1. Introduction

Recently, dye-sensitized solar cells (DSSCs) have gained much attention in solar energy studies because they are high-efficiency materials and can be easily fabricated compared to other solar cells, such as silicon [

1,

2]. In addition, these solar cells are feasible to produce at low cost. Titanium dioxide (TiO

2) photoelectrode plays an essential role in DSSC devices because it enables DSSC to function, which needs the dye molecules to be attached to the TiO

2 particle surface. Here, the molecules absorb sunlight, and electrons from the primary state will be excited to a high level, from where they pass into the conduction band of TiO2. Electrons permeate through the TiO

2 nanoporous structure to the transparent conducting film, flowing through the external load to the counter electrode. Therefore, the performance of DSSCs depends on many factors, such as the film's structure, morphology, and thickness, the type of dye and electrolyte, and the electrical resistance of the electrodes [

3,

4]. The film surface must be porous, the adhesion to the surface must be good, and the TiO

2 particles must be well interconnected. The particles should also be designed in nano-sized [

5,

6]. Significantly, the key factors influencing the performance of DSSC devices are the transparent surface characteristics and electrical resistance. In DSSC devices, there are two types of transparent conductive oxides (TCOs), including fluorine-doped tin oxide (FTO) and indium-doped tin oxide (ITO). Although FTO is currently the most widely used, it has several disadvantages, like rough surface and lower transparency. Meanwhile, ITO has lower sheet resistance, better stability and adhesion, can be fabricated on a larger surface, and has a lower processing temperature than FTO. ITO materials are generally n-type semiconductors with an optical bandgap greater than 3.4 eV [

7,

8]. Several research groups have previously reported and suggested that modifying the surface properties of ITO is an essential step for the fabrication of solar cell devices [

9,

10,

11,

12,

13]. Various methods have been developed for preparing ITO surfaces, including ultraviolet-ozone treatment [

14,

15,

16], wet treatment annealing process [

17,

18], and gas plasma [

19,

20]. Among these, oxygen plasma is a promising therapy because of its many advantages, outstanding functionality, smoothest surface, and lowest sheet resistance [

21,

22,

23]. However, improving the ITO surface with a technique conducive to depositing a good-quality film is necessary. A bias applied to the surface can attract positive ions in the plasma to attack the grown film [

24,

25,

26]. This bombardment causes the molecules and clusters to condense on the surface to gain energy, and the molecules detach from the film with weak bonds [

27]. This type of bombardment is beneficial to the crystallinity of the film, and the effect of suitable ions on the deposited film improves the film's properties [

28,

29,

30].

In this study deposited the ITO films on glass substrates by E-beam evaporation with glancing angle deposition. Then, the ITO was deposited on glass treated by oxygen plasma with a bias-magnetron RF sputtering process. The effects of oxygen gas content on the film surfaces and electrical, optical, and efficiency of DSSC devices were evaluated.

2. Materials and Methods

2.1. ITO Film Fabrication

To prepare the ITO films, the evaporation material used indium tin oxide pieces, which had a compound of indium oxide (In2O3) with tin (SnO2) at 99.99% purity, produced by Kurt J. Lesker Company, United States. The samples used glass substrates produced by As One Corporation, Osaka, Japan. The film depositing machine used a DVB-SJC model manufactured by Denton Vacuum Inc., United States. The electron beam generator used a TFl-270-01 model of 4 crucibles manufactured by Denton company, England. During the deposition process, argon gas (Ar) of 13 sccm and oxygen gas (O2) of 8 sccm were used. The pressure in a chamber was pumped down to 2.6 x 10-5 Torr at room temperature.

2.2. Oxygen Plasma Treatment with Bias-Magnetron RF Sputtering Process

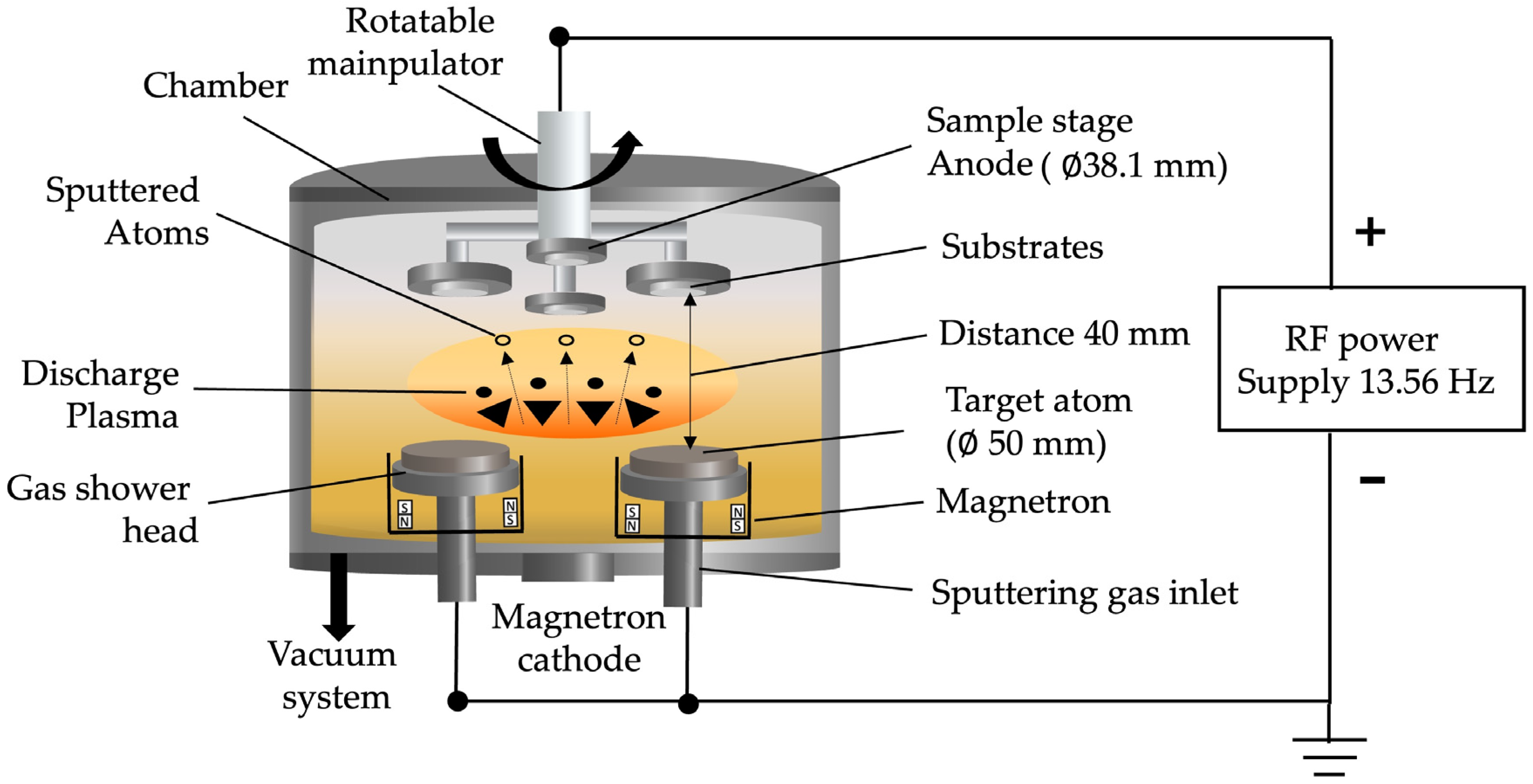

The next step is to treat the ITO films using a bias-magnetron RF sputtering process. The equipment applied with the sputtering machine used ATC 2000-F, manufactured by AJA International, Inc., United States, as shown in

Figure 1. During the oxygen plasma treatment process, argon gas (20 sccm) is used as an inert gas. The substrate bias can be adjusted from -100 to +100 V, and only the oxygen gas ratio was varied by 20 sccm, 40 sccm, 60 sccm, 80 sccm, and 100 sccm, in order to examine the effect of oxygen plasma on the composition changes of the ITO films. The pressure inside the chamber was pumped to 2.6 x 10

-2 Torr.

2.3. Dye-Sensitized Solar Cell Preparation

In this work, ITO was cut into 2 x 3 cm sizes to investigate the efficiency of solar cells. The fabrication of DSSC devices was done by a screen-printing technique [

31]. At the beginning of the process, the prepared devices were put into an oven at 60 C for 1 hour, then burned at 450 C for 2 hours. N719 dye is used as the photosensitizer material manufactured by Ossila Ltd., United Kingdom. N719 dye was injected into the cells and covered with parafilm to prevent evaporation. The cells were then left for 48 hours. After that, the cells were assembled and tested for efficiency.

2.4. Characterization Method

The diffraction pattern was tested and compared with the JCPDS standard values using an X-ray diffractometer (XRD) of the TTRAIII model manufactured by Rigaku company, Japan. Moreover, inspection was performed using the grazing incidence X-ray diffraction (GIXRD) method. Field emission scanning electron microscope: FE-SEM of the S4700 model, manufactured by Hitachi company, Japan, was used to examine the thickness of thin films in a cross-sectional imaging system and to determine the grain size in the surface imaging system at different depositing conditions. UV-vis spectrophotometer model Cary 7000 UMS (Agilent Technologies company, United States) was used to analyze the optical properties of ITO film within the measurement range of 200-2200 nm, displaying the percentage transmittance (%T). The point probe model RM3 (Jandell company, United Kingdom) was used to measure electrical properties with the Hall effect model HMS-3000 (Ecopia Corporation, Republic of Korea). In addition, solar simulator model XPS-300 (Solar light company, Inc., United States) was used to test the efficiency of DSSC devices under the short circuit current or current density (Jsc), open circuit voltage (Voc), maximum current (Imax), maximum power (Pmax) and fill factor (FF).

3. Result

The characterization of ITO films prepared by E-beam Evaporation with glancing angle deposition was performed via using the sputter etching process under oxygen plasma treatment with different gas supplies of 20 sccm, 40 sccm, 60 sccm, 80 sccm, and 100 sccm. During the sputter etching process on ITO film with oxygen plasma discharge, the reactor chamber is filled with a weakly ionized plasma, which consists of an ionized gas containing electron (

), positively charged ions (

), negatively charged ions (

), and a large number of neutral species such as and atoms. The species diffusing to the surface causes crystal changes. In this case, when the plasma is turned off while oxygen gas is introduced into the reactor chamber at a constant rate, the analysis of the plasma diagnosis in the form of that is determined by the following reactions [

32,

33,

34].

