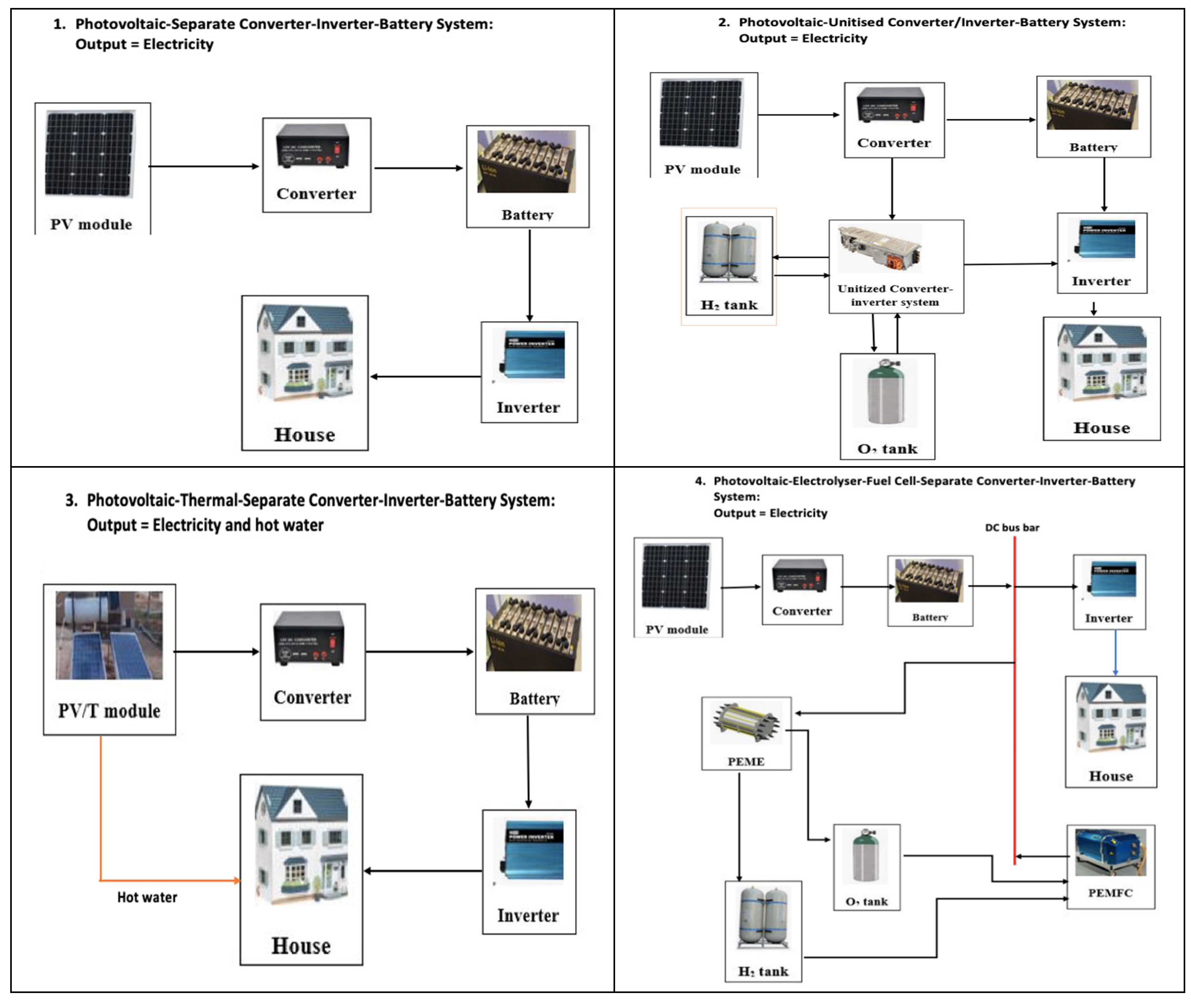

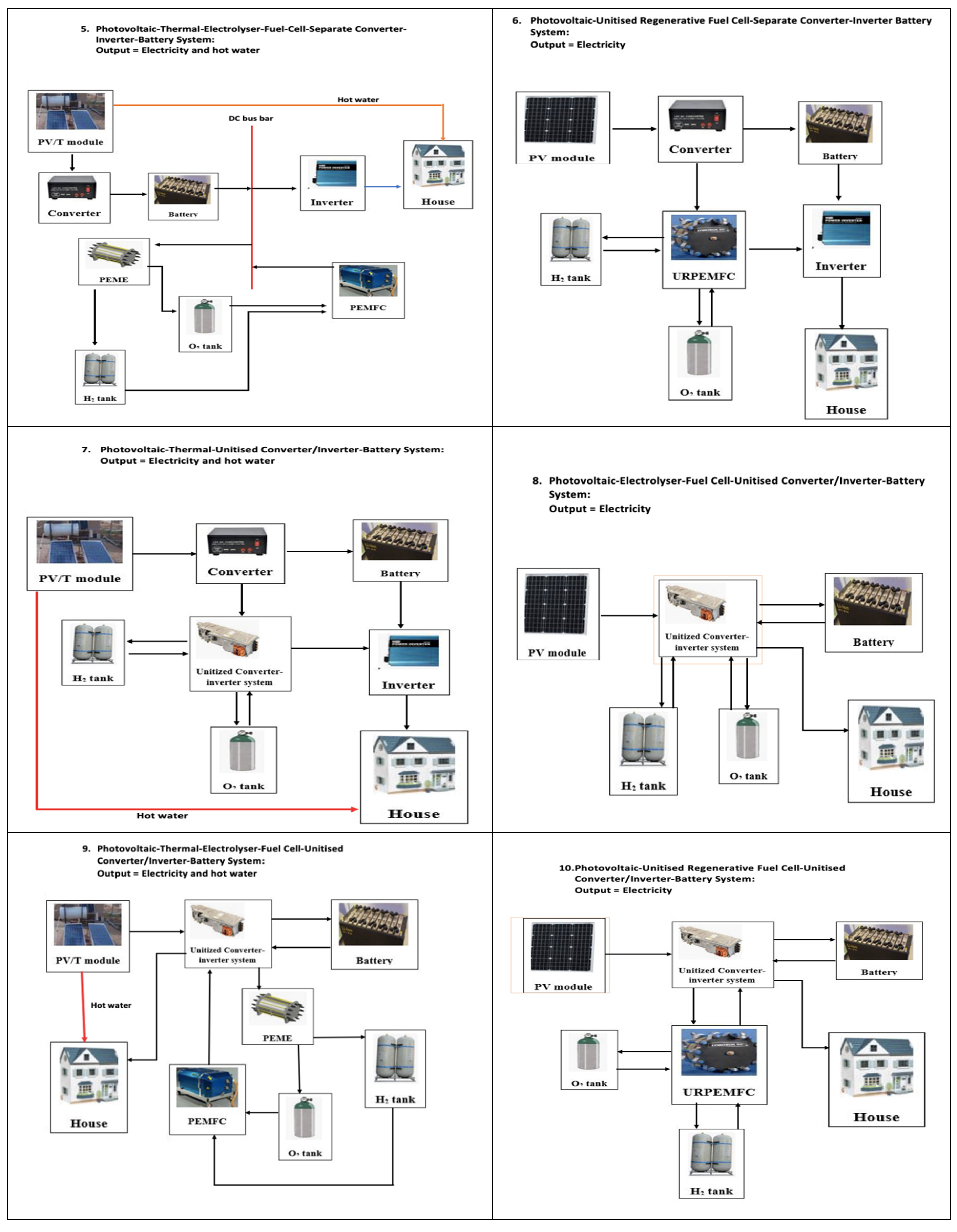

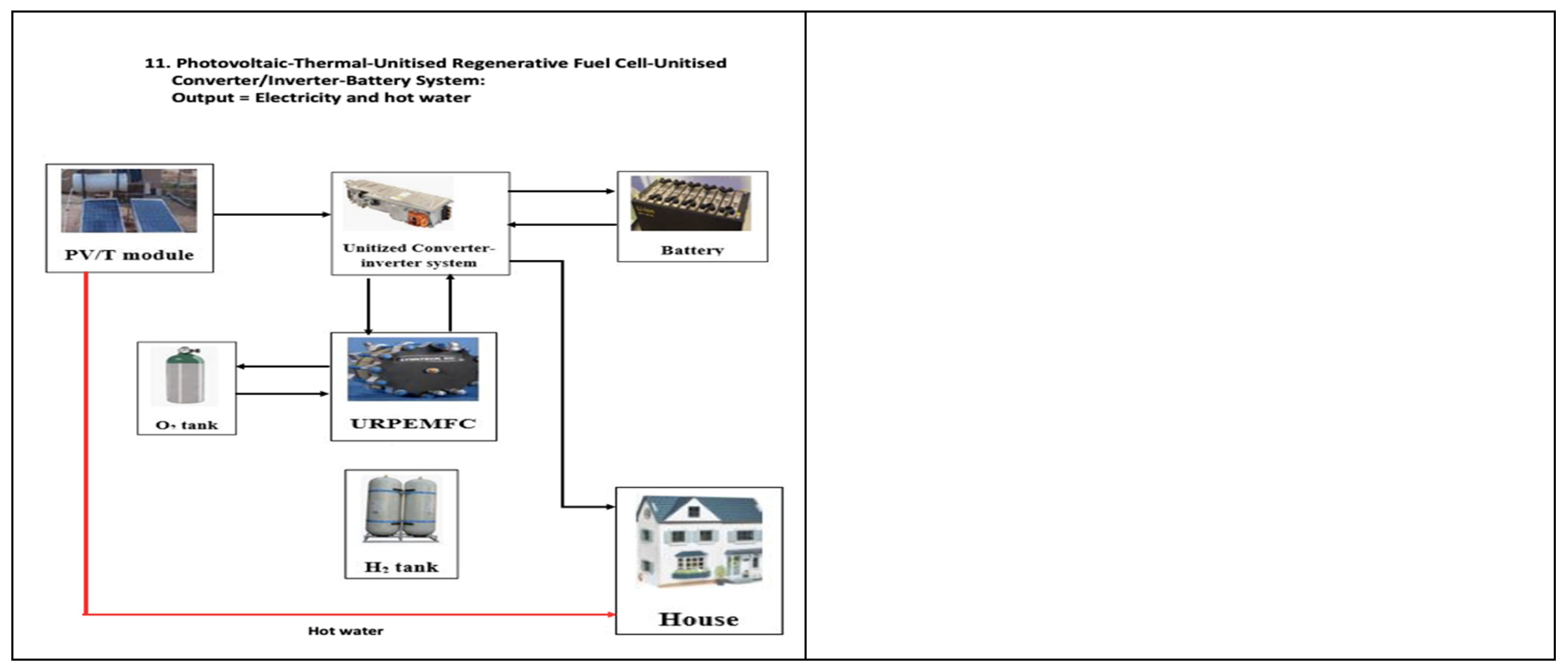

The members of the family of IPVFC systems use solar energy, which is the most abundant renewable energy source in nature, to generate electricity or electricity and hot air/water. This section will apply domain-based systems thinking and model-based systems engineering to propose eleven configurations that will be the focus of this study. There could be other configurations within the design space depending on the creativity, innovation, technical ability and resources at the disposal of designers or manufacturers.

Table 1 presents the composition of the IPVFC systems with their reference number. To facilitate interpretation, “separate” means that the modules exist independently. An example is “separate converter and inverter” which is written with a hyphen (-) as a convention. The two modules can be combined into one module to create a unitised converter/inverter system, which is written with a slash sign (/) as a convention. The purpose of unitisation is to reduce the cost and complexity of the overall system and also manufacture the two modules from the same factory to reduce the risks of sourcing the two modules from different locations. These interpretations applies to the combination of separate electrolyser and fuel cell into unitised regenerative fuel cell systems that can generate hydrogen as well as reverse the process to generate electricity at a reduced cost and complexity [

24].

