1. Introduction

As the world’s largest developing country, China has long faced huge environmental challenges [

1,

2], and China’s industrial structure transformation and supply-side structural reform focus on the development of new energy vehicles, which is also a key part of the realization of green economy, has become an important part of strategic emerging industries [

3,

4,

5]. It turns out that the traditional vehicle supply chain structure cannot meet the growth demand of the new energy vehicle industry, so in recent years, various enterprises have made efforts to promote the transformation and construction of green supply chain, in order to achieve the goal of sustainable growth of enterprises [

6,

7]. Driven by technological innovation, they implement carbon emission reduction responsibilities in green procurement, production, operation and other links, while focusing on the development of green technologies, products and full-link solutions, so as to promote enterprises to achieve energy conservation and emission reduction goals, and help speed up the green transformation of China’s transportation industry and manufacturing industry [

8,

9,

10,

11,

12].

Such green supply chain construction is seen as part of the goal of achieving "carbon peaking and carbon neutrality", because the larger framework requires not only carbon reduction, but also environmental and social sustainability considerations [

13,

14]. The "carbon peaking and carbon neutrality" goal emphasizes the reduction of carbon emissions while paying attention to ecological environment and social responsibility, so the adoption of green supply chain strategy can more comprehensively meet this goal [

15,

16,

17]. By adopting the coordinated development of environmental protection, social responsibility and economic efficiency, enterprises can better adapt to the future sustainable business environment. From a theoretical perspective, the evaluation of an enterprise’s green supply chain performance is a systematic, comprehensive and tedious process. The evaluation of new energy enterprises from the perspective of "carbon peaking and carbon neutrality" involves multiple disciplines and theories. The theory of green development and the theory of corporate social responsibility run through the theoretical basis of this paper. In this paper, the application of the theory of green development is reflected as a focus on the analysis of the green supply chain of leading enterprises in the new energy vehicle industry, which raises the level of enterprise environmental protection, energy consumption and investment in green development. The latter theory of corporate social responsibility emphasizes that only when an enterprise attaches importance to the balance between economic benefits, environmental protection and social responsibility and achieves good performance in all these aspects can it achieve its own sustainable development [

18]. The application of this theory is reflected in the comprehensive evaluation of corporate finance performance, environment performance, operation performance and innovation performance in this paper. With the enrichment and improvement of the green supply chain theory, and through the practical application and promotion of the green supply chain performance evaluation system of new energy enterprises, the industry’s understanding of environment performance can be enhanced to a certain extent, so as to effectively promote the steady realization of the "carbon peaking and carbon neutrality" goal [

17,

19,

20,

21].

Many countries and regions in the world have issued zero carbon or carbon neutral strategic goals, so the vigorous development of green supply chain is conducive to the new energy industry. From the enterprise level, for new energy vehicle enterprises, based on the urgent requirements for industrial structure transformation and upgrading, new energy vehicle companies need to actively evaluate their own green supply chain implementation benefits. Comprehensively and reasonably examine the impact of the implementation of green supply chain strategy on each link of the enterprise, so as to enable managers to grasp the development context of the enterprise more carefully, help the enterprise improve resource utilization rate, optimize its own management mode, reduce business risks, enhance its comprehensive competitiveness and better assume social responsibilities to strive for better reputation and more market opportunities in the ever-changing market competition. From the perspective of investors, the performance evaluation completed by the comprehensive evaluation criteria system composed of green supply chain related data publicly disclosed by enterprises can quantify the implementation effect of green supply chain of enterprises to a certain extent, provide investors with open, transparent and sustainable investment information, and enable investors to visualize their investment expectations.

This paper takes "B" company (Hereinafter referred to as "BC") as the evaluation research object and mainly includes the following five sections. Firstly, the paper introduces the research background, the theoretical, and practical significance of the research in

Section 1. Secondly, the relevant researches are analyzed and summarized in

Section 2. Thirdly, the green supply chain performance evaluation criteria system is constructed in

Section 4. Then, based on Entropy-Weight TOPSIS method, BC’s green supply chain performance comprehensive evaluation is proposed in

Section 5. Finally, the conclusion and limitation are give in

Section 6.

2. Literature Review

Based on the relevant search of CNKI(China National Knowledge Infrastructure) database and the analysis of CiteSpace, it is found that Chinese researches on green supply chain mainly involve government subsidies, fairness concerns, green innovation, information sharing and other aspects. The research results of these literature provide an important reference for the subsequent analysis and summary of the development and current situation of green supply chain in this paper.

In the important research field of green supply chain and enterprise performance, Fang et al. [

22] used meta-analysis to evaluate the relationship between green supply chain management measures and enterprise performance, and came to the conclusion that green supply chain management practices have the greatest impact on environmental performance, pointing out that enterprises should start with internal green management practices. Su et al. [

23] established the overall performance evaluation system of green supply chain with four dimensions, including finance, operation, innovation and carbon emission reduction, using the hierarchical variable weight comprehensive evaluation method, and conducted an applied research on the green petrochemical supply chain of a province. Lu et al. [

24] adopted the empowerment method combining AHP and entropy value method, and used the fuzzy matter element analysis method to evaluate the green supply chain performance of five listed manufacturing enterprises, including five aspects of finance, customers, business processes, green, low-carbon and future development.

According to the relevant search of WOSCC (Web of Science Core Collection) database, the number of research literature on green supply chain and new energy vehicles has been increasing in the past five years. Through CiteSpace analysis, it can be seen that the green supply chain related literature mainly involves government intervention, supply chain risk avoidance, green supply chain performance evaluation, performance evaluation model, etc. The research results of these literature provide important references for the subsequent theoretical analysis and summary of this paper and the design of evaluation system. At the same time, the nearly 500 literature related to new energy vehicles analyzed, involving hybrid electric vehicles, fuel consumption reduction, power batteries, energy prices, etc. The research results of these literature provide important references for this paper to analyze the development focus of new energy vehicle industry, determine evaluation criteria, and propose relevant solutions.