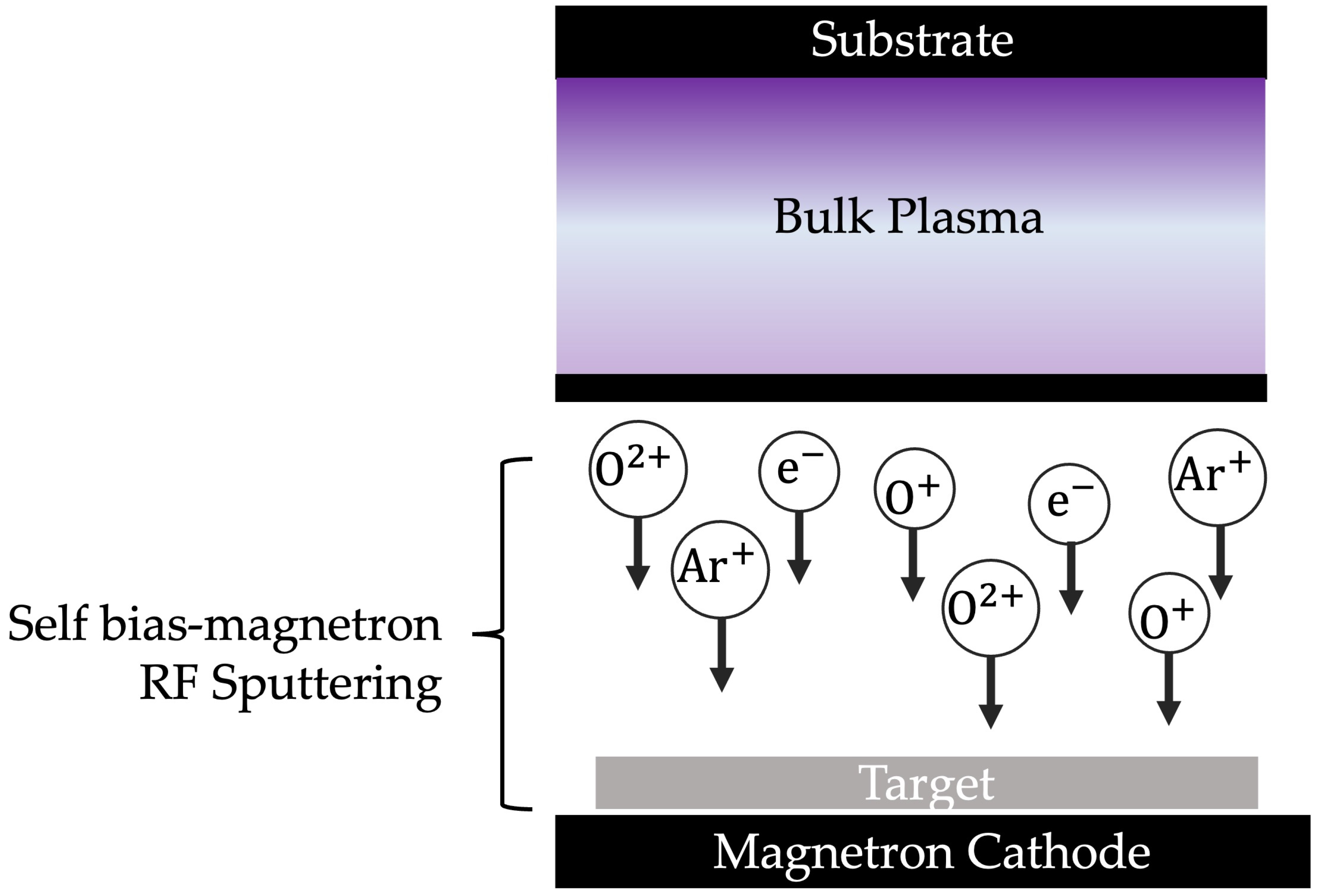

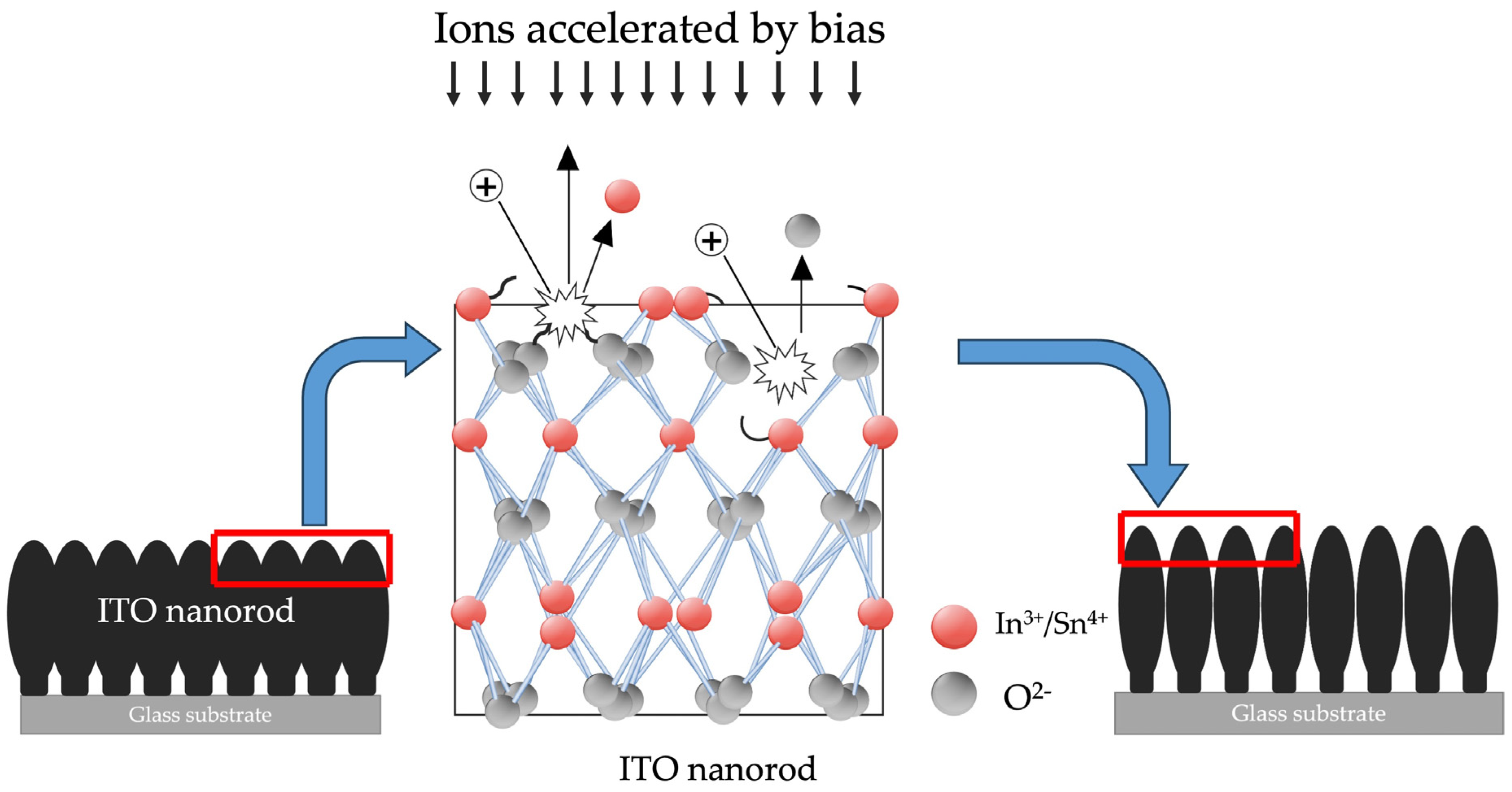

Figure 2 and

Figure 3 shows the surface mechanism of oxygen plasma treated on ITO-nanorod substrates by bias-magnetron RF sputtering process of the varying gas flow rate of 20, 40, 60, 80, and 100 sccm. During the RF sputtering process, the RF power generator changes the target electrode, attracting electrons and ions alternately. For this, electrons are lighter than ions and have a higher mobility. Thus, they collide with the target more often, resulting in excess negative charge and a direct electric field formation on the target [

35].

3.1. ITO Film Structure

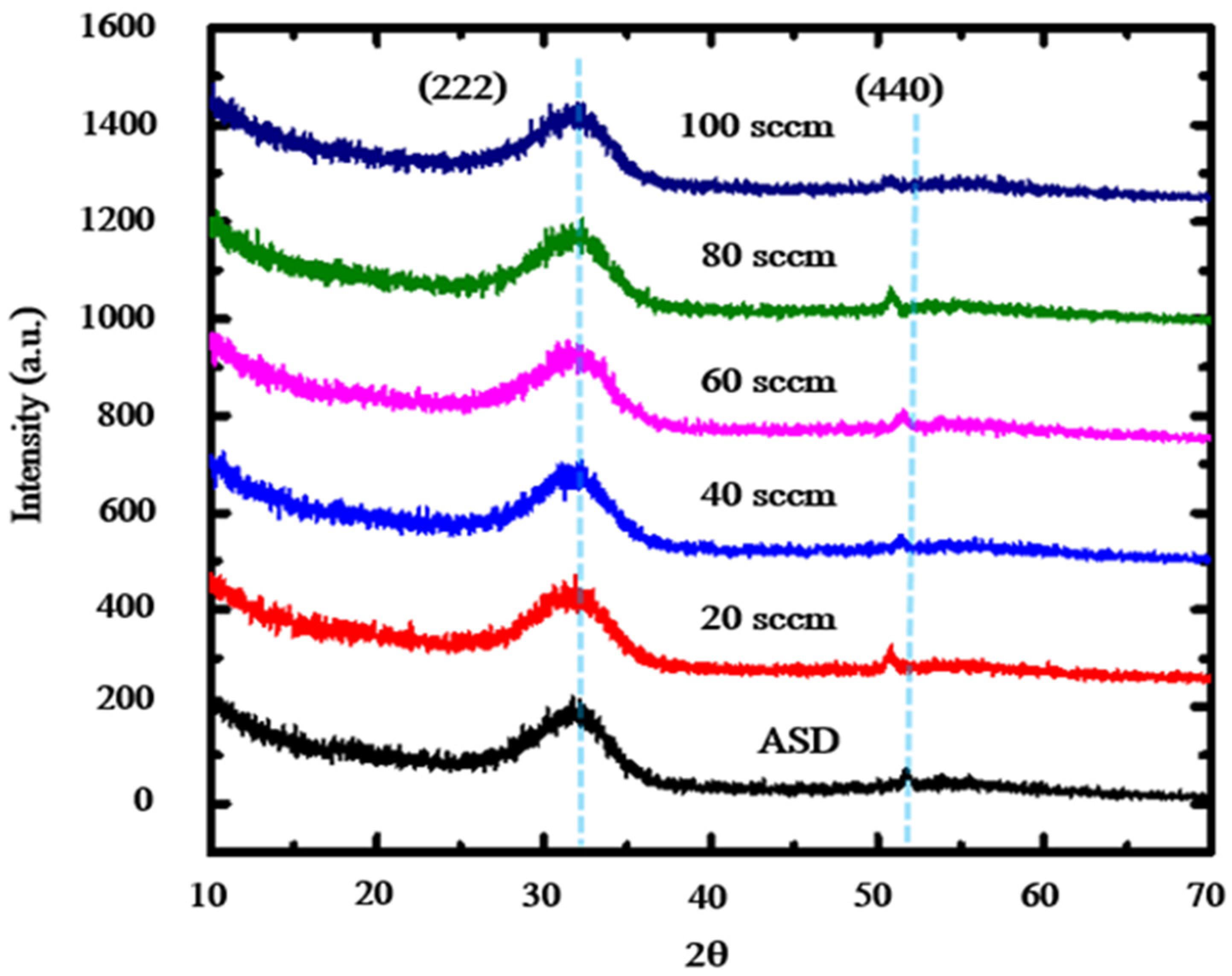

Figure 4 illustrates the X-ray diffraction patterns of ITO film before oxygen plasma treatment (As-deposited: ASD) and after oxygen plasma treatment at a flow rate of 20, 60, 80, and 100 sccm as can be seen in the figure; the X-ray diffraction patterns of the ITO surface show diffraction planes at (222) and (440) with 2 of 30.7 and 51.3, respectively. When considering the intensity of the peaks from all apparent planes (222 and 440), it was found that when the oxygen gas flow rate increased, the crystal structure after plasma treatment changed slightly.