Systems 1, 2, 4, 6, 8 and 10 produce electricity as the functional output. This implies that the applications of any of the systems is for generation of electrical energy. The use of electrolyser and fuel cell was to conserve excess electrical energy that may be generated by the PV module more than the capacity of the batteries. Adding electrolyser and fuel cell also add reliability and robustness to the systems since solar energy is not available at night or during unfavourable weather conditions; meanwhile having a back-up power supply could be mission critical for some use cases.

Systems 3, 5, 7, 9 and 11 produce both electrical and thermal energies that can be used for diverse applications depending on the end-use. This design has improved exergy efficiency because more solar energy is harnessed from the same surface area. Nonetheless, there is an increased complexity and cost associated with the extraction, transportation and storage of thermal energy. The diagrams representing the eleven systems are presented in the Appendix section.

The family of IPVFC system can be used for domestic and industrial applications, in electric and hydrogen cars, for remote power source during camping, exploration and mining activities, in boats and unmanned aerial vehicles, and as distributed power generators in schools, hospitals, markets, parks, religious buildings, library, ICT hubs in developing countries with no reliable power supply from the national grid.

3. Research Methodology

There were three approaches adopted in this study. First was a domain-based systems thinking approach which employs creative and analytic thinking processes to explore the interrelationships between the domains of design, function, use case, manufacturing, supply chain and demand of the family of IPVFC systems in a systematic way [

7]. Domain-based systems and systematic thinking enabled a contextualisation of the complexities around the systems under consideration. Each member of the family of IPVFC systems is a system with inputs, processes and outputs. The manufacturing firm that can assemble the systems is conceptualised as a system in which the modules, labour, capital, processes, information, technologies, etc can be used to facilitate an assemble of IPVFC systems. The supply chain network design creates a system in which raw materials and information flow from one partner to another to ultimately satisfy the needs of the end-users of IPVFC system.

The second method incorporated into this study was model-based system engineering to explore a wide range of system configurations based on models instead of an experimental approach which will be quite expensive. The model-based approach focused on the modular architecture to allow design changes to be made to subassemblies [

25]. An example is utilising waste heat from PV module to heat fluid thereby creating a PV/T module [

19]. The fundamental thermodynamic principle in creating variants was based on an attempt to utilise waste energy to perform additional thermal work; and this drove the complexity and cost of the IPVFC system [

26]. Unitisation was used as a design principle to merge two closely related modules to create a single module as in unitised regenerative fuel cell and unitised converter/inverter module.

Table 2 shows the number of modules used to create the eleven systems from the design space containing PV, PV/T, BAT, INV, CON, UCONV/INV, EL, FC and URFC.

The third method used in this study was an online survey to get original data from respondents to test the hypothesis and gain insights into the level of demand based on the choices of the respondents. Google form was used to create an online survey, which contains only one question, but it included all the images of the family of IPVFC systems in the Appendix section. The question was:

“If you wanted one of the IPVFC systems to be developed for you, which one would it be?”.

The respondents were instructed in the description to act as a customer who needs one of the IPVFC systems and choose a system that they think will be suitable for them. The description of the outputs of the eleven systems was presented alongside the images showing the components. The images improved the visual appeal of the systems and made the systems easily distinguishable. The online survey was distributed on various methods including asking individuals directly to complete it via email, posting the survey on LinkedIn, WhatsApp groups and Facebook.

Pareto analysis was used to rank the choices of the respondents. The result was further processed to facilitate a discussion on the manufacturing management of the family of IPVFC systems.

4. Results and Discussion

To systematically explore manufacturing strategies for the family of IPVFC systems, the first endeavour was to examine the hypothesis in the light of the survey data to address research objective 1. The second task was to discuss the modularity in design of the family of IPVFC systems to address research objective 2. The insights from research objectives 1 and 2 were contextualised to determine the manufacturing and management principles that can facilitate the manufacturing of the family of IPVFC systems.

