Submitted:

28 August 2024

Posted:

29 August 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

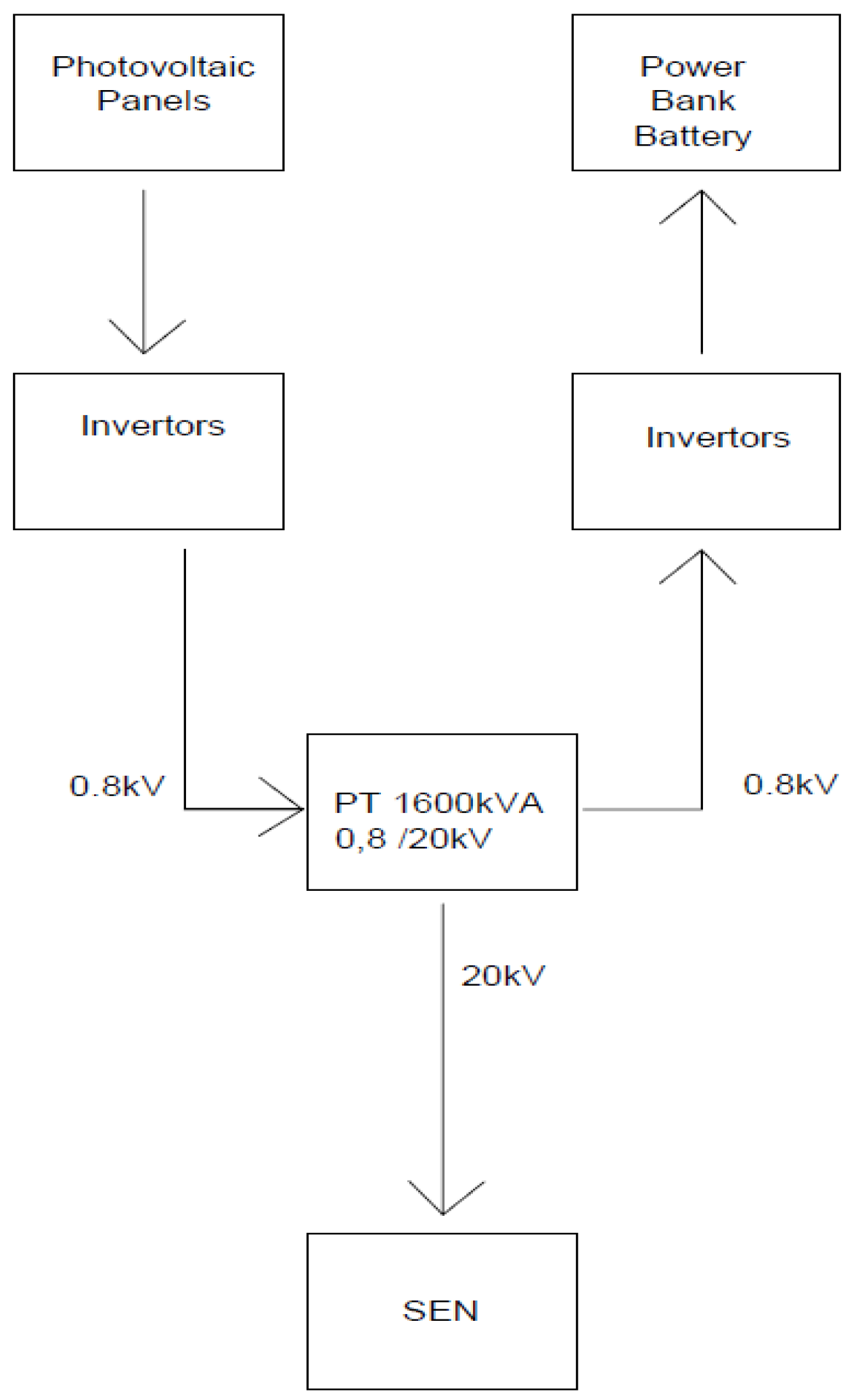

2. Description of the Photovoltaic Park

3. System Analysis

3.1. The Technical Characteristics of the Photovoltaic Panels

3.2. The Technical Characteristics of the Invertors

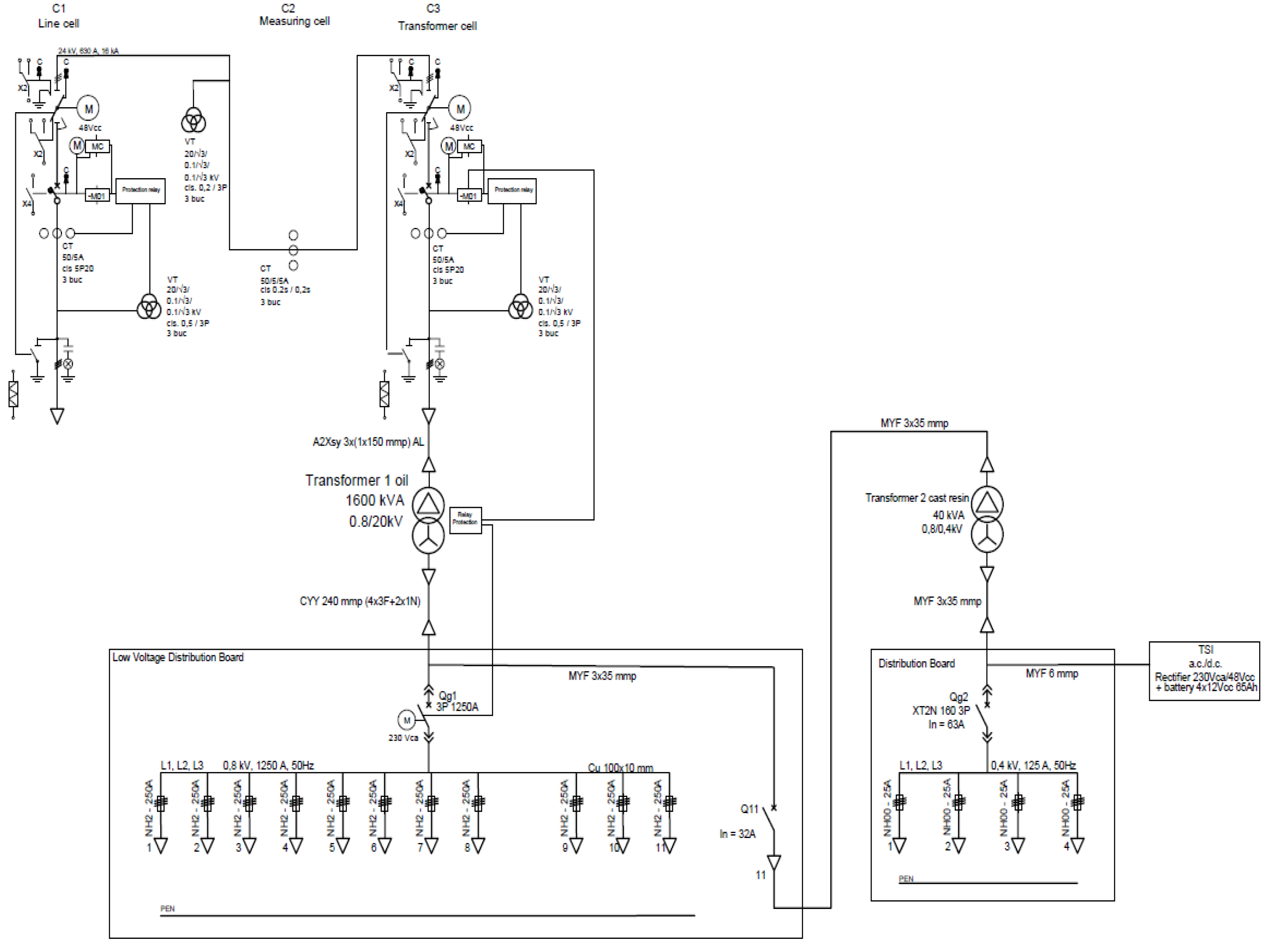

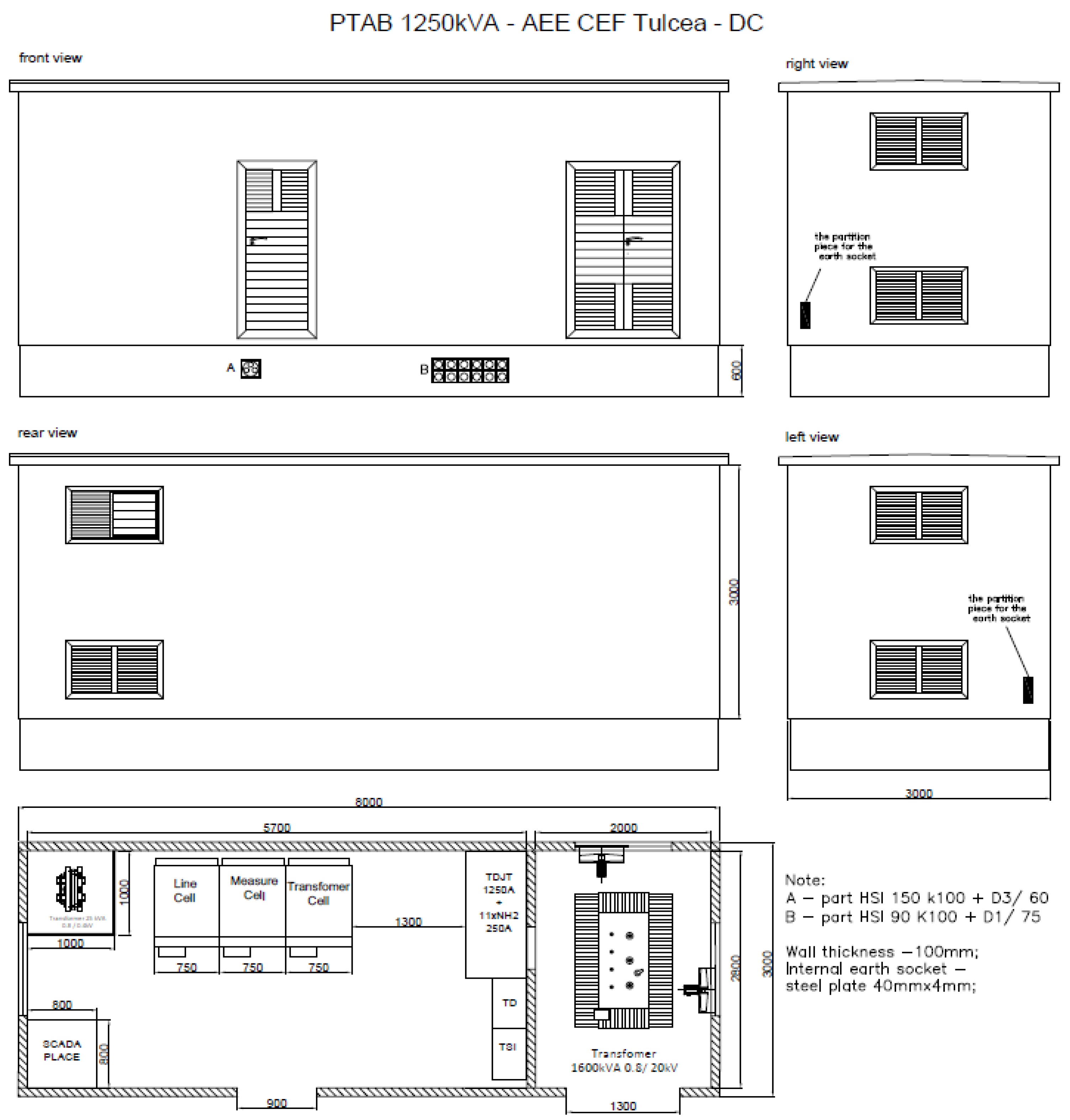

3.3. The Technical Characteristics of the Transformation Substation in the Concrete Tire

4. Photovoltaic Park Simulation

4.1. Description of the Simulation

