Submitted:

23 August 2024

Posted:

27 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

3. Results and Discussion

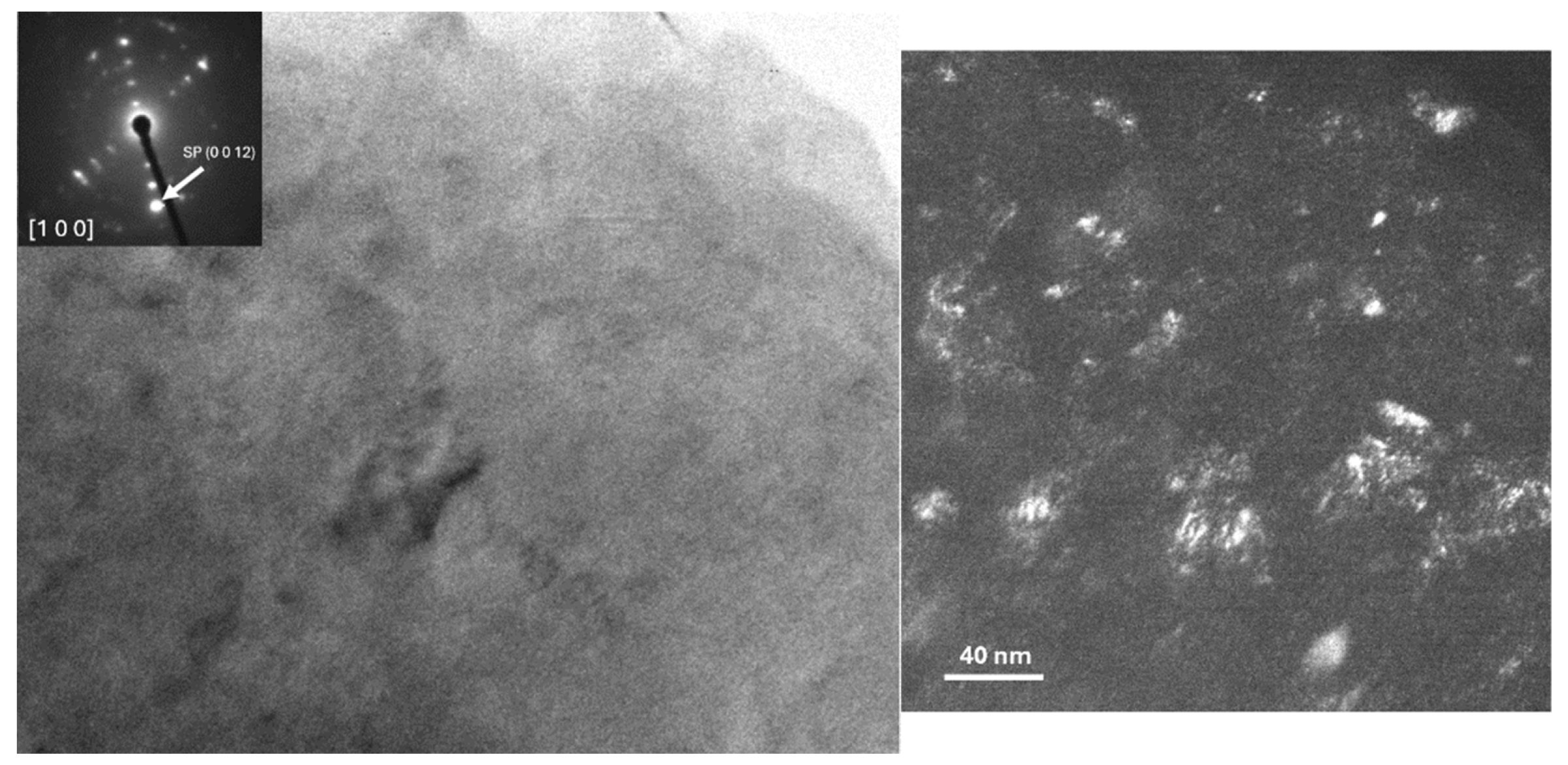

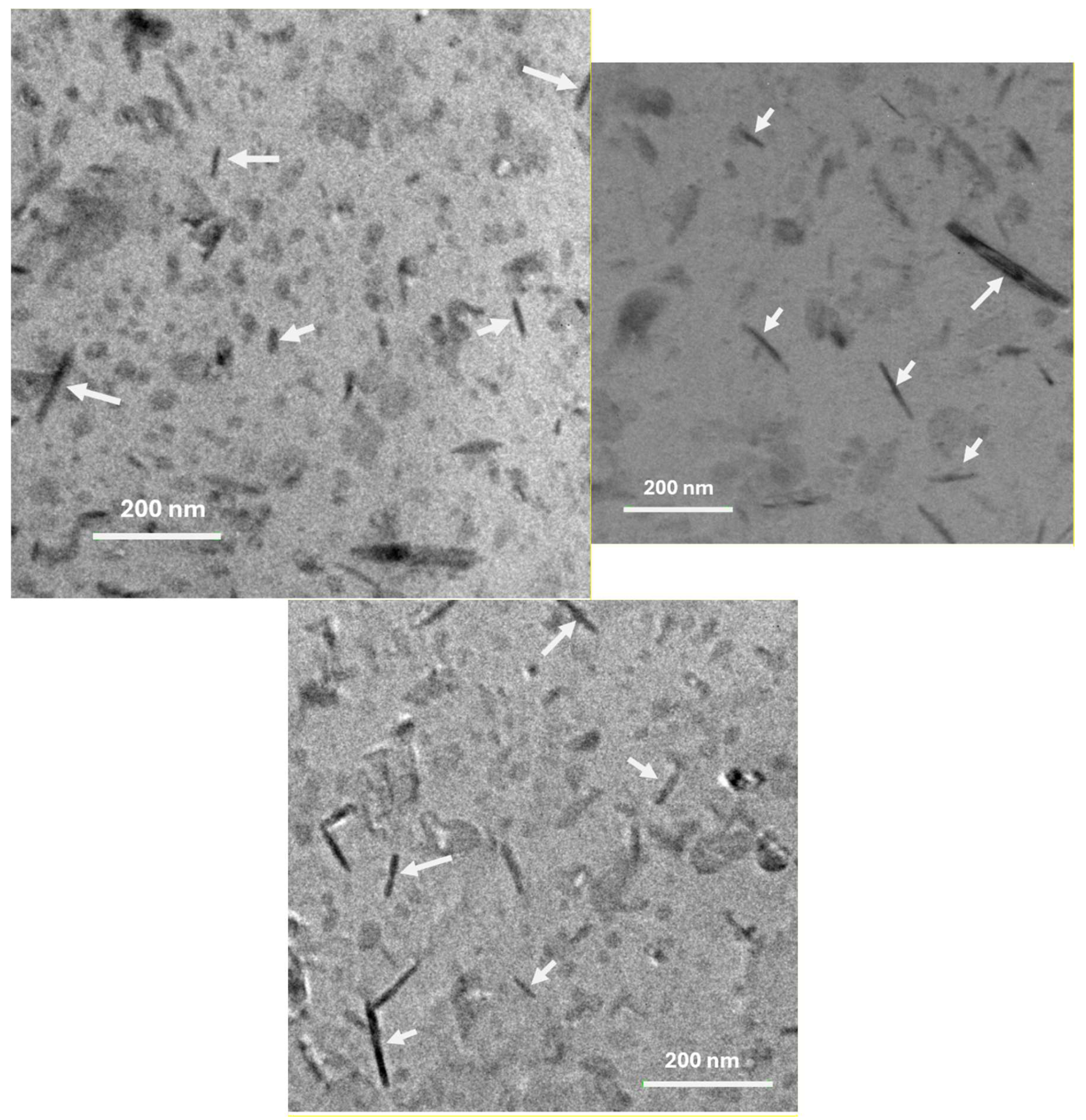

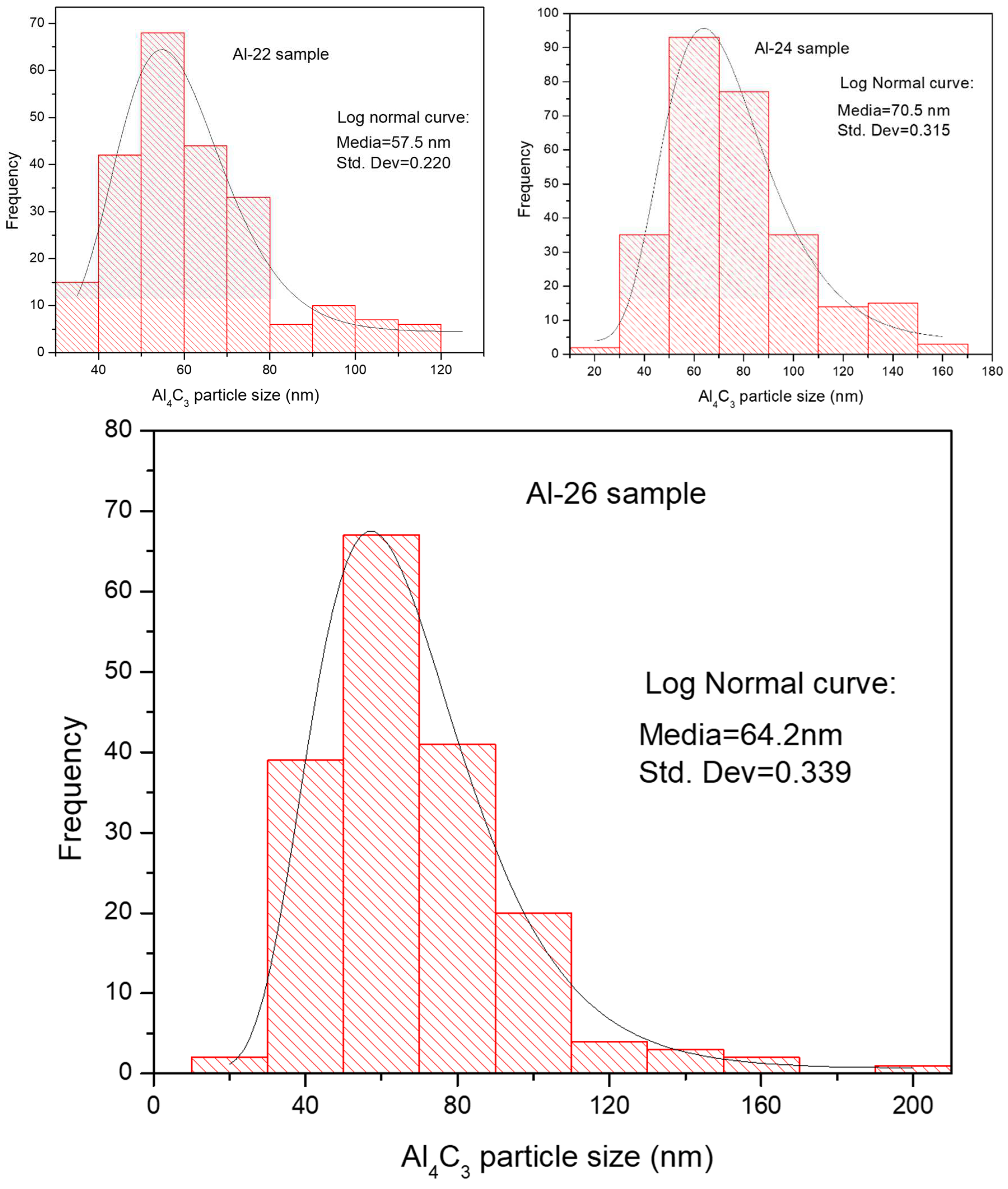