Hypothesis testing generally depends on the framing of the null and alternate hypotheses. In this case, the null and alternate hypothesis were stated thus:

The assumption behind the hypothesis construction was that System 1 might be preferred by a significant number of respondents based on ubiquity, familiarity, cost, complexity, efficiency, functionality and sustainability. These are some possible reasons that the respondents are likely to base their single choice. System 1 is the most used member of the family of IPVFC system, and it is the cheapest as well. All the customers are aware that it does not use fossil fuel and therefore, it is a sustainable energy system which uses solar energy as primary source of energy to achieve certain functionality. Determining the overall efficiency of the system is a technical decision and our previous study clearly concluded that increasing the complexity of IPVFC system will increase the cost but it must not necessarily increase the efficiency [

26].

The second point that needs contextualising is that applying central limiting theorem [

3] to generate more data was not necessary in this study because the construction of the hypothesis sought to establish the level of deviation of demand of other systems from System 1 to inform the manufacturing strategy. In other words, if a significant number of respondents chose System 1, it is justifiable not to explore manufacturing strategies to cater for the family of IPVFC systems. Alternatively, if respondents chose significantly different IPVFC systems, it becomes justifiable to seek manufacturing strategies that are appropriate for a low volume and high variety products.

From

Table 1, only 17% of respondents chose System 1. Although System 1 ranked second which tends to validate that respondents may have chosen the system because of its ubiquity, familiarity, simplicity and cost-effectiveness, the percentage falls significantly below average. This implies that the null hypothesis should be rejected whilst the alternate hypothesis should be accepted that “Not all customers prefer photovoltaic-battery-inverter system configuration (System 1)” even with its perceived ubiquity, familiarity, simplicity and cost-effectiveness. Although 17% preference for System 1 is significant compared to four members of the family of IPVFC systems (Systems 2, 6, 8 and 9) that got only 2% of the responses, it only indicates that there is a likelihood that the demand for System 1 will be among the top 42% of the total demand.

Table 3.

Results of the survey on the family of IPVFC Systems.

Table 3.

Results of the survey on the family of IPVFC Systems.

| Systems |

Module composition |

Respondents |

Cumulative |

Percent |

| System 3 |

Photovoltaic-Thermal-Separate Converter/Inverter-Battery System |

13 |

13 |

25% |

| System 1 |

Photovoltaic-Separate Converter-Inverter-Battery System |

9 |

22 |

42% |

| System 7 |

Photovoltaic-Thermal-Unitised Converter/Inverter-Battery System |

8 |

30 |

57% |

| System 11 |

Photovoltaic-Thermal-Unitised Regenerative Fuel cell -Unitised Converter/Inverter-Battery System |

7 |

37 |

70% |

| System 10 |

Photovoltaic-Unitised Regenerative Fuel cell -Unitised Converter/Inverter-Battery System |

5 |

42 |

79% |

| System 5 |

Photovoltaic-Thermal-Electrolyser-Fuel Cell-Separate Converter-Inverter-Battery System |

4 |

46 |

87% |

| System 4 |

Photovoltaic-Electrolyser-Fuel Cell-Separate Converter-Inverter-Battery System |

3 |

49 |

92% |

| System 2 |

Photovoltaic-Unitised Converter/Inverter-Battery System |

1 |

50 |

94% |

| System 6 |

Photovoltaic-Unitised Regenerative Fuel cell -Separate Converter-Inverter-Battery System |

1 |

51 |

96% |

| System 8 |

Photovoltaic-Electrolyser- Fuel cell -Unitised Converter/Inverter-Battery System |

1 |

52 |

98% |

| System 9 |

Photovoltaic-Thermal-Electrolyser- Fuel cell -Unitised Converter/Inverter-Battery System |

1 |

53 |

100% |

| Total |

|

|

53 |

|

An interesting result that emerged from this study was that respondents chose Systems 3, 7, 11 and 5 that contained PV/T modules, and this agrees with our previous study on energy and exergy analysis of IPVFC systems, in which the efficiency of IPVFC systems with PV/T were higher than equivalent systems with PV module [