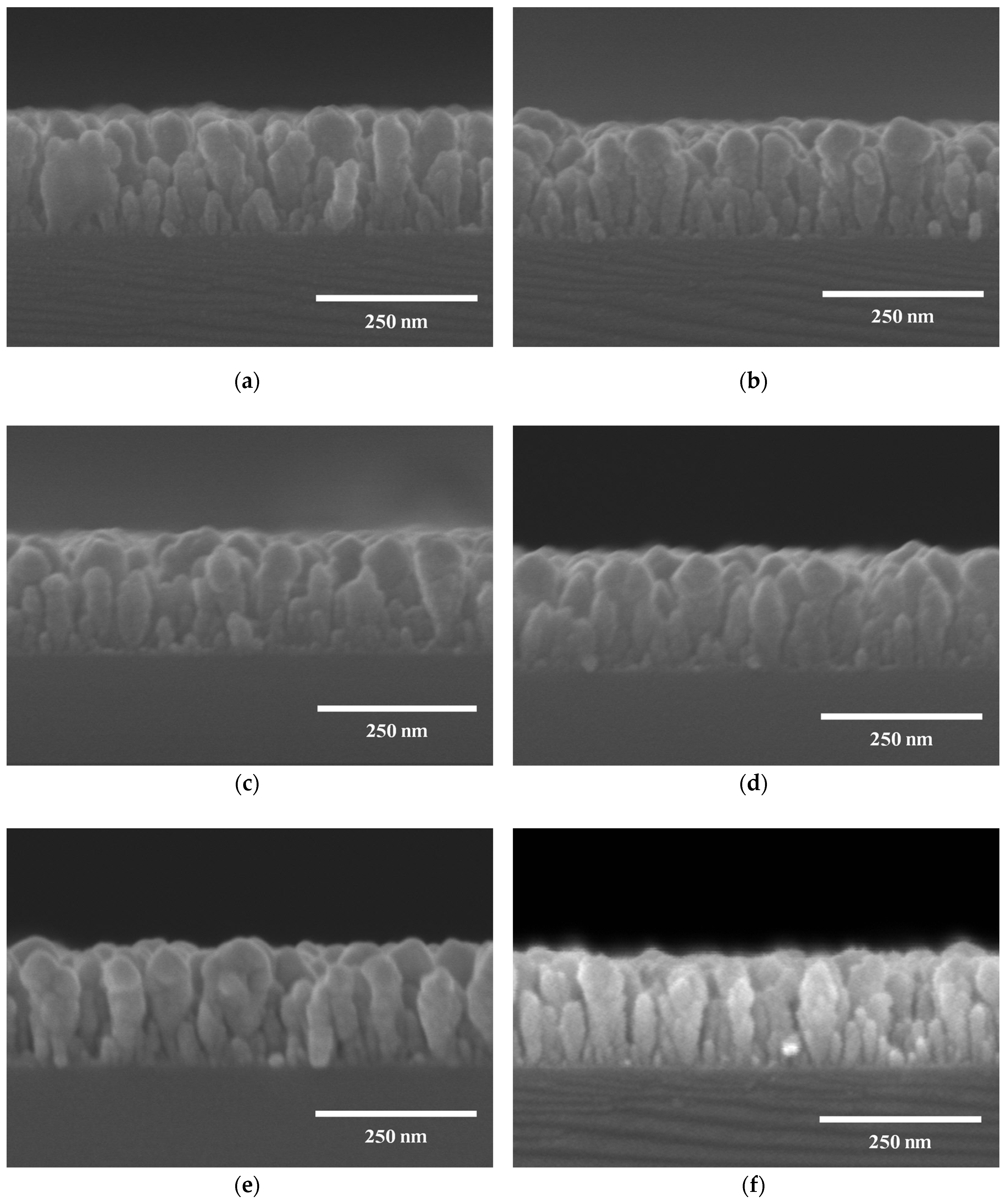

The surface analysis of ITO films grown on plasma treatment under different oxygen gas supplies at a flow rate of 20, 40, 60, 80, and 100 sccm was performed using the scanning electron microscopy analysis method. The results of cross-sectional photographs are shown in

Figure 5. The photographs show the structure of the films grown on the substrate as nanorods or ITO-nanorods, relating to

Figure 3. Similarly,

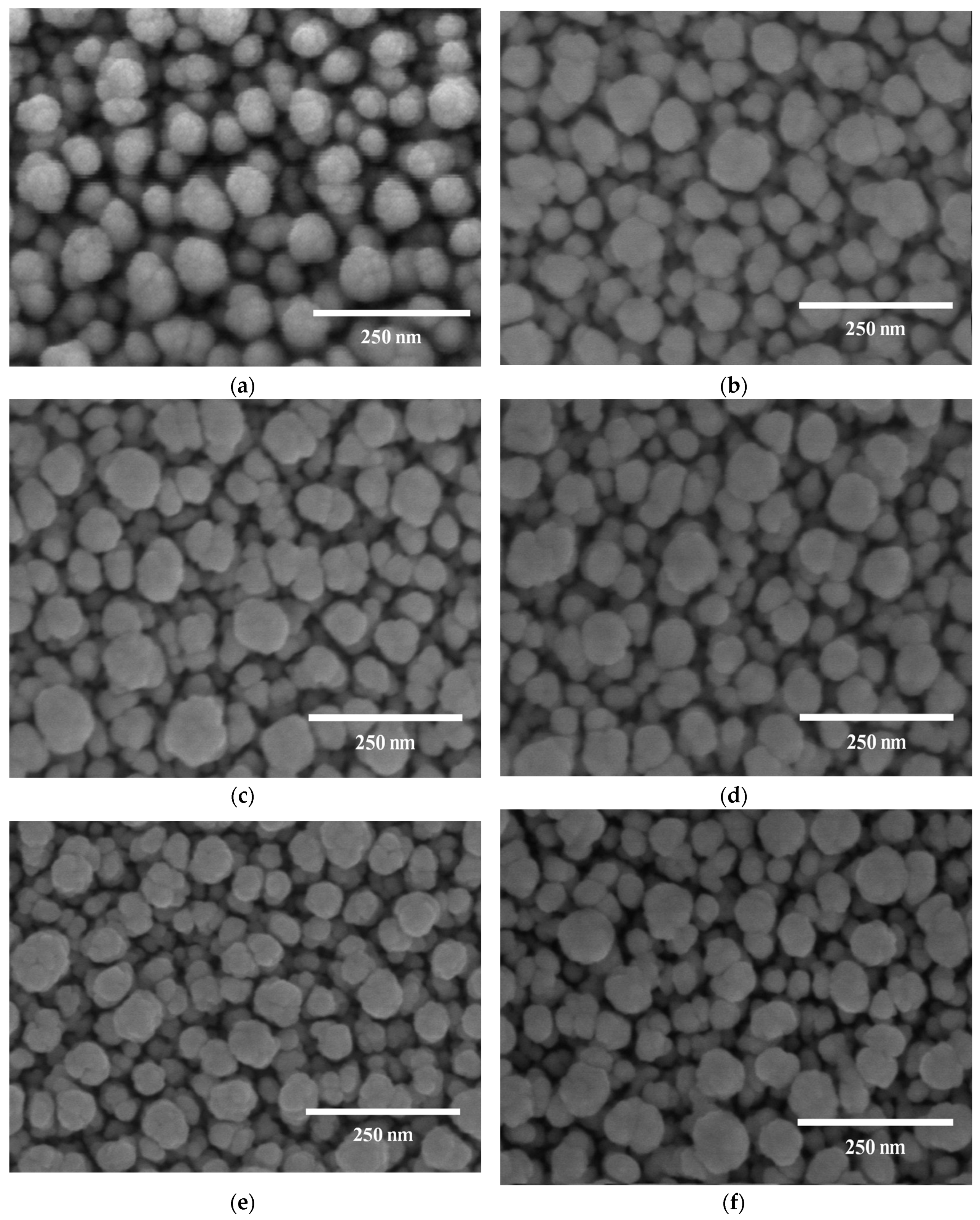

Figure 6 displays the photograph characteristics of the top film surface. The figure shows the apparent changes in the ITO-nanorod surface treated with oxygen plasma. When the oxygen gas flow rate increases to 100 sccm, the crystal size becomes smaller and separated compared to a lower oxygen gas flow rate. The result is due to the influence of plasma etching on the ITO-nanorod surface, which results in breaking ITO bonds and changing the top film layer.

