The structural characteristics of body armors are equally important to their ballistic limit velocity V50. With carefully designed structural layouts, body armors can further improve their penetration resistance while maintaining lightness and comfort. Therefore, this section reasonably varies the number of layers and the interlayer bonding strength of the body armor target plate to study the impact mechanism of these structural characteristics on its ballistic limit velocity V50.

4.2.1. The Impact of the Number of Layers on the V50 of the Body Armor Target Plate

Based on the original body armor target plate model (23 layers, total thickness 4.124 mm), several other finite element models of body armor target plates with the same thickness but different numbers of layers were established. Finite element simulations were performed on each of these models, and the ballistic limit velocity V

50 results for body armor target plates with the same thickness but different numbers of layers were obtained and listed in

Table 8.

According to the results in

Table 8, when the number of layers is reduced from 23 to 13 or 18, the ballistic limit velocity V

50 does not change. However, when the number of layers is further reduced to 8, the ballistic limit velocity V

50 significantly increases from 555 m·s

-1 to 605 m·s

-1, with an increase of 9.01%. On the other hand, when the number of layers is increased from 23 to 28, the ballistic limit velocity V

50 decreases from 555 m·s

-1 to 545 m·s

-1, with a decrease of 1.80%. When the number of layers continues to increase, the ballistic limit velocity V

50 dose no longer changed. This indicates that increasing the number of layers beyond the original number has a very minimal impact on the ballistic limit velocity V

50, while appropriately reducing the number of layers can improve the ballistic limit velocity V

50.

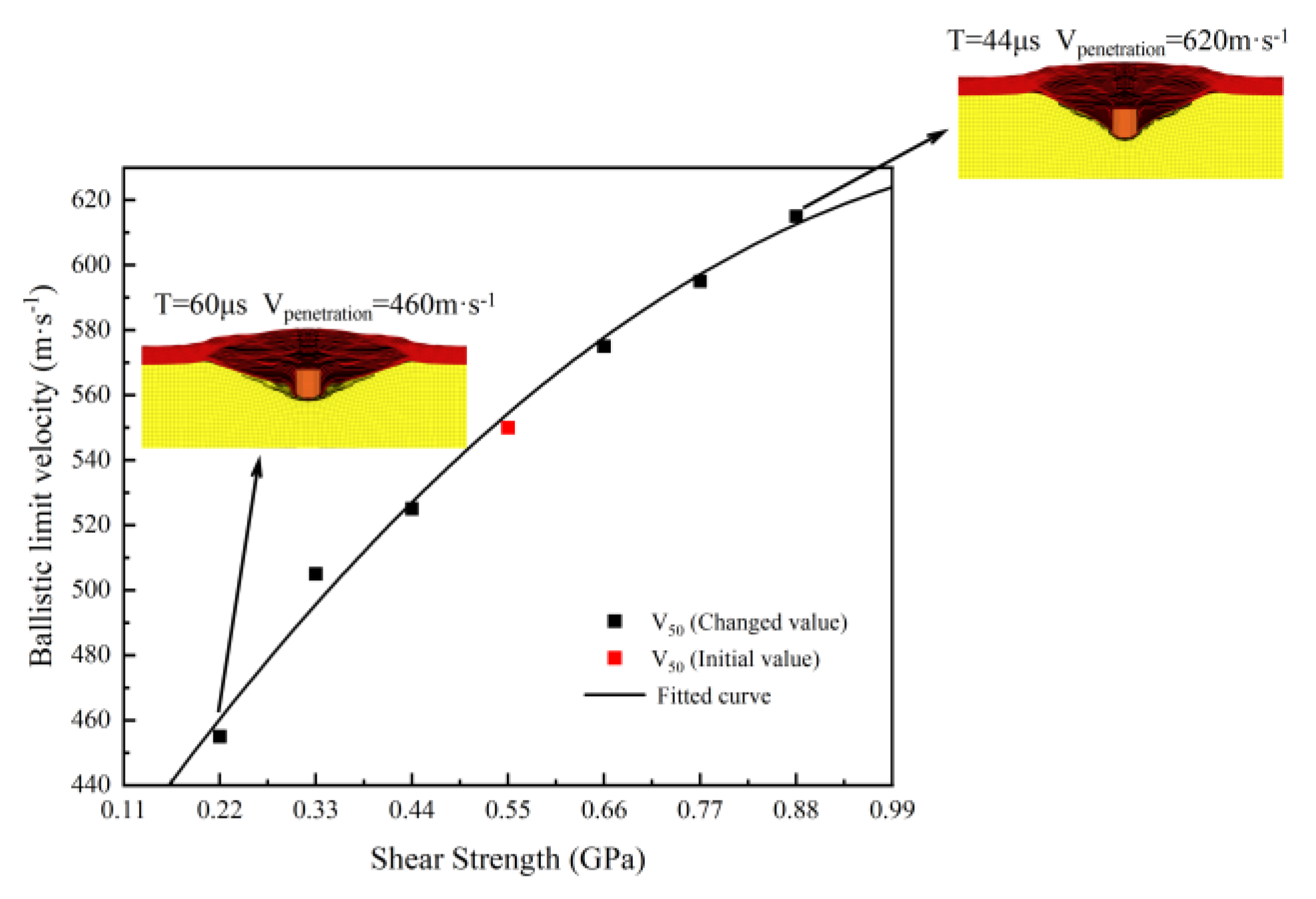

From the trend of the ballistic limit velocity V

50 of the body armor target plates with respect to the number of layers in

Figure 7, it can be seen that when the total thickness of the body armor target plate remains unchanged, the ballistic limit velocity V

50 generally shows a decreasing trend as the number of layers increases. The fitted function curve shows that when the number of layers in the body armor target plate is above 13, the change in ballistic limit velocity is not significant. However, when the number of layers decreases to below 13, the ballistic limit velocity V

50 increases significantly.

By comparing differences in damage patterns between body armor target plates of 8 layers and 38 layers, it can be observed that tensile deformation is not significant in both cases, indicating that shear failure is the dominant failure mechanism in these situations. With the total thickness kept constant, as the number of layers increases, the thickness of each layer decreases correspondingly, leading to a significant reduction in the shear resistance of each layer. This structural weakness allows high-speed fragments to penetrate each layer of the target plate relatively easily. Conversely, when the number of layers in the body armor target plate is significantly reduced, the thickness of each layer increases correspondingly, thereby enhancing the shear resistance of each layer. This enhanced shear performance effectively slows down the velocity of the fragments in the initial penetration stage, reducing their ability to penetrate subsequent layers. Therefore, the ballistic limit velocity V50 of body armor target plates significantly increases when the number of layers is reduced.

