1. Introduction

In the current global process of technological revolution and industrial transformation, automobiles, deeply integrated with energy, transportation, and communication technologies, have garnered significant attention from industry, academia, and research institutions.With the trends of electrification and intelligent networking driving the automotive industry, new energy vehicles (NEVs) integrate cutting-edge technologies such as new energy sources, innovative materials, big data, and artificial intelligence (AI). This transformation from traditional transportation tools to mobile intelligent terminals, energy storage units, and digital spaces supports the construction of a clean and beautiful world and the building of a community with a shared future for mankind [

1]. In recent years, supported by strategic planning and policies globally, NEVs have emerged as the primary direction for the transformation and development of the global automotive industry and as a key driver for sustainable economic growth. Developing NEVs is an essential path for countries to become automotive powerhouses and serves as a critical strategy to address global climate change and promote green energy development [

2,

3].

From a developmental perspective, pure electric vehicles (PEVs), range-extended hybrid electric vehicles (REHEVs), plug-in hybrid electric vehicles (PHEVs), and fuel cell electric vehicles (FCEVs) are the main future product routes, offering stronger competitive and attractive advantages compared to traditional vehicles. Among these, PEVs have become the focus of research and industrial layout investments for automotive enterprises due to their relatively straightforward technological implementation, high user acceptance, and strong governmental support [

4,

5].

During the marketization of electric vehicles, the powertrain system, as a core component, profoundly influences the vehicle’s overall performance and user experience. The current industry commonly employs three pillars for powertrain system functional testing and quality assurance: simulation testing, closed-track testing, and real-vehicle testing [

6]. Among them, the closed-track testing offers controlled environments and high repeatability but is limited to a controlled environment, which can’t fully cover the working conditions of the product.The real-vehicle testing, conducted on open roads, benefits from authentic traffic conditions but poses risks of traffic interference and extended test cycles. Simulation testing, using computer models and virtual environments, assesses and verifies the performance and safety of power systems at a lower cost and with flexible testing scenarios, replicating specific operational conditions and providing abundant test data.

Digital twin (DT) technology involves creating a virtual simulation model corresponding to a real-world object, updated and optimized in real-time through data feedback. Widely applied in automotive manufacturing, aerospace, and healthcare, DT enables simulation mapping of physical components and constructed models in virtual spaces during simulation tests, reflecting the actual operational status of physical equipment and enhancing development and testing efficiency [

7,

8]. Particularly in the NEV sector, in order to adapt to the development concept of short iteration cycle of electric vehicle models, frequent product updates, and fast time-to-market, the digital twin simulation test before the prototype trial production, as an indispensable design method, can provide maximum help for the enterprise to develop their products as quickly as possible, and to save the cost of expenses, which is vigorously promoted by the automotive industry. [

9].Therefore, the application of DT technology has gained promotion within the field of automotive testing.

In the process of landing the application of digital twin simulation test technology, different departments adopt different focus points and technical paths. Regarding technical path realization, Zhao Shulian et al. from China Automotive Research Institute proposed a digital twin-based test and evaluation method for intelligent vehicles. They combined real test vehicles and simulation test tools to build a digital twin autonomous driving test platform to achieve the verification of algorithms, and to achieve the effective mapping and combination of vehicles travelling in the real test site with the virtual test environment [

10]. Based on the designed data acquisition platform, Zhang Shiyuan of Chang’an University conducted research in three parts: system hardware deployment and connection, sensor data acquisition and processing, and system communication connection and data transmission, constructed a digital twin test landscape, and proved through experiments that the trajectory prediction method can control the positional error between the digital twin vehicle and the real vehicle to the centimeter level [

11].

In terms of taking digital twin as the focus point for landing, Jiangnan Yu [

12] et al. from Wuhan University of Technology established a pure electric vehicle model and a closed-loop model of rapid prototyping controller applied to simulation testing, and carried out open-loop and closed-loop digital twin testing between the vehicle controlled object model and control strategy to verify the effectiveness and necessity of HiL simulation testing from the functional level. Han Yawei et al. from Shanghai Motor Vehicle Inspection Centre, for the motor control unit (MCU), the core driving component of the electric vehicle power system, tested the controller’s ability to dispose of faults when faced with a digital-twin-based scenario and then evaluated the controller’s functionality [

13]. Liu Jiangbo et al. from Jianghuai Automobile Group set up a multi-ECU (electronic control unit) joint debugging hardware-in-the-loop stand based on the DT real-time simulation system, and tested the reasonableness of the design matching between different ECUs of the system, aiming at realizing the research on the safety and reliability of the whole vehicle’s electronic and electrical architecture [

14].