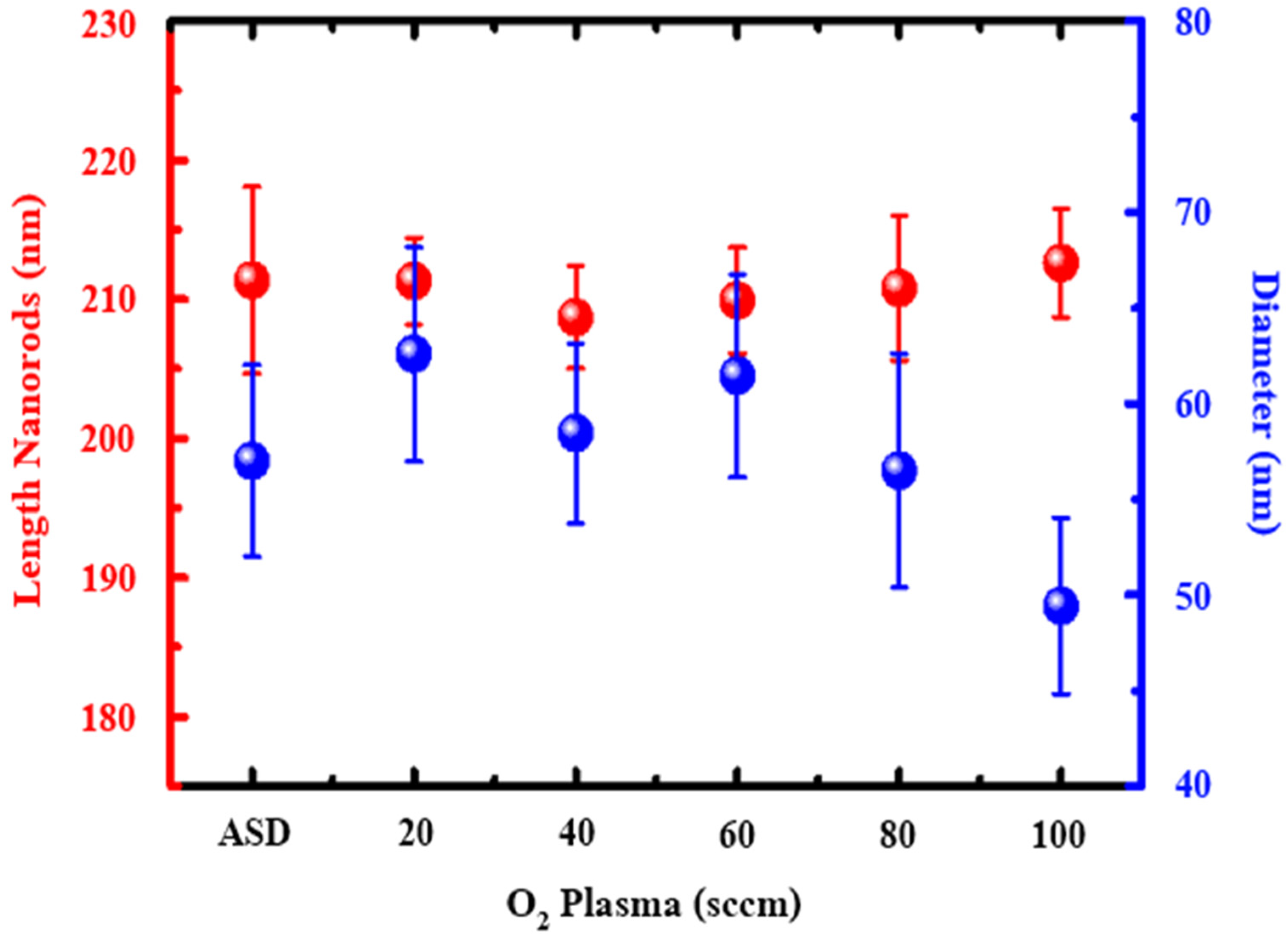

Additionally, the diameter and length of ITO-nanorod structures treated with oxygen plasma at different flow rates were analyzed, and the average values were calculated using Gaussian distribution [

36] according to equation 5.

Where the Gaussian function value is

, a is the mean value, the standard deviation is

, and X is the diameter measurement of each grain in nanometers.

Figure 7 illustrates the relationship graph from the calculation of the diameter and length of ITO-nanorod, which compares the samples between as-deposited film and ITO-nanorod treated with oxygen plasma. The results exhibit that the adjustment of oxygen gas flow rate in the plasma process affects the change in the size of the nanorods, with the length of ITO-nanorods ranging from 199-211 nm. When considering the size of the nanorods in the blue graph at different oxygen gas flow rates, it was found that when the oxygen gas flow rate increased, the nanorod size gradually decreased. The nanorods show the smallest size at a flow rate of 100 sccm compared with other flow rate conditions. Since at a flow rate of 100 sccm, the concentration of oxygen particles is the highest when the plasma is generated, resulting in the ionization of a large amount of oxygen gas. In this case, when stimulated by a biased process, causing more energy to break the bonds on ITO-nanorod surfaces, resulting in smaller nanorod size, the bond-breaking reaction can be seen in

Figure 3.

3.2. Optical Properties

The light transmittance was analyzed by a spectrophotometer measuring from the 250-2000 nm wavelength range. The comparison between glass substrate, as-deposited film, and ITO-nanorod treated with oxygen plasma of varying gas content at 20, 40, 60, 80, and 100 sccm is displayed in

Figure 8. From the spectral lines, it was found that the light transmittance of the plasma-treated ITO-nanorod film was in a good range and was close to each other in the visible wavelength range of 380-750 nm, which is the appropriate wavelength. The overall transmittance values are approximately 85%.

