Submitted:

20 August 2024

Posted:

21 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Solution Mixture for 1H-NMR Measurement

2.3. Preparation of Melt Blending

2.4. Fourier Transform Infrared Spectroscopy (FTIR)

2.5. Thermogravimetric Analysis (TGA)

2.6. Differential Scanning Calorimetry (DSC)

3. Results and Discussions

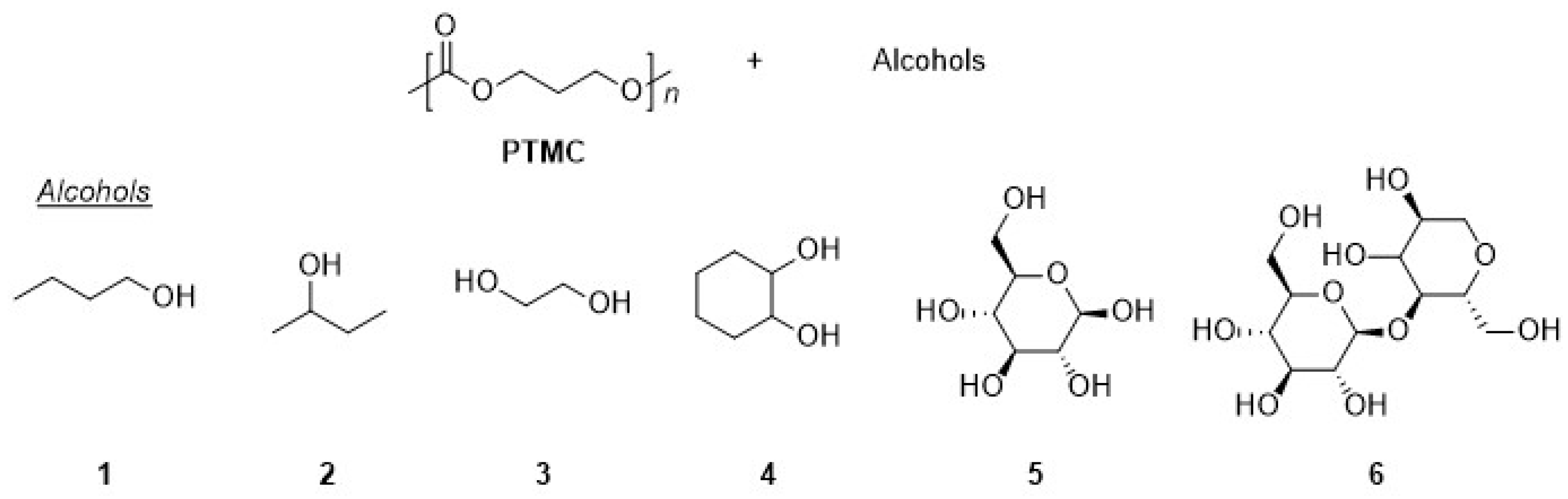

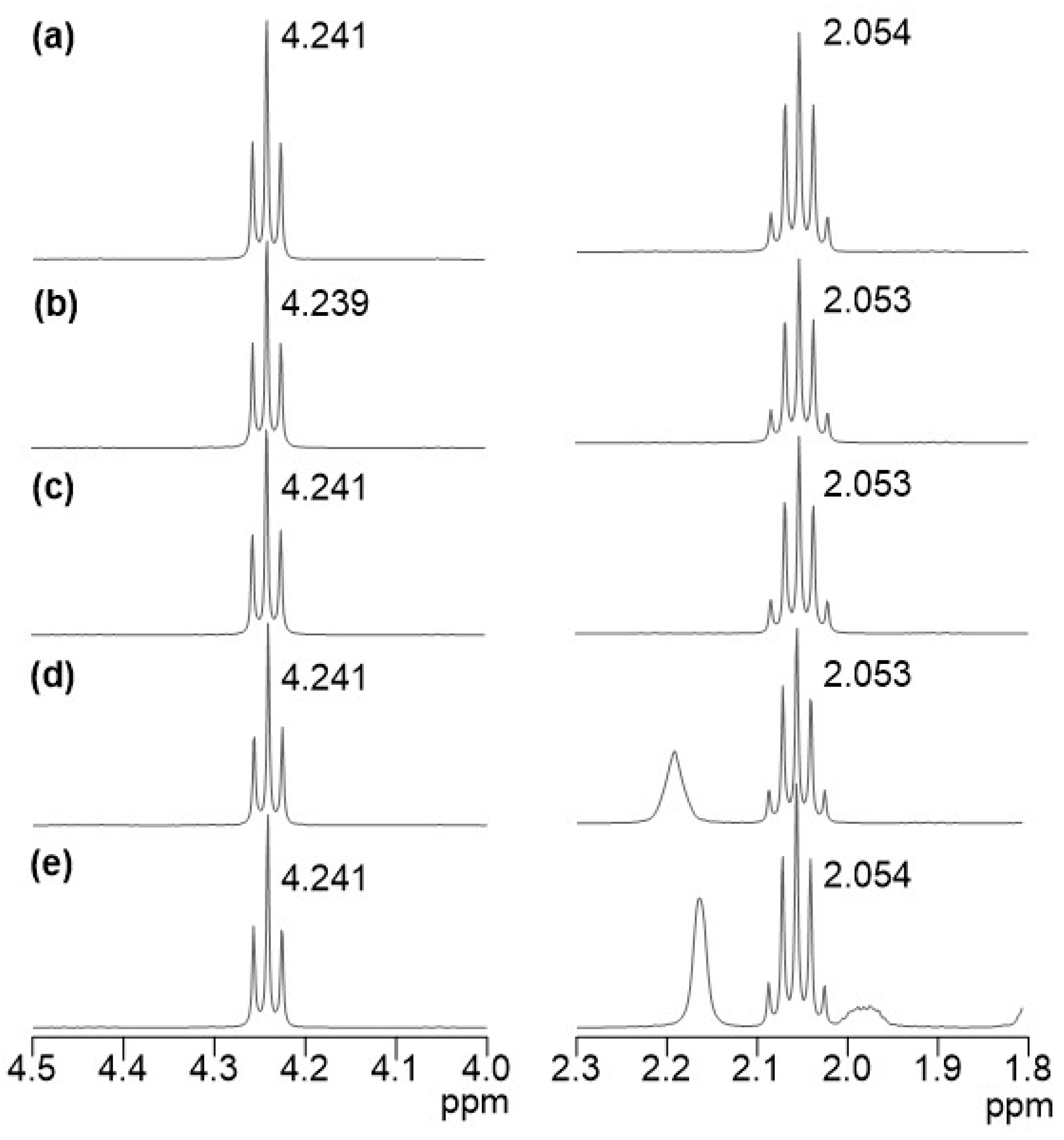

3.1. Interaction Study of Mixed Solution