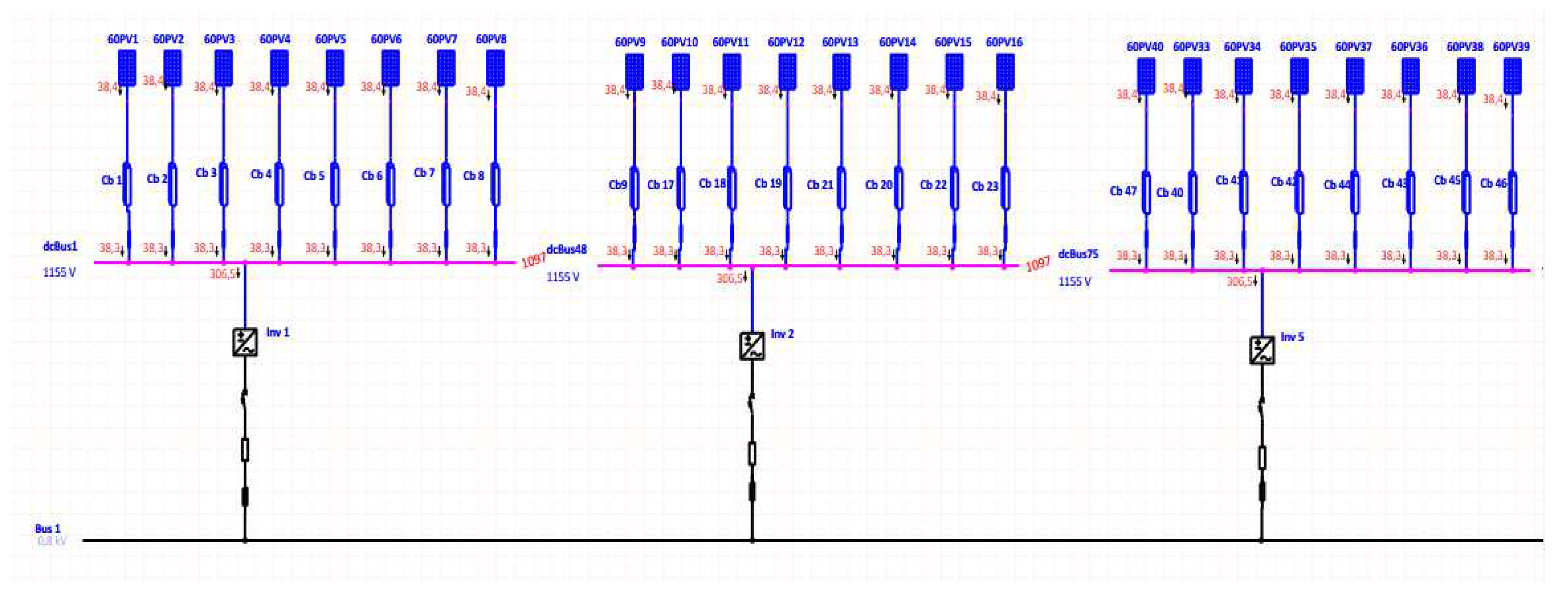

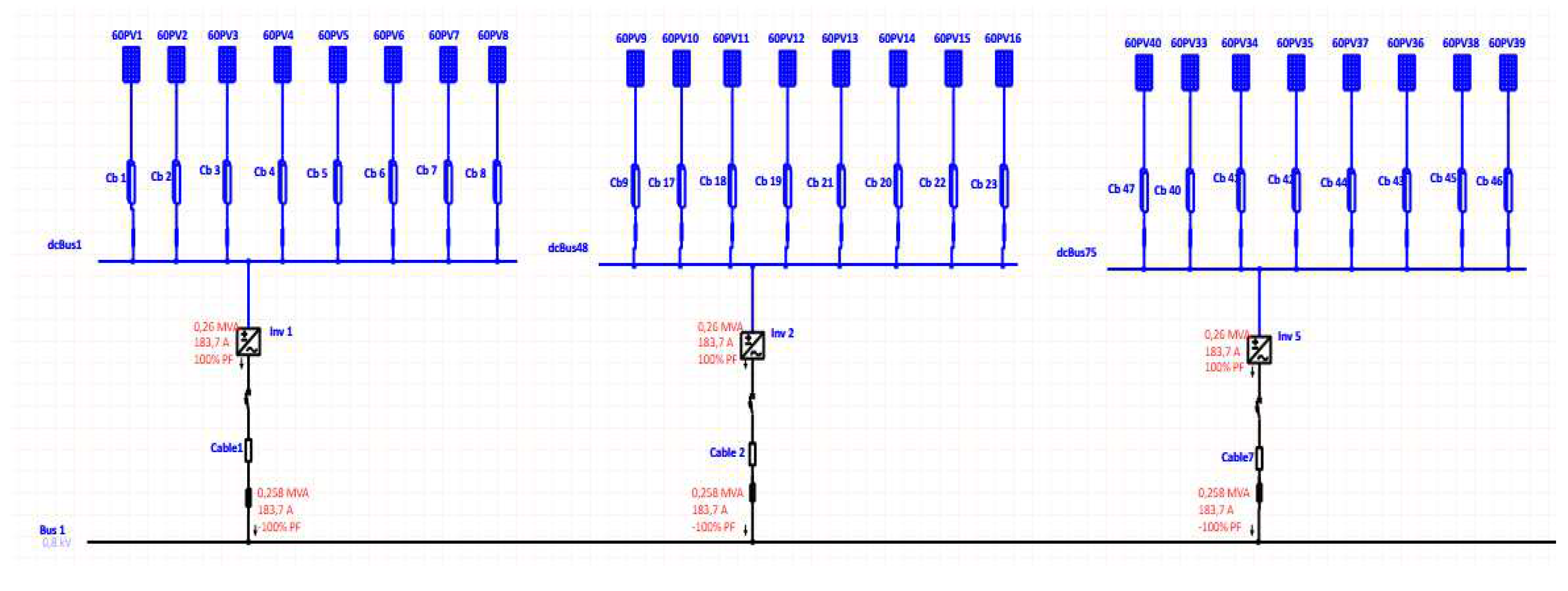

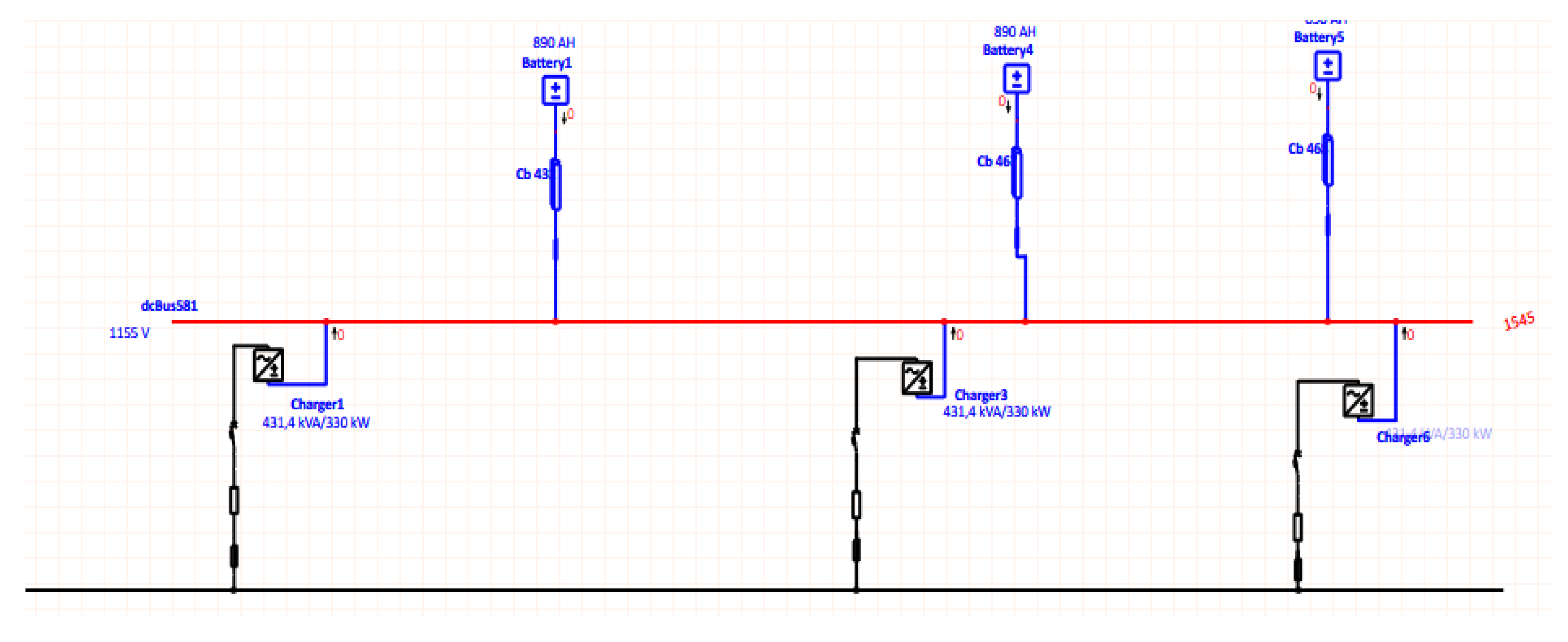

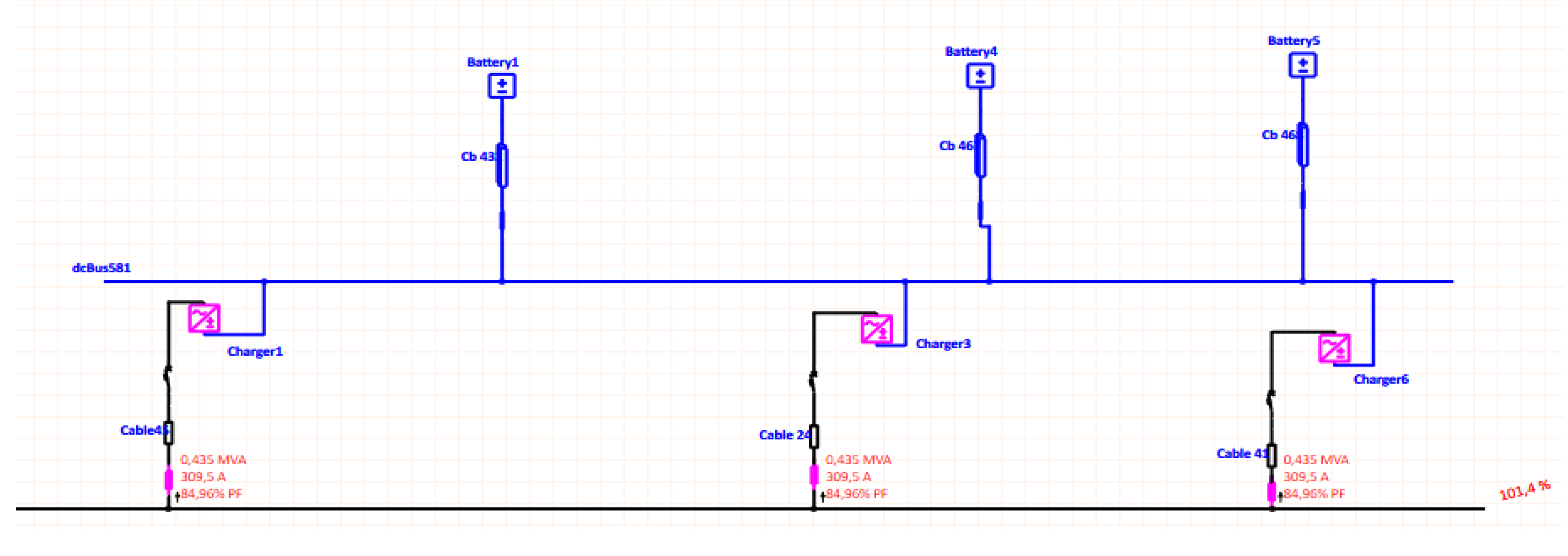

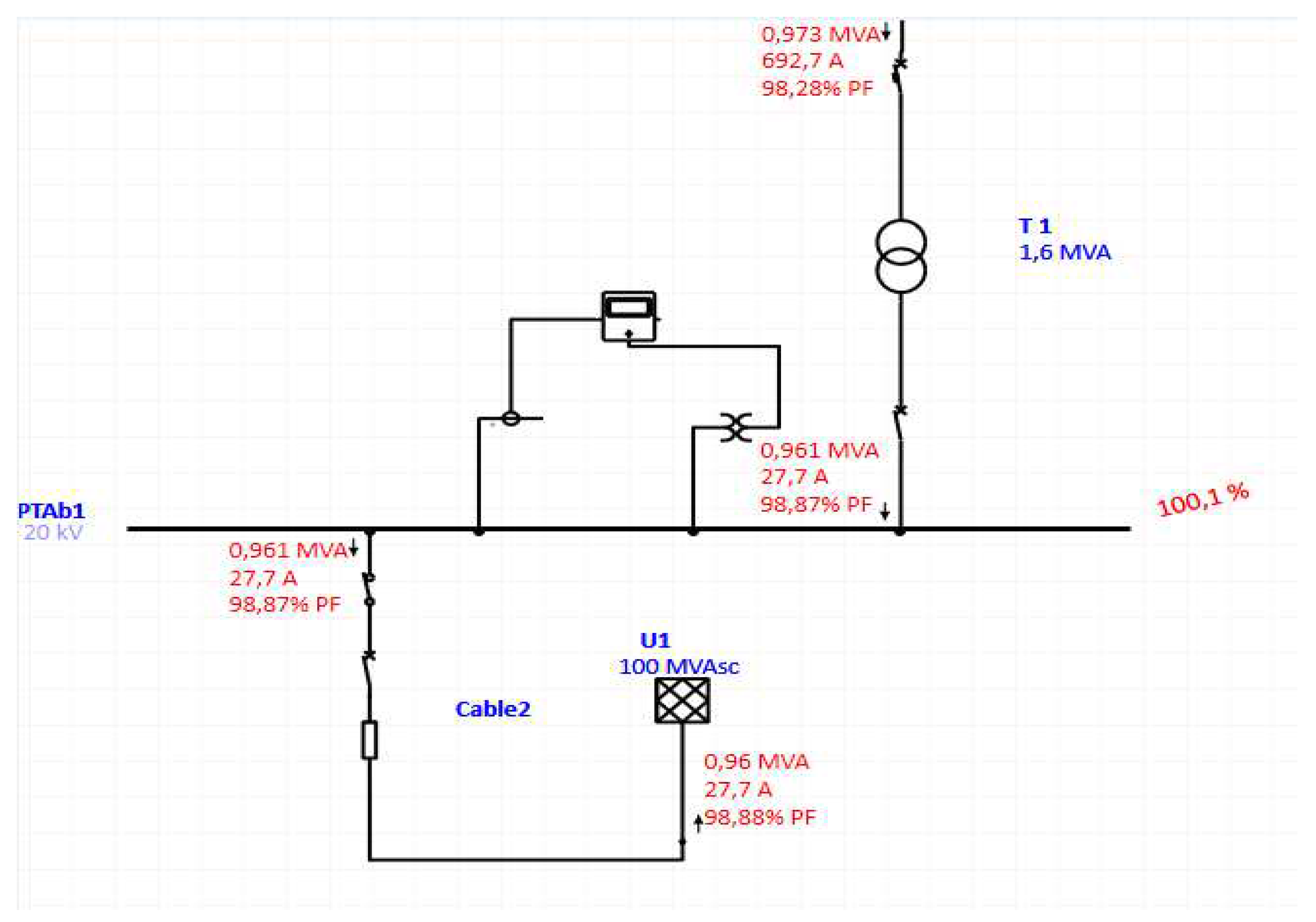

4.2. Simulation in ETAP

4.3. Economic Calculation

5. Conclusion

Author Contributions

Data Availability Statement

6. Acknowledgment

Conflicts of Interest

References

- Kymakis, E.; Kalykakis, S.; Papazoglou, T.M. Performance analysis of a grid connected photovoltaic park on the island of Crete. Energy Convers. Manag. 2009, 50, 433–438. [Google Scholar] [CrossRef]