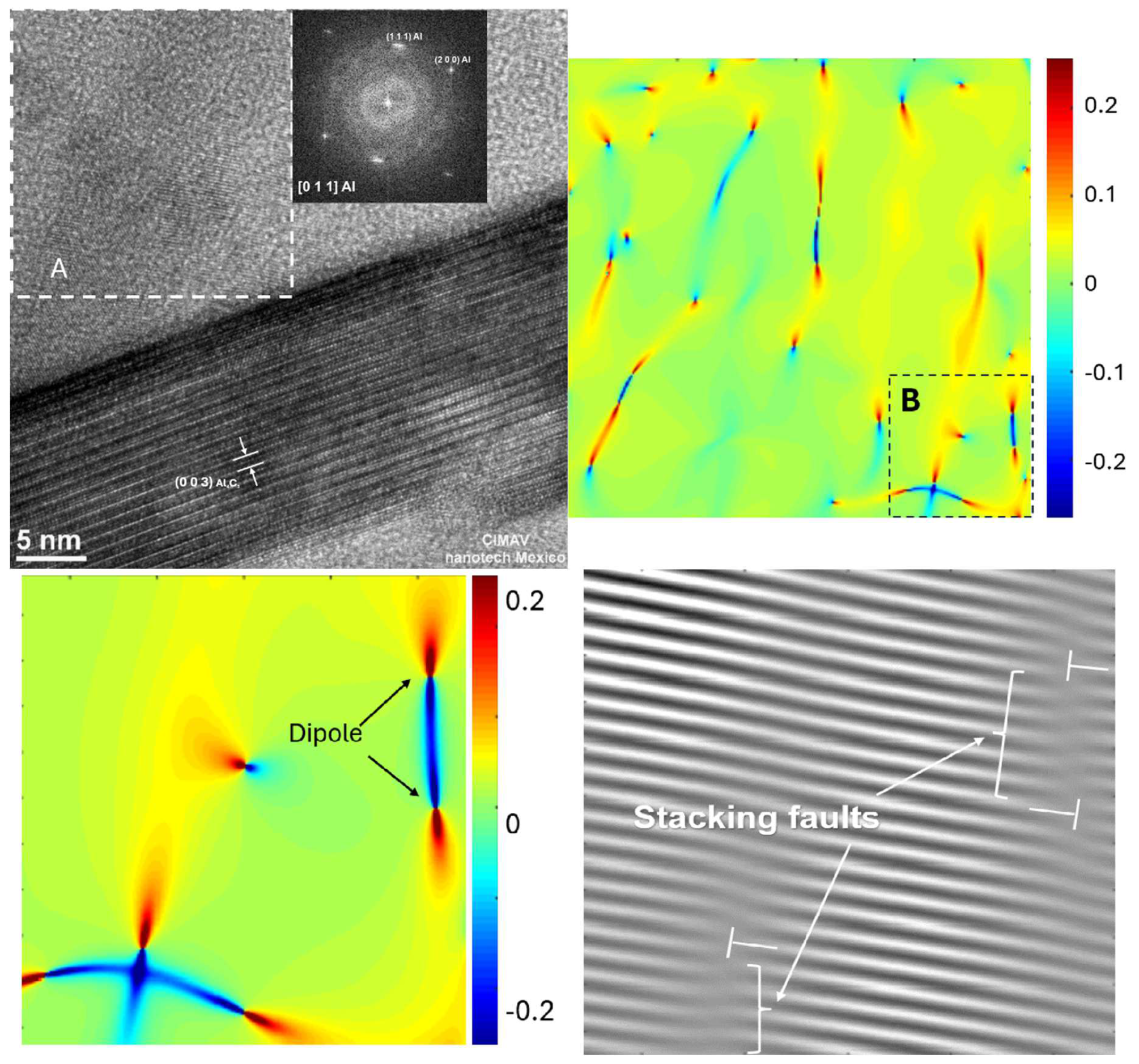

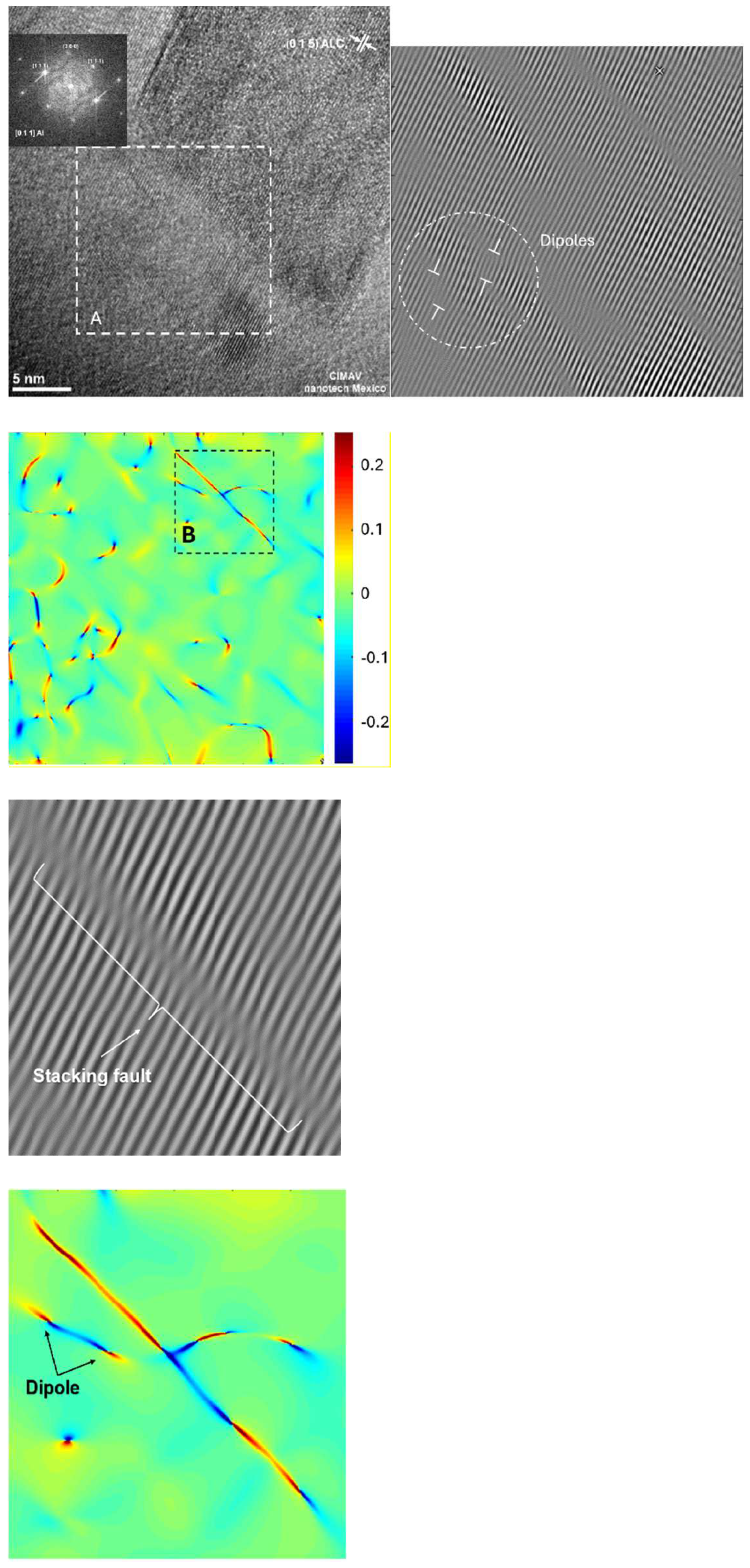

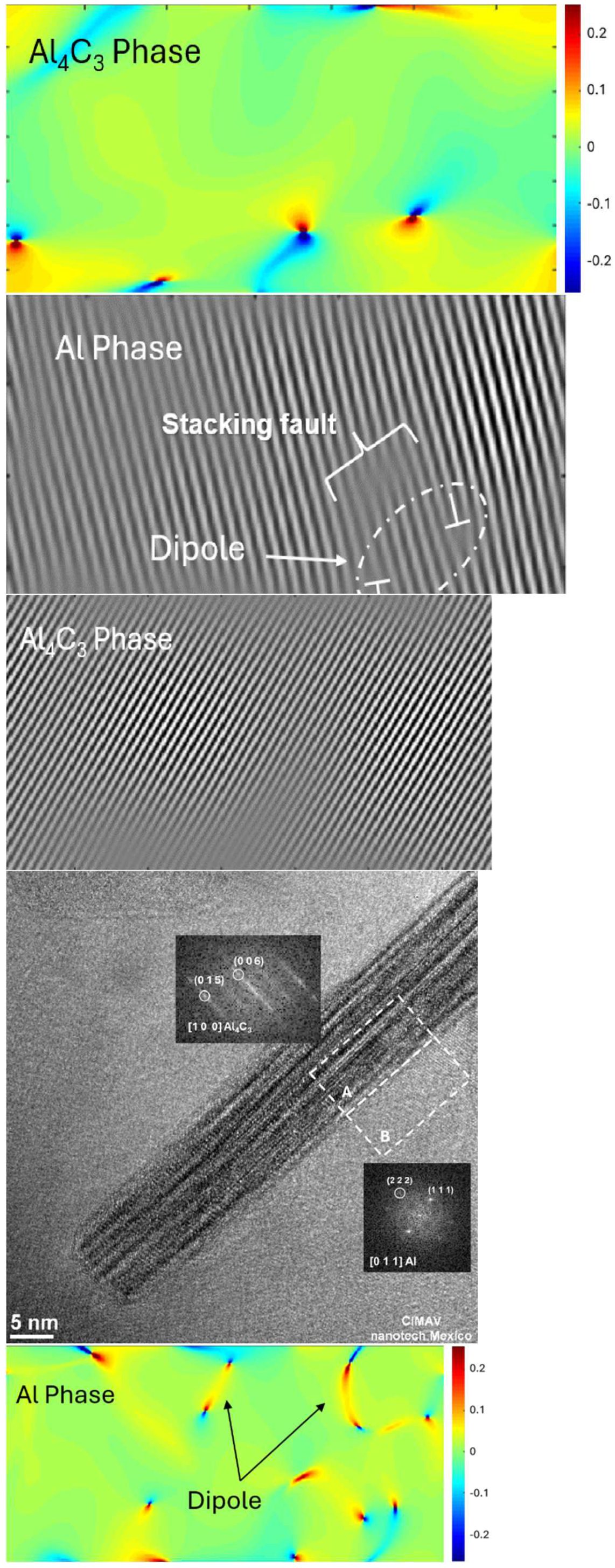