Although the aforementioned studies achieve certain breakthroughs in the application of digital twin technology and simulation testing for automotive products, these findings often focus solely on individual performance metrics, neglecting the overall hierarchy and complexity of the system. This oversight results in experimental outcomes that fail to comprehensively reflect the performance of the powertrain under various operating conditions. Consequently, there is an urgent need to develop a testing methodology specifically tailored for powertrains. This methodology should be designed from the perspective of system engineering in the forward development of electric vehicles, ensuring comprehensive coverage testing of the fundamental functions and fault handling mechanisms of the tested products. This approach aims to enhance the scientific rigor and practical relevance of product development, thereby strategically alleviating concerns related to the prolonged development cycles and difficult-to-manage risks faced by research and development organizations. Ultimately, this will provide a foundation for the optimization and upgrading of electric vehicles.

Therefore, this paper proposes the Sandian testing scheme based on a digital twin framework, focusing on the testing of the powertrain components, including the motor, battery, and electronic control systems. The primary advantage of this testing approach lies in its ability to effectively mitigate personnel injury during the experimental process while significantly enhancing testing efficiency. The key benefits of implementing this scheme include the replacement of potentially hazardous signals during actual driving with simulated signals generated by the digital twin, thereby avoiding unsafe conditions for testers during the functional verification phase of the electric vehicle’s powertrain. Another advantage of the three-in-one system testing is its capability to substantially reduce the experimental costs associated with the electric vehicle development phase. Compared to manual road testing with real vehicles, testing on a powertrain DT platform allows for significant flexibility in selecting controlled experimental conditions and parameter settings according to testing requirements, thereby alleviating the risks associated with lengthy research and development testing cycles. Additionally, the Sandian testing system supports the reproduction of fault conditions, enabling the focused recreation of critical test scenarios, which facilitates data collection and problem identification by the experimental personnel. In summary, the proposed testing based on DT technology effectively controls testing risks and optimizes testing costs while ensuring reliable results.

Considering that testing with a single critical component controller does not fully reflect the signal logic interactions of the powertrain during actual operations, and recognizing that real-vehicle testing fails to accommodate rapid parameter design and safe implementation of extreme operating conditions, this paper proposes a digital twin simulation testing strategy based on a multi-controller Hardware-in-the-Loop (HiL) framework. The study focuses on the functional testing of electric vehicle powertrains and presents a detailed technical scheme for the multi-controller HiL simulation platform through the analysis of the characteristics of digital twin testing methods. Building upon the functional definitions provided by the vehicle development phase, testing use cases are developed based on the characteristics of the simulation platform. This enables functional testing under common operating conditions as well as powertrain testing under fault injection scenarios with extreme parameter conditions. Through data analysis and criterion evaluation, this approach offers substantial support for the development of functional strategies and the enhancement of fault handling mechanisms.

The subsequent sections are as follows:

Section 1 introduces the digital twin system framework for powertrain systems;

Section 2 elaborates on existing the Sandian DT solutions;

Section 3 details the construction of the digital twin testing platform;

Section 4 discusses test case development;

Section 5 analyzes test results and challenges;

Section 6 concludes with future outlooks.

2. Digital Twin Powertrain System Framework

In relation to the reference architecture for digital twins, the team led by Tao Fei at Beihang University proposes a five-dimensional model, which specifically includes Physical Equipment, Virtual Equipment, Connection, Digital Twin Data, and Services. These five modules facilitate the integration of cyber-physical systems, the fusion of cyber-physical data, bidirectional interaction between the virtual and physical realms, and data services [

15]. In the context of electric vehicle powertrains, the Vehicle Controller Unit (VCU), Motor Controller Unit (MCU), and Battery Management Unit (BMS) are essential critical components, and they become focal points for simulation testing research[

16].Accordingly, this paper builds upon the aforementioned five-dimensional model to propose a “Twin-Reality-User Domain” framework for testing critical components within the powertrain. This approach supports the simulation of the physical processes and system behaviors of the VCU, BMS, and MCU under real vehicle operating conditions by establishing mathematical models within a computer environment. This facilitates testing, research, and optimization from the source level.

