1. Introduction

Ethiopia is characterized by a complex geological structure and rugged topography, with extremely diverse hydrogeological conditions. These include (a) Neoproterozoic, low to high-grade metamorphic rocks that are part of the Arabian-Nubian Shield, overlain by (b) platform sedimentary units ranging from the Lower Paleozoic to the Paleogene, as seen in the large Ogaden Basin, Blue Nile Basin, and Mekele Basin, and (c) Eocene to Holocene volcanic rocks and volcaniclastic deposits associated with the active NNE-SSV trending Main Ethiopian Rift [

1,

2]. Especially in light of these specific natural factors, Ethiopia faces a pressing challenge in ensuring access to clean and sustainable water sources for its burgeoning population. With over 60 million people lacking access to clean water, Ethiopia ranks among the countries with the lowest water supply coverage in sub-Saharan Africa [

3]. Compounded by climate variability, recurrent droughts and geological risks associated with slope deformations the country’s water resources are under significant strain, threatening the livelihoods and well-being of millions of Ethiopians [

4]. Inadequate infrastructure and poor water management exacerbate the situation, further deepening the water crisis in both rural and urban areas [

5]. Utilizing groundwater presents a promising avenue for mitigating water stress and ensuring sustainable water access in Ethiopia. Groundwater resources, if managed effectively, offer a reliable and resilient water source, particularly in regions where surface water availability is limited or erratic [

6]. However, unlocking the potential of groundwater requires strategic decision-making in well drilling and placement.

Well drilling decision-making holds significant importance in optimizing groundwater utilization for sustainable development in Ethiopia. The strategic placement of wells with regard to hydrogeological conditions can enhance water access, improve agricultural productivity, and support rural livelihoods. Moreover, optimizing well placement and layout is essential for ensuring the long-term sustainability of groundwater resources. By strategically locating wells and optimizing their layout, we can minimize water wastage, reduce energy consumption, and mitigate the risk of groundwater depletion. This holistic approach to groundwater management not only benefits farming communities but also contributes to broader societal goals such as poverty reduction, food security, and environmental sustainability [

7].

There are two main optimization techniques that have been applied in well placement problems: conventional optimization methods and non-conventional methods. Conventional optimization methods have been extensively employed for well placement optimization in utilizing groundwater for irrigation. Drawing insights from a previous study [

8], conventional approaches often utilize mathematical programming techniques such as linear programming (LP), nonlinear programming (NLP), integer programming (IP), mixed-integer programming (MIP), stochastic mixed integer programming (SMIP), and adjoint methods. In 2014, Tafteh et al. formulated a LP model for the optimization of irrigation water distribution [

9]. Studies by authors such as Ma et al. (2019) [

10] and Kuvichko and Ermolaev (2020) [

11] have demonstrated the efficacy of MIP in optimizing well locations. Also, research by Liu et al. (2015) has optimized the layout of pumping wells based on NLP models for irrigation planning and management [

12]. Additionally, Halilovic et al. (2022) introduced a new gradient-based optimization method using the adjoint approach for well layouts in groundwater heat pumps, facilitating continuous well locations and accommodating a large number of wells. Their method demonstrates versatility in optimizing layouts for multiple neighboring or single systems, as evidenced by a real case study involving 10 systems, showcasing its practical applicability [

13]. Furthermore, the study by Bayer et al. in 2008 introduced a novel approach to solving stochastic optimization problems with multiple equally probable realizations of uncertain parameters, utilizing dynamically ordered stacks of realizations during the search process. By applying this technique to a water supply well field design problem, the study demonstrates that simple stack ordering can significantly reduce computational effort by up to 97% without compromising optimization results, offering promise for similar water management and reliability-based design challenges [

14]. However, despite their ability to ensure optimality under certain conditions, conventional methods may encounter challenges, such as getting trapped in local optima.

In contrast, gradient-free optimization methods as non-conventional methods present promising alternatives for well placement optimization in irrigation systems, offering robustness against complex objective functions and solution spaces. Researchers such as Emerick et al. (2009) implemented a genetic algorithm to optimize the number and location of the wells [

15]. Investigations by researchers such as Sharifipour et al. (2021) have explored the application of shuffled frog leaping algorithm, particle swarm optimization and genetic algorithm in optimizing well placement problems. They found that the shuffled frog leaping algorithm outperformed other algorithms, demonstrating superior objective function values and well spacing in both intermediate and late optimization stages [

16]. These gradient-free optimization techniques, as highlighted in [

8], do not rely on gradient information and employ diverse search strategies to explore solution spaces iteratively. While they provide flexibility and scalability, a notable disadvantage of gradient-free optimization methods is their potential for slower convergence compared to gradient-based methods, which can result in longer computational times, particularly for high-dimensional optimization problems and large-scale irrigation systems. AlQahtani et al. (2013) conducted a comparison between evolutionary metaheuristics and mathematical optimization methods for the well placement problem. Their study revealed that mathematical optimization outperformed genetic algorithms by yielding superior solutions in a shorter computational timeframe [

17].

Many previous research studies have investigated the optimization of pumping well layouts to enhance groundwater extraction efficiency. However, some of the studies focus on deterministic models that may not adequately account for the uncertain water demand and the need for sustainable groundwater development [

9,

10,

11,

12,

18]. Additionally, some papers have relied on simplified models that assume an infinite aquifer, overlooking the potential risks of groundwater depletion and adverse environmental impacts [

10,

12]. To ensure the sustainable development of groundwater resources, it is essential to incorporate groundwater level and recharge parameters into the optimization model. By considering the variability of groundwater levels and recharge rates over different space, as well as the finite nature of aquifers, these parameters can provide valuable insights into the long-term viability of well placement strategies. Moreover, integrating sustainability constraints into the optimization framework can help balance water extraction with aquifer replenishment, thus safeguarding groundwater resources for future generations.

In this study, we chose to use mixed-integer programming (MIP) and two-stage stochastic mixed-integer programming (SMIP) over non-conventional methods such as genetic algorithms or shuffled frog leaping. The primary reason for this choice is the deterministic nature of MIP and its proven effectiveness in handling well placement optimization problems with precise constraints and objectives. Additionally, two-stage SMIP allows us to incorporate uncertainty in demand scenarios, providing a more robust solution under varying conditions. While non-conventional methods like genetic algorithms and shuffled frog leaping offer flexibility and robustness, they often require more computational effort and may not guarantee optimal solutions. Our initial focus on MIP and two-stage SMIP was due to their structured approach and computational efficiency, making them suitable for the preliminary phase of this research.

This study aims to model and optimize optimal drilling locations to minimize costs while meeting farm demand and ensuring sustainable groundwater development for subsistence agriculture in water-scarce regions. To achieve this objective, deterministic mixed-integer programming (MIP) and two-stage stochastic mixed-integer programming models are constructed. The two-stage stochastic model offers the benefit of long-term planning by considering uncertain demand scenarios. Therefore, our focus in this study is on the two-stage SMIP. These models are developed using predicted groundwater levels [

19] and estimated groundwater recharge [

20] from our previous studies conducted in a larger region that encompasses the current study area. The specific study area selected for analysis is a small region in the western flank of the the Bilate watershed (westernmost part of the Sidama Region) in southern Ethiopia.

In this study, we explore uncertain demand scenarios for the two-stage SMIP, employing various distributions, and compare the resulting outcomes. Additionally, we present maps illustrating the layout of wells for each experiment and include an analysis of the impact of selected parameters. The remainder of this paper is organized as follows:

Section 2 delineates the problem formulation for both the deterministic and stochastic models and provides an overview of the study area and the data utilized;

Section 3 offers a comprehensive presentation of the main results from the optimization models and shows optimal well layouts;

Section 4 discusses the impact of different parameters and provides an analysis on out-of-sample performance; finally,

Section 5 concludes the paper, summarizing key findings and suggesting potential avenues for future research.

3. Results

In this study, the Gurobi solver was used to address the optimization problems, ensuring efficient and accurate solutions [

29]. The software tools employed included Python 3.12 for scripting and algorithm implementation [

30], and QGIS 3.24.1 for geographic data processing and visualization [

31]. These tools provided a robust framework for developing and analyzing the well placement optimization problem.

3.1. Model Optimization Results

Three models were employed in this study: a deterministic mixed-integer programming (MIP) model with demand values set at 800, 900, 1000, 1100, and 1200; a two-stage stochastic mixed-integer programming (SMIP) model with demand scenarios randomly generated from different uniform distributions (U(400, 1200), U(500, 1300), U(600, 1400), U(700, 1500), and U(800, 1600)); and another two-stage SMIP model with demand scenarios randomly generated from five different normal distributions with means of 800, 900, 1000, 1100, and 1200, each with a standard deviation of 300. The means of the demand scenarios generated from each uniform distribution are 800, 900, 1000, 1100, and 1200, which match the settings of the deterministic MIP model. A similar rationale applies to the two-stage SMIP model with the normal distribution. The results show that the average total costs for the three models were 42,264,421, 42,298,103, and 42,317,641, respectively (Table 4.1).

Table 1.

Results for the optimization models.

Table 1.