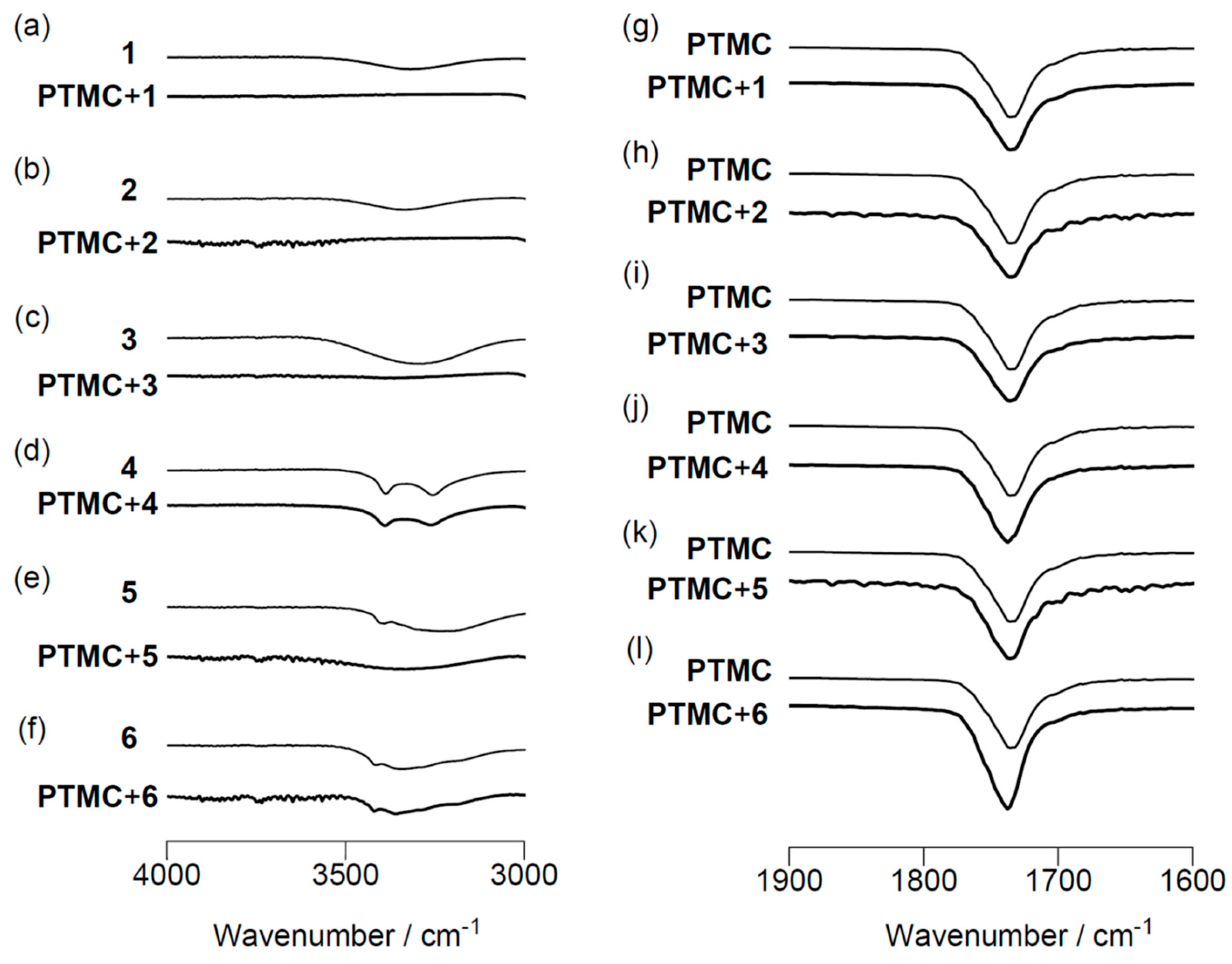

3.2. Interaction Study of Blend at Solid State

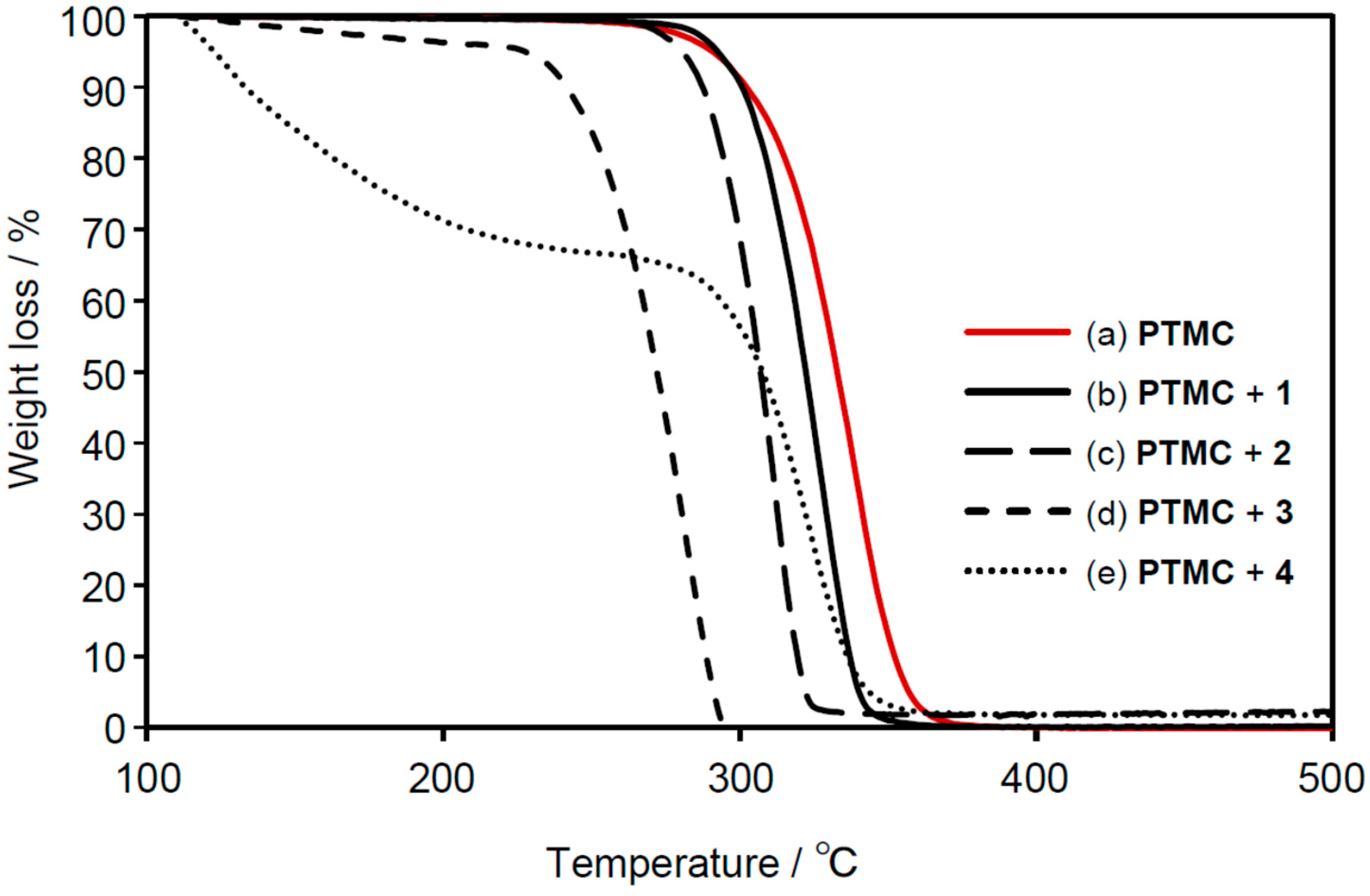

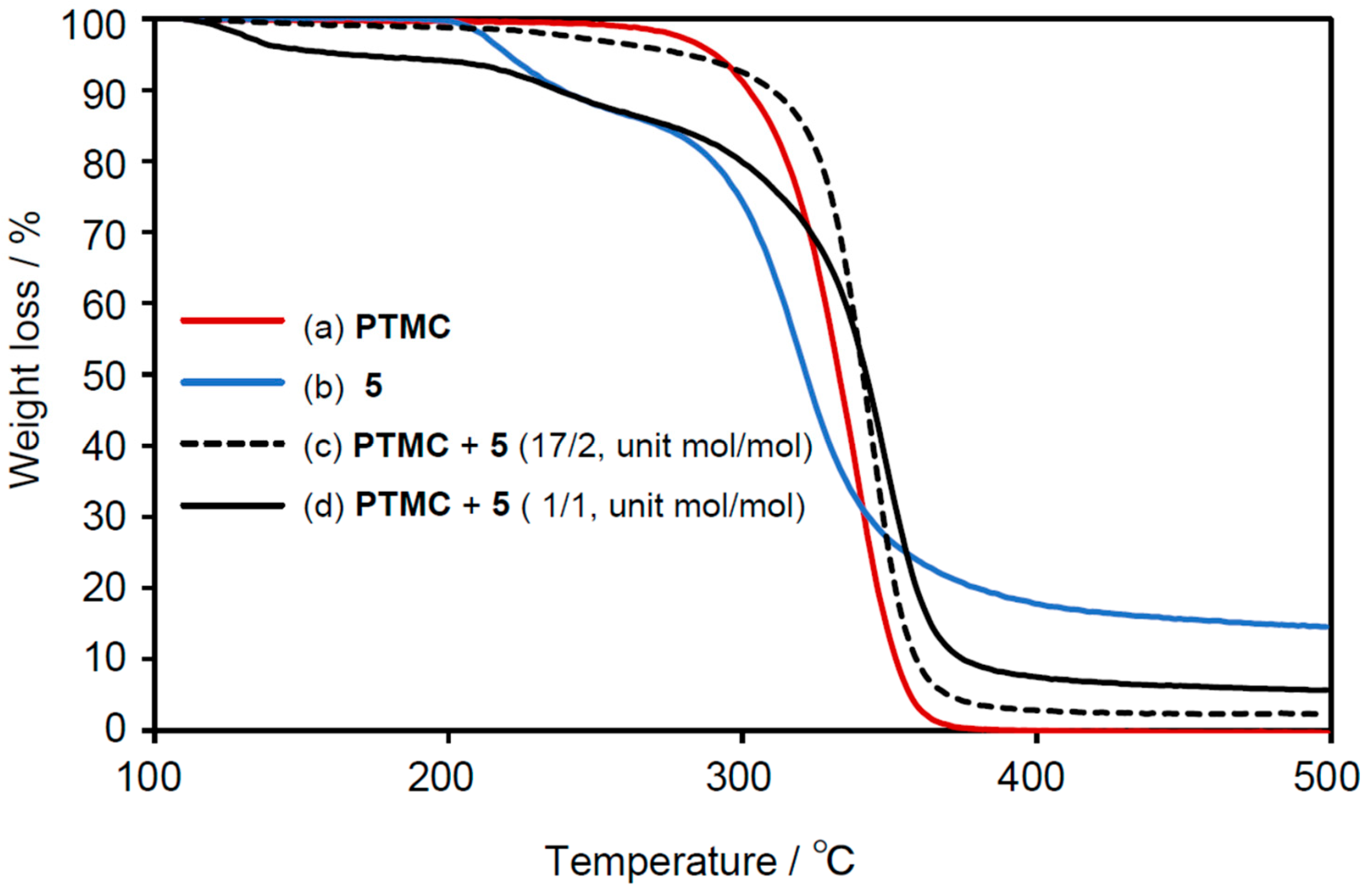

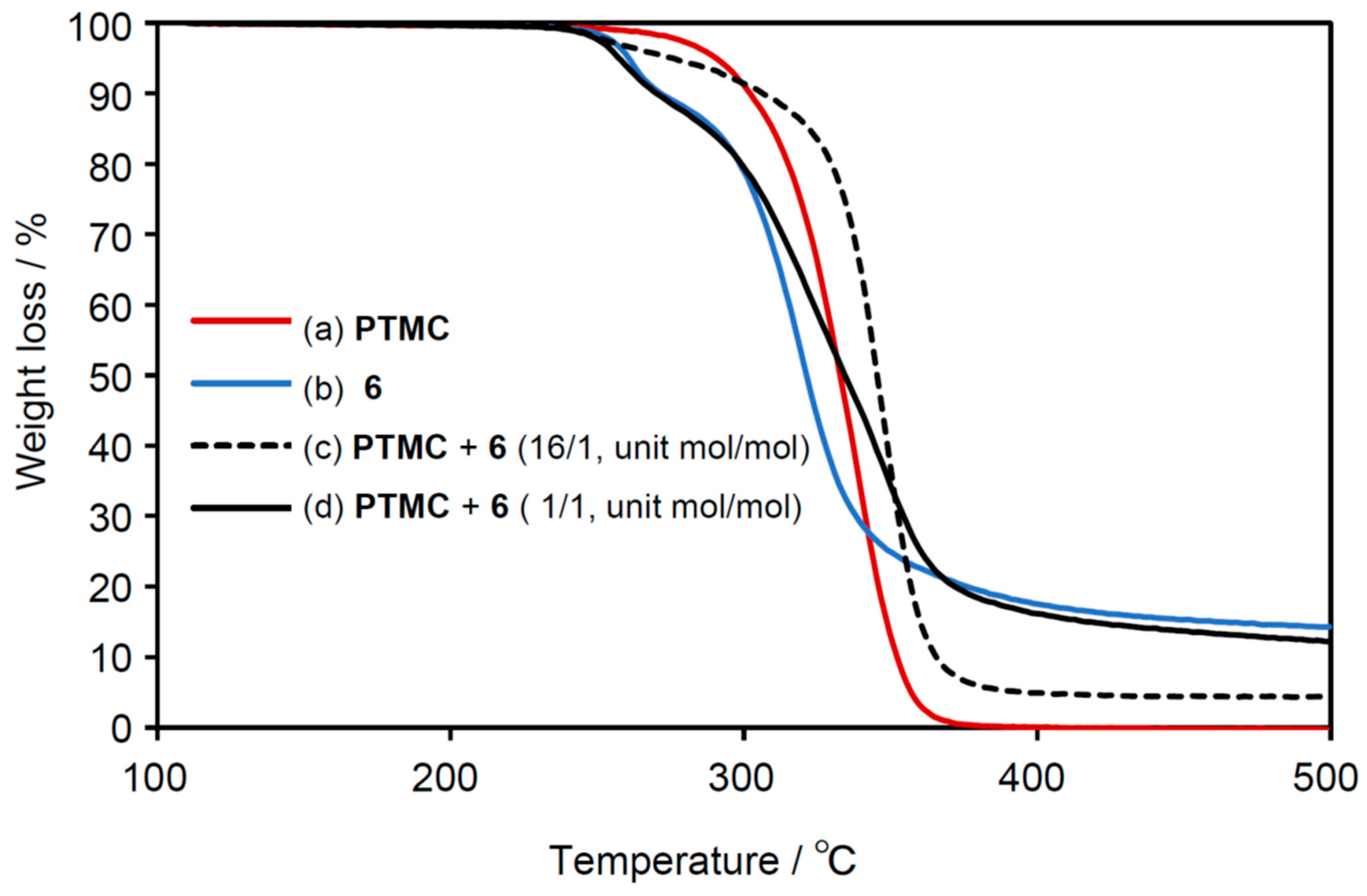

3.3. Interaction Effects on Thermal Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fukushima, K. Poly(Trimethylene Carbonate)-Based Polymers Engineered for Biodegradable Functional Biomaterials. Biomater. Sci. 2016, 4, 9–24. [Google Scholar] [CrossRef] [PubMed]