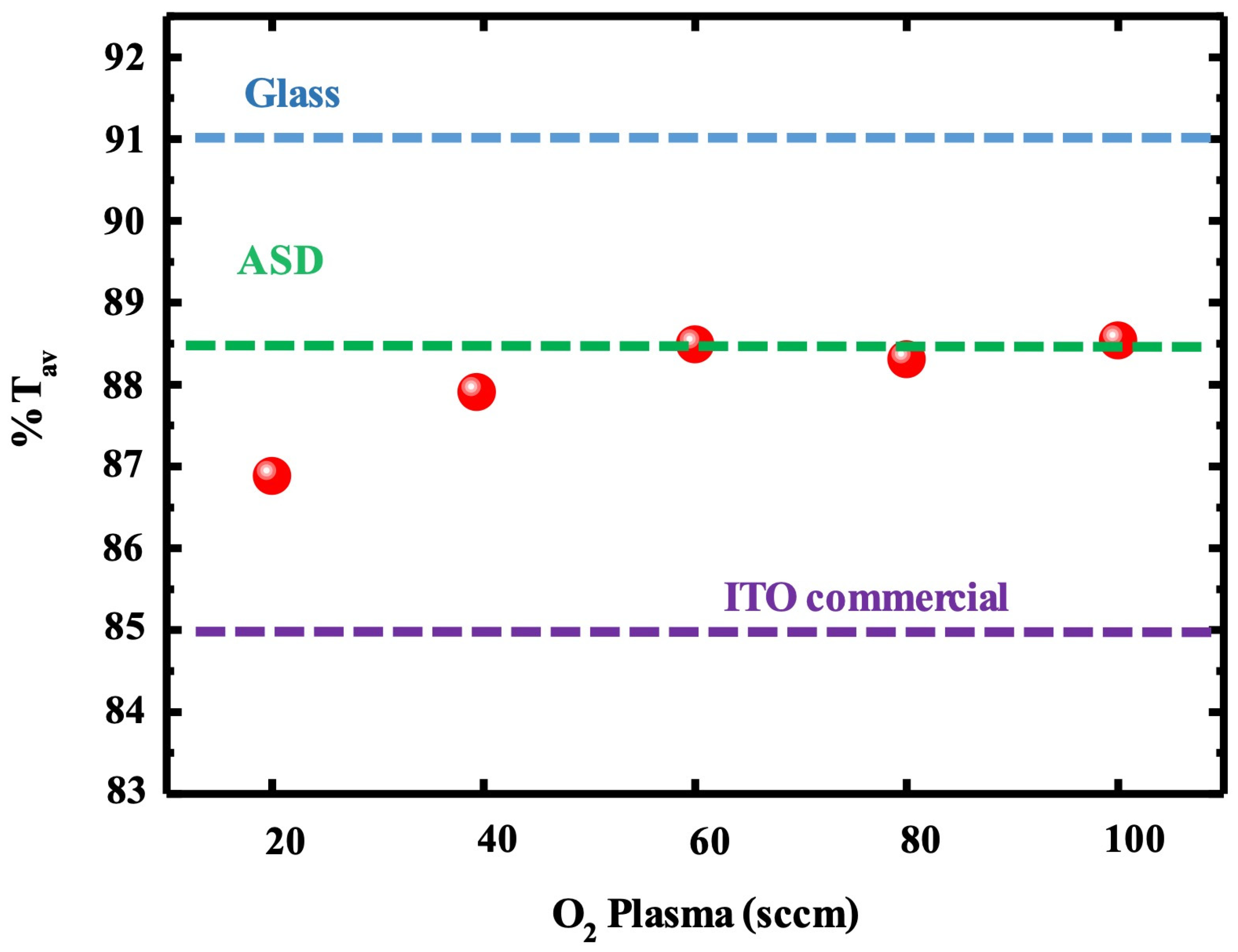

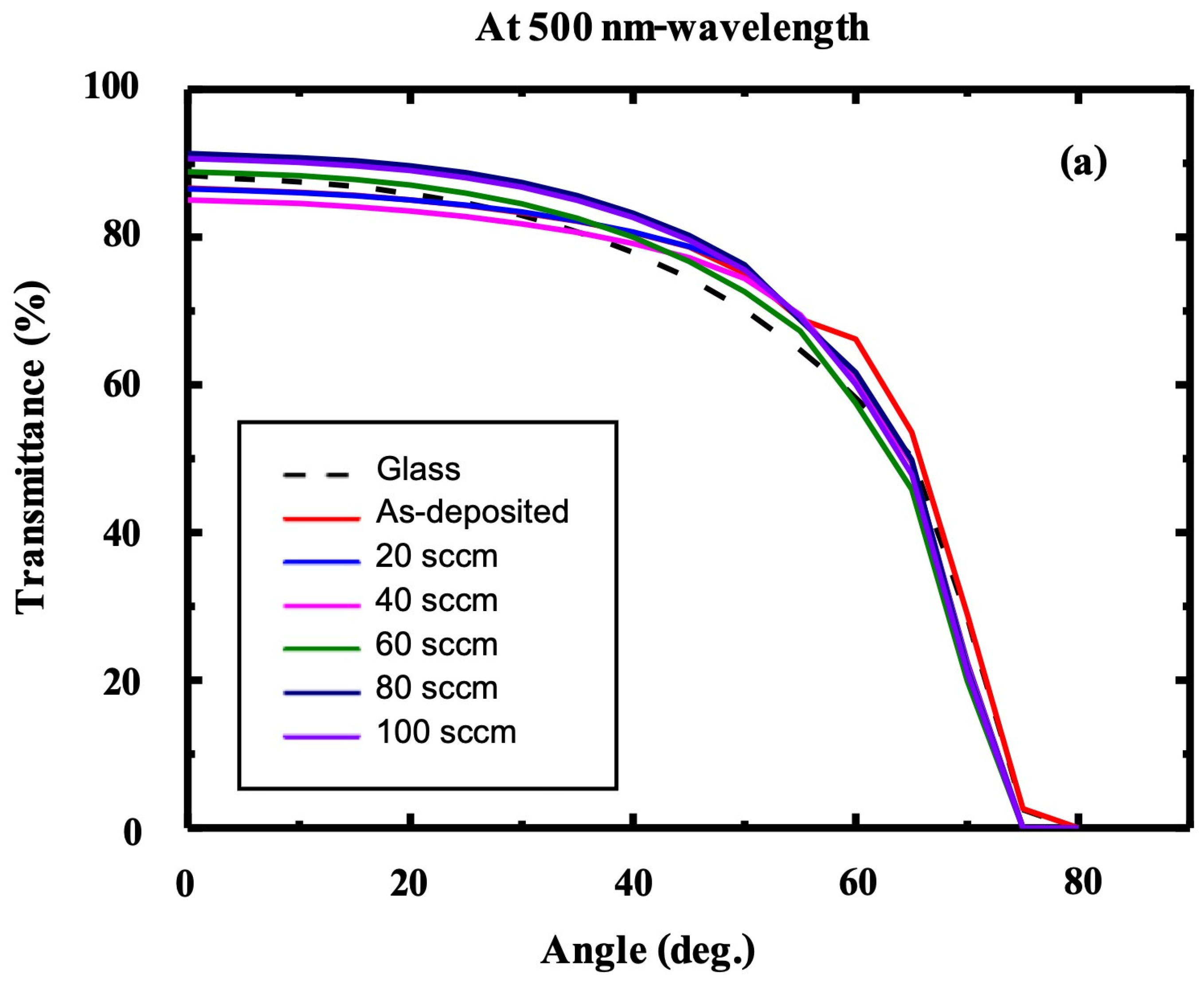

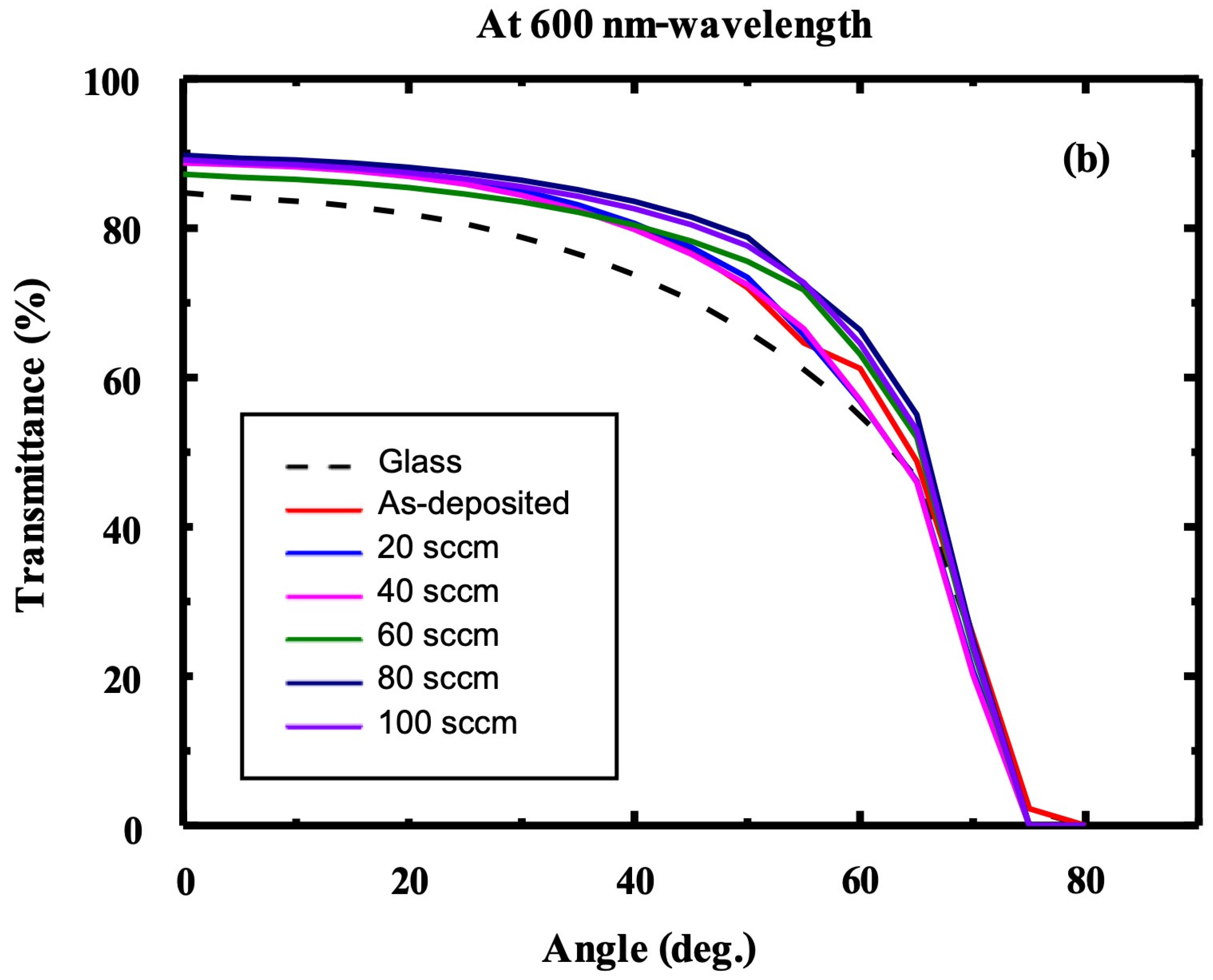

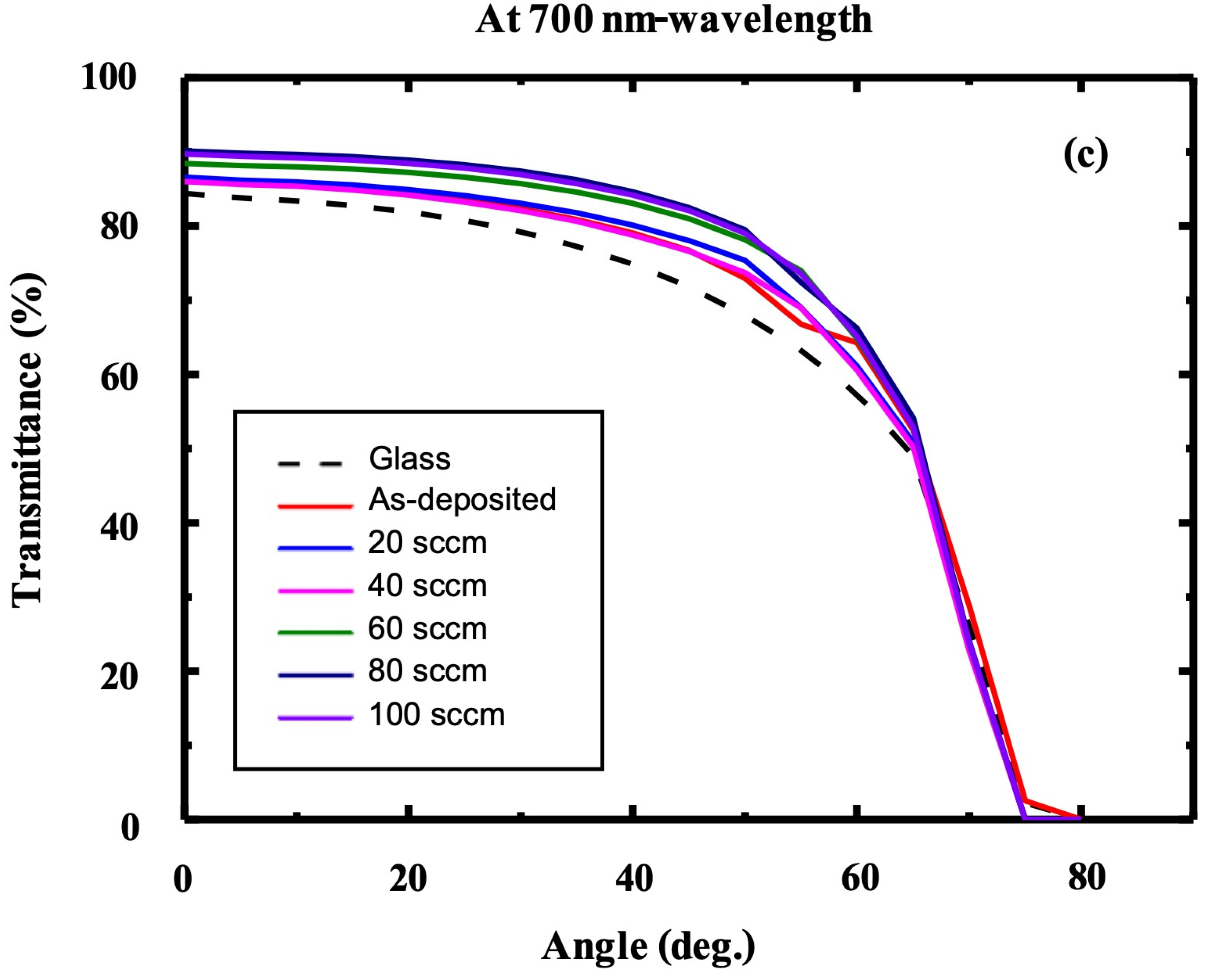

Furthermore, the average transmittance in the visible range (400-700 nm) of ITO-nanorod films treated with oxygen plasma under different gas flow rates of 20, 40, 60, 80, and 100 sccm was calculated and compared with glass, as-deposited film, and ITO commercial, as shown in

Figure 9. As can be seen in the graph, the average transmittance in the visible range of the plasma-treated ITO-nanorod film increases with the increase of the oxygen gas flow rate. Due to the increased self-collision of oxygen ions at higher concentrations, a correspondingly higher average transmittance change is achieved. Then, the omnidirectional characteristics were analyzed at 500, 600, and 700 nm wavelength of the glass substrate, as-deposited film, and treated with oxygen plasma of varying gas 20, 40, 60, 80, and 100 sccm. It was measured at the incident angle between 0

and 80

. The analysis results are illustrated in

Figure 10,

Figure 11 and

Figure 12. From the spectrum, the results found that a percentage of light-transmittance at incident angles of ITO-nanorod treated with oxygen plasma was close in overall cases of gas content. Compared with glass, ITO-nanorod films treated with oxygen plasma have a higher light transmittance. Therefore, optimizing light transmittance value is suitable as a thin transparent conductive oxide film in solar cells.