Results for the optimization models.

| Deterministic MIP with fixed demand |

|---|

| Demand (kg/km2) |

800 |

900 |

1000 |

1100 |

1200 |

Average |

| Optimized number of wells |

43 |

44 |

45 |

46 |

46 |

45 |

| Total costs (USD) |

42177807 |

42224273 |

42265578 |

42306933 |

42347516 |

42264421 |

| Total fixed construction costs (USD) |

215000 |

220000 |

225000 |

230000 |

230000 |

224000 |

| Total drilling costs (USD) |

41719176 |

41728938 |

41738701 |

41748463 |

41758326 |

41738721 |

| Total transportation costs (USD) |

243631 |

275335 |

301877 |

328470 |

359190 |

301700 |

| Two-stage SMIP (Demand scenarios: uniform distribution) |

| Demand Instance |

U(400, 1200) |

U(500, 1300) |

U(600, 1400) |

U(700, 1500) |

U(800, 1600) |

Average |

| Optimized number of wells |

45 |

45 |

46 |

46 |

46 |

45.6 |

| Total costs (USD) |

42215743 |

42256368 |

42297266 |

42339950 |

42381187 |

42298103 |

| Total fixed construction costs (USD) |

225000 |

225000 |

230000 |

230000 |

230000 |

228000 |

| Total drilling costs (USD) |

41748893 |

41758756 |

41768351 |

41778241 |

41787793 |

41768406 |

| Total transportation costs (USD) |

241850 |

272612 |

298915 |

331709 |

363394 |

301696 |

| Two-stage SMIP (Demand scenarios: normal distribution) |

| Demand Instance |

N(800, 300) |

N(900, 300) |

N(1000, 300) |

N(1100, 300) |

N(1200, 300) |

Average |

| Optimized number of wells |

44 |

44 |

46 |

46 |

46 |

45.2 |

| Total costs (USD) |

42233743 |

42275352 |

42316817 |

42360022 |

42402269 |

42317641 |

| Total fixed construction costs (USD) |

220000 |

220000 |

230000 |

230000 |

230000 |

226000 |

| Total drilling costs (USD) |

41762470 |

41772055 |

41783204 |

41793020 |

41802142 |

41782578 |

| Total transportation costs (USD) |

251273 |

283297 |

303613 |

337002 |

370127 |

309062 |

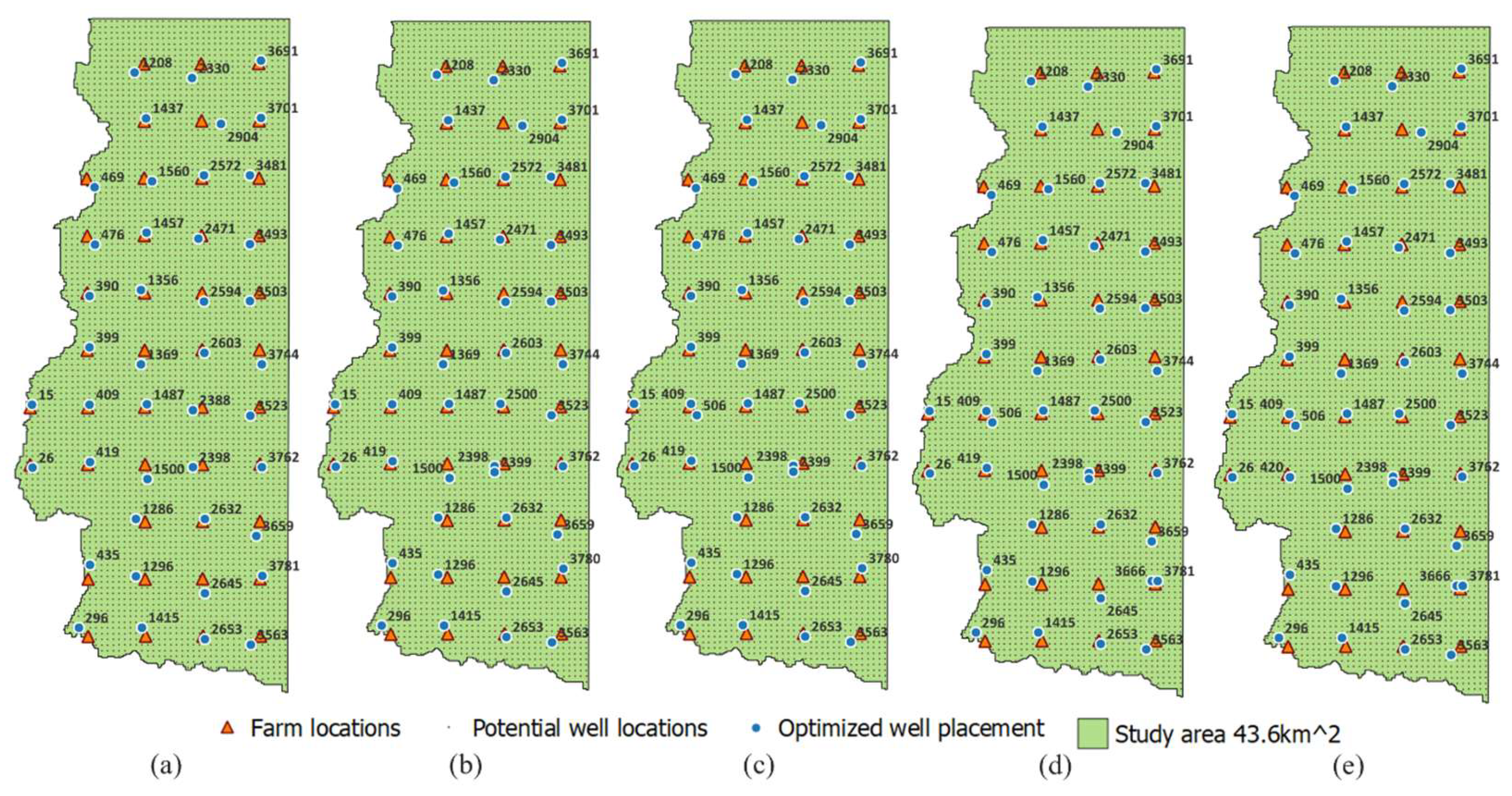

3.2. Optimal Well Layouts

As demand values increased in the deterministic MIP model, the number of wells placed also increased, leading to higher total costs. For uniform distribution demand scenarios, slightly more wells were placed, but the total costs were lower than those from models with demand scenarios generated from a normal distribution, possibly due to deeper wells being placed, leading to higher drilling costs.

Table 1 summarizes the optimized number of wells, total costs, and cost components for the three models.