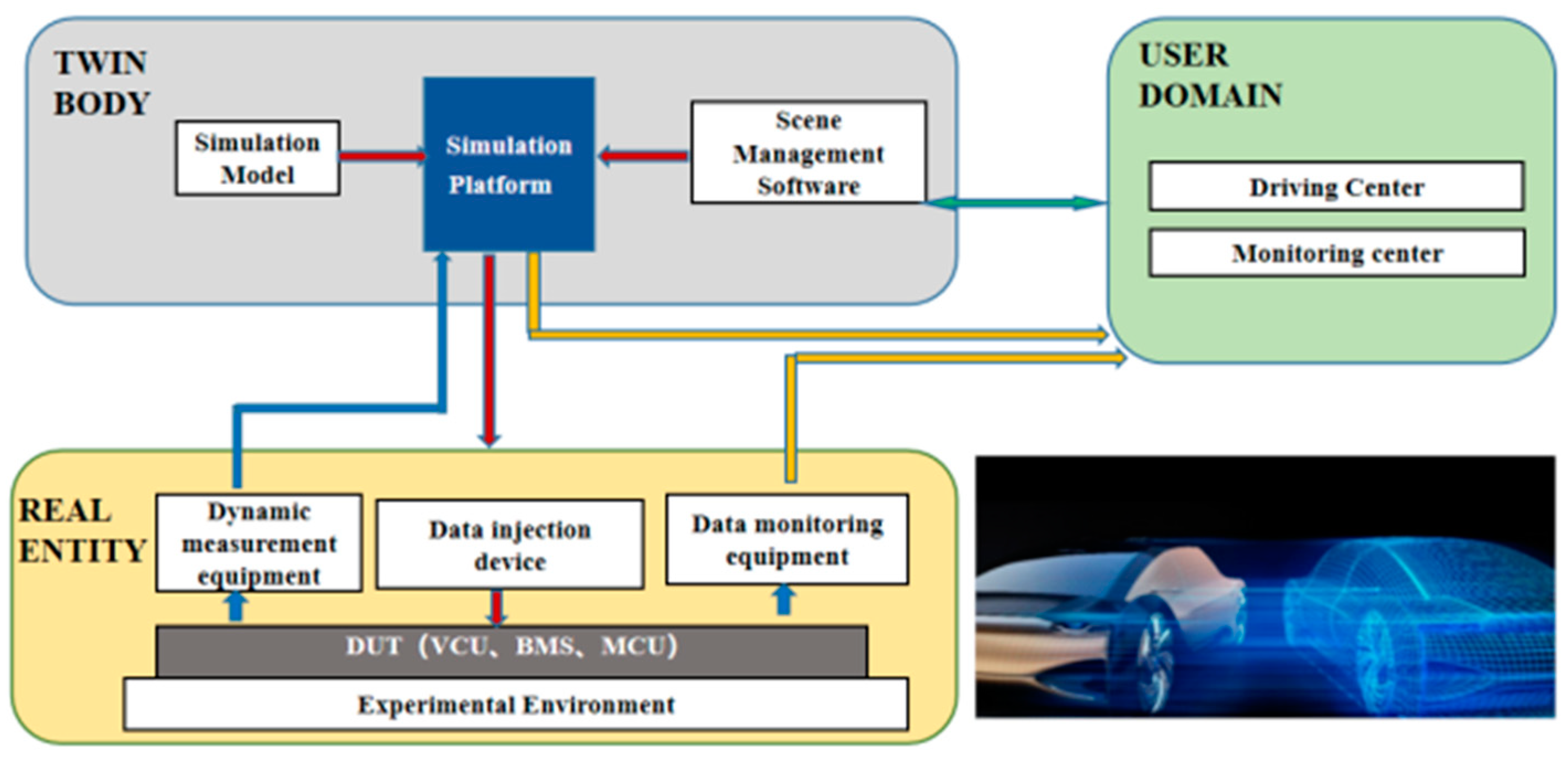

As shown in

Figure 1, the DT powertrain system consists of three components: the twin module centered on the simulation platform, which primarily includes the virtual test environment and testing scenarios; the physical entity module centered on the tested objects and real testing environment, which mainly encompasses industrial computers and key data processing devices; and the user domain module focused on driving and monitoring, with the primary goal of evaluating the test result data.

During system operation, the simulation platform generates the necessary simulation signals to maintain the proper functioning of the tested controllers, including bus communications (CAN), hardwired signals, and Ethernet signals, collectively constructing a virtual digital vehicle. The virtually constructed vehicle transmits target test information to the powertrain’s critical component controllers via the industrial computer and data injection devices. Subsequently, the physical controllers respond to the received operating condition and environmental parameter information, while outputting typical powertrain parameters (such as voltage, current, torque, and speed) to the virtual digital vehicle model, effectively mapping the operational state of the controller within the simulation environment, thus realizing the simulation of the “digital-physical” system.

During this process, the user interface outputs simulated driver-triggered signals (such as throttle and brake signals) to the closed-loop simulation model. The real-time transmission method based on TCP/UDP protocol synchronizes the vehicle’s operating status between the virtual world and the real environment. At the same time, adjustments are made in response to data monitored by and dynamic measurements from monitoring devices, ensuring the stable closed-loop operation of the entire digital twin testing platform.

The Digital twin technology involves the digitization of physical characteristics, operating states, and environmental information of tangible objects. Its fundamental concept is to collect data from the physical world, establish corresponding digital models, and seamlessly connect these models with the physical objects in virtual space [

17]. The proposed “Twin-Reality-User Domain” system architecture demonstrated in this paper exhibits high fidelity characteristics, ensuring precise and reliable simulations and providing a robust platform for testing and verification of electric vehicle powertrains.

3. Technical Scheme of Digital Twin Test Bench

In addressing project requirements, this chapter focuses on the practical implementation of a digital twin simulation platform based on the powertrain digital twin system architecture. The simulation platform consists of three main components: hardware, software modules, and the tested objects [

18]. Together, these components simulate the relevant parameters of the critical controllers within the powertrain, laying the groundwork for the simulation testing of these controllers.