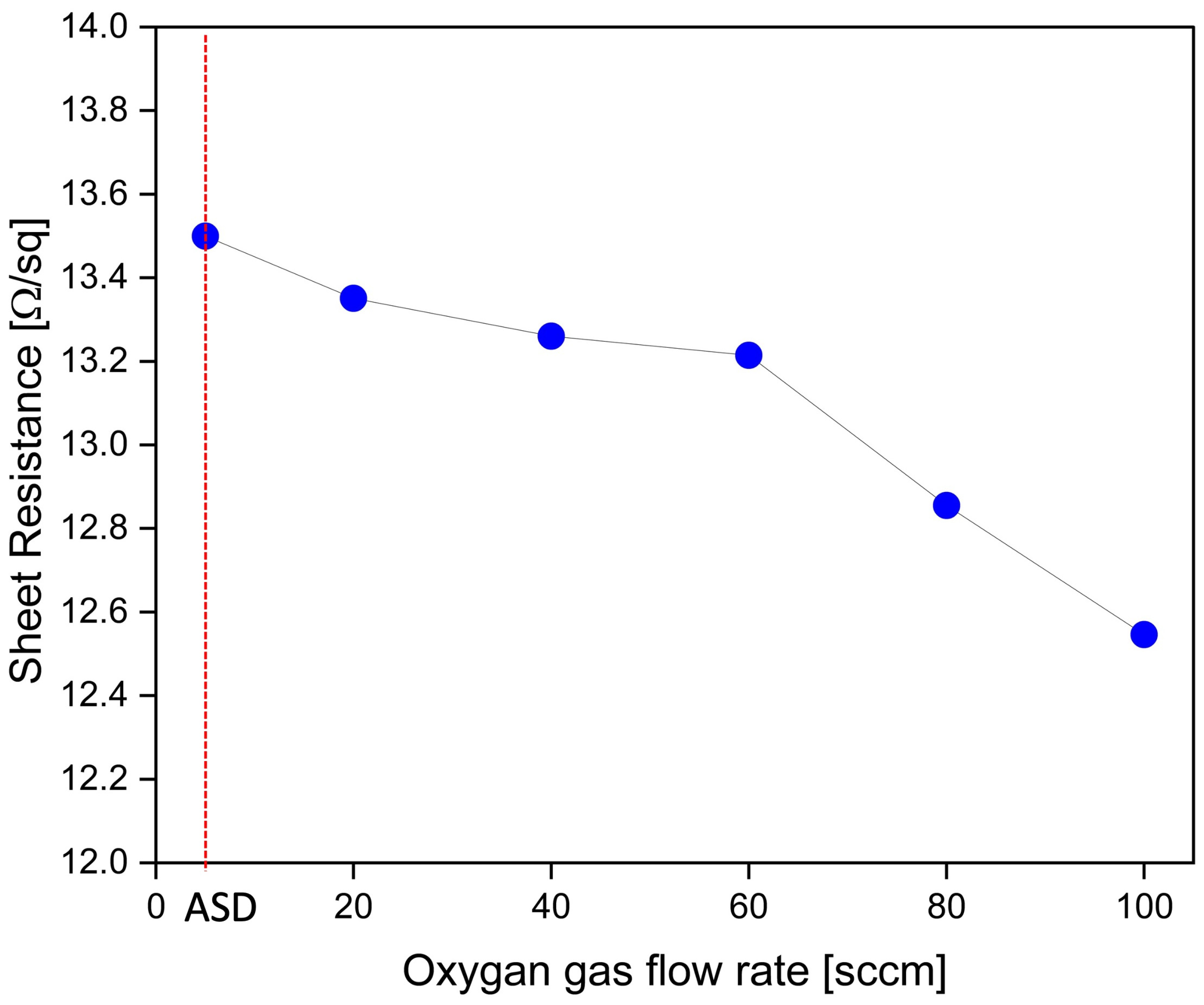

3.3. Electrical Properties

Figure 13 shows the electrical properties of ITO-nanorod treated with oxygen plasma at gas contents 20, 40, 60, 80, and 100 sccm, compared to as-deposited film. From the electrical properties test results, it was found that when the oxygen gas flow rate increased, the sheet resistance value gradually decreased. It was found that the oxygen gas flow rate of 100 sccm showed the lowest sheet resistance value. On the contrary, the as-deposited film gave the highest sheet resistance value. In this, the decrease in sheet resistance is because of the bombardment of oxygen ions with the film surface with the highest oxygen concentration. Thus, it has a higher ability to attack the ITO-nanorod film surface, which exhibits the lowest sheet resistance. With this low resistance, ITO-nanorod films will greatly benefit DSSCs, as they will enable efficient charge transfer and reduce energy loss in the cells.

3.4. Efficiency of Dye-Sensitized Solar Cell

In the photovoltaic performance, the DSSC structure is defined as follows: ITO-nanorod treated with oxygen plasma used as a working electrode, deposited with TiO

2, N 719 dye used as the photosensitizer,

used as electrolyte [

37], and platinum (Pt) used as the counter electrode. Thus, the assembly structure of the DSSC device is glass-deposited ITO-nanorod/TiO

2/(

)/Pt, respectively [

38,

39,

40,

41].

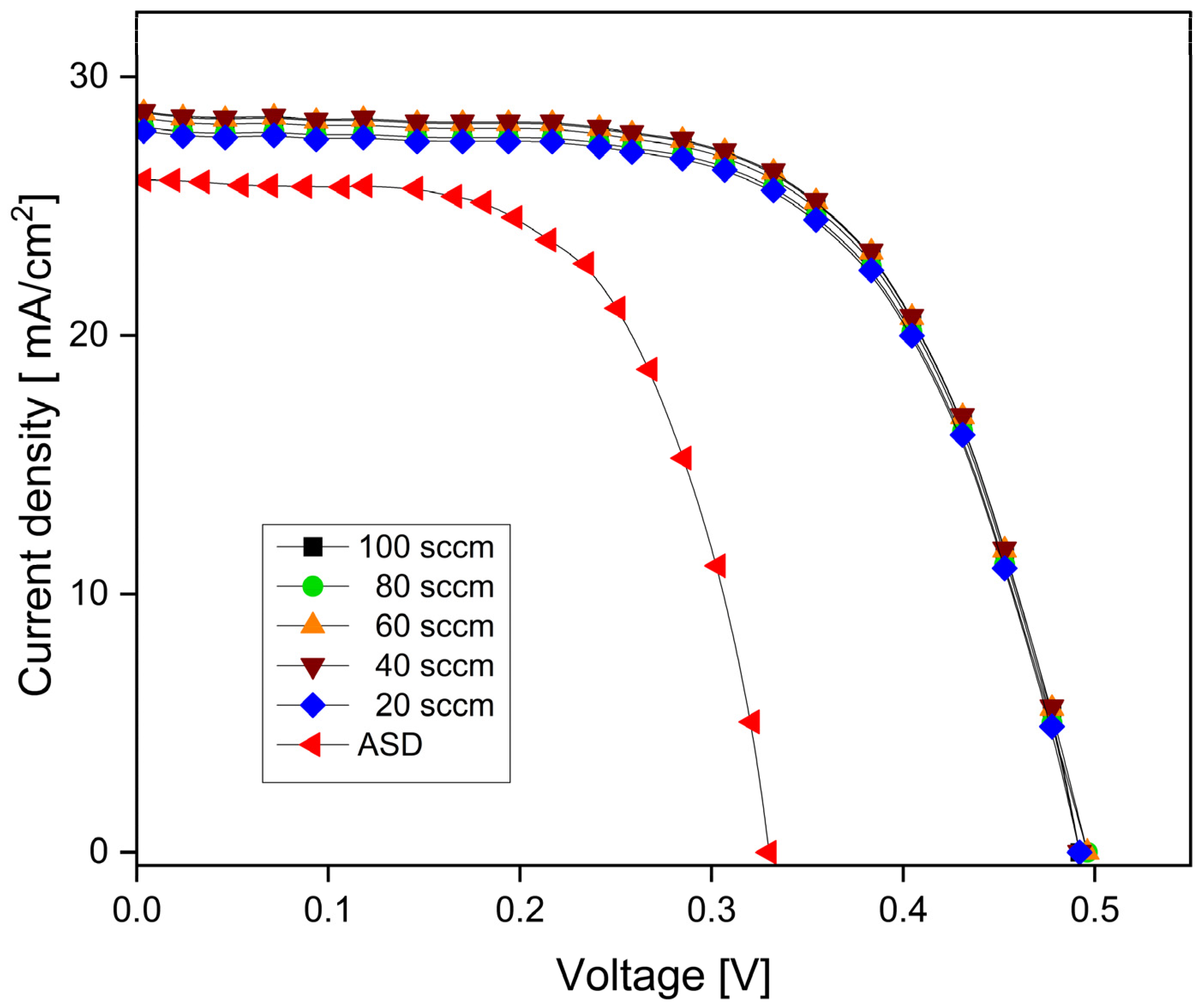

Figure 14 illustrates the I-V characterization on ITO-nanorod film applied with DSSC devices. The overall efficiency (

) of DSSC, meaning the percentage of solar energy that shines on a photovoltaic device, which is converted into electricity, was tested by J

sc, V

oc, and FF, which are calculated by equation (5) [

42], as shown these parameters in

Table 1.

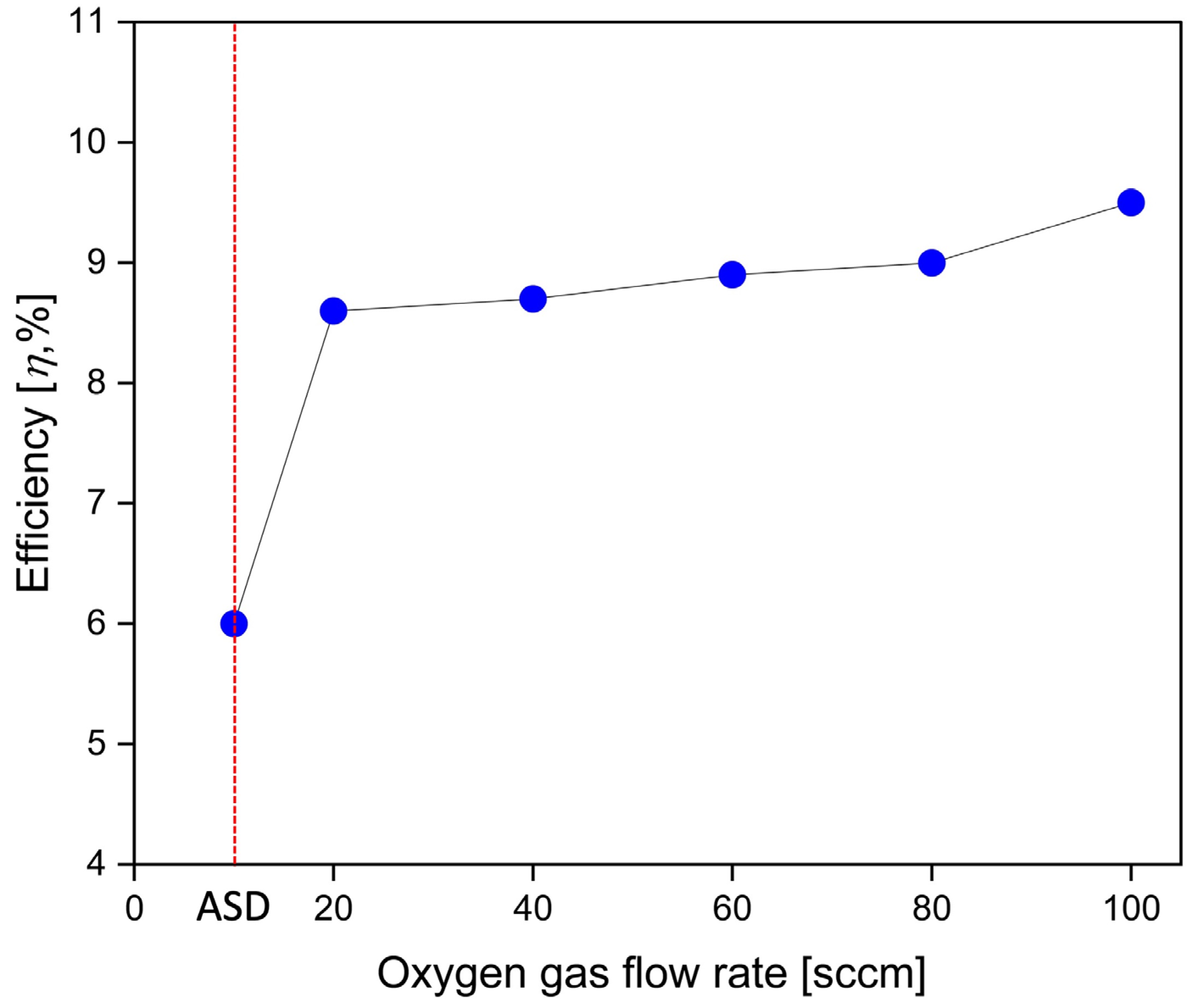

Figure 15 shows the overall efficiency of DSSC devices comparing as-deposited film and ITO-nanorod film treated with oxygen plasma in different conditions of gas flow rates. The trend illustrates that when the oxygen gas flow rate is increased, the efficiency of the photovoltaic improves. Compared with as-deposited film, the samples treated with oxygen plasma exhibited higher efficiency, especially at an oxygen gas flow rate of 100 sccm, showing the highest efficiency of 9.5 %. It produces higher energy oxygen plasma with more oxygen gas ions. When falling to ITO-nanorod substrates, the substrate surface is modified by enhancing the roughness of the ITO-nanorod (working electrode) to allow greater dye absorption. This results in better light harvesting efficiency, leading to improved performance of DSSC devices based on ITO-nanorod deposited on a glass substrate.