26]. This may explain why System 3, which was described as having the capacity to produce electricity and hot water/air, ranked first. This means that the respondents may have considered the functionality of a system that can generate two forms of energy (electrical and thermal) and the ranking of System 3 was validated by trailing PV/T-based Systems 7, 11 and 5. System 9 has a PV/T component but the perception of complexity may have affected how respondents evaluated it. It is normal to think that the acquisition cost and the operating cost of a complex system will be higher than that of a simpler system as was also established in Ogbonnaya [

26]

These findings support modularisation strategy to achieve alignment in the manufacturing of modules that can be used to configure different members of the family of IPVFC systems to meet customers’ needs. Grouping the products based on the prime mover (PV or PV/T) can facilitate a speedy assessment of the requirements of the configuration demanded by the customer. During assembly operation, not all the stations where the modules are stored will be visited every time a customer’s order is fulfilled. From

Table 4, it is apparent that all the systems require battery. This information is of strategic relevance because a company assembling IPVFC systems may decide to invest in manufacturing the battery module since all the systems need the battery. For every demand of any of the IPVFC system, battery module will be demanded, thereby creating a dependent demand scenario in which the demand for batteries varies with the number of systems demanded and the capacity of the IPVFC system. This vertical integration strategy to manufacture battery can be embedded into a manufacturer’s firm depending on the strategic choices of the firm. It may be more profitable and efficient to outsource the manufacturing of the battery while the firm focuses on the downstream part of the supply chain.

There are two scenarios considered in this study – a layout in which assembly can take place and a layout in which components are stored and dispatched to meet order. These scenarios are presented with an acknowledgement that the manufacturing layout or warehouse layout is not cast in stone. As such, the overall layout depends on the existing manufacturing system or the strategic objectives of the firm. In this study, the assumption was that the firm assembles the system onsite. In other words, the facility is used as a warehouse to store the components such that the components can be picked and quality checked before delivered and installed in the end-user’s location. This can also serve a scenario where the customer wishes to install the system using their engineers. The supply chain implication is that some modules can be sent to the site from the original equipment manufacturer (OEM) thereby reducing the logistic implications of moving the modules to the warehouse first, storing them before moving them to the location of installation.

On the other hand, the assembly layout requires complete or partial assembly and testing before the IPVFC system is transported to the end-user’s location for final installation and testing for quality assurance. This will not be suitable for large-scale installations. Again, the business strategy and performance objectives of the organisation will determine how the assembly layout will be configured. The schematic diagram in Figure 1 shows the highest level of abstraction of the possible U-shape layout of the storage of the modules. It does not show the detailed flow of parts of the modules, wiring requirements, system health monitoring devices (temperature, pressure, humidity, flow rate, etc), instrumentation, piping, storage systems, etc. These details can be provided and possibly standardised by the manufacturer to facilitate lean and agile manufacturing processes. This will require a firm-based manufacturing systems engineering and additional research to plan the value stream mapping to achieve a lean and agile operation.

Figure 1.

Proposed Warehouse layout for onsite installation.

Figure 1.

Proposed Warehouse layout for onsite installation.

The proposed layout is designed to manage the manufacturing of all the members of the family of IPVFC systems. An example of how an order for System 1 can be fulfilled as been illustrated. Initially, modules received from original equipment manufacturers (OEMs) are checked for quality. The modules can then be stored at clearly marked stations or storage area. When an order is placed, the relevant modules required to configure the system are picked up and checked for quality. The modules can be assembled onsite or within the facility depending on the nature of the operation. To reduce inventories at the OEM level, it may be appropriate to adopt make-to-order based on the dependent demand of the manufacturers that will adopt assemble-to-order based on the demand specifications from the customers. Due to uncertainties in the demand of the systems, there is a need to adopt a collaborative approach with all the partners in the supply chain to maintain an efficient and stable supply chain dynamics,

5. Conclusions

This study explored how the family of Integrated Photovoltaic-Fuel Cell Systems can be manufactured based on lean and agile principles, leveraging the inherent modularity in design of the systems. To achieve this, model-based systems engineering, domain-based systems thinking, and the use of an online survey were employed.