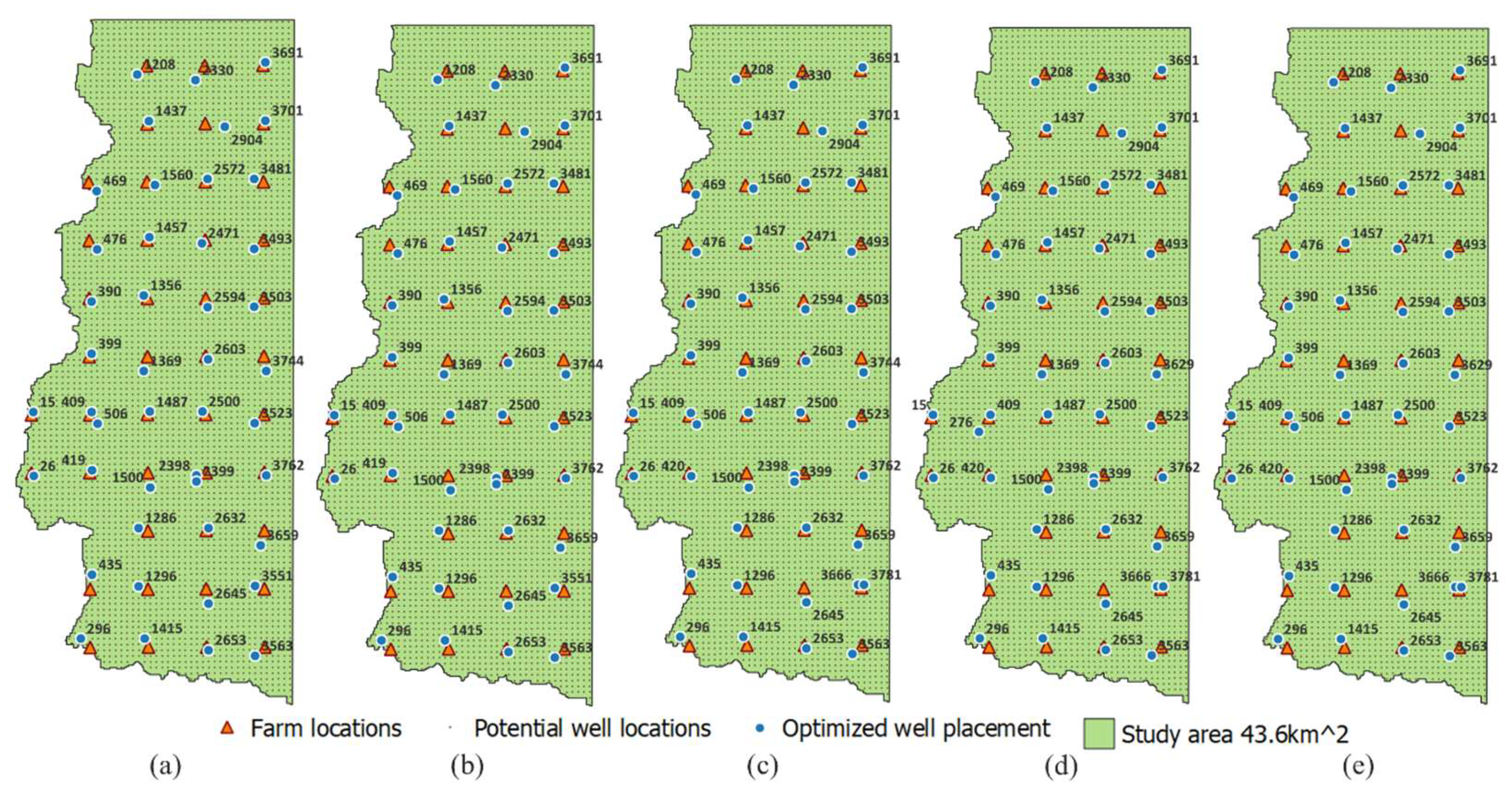

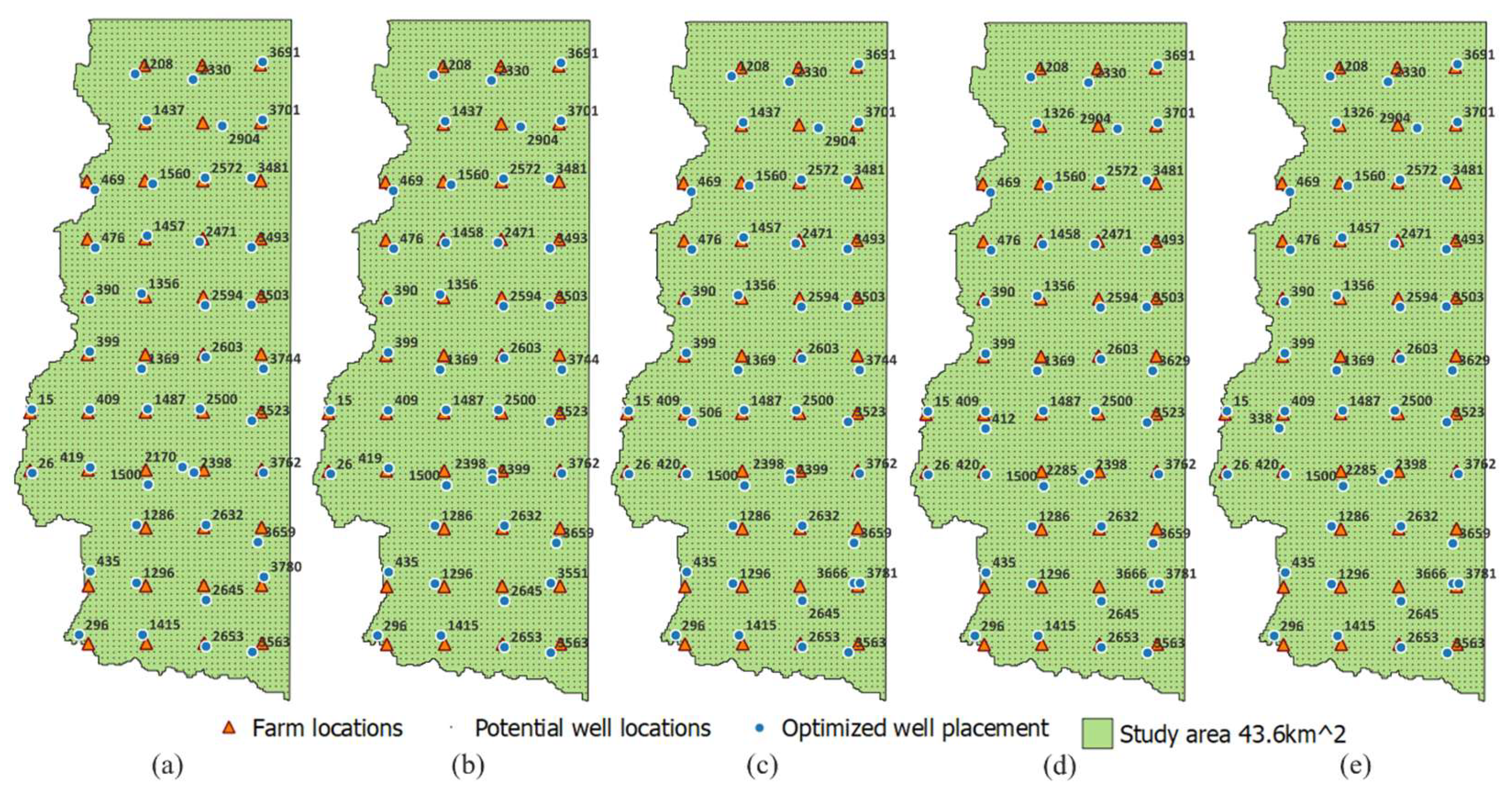

Maps were created to illustrate the optimized well placement for each experiment and each model (

Figure 4,

Figure 5 and

Figure 6). In the deterministic MIP model experiments, well placements/layouts were largely similar, with differences observed in the placement of wells 419, 420, 506, 3666, 3780, and 3781 across experiments based on assumed water demand. For the two-stage SMIP model using different uniform distributions, wells 276, 419, 420, 3551, 3666, 3781, 3629, and 3744 were placed slightly differently across experiments. With an increase in the mean demand, the number of wells placed slightly increased. In the two-stage SMIP model using a normal distribution, decisions regarding the placement of wells 338, 419, 420, 506, 1457, 1458, 2170, 2398, 2285, 3551, 3629, 3666, 3744, 3780, and 3781 varied slightly across models.

4. Discussion

4.1. Impact of Different Parameters

In this study, we consider the experiment for the uniform distribution U(600, 1400) for the demand scenarios of the two-stage SMIP as the base model. The impact of different parameters demonstrated in this section are created based on this model.

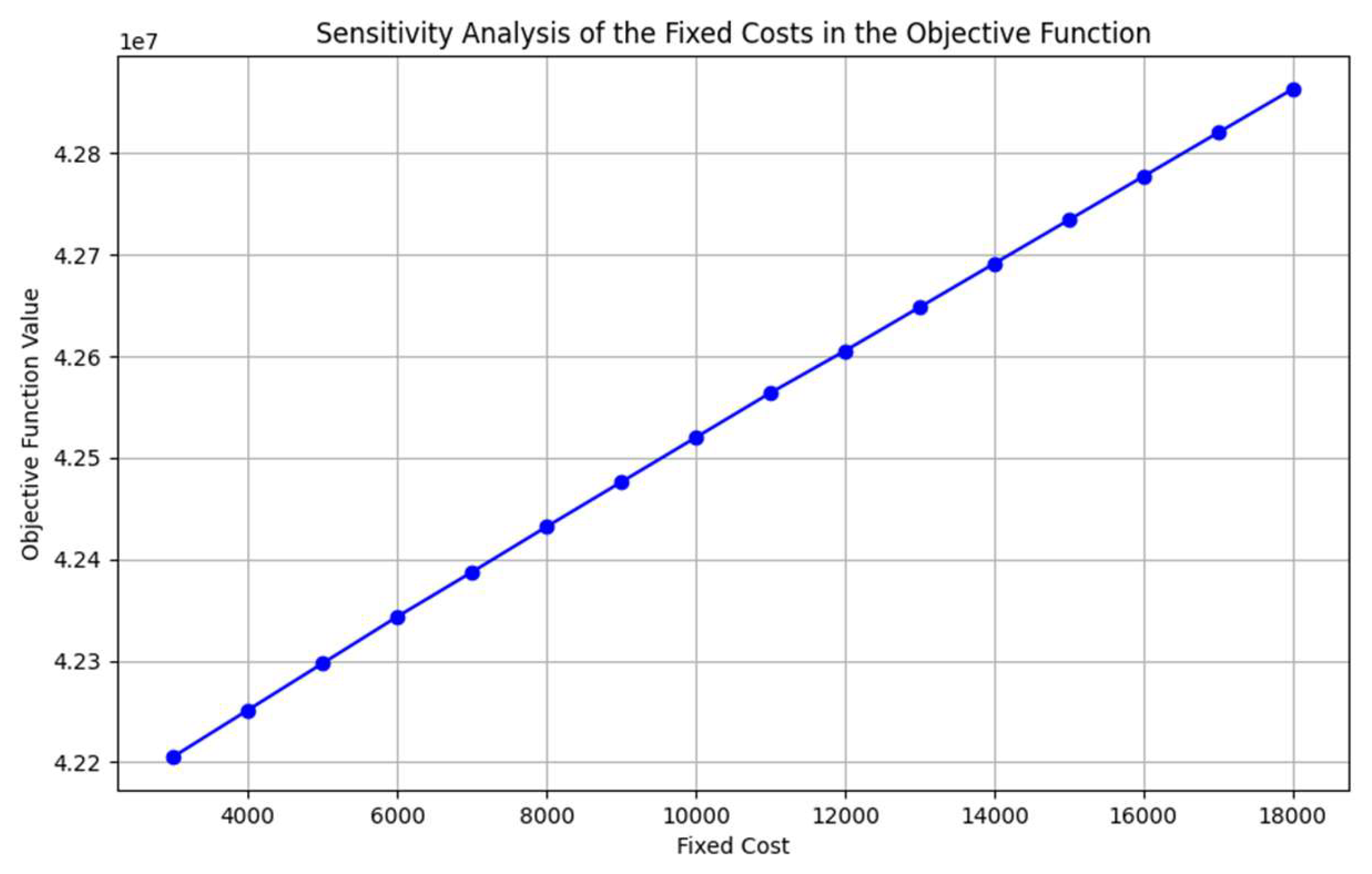

4.1.1. Impact of Different Fixed Construction Costs

The fixed construction costs are the coefficients of the decision variable

(whether to place a well at location

j). The objective total costs include three components: total fixed construction costs, total per-meter drilling costs (also known as unit costs), and total transportation costs. The range of fixed construction costs is set from 3000 to 18000, with an increment of 1000. As the fixed construction costs increase (

Figure 7), the total costs also rise.