As for the study of green supply chain, Yaw Agyabeng-Mensah et al. [

25] conducted an empirical analysis on 139 manufacturing companies by using partial least squares structural equation model, and found that internal green supply chain practices have a positive impact on enterprise performance by influencing green human resource management and supply chain environmental cooperation. Mahak Sharma et al. [

26] conducted an empirical analysis on the data of more than 300 manufacturing enterprises in the UK from the perspective of the environment in the supply chain, and found that green supply chain management practices have a positive impact on enterprise performance, and affect the visibility, elasticity and robustness of the supply chain. Jairo J et al. [

27], through structural equation modeling of more than 200 Brazilian metal machinery enterprises, obtained the result that enterprises need to prioritize some green supply chain management practices to help them improve their innovation process and improve their overall performance.

In terms of performance evaluations of vehicle supply chains, in the past five years, the focus of papers has mainly focused on supplier selection. For example, Nguyen et al. [

28] aim to evaluate and select the best Chain Logistics service Providers (CLP) regarding their sustainability performance based on a multi-criteria decision making (MCDM)-based framework. Yang et al. [

29] present a linguistic Pythagorean hesitant fuzzy MULTIMOORA method to investigate the selection of 3PRL providers for Electric Vehicle Power Battery Recycling (EVPBR). Snásel et al. [

30] introduce a new weighting method based on rankability in MCDM, address the limitations of the entropy-based method, and present a fuzzy MCDM model for handling uncertainty in the oil supplier selection.

Referring to the academic research on green supply chain, vehicle supply chain and their performance, it can be seen that most articles tend to analyze the impact of green supply chain on the performance of multiple enterprises in a certain industry or region from a macro perspective, but there is a lack of detailed analysis of the green supply chain performance of micro-enterprises. Moreover, scholars differ in the establishment of the evaluation criteria system and the selection of evaluation methods. Scholars mainly choose fuzzy comprehensive evaluation method, DEA method, analytic hierarchy process, balanced scorecard, etc., in the selection of evaluation methods, and many choose Delphi method in weight calculation, which provides ideas for this paper to choose an objective weight calculation method. In the dimension setting of the evaluation criteria system, the selection of scholars provides a theoretical basis for the integration of the green dimension and the innovation dimension in this paper, and the selection of specific criteria also provides a reference for this paper, such as criteria to measure development ability and sales volume of green products, which are all new perspectives. In addition, it can be seen that many scholars have included the whole life cycle of products in the scope of green supply chain management practice, which provides a more practical academic reference for this paper to take vehicle enterprises as the research object. Therefore, this paper evaluates and analyzes BC’s green supply chain performance by dividing the performance evaluation dimensions into finance, green, operation and innovation from a micro perspective, in order to enrich the relevant literature on green supply chain performance evaluation.

3. Construction of Green Supply Chain Performance Evaluation Criteria System

3.1. Selection of Evaluation Method

The evaluation criteria system for enterprises is a complex system, so it is necessary to choose the appropriate scientific evaluation method according to the specific situation. The comprehensive evaluation of an enterprise’s benefits in a certain aspect often has multiple characteristics, and the advantages and disadvantages of these criteria are not consistent. Such an evaluation process that requires consideration of multiple criteria and multiple objects is a comprehensive evaluation, which can help us better grasp the overall level of enterprise operation [

31]. By analyzing and sorting out the existing literature, this paper chooses to combine the entropy value method and TOPSIS method, that is, Entropy-Weight TOPSIS method, to evaluate the performance of the green supply chain. The entropy method calculates the information entropy of the criteria, and then assigns the weight according to the different degree of its influence on the whole system. This method does not require subjective judgment and can accurately reflect the relative importance of criteria [

32,

33]. TOPSIS method, as a comprehensive evaluation method, was first proposed by C. L. Hwang and other scholars [

34]. It is a research method that calculates the distance between the evaluated object and its optimal and worst solution to carry out multi-objective decision analysis, and find out the strongest competitiveness among multi-schemes and multi-objects. This method can make full use of the original data to better describe the comprehensive impact degree of multiple influence criteria, and there is no strict limit on the sample size and the number of criteria. The positive and negative ideal solutions are considered at the same time, so that the overall situation of the object can be comprehensively evaluated. In this paper, the importance degree of each criterion is accurately calculated by the objective weighting, and the TOPSIS method is used to make up for the deficiency of entropy method only for weight calculation. This method can overcome subjective interference, and is suitable for research problems that need to improve the practice process and put forward optimization suggestions.

3.2. Principles of Criteria Selection

To evaluate the implementation of an enterprise’s green supply chain, it is necessary to establish an evaluation criteria system. In the process of constructing the enterprise green supply chain performance evaluation criteria system, how to choose the appropriate and reasonable evaluation criteria is the focus of whether the evaluation system can achieve accurate evaluation. This paper aims to evaluate the comprehensive performance of the green supply chain, while most enterprises’ performance evaluation criteria are limited to the analysis of financial data, which lacks scientific and objective and has a certain lag. With the in-depth implementation of green supply chain practice, the green supply chain performance evaluation system needs to integrate various factors and establish a comprehensive, reasonable and focused evaluation system.

When selecting criteria, this paper considers the following principles:

(1) Comprehensive principle. The operation of the enterprise supply chain involves multiple links and objects in the upper, middle and lower reaches, and runs through multiple departments within the enterprise. Therefore, the criteria to measure its performance should be comprehensive and can be evaluated from multiple dimensions, making the entire evaluation system complete and effective, and finally comprehensively reflecting the realization of the enterprise’s finance, green, operation and innovation.

(2) Combining science with objectivity. The establishment of the evaluation system based on the principle of combining science and objectivity and the selection of criteria must rely on scientific theories and evidence, while using scientific models and calculation methods. At the same time, it is also necessary to objectively select performance evaluation criteria, avoid subjective and empirical criteria, and each criterion needs to have a clear definition and explanation. So that the final evaluation results can truly reflect the performance level of the company, and its results have a certain reference value.

(3) Pertinence principle. After comprehensive multi-dimensional consideration, the evaluation of the company’s green supply chain performance should also have a focus, that is, more green-oriented criteria should be selected from a large number of data, so that the evaluation results can better evaluate the level of environmental protection and sustainable development of the company.

(4) Operability principle. When constructing green supply chain evaluation index system, Olugu et al. point out that the complexity of its design should be reduced [

35]. Based on the availability of data and the simplicity of the calculation, the selection of criteria needs to make their data available and can be verified repeatedly, while avoiding the use of overly complex criteria to ensure that the data is easy to collect and calculate.