Of the eleven systems proposed in this study, the Photovoltaic-Thermal-Separate Converter/Inverter-Battery System (System 3) received 25% of the responses. Only 17% of respondents chose the Photovoltaic-Separate Converter-Inverter-Battery System (System 1). Although System 1 ranked second which tends to validate that respondents may have chosen the system because of its ubiquity, familiarity, simplicity and cost-effectiveness, the percentage falls significantly below average, thereby necessitating the alternate hypothesis that supports modularisation. Nonetheless, 17% preference for System 1 was significant compared to four members of the family of IPVFC systems (Systems 2, 6, 8 and 9) that received only 2% of the responses; but this indicated that there was a likelihood that the demand for System 1 will be among the top 42% of the total demand for the family of IPVFC systems. The demand pattern suggested that a systemic and systematic configuration of the manufacturing operation and supply chain of the components of the family of IPVFC systems could meet customer demand whilst reducing inefficiencies and waste due to inventory management.

Overall, the manufacturing system configuration preferred by a manufacturer will depend on the nature of the company, strategy of the company and the performance objectives of the company. While there are research opportunities to implement these findings, it can be concluded that modularity in design inherent in the family of IPVFC systems should be managed through appropriate design of the supply chain networks and an operation that is inclined towards lean and agile manufacturing operations.

Author Contributions

Conceptualization, CO. and GH.; methodology, CO and GH.; software, GH.; validation, CO; formal analysis, CO and GH.; investigation, GH.; resources, CO; data curation, GH; writing—original draft preparation, GH; writing—review and editing, CO; visualization, GH; supervision, CO; project administration, GH; All authors have read and agreed to the published version of the manuscript.”.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Acknowledgments

Thank you for the feedback Dr Ehsan Sabet.

Conflicts of Interest

The authors declare no conflicts of interest.

Appendix: Configurations of the Family of IPVFC Systems

References

- Ogbonnaya, C.; Abeykoon, C.; Damo, U.M.; Turan, A. The Current and Emerging Renewable Energy Technologies for Power Generation in Nigeria: A Review. Therm. Sci. Eng. Prog. 2019. [Google Scholar] [CrossRef]

- Dincer, I. Renewable Energy and Sustainable Development: A Crucial Review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Turan, A.; Abeykoon, C. Novel Thermodynamic Efficiency Indices for Choosing an Optimal Location for Large-Scale Photovoltaic Power Generation. J. Clean. Prod. 2020. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Abeykoon, C.; Nasser, A.; Turan, A.; Ume, C.S. Prospects of Integrated Photovoltaic-Fuel Cell Systems in a Hydrogen Economy: A Comprehensive Review. Energies 2021. [Google Scholar] [CrossRef]

- Nnabuife, S.G.; Ugbeh-Johnson, J.; Okeke, N.E.; Ogbonnaya, C. Present and Projected Developments in Hydrogen Production: A Technological Review⁎. Carbon Capture Sci. Technol. 2022. [Google Scholar] [CrossRef]

- Fay, M.; Hallegatte, S.; Vogt-Schilb, A.; Rozenberg, J.; Narloch, U.; Kerr, T. Decarbonizing Development: Three Steps to a Zero-Carbon Future; The World Bank, 2015; ISBN 978-1-4648-0479-3.

- Ogbonnaya, C. Domain-Based Systems and Systematic Thinking; KDP Publishing: Great Britain, 2024. [Google Scholar]

- Melton, H.; Tempero, E. Towards Assessing Modularity. In Proceedings of the First International Workshop on Assessment of Contemporary Modularization Techniques (ACoM ’07); IEEE, May 2007; pp. 3–3. [Google Scholar]

- Persson, M.; Åhlström, P. Managerial Issues in Modularising Complex Products. Technovation 2006, 26, 1201–1209. [Google Scholar] [CrossRef]

- Ogbonnaya, Chukwuma; Turan, Ali; Abeykoon, C. Modularization of Integrated Photovoltaic-Fuel Cell System for Remote Distributed Power Systems. In Industry 4.0 – Shaping The Future of The Digital World; CRC Press, 2020; p. 6 ISBN 9780367823085.