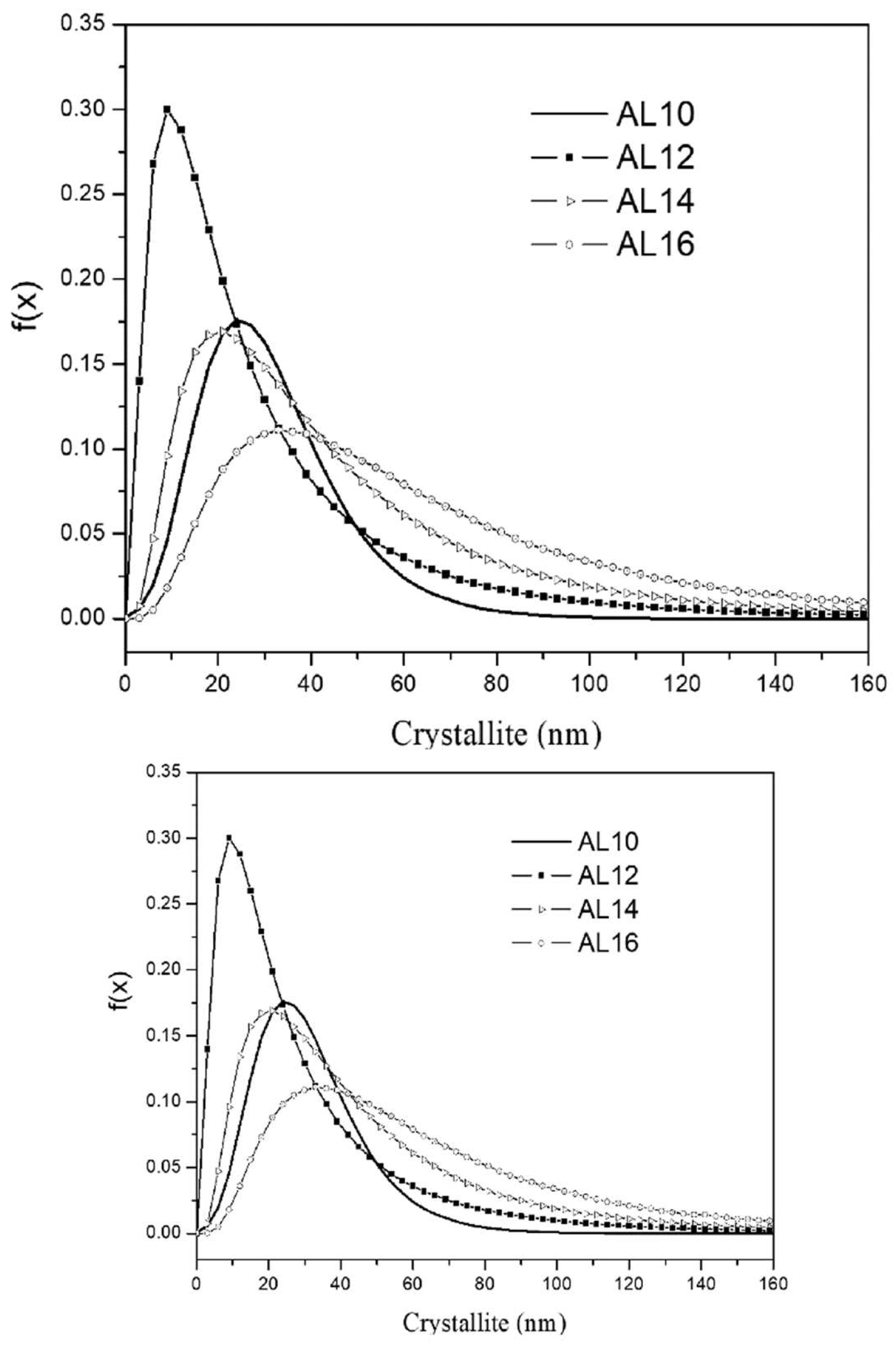

3.1. Microstructural Analysis

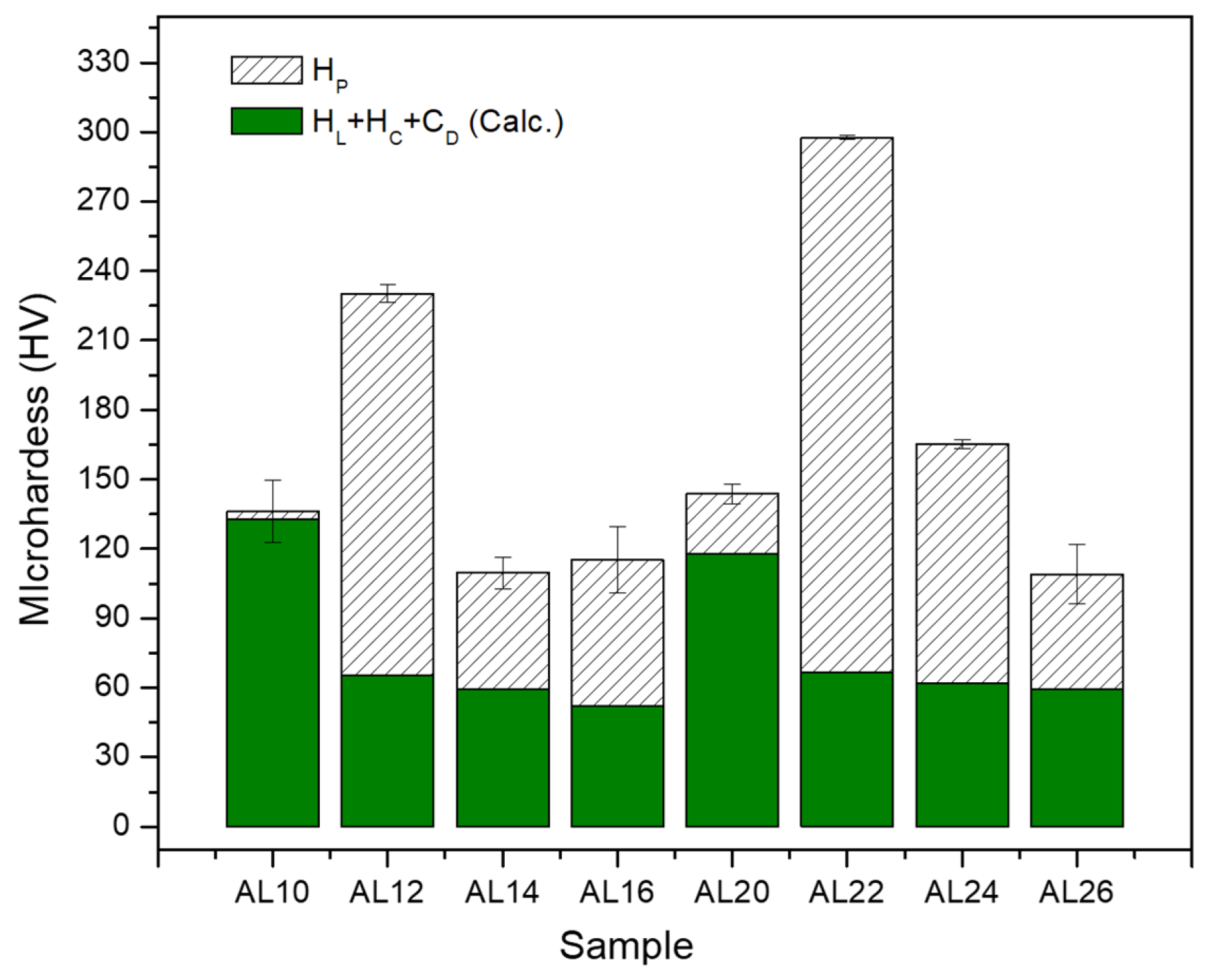

3.2. Hardness Analysis

3.3. Results Discussion

4. Conclusions

References

- Pan, S.; Wang, T.; Jin, K.; Cai, X. Understanding and designing metal matrix nanocomposites with high electrical conductivity: a review. J. Mater. Sci. 2022, 57, 6487–6523. [Google Scholar] [CrossRef]