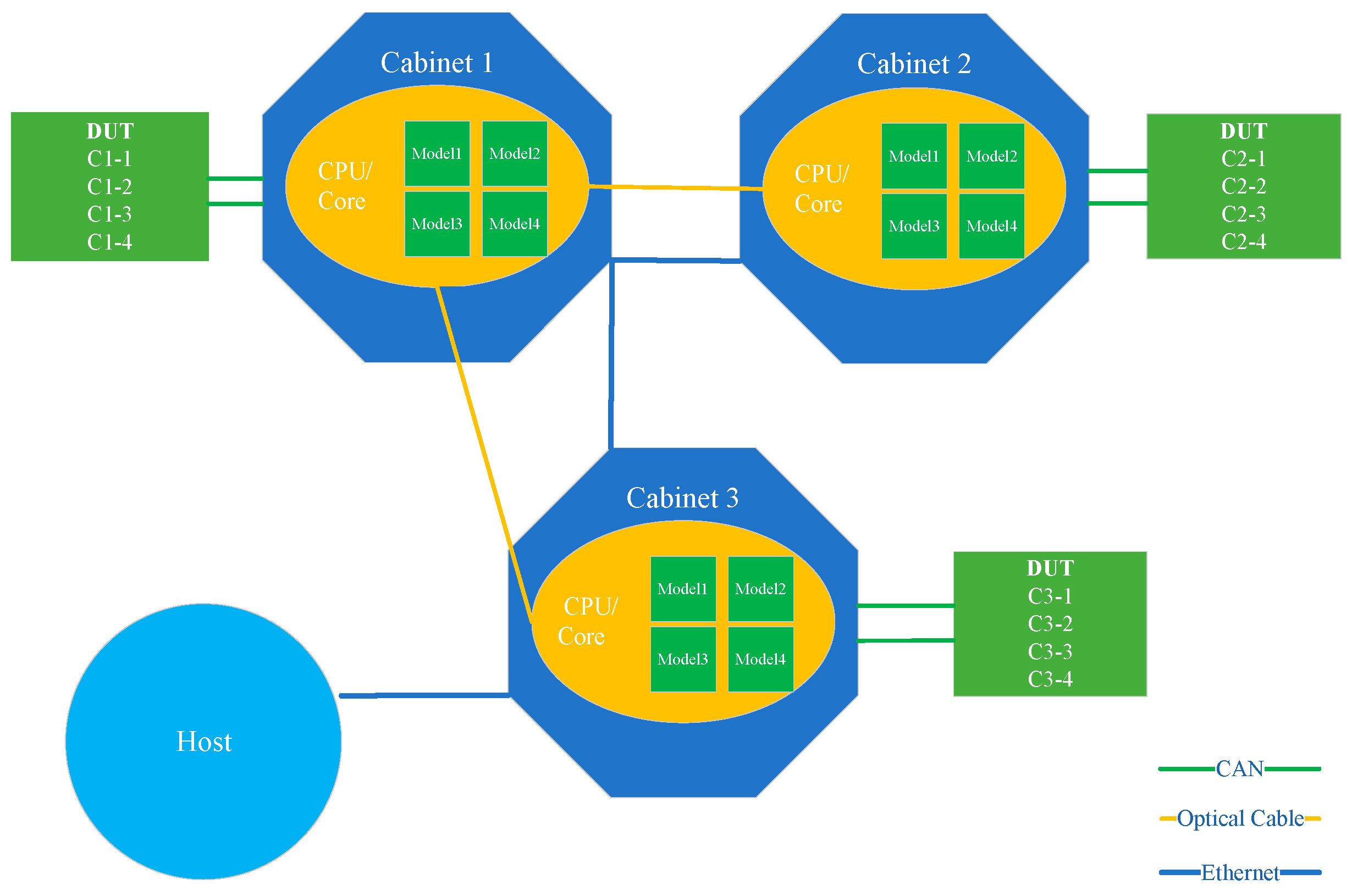

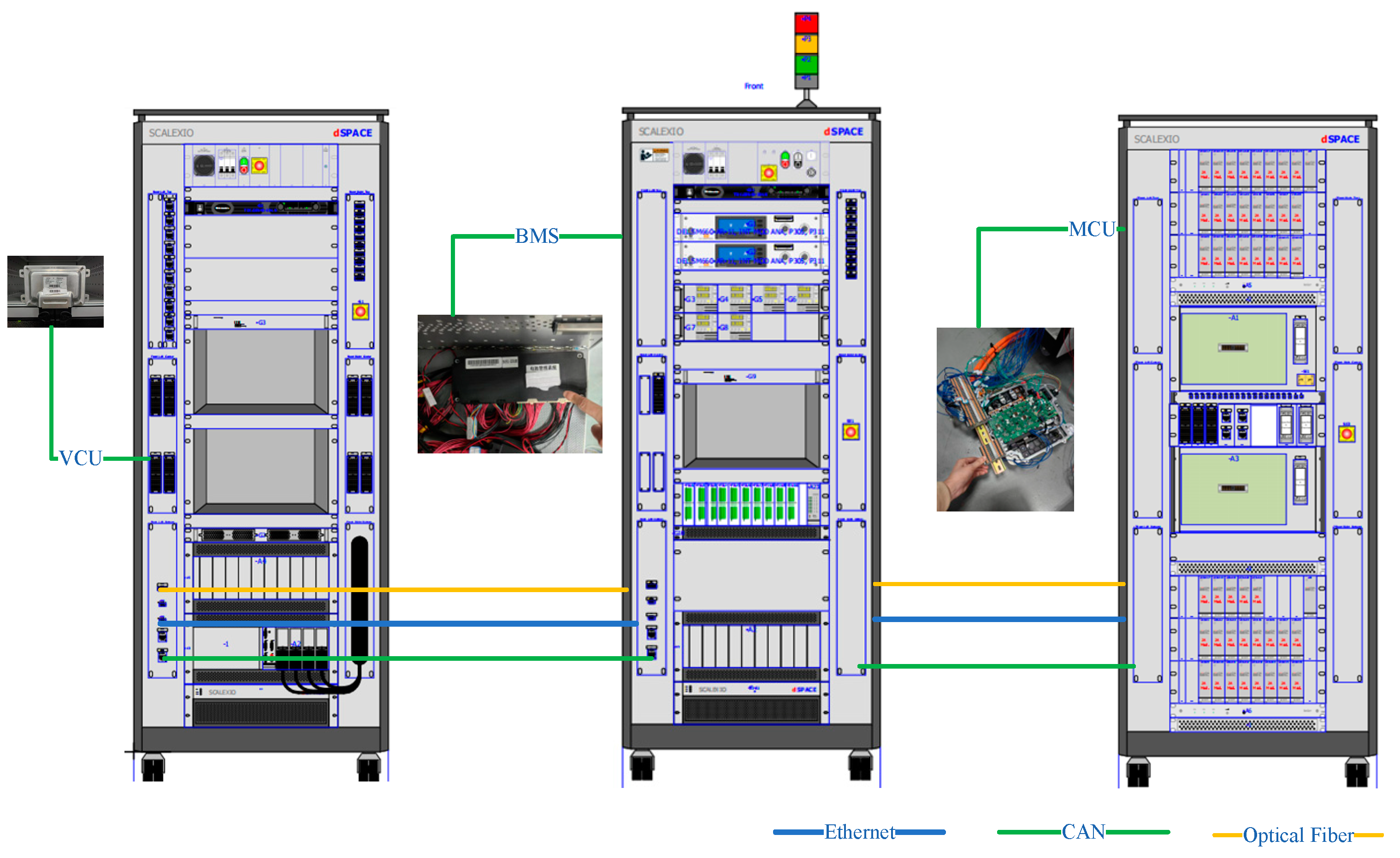

For the project under study, a multi-cabinet coordinated tuning approach is adopted to facilitate the signal interaction process among the powertrain’s critical component controllers. The structure of the digital twin simulation platform for the powertrain is illustrated as follows.

Figure 2.

Schematic diagram of the multi-cabinet intermodulation program.

Figure 2.

Schematic diagram of the multi-cabinet intermodulation program.

In the figure, the equivalent hardware component is represented as the cabinet, which comprises an industrial computer, a data acquisition and monitoring system, and a real-time control system. The real-time control system utilizes a dedicated DSPACE board module that includes digital-analog acquisition modules and CAN communication modules, facilitating data communication and recording between real controllers and actuators while adhering to international communication standards such as ISO 11898 and SAE J2602. The tested objects refer to the combination of the VCU, BMS, and MCU within the three-in-one system.

During the multi-cabinet coordinated debugging process, a specific hardware device is selected as the master cabinet. Typically, the most computationally intensive component is chosen to serve as the master cabinet since it operates the dynamic model [

19]. If one cabinet employs multi-core computation during debugging, that cabinet becomes the master. Additionally, a communication network between the cabinets must be established. The cabinets are connected serially, such that one cabinet can communicate with a maximum of two other cabinets at any given time. For instance, in the configuration HIL1—HIL2—HIL3—HILx, communication between HIL1 and HIL3 must occur through HIL2. Therefore, it is essential to select components with higher signal interactions as the master cabinet to avoid unnecessary delays caused by excessive signal forwarding between cabinets.