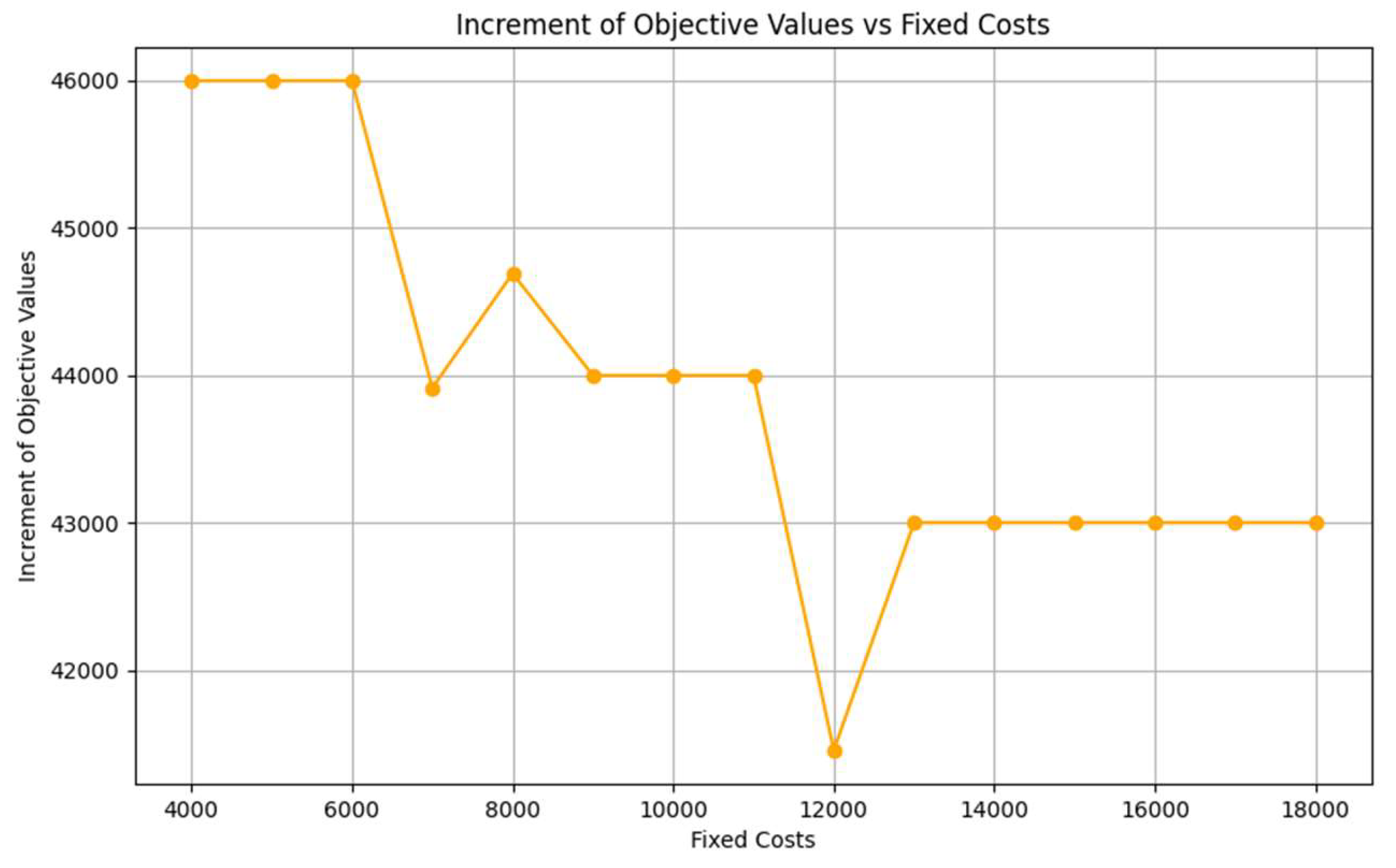

The differences between consecutive objective values are calculated and plotted in

Figure 8. From this plot, we can see that when the fixed cost increases from 5000 to 6000, the difference between the objective values is 46000. When the fixed cost increases from 6000 to 7000, the difference is approximately 44000. This clear drop from 46000 to 44000 occurs because, when the fixed cost increases from 6000 to 7000, the total number of wells placed decreases from 46 to 45. Additionally, the well layout changes, indicating that the model chooses to drill deeper wells with higher drilling costs rather than maintaining the same number of wells with higher construction costs to minimize the total costs. Another observation is an increase in total cost from 44,000 to 44,700. This occurs because, when the fixed costs increase from 7,000 to 8,000, the number of wells decreases from 45 to 44. Consequently, the well layout changes to satisfy the water demand, leading to approximately 7,600 higher transportation costs and 100 higher per-meter drilling cost at the 8,000 fixed cost compared to the 7,000 fixed cost. Additionally, there is a notable drop in total cost from 44,000 to 41,454. This decrease happens because, when the fixed costs increase from 11,000 to 12,000, the number of wells to be placed decreases from 44 to 43. Subsequently, the number of wells placed remains constant at 43, resulting in a consistent difference of 43000 in objective values as the fixed construction cost increases by increments of 1000.

4.1.2. Impact of Different Per-Meter Drilling Costs

The per-meter drilling costs are the coefficient of the decision variable

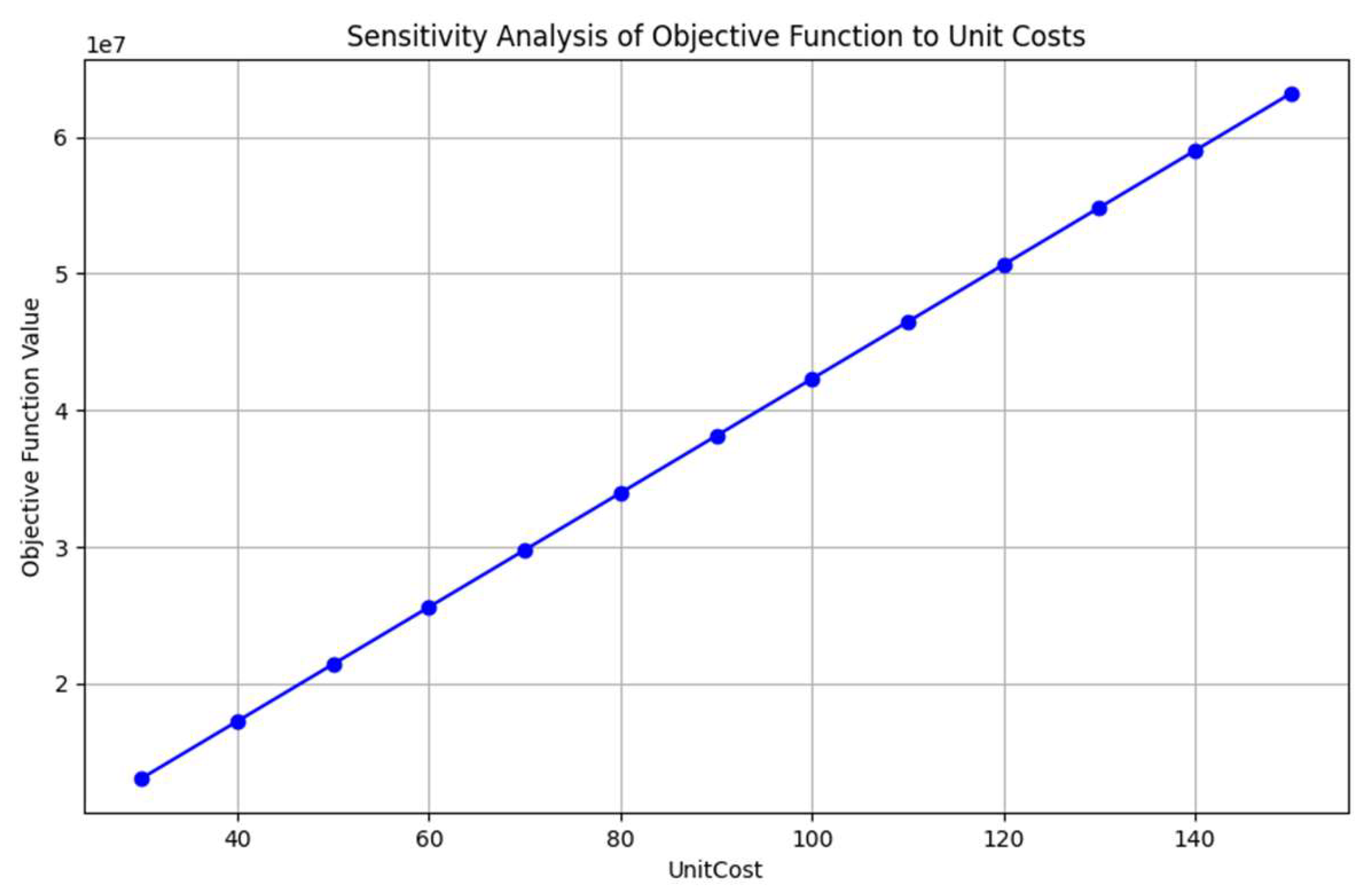

(depth of the well placed at location j). Similarly, the range of the per-meter drilling costs is set from 30 to 150, with an increment of 10. As the per-meter drilling costs increase, the total costs also rise (

Figure 9).