3.3. Green Supply Chain Performance Evaluation Criteria Selection

The goal of green supply chain management is to pursue the performance of the whole supply chain under the premise of environmental protection, which has many elements and evaluation criteria. In view of this, on the basis of the principle of criteria selection, this paper draws on the evaluation existing criteria system established by scholars, refers to relevant policy documents and publicly released criteria, and integrates green criteria into the traditional evaluation system according to the characteristics of new energy vehicles, so as to make the entire evaluation system more perfect and closer to the strategic layout of enterprise green supply chain.

This paper divides the performance of green supply chain into four dimensions to construct an evaluation criteria system. Based on the triple bottom line theory proposed by British scholar John Elkington [

18], that is, corporate social responsibility is divided into three aspects: economic, environmental and social. At the same time, based on the clear guidance on the innovation ability of green supply chain development, green supply chain innovation has begun to evolve into a new paradigm of green supply chain management, helping enterprises to respond to environmental challenges more effectively [

36]. This paper integrates the four dimensions of finance performance, environment performance, operation performance and innovation performance as first-level evaluation criteria, and sets specific second-level evaluation criteria under them. According to the principle of operability, the number of second-level evaluation criteria is four to six, after determining the criteria dimension, the appropriate criteria and data are selected according to the specific situation of the enterprise and relevant research and documents.

3.3.1. Finance Performance Criteria

Finance performance is mainly used to evaluate the economic benefits of an enterprise, which can fully express the comprehensive operational status of an enterprise. At present, the research on performance evaluation has been relatively complete and in-depth, and the analysis dimensions of the existing financial criteria are mainly divided into four aspects: solvency, operation ability (that is, asset management ability), profitability and development ability. From the perspective of green supply chain, based on the pertinency principle of criteria selection, this paper selects four second-level evaluation criteria, namely asset-liability ratio, inventory turnover ratio, cost-expense profit rate and net profit growth rate, to evaluate finance performance on behalf of four dimensions respectively.

(1) Asset-liability ratio. It reflects the source of funds and degree of financial risk of an enterprise’s business activities. As a negative criterion, the lower the value of this criterion is not the better. Too low the asset-liability ratio indicates that the enterprise has poor investment and financing ability, which restricts the development of the enterprise, while too high the enterprise faces the risk of bankruptcy liquidation. It is related to the ability of an enterprise to operate and invest.

(2) Inventory turnover. As one of the criteria to measure the operation capacity of an enterprise, inventory turnover ratio is also an important analytical criterion in the supply chain, reflecting the inventory management ability of an enterprise and the utilization rate of funds in the production and operation process. It can judge and forecast the cash flow of an enterprise from the financial perspective, so as to evaluate the level of enterprise demand and supply chain operation.

(3) The profit rate of cost expense. Generally, we have:

It reflects the net profit created by each cost invested by the enterprise. The higher this criterion, the more profits created by the enterprise investment. This criterion is increasing, when sales grow or costs save.

(4) Net profit growth rate.

As one of the criteria to measure the developmental ability of an enterprise, it reflects the growth rate of the enterprise’s net profit year-on-year. The higher the value indicates that the enterprise’s earning power is stronger, the growth rate is better, and it is more favored by consumers and the market.

3.3.2. Environment Performance Criteria

Environment performance criteria are mainly used to evaluate the level of an enterprise energy management, energy conservation, emission reduction, environmental protection and other aspects in the production and operation process. Evaluating the environment performance of new energy vehicle enterprises is the focus of measuring the overall performance level of the green supply chain enterprises. Based on the "Environmental Information Disclosure Guidelines for Listed Companies" and the "Sustainable Development Reporting Guidelines of the Global Reporting Initiative (GRI)", and on the basis of existing research by scholars, this paper considers the availability of data, and selects five criteria of electricity consumption, total water consumption, total greenhouse gas emissions, packaging material usage, and industrial wastewater emissions to measure the enterprise’s environment performance.

3.3.3. Operation Performance Criteria

Operation performance criteria mainly reflect the operating results of the main business of the enterprise and the feedback of the market to the enterprise, as well as the contribution of the enterprise to the society after obtaining a lot of profits. The evaluation of its operation performance can better meet the needs of customers, and promote the improvement of the social value and reputation of the enterprise. With reference to the "Guidelines for Compiling Corporate Social Responsibility Reports" in China and the criteria selected by relevant scholars, this paper selects five criteria of new energy passenger car sales, national market share, customer satisfaction, tax contribution rate and public welfare expenditure as the measurement criteria of operation performance.

3.3.4. Innovation Performance Criteria

Maintaining innovation is an important source of rapid growth and competitive advantage for enterprises. Green products, as the top priority of new energy vehicles’ green layout in the whole industrial chain, are the best representative of insistence on independent innovation over the years. Therefore, selecting certain innovation criteria can help enterprises to activate their innovative ability, coordinate various factors of R&D investment, and rationalize their innovation decisions. This paper refers to the relevant criteria selected by existing scholars, and finally determines four criteria, namely, the amount of green patents obtained, the proportion of R&D personnel, the proportion of R&D investment in operating income, and the proportion of capitalized R&D investment in R&D investment, to measure the innovation performance of enterprises.

3.4. Establishment of Evaluation Criteria System

The previous part describes the selection of the green supply chain performance evaluation criteria. The green supply chain evaluation criteria system is established on the basis of four aspects: finance performance, environment performance, operation performance and innovation performance, and a total of 18 second-level evaluation criteria are set up under the four first-level evaluation criteria as shown in

Table 1.

4. Comprehensive Evaluation of the Green Supply Chain Performance Based on Entropy-Weight TOPSIS Method

4.1. Weight Determination – Entropy-Weight Method

1. Construct the original matrix

The original criteria data matrix

is constructed according to the performance evaluation criteria system of the green supply chain. Assuming that there are

n evaluation criteria and

m evaluation objects in the matrix. The original matrix

X is:

2. Normalization processing

Assuming represents the specific value of the i-th evaluation criterion for the j-th evaluation object, because the dimensions of the criteria are different and there are positive and negative points, it is impossible to directly compare, so it is necessary to normalize the original data and convert negative criteria into positive criteria before the subsequent calculation is carried out.

Transformation processing. For negative criteria, adopts reciprocal transformation method, which is shown in Eq.