In summary, when the total thickness remains constant, a smaller number of layers can improve the shear resistance of the structure, thereby enhancing the overall protective performance of the body armor target plate, leading to an increase in the ballistic limit velocity V

50. This conclusion is slightly different from that of Zhang et al. [

39], possibly because the total thickness of the laminated plates in their study was much greater than the thickness of the body armor target plates provided in this study. When the number of layers increases, the thickness of each target plate layer does not excessively small, so the shear resistance of each layer remains relatively high, leading to different results. Additionally, their study considered the cross-laminated structure of UHMWPE, which might be another reason explaining the difference. Therefore, when the total thickness of the body armor target plate is relatively thin, having too many layers can reduce its penetration resistance.

4.2.2. The Impact of Interlayer Strength on the V50 of the Body Armor Target Plate

The above studies respectively examined the effects of the material properties and the number of layers of body armor target plates on their ballistic limit velocity V

50. When considering the above factors, the bonding between the layers of the body armor target plates was not taken into account, so the contact between each layer of the target plates was set to *CONTACT_AUTOMATIC_SURFACE_TO_SURFACE. This section studies the effect of interlayer strength of body armor target plates on their ballistic limit velocity V

50. Therefore, the contact between each layer of the target plates was changed to *CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_TIEBREAK, which allowed for the failure of the bonded interface between the two contacting surfaces during the contact process. The interlayer failure criterion is shown in equation 10, where NFLS and SFLS represent the interlayer normal strength and the interlayer shear strength, respectively [

40], σ

n and σ

s represent the normal failure stress and shear failure stress of the adhesive layer, respectively. The parameters of normal and interlayer shear strength [

41] are shown in

Table 9. Based on the above interlayer failure strength, the impact of changes in interlayer strength on the ballistic limit velocity V

50 of the body armor target plates was studied.

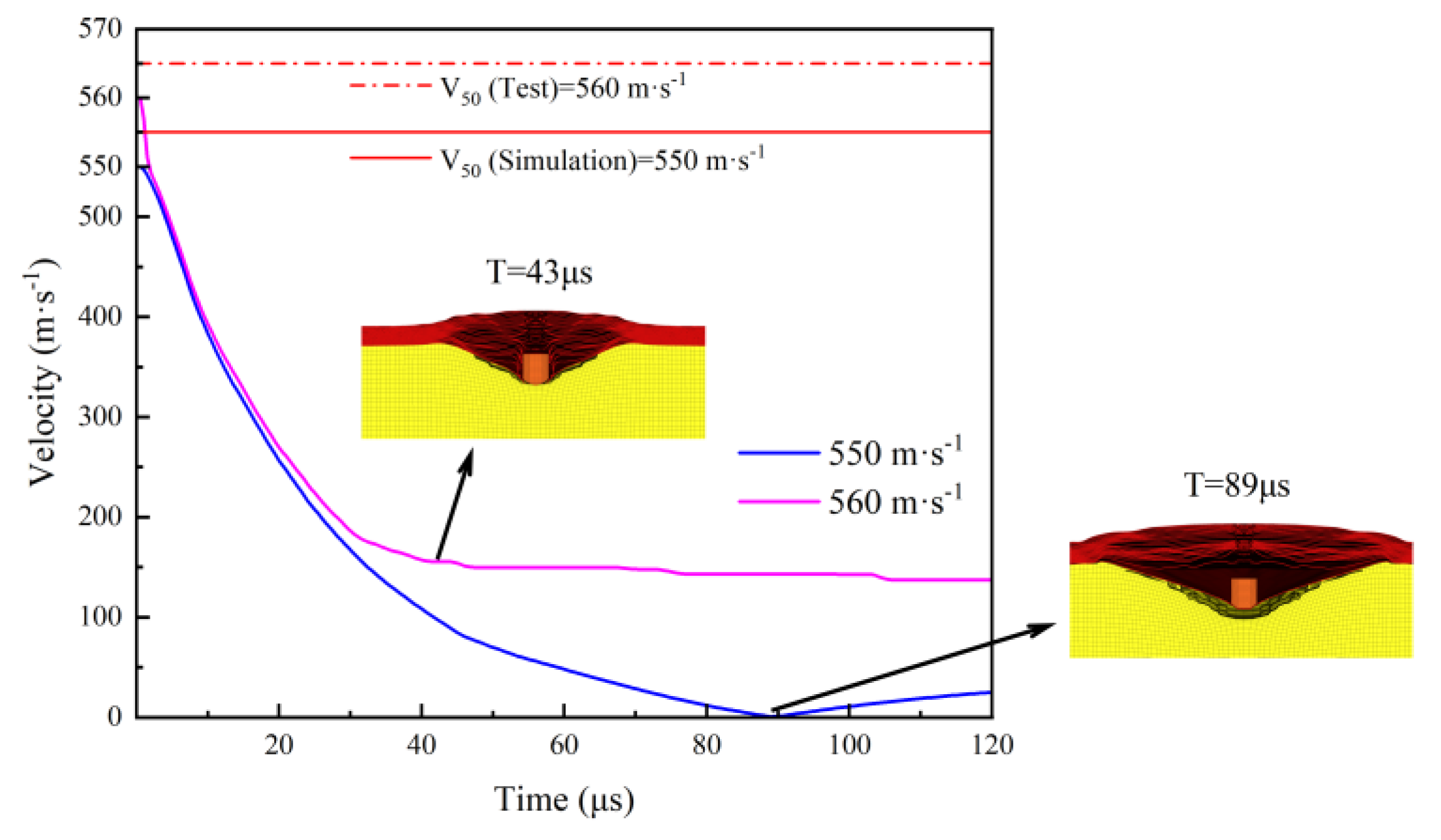

When the interlayer failure strength shown in

Table 9 is added to the body armor target plate in the finite element model, the ballistic limit velocity V

50 of the body armor target plate decreases from 555 m·s

-1 to 525 m·s

-1, a reduction of 5.41%. Additionally, the damage process diagrams of the body armor target plates in both cases (without interlayer bonding and with the interlayer strength shown in

Table 9) are presented in

Figure 8.