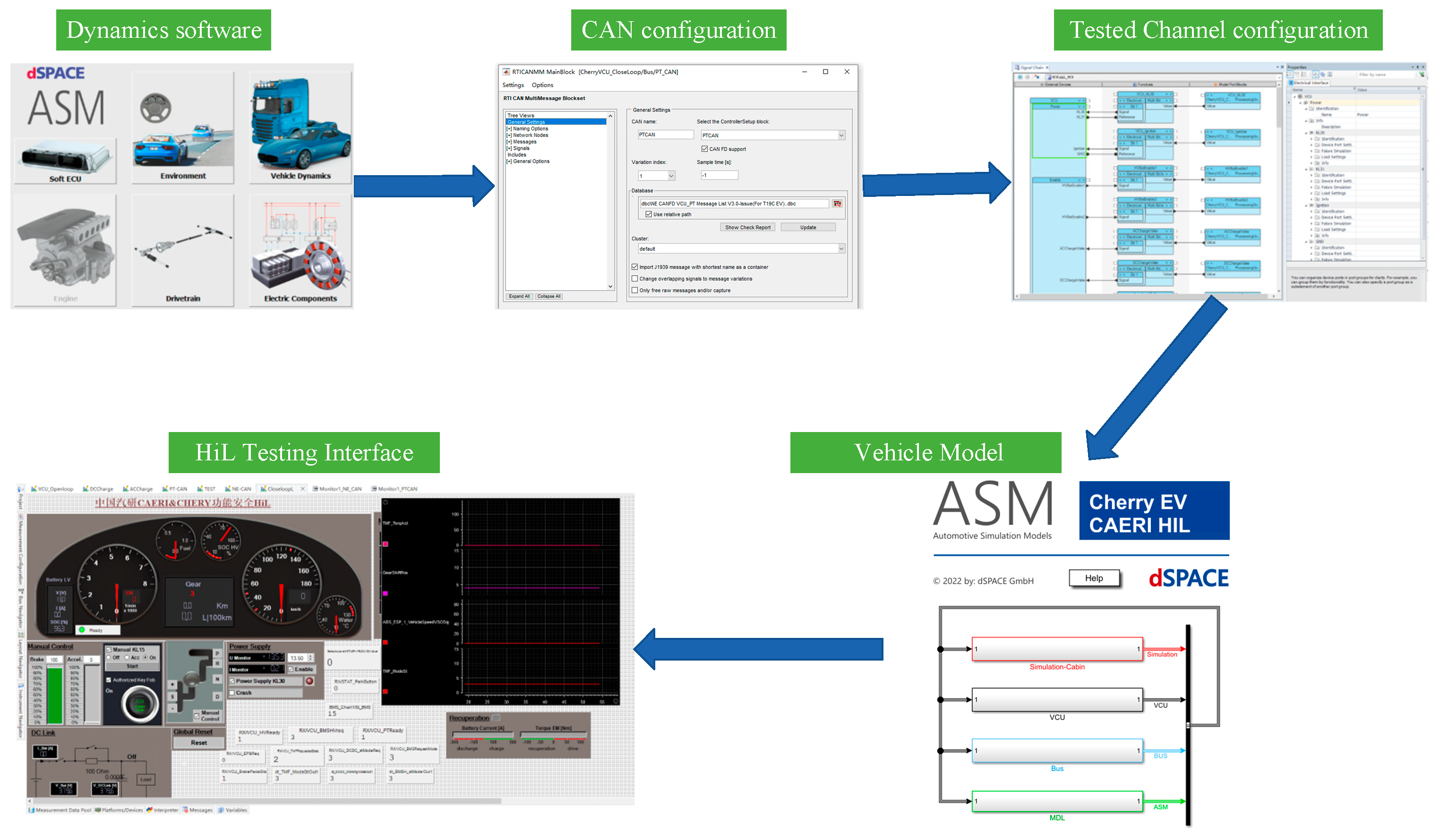

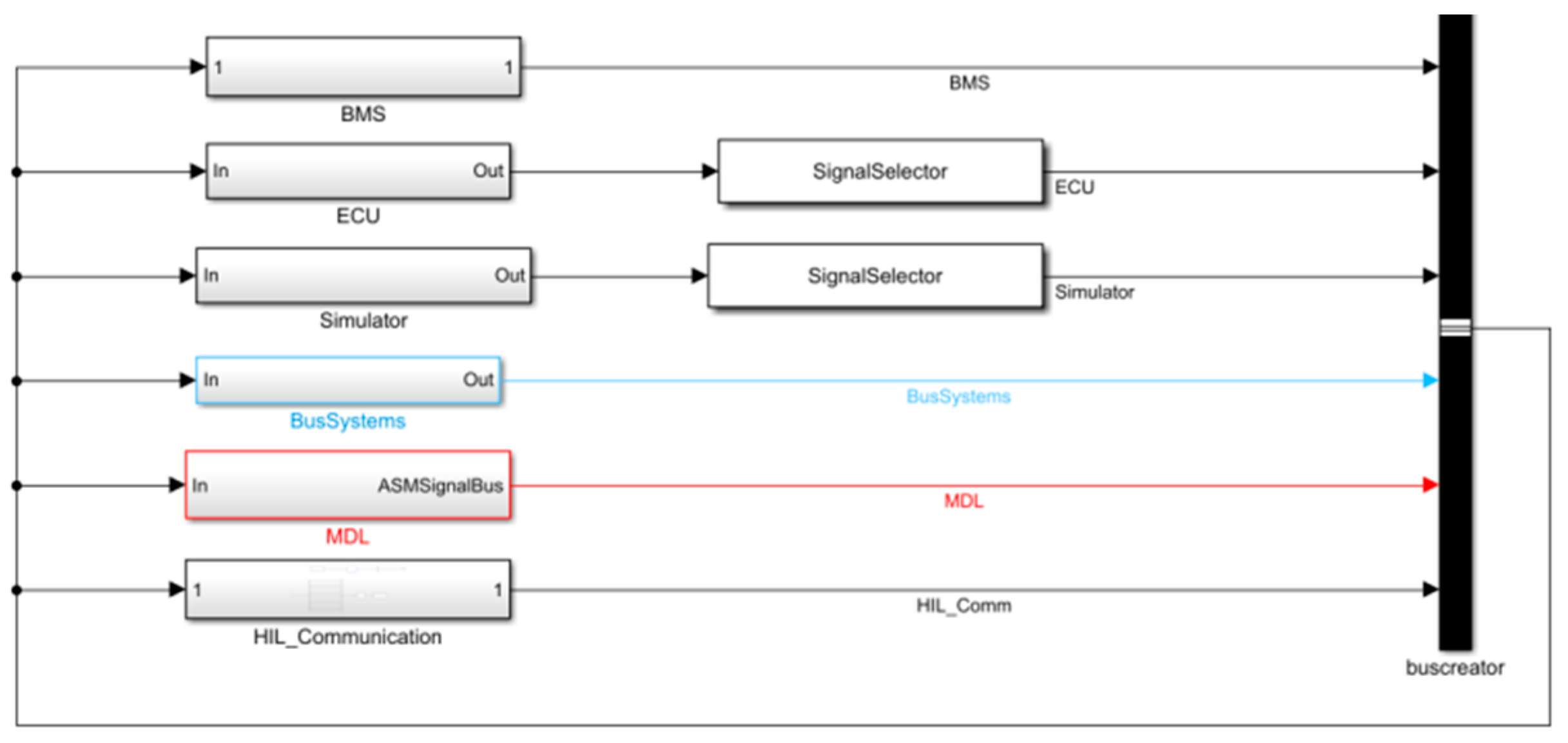

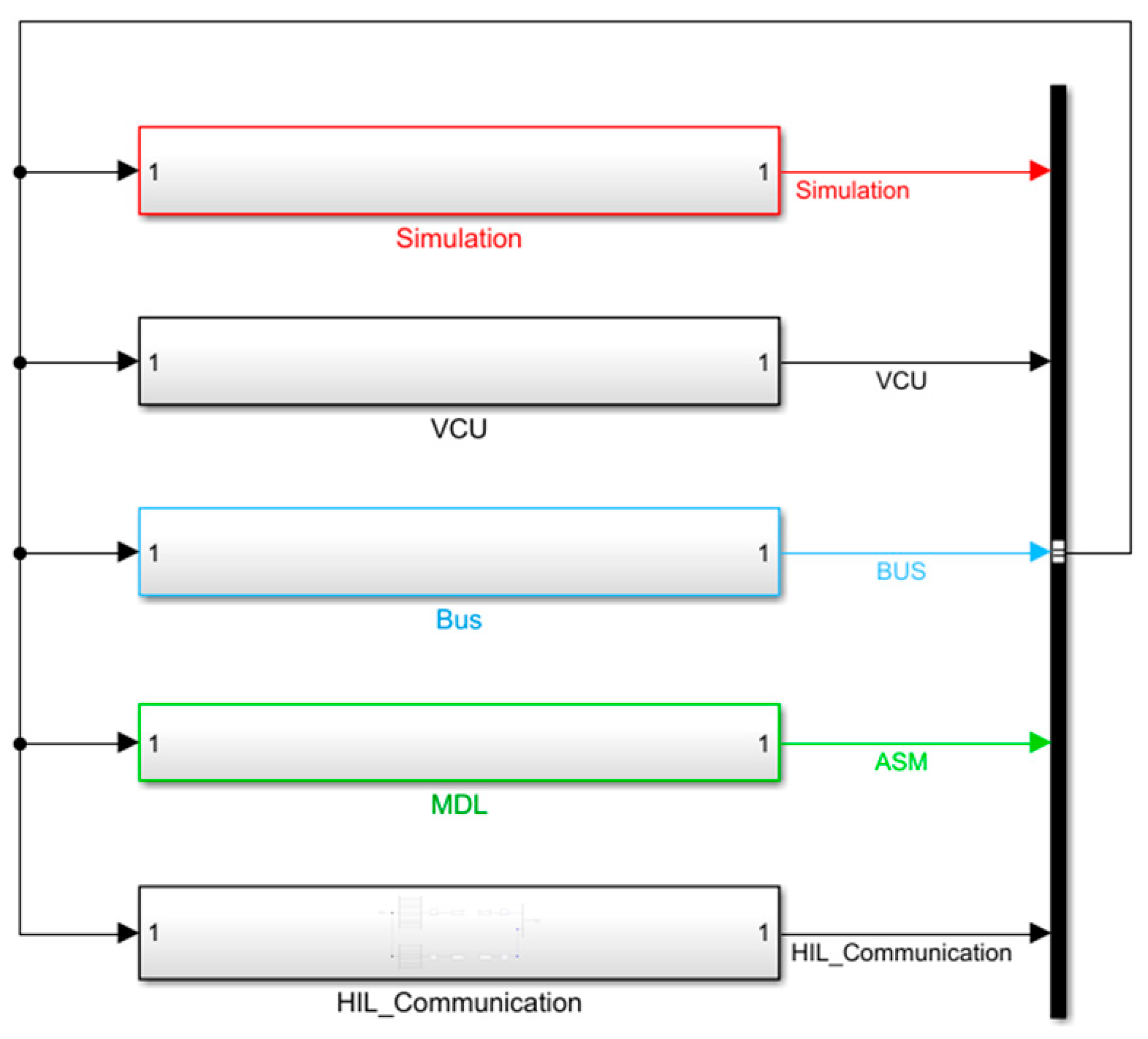

Regarding the upper computer software platform, ASM is utilized for constructing the vehicle dynamics model, while MATLAB is employed for building the powertrain simulation platform. Configuration and Control Desk software are used to configure the entire experimental environment and to create the testing interface and typical parameter settings, respectively. Automation software allows for signal recording of test cases and the generation of reports.

In summary, the main tasks associated with the simulation testing platform include: creating signal lists, developing and configuring I/O models, modeling the simulated vehicle, and conducting both open-loop and closed-loop testing of controllers. The system is ultimately debugged to a normal operational state by collecting the relevant signals, providing a foundation for subsequent functional testing and fault injection.

Taking the vehicle’s basic signals as an example, the technical scheme implemented by the platform follows this pathway: the simulation platform converts the corrected electrical signal information into drive pedal positions or brake switch signals to control the digital twin vehicle. This is achieved by utilizing the established MATLAB/Simulink simulation platform to validate safety control strategies. This technical scheme supports the injection of signals from the source level, ensuring high precision and reliability in simulations and maximally replicating the operating conditions of real vehicles.