4. Discussion

The study's main objective is to create a new material for working electrodes to achieve DSSC with cost-effective, environmentally sustainable, and simple synthesis. This research emphasizes the critical use of plasma technology to modify the material's surface to investigate a relationship between the structure of the dye and the device's performance. This is necessary to know to develop new devices using environmentally friendly materials. Regarding the proposed stability, the critical issue is to improve the efficiency of solar energy conversion to meet the demand for electricity and energy. Therefore, we propose to improve the efficiency of DSSC based on the use of plasma technology to attack the material surface at the nanoscale level of the working electrode layer. It can be confirmed that plasma technology can penetrate the nanoscale particles to break the bonds and produce suitable properties for application.

The research results found that using plasma to treat the material surface with different gas flow rates affected several properties of the film. At first, in terms of the structure of the film layer, the result shows that when the oxygen gas flow rate is increased, the nanostructure of the ITO layer changes, and the grain size decreases because of the plasma attack on the In3+/Sn4+ bonds. Secondly, when increasing the oxygen gas flow rate, the result exhibits improved optical properties of the film, which is suitable for use as transparent conductive properties in solar cell devices. Thirdly, when the oxygen gas flow rate increases, the sheet resistance decreases, which is an advantage of the electrical properties that will help the solar cell device transfer charge quickly and reduce energy loss. Finally, when the oxygen gas flow rate increases, the solar cell's efficiency can be increased compared to the average film not treated with plasma.

Therefore, in the near future, we will develop a simple treatment system using low-cost materials such as nitrogen gas or atmospheric pressure to prepare ITO films with better quality and solar cell performance by oxygen plasma treatment.

5. Conclusions

This work successfully fabricated ITO-nanorod films using E-beam evaporation with the glancing angle deposition method. Nanorods illustrated the obtained films. The ITO-nanorod film was treated with oxygen plasma via a bias-magnetron RF sputtering process. To investigate the exceptional result, the oxygen gas flow rate varied by 20, 40, 60, 80, and 100 sccm. Thus, the oxygen plasma treatment has been proven effective in promoting the crystallization of ITO films, resulting in changes in their optical and electrical properties. Notably, the efficiency of DSSC devices can improve through oxygen plasma treatment.

Author Contributions

Conceptualization, W.P. and N.M.; methodology, S.A.; software, T.T.; validation, X.X., Y.Y. and W.P. and N.K.; formal analysis, S.A and T.T..; investigation, A.S.; resources, N.K.; data curation, W.P.; writing—original draft preparation, N.M. and A.S.; writing—review and editing, S.A.; visualization, T.M and K.T.; supervision, N.K. and N.K.; project administration, N.M.; funding acquisition, All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Royal Golden Jubilee (RGJ) Ph.D scholarship from the National Research Council of Thailand under the Ministry of Higher Education, Science, Research, and Innovation, grant number N41A650091 and this work is also supported by the project of the Research, Innovation, Partnerships Office (RIPO) with Financial Support from Faculty of Industrial Education and Technology.

Acknowledgments

The materials and equipment is supported by a School of Energy Environment and Materials under Energy Technology program, King Mongkut’s University of Technology Thonburi (KMUTT), Bangkok, Thailand.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tedla, A., Tai, Y. Influence of binary solvent system on the stability and efficiency of liquid dye sensitized solar cells. J. Photochem. Photobiol. A: Chem. 2018, 358, 70-75. [CrossRef]

- Han, K.-S., Shin, J.-H., Yoon, W.-Y., Lee, H. Enhanced performance of solar cells with anti-reflection layer fabricated by nano-imprint lithography. Sol. Energy Mater. Sol. Cells 2011, 95, pp. 288-291. [CrossRef]

- Agrawal, N., Ansari, M.Z., Majumdar, A., Gahlot, R., Khare, N. Efficient up-scaling of organic solar cells. Sol. Energy Mater. Sol. Cells 2016, 157, 960-965. [CrossRef]

- Sharma, K., Sharma, V., Sharma, S.S. Dye-sensitized solar cells: fundamentals and current status. Nanoscale Res. Lett. 2018, 13, 381. [CrossRef]

- Bu, I.Y.Y., Zheng, J. A new type of counter electrode for dye sensitized solar cells based on solution processed SnO2 and activated carbon. Mater. Sci. Semicond. 2015, 39, 223-228. [CrossRef]

- Kao, M.C., Chen, H.Z., Young, S.L. Dye-sensitized solar cells with TiO2 nanocrystalline films prepared by conventional and rapid thermal annealing processes. Thin Solid Films 2011, 519, 3268-3271. [CrossRef]

- Guillen, C., Herrero, J. Influence of oxygen in the deposition and annealing atmosphere on the characteristics of ITO thin films prepared by sputtering at room temperature. Vacuum 2006, 80, 615-620. [CrossRef]

- Hichou, A.E., Kachouane, A., Bubendorff, J.L., Addou, M., Ebothe, J., Troyon, M., Bougrine, A. Effect of substrate temperature on electrical, structural, optical and cathodoluminescent properties of In2O3-Sn thin films prepared by spray pyrolysis. Thin Solid Films 2004, 458, 263-268. [CrossRef]

- Kawashima, T., Ezure, T., Okada, K., Matsui, H., Goto, K., Tanabe, N. FTO/ITO double-layered transparent conductive oxide for dye-sensitized solar cells. J. Photochem. Photobiol., A. 2004, 164, 199-202. [CrossRef]

- Wang, H.-W., Ting, C.-F., Hung, M.-K., Chiou, C.-H., Liu, Y.-L., Liu, Z., Ratinac, K.R., Ringer, S.P. Three-dimensional electrodes for dye-sensitized solar cells: synthesis of indium-tin-oxide nanowire arrays and ITO/TiO2 core-shell nanowire arrays by electrophoretic deposition. Nanotechnology 2009, 20, 055601. [CrossRef]

- Shikoh, A.S., Ahmad, Z., Touati, F., Shakoor, R.A., Al-Muhtaseb, S.A. Optimization of ITO glass/TiO2 based DSSC photo-anodes through electrophoretic deposition and sintering techniques. Ceram. Int. 2017, 43, 10540-10545. [CrossRef]

- Peng, Y., Zhang, L., Cheng, N., Andrew, T.L. ITO-free transparent organic solar cell with distributed bragg reflector for solar harvesting windows. Energies 2017, 10, 707. [CrossRef]

- Upadhyaya, H.M., Senthilarasu, S., Hsu, M.-H., Kumar, D.K. Recent progress and the status of dye-sensitised solar cell (DSSC) technology with state-of-the-art conversion efficiencies. Sol. Energy Mater. Sol. Cells 2013, 119, 291-295. [CrossRef]

- Kim, S.Y., Lee, J.-L., Kim, K.-B., Tak, Y.-H. Effect of ultraviolet-ozone treatment of indium-tin-oxide on electrical properties of organic light emitting diodes. J. Appl. Phys. 2004, 95, 2560-2563. [CrossRef]

- Cho, J.M., Kwak, S.-W., Aqoma, H., Kim, J.W., Shin, W.S., Moon, S.-J., Jang, S.-Y., Jo, J. Effects of ultraviolet-ozone treatment on organic-stabilized ZnO nanoparticle-based electron transporting layers in inverted polymer solar cells. Org. Electron. 2014, 15, 1942-1950. [CrossRef]

- Farina, F.E., Azmi, W.S.B., Harafuji, K. Ultraviolet-ozone anode surface treatment and its effect on organic solar cells. Thin Solid Films 2017, 623, 72-83. [CrossRef]

- Aegerter, M.A., Al-Dahoudi, N. Wet-chemical processing of transparent and antiglare conducting ITO coating on plastic substrates. J. Solgel Sci. Technol. 2003, 27, 81-89. [CrossRef]

- Legnani, C., Lima, S.A.M., Oliveria, H.H.S., Quirino, W.G., Machado, R., Santos, R.M.B., Davolos, M.R., Achete, C.A., Cremona, M. Indium tin oxide films prepared via wet chemical route. Thin Solid Films 2007, 516, 193-197. [CrossRef]

- Khachatryan, H., Kim, D.-J., Kim, M., Kim, H.-K. Roll-to-Roll fabrication of ITO thin film for flexible optoelectronics applications: The role of post-annealing. Mater. Sci. Semicond. 2018, 88, 51-56. [CrossRef]

- Qin, G., Fan, L., Watanabe, A. Formation of indium tin oxide film by wet process using laser sintering. J. Mater. Process. Technol. 2016, 227, 16-23. [CrossRef]

- Park, Y.S., Kim, E., Hong, B., Lee, J. Characteristics of ITO films with oxygen plasma treatment for thin film solar cell applications. Mater. Res. Bull. 2013, 48, 5115-5120. [CrossRef]

- He. P., Wang, S.D., Wong, W.K., Cheng. L.F., Lee, C.S., Lee, S.T., Liu, S.Y. Vibrational analysis of oxygen-plasma treated indium tin oxide. Chem. Phys. Lett. 2003, 370, 795-798. [CrossRef]

- Lu, ., Wu, Y., Guo, J., Lu, G., Wang, Y., Shen, J. Surface treatment of indium tin oxide by oxygen-plasma for organic light-emitting diodes. Mater. Sci. Eng. B. 2003, 97, 141-144. [CrossRef]

- Calnan, S., Upadhyaya, H.M., Dann, S.E., Thwaites, M.J., Tiwari, A.N. Effects of target bias voltage on indium tin oxide films deposited high target utilisation sputtering. Thin Solid Films 2007, 515, 8500-8504. [CrossRef]

- Maissel, L.I., Schaible, P.M. Thin films deposited by bias sputtering. J. Appl. Phys. 1965, 36, 237-242. [CrossRef]

- Stamate, E. Lowering the resistivity of aluminum doped zinc oxide thin films by controlling the self-bias during RF magnetron sputtering. Surf. Coat. Technol. 2020, 402, 126306. [CrossRef]

- Liang, L.Y., Cao, H.T., Liu, Q., Jiang, K.M., Liu, Z. M., Zhuge, F., Deng, F.L. Substrate biasing effect on the physical properties of reactive RF-magnetron-sputtered aluminum oxide dielectric films on ITO glasses. ACS Appl. Mater. Interfaces 2014, 6, 2255-2261. [CrossRef]

- Lee, J., Jung, H., Lim, D., Yang, K., Song, W., Yi, J. Effects of bias voltage on the properties of ITO films prepared on polymer substrates. Thin Solid Films 2005, 480-481, 157-161. [CrossRef]

- Zhao, L., Zhou, Z., Peng, H., Cui, R. Indium tin oxide thin films by bias magnetron rf sputtering for heterojunction solar cells application. Appl. Surf. Sci. 2005, 252, 385-392. [CrossRef]