- Saboori, A.; Moheimani, S.K.; Dadkhah, M.; Pavese, M.; Badini, C.; Fino, P. An Overview of Key Challenges in the Fabrication of Metal Matrix Nanocomposites Reinforced by Graphene Nanoplatelets. Metals 2018, 8, 172. [Google Scholar] [CrossRef]

- Rohatgi, P.K.D., Schultz, B.F., Ferguson, J.B. (2013). Synthesis and Properties of Metal Matrix Nanocomposites (MMNCS), Syntactic Foams, Self Lubricating and Self-Healing Metals. In: Marquis, F. (eds) Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing. Springer, Cham. [CrossRef]

- Patro, L. Role of mechanical milling on the synthesis and ionic transport properties of fast fluoride ion conducting materials. J. Solid State Electrochem. 2020, 24, 2219–2232. [Google Scholar] [CrossRef]

- Sambathkumar, M.; Gukendran, R.; Mohanraj, T.; Karupannasamy, D.K.; Natarajan, N.; Christopher, D.S. A Systematic Review on the Mechanical, Tribological, and Corrosion Properties of Al 7075 Metal Matrix Composites Fabricated through Stir Casting Process. Adv. Mater. Sci. Eng. 2023, 2023, 1–17. [Google Scholar] [CrossRef]

- Anuar, N.F.B.W.; Salleh, M.S.; Omar, M.Z.; Zamri, W.F.H.W.; Ali, A.M.; Samat, S. Wear properties of graphene-reinforced aluminium metal matrix composite: A review. Rev. Adv. Mater. Sci. 2023, 62. [Google Scholar] [CrossRef]

- Zhang, Z.; Ódor, O.; Farkas, D.; Jóni, B.; Ribárik, G.; Tichy, G.; Nandam, S.-H.; Ivanisenko, J.; Preuss, M.; Ungár, T. Dislocations in Grain Boundary Regions: The Origin of Heterogeneous Microstrains in Nanocrystalline Materials. Met. Mater. Trans. A 2019, 51, 513–530. [Google Scholar] [CrossRef]

- Pinate, S.; Ghassemali, E.; Zanella, C. Strengthening mechanisms and wear behavior of electrodeposited Ni–SiC nanocomposite coatings. J. Mater. Sci. 2022, 57, 16632–16648. [Google Scholar] [CrossRef]

- Ståhlkrantz, A.; Hedström, P.; Sarius, N.; Borgenstam, A. Influence of Austempering Conditions on Hardness and Microstructure of Bainite in Low-Alloyed Steel. Met. Mater. Trans. A 2023, 55, 209–217. [Google Scholar] [CrossRef]

- Ribárik, G.; Jóni, B.; Ungár, T. The Convolutional Multiple Whole Profile (CMWP) Fitting Method, a Global Optimization Procedure for Microstructure Determination. Crystals 2020, 10, 623. [Google Scholar] [CrossRef]

- Ungár, T.; Dragomir, I.; Révész, O.; Borbély, A. The contrast factors of dislocations in cubic crystals: the dislocation model of strain anisotropy in practice. J. Appl. Crystallogr. 1999, 32, 992–1002. [Google Scholar] [CrossRef]

- Borbély, J. D.-Cernatescu, C. Ribarik and T. Ungar: J. Appl. Crystallogr. 36 (2003) 160 162.

- Wilkens, M. The determination of density and distribution of dislocations in deformed single crystals from broadened X-ray diffraction profiles. Phys. Status solidi (a) 1970, 2, 359–370. [Google Scholar] [CrossRef]

- Ribárik, G.; Jóni, B.; Ungár, T. The Convolutional Multiple Whole Profile (CMWP) Fitting Method, a Global Optimization Procedure for Microstructure Determination. Crystals 2020, 10, 623. [Google Scholar] [CrossRef]

- Santos-Beltrán, A.; Goytia-Reyes, R.; Morales-Rodriguez, H.; Gallegos-Orozco, V.; Santos-Beltrán, M.; Baldenebro-Lopez, F.; Martínez-Sánchez, R. Characterization of Al–Al4C3 nanocomposites produced by mechanical milling. Mater. Charact. 2015, 106, 368–374. [Google Scholar] [CrossRef]

- M. Klinger. CrysTBox - Crystallographic Toolbox. Institute of Physics of the Czech Academy of Sciences, Prague, 2015. ISBN 978-80-905962-3-8. URL http://www.fzu.cz/~klinger/crystbox.