4. At the same time, for negative data, using the interval method, the data is converted into a positive interval, so that the result can facilitate the subsequent calculation:

where

is the original data and

is the data after the transformation processing.

Normalized processing. There is a large difference in the range of data values between the criteria of the original data. The sum of squares normalization method can better avoid the imbalance caused by the range gap between the criteria on the calculation results, and can improve the accuracy of the results:

where

is the data after the transformation processing and

is the element in the normalized matrix

P referring to the value of the

i-th evaluation criterion of the

j-th evaluation object after normalization.

3. Calculation of the weight

The evaluation needs to be carried out by calculating the weight of each criterion. The higher the weight, the higher the importance of the criterion, and the lower the weight, the lower the importance of the criterion. To calculate the weight, it is necessary to first calculate the ratio of the j-th evaluation object in the i-th evaluation criterion, and then calculate the entropy of the i-th evaluation criterion through the ratio, and finally obtain the weight of each criterion. The calculation process is as follows:

(1) The ratio of the

j-th evaluation object to the

i-th evaluation criteria.

where

is the ratio of the

j-th evaluation object to the

i-th evaluation criterion and

is the value of the

i-th evaluation criterion of the

j-th evaluation object after normalization.

(2)Calculate the entropy of the

i-th evaluation criterion by the proportion.

where

is the entropy of the

i-th evaluation criterion,

m is the number of evaluation objects, and

is the ratio of the

j-th evaluation object to the

i-th evaluation criterion.

(3)Calculate the difference coefficient (i.e. information utility value) of the

i-th evaluation criterion by the entropy value.

where

is the difference coefficient of the the

i-th evaluation criterion and

is the entropy of the

i-th evaluation criterion.

(4)Calculate the weight of the

i-th evaluation criterion by the difference coefficient.

where

is the weight of the

i-th evaluation criterion and

is the difference coefficient of the the

i-th evaluation criterion.

The information entropy represents the degree of uncertainty and disorder. The greater the criterion value, the higher the uncertainty, reflecting that the criterion contains less information, so it has less weight.

4.2. Comprehensive Evaluation – TOPSIS Method

1. The weighted normalized matrix is obtained by calculating the normalized matrix and criteria weights:

where

is the element in the weighted normalized matrix

R,

is the weight of the

i-th evaluation criterion, and

is the element in the normalized matrix

P referring to the value of the

i-th evaluation criterion of the

j-th evaluation object after normalization.

2. Calculate the positive and negative ideal solutions. The positive ideal solution means that it is expected to happen, and the negative ideal solution means that it is not expected to happen which are calculated as follows.

where

is the positive ideal solution and

represents the maximum of the

i-th evaluation criterion in the weighted normalized matrix

R, namely the most ideal solution.

where

is the negative ideal solution and

represents the minimum of the

i-th evaluation criterion in the weighted normalized matrix

R, namely the least ideal solution.

3. Euclidean distance measurement is used to calculate the Euclidean distance between each evaluation object and its positive and negative ideal solutions, which is shown in Eq.

13 and Eq.

14.

where

is the distance from the positive ideal solution,

is the positive ideal solution and

is the element in the weighted normalized matrix.

where

is the distance from the negative ideal solution,

is the positive ideal solution and

is the element in the weighted normalized matrix.

4. Calculated the relative closeness

. The relative closeness

measures the development level of enterprise green supply chain performance. The closer the relative closeness

is to 1, the closer the evaluation objective is to the most ideal solution. The closer it is to 0, the closer the evaluation object is to the least ideal solution.

where

is the relative closeness,

is the distance from the positive ideal solution, and

is the distance from the negative ideal solution.

5. Case Study

5.1. Data Source and Processing

As the research object of this paper, BC is evaluated and analyzed in this section under the background of the "carbon peaking and carbon neutrality". All data are from public data of BC Annual Report, BC Sustainability Report, CAACS Survey and CNRDS China Research Data service platform, and the data source is real. This paper selects total 18 criteria to evaluate BC’s finance performance, environment performance, operation performance and innovation performance from 2018 to 2022.

5.2. Weight determination of BC’s green supply chain performance

1. The raw data corresponding to each criterion is shown in

Table 2.

2. This paper selects the data of BC from 2018 to 2022 for evaluation. The normalized matrix obtained through Equation (

4) and (

5) is shown in

Table 3:

3. Based on Equation (

6)–(

9), the weight of each criterion is calculated. Calculation results are shown in

Table 4.

The greater the entropy of a criterion, the less information the criterion covers, so the smaller the weight value is given. As can be seen from

Table 4, the largest information entropy

is Customer Satisfaction, indicating that the criterion carries the smallest amount of information, so its weight is the smallest. The information entropy values of new energy passenger vehicle sales volume and public welfare expenditure are small, indicating that the information carried by them is more important. These two criteria belong to the dimension of operation performance, indicating that enterprises regard operational efficiency and social responsibility as the primary goals. In addition, the weight of the environment performance is 0.0693, which reflects the greater uncertainty contained in environment performance.

5.3. Comprehensive evaluation of BC’s green supply chain performance

1. The weighted normalized matrix of BC’s green supply chain performance is obtained by Equation (

10) and the results are given in

Table 5.

2. The positive and negative ideal solutions are calculated by Equations (

11) and (

12). The calculation results are shown in

Table 6.

3. The distance of the positive and negative ideal solutions and the relative closeness are calculated by Equation (

13)–(

15). The calculation results are shown in

Table 7.

5.4. Analysis of Evaluation Results

From the comprehensive evaluation values in

Table 7, the ranking of BC’s green supply chain performance comprehensive evaluation from 2018 to 2022 is: 2022 >2021 >2018 >2020 >2019. Due to the impact of the epidemic at the end of 2019, enterprises are greatly affected, and the comprehensive performance evaluation score 0.0856 in 2019 is the lowest. However, it gradually recovered and achieved the highest overall performance evaluation score 0.8917 in 2022. The company shows good comprehensive strength and crisis response ability.

Then, the normalized data are substituted into the Entropy-Weight TOPSIS method to calculate the local relative closeness of the finance performance, the environment performance, the operation performance, and the innovation performance respectively, so as to obtain the comprehensive score of each dimension, as shown in

Table 8, and then analyze the impact of green supply chain practices on the performance of each dimension. The final results are normalized to facilitate the comparison.