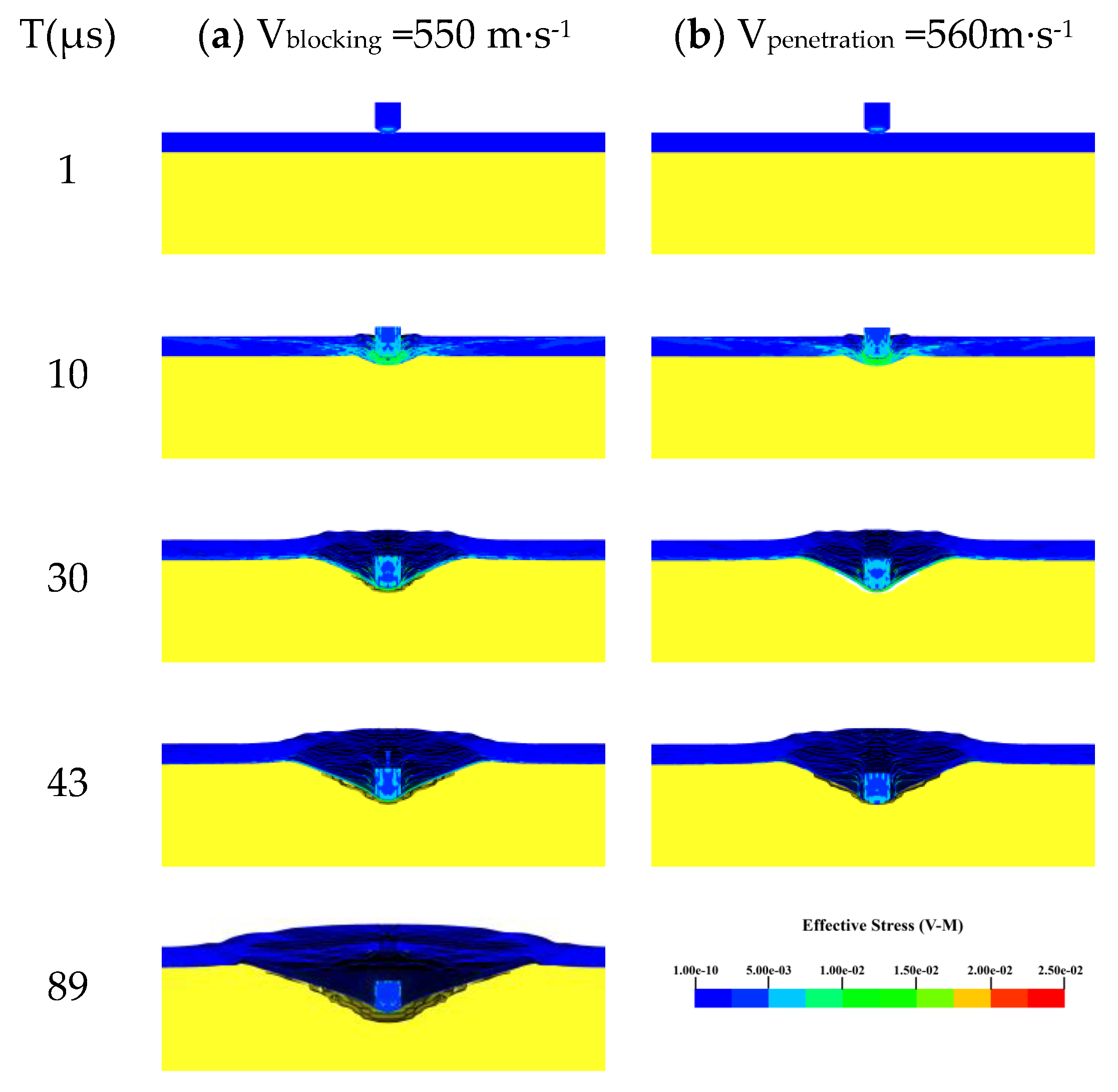

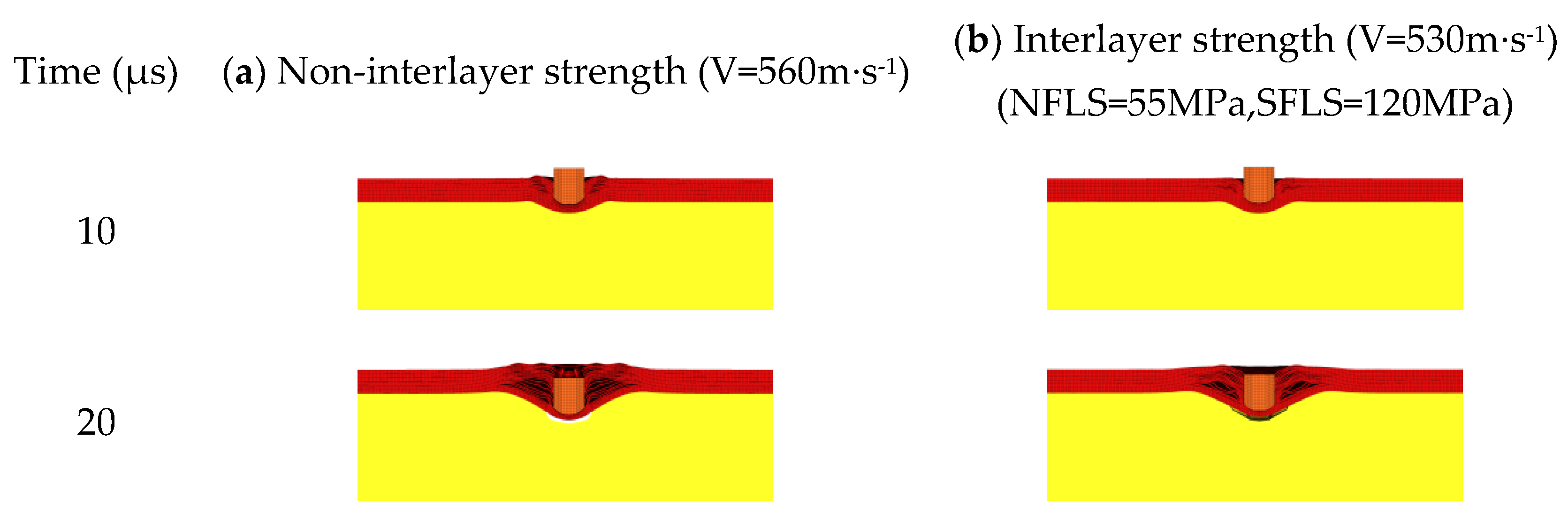

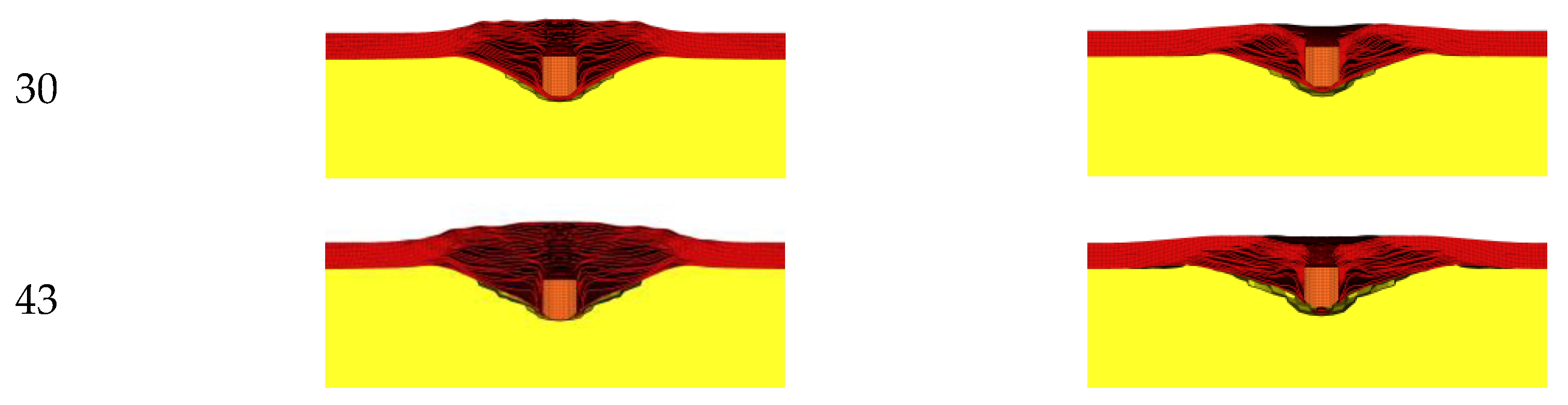

From

Figure 8, the damage process of body armor target plates with and without interlayer strength shows that the presence or absence of interlayer bonding has little effect on the shear failure of the body armor target plates, with both exhibiting similar damage forms within the first 20 μs. When the fragments continue to penetrate and reach 30 μs, delamination of the body armor target plates begins to occur. At this point, the body armor target plates without interlayer bonding exhibit more pronounced delamination and slightly greater back deformation compared to the body armor target plates with interlayer strength (NFLS = 55 MPa, SFLS = 120 MPa). At 43 μs, both types of plates are penetrated, with the delamination and back deformation of the non-bonded body armor target plates being significantly greater than those with the interlayer strength (NFLS = 55 MPa, SFLS = 120 MPa). In the later stages of fragment penetration, the non-bonded body armor target plates exhibit more significant delamination and greater tensile deformation. Therefore, the ballistic limit velocity V