- Garcia, A.; Greenwood, P.; Heineman, G.; Walker, R.; Cai, Y.; Yang, H.Y.; Baniassad, E.; Lopes, C.V.; Schwanninger, C.; Zhao, J. Assessment of Contemporary Modularization Techniques - ACoM’07. ACM SIGSOFT Softw. Eng. Notes 2007, 32, 31–37. [Google Scholar] [CrossRef]

- Pakkanen, J.; Juuti, T.; Lehtonen, T.; Mämmelä, J. Why to Design Modular Products? Procedia CIRP 2022, 109, 31–36. [Google Scholar] [CrossRef]

- Monden, Y. TOYOTA Production System: An Integrated Approach to Just-In-Time, Fourth Edition; Taylor & Francis Group, LLC: Boca Raton, 2011; ISBN 9781466504516. [Google Scholar]

- Slack, Nigel; Brandon-Jones, Alistair; Burgess, N. Operations Management; 10th ed.; Pearson, 2022; ISBN 9781292408248.

- Olhager, J. The Role of the Customer Order Decoupling Point in Production and Supply Chain Management. Comput. Ind. 2010, 61, 863–868. [Google Scholar] [CrossRef]

- FISHER, M.; HAMMOND, J.; OBERMEYER, W.; RAMAN, A. CONFIGURING A SUPPLY CHAIN TO REDUCE THE COST OF DEMAND UNCERTAINTY. Prod. Oper. Manag. 1997, 6, 211–225. [Google Scholar] [CrossRef]

- Ogbonnaya, C. LEAN and AGILE SERVICES: Inspiring Service Industry Change Through Story: The Lean Thinking Way.; KDP Publishing: Great Britain, 2023. [Google Scholar]

- Ogbonnaya, C.; Turan, A.; Abeykoon, C. Robust Code-Based Modeling Approach for Advanced Photovoltaics of the Future. Sol. Energy 2020, 199, 521–529. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Turan, A.; Abeykoon, C. Numerical Integration of Solar, Electrical and Thermal Exergies of Photovoltaic Module: A Novel Thermophotovoltaic Model. Sol. Energy 2019, 185, 298–306. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Abeykoon, C.; Nasser, A.; Turan, A. A Computational Approach to Solve a System of Transcendental Equations with Multi-Functions and Multi-Variables. Mathematics 2021. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Abeykoon, C.; Nasser, A.; Turan, A. Radiation-Thermodynamic Modelling and Simulating the Core of a Thermophotovoltaic System. Energies 2020. [Google Scholar] [CrossRef]

- Ogbonnaya, C.; Abeykoon, C.; Nasser, A.; Ume, C.S.; Damo, U.M.; Turan, A. Engineering Risk Assessment of Photovoltaic-Thermal-Fuel Cell System Using Classical Failure Modes, Effects and Criticality Analyses. Clean. Environ. Syst. 2021, 2, 100021. [Google Scholar] [CrossRef]

- Ogbonnaya, C. Integrated Photovoltaic-Fuel Cell Generation Methodologies: Design, Development and Optimisation for Distributed Applications., The University of Manchester, United Kingdom, 2021.

- Ogbonnaya, C.; Abeykoon, C.; Nasser, A.; Turan, A. Unitized Regenerative Proton Exchange Membrane Fuel Cell System for Renewable Power and Hydrogen Generation: Modelling, Simulation, and a Case Study. Clean. Eng. Technol. 2021, 4, 100241. [Google Scholar] [CrossRef]

- Hansen, P.K.; Sun, H. Complexity in Managing Modularization. In Proceedings of the 2011 International Conference on Information Management, Innovation Management and Industrial Engineering; IEEE, November 2011; pp. 537–540.

- Ogbonnaya, C.; Turan, A.; Abeykoon, C. Energy and Exergy Efficiencies Enhancement Analysis of Integrated Photovoltaic-Based Energy Systems. J. Energy Storage 2019, 26, 101029. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).