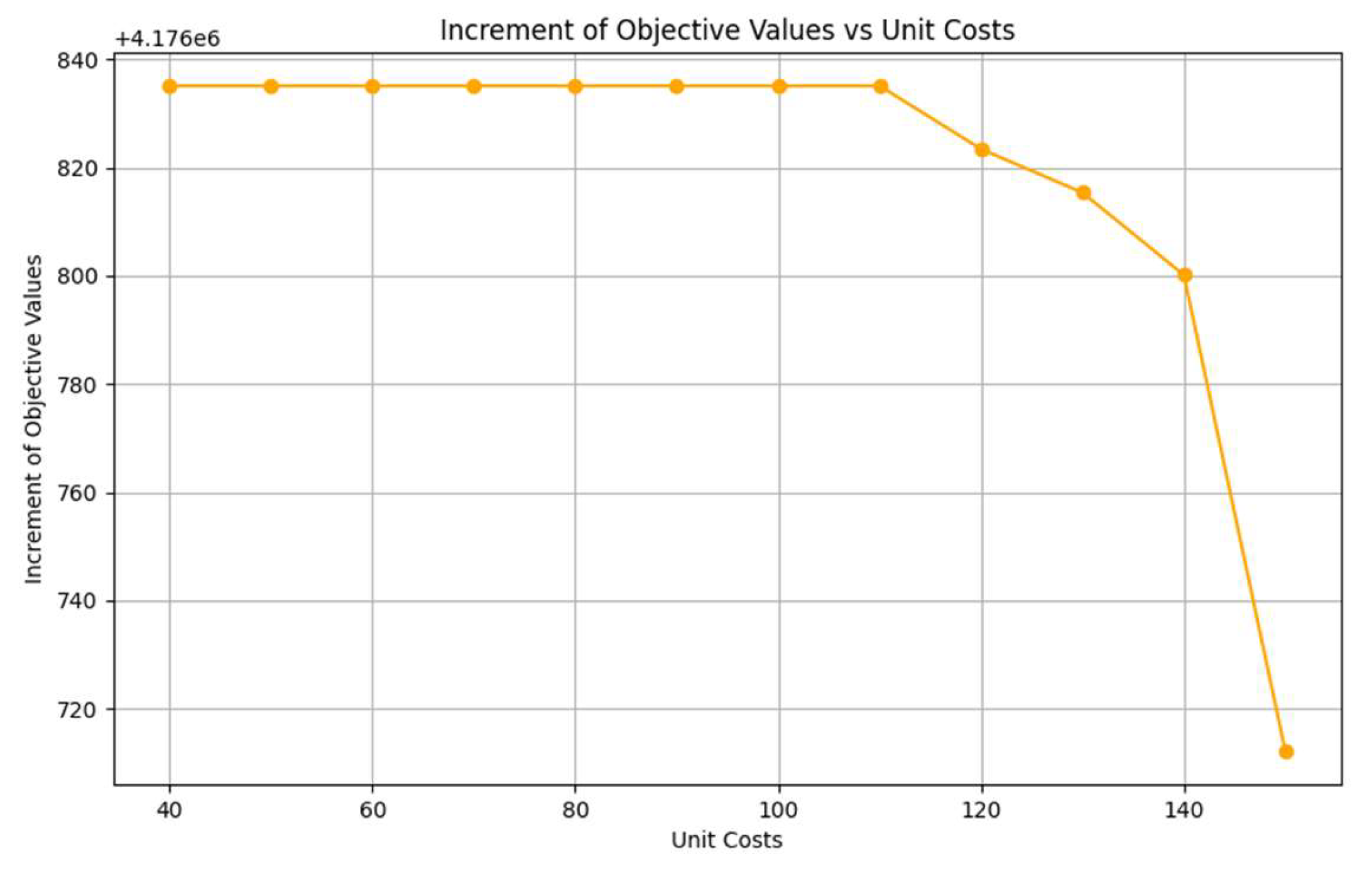

Figure 10 shows the differences between consecutive objective values as the per-meter drilling cost increases. From this plot, we can see a clear drop in the increment of the objective when the per-meter drilling cost increases from 110 to 120. This occurs because, as the per-meter drilling cost becomes higher, the model tends to select shallower wells that are slightly farther from the farm to minimize the total costs.

4.1.3. Impact of Different Demand Scenarios

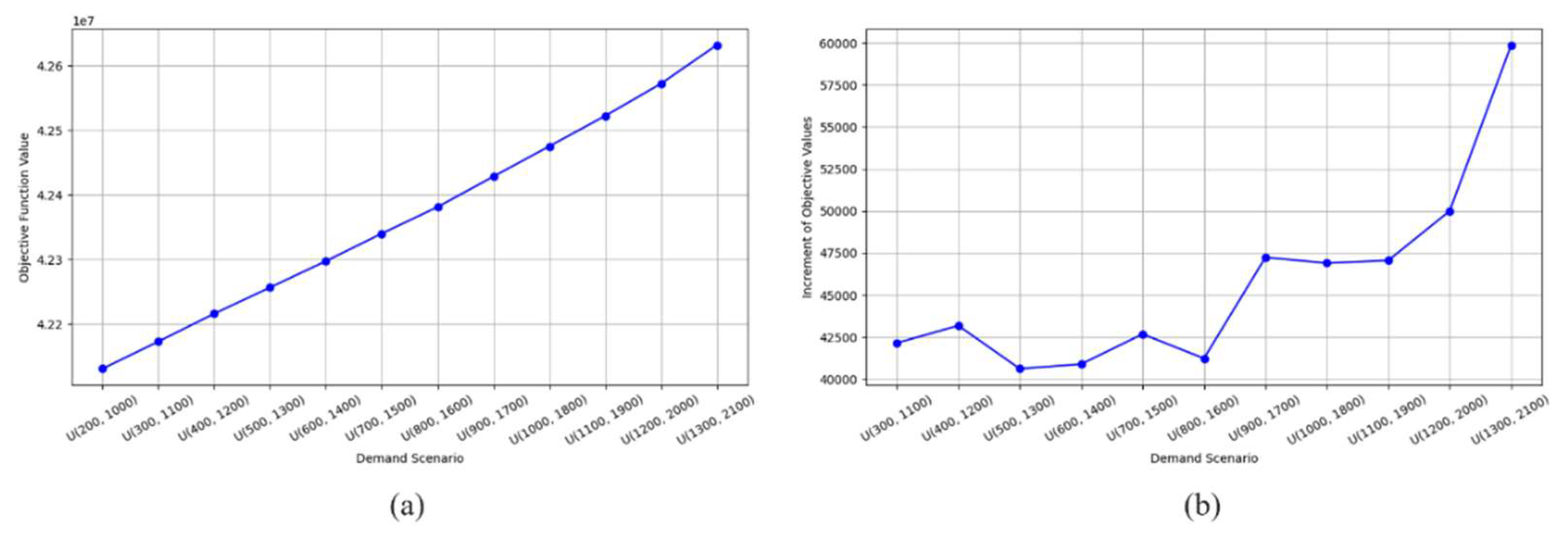

Since the demand scenarios are generated randomly, the increments in the objective values between each pair of demand scenarios are not constant. Some increments are big and some are small. Two big increment examples are described next.

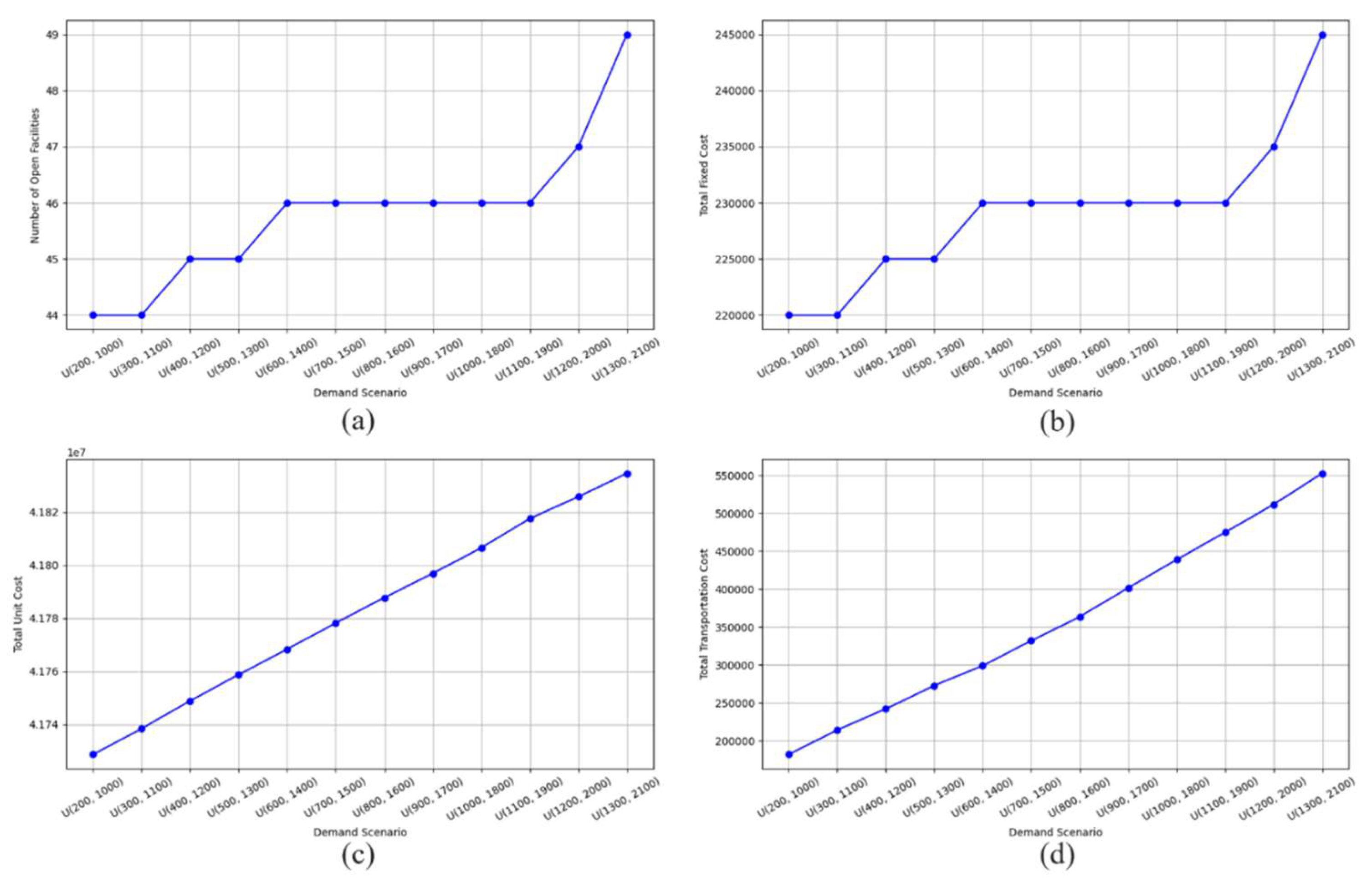

First, in

Figure 11 (b), there is an obvious increase in the objective values when moving from U(1200, 2000) to U(1300, 2100). This can be explained by the fact that as the mean demand increases from 1600 to 1700, the number of open wells increases from 47 to 49. This increase in the number of open wells is the main contributor to the substantial increment in the objective values (

Figure 12 (a)).

When increasing the demand range from U(600, 1400) to U(1100, 1900), the number of open wells remains the same (

Figure 12 (a)). However, the objective values see a greater increase when moving from U(800, 1600) to U(900, 1700), see

Figure 11 (a). This phenomenon can be explained by the fact that as the mean demand increases, different well layouts are likely to be required to meet the rising demand. This leads to higher transportation costs and necessitates deeper wells, which increases capacity and results in higher total drilling costs. Note that the capacity directly impacts the total quantity of water transported from the well to the farm, which in turn affects the demand (

Figure 12).

4.2. Out-of-Sample Performance

To evaluate out-of-sample performance, we first formulate the problem with a deterministic demand (in-sample demand data) and solve it. The solution of the first-stage decision variables, whether to place a well at site j () and the depth of the well to drill at site j (), is then fixed. Using these fixed first-stage decision variables, we solve a new problem with stochastic demand scenarios (out-of-sample demand data) to obtain the objective values. By fixing the same first-stage decision variable results, the second-stage demand scenarios can be randomly generated from the same distribution multiple times, producing a set of objective values.

Next, we formulate the problem with a stochastic demand scenario (in-sample demand data) and solve it. The solutions of the first-stage decision variables are then fixed to solve a problem with the same stochastic demand scenario (out-of-sample demand), but with newly randomly generated demand scenarios, iterating this process multiple times to obtain objective values. Finally, the two cases—the deterministic case and the stochastic case—can be compared by analyzing the mean and standard deviation of their objective values to evaluate out-of-sample performance.