According to the relative closeness of BC’s first-level evaluation criteria in

Table 8, the evaluation score trends of four dimensions are different with the comprehensive evaluation score. In order to show the changing trend, the relative closeness trends of BC’s first-level evaluation criteria are shown in

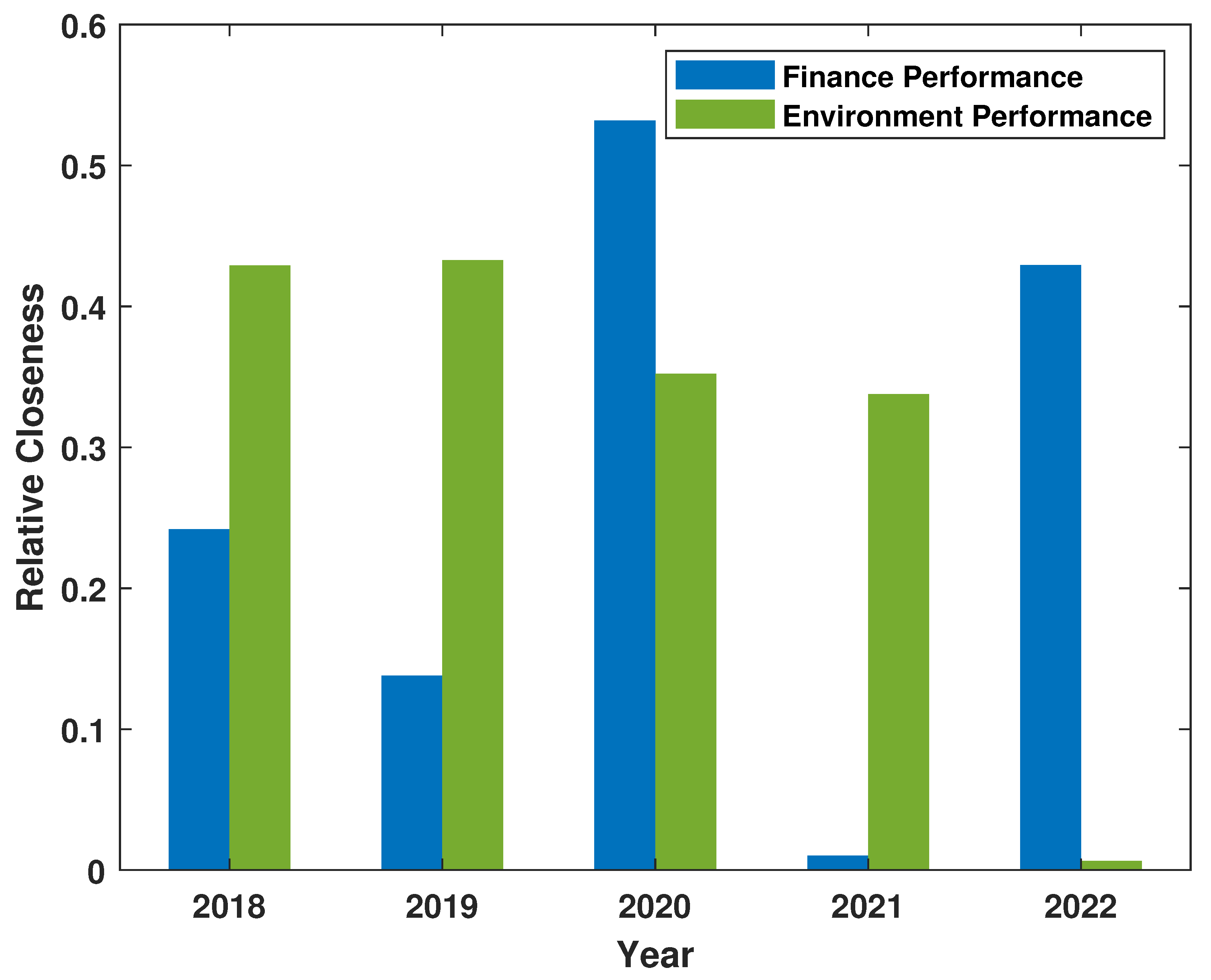

Figure 1.

Among four performance dimensions, the environment performance has the highest comprehensive evaluation score 0.4328 in 2019, while it has the lowest score 0.0065 in 2022. From 2018 to 2021, the relative closeness of the environment performance is always at a relatively stable and high level which illustrates that the company attaches importance to green development. In fact, the company is committed to reducing environmental pollution, and continues to reduce its own fossil energy consumption and unit carbon dioxide emissions by strengthening energy management, promoting energy-saving transformation, and reducing pollutant emissions. The environment performance has a little improvement between 2018 and 2019, but it has a downward trend since 2019. Between 2019 and 2022, BC’s market scale expanded, the demand soared, and the production volume rose sharply, but at the same time, the top-level design of the implementation of the green goal just entered a new stage of more perfect. The sudden decline in environment performance trend is within a reasonable range. In addition, the green practice established by the company in the whole process of production and operation layout of green supply chain makes up for the excessive emission of pollutants and energy consumption than in previous years, but the investment paid needs a long time to pay back, and can not work quickly.

Also in

Figure 1, the finance performance and the innovation performance change in the opposite direction, which illustrates that the innovation needs to invest a lot of capital, technology and talent costs. When the company makes innovation including green innovation, its financial performance is affected.