- Honda, S.-i., Chihara, K., Watamori, M., Oura, K. Depth profiling of oxygen content of indium tin oxide fabricated by bias sputtering. Appl. Surf. Sci. 1997, 113-114, 408-411. [CrossRef]

- Perez, I., Sosa, V., Perera, F.G., Galindo, J.T.E., Enriquez-Carrejo, J.L., Gonzalez, P.G.M. Effect of ion bombardment on the chemical properties of crystalline tantalum pentoxide films. Vacuum 2019, 165, 274-282. [CrossRef]

- Rizzo, A., Signore, M.A., Valerini, D., Altamura, D., Cappello, A., Tapfer, L. A study of suppression effect of oxygen contamination by bias voltage in reactively sputtered ZrN films. Surf. Coat. Technol. 2012, 206, 2711-2718. [CrossRef]

- Yamamoto, T., Nomoto, J., Kitami, H., Sakemi, T., Makino, H., Kobayashi, K., Aoki, Y., Kishimoto, S. Design of advanced functional ZnO conductive thin films with arc plasma. J. Vac. Soc. Jpn. 2017, 60, 292-299. [CrossRef]

- Holland, L., Ojha, S.M. The chemical sputtering of graphite in an oxygen plasma. Vacuum 1976, 26, 53-60. [CrossRef]

- Rosemann, N., Ortner, K., Petersen, J., Schadow, T., Baker, M., Brauer, G., Rosler, J. Influence of bias voltage and oxygen flow rate on morphology and crystallographic properties of gas flow sputtered zirconia coatings. Surf. Coat. Technol. 2015, 276, 668-676. [CrossRef]

- Gaussian function. Available online: https://en.wikipedia.org/wiki/Gaussian_function (accessed on 15 February 2024).

- Tennakone, K., Kumara, G.R.R.A., Kottegoda, I.R.M., VPS, P. An efficient dye-sensitized photoelectrochemical solar cell made from oxides of tin and zinc. Chem. Comn. 1999, 1, 15-16. [CrossRef]

- Fung, A.K.M., Chiu, B.K.W., Lam, M.H.W. Surface modification of TiO2 by a ruthenium (II) polypyridyl complex via silyl-linkage for sensitized photocatalytic degradation of carbon tetrachloride by visible irradiation. Water Res. 2003, 37, 1939-1947. [CrossRef]

- Zaban, A., Ferrere, S., Gregg, B.A. Relative Energetics at the semiconductor/sensitizing dye/electrolyte interface. J. Phys. Chem. B 1998, 102, 452-460. [CrossRef]

- Fakharuddin, A., Jose, R., Brown, T.M. Fabregat-Santiago, F., Bisquert, J. A perspective on the production of dye-sensitized solar modules. Energy Environ. Sci. 2014, 7, 3952-3981. [CrossRef]

- Wang, M., Anghel, A.M., Marsan, B., Cevey Ha, N.L., Pootrakulchote, N., Zekeeruddin, S.M., Grätzel, M. CoS supersedes Pt as efficient electrocatalyst for triiodide reduction in dye-sensitized solar cells. J. Am. Chem. Soc. 2009, 131, 15976-15977. [CrossRef]

- Murakami, T.N., Gratzel, M. Counter electrode for DSC: application of functional materials as catalysts. Inorganica Chim. Acta, 2008, 361, 572-580. [CrossRef]

Figure 1.

Schematic diagram showing equipment of deposition machine applied with plasma treatment process with bias-magnetron RF sputtering of varying gas at contents 20 sccm, 40 sccm, 60 sccm, 80 sccm, and 100 sccm.

Figure 1.

Schematic diagram showing equipment of deposition machine applied with plasma treatment process with bias-magnetron RF sputtering of varying gas at contents 20 sccm, 40 sccm, 60 sccm, 80 sccm, and 100 sccm.

Figure 2.

Bias-magnetron RF sputtering mechanism used for oxygen plasma treatment on ITO-nanorod film under different oxygen gas flow rates of 20, 40, 60, 80, 100 sccm.

Figure 2.

Bias-magnetron RF sputtering mechanism used for oxygen plasma treatment on ITO-nanorod film under different oxygen gas flow rates of 20, 40, 60, 80, 100 sccm.

Figure 3.

Processing of oxygen plasma bombardment to the ITO-nanorod surfaces driving under bias-magnetron RF sputtering method with different gas conditions of 20, 40, 60, 80, and 100 sccm.

Figure 3.

Processing of oxygen plasma bombardment to the ITO-nanorod surfaces driving under bias-magnetron RF sputtering method with different gas conditions of 20, 40, 60, 80, and 100 sccm.

Figure 4.

X-ray diffraction patterns of ITO films preparing with E-beam evaporation with glancing angle deposition and treated by oxygen plasma of varying oxygen gas, such as 20, 40, 60, 80, and 100 sccm.

Figure 4.

X-ray diffraction patterns of ITO films preparing with E-beam evaporation with glancing angle deposition and treated by oxygen plasma of varying oxygen gas, such as 20, 40, 60, 80, and 100 sccm.

Figure 5.

Cross-section images of scanning electron microscopy analysis on ITO-nanorod deposited on glass substrate treated by oxygen plasma of varying gas flow rate comparing with as-deposited film: (a) as-deposited; (b) 20 sccm; (c) 40 sccm; (d) 60 sccm; (e) 80 sccm; (f) 100 sccm.

Figure 5.

Cross-section images of scanning electron microscopy analysis on ITO-nanorod deposited on glass substrate treated by oxygen plasma of varying gas flow rate comparing with as-deposited film: (a) as-deposited; (b) 20 sccm; (c) 40 sccm; (d) 60 sccm; (e) 80 sccm; (f) 100 sccm.

Figure 6.

Top-image of scanning electron microscopy analysis (top view) of on ITO-nanorod deposited on glass substrate treated by oxygen plasma of varying gas flow rate comparing with as-deposited film: (a) as-deposited; (b) 20 sccm; (c) 40 sccm; (d) 60 sccm; (e) 80 sccm; (f) 100 sccm.

Figure 6.

Top-image of scanning electron microscopy analysis (top view) of on ITO-nanorod deposited on glass substrate treated by oxygen plasma of varying gas flow rate comparing with as-deposited film: (a) as-deposited; (b) 20 sccm; (c) 40 sccm; (d) 60 sccm; (e) 80 sccm; (f) 100 sccm.

Figure 7.

Relationship of length nanorods and diameter size on ITO-nanorod calculated by Gaussian distribution comparing between as-deposited film and oxygen plasma treatment at 20, 40, 60, 80, and 100 sccm.

Figure 7.

Relationship of length nanorods and diameter size on ITO-nanorod calculated by Gaussian distribution comparing between as-deposited film and oxygen plasma treatment at 20, 40, 60, 80, and 100 sccm.

Figure 8.

Transmittance spectra of the ITO-nanorod films compared with clear glass, as-deposited film and treated with oxygen plasma content of 20, 40, 60, 80, 100 sccm preparing via bias-magnetron RF sputtering process.

Figure 8.

Transmittance spectra of the ITO-nanorod films compared with clear glass, as-deposited film and treated with oxygen plasma content of 20, 40, 60, 80, 100 sccm preparing via bias-magnetron RF sputtering process.

Figure 9.

Average transmittance in the visible range of the ITO-nanorod films compared with clear glass, as-deposited film and treated with oxygen plasma content of 20, 40, 60, 80, 100 sccm preparing via bias-magnetron RF sputtering process.

Figure 9.

Average transmittance in the visible range of the ITO-nanorod films compared with clear glass, as-deposited film and treated with oxygen plasma content of 20, 40, 60, 80, 100 sccm preparing via bias-magnetron RF sputtering process.

Figure 10.

Omnidirectional characteristics on transmittance properties of ITO-nanorod treated with oxygen plasma under gas content 20, 40, 60, 80, 100 sccm comparing to glass substrate and as-deposited film at 500 nm-wavelength.

Figure 10.

Omnidirectional characteristics on transmittance properties of ITO-nanorod treated with oxygen plasma under gas content 20, 40, 60, 80, 100 sccm comparing to glass substrate and as-deposited film at 500 nm-wavelength.

Figure 11.

Omnidirectional characteristics on transmittance properties of ITO-nanorod treated with oxygen plasma under gas content 20, 40, 60, 80, 100 sccm comparing to glass substrate and as-deposited film at 600 nm-wavelength.

Figure 11.

Omnidirectional characteristics on transmittance properties of ITO-nanorod treated with oxygen plasma under gas content 20, 40, 60, 80, 100 sccm comparing to glass substrate and as-deposited film at 600 nm-wavelength.

Figure 12.

Omnidirectional characteristics on transmittance properties of ITO-nanorod treated with oxygen plasma under gas content 20, 40, 60, 80, 100 sccm comparing to glass substrate and as-deposited film at 700 nm-wavelength.

Figure 12.

Omnidirectional characteristics on transmittance properties of ITO-nanorod treated with oxygen plasma under gas content 20, 40, 60, 80, 100 sccm comparing to glass substrate and as-deposited film at 700 nm-wavelength.

Figure 13.

Electrical properties on ITO-nanorod film treated by oxygen plasma comparing with as-deposited film using four point probe technique.

Figure 13.

Electrical properties on ITO-nanorod film treated by oxygen plasma comparing with as-deposited film using four point probe technique.

Figure 14.

I-V characteristics of dye-sensitized solar cell on ITO-nanorod treated with oxygen plasma of varying gas contents at 20, 40, 60, 80, 100 sccm providing via bias-magnetron RF sputtering process.

Figure 14.

I-V characteristics of dye-sensitized solar cell on ITO-nanorod treated with oxygen plasma of varying gas contents at 20, 40, 60, 80, 100 sccm providing via bias-magnetron RF sputtering process.

Figure 15.

Efficiency of dye-sensitized solar cell of dye-sensitized solar cell on ITO-nanorod treated with oxygen plasma of varying gas contents at 20, 40, 60, 80, 100 sccm providing via bias-magnetron RF sputtering process.

Figure 15.

Efficiency of dye-sensitized solar cell of dye-sensitized solar cell on ITO-nanorod treated with oxygen plasma of varying gas contents at 20, 40, 60, 80, 100 sccm providing via bias-magnetron RF sputtering process.

Table 1.

Photovoltaic parameters of dye-sensitized solar cell based on the ITO-nanorod films treated by oxygen plasma of varying gas contents at 20-100 sccm.

Table 1.

Photovoltaic parameters of dye-sensitized solar cell based on the ITO-nanorod films treated by oxygen plasma of varying gas contents at 20-100 sccm.

| ITO substrate |

|

[mV] |

[%] |

Efficiency

|

| As-deposited |

26.8 |

336 |

63 |

6 |

| 20 sccm |

27.9 |

491 |

66 |

8.6 |

| 40 sccm |

28.1 |

493 |

66 |

8.7 |

| 60 sccm |

28.5 |

494 |

67 |

8.9 |

| 80 sccm |

28.8 |

497 |

66 |

9.2 |

| 100 sccm |

29.3 |

500 |

70 |

9.51

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).