In this study, four cases were investigated, each iterated 50 times. The uniform distribution was chosen to range from 600 to 1400, with a mean of 1000. For the normal distribution, a mean of 1000 and a standard deviation of 155 were selected. This choice was made to ensure that 99% of the values fall between 600 and 1400 in a normal distribution, as the standard deviation is approximately calculated as 400/2.576 = 155. The deterministic demand was set at 1100. This value was chosen instead of 1000 to ensure the feasibility of the model.

It is important to note that the number of wells to place is 45 for the deterministic MIP with a demand of 1000. In contrast, the SMIP with demand scenarios generated from a uniform distribution U(600, 1400) indicates that 46 wells should be placed. Therefore, if we use an in-sample demand with a deterministic value of 1000, the placement of 45 wells may not satisfy the out-of-sample demand scenarios generated from U(600, 1400).

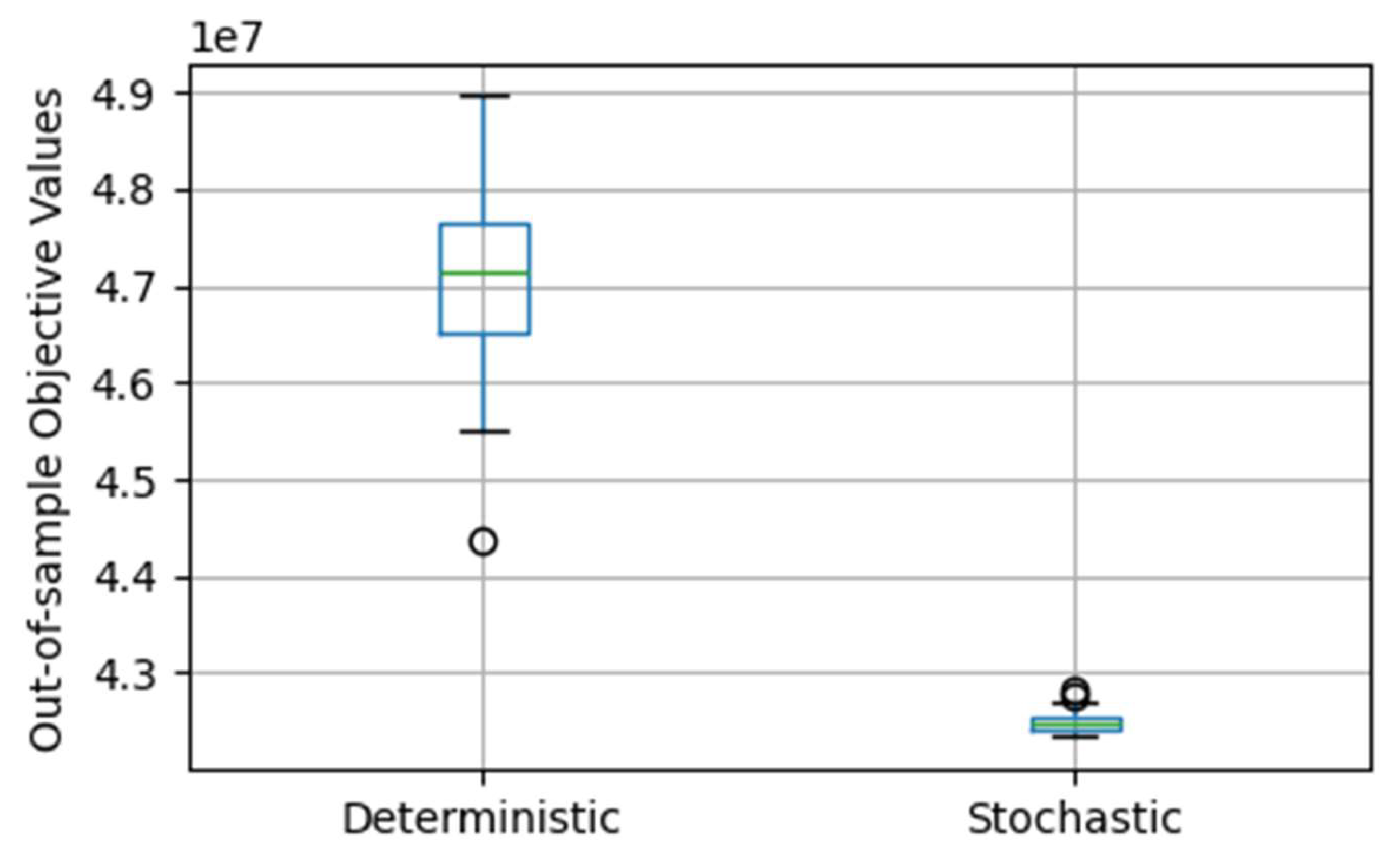

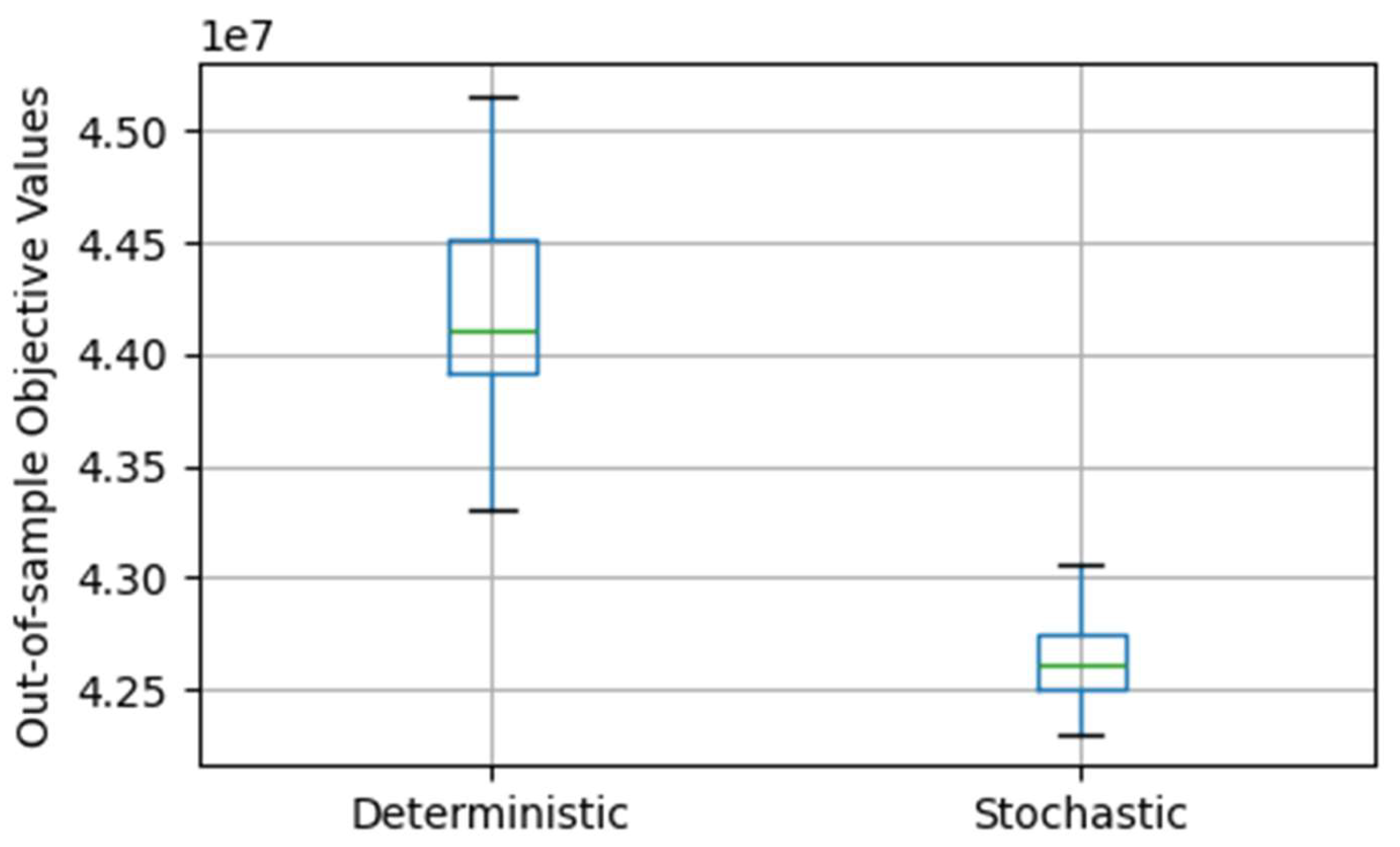

The mean and standard deviation of the objective values from experiments using the out-of-sample demand data for the four cases are summarized in

Table 2. We compared Case 1 with Case 2 and Case 3 with Case 4, and created boxplots in

Figure 13 and

Figure 14. The results indicate that the deterministic case 1 achieves 11% higher average out-of-sample objective costs compared to the stochastic case 2. Additionally, the average costs for deterministic case 3 are 4% higher than those for stochastic case 4. This demonstrates that the stochastic approach yields lower average costs and is more effective than the deterministic approach. The boxplots also show that the stochastic cases perform better than the deterministic cases, with tighter distributions and lower variability in the objective values. This indicates that the stochastic models consistently perform better across a wider range of out-of-sample scenarios. The solutions are more flexible and resilient to changes in demand, providing a more robust long-term strategy for well placement and resource allocation in groundwater management.