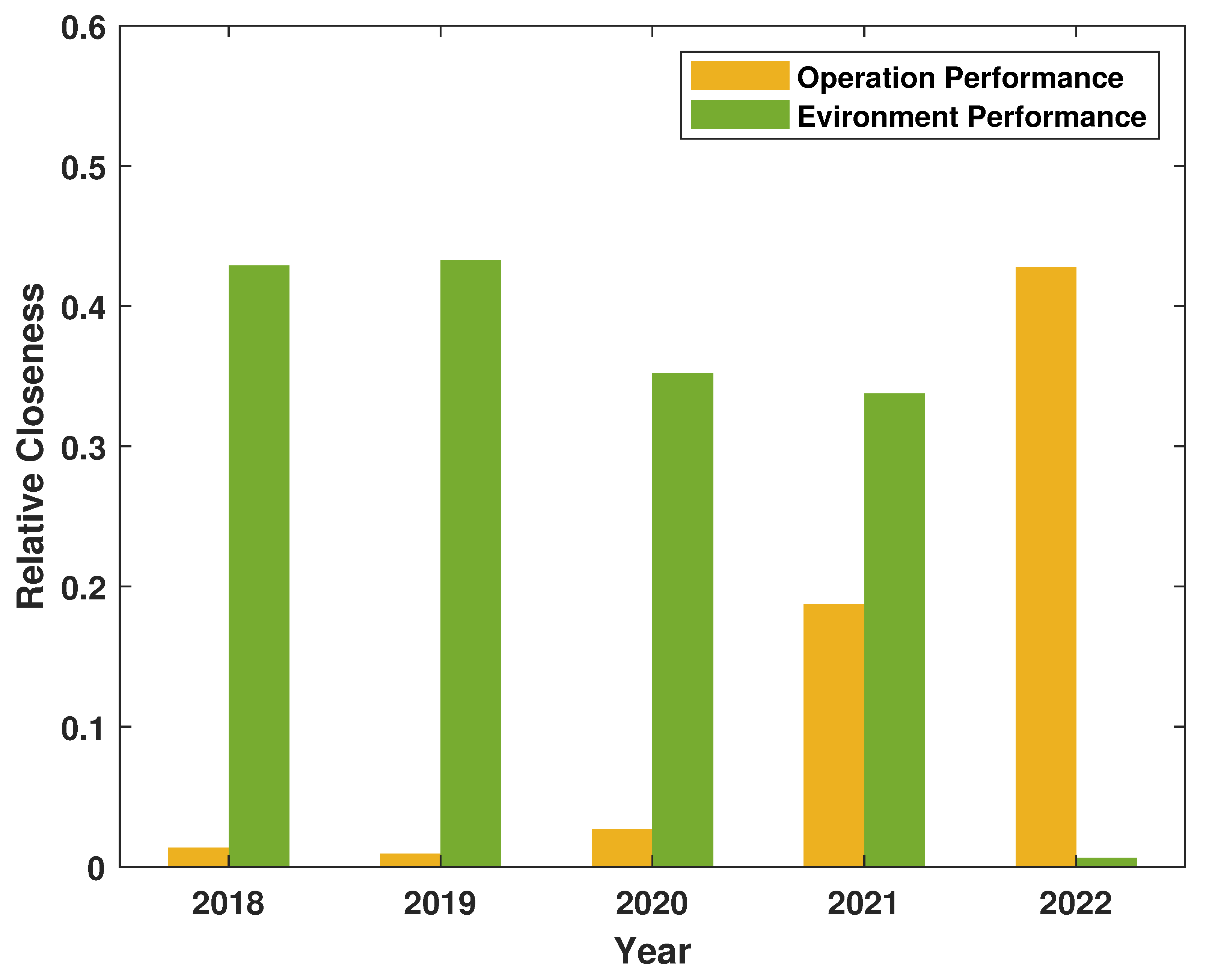

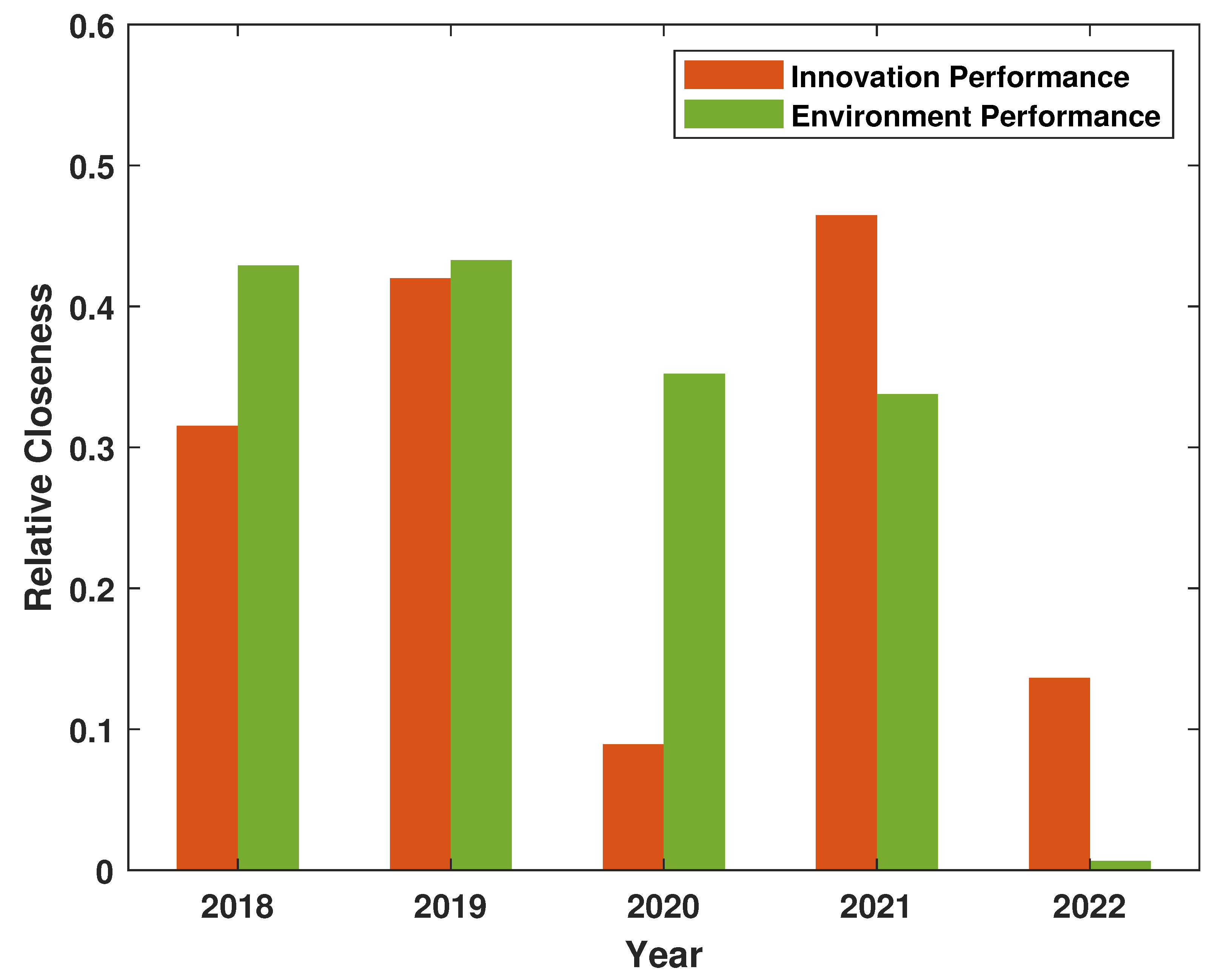

In order to analyze the impact of green supply chain practice on the performance of each dimension, taking the environment performance as the baseline, the histograms of the performance dimensions are also respectively analyzed in

Figure 2,

Figure 3 and

Figure 4.