- J. Syllignakis and T. M. Papazoglou, “Study of Impact on Crete system operation of the Atherinolakos power plant,” in Proceedings of the 41st international universities power engineering conference, IEEE, 2006, pp. 482–485.

- Jafari, H.; Habibi, M. High-Voltage Charging Power Supply Based on an LCC-Type Resonant Converter Operating at Continuous Conduction Mode. IEEE Trans. Power Electron. 2019, 35, 5461–5478. [Google Scholar] [CrossRef]

- Lazaroiu, A.C.; Osman, M.G.; Strejoiu, C.-V.; Lazaroiu, G. A Comprehensive Overview of Photovoltaic Technologies and Their Efficiency for Climate Neutrality. Sustainability 2023, 15, 16297. [Google Scholar] [CrossRef]

- Yoo, C.-B. Park, and J. Lee, “A study on design of photovoltaic system using electrical railway stations,” in 2016 19th International Conference on Electrical Machines and Systems (ICEMS), IEEE, 2016, pp. 1–5.

- M. E. Vanggaard and D. T. Lund, “Design of a standalone PV system for Greenland, Dep. of Civil Engineering, Danmarks Tekn,” Univ.(DTU), 2009.

- N. D. Hatziargyriou, A. Tsikalakis, and A. Androutsos, “Status of distributed generation in the Greek islands,” in 2006 IEEE Power Engineering Society General Meeting, IEEE, 2006, pp. 6-pp.

- Inginerie mecanică și a instalațiilor.” Accessed: Jul. 08, 2024. [Online]. Available: https://www.eplan.

- “O gamă de produse care oferă soluții solare fiabile | FusionSolar România.” Accessed: Jul. 08, 2024. [Online]. Available: https://solar.huawei.

- Lazaroiu, G.; Osman, M.G.; Strejoiu, C.-V. Performance Evaluation of Renewable Energy Systems: Photovoltaic, Wind Turbine, Battery Bank, and Hydrogen Storage. Batteries 2023, 9, 468. [Google Scholar] [CrossRef]

- Lakervi, E.; Holmes, E.J. Electricity Distribution Network Design; Institution of Engineering and Technology (IET): Stevenage, Hertfordshire, United Kingdom, 2003. [Google Scholar]

- Osman, M.G.; Strejoiu, C.-V.; Panait, C.; Lazaroiu, A.C.; Lazaroiu, G. Microgrid Model for Evaluating the Operational Dynamics of Solar-Powered Hydrogen Production. 2024 9th International Conference on Energy Efficiency and Agricultural Engineering (EE&AE), Bulgaria.

- Wang, C.; He, S.; Liu, L.; Li, X.; Gao, L. Tradeoff between the efficiency penalty and load depth in a coal-fired power plant with CO2 capture under partial load conditions. Energy Convers. Manag. 2023, 278. [Google Scholar] [CrossRef]

- Silva, M.; Castro, R.; Batalha, M. Technical and Economic Optimal Solutions for Utility-Scale Solar Photovoltaic Parks. Electronics 2020, 9, 400. [Google Scholar] [CrossRef]

- M. Radic and D. Jovanovic, “Methodology for determination of 110/35 kV and 110/20 kV substation revitalization order,” in CIRED 2009-20th International Conference and Exhibition on Electricity Distribution-Part 1, IET, 2009, pp. 1–5.

- Decker, B.; Jahn, U. Performance of 170 grid connected PV plants in Northern Germany—Analysis of yields and optimization potentials. Sol. Energy 1997, 59, 127–133. [Google Scholar] [CrossRef]

- M. T. Hagh, “DESIGN AND INSTALLATION OF FIRST 20 kV SPACER CABLE IN IRAN,” in 21st International Conference on Electricity Distribution, CIRED, 2011, pp. 6–9.

- Crowe, R. The Treaty of Lisbon: A Revised Legal Framework for the Organisation and Functioning of the European Union. ERA Forum 2008, 9, 163–208. [Google Scholar] [CrossRef]

- P. E. Mark Rossow, “Grid Energy Storage”.

- S. Ziuku and E. L. Meyer, “Economic viability of a residential building integrated photovoltaic generator in South Africa,” International Journal of Energy and Environment, vol. 3, no. 6, pp. 905–914, 2012.

- Solar Cell Supplier - China Seraphim Solar Panel.” Accessed: Jul. 08, 2024. [Online]. Available: https://www.seraphim-energy.

- M. Widatalla and H. Zinko, “Designing a Photovoltaic Solar Energy System for a Commercial Building. Case Study: Rosa Park Hotel in Khartoum-Sudan,” in World Renewable Energy Congress-Sweden, 2011.

- Omer, A.M. Compilation and evaluation of solar and wind energy resources in Sudan. Renew. Energy 1997, 12, 39–69. [Google Scholar] [CrossRef]

- Lazaroiu, A.C.; Osman, M.G.; Strejoiu, C.-V.; Lazaroiu, G. A Comprehensive Overview of Photovoltaic Technologies and Their Efficiency for Climate Neutrality. Sustainability 2023, 15, 16297. [Google Scholar] [CrossRef]

- Razazian, K.; Umari, M.; Kamalizad, A.; Loginov, V.; Navid, M. G3-PLC specification for powerline communication: Overview, system simulation and field trial results. IEEE ISPLC 2010 - International Symposium on Power Line Communications and its Applications, pp. 2010. [Google Scholar] [CrossRef]

- H. Müller and T. Connor, “New 20kV network concept for an existing distribution network,” in 2010 China International Conference on Electricity Distribution, CICED 2010, IEEE, 2010, pp. 1–7.

- Ciulica, D.; Rob, R. Internal services simulation control in 220/110kV power transformer station Mintia. IOP Conf. Series: Mater. Sci. Eng. 2018, 294, 012009. [Google Scholar] [CrossRef]

- Scognamiglio, A. ‘Photovoltaic landscapes’: Design and assessment. A critical review for a new transdisciplinary design vision. Renew. Sustain. Energy Rev. 2015, 55, 629–661. [Google Scholar] [CrossRef]

- Botsaris, P.N. An approach of the spatial planning of a photovoltaic park using the Constructal Theory. Sustain. Energy Technol. Assessments 2015, 11, 11–16. [Google Scholar] [CrossRef]

- Z. Wu, “Study on selection of transformer capacity and conductor cross-section related to 20kV network in high voltage distribution network,” in 2010 China International Conference on Electricity Distribution, CICED 2010, IEEE, 2010, pp. 1–6.

- Medio, S. Photovoltaic Design Integration at Battery Park City, New York. Buildings 2013, 3, 341–356. [Google Scholar] [CrossRef]

- Roboam, X.; Sareni, B.; Andrade, A. More Electricity in the Air: Toward Optimized Electrical Networks Embedded in More-Electrical Aircraft. IEEE Ind. Electron. Mag. 2012, 6, 6–17. [Google Scholar] [CrossRef]

- Knight, U. The logical design of electrical networks using linear programming methods. Proc. IEE Part A: Power Eng. 1960, 107, 306–314. [Google Scholar] [CrossRef]

- Dorel, S.; Osman, M.G.; Strejoiu, C.-V.; Lazaroiu, G. Exploring Optimal Charging Strategies for Off-Grid Solar Photovoltaic Systems: A Comparative Study on Battery Storage Techniques. Batteries 2023, 9, 470. [Google Scholar] [CrossRef]

- Ogden, J.M. Cost and performance sensitivity studies for solar photovoltaic/electrolytic hydrogen systems. Sol. Cells 1991, 30, 515–523. [Google Scholar] [CrossRef]

- Sidrach-De-Cardona, M.; López, L.M. Performance analysis of a grid-connected photovoltaic system. Energy 1999, 24, 93–102. [Google Scholar] [CrossRef]

- E. D. Dunlop, “Lifetime performance of crystalline silicon PV modules,” in 3rd World Conference onPhotovoltaic Energy Conversion, 2003. Proceedings of, IEEE, 2003, pp. 2927–2930.

- B. Croxford and M. Rizig, “Is photovoltaic power a cost-effective energy solution for rural peoples in western Sudan?,” 2006.

- H. Ritchie, P. Rosado, and M. Roser, “Greenhouse gas emissions,” Our world in data, 2023.

- Acasa – Td Proelectric.” Accessed: Jul. 08, 2024. [Online]. Available: https://td-proelectric.

- Home - SEL, S.p.A. Experience and innovation at Your service.” Accessed: Jul. 08, 2024. [Online]. Available: https://www.sel-electric.

- Grupul ABB - Tehnologii digitale de vârf pentru industrie.” Accessed: Jul. 08, 2024. [Online]. Available: https://new.abb.

- AutoCAD Web App - Sign In | Online CAD Editor & Viewer | Autodesk.” Accessed: Jul. 08, 2024. [Online]. Available: https://web.autocad.

- System Modeling & Visualization.” Accessed: Jul. 08, 2024. [Online]. Available: https://etap.

- S. Enache, A. Campeanu, I. Vlad, and M. A. Enache, “Optimization of Design of Very High Power Transformers in Power System,” in 12th International Symposium on Advanced Topics in Electrical Engineering, ATEE 2021, IEEE, 2021, pp. 1–6. [CrossRef]

| Cell type | P type Mono-crystalline |

| No. of cells | 132 |

| Dimensions | 2384×1303×35mm |

| Weight | 38.5 kg |

| Front Glass | 2.0mm, AR coating semi-tempered glass, low iron |

| Frame | Anodized Aluminium Alloy |

| Jonction Box | IP68, 3 diodes |

| Output Cables | 4.0mm2, 250mm(+)/350mm(-) or Customized Length |

| Module type | SRP-670-BMC-BG | |

| Testing condition | STC | NOCT |

| Maximum Power (Pmax) | 670Wp | 504Wp |

| Maximum Power Voltage (Vmp) | 44.3V | 41.38V |

| Maximum Power Current (Imp) | 19.24A | 15.55A |

| Open-circuit Voltage (Voc) | 37.22V | 34.15V |

| Short-circuit Current (Isc) | 18.01A | 14.76A |

| Module Efficiency STC (%) | 21.57% | |

| Operational temperature | -40℃~+85℃ |

| Maximum system voltage | 1500VDC (IEC) |

| Maximum series fuse rating | 30A |

| Power tolerance | 0~+3% |

| Nominal operating cell temperature (NOCT) | 45±2℃ |

| Refer. Bifacial Factor | 70±10% |

| Temperature coefficient of Isc | 0.05%/℃ |

| Temperature coefficient of Voc | -0.26%/℃ |

| Temperature coefficient of Pmax | -0.34%/℃ |

| Efficiency | |

| Max. Efficiency | ≥99.0% |

| European Efficiency | ≥98.8% |

| Input | |

| Max. Input Voltage | 1,500 V |

| Number of MPP Trackers | 6 |

| Max. Current per MPPT | 65 A |

| Max. Short Circuit Current per MPPT | 115 A |

| Max. PV Inputs per MPPT | 4/5/5/4/5/5 |

| Start Voltage | 550 V |

| MPPT Operating Voltage Range | 500 V ~ 1,500 V |

| Nominal Input Voltage | 1,080 V |

| Output | |

| Nominal AC Active Power | 300,000 W |

| Max. AC Apparent Power | 330,000VA |

| Max. AC Active Power (cosφ=1) | 330,000 W |

| Nominal Output Voltage | 800 V,3W + PE |

| Rated AC Grid Frequency | 50 Hz / 60 Hz |

| Nominal Output Current | 216.6 A |

| Max. Output Current | 238.2 A |

| Adjustable Power Factor Range | 0.8 LG ... 0.8 LD |

| Total Harmonic Distortion | <1% |

| Performance of grid-connected PV: | |

| Power for each panel: | 504 W |

| Power for each invertor: | 330 kW |

| The total power produced by the photovoltaic panels: | 2640 kW |

| Yearly PV energy production: | 3620 MWh |

| Total expenses: | |

| Cost for PV: | 2640000 € |

| Cost for Battery: | 45000 € |

| Cost for DC cable: | 15000 € |

| Cost for PT: | 250000 € |

| Variable Cost: | 150000 € |

| Total Cost: | 3100000 € |

| Investment recovery 2022: The investment will be recovered in 5 years | |

| Taking into account the price for the date of 06.09.2022: | 370 €/MWh |

| For 1.551 GWh injected into the network: | 573870 € |

| Investment recovery 2019: The investment will be recovered in 20 years | |

| Taking into account the price for the 2019: | 100 €/MWh |

| For 1.551 GWh injected into the network: | 155100 € |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).