5. Conclusions

In this study, we formulated both deterministic MIP and two-stage SMIP problems to optimize well placement with minimal total costs while satisfying farm demand and ensuring sustainable groundwater extraction. Experiments were conducted with different distributions of demand scenarios for the two-stage SMIP models. The results show that the average total costs for the MIP are slightly higher than those for the SMIP models. This is intuitive because the two-stage stochastic model incorporates the benefit of long-term planning by considering uncertain demand scenarios. By accounting for these uncertainties, the SMIP can optimize well placement more effectively over time, potentially avoiding costly misallocations and adjustments that a deterministic MIP model might incur when it does not account for demand variability. Consequently, the SMIP’s more comprehensive approach can lead to more cost-effective solutions in the long run. Maps of well placement for each experiment have been created, revealing slight changes in the layout of the wells near a few farms in the south across different experiments with varying the demand scenarios. In practice, this could guide drilling decisions by incorporating expert judgment based on soil conditions and geographic features. The analysis of the impact of varying fixed construction costs, per-meter drilling costs, and demand scenarios on the objective values shows that total costs increase with these costs and demand. The increments in objective values relative to these three parameters have also been examined and explained. The results of the out-of-sample performance show that the stochastic cases perform better than the deterministic cases, with tighter distributions and lower variability in the objective values, indicating that the solution from the stochastic models are more flexible and resilient to changes in demand.

The optimization study has several limitations that should be acknowledged. Firstly, the model is restricted to a very small region due to computational constraints, which limits the generalizability of the findings to larger areas. This restriction means that the results may not fully capture the complexities and variances that could occur in a broader geographical context. Secondly, the study does not incorporate data on the actual locations of farms, which is crucial for accurate well placement and optimizing irrigation strategies. Without this data, the model’s applicability to real-world scenarios is limited. Additionally, while the study examines the uncertainty of demand scenarios, it does not consider other important uncertainties, such as variations in static water levels and groundwater recharge. These factors could significantly impact the effectiveness of the well placement optimization and should be included in future research to provide a more comprehensive analysis.

Future research could focus on conducting extensive scenario analyses to explore the impacts of different demand scenarios on well placement optimization, which could provide valuable insights into the robustness and reliability of the model under various geological and hydrogeological conditions. Examining the effect of uncertainty in static water levels and groundwater recharge should be considered, also with regard to the progressing climate change. Additionally, exploring and comparing different optimization methods could provide a broader perspective on the most effective approaches for well placement optimization. This development could enable optimizing well placement over a larger region, potentially providing a broader impact. Furthermore, collecting data on the actual locations of farms is crucial for more accurate well placement. Another future research direction could be developing adaptive optimization techniques that can dynamically update well placement decisions based on real-time data and changing conditions, which could enhance the flexibility and responsiveness of the decision support system.

Author Contributions

Conceptualization, W.L. and K.B.L.; methodology, W.L.; software, W.L.; validation, W.L., M.M.F., K.B.L., P.H., R.D.-B. and K.V.; formal analysis, W.L.; investigation, W.L. and K.B.L.; resources, M.M.F., R.D.-B., and K.V.; data curation, W.L.; writing—original draft preparation, W.L.; writing—review and editing, W.L., M.M.F., K.B.L., P.H., R.D.-B, and K.V.; visualization, W.L.; supervision, K.B.L., P.H., and R.D.-B.; project administration, K.B.L., P.H., and R.D.-B.; funding acquisition, K.B.L., P.H., R.D.-B, and K.V. All authors have read and agreed to the published version of the manuscript.

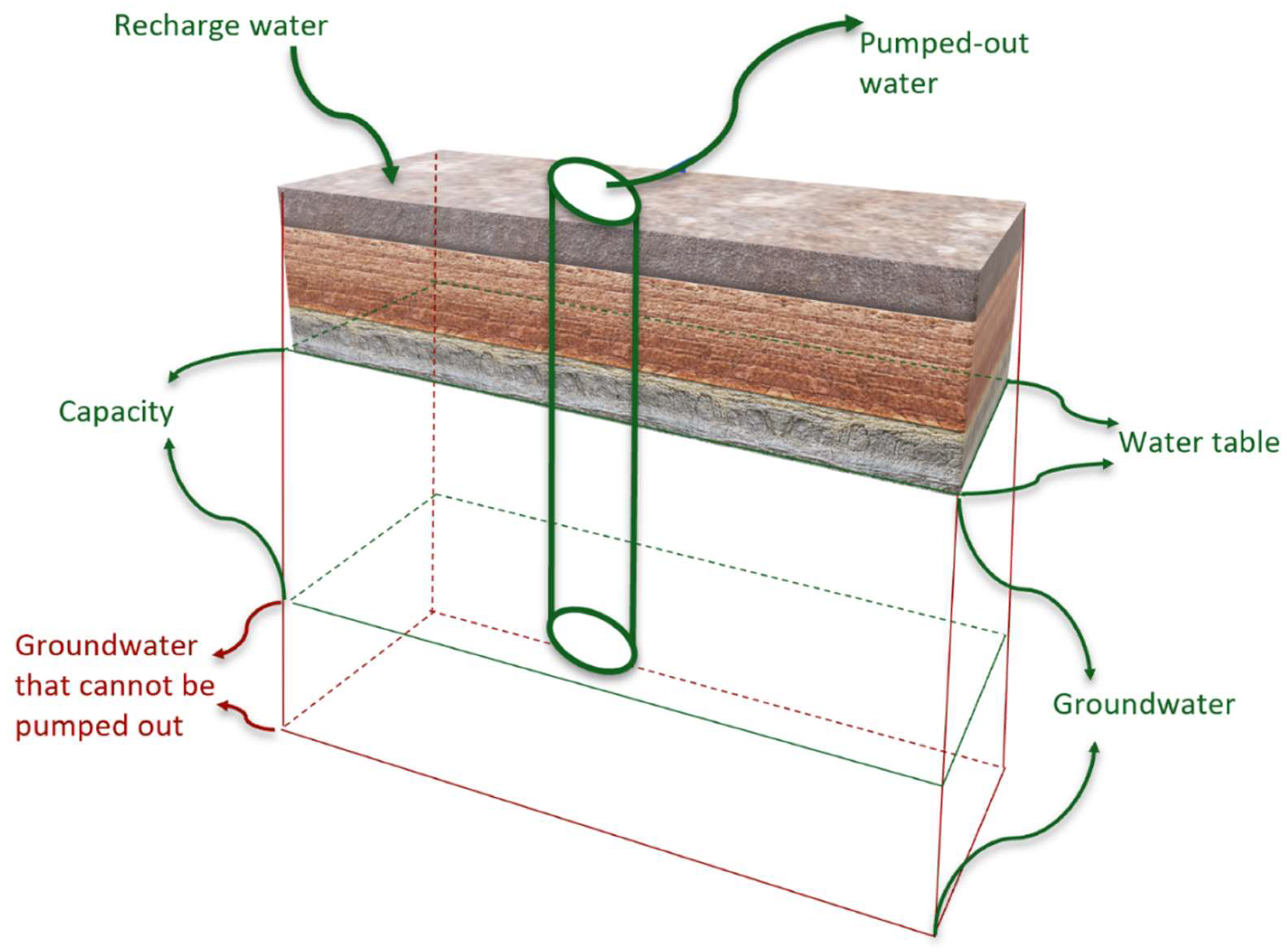

Figure 1.

Conceptual plot illustrating the capacity of a well (Constraint (3) and (4)). The volume of groundwater below the deepest point of the well cannot be pumped out for drinking or irrigation.

Figure 1.

Conceptual plot illustrating the capacity of a well (Constraint (3) and (4)). The volume of groundwater below the deepest point of the well cannot be pumped out for drinking or irrigation.

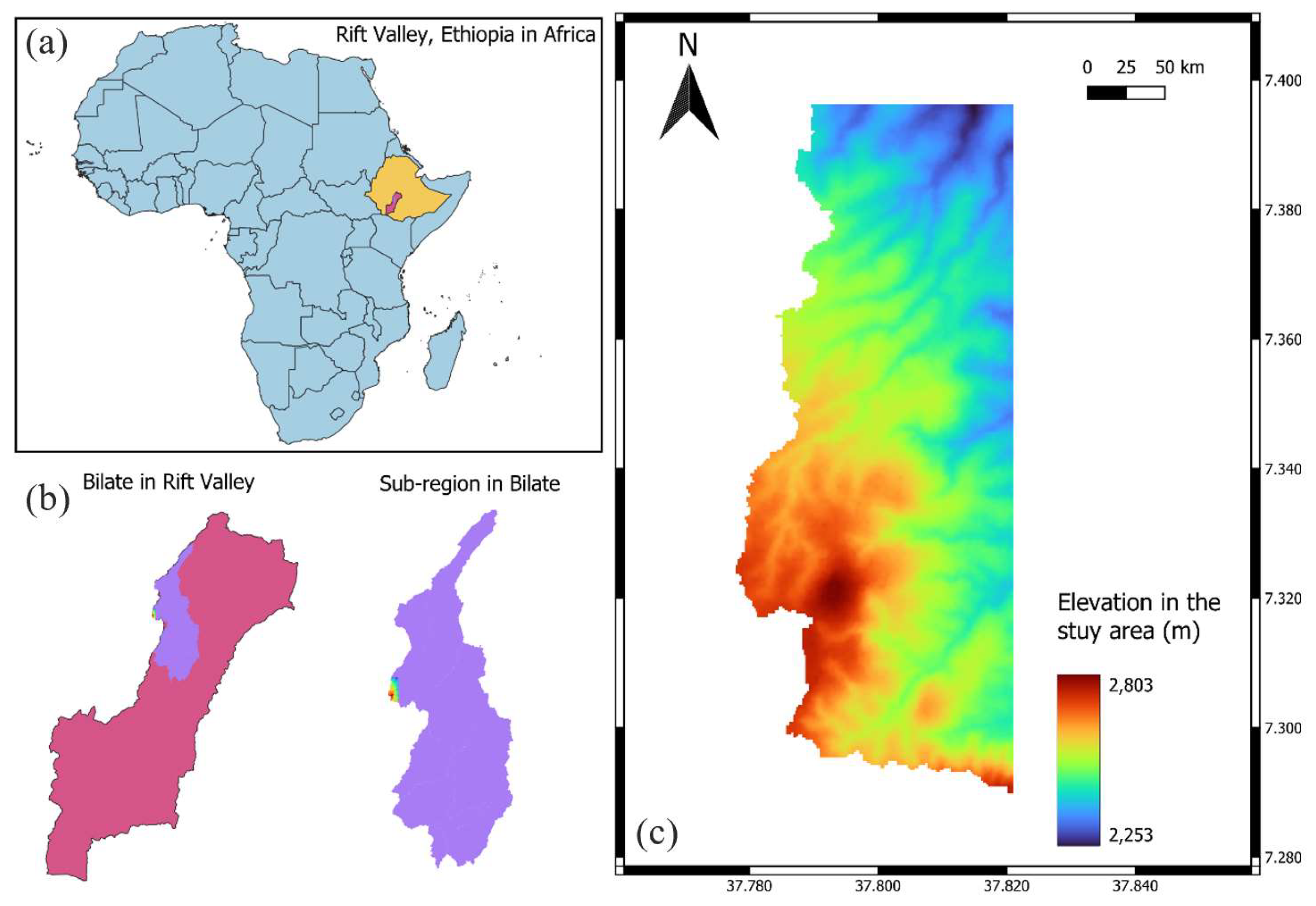

Figure 2.