In

Figure 2, the finance performance has the highest evaluation score in 2020, while it has the lowest score in 2021. If the environment performance is taken as the benchmark reference, the change of the finance performance fluctuates greatly and is basically opposite to the environment performance. The layout of green supply chain is overall and systematic, and green products, as the main product of BC, need to invest a lot of capital, technology and talent costs, which has a great impact on the finance performance. In addition, compared with

Figure 1, the finance performance significantly fluctuates after 2018, but the comprehensive performance does not fluctuate greatly, which is enough to show that the benefits brought by the practice in the environment and operation greatly adjusted the fluctuation in the finance performance.

In

Figure 3, it shows that the operation performance scores the highest in 2022 and the lowest in 2019. After 2019, the gradually rising relative closeness of the operational performance indicates that its operational activities have achieved higher benefits and better results. The trend of the operation performance increases greatly and is basically opposite to the environment performance which reflects the continuing development of enterprises and the lag of the environmental protection benefits.

Comparing the innovation performance and the environment performance in

Figure 4, it can be found that the relative closeness between innovation performance and environment performance has the same change trend after 2019, indicating that the enterprise shows a positive relation between the environment performance and the innovation performance. In fact, as a new energy vehicle enterprise, BC has invested a considerable amount of resources in green innovation research. It also shows that its innovation results are rewarded in terms of the environment performance. BC focuses on the green technology research, and the results achieved provide a steady stream of innovation energy for enterprise benefits and the implementation of the green supply chain.

6. Conclusions

Based on the in-depth analysis of the green supply chain performance, under the "carbon peaking and carbon neutrality" goals, this paper combines the green development theory and the corporate social responsibility theory to build a green supply chain performance evaluation system, which includes 18 evaluation criteria from four dimensions: finance performance, environment performance, operation performance and innovation performance. By using Entropy-Weight TOPSIS comprehensive evaluation method, the green supply chain performance of BC from 2018 to 2022 is comprehensively and objectively evaluated.

To sum up, BC’s green supply chain practice under the "carbon peaking and carbon neutrality" goals has set a model for the new energy vehicle industry, but it still needs to be continuously improved and perfected. It is hoped that the research in this paper can provide a useful reference for other new energy vehicle enterprises, and jointly promote the green and sustainable development of the new energy vehicle industry.

In the process of writing this paper, due to authors’ limited knowledge and the difficulty in obtaining some enterprise data, there are still some shortcomings in this paper, and there are still places to learn and improve and in-depth discussion: 1. In the process of criteria construction, some data are difficult to obtain. In the future, more external criteria should be selected to evaluate the performance and the impact of enterprises green practices. 2. Although the years analyzed in this paper are defined based on current situation, since the benefits generated by innovation achievements and green supply chain practices are long-term, data with a wider time span can be selected to evaluate the long-term performance level of enterprises, so that the results can reflect the situation more clearly.

Author Contributions

Conceptualization, S.C.; methodology, S.C.; software, R.D.; validation, R.D.; formal analysis, S.C.; investigation, R.D.; resources, R.D.; data curation, R.D.; writing—original draft preparation, R.D.; writing—review and editing, S.C.; visualization, R.D.; supervision, S.C.; project administration, S.C.; funding acquisition, S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Chengdu University of Information Technology project under the grant number KYTZ2022125.

Conflicts of Interest

The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

References

- Zhai, T. Environmental challenges, opportunities, and policy implications to materialize China’s green belt and road initiative. Sustainability 2021, 13, 10428. [CrossRef]

- Liu, Y.; Wang, Q.; Huang, B.; Zhang, X.; Wang, X.; Long, Y. Status and challenges of green manufacturing: Comparative analysis of China and other countries. Resources, Conservation and Recycling 2023, 197, 107051. [CrossRef]

- Waqas, M.; Honggang, X.; Ahmad, N.; Khan, S.A.R.; Ullah, Z.; Iqbal, M. Triggering sustainable firm performance, supply chain competitive advantage, and green innovation through lean, green, and agile supply chain practices. Environmental Science and Pollution Research 2022, pp. 1–22. [CrossRef]

- Ye, Y.; Lau, K.H. Competitive green supply chain transformation with dynamic capabilities—an exploratory case study of Chinese electronics industry. Sustainability 2022, 14, 8640. [CrossRef]

- Nabeeh, N.A.; Abdel-Basset, M.; Soliman, G. A model for evaluating green credit rating and its impact on sustainability performance. Journal of Cleaner Production 2021, 280, 124299. [CrossRef]

- Kar, S.K.; Sinha, A.S.K.; Bansal, R.; Shabani, B.; Harichandan, S. Overview of hydrogen economy in Australia. Wiley Interdisciplinary Reviews: Energy and Environment 2023, 12, e457. [CrossRef]

- Kamble, S.S.; Gunasekaran, A. Analysing the role of Industry 4.0 technologies and circular economy practices in improving sustainable performance in Indian manufacturing organisations. Production planning & control 2023, 34, 887–901. [CrossRef]

- Liu, H.; Fan, L.; Shao, Z. Threshold effects of energy consumption, technological innovation, and supply chain management on enterprise performance in China’s manufacturing industry. Journal of environmental management 2021, 300, 113687. [CrossRef]

- Wan, X.; Wang, Y.; Qiu, L.; Zhang, K.; Zuo, J. Executive green investment vision, stakeholders’ green innovation concerns and enterprise green innovation performance. Frontiers in Environmental Science 2022, 10, 997865. [CrossRef]