- Pêgo, A.P.; Van Luyn, M.J.A.; Brouwer, L.A.; Van Wachem, P.B.; Poot, A.A.; Grijpma, D.W.; Feijen, J. In Vivo Behavior of Poly(1,3-Trimethylene Carbonate) and Copolymers of 1,3-Trimethylene Carbonate with D,L-Lactide or ε-Caprolactone: Degradation and Tissue Response. J. Biomed. Mater. Res. A 2003, 67, 1044–1054. [Google Scholar] [CrossRef]

- Zhu, K.J.; Hendren, R.W.; Jensen, K.; Pitt, C.G. Synthesis, Properties, and Biodegradation of Poly (1,3-Trimethylene Carbonate). Macromolecules 1991, 24, 1736–1740. [Google Scholar] [CrossRef]

- Pêgo, A.P.; Grijpma, D.W.; Feijen, J. Enhanced Mechanical Properties of 1,3-Trimethylene Carbonate Polymers and Networks. Polymer 2003, 44, 6495–6504. [Google Scholar] [CrossRef]

- Tempelaar, S.; Mespouille, L.; Dubois, P.; Dove, A.P. Organocatalytic Synthesis and Postpolymerization Functionalization of Allyl-Functional Poly(Carbonate)s. Macromolecules 2011, 44, 2084–2091. [Google Scholar] [CrossRef]

- Nederberg, F.; Lohmeijer, B.G.G.; Leibfarth, F.; Pratt, R.C.; Choi, J.; Dove, A.P.; Waymouth, R.M.; Hedrick, J.L. Organocatalytic Ring Opening Polymerization of Trimethylene Carbonate. Biomacromolecules 2007, 8, 153–160. [Google Scholar] [CrossRef]

- Tempelaar, S.; Mespouille, L.; Coulembier, O.; Dubois, P.; Dove, A.P. Synthesis and Post-Polymerisation Modifications of Aliphatic Poly(Carbonate)s Prepared by Ring-Opening Polymerisation. Chem. Soc. Rev. 2013, 42, 1312–1336. [Google Scholar] [CrossRef]