(a) Location of southern part of the Main Ethiopian Rift in Ethiopia, Africa; (b) Bilate watershed (violet polygon) within the Southern Main Ethiopian Rift Valley (left) and the location of the study area within Bilate watershed (right); (c) Simplified digital elevation model (DEM) of the area of interest (on the western edge of the Bilate watershed).

Figure 2.

(a) Location of southern part of the Main Ethiopian Rift in Ethiopia, Africa; (b) Bilate watershed (violet polygon) within the Southern Main Ethiopian Rift Valley (left) and the location of the study area within Bilate watershed (right); (c) Simplified digital elevation model (DEM) of the area of interest (on the western edge of the Bilate watershed).

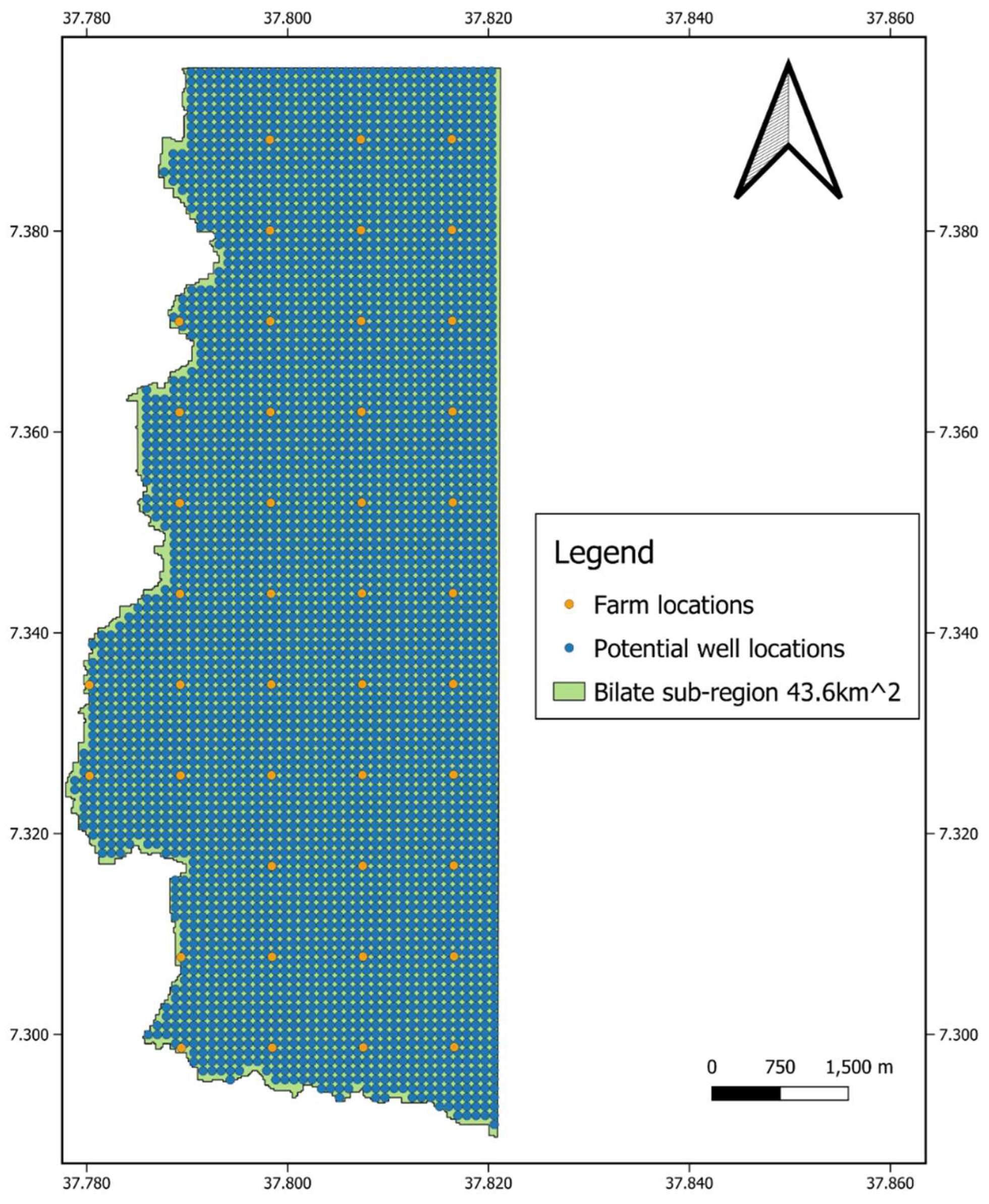

Figure 3.

Farm and potential well locations in the study area (western flank of Bilate watershed).

Figure 3.

Farm and potential well locations in the study area (western flank of Bilate watershed).

Figure 4.

(a) to (e) Five deterministic MIP experiments assuming water demands of 800, 900, 1000, 1100, and 1200 kg/km², respectively. (Note: The numbers on the map represent the well ID). The layout of a few wells is different across different models including well ID 419, 420, 506, 3666, 3780, and 3781.

Figure 4.

(a) to (e) Five deterministic MIP experiments assuming water demands of 800, 900, 1000, 1100, and 1200 kg/km², respectively. (Note: The numbers on the map represent the well ID). The layout of a few wells is different across different models including well ID 419, 420, 506, 3666, 3780, and 3781.

Figure 5.

(a) to (e) Illustration of five two-stage SMIP experiments depicting water demand scenarios randomly generated from five uniform distributions: U(400, 1200), U(500, 1300), U(600, 1400), U(700, 1500), and U(800, 1600), respectively. (Note: The numbers on the map represent the well ID). The layout of a few wells is different across different models including well ID 276, 419, 420, 3551, 3666, 3781, 3629, and 3744.

Figure 5.

(a) to (e) Illustration of five two-stage SMIP experiments depicting water demand scenarios randomly generated from five uniform distributions: U(400, 1200), U(500, 1300), U(600, 1400), U(700, 1500), and U(800, 1600), respectively. (Note: The numbers on the map represent the well ID). The layout of a few wells is different across different models including well ID 276, 419, 420, 3551, 3666, 3781, 3629, and 3744.

Figure 6.

(a) to (e) Visualization of five two-stage SMIP experiments depicting water demand scenarios randomly generated from five normal distributions: N(800, 300), N(900, 300), N(1000, 300), N(1100, 300), and N(1200, 300), respectively. (Note: The numbers on the map represent the well ID). The layout of a few wells is different across different models including well ID 338, 419, 420, 506, 1457, 1458, 2170, 2398, 2285, 3551, 3629, 3666, 3744, 3780, and 3781.

Figure 6.

(a) to (e) Visualization of five two-stage SMIP experiments depicting water demand scenarios randomly generated from five normal distributions: N(800, 300), N(900, 300), N(1000, 300), N(1100, 300), and N(1200, 300), respectively. (Note: The numbers on the map represent the well ID). The layout of a few wells is different across different models including well ID 338, 419, 420, 506, 1457, 1458, 2170, 2398, 2285, 3551, 3629, 3666, 3744, 3780, and 3781.

Figure 7.

Impact of the fixed construction costs on the objective values.

Figure 7.

Impact of the fixed construction costs on the objective values.

Figure 8.

Increment of objective values vs fixed construction costs.

Figure 8.

Increment of objective values vs fixed construction costs.

Figure 9.

Impact of the different per-meter drilling costs on the objective values.

Figure 9.

Impact of the different per-meter drilling costs on the objective values.

Figure 10.

Increment of objective values vs per-meter drilling costs (unit costs).

Figure 10.

Increment of objective values vs per-meter drilling costs (unit costs).

Figure 11.

(a) Objective values vs different demand scenarios (b) Increment of the objective values vs different demand scenarios.

Figure 11.

(a) Objective values vs different demand scenarios (b) Increment of the objective values vs different demand scenarios.

Figure 12.

(a) Number of open wells vs demand scenarios; (b) Total fixed costs vs demand scenarios; (c) Total unit costs vs demand scenarios; (4) Total transportation costs vs demand scenarios.

Figure 12.

(a) Number of open wells vs demand scenarios; (b) Total fixed costs vs demand scenarios; (c) Total unit costs vs demand scenarios; (4) Total transportation costs vs demand scenarios.

Figure 13.

Comparison of the out-of-sample performance between a deterministic in-sample demand and a stochastic out-of-sample demand generated from a U(600, 1400).

Figure 13.

Comparison of the out-of-sample performance between a deterministic in-sample demand and a stochastic out-of-sample demand generated from a U(600, 1400).

Figure 14.

Comparison of the out-of-sample performance between a deterministic in-sample demand and a stochastic out-of-sample demand generated from a N(1000, 155).

Figure 14.

Comparison of the out-of-sample performance between a deterministic in-sample demand and a stochastic out-of-sample demand generated from a N(1000, 155).

Table 2.

Results of the out-of-sample performance.

Table 2.

Results of the out-of-sample performance.

| |

Case 1 |

Case 2 |

Case 3 |

Case 4 |

| In-sample demand |

Deterministic with demand=1100 |

Uniform distribution |

In-sample demand |

Deterministic with demand=1100 |

| Out-of-sample demand |

Uniform distribution |

Out-of-sample demand |

Uniform distribution |

Out-of-sample demand |

| Mean |

47124183 |

42494243 |

44200128 |

42625237 |

| Standard deviation |

938970 |

107608 |

437315 |

172968 |