Figure 3.

Schematic diagram of DT bench technology scheme.

Figure 3.

Schematic diagram of DT bench technology scheme.

4. Testing Platform for Sandian Digital Twin System

The digital twin system testing platform consists of two main components: hardware and software [

20]. This chapter provides a detailed discussion of the structure and construction logic of each component based on the specific requirements of the Sandian system project.

4.1. Hardware Configuration

The focal point of the Sandian testing system platform is the connection between the tested components and the cabinet, particularly the data connections between the actual controllers and their corresponding digital twins [

21]. Given the characteristics of multi-cabinet coordination, the wiring arrangement and linkage for the critical components of powertrain system—VCU, MCU, and BMS—is outlined in

Table 1.

In the table, Xr (X=P/E/B) indicates that the two controllers in the three CAN lines are connected as actual lines, Xv (X=P/E/B) indicates that the two controllers in the three CAN lines are connected as virtual twins, and VCUt indicates that the two controllers are connected by forwarding signals through virtualised VCUs.

Considering that the VCU serves as the central control unit for the vehicle power system, this project adopts a configuration where Module 1 links to the VCU as the main cabinet, while Cabinets 2 and 3 are connected to the BMS (including both primary and secondary components) and MCU, respectively. Signal interaction among the three cabinets is facilitated through optical cables and Ethernet, while signal transmission and communication between the cabinets and the control unit under test are conducted via the CAN bus. The schematic diagram of the hardware-in-the-loop testing hardware connections is illustrated in

Figure 4 below.

4.2. Software Modelling

The software component of the digital twin testing platform is primarily responsible for translating the computational logic and intrinsic relationships between the signals of various controllers into unified mathematical expression models for testing purposes [

22]. This section discusses typical components of the three-in-one system: the vehicle paramodel, motor paramodel, and battery paramodel. According to the project database, the vehicle characteristics are summarized in

Table 2.

4.2.1. Vehicle Longitudinal Dynamics Para Model

The vehicle longitudinal dynamics model plays a critical role in automotive engineering by simulating the dynamic behavior of the vehicle under various driving conditions, particularly during acceleration and braking, thus assisting engineers in analyzing vehicle handling and safety [

23]. According to automotive theory:

where Ft is the driving force of the whole vehicle; Ff is the rolling friction resistance; Fw is the air resistance when the vehicle is travelling; Fi is the ramp resistance of the vehicