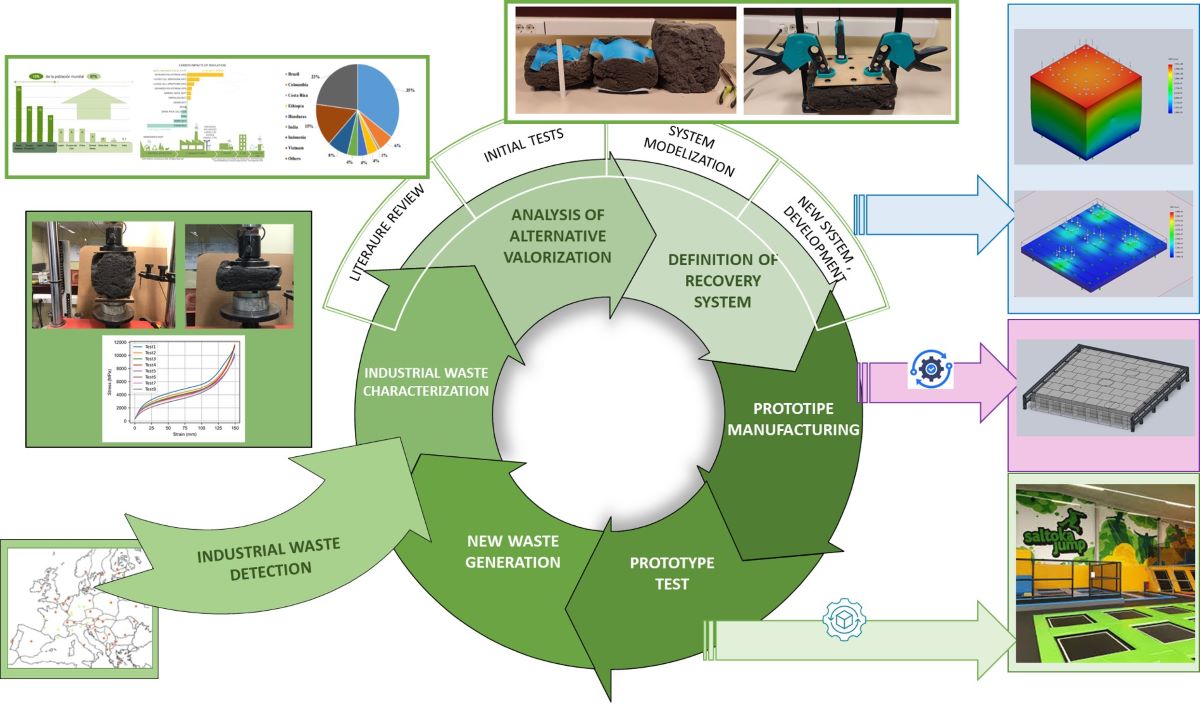

1. Introduction

The general objective of the research is to develop a technological application for the use of exhausted foam materials or textile elements generated in leisure facilities to convert them into impact absorption systems enabling the reuse of contaminating elements such as textiles and foam in leisure-related applications, where protection against impact and energy absorption when it occurs is key to ensure the safety of the facilities.

The increase in textile consumption and the trend towards fast fashion among consumers have led to a rapid global increase of textile waste in the municipal solid waste (MSW) stream. Worldwide, 75% of textile waste is landfilled, while only 25% is recycled or reused [

1]. With respect to waste management, the most common current opinion is to prioritize the reuse of products over the recycling of materials, with landfill disposal being the least desirable option. In the case of textiles and products made of similar materials such as foam, all these alternatives are feasible; however, there is currently a lack of effective techniques for recycling materials [

2]. The reuse of these products in their original form is a common practice in domestic waste management [

3], but currently, if we analyze the problem from an industrial point of view, we still do not have the capacity to do so.

Industrial textile waste is considered “dirty waste” generated from commercial and industrial textile applications.

The expansion of the textile and leisure industry has led to a rapid global increase in textile waste. Many techniques to recycle textile materials are being developed due to the increasing consumption of these materials [

4,

5,

6,

7,

8]. .However, several studies have shown the importance of reusing products based on these materials since, for every kg reused or recycled, textiles save more greenhouse gases than paper, plastic and glass combined [

9]

It is therefore necessary to generate knowledge about the reuse of these materials without the need to recycle or destroy them, thus contributing to a dramatic reduction in the environmental impact of these products.. This development will allow the reuse of waste generated in the recreational facilities and thus reduce the overall environmental impact by taking advantage of the materials and their technical characteristics and the specific environmental impact of materials such as polyurethanes or textile products.

The study is based on the properties of the Polyurethane foam, PU foam, as well as the different ways of simulation by a computer, running a finite element program in order to adjust the curve tension-strain obtained through the tests applied on the material so that using formulas of the energy of deformation it could be possible to have a material model for using it in order to simulate and obtain better designs.

Foam is a set of technical foams used for different applications related to sports, industry in sectors such as automotive, railway, aeronautics, naval, logistics, health, electronics, technical footwear, renewable industries or food industry, packaging and construction. In view of all these applications, the apparent possibility of reusing foam from leisure facilities (mainly in swimming pools such as the one in the photograph) for any other application seems simple.

The problem is due to the fact that the foam is used in contact with people and the deterioration of the material makes it necessary to periodically change the material to prevent it from appearing damaged and even unhealthy.

Foam is a porous material made from plastic that is formed by an aggregation of bubbles. It is therefore a very light and shock-absorbing material that can be reused, suitably treated or presented.

The need for shock protection elements in leisure systems and the real need to make use of materials has created an opportunity to develop new elements for impact absorption systems. At present, the elements for impact protection are standard elements manufactured industrially from raw material, which in the case of plastic elements means production from fossil raw materials.

The development of a technical solution for the use of foam and textiles out of use generated in leisure centers will provide a new way for the recycling of materials of complicated process. The manufacturing companies that use foam by introducing air into the chemical compositions generate waste in the machining of the materials due to their own production process, and there are hardly any solutions for the recyclability of the waste generated. This problem increases in companies using foam elements, which in the case of waste generation due to loss of functionality or for other reasons, the only alternative is disposal in a landfill.

1. Objective of the Study

The primary objective of this study is to develop a technological application for repurposing spent foam materials and textile elements from leisure facilities into impact absorption systems. This development aims to facilitate the reuse of waste generated within these facilities, thereby reducing global environmental impact by utilizing the materials' inherent technical characteristics and addressing the specific environmental impact of materials such as polyurethanes and textiles.

To achieve this primary objective, the study will be developed in several phases. First, a knowledge base will be established to understand the impact absorption capacity of foam after its lifecycle in leisure systems. This phase will explore its potential reintegration into impact absorption elements, either as part of broken resistant elements or new protections. Subsequently, the behavior of waste textiles in impact absorption will be analyzed to determine their combined use with foam for developing new anti-impact systems.

Further phases will focus on enabling the reuse of contaminating elements such as textiles and foam in leisure-related applications, ensuring impact protection and energy absorption to guarantee the safety of the facilities. The study will also promote the use of well-maintained protections to minimize impact on individuals in the event of a collision, determining safe conditions for protections and developing rapid adaptation methodologies based on these anti-impact materials. Finally, technical solutions will be developed to create alternative impact safety elements through the recycling of materials like foam and textiles, guided by technical and scientific criteria to ensure effectiveness and sustainability.

2. Materials and Methods

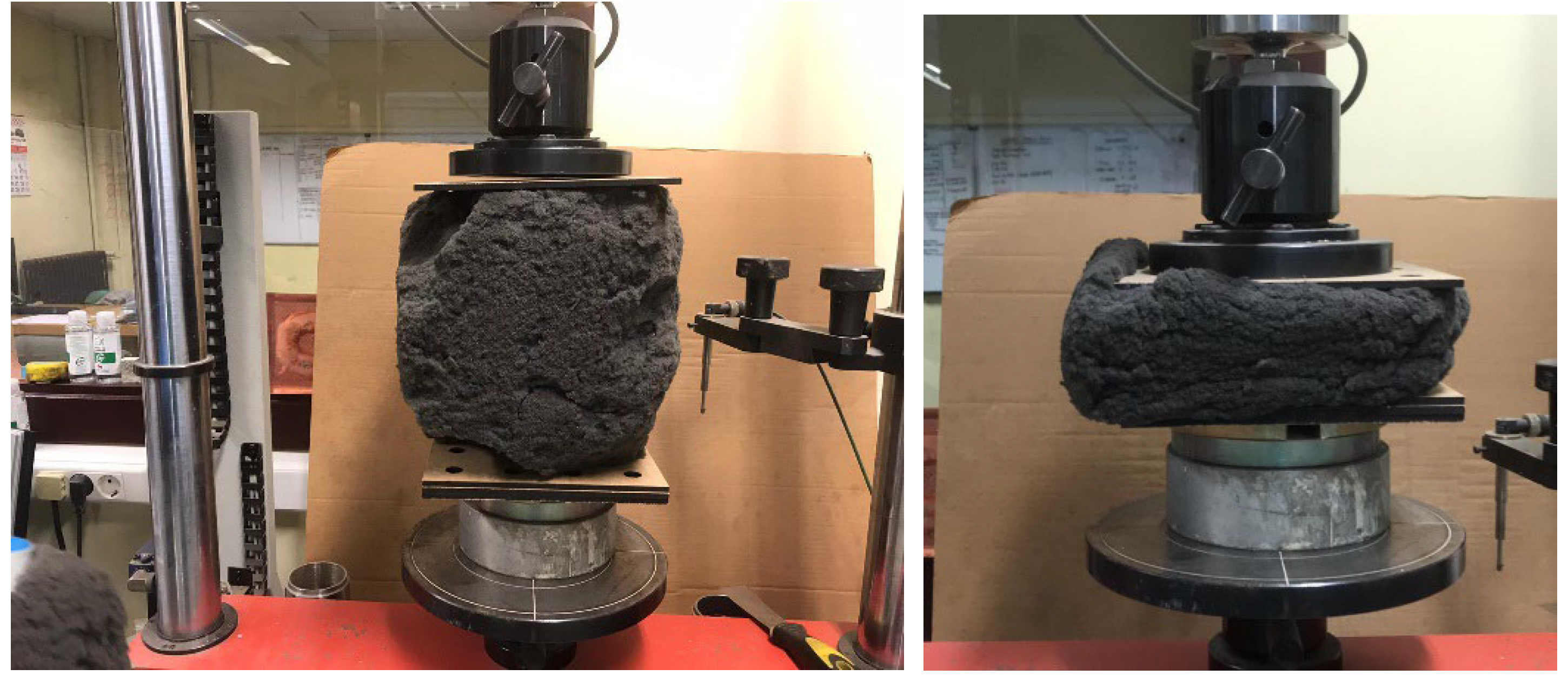

Five different specimens of foam were tested using as a reference the Uniaxial compression test: DIN 53577 to know the deformation as a function of the applied stress, observing that the process. The DIN 53577 test is a type of CLD (Compression Load Deflection) test. It is a test widely used throughout Europe by foam manufacturers.

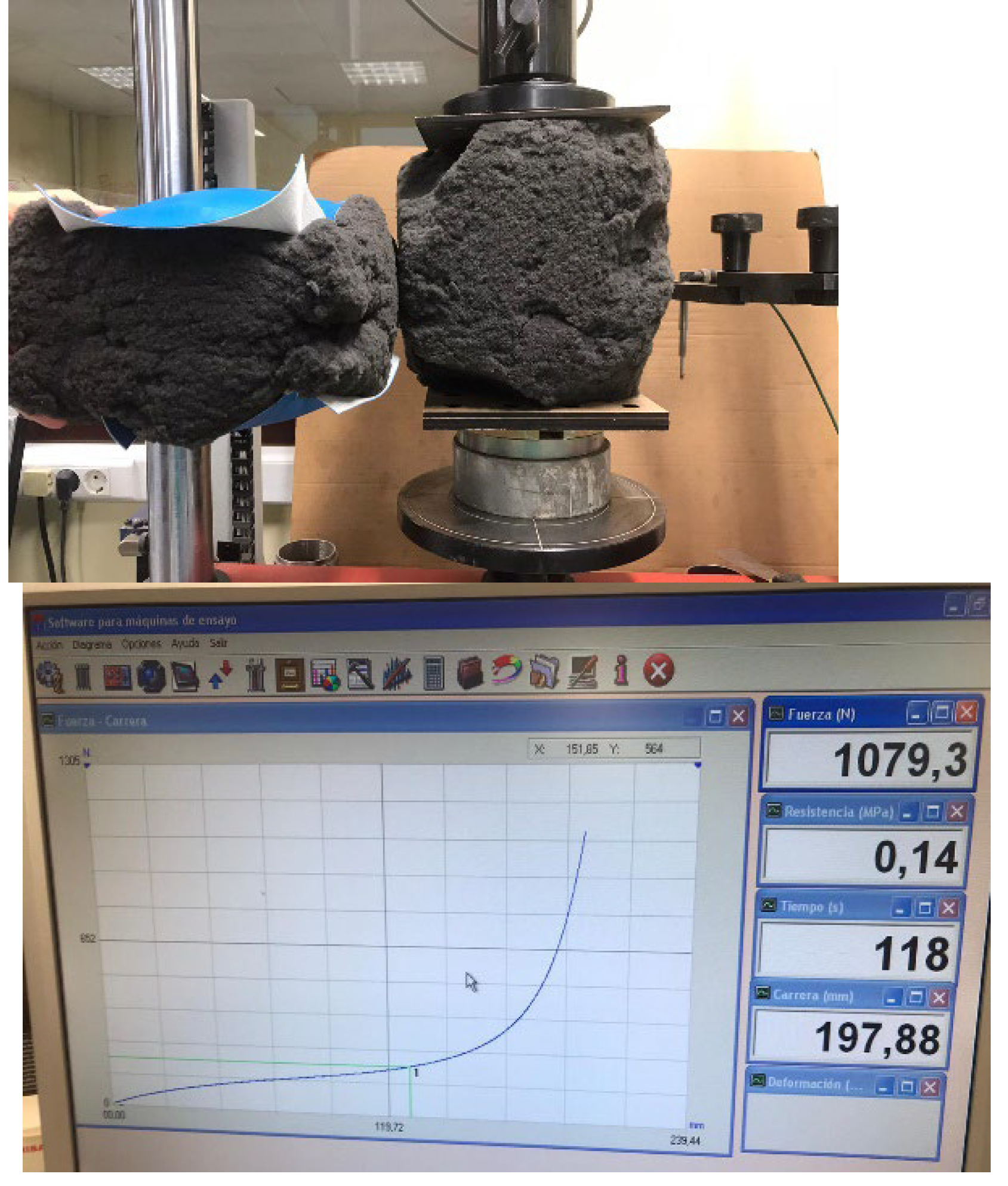

Although It uses a foam specimen of dimensions 100 x 100 x 50 mm, The Specimens tested dimensions were of 200mmx200mmx200mm as it could be seen on

Figure 1

Figure 2 provides a clear and concise description of the content depicted in the figure, emphasizing the test and the tools used for data acquisition.

The test proceeds first to measure the thickness dimensions of the foam sample (pre-loaded). It is then compressed to a deformation of 25% at a defined rate. Then it does the same with a deformation of 40%. Finally, it is compressed to 60% of its original thickness shape and the force required to do this is measured and recorded.

This test involves applying a compressive force to the specimen and measuring the deformation of the material. Each specimen was tested 8 times using the same compressive test in order to know the coefficient variation

Based on the data obtained in the laboratory and in the joint tests carried out, the behavior of the material has been modeled, according to the following calculation results

3. Results

3.1. Characterization of Compressive Behavior in Foam: Analysis and Curve Fitting

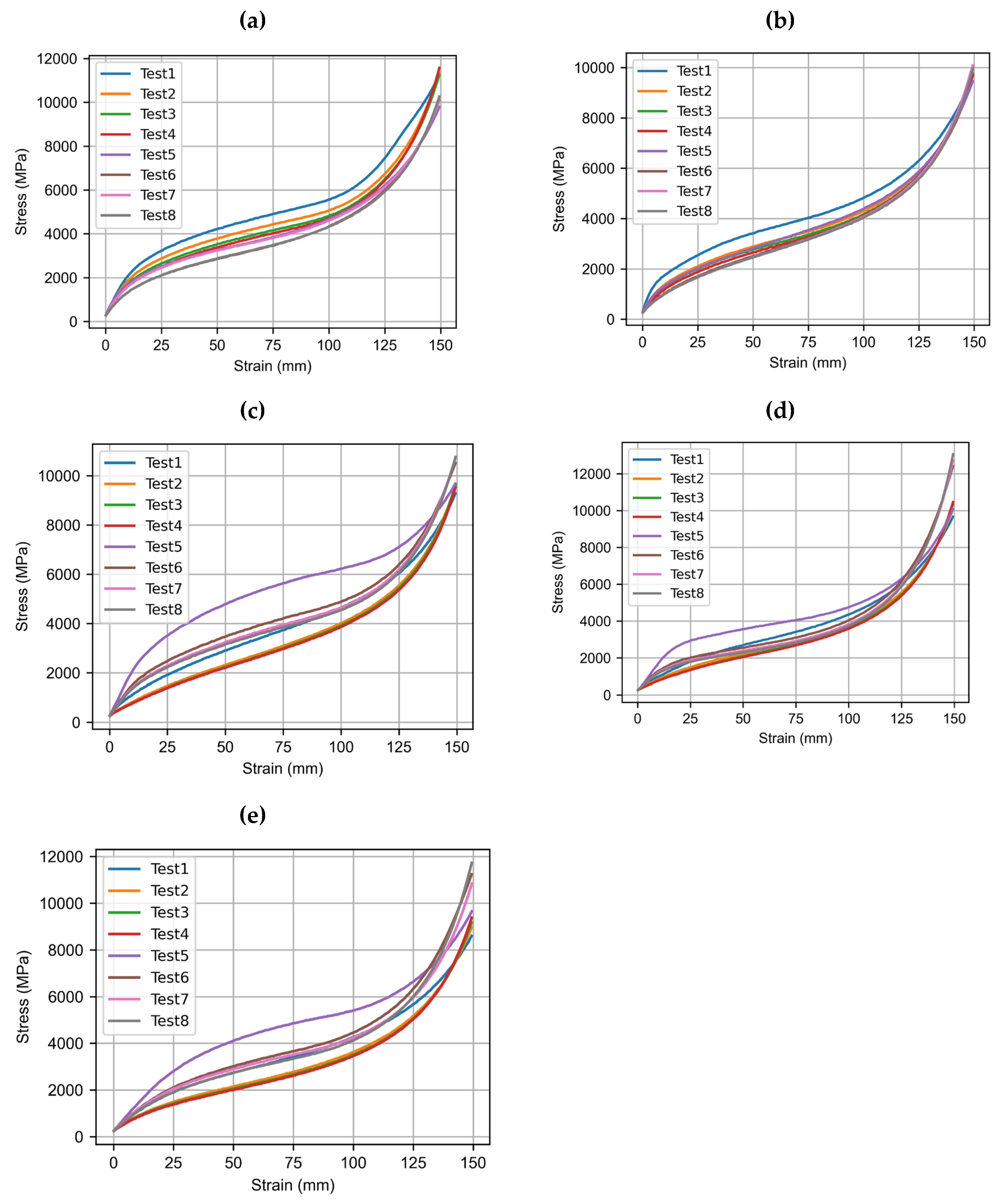

The

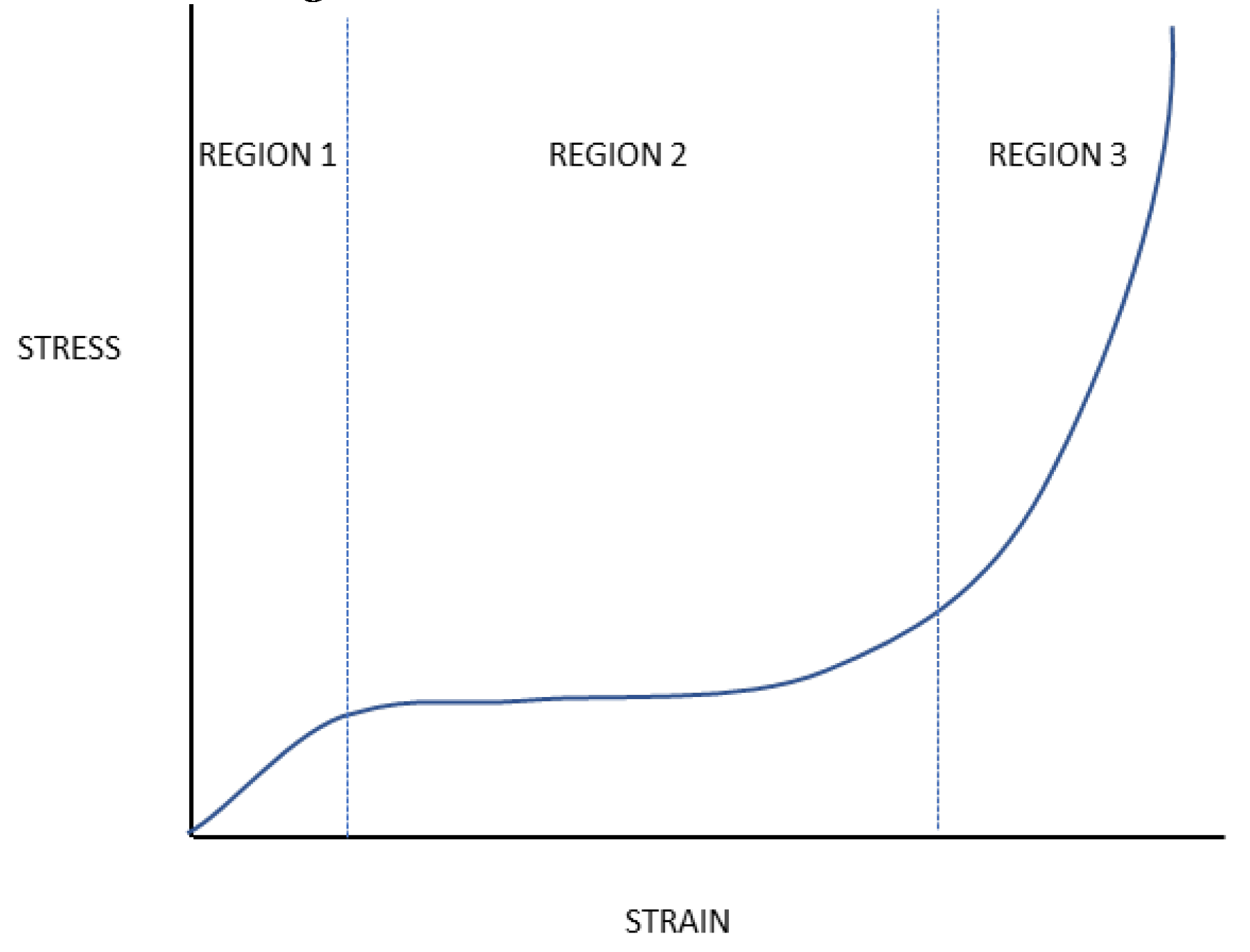

Figure 3 presents the stress-strain curves obtained from uniaxial compression tests conducted on five different foam specimens, each tested 8 times under the same compression conditions. These tests were performed using the DIN 53577 Compression Load Deflection (CLD) methodology, a widely recognized standard in Europe for assessing the compressive behavior of foam materials. Each foam specimen, with dimensions of 200mm x 200mm x 200mm, was subjected to eight repeated compressive tests to evaluate the consistency and reliability of its mechanical properties. The larger specimen size used in these tests, compared to the standard dimensions (100mm x 100mm x 50mm), provides a more comprehensive understanding of the foam's behavior under significant loading conditions. The resulting stress-strain curves illustrate the characteristic deformation behavior of the foam, capturing the initial elastic response, the plateau associated with cell collapse, and the final densification stage.

The stress-strain curves of the foam demonstrate a consistent progression through distinct regions. Initially, all curves exhibit a linear increase in stress with strain, reflecting elastic behavior where the foam deforms proportionally to the applied stress. This initial section, known as the Linear Region, aligns with Region 1 where cell walls bend without collapsing. Following this, a noticeable plateau appears in the curves, marking the Plateau Region. In this middle section, corresponding to Region 2, the foam’s cells begin to collapse, resulting in significant deformation with minimal increase in stress. As strain continues to increase, the curves show a sharp rise in stress during the Densification Region, indicating that the foam is undergoing densification in Region 3. At this stage, the cell walls are fully compressed, leading to a considerable increase in material stiffness.

Across multiple tests, the foam demonstrates good reproducibility, with curves for each specimen closely overlapping. This consistency is crucial for ensuring reliable performance in applications. However, slight deviations are observed in some tests, such as Test 8, particularly within the densification region. These minor variations might be attributed to small differences in foam structure or test conditions. Overall, the foam’s compressive behavior remains consistent across different iterations, reinforcing its reliability.

When comparing specimens, the stress-strain behavior is notably similar across all five samples, indicating uniform material properties. This consistency is essential for practical applications, ensuring reliable performance. Although the point where densification begins varies slightly between specimens, this variation is likely due to differences in foam density or minor manufacturing inconsistencies. The tested specimens, being significantly larger than the standard size specified in DIN 53577 (200mm x 200mm x 200mm), might exhibit different stress distributions. Nonetheless, the overall similarity in behavior suggests that the increased size did not introduce significant variability in the results.

Figure 4.

Stress-strain curves of foam specimens demonstrating the linear, plateau, and densification regions in: (a) specimen 1, (b) specimen 2, (c) specimen 3, (d) specimen 4 and (e) specimen 5.

Figure 4.

Stress-strain curves of foam specimens demonstrating the linear, plateau, and densification regions in: (a) specimen 1, (b) specimen 2, (c) specimen 3, (d) specimen 4 and (e) specimen 5.

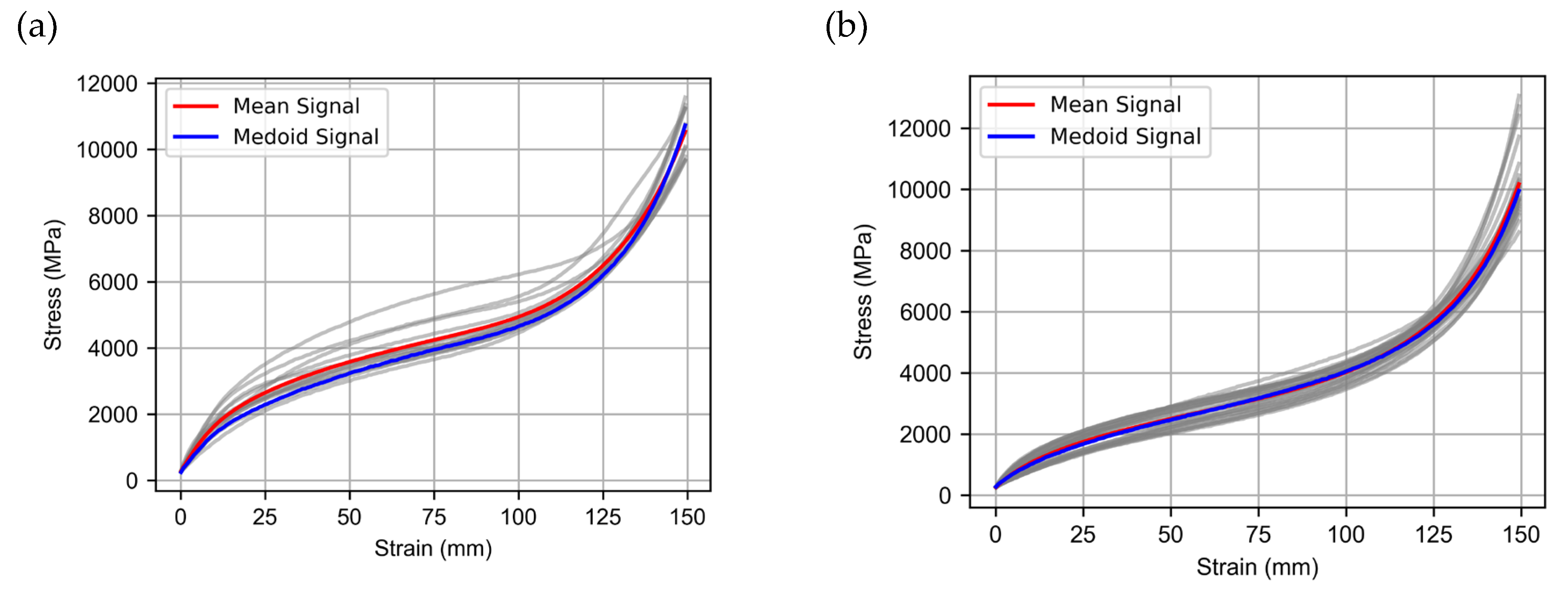

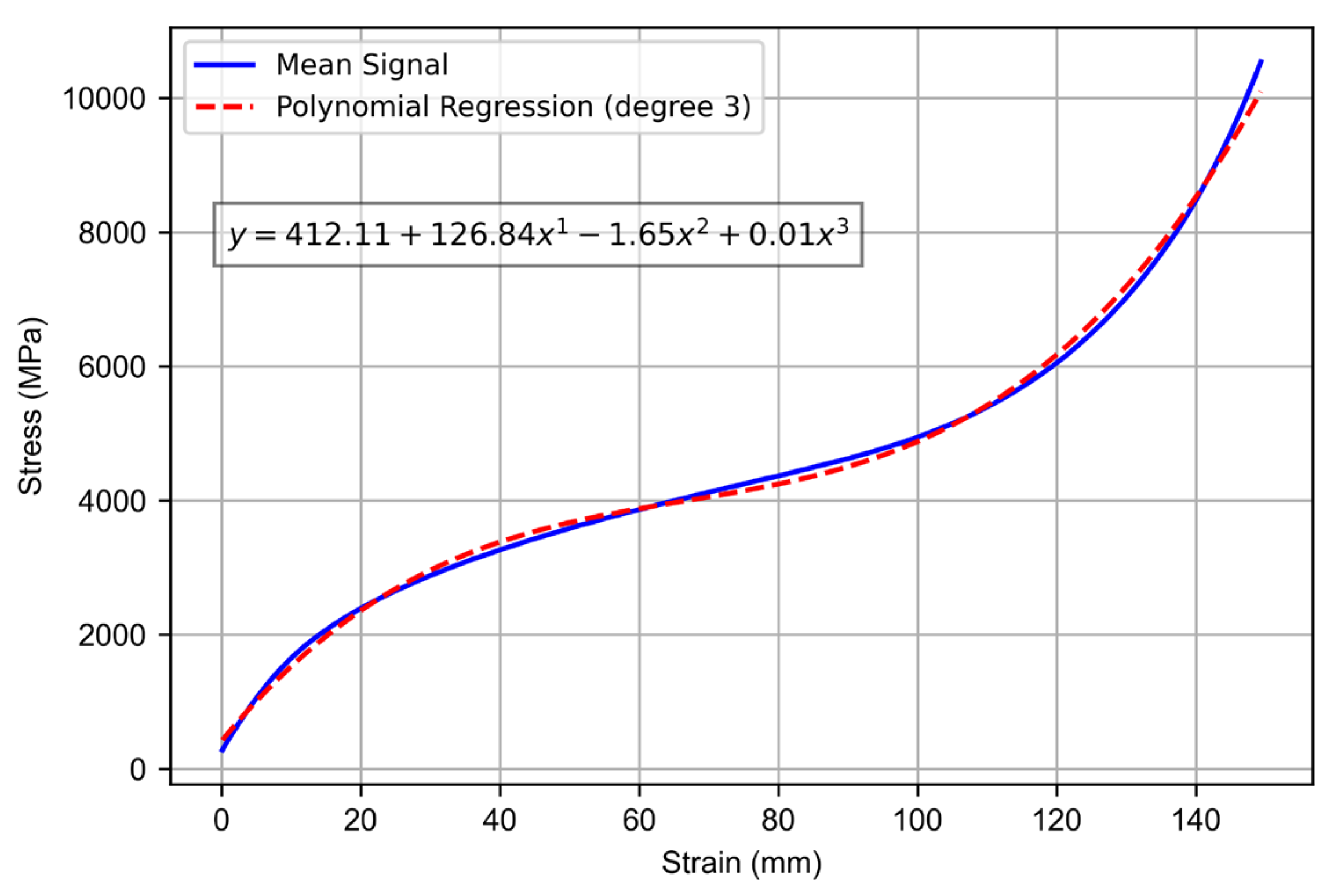

The graphs offer a thorough understanding of the compressive behavior of the foam specimens. The foam exhibits consistent performance across various specimens and test iterations, with clear linear, plateau, and densification regions evident in the stress-strain curves. This high level of reproducibility underscores the foam’s reliable and predictable mechanical properties under compression. Consequently, the foam appears well-suited for applications requiring uniform compressive strength and deformation characteristics. Further analysis could involve calculating precise values for the modulus of elasticity in the linear region, the plateau stress, and the strain at which densification commences, providing more quantitative insights into the material's properties. Ultimately, the goal is to develop an equation for the characteristic curve based on these extensive tests to better describe the foam's behavior.

The curves illustrate consistent performance across different specimens and test iterations, despite some observed hysteresis in the initial iteration of each specimen, where higher stress-strain values were recorded. This indicates that, while the tests are reproducible, the first iteration may slightly deviate, suggesting a need to account for hysteresis when developing the characteristic curve equation.

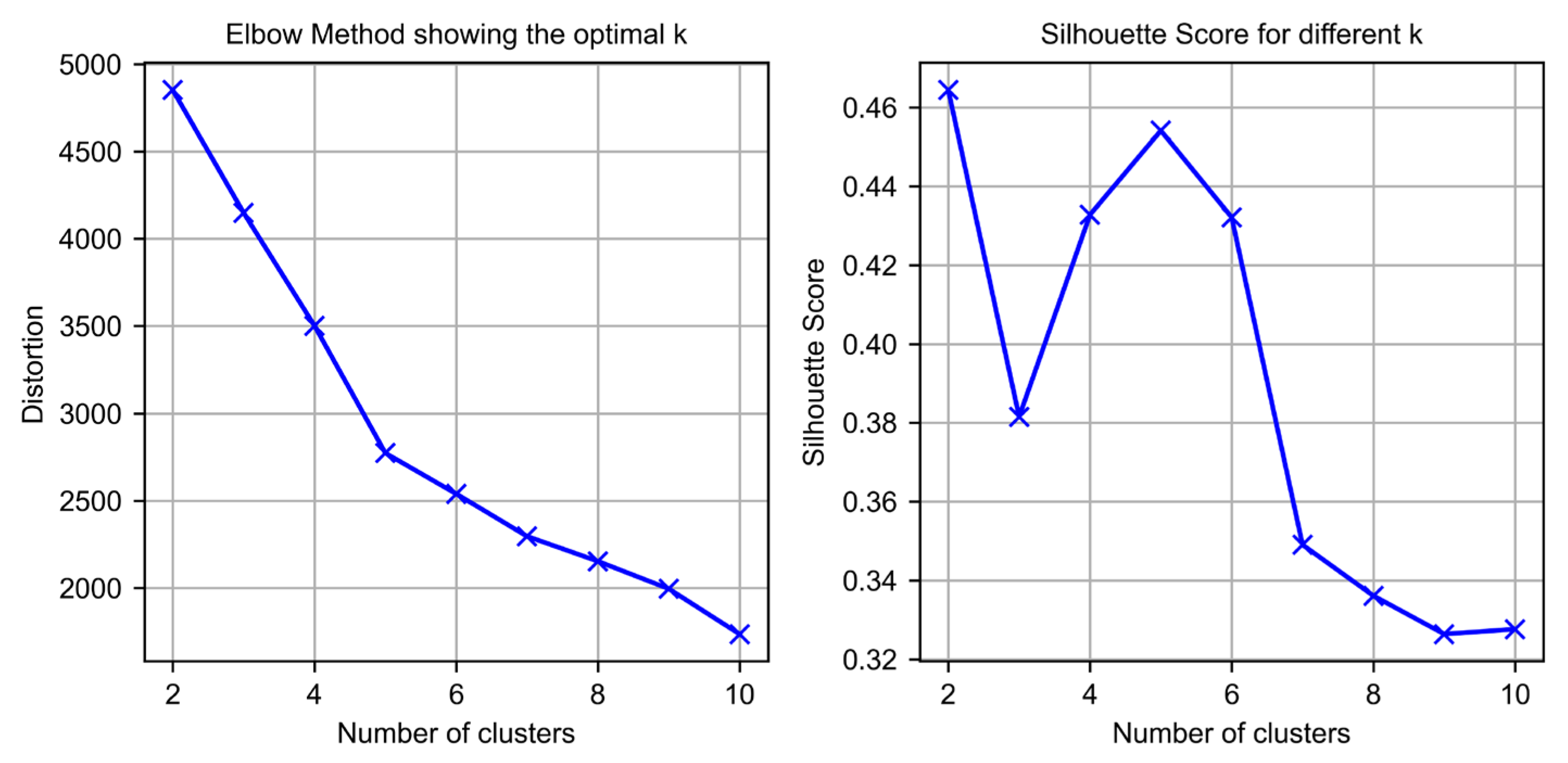

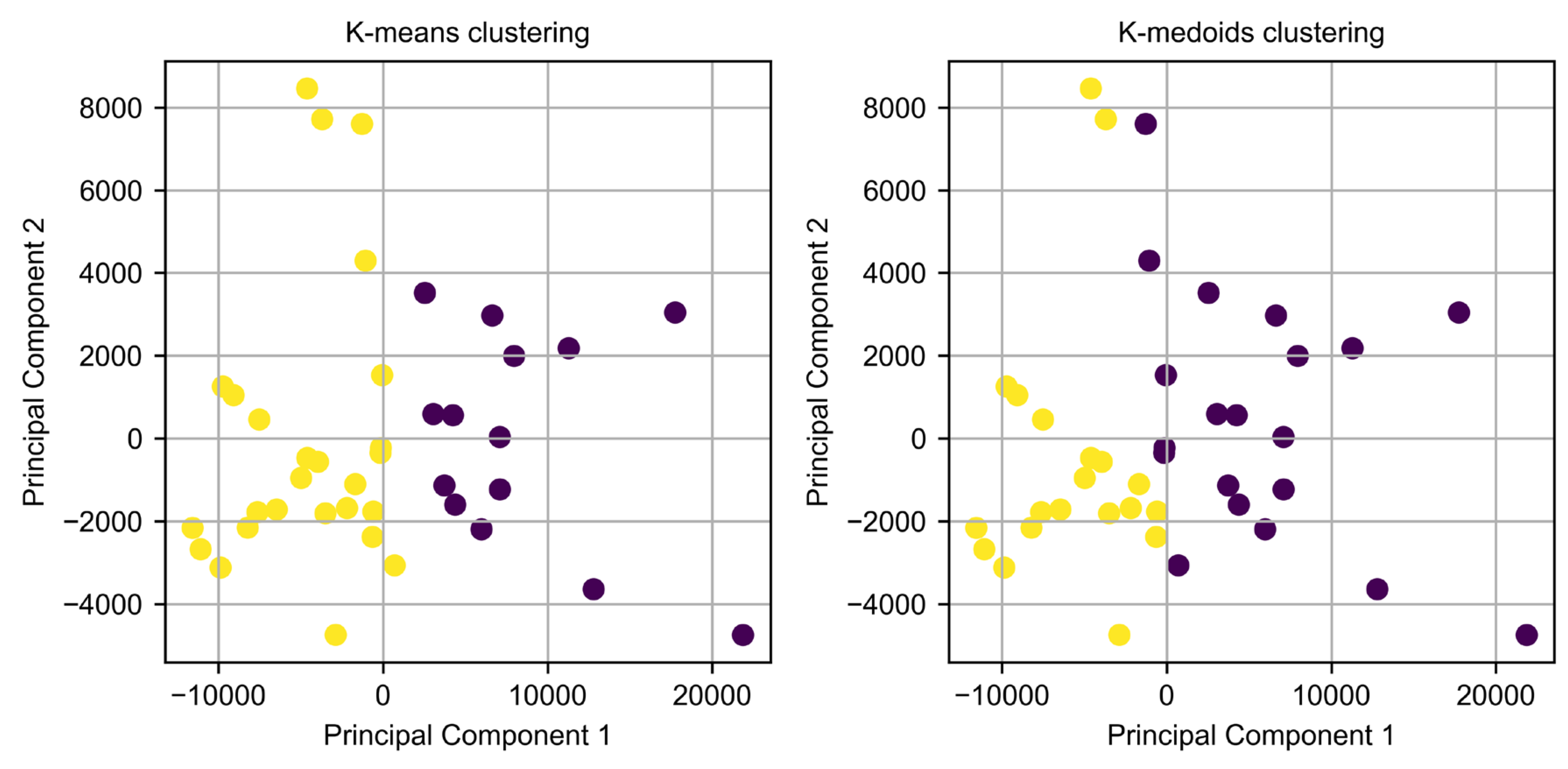

To cluster these signals and calculate the most representative signal of the largest group—assuming the initial signals are discarded—k-means and k-medoids are used, and the results compared without prior knowledge of the number of clusters. The steps in Python are as follows: i) Data Preparation: The signals are organized in a matrix, with each row representing one signal, ii) Calculation of Statistics: Statistical measures such as mean, variance, etc., can be used, or the entire signals can be directly employed, iii) Application of Clustering Algorithms: k-means and k-medoids are applied for clustering. To determine the optimal number of clusters, the elbow method or the silhouette criterion can be used, and iv) Comparison of Results: The outcomes of both methods are evaluated and compared, similar to what is done in [

11,

12].

With the focus on clustering the signals based on their compressive stress-strain characteristics next steps are followed. The first major step is determining the optimal number of clusters. To cluster signals based on their compressive stress-strain characteristics, the initial task is to determine the optimal number of clusters. This is achieved through the use of two key methods: the "elbow method" and silhouette scores. The elbow method involves evaluating the sum of distortions across a range of cluster numbers (k). Distortion is quantified as the average distance between each data point and the nearest cluster center. By plotting these distortions against the number of clusters, a distinct "elbow" shape often emerges. This elbow represents a point where increasing the number of clusters yields diminishing returns in reducing distortion, suggesting the optimal number of clusters. In parallel, silhouette scores are computed for each value of k. These scores measure the extent to which each data point is similar to points in its own cluster compared to points in other clusters. A higher silhouette score indicates better-defined clusters. By plotting silhouette scores, the peak of the curve helps to identify the value of k that results in the most coherent clustering structure. Together, the elbow method and silhouette scores provide a robust approach to selecting the number of clusters, ensuring that the clustering solution is both effective and interpretable. In the Figure 6 these results are shown to visually identify the optimal k, where the elbow in the distortion curve and the peak in the silhouette score indicate the most appropriate cluster count.

Figure 5.

Optimal number of clusters determined using the elbow method and silhouette scores.

Figure 5.

Optimal number of clusters determined using the elbow method and silhouette scores.

Once the optimal number of clusters is determined, both K-means and K-medoids clustering algorithms are applied. The clusters are visually represented in

Figure 6 using a 2D projection of the signals obtained through Principal Component Analysis (PCA).

For each cluster, the

Figure 8 plots all signals in grey, highlighting the mean signal and the medoid (central point) of the clusters in red and blue, respectively. The process helps identify groups of signals with similar behavior, as well as representative signals for each group, which is crucial for understanding the underlying patterns in the data.

In the final step a polynomial regression is performed to model the relationship between strain and stress for the mean signal of the second cluster as it can be seen in

Figure 9.

3.2. New Recovered Foam Impact Absorption System Modelization

Once the materials to be reused in the final design of the system have been characterized, a modeling of both the individual elements and the total designed set has been carried out in order to perform a finite element analysis, thus ensuring the correct functioning of the system in the protection of the users in the dynamic leisure facilities.

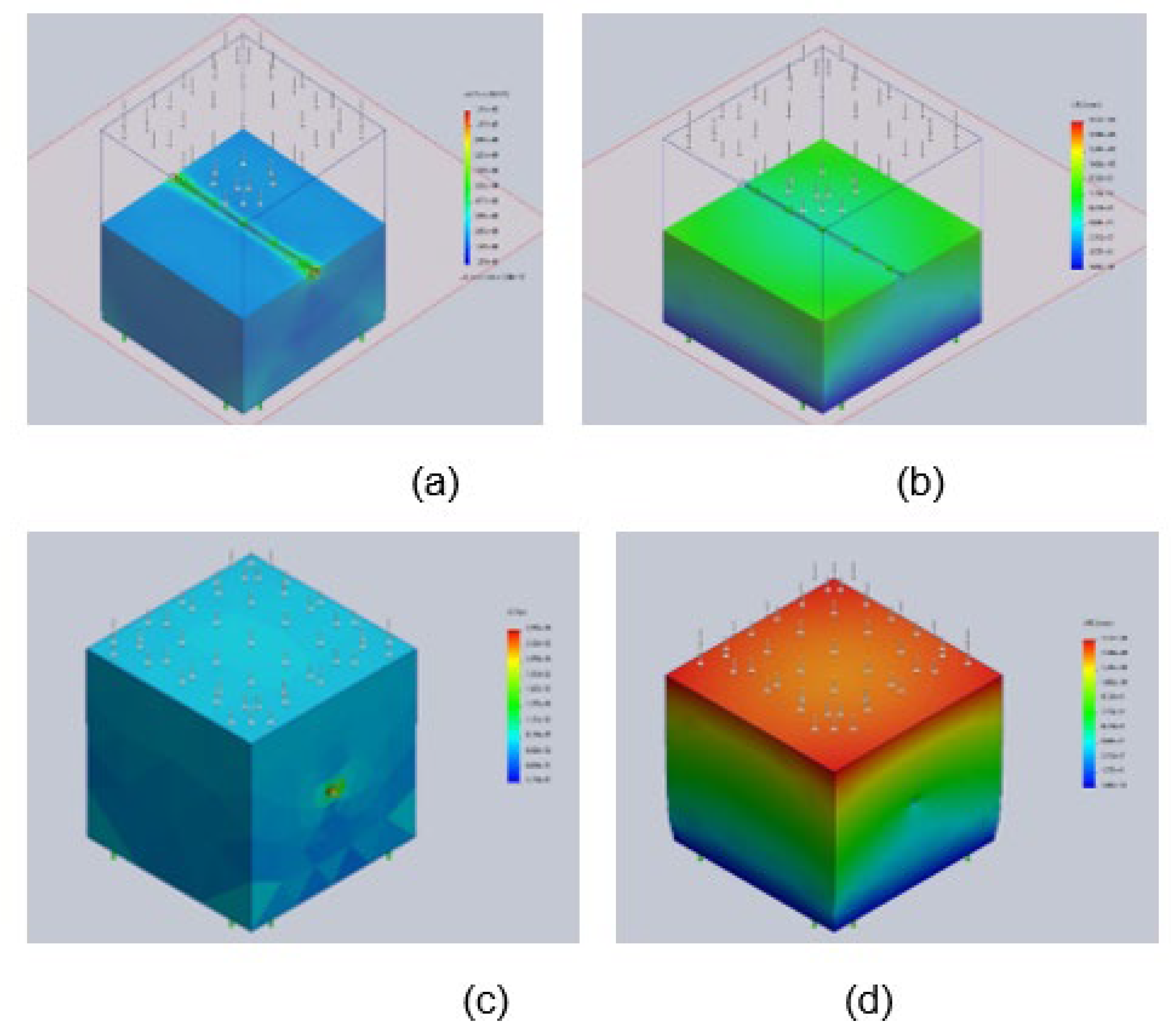

3.2.1. Cube Modelization

Three different configurations for different compression deformation ratios were simulated: 25% 50% & 75% to choose the best configuration that maintains the safety of the users and facilitates its manufacture and assembly. In this modelization has been included an element wich will keep the cubes on the right place when an impact will occur, as it could be seen on

Figure 10.