- Yu, W.; Maynard, E.; Chiaradia, V.; Arno, M.C.; Dove, A.P. Aliphatic Polycarbonates from Cyclic Carbonate Monomers and Their Application as Biomaterials. Chem. Rev. 2021, 121, 10865–10907. [Google Scholar] [CrossRef]

- Amsden, B. In Vivo Degradation Mechanisms of Aliphatic Polycarbonates and Functionalized Aliphatic Polycarbonates. Macromol. Biosci. 2021, 21, 2100085. [Google Scholar] [CrossRef]

- Zhang, Z.; Kuijer, R.; Bulstra, S.K.; Grijpma, D.W.; Feijen, J. The in Vivo and in Vitro Degradation Behavior of Poly(Trimethylene Carbonate). Biomaterials 2006, 27, 1741–1748. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Y.; Zhao, X.; Mao, H.; Gu, Z. Investigating the Biodegradation Mechanism of Poly(trimethylene carbonate): Macrophage-Mediated Erosion by Secreting Lipase. Biomacromolecules 2023, 24, 921–928. [Google Scholar] [CrossRef]

- Nag, A.; Arifianti, A.E.; Khankhuean, A.; Ajiro, H. Polymer Blends Using Poly(Trimethylene Carbonate). Eur. Polym. J. 2024, 214, 113146. [Google Scholar] [CrossRef]

- Edlund, U.; Albertsson, A.C. Copolymerization and Polymer Blending of Trimethylene Carbonate and Adipic Anhydride for Tailored Drug Delivery. J. Appl. Polym. Sci. 1999, 72, 227–239. [Google Scholar] [CrossRef]

- Qi, J.; Feng, S.; Liu, X.; Xing, L.; Chen, D.; Xiong, C. Morphology, Thermal Properties, Mechanical Property and Degradation of PLGA/PTMC Composites. J. Polym. Res. 2020, 27, 387. [Google Scholar] [CrossRef]

- Liu, D.; Li, H.; Jiang, L.; Chuan, Y.; Yuan, M.; Chen, H. Characterization of Active Packaging Films Made from Poly(Lactic Acid)/Poly(Trimethylene Carbonate) Incorporated with Oregano Essential Oil. Molecules 2016, 21, 21060695. [Google Scholar] [CrossRef]

- Qin, Y.; Yang, J.; Xue, J. Characterization of Antimicrobial Poly(Lactic Acid)/Poly(Trimethylene Carbonate) Films with Cinnamaldehyde. J. Mater. Sci. 2015, 50, 1150–1158. [Google Scholar] [CrossRef]

- Zhang, S.; Li, H.; Yuan, M.; Yuan, M.; Chen, H. Poly(Lactic Acid) Blends with Poly(Trimethylene Carbonate) as Biodegradable Medical Adhesive Material. Int. J. Mol. Sci. 2017, 18, 2041. [Google Scholar] [CrossRef]

- Terao, K.; Miyake, J.; Watanabe, J.; Ikeda, Y. Surface Properties of Ultra-Thin Membrane Composed of Polycarbonate and Polylactide. Trans. Mater. Res. Soc. J. 2011, 36, 557–560. [Google Scholar] [CrossRef]

- Zhang, X.; Geven, M.A.; Wang, X.; Qin, L.; Grijpma, D.W.; Peijs, T.; Eglin, D.; Guillaume, O.; Gautrot, J.E. A Drug Eluting Poly(Trimethylene Carbonate)/ Poly(Lactic Acid)-Reinforced Nanocomposite for the Functional Delivery of Osteogenic Molecules. Int. J. Nanomedicine 2018, 13, 5701–5718. [Google Scholar] [CrossRef]

- Liu, D.; Li, H.; Zhou, G.; Yuan, M.; Qin, Y. Biodegradable Poly(Lactic-Acid)/Poly(Trimethylene-Carbonate)/Laponite Composite Film: Development and Application to the Packaging of Mushrooms (Agaricus Bisporus). Polym. Adv. Technol. 2015, 26, 1600–1607. [Google Scholar] [CrossRef]

- Qin, Y.; Yuan, M.; Li, L.; Quo, S.; Yuan, M.; Li, W.; Xue, J. Use of Polylactic Acid/Polytrimethylene Carbonate Blends Membrane to Prevent Postoperative Adhesions. J. Biomed. Mater. Res. B Appl Biomater 2006, 79, 312–319. [Google Scholar] [CrossRef]

- Terao, K.; Miyake, J.; Watanabe, J.; Ikeda, Y. Regulation of Protein Loading on Poly(Trimethylene Carbonate), Poly(l-Lactic Acid), and Their Copolymer: Effect of Surface Enrichment by Polymer Crystallinity. Mater. Sci. Eng. C 2012, 32, 988–993. [Google Scholar] [CrossRef]

- Qi, J.; Zhang, Y.; Liu, X.; Zhang, Q.; Xiong, C. Preparation and Properties of a Biodegradable Poly(Lactide-Co-Glycolide)/Poly(Trimethylene Carbonate) Porous Composite Scaffold for Bone Tissue Engineering. New J. Chem. 2020, 44, 14632–14641. [Google Scholar] [CrossRef]

- Qi, J.; Xiao, J.; Zhang, T.; Zhang, Y.; Xiong, C. Investigation of the Nano-Hydroxyapatite with Different Surface Modifications on the Properties of Poly(Lactide-Co-Glycolide Acid)/Poly(Trimethylene Carbonate)/Nano-Hydroxyapatite Composites. Colloid Polym. Sci. 2020, 299, 623–635. [Google Scholar] [CrossRef]

- Zhang, J.; Luo, L.; Lyu, S.; Pudil, B.; Schley, J.; Benz, M.; Buckalew, A.; Chaffin, K.; Hobot, C.; Sparer, R. Unique Microstructure and Mechanical Properties from Melt Processing Poly(Lactide-Co-Glycolide)/Poly(Trimethylene Carbonate). Mater. Res. Soc. Symp. Proc. 2010, 1239. [Google Scholar] [CrossRef]

- Han, J.; Branford-White, C.J.; Zhu, L.M. Preparation of Poly(ε-Caprolactone)/Poly(Trimethylene Carbonate) Blend Nanofibers by Electrospinning. Carbohydr. Polym. 2010, 79, 214–218. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, G.; Li, H.; Jina, X. Preparation of Electrospun Poly (ε-Caprolactone)/Poly (Trimethylene-Carbonate) Blend Scaffold for in Situ Vascular Tissue Engineering. Adv. Mat. Res. 2013, 629, 60–63. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Z.; Gu, J.; Zhou, W.; Liang, X.; Zhou, G.; Han, C.C.; Xu, S.; Liu, Y. Mechanism of a Long-Term Controlled Drug Release System Based on Simple Blended Electrospun Fibers. J. Controlled Release 2020, 320, 337–346. [Google Scholar] [CrossRef]

- Jiang, T.; Zhang, G.; He, W.; Li, H.; Jin, X. The Tissue Response and Degradation of Electrospun Poly(ε -Caprolactone)/Poly(Trimethylene-Carbonate) Scaffold in Subcutaneous Space of Mice. J. Nanomater. 2014, 2014, 837695. [Google Scholar] [CrossRef]

- Bat, E.; Kothman, B.H.M.; Higuera, G.A.; van Blitterswijk, C.A.; Feijen, J.; Grijpma, D.W. Ultraviolet Light Crosslinking of Poly(Trimethylene Carbonate) for Elastomeric Tissue Engineering Scaffolds. Biomaterials 2010, 31, 8696–8705. [Google Scholar] [CrossRef]

- Liang, J.; Grijpma, D.W.; Poot, A.A. Tough and biocompatible hybrid networks prepared from methacrylated poly(trimethylene carbonate) (PTMC) and methacrylated gelatin. Eur. Polym. J. 2020, 123, 109420. [Google Scholar] [CrossRef]

- Eriksson, T.; Mace, A.; Mindemark, J.; Brandell, D. The Role of Coordination Strength in Solid Polymer Electrolytes: Compositional Dependence of Transference Numbers in the Poly(ϵ-Caprolactone)-Poly(Trimethylene Carbonate) System. Phys. Chem. Chem. Phys. 2021, 23, 25550–25557. [Google Scholar] [CrossRef]

- Derewenda, Z.S. C-H Groups as Donors in Hydrogen Bonds: A Historical Overview and Occurrence in Proteins and Nucleic Acids. Int. J. Mol. Sci. 2023, 24, 1–23. [Google Scholar] [CrossRef]

- Wan, Q.; Thompson, B.C. Control of Properties through Hydrogen Bonding Interactions in Conjugated Polymers. Adv. Sci. 2024, 11, 1–26. [Google Scholar] [CrossRef]

- Ma, Y.; Song, F.; Yu, J.; Wang, N.; Jia, P.; Zhou, Y. Combining Renewable Eleostearic Acid and Eugenol to Fabricate Sustainable Plasticizer and its Effect of Plasticizing on PVC. J. Polym. Environ. 2022, 30, 2099–2108. [Google Scholar] [CrossRef]

- Surendren, A.; Mohanty, A.K.; Liu, Q.; Misra, M. A Review of Biodegradable Thermoplastic Starches, Their Blends and Composites: Recent Developments and Opportunities for Single-use Plastic Packaging Alternatives. Green Chem. 2022, 24, 8606–8636. [Google Scholar] [CrossRef]

- Goswami, S.R.; Nair, S.S.; Wang, S. Yan, N. Recent Progress on Starch Maleate/Polylactic Acid Blends for Compostable Food Packaging Applications. ACS Sustain. Chem. Eng. 2022, 10, 3–15. [Google Scholar] [CrossRef]

- Vieira, M.G.A.; Da Silva, M.A.; Dos Santos, L.O.; Beppu, M.M. Natural-Based Plasticizers and Biopolymer Films: A Review. Eur. Polym. J. 2011, 47, 254–263. [Google Scholar] [CrossRef]

- Choi, J.S.; Park, W.H. Effect of Biodegradable Plasticizers on Thermal and Mechanical Properties of Poly(3-Hydroxybutyrate). Polym. Test. 2004, 23, 455–460. [Google Scholar] [CrossRef]

- Matveev, Y.; Grinberg, Vy.; Tolstoguzov, V. The Plasticizing Effect of Water on Proteins, Polysaccharides and Their Mixtures. Glassy State of Biopolymers, Food and Seeds. Food Hydrocoll 2000, 14, 425–437. [Google Scholar] [CrossRef]

- Dharmalingam, K.; Ramachandran, K.; Sivagurunathan, P.; Kalamse, G.M. Molecular Interactions in Alcohol-Ethyl Methacrylate Mixtures. Spectrochim Acta A 2008, 69, 467–470. [Google Scholar] [CrossRef]

- Mathis, C.H.; Divandari, M.; Simic, R.; Naik, V. V.; Benetti, E.M.; Isa, L.; Spencer, N.D. ATR-IR Investigation of Solvent Interactions with Surface-Bound Polymers. Langmuir 2016, 32, 7588–7595. [Google Scholar] [CrossRef]

- Omar, A.A.; Hanafi, M.H.M.; Razak, N.H.; Ibrahim, A.; Razak, N.A.A. A Best-Evidence Review of Bio-Based Plasticizer and the Effects on the Mechanical Properties of PLA. Chem. Eng. Trans. 2021, 89, 241–246. [Google Scholar]

- Hess, F.; Kipping, T.; Weitschies, W.; Krause, J. Understanding the Interaction of Thermal, Rheological, and Mechanical Parameters Critical for the Processability of Polyvinyl Alcohol-Based Systems during Hot Melt Extrusion. Pharmaceutics 2024, 16, 472. [Google Scholar] [CrossRef]

- Eslami, Z.; Elkoun, S.; Robert, M.; Adjallé, K. A Review of the Effect of Plasticizers on the Physical and Mechanical Properties of Alginate-Based Films. Molecules 2023, 28, 6637. [Google Scholar] [CrossRef]

- Alee, M.; Fu, J.; Duan, Q.; Yang, M.; Liu, H.; Zhu, J.; Xianyang, B.; Chen, L.; Yu, L. Plasticizing Effectiveness and Characteristics of Different Mono-Alcohols, Di-Alcohols, and Polyols for Starch-Based Materials. Starch/Staerke 2023, 75, 2300059. [Google Scholar] [CrossRef]

- Galdeano, M.C.; Grossmann, M.V.E.; Mali, S.; Bello-Perez, L.A.; Garcia, M.A.; Zamudio-Flores, P.B. Effects of Production Process and Plasticizers on Stability of Films and Sheets of Oat Starch. Mater. Sci. Eng. C 2009, 29, 492–498. [Google Scholar] [CrossRef]

- Dickey, A.N.; Faller, R. Investigating Interactions of Biomembranes and Alcohols: A Multiscale Approach. J. Polym. Sci. Part B: Polym. Phys. 2005, 43, 1025–1032. [Google Scholar] [CrossRef]

- Dai, F.; Zhuang, Q.; Huang, G.; Deng, H.; Zhang, X. Infrared Spectrum Characteristics and Quantification of OH Groups in Coal. ACS Omega 2023, 8, 17064–17076. [Google Scholar] [CrossRef]

- Feller, S.E.; Brown, C.A.; Nizza, D.T.; Gawrisch, K. Nuclear Overhauser Enhancement Spectroscopy Cross-Relaxation Rates and Ethanol Distribution across Membranes. Biophys. J. 2002, 82, 1396–1404. [Google Scholar] [CrossRef]

- Magoń, A.; Pyda, M. Melting, Glass Transition, and Apparent Heat Capacity of α-d-Glucose by Thermal Analysis. Carbohydr. Res. 2011, 346, 2558–2566. [Google Scholar] [CrossRef]

- Lee, J.W.; Thomas, L.C.; Schmidt, S.J. Investigation of the Heating Rate Dependency Associated with the Loss of Crystalline Structure in Sucrose, Glucose, and Fructose Using a Thermal Analysis Approach (Part I). J. Agric. Food Chem. 2011, 59, 684–701. [Google Scholar] [CrossRef] [PubMed]

- Hurtta, M.; Pitkänen, I.; Knuutinen, J. Melting Behaviour of D-Sucrose, D-Glucose and D-Fructose. Carbohydr. Res. 2004, 339, 2267–2273. [Google Scholar] [CrossRef]

| Sample | T10 (°C) | Tg (°C) | Tm (°C) | △Hm (J/g) |

|---|---|---|---|---|

| PTMC | 302 | -22.4 | 80 | -97 |

| PTMC and 5 (1:1) | 239 | -18.5 | 56 | -0.42 |

| PTMC and 5 (17:2) | 310 | -17.3 | 46 | -0.64 |

| PTMC and 6 (1:1) | 270 | -19.6 | 66 | -4.56 |

| PTMC and 6 (16:1) | 307 | -16.1 | 63 | -7.84 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).