- Hÿtch, M.; Snoeck, E.; Kilaas, R. Quantitative measurement of displacement and strain fields from HREM micrographs. Ultramicroscopy 1998, 74, 131–146. [Google Scholar] [CrossRef]

- Ungár, T.; Gubicza, J.; Ribárik, G.; Borbély, A. Crystallite size distribution and dislocation structure determined by diffraction profile analysis: principles and practical application to cubic and hexagonal crystals. J. Appl. Crystallogr. 2001, 34, 298–310. [Google Scholar] [CrossRef]

- Cahn, R.W.; Haasen, P.; Argon, A.S. Physical metallurgy, In: Elsevier Science, B.V. (Ed.), Mechanical Properties of Single-Phase Crystalline Media, Deformation at Low Temperature, fourth Mat Sci Eng A-Struct ed.; Elsevier Science B.V.: Amsterdam, The Netherlands, 1996; pp. 1878–1955. [Google Scholar]

- Orozco, V.G.; Beltrán, A.S.; Beltrán, M.S.; Prieto, H.M.; Orozco, C.G.; Guel, I.E. Effect on Microstructure and Hardness of Reinforcement in Al–Cu with Al4C3 Nanocomposites. Metals 2021, 11, 1203. [Google Scholar] [CrossRef]

- Feijoo, I.; Pena, G.; Cristóbal, M.J.; Cabeza, M.; Rey, P. Effect of Carbon Nanotube Content and Mechanical Milling Conditions on the Manufacture of AA7075/MWCNT Composites. Metals 2022, 12, 1020. [Google Scholar] [CrossRef]

- Lee, W.-R.; Kim, M.G.; Choi, J.-R.; Park, J.-I.; Ko, S.J.; Oh, S.J.; Cheon, J. Redox−Transmetalation Process as a Generalized Synthetic Strategy for Core−Shell Magnetic Nanoparticles. J. Am. Chem. Soc. 2005, 127, 16090–16097. [Google Scholar] [CrossRef]

- Ferguson, J.B.; Lopez, H.; Kongshaug, D.; Schultz, B.; Rohatgi, P. Revised Orowan Strengthening: Effective Interparticle Spacing and Strain Field Considerations. Met. Mater. Trans. A 2012, 43, 2110–2115. [Google Scholar] [CrossRef]

- Kim, J.; Ghaffarian, H.; Kang, K. The lattice dislocation trapping mechanism at the ferrite/cementite interface in the Isaichev orientation relationship. Sci. Rep. 2021, 11, 1–8. [Google Scholar] [CrossRef]

- Charleston, J.; Agrawal, A.; Mirzaeifar, R. Effect of interface configuration on the mechanical properties and dislocation mechanisms in metal graphene composites. Comput. Mater. Sci. 2020, 178, 109621. [Google Scholar] [CrossRef]

- Jayaseelan, J.; Pazhani, A.; Michael, A.X.; Paulchamy, J.; Batako, A.; Guruswamy, P.K.H. Characterization Studies on Graphene-Aluminium Nano Composites for Aerospace Launch Vehicle External Fuel Tank Structural Application. Materials 2022, 15, 5907. [Google Scholar] [CrossRef] [PubMed]

- Hou, Y.N.; Yang, K.M.; Song, J.; Wang, H.; Liu, Y.; Fan, T.X. A crystal plasticity model for metal matrix composites considering thermal mismatch stress induced dislocations and twins. Sci. Rep. 2021, 11, 1–13. [Google Scholar] [CrossRef]

- Wong, C.S.; Pramanik, A.; Basak, A.K. Residual stress generation in metal matrix composites after cooling. Mater. Sci. Technol. 2018, 34, 1388–1400. [Google Scholar] [CrossRef]

- Tochigi, E.; Nakamura, A.; Shibata, N.; Ikuhara, Y. Dislocation Structures in Low-Angle Grain Boundaries of α-Al2O3. Crystals 2018, 8, 133. [Google Scholar] [CrossRef]

- Föll, H.; Ast, D. TEM observations on grain boundaries in sintered silicon. Philos. Mag. A 1979, 40, 589–610. [Google Scholar] [CrossRef]

- Belov, A.; Scholz, R.; Scheerschmidt, K. Dissociation of screw dislocations in (001) low-angle twist boundaries: A source of the 30 o partial dislocations in silicon. Philos. Mag. Lett. 1999, 79, 531–538. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, M.P.; Da Yu, Y.; Skaret, P.C.; Roven, H.J. Microstructural Characterization of an Al-Mg-Si Aluminum Alloy Processed by Equal Channel Angular Pressing. Mater. Sci. Forum 2013, 745-746, 303–308. [Google Scholar] [CrossRef]

- Gilman, J.J. Influence of dislocation dipoles on physical properties. Discuss. Faraday Soc. 1964, 38, 123–137. [Google Scholar] [CrossRef]

- Cao, Y.; Zhu, P.; Yang, Y.; Shi, W.; Qiu, M.; Wang, H.; Xie, P. Dislocation Mechanism and Grain Refinement of Surface Modification of NV E690 Cladding Layer Induced by Laser Shock Peening. Materials 2022, 15, 7254. [Google Scholar] [CrossRef]

- Ni, K.; Wang, H.; Guo, Q.; Wang, Z.; Liu, W.; Huang, Y. The Construction of a Lattice Image and Dislocation Analysis in High-Resolution Characterizations Based on Diffraction Extinctions. Materials 2024, 17, 555. [Google Scholar] [CrossRef] [PubMed]

- The Convolutional Multiple Whole Profile (CMWP) Fitting Method, a Global Optimization Procedure for Microstructure Determination Gábor Ribárik, Bertalan Jóni and Tamás Ungár.

- Kroupa, F. DISLOCATION DIPOLES AND DISLOCATION LOOPS. Le J. de Phys. Colloq. 1966, 27, C3–154. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).