For this modelization, a curvature-based solid mesh with 16 Jacobian points was used for high quality meshing using high order quadratic elements that ensured high mesh quality. Different sizes and number of nodes were used, although the results obtained did not show significant differences, so the mesh with the lowest computational cost (3840 nodes, 2550 elements, 99.3% of elements with aspect ratio less than 3 and 0 distorted elements) was chosen.

The results of the FMEA analysis confirmed that the old foam cubes that were to be discarded can perform the necessary protective function by ensuring a maximum deformation of 50% desired to ensure the health of users in leisure facilities of this type.

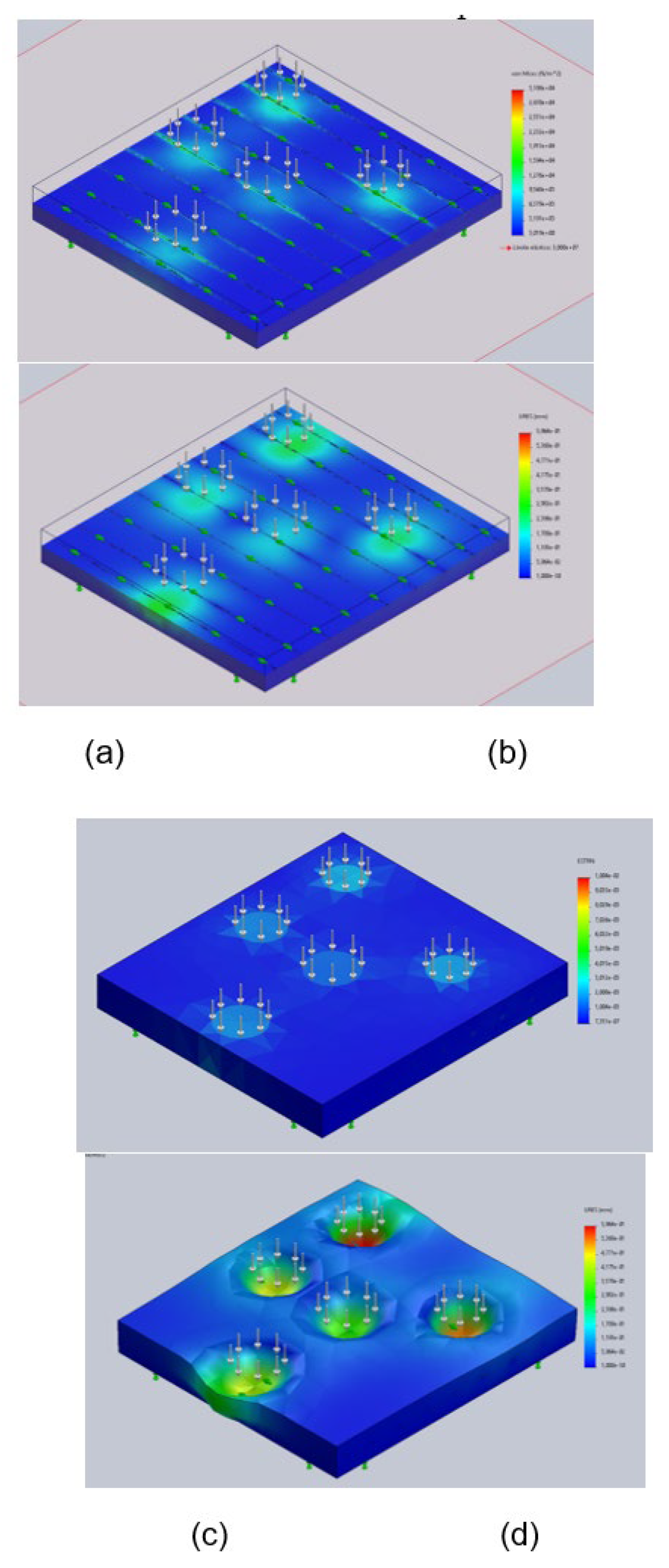

3.2.1. New Recovered Foam Impact Absorption System Modelization

Before proceeding to the fabrication of the prototypes of the newly designed impact absorption system, we proceeded to model the performance of the cube assembly against the impact of five users (100 kg/user) simultaneously.

For this purpose, the same parameters of the solver and the material simulated in the individual cube were used, requiring 178604 nodes and 124230 elements.

As it could be seen on

Figure 11 the maximum stress reached in the simulation is 3,188e+04N/m^2 and the maximum strain and the maximum strain drops to 0.5mm

The results of the simulation of the elements as a whole demonstrated the capacity of the material to ensure the physical safety of the users, since the limits established in the previous analysis of 50% of the deformation and ten percent of the deformation were not exceeded.

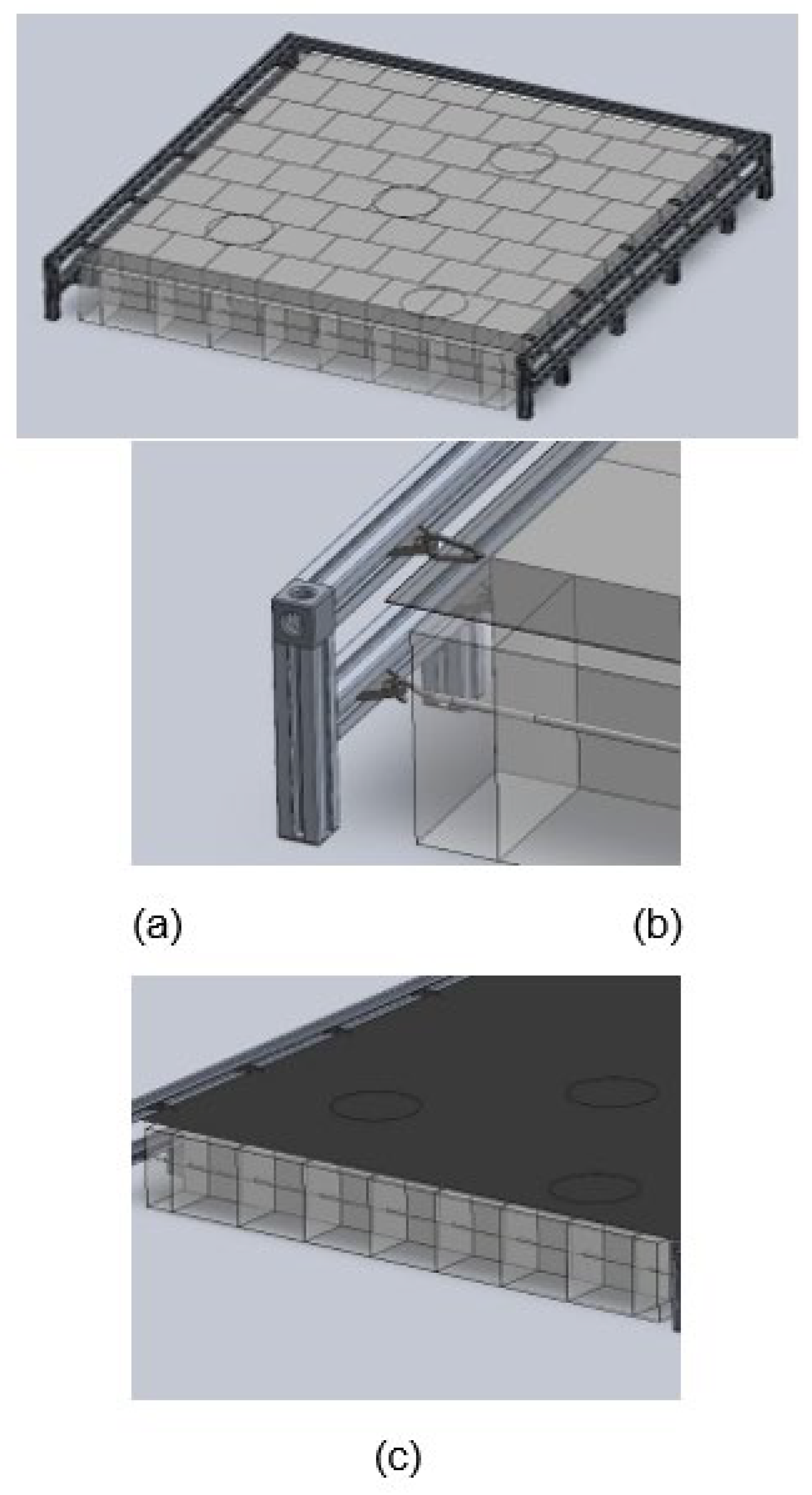

3.3. New Recovered Foam Impact Absorption System Design & Manufature

The newly designed system features a set of reused buckets connected by longitudinal ropes, which ensure that the buckets remain in the correct working position in the event of a fall. These ropes are attached to a metal framework that maintains the tension of the ropes while also supporting a canvas. The canvas serves two purposes: it ensures the system remains clean and allows the buckets to deform according to the severity of an impact.

The most important design parameters considered were:

Maximizing the use of recycled materials: The system prioritizes the reuse of available materials, especially the buckets, to minimize environmental impact.

Modularity of the design: The system is designed to be modular, allowing for easy adaptation to different spaces and requirements. This modularity also facilitates installation and maintenance.

Ease of maintenance and bucket replacement: The system is designed so that buckets can be easily replaced or maintained without needing to disassemble the entire structure. This ensures greater durability and long-term functionality.

In

Figure 12 it could be seen the detail of the technical solution achieved, which is made up of the following elements:.

Modular metal structure that serves as a resistant frame and allows the use of standard joining elements, allowing the goal of ease of assembly and maintenance and adaptability to various spaces to be achieved.

A unifying canvas from textile waste in the manufacture of other protection elements of the same leisure center. This canvas provides uniformity, limits the movements of the unitary foam elements and allows the hygiene of the system to be maintained.

A set of unitary foam elements reused from the previous activity of the leisure facility and that were previously eliminated by sending them to landfill, joined together by central wire ropes that make them work as a single protective element

Some union elements of the protective canvas and foam elements to the structure for easy maintenance and installation

4. Conclusions

The presented paper focuses on developing sustainable impact absorption systems by repurposing deteriorated foam and textile materials from leisure facilities. This initiative aims to address the challenges of foam degradation, enhancing both environmental sustainability and safety. This approach represents a significant advancement in creating effective anti-impact measures while contributing to environmental conservation. The following conclusions emerge from the work carried out:

The study provides a detailed analysis of the compressive behaviour of foam specimens using stress-strain curves, revealing consistent performance across multiple tests and specimens. The study provides a detailed analysis of the compressive behaviour of the foam specimens by means of stress-strain curves, revealing consistent performance across multiple tests and specimens.

Depending on the orientation of the cube, the pressure that causes a given deformation varies (anisotropy). It is also observed that, with the exception of isolated cases, as the cube is subjected to several tests, it deforms more under the same load.

The Characterization tests of the deteriorated material cubes showed that their ability to absorb impacts has not been greatly affected and they can be reused in impact absorption systems.

The finite element modeling of both the individual elements and the newly designed system has allowed us to test the performance against multiple falls of users ensuring their safety and physical integrity

With the design of the new technical solution achieved, the environmental impact of the company has been drastically reduced since it has been based on the reuse of discarded materials in the other activities of the facility.

Likewise, the safety of users of active leisure centers has been greatly increased, allowing the prevention of injuries resulting from falls and blows against rigid elements of the facility.

Author Contributions

Conceptualization, methodology formal analysis, Marcelino Sádaba, Sara; software; validation, Benito Hernandez, Pablo. and Veiga Suarez, Fernando; investigation, Martin Antunes, Miguel Ángel and Villanueva Roldan, Pedro.; writing—original draft preparation, Marcelino Sádaba, Sara & Veiga Suarez, Fernando.; writing—review and editing, Marcelino Sádaba, Sara & Veiga Suarez, Fernando; supervision, project administration & funding acquisition, Marcelino Sádaba, Sara. All authors have read and agreed to the published version of the manuscript.

Funding

“This research was funded by GOBIERNO DE NAVARRA, grant number 0011-1365-2022-000321” SISTEMAS DE ABSORCIÓN DE IMPACTO DE FOAM RECUPERADO - CLASHFOAM.

Data Availability Statement

We encourage all authors of articles published in MDPI journals to share their research data. In this section, please provide details regarding where data supporting reported results can be found, including links to publicly archived datasets analyzed or generated during the study. Where no new data were created, or where data is unavailable due to privacy or ethical restrictions, a statement is still required. Suggested Data Availability Statements are available in section “MDPI Research Data Policies” at

https://www.mdpi.com/ethics.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Juanga-Labayen, J.P.; Labayen, I.V.; Yuan, Q. A Review on Textile Recycling Practices and Challenges. Textiles 2022, 2, 174–188. [Google Scholar] [CrossRef]

- Zamani, B.; Svanstr¨om, M.; Peters, G.; Rydberg, T. A Carbon Footprint of Textile Recycling. A Case Study in Sweden. Journal of Industrial Ecology 2008, 19. [Google Scholar] [CrossRef]

- Hawley, J.M. Textile Recycling as a System: A Micro/Macro Analysis. Journal of Family and Consumer Sciences 2000, 92, 40. [Google Scholar]

- Navone, L.; Moffitt, K.; Hansen, K.-A.; Blinco, J.; Payne, A.; Speight, R. Closing the Textile Loop: Enzymatic Fibre Separation and Recycling of Wool/Polyester Fabric Blends. J. Waste Manag. 2020, 102, 149–160. [Google Scholar] [CrossRef] [PubMed]

- Koszewska, M. Challenges for the Textile and Clothing Industry. Autex Res. J. 2018, 18, 337–347. [Google Scholar] [CrossRef]

- Valverde, I.C.; Castilla, L.H.; Nuñez, D.F.; Rodriguez-Senıín, E.; de la Mano Ferreira, R. Development of New Insulation Panels Based on Textile Recycled Fibers. Waste Biomass Valor 2013, 4, 139–146. [Google Scholar] [CrossRef]

- Damayanti, D.; Wulandari, L.A.; Bagaskoro, A.; Rianjanu, A.; Wu, H.-S. Possibility Routes for Textile Recycling Technology. Polymers 2021, 13, 3834. [Google Scholar] [CrossRef] [PubMed]

- Pensupa, N.; Leu, S.-Y.; Hu, Y.; Du, C.; Liu, H.; Jing, H.; Wang, H.; Lin, C.S.K. Recent Trends in Sustainable Textile Waste Recycling. Methods: Current Situation and Future Prospects. Current Opinion in Green and Sustainable Chemistry 2017. [Google Scholar] [CrossRef]

- Chavan, J. Environmental Sustainability through Textile Recycling. Textile Sci Eng 2014, S2. [Google Scholar] [CrossRef]

- Eaves, D. Handbook of Polymer Foams; Rapra Technology Limited, 2004. ISBN 978-1-84735-054-1.

- Diez-Olivan, A.; Penalva, M.; Veiga, F.; Deitert, L.; Sanz, R.; Sierra, B. Kernel Density-Based Pattern Classification in Blind Fasteners Installation. In Proceedings of the Hybrid Artificial Intelligent Systems; Martínez de Pisón, F.J., Urraca, R., Quintián, H., Corchado, E., Eds.; Springer International Publishing: Cham, 2017; pp. 195–206. [Google Scholar]

- Ortego, P.; Diez-Olivan, A.; Del Ser, J.; Veiga, F.; Penalva, M.; Sierra, B. Evolutionary LSTM-FCN Networks for Pattern Classification in Industrial Processes. Swarm and Evolutionary Computation 2020, 54. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).