- Yin, S.; Yu, Y. An adoption-implementation framework of digital green knowledge to improve the performance of digital green innovation practices for industry 5.0. Journal of Cleaner Production 2022, 363, 132608. [CrossRef]

- Gawusu, S.; Zhang, X.; Jamatutu, S.A.; Ahmed, A.; Amadu, A.A.; Djam Miensah, E. The dynamics of green supply chain management within the framework of renewable energy. International Journal of Energy Research 2022, 46, 684–711. [CrossRef]

- Tian, C.; Li, X.; Xiao, L.; Zhu, B. Exploring the impact of green credit policy on green transformation of heavy polluting industries. Journal of Cleaner Production 2022, 335, 130257. [CrossRef]

- Liu, L.; Jiang, J.; Bian, J.; Liu, Y.; Lin, G.; Yin, Y. Are environmental regulations holding back industrial growth? Evidence from China. Journal of Cleaner Production 2021, 306, 127007. [CrossRef]

- Zhang, Q.; Tang, Y.; Bunn, D.; Li, H.; Li, Y. Comparative evaluation and policy analysis for recycling retired EV batteries with different collection modes. Applied Energy 2021, 303, 117614. [CrossRef]

- Dudek, M.; Bashynska, I.; Filyppova, S.; Yermak, S.; Cichoń, D. Methodology for assessment of inclusive social responsibility of the energy industry enterprises. Journal of Cleaner Production 2023, 394, 136317. [CrossRef]

- Xiao, Y.; Li, Y.; Huang, H. Conflict or coordination? Assessment of coordinated development between socioeconomic and ecological environment in resource-based cities: Evidence from Sichuan province of China. Environmental Science and Pollution Research 2021, 28, 66327–66339. [CrossRef]

- Ye, C.; Pi, J.; Chen, H. Coupling coordination development of the logistics industry, new urbanization and the ecological environment in the Yangtze River economic belt. Sustainability 2022, 14, 5298. [CrossRef]

- Elkington, J. The triple bottom line for 21st century business. Journal of Experimental Psychology: General 1997, 136.

- Kao, F.C.; Huang, S.C.; Lo, H.W. A rough-fermatean DEMATEL approach for sustainable development evaluation for the manufacturing industry. International journal of fuzzy systems 2022, 24, 3244–3264. [CrossRef]

- Huang, X.; Lu, X.; Sun, Y.; Yao, J.; Zhu, W. A Comprehensive Performance Evaluation of Chinese Energy Supply Chain under “Double-Carbon” Goals Based on AHP and Three-Stage DEA. Sustainability 2022, 14, 10149. [CrossRef]

- Tian, G.; Lu, W.; Zhang, X.; Zhan, M.; Dulebenets, M.A.; Aleksandrov, A.; Fathollahi-Fard, A.M.; Ivanov, M. A survey of multi-criteria decision-making techniques for green logistics and low-carbon transportation systems. Environmental Science and Pollution Research 2023, 30, 57279–57301. [CrossRef]

- Chencheng, F.; Jiantong, Z. The impact of green supply chain management on firm performance: a meta-analysis study. Science and Technology Management Research 2017, pp. 234–240.

- Ming, S.; Xiaoning, R. Overall performance evaluation and application of green supply chain under the goal of "double carbon" : a case study of a green petrochemical supply chain. Communication of Finance and Accounting 2023, pp. 110–115.

- Zhengnan, L.; Chaohua, Z.; Yusen, L. Research on green supply chain performance evaluation of manufacturing enterprises under "dual carbon" target. Ecological Economy 2023, pp. 58–66.

- Agyabeng-Mensah, Y.; Ahenkorah, E.; Afum, E.; Agyemang, A.N.; Agnikpe, C.; Rogers, F. Examining the influence of internal green supply chain practices, green human resource management and supply chain environmental cooperation on firm performance. Supply Chain Management: An International Journal 2020, 25, 585–599. [CrossRef]

- Sharma, M.; Dhir, A.; AlKatheeri, H.; Khan, M.; Ajmal, M.M. Greening of supply chain to drive performance through logical integration of supply chain resources. Business Strategy and the Environment 2023, 32, 3833–3847. [CrossRef]

- Assumpção, J.J.; Campos, L.M.; Plaza-Úbeda, J.A.; Sehnem, S.; Vazquez-Brust, D.A. Green supply chain management and business innovation. Journal of Cleaner Production 2022, 367, 132877. [CrossRef]

- Nguyen, N.A.T.; Wang, C.N.; Dang, L.T.H.; Dang, L.T.T.; Dang, T.T. Selection of cold chain logistics service providers based on a grey AHP and grey COPRAS framework: a case study in Vietnam. Axioms 2022, 11, 154. [CrossRef]

- Yang, C.; Wang, Q.; Pan, M.; Hu, J.; Peng, W.; Zhang, J.; Zhang, L. A linguistic Pythagorean hesitant fuzzy MULTIMOORA method for third-party reverse logistics provider selection of electric vehicle power battery recycling. Expert Systems with Applications 2022, 198, 116808. [CrossRef]

- Snášel, V.; Perfilieva, I.; Singh, M.; Pant, M.; Alijani, Z.; Kong, L. A rankability-based fuzzy decision making procedure for oil supplier selection. Applied Soft Computing 2023, 149, 110956. [CrossRef]

- Weihua, S. Research on theory and method of multi-criteria comprehensive evaluation. PhD thesis, Xiamen University, 2000.

- Elsayed, E.A.; Dawood, A.S.; Karthikeyan, R. Evaluating alternatives through the application of TOPSIS method with entropy weight. Int. J. Eng. Trends Technol 2017, 46, 60–66. [CrossRef]

- Chen, C.H. A hybrid multi-criteria decision-making approach based on ANP-entropy TOPSIS for building materials supplier selection. Entropy 2021, 23, 1597. [CrossRef]

- Lai, Y.J.; Liu, T.Y.; Hwang, C.L. Topsis for MODM. European journal of operational research 1994, 76, 486–500. [CrossRef]

- Olugu, E.U.; Wong, K.Y. A study on the validation of green supply chain performance measures in the automotive industry. Commun. IBIMA 2011, 2011, 1–14. [CrossRef]

- Yunting, F.; Kee-hung, L.; Qinghua, Z. Green supply chain innovation: Emergence, adoption, and challenges. International Journal of Production Economics 2022, 248, 108497. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).