50 of the non-bonded body armor target plates is higher than that of the body armor target plates with the above interlayer strength (NFLS = 55 MPa, SFLS = 120 MPa).

Based on the above results, interlayer strength has a certain impact on the ballistic limit velocity V

50 of body armor target plates. Therefore, based on the interlayer strengths listed in

Table 9, the interlayer normal strength and interlayer shear strength are proportionally varied to explore the impact of interlayer strength changes on the ballistic limit velocity V

50 of body armor target plates.

First, the interlayer normal strength is proportionally varied while keeping the interlayer shear strength constant, and the results obtained from numerical simulations are listed in

Table 10.

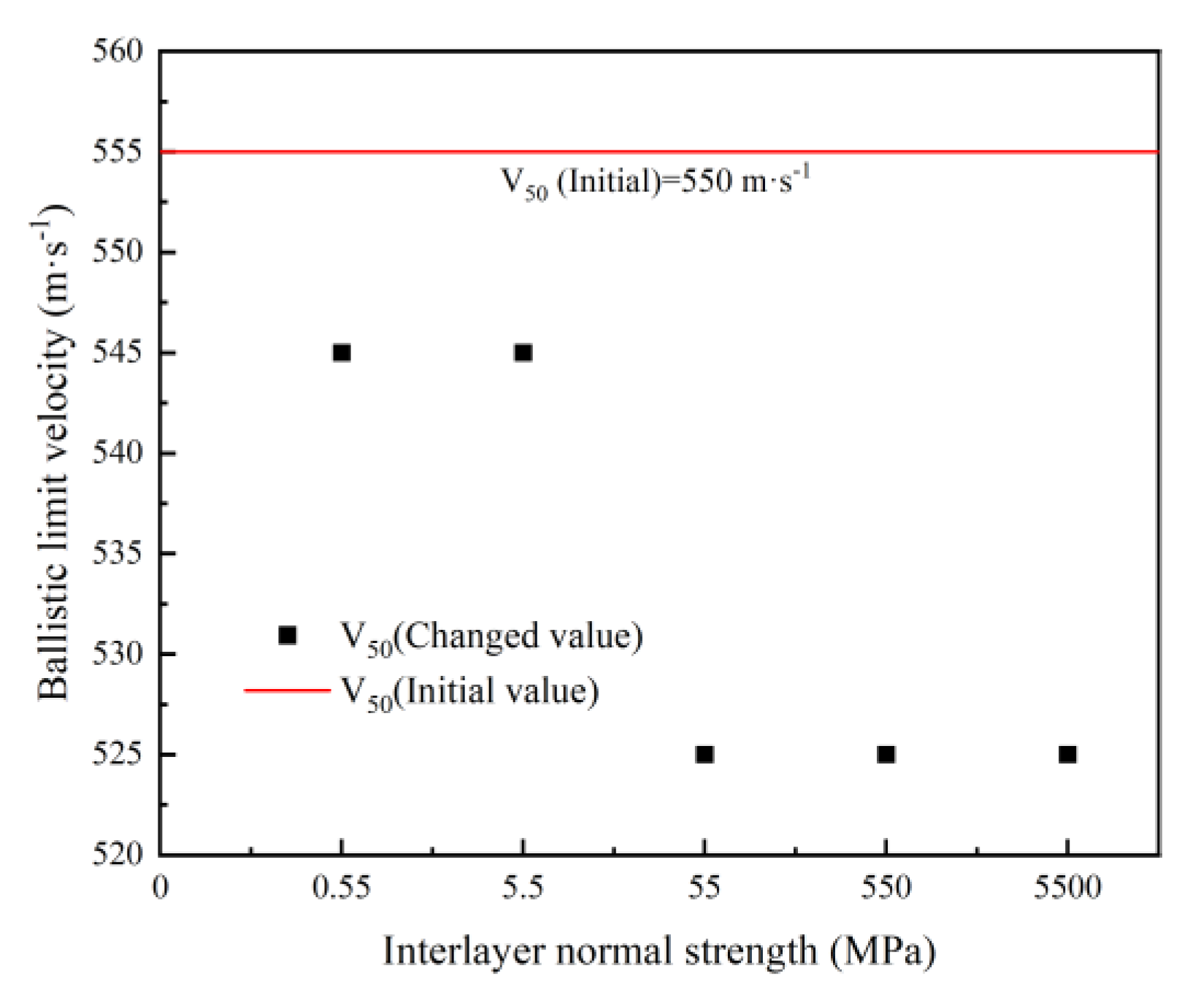

From

Table 10, it can be seen that when the interlayer normal strength of the body armor target plate is 0.55 MPa and the interlayer shear strength is 120 MPa, the ballistic limit velocity V

50 of the body armor target plate decreases from 555 m·s

-1 to 545 m·s

-1, a reduction of 1.80%. When the interlayer normal strength is 5500 MPa and the interlayer shear strength is 120 MPa, the ballistic limit velocity V

50 decreases from 555 m·s

-1 to 525 m·s

-1, a reduction of 5.41%.

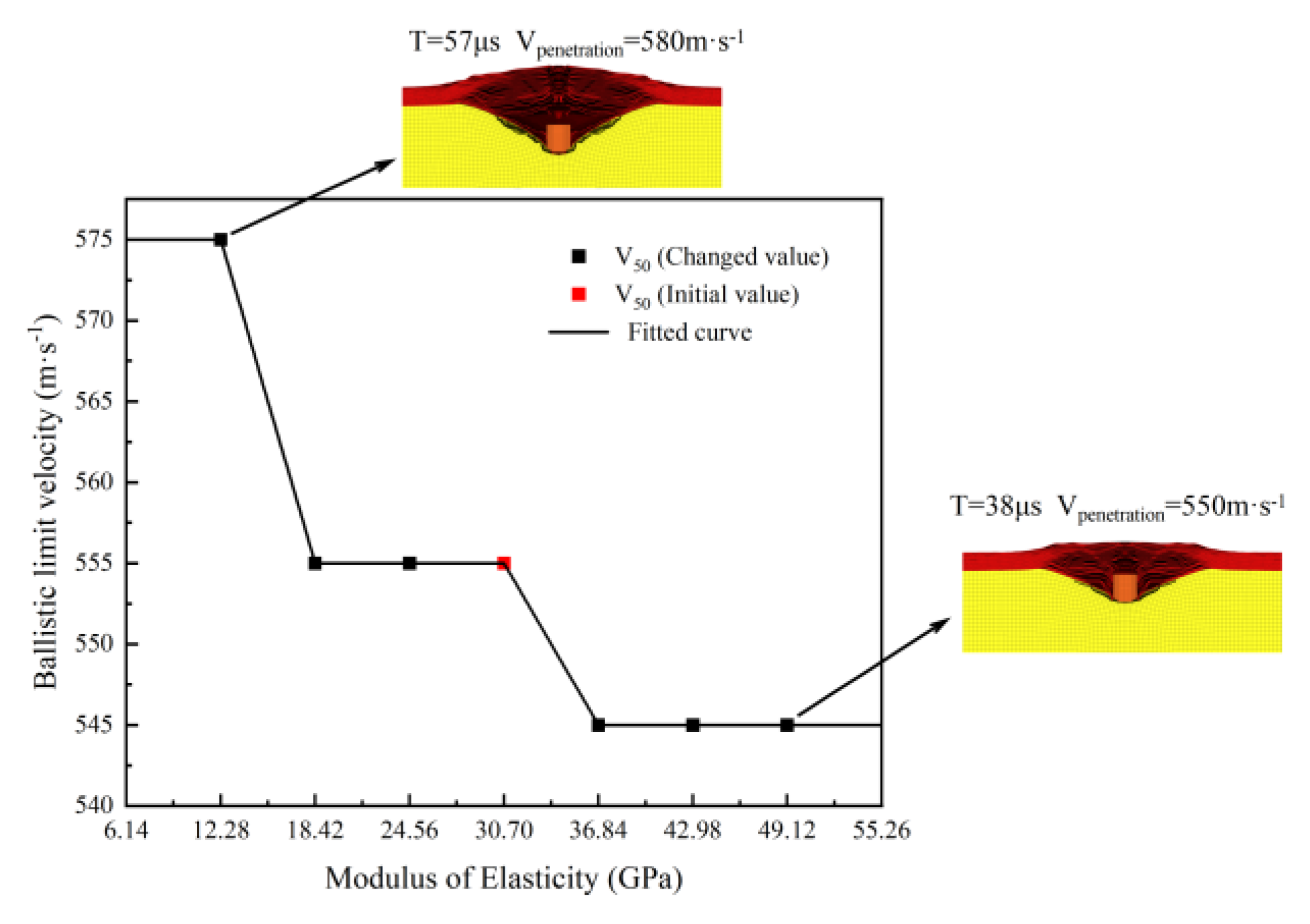

From

Figure 9, it can be observed that the ballistic limit velocity V

50 of the body armor target plate decreases gradually with the increase in interlayer normal strength. Moreover, the ballistic limit velocity V

50 of all body armor target plates with the interlayer strength values listed in

Table 10 is lower than that of the body armor target plates without interlayer bonding.

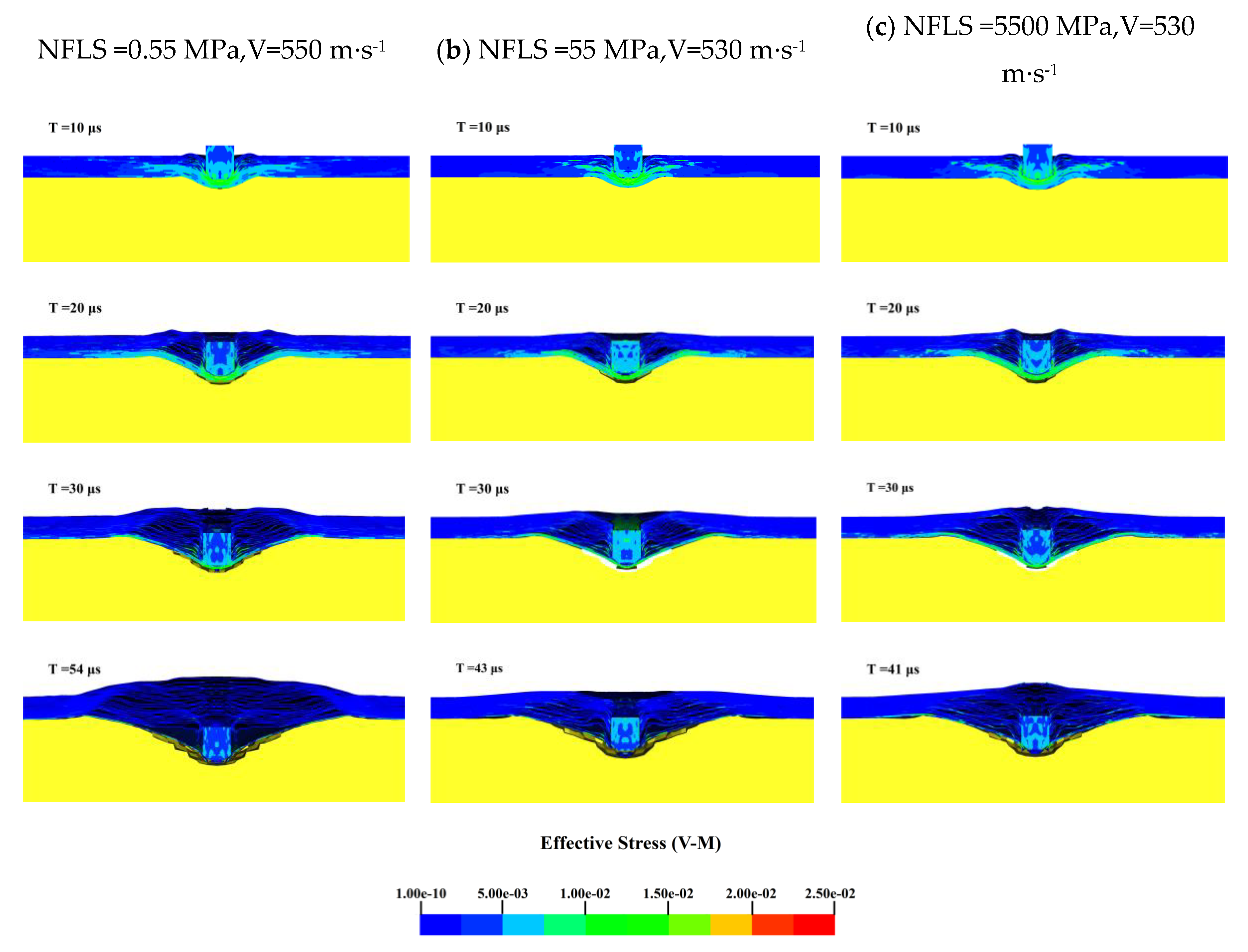

To further determine the effect of the interlayer normal strength on the ballistic limit velocity V

50 of the body armor target plate, the Von-Mises stress cloud diagrams for NFLS values of 0.55, 55, and 5500 MPa when SFLS is 120 MPa are shown in

Figure 10. The penetration process is analyzed accordingly.

From the Von-Mises stress cloud diagrams in

Figure 10 for NFLS values of 0.55, 55, and 5500 MPa, it can be seen that during the initial 20 μs, the failure modes of the body armor target plates for the three interlayer strengths are essentially the same, all exhibiting shear failure with similar stress levels. When penetration continues up to 30 μs, the delamination and back deformation of the target plates differ due to the varying interlayer normal strengths. At an NFLS of 0.55 MPa, the delamination and back deformation of the body armor target plate are significantly greater than at NFLS values of 55 MPa and 5500 MPa. For NFLS values of 55 MPa and 5500 MPa, the failure modes of the body armor target plates are the same at large. Thus, it can be concluded that once the interlayer normal strength of the body armor target plate increases beyond a certain range, further increases in interlayer normal strength have a minimal impact on the ballistic limit velocity V

50.

After analyzing the effect of interlayer normal strength on the ballistic limit velocity V

50 of the body armor target plate, the focus shifts to studying the effect of interlayer shear strength on the ballistic limit velocity V

50 of the body armor target plate. By keeping the interlayer normal strength constant (NFLS = 55 MPa) and proportionally varying the interlayer shear strength, the influence of changes in interlayer shear strength on the ballistic limit velocity V

50 of the body armor target plate is studied. The obtained results are presented in

Table 11.

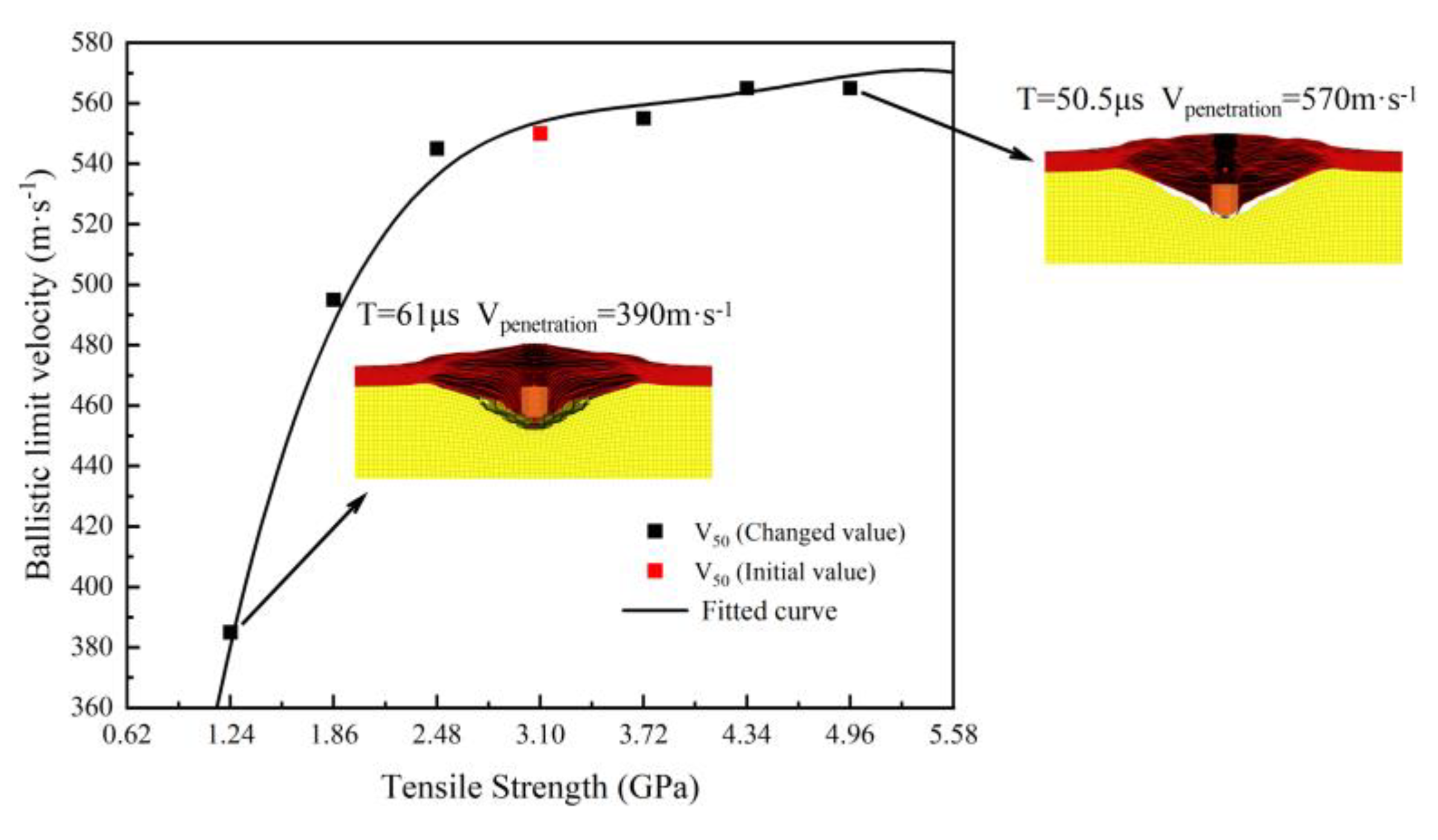

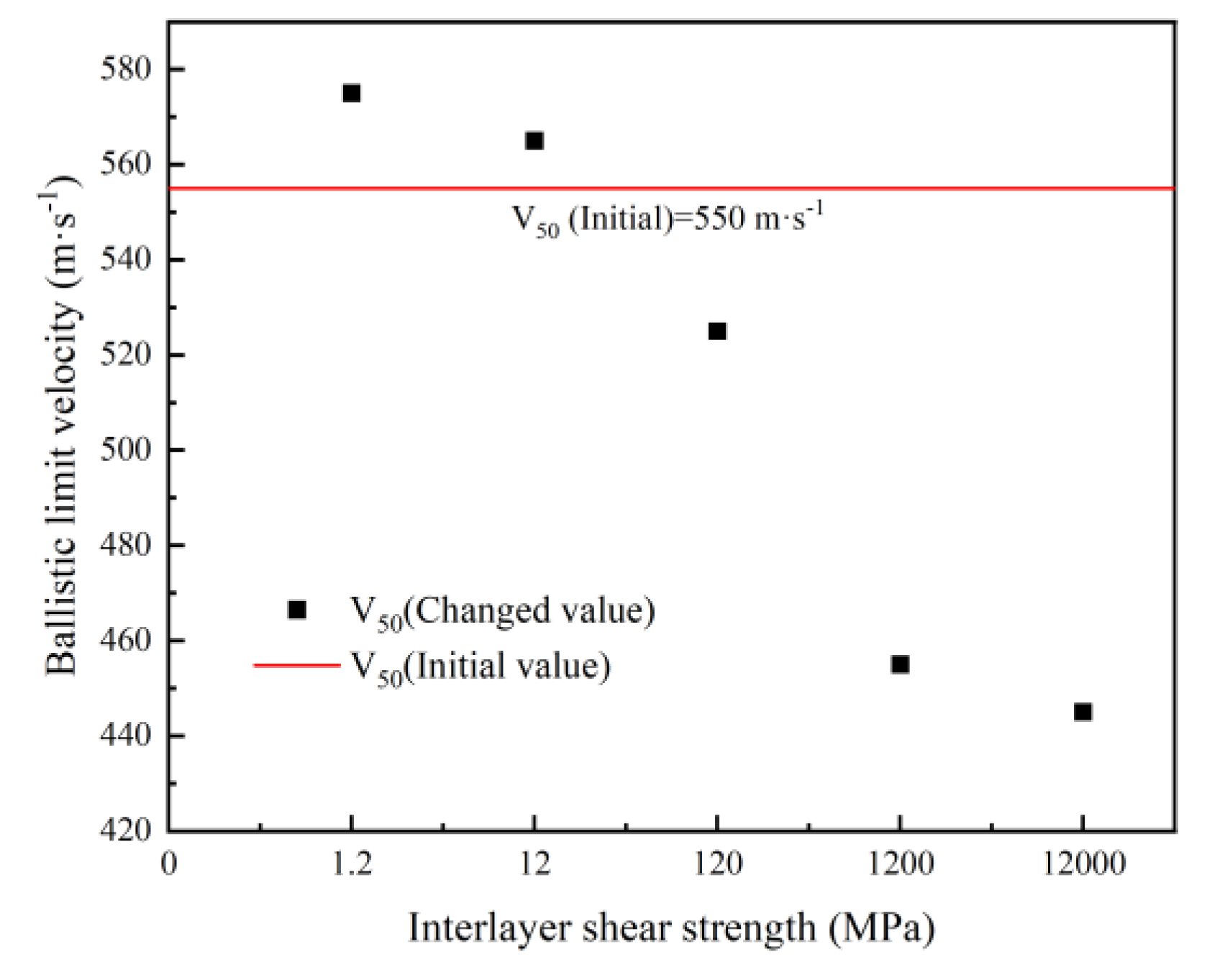

From

Table 11, when the interlayer shear strength is 1.2 MPa and the interlayer normal strength is 55 MPa, the ballistic limit velocity V

50 of the body armor target plate increases from 555 m·s

-1 to 575 m·s

-1, with an increase of 3.60%. Conversely, when the interlayer shear strength is 12,000 MPa and the interlayer normal strength is 55 MPa, the ballistic limit velocity V

50 decreases from 555 m·s

-1 to 445 m·s

-1, with a decrease of 19.82%.

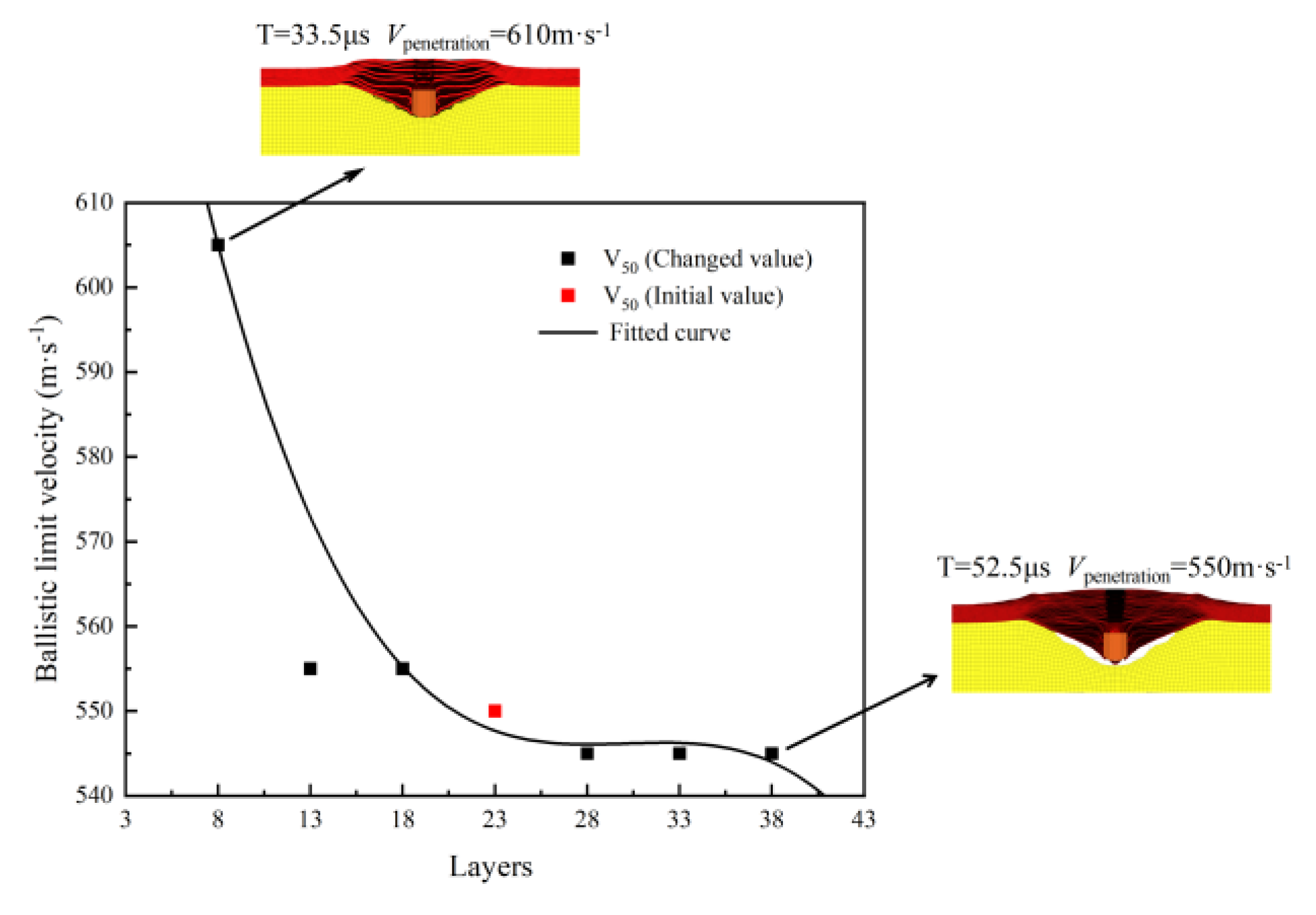

From the trend in

Figure 11 showing the ballistic limit velocity with changes in interlayer shear strength, when the interlayer shear strength of the body armor target plate is 1.2 or 12 MPa, its ballistic limit velocity V

50 is greater than that of the target plate without interlayer bonding. However, as the interlayer shear strength continues to increase, the ballistic limit velocity V

50 becomes lower than that of the target plate without interlayer bonding. Additionally, the ballistic limit velocity V

50 of the body armor target plate tends to decrease with increasing interlayer shear strength.

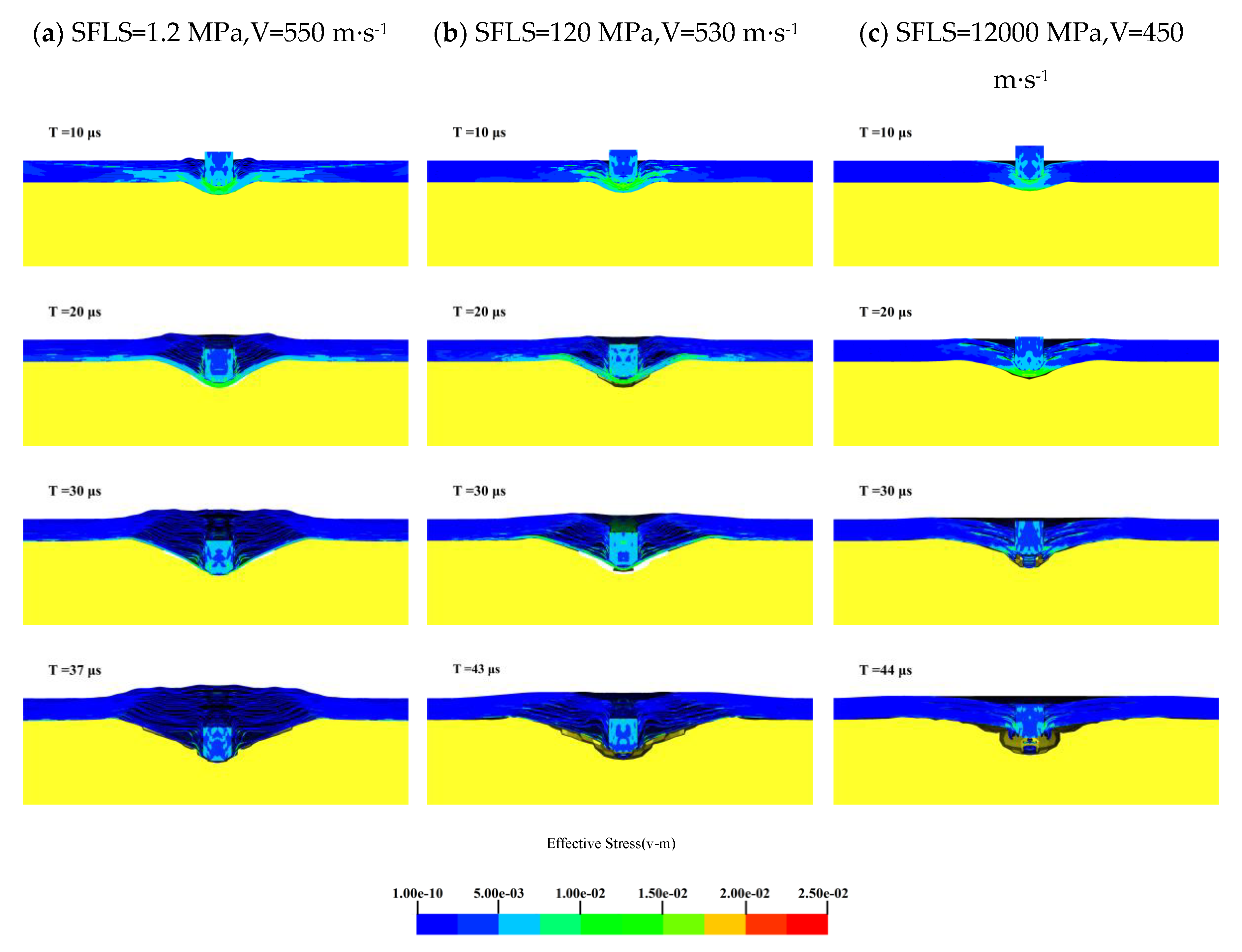

To further determine the effect of interlayer shear strength on the ballistic limit velocity V

50 of the body armor target plate, the Von-Mises stress cloud diagrams for SFLS values of 1.2, 120, and 12,000 MPa when NFLS is 55 MPa are shown in

Figure 12. The penetration process is analyzed accordingly.

From the Von-Mises stress cloud diagrams in

Figure 12 for SFLS values of 1.2, 120, and 12,000 MPa, as the interlayer shear strength of the body armor target plate increases, delamination and tensile deformation significantly decrease. At an SFLS of 1.2 MPa, the body armor target plate primarily experiences shear failure in the first 20 μs, significant tensile deformation at 30 μs, and penetration by 37 μs. When SFLS is 120 MPa, the failure mode of the body armor target plate is essentially the same as at 1.2 MPa, but both delamination and tensile deformation are less than at 1.2 MPa. At an SFLS of 12,000 MPa, the failure mode of the body armor target plate is completely different from the previous two; the plate mainly undergoes shear failure and shear plugging with almost no interlayer delamination or tensile deformation. At this point, the failure mode of the body armor target plate is like that of a single-layer plate of the same thickness.

In summary, the interlayer strength of the body armor target plate has a significant impact on its ballistic performance, with the effect of interlayer shear strength being much greater than that of interlayer normal strength. When the body armor target plate has appropriate interlayer strength, the delamination between the layers can also dissipate part of the projectile’s kinetic energy, making it more difficult to penetrate the target plate. However, if the interlayer strength is too high, the body armor target plate behaves like a single-layer plate of the same thickness, and its failure mode is entirely different from that of a multi-layered structure. In this case, the primary causes of failure are shear failure and shear plugging, with almost no delamination or tensile deformation occurring [

42]. Therefore, determining the appropriate interlayer strength between the layers of the body armor target plate is crucial for enhancing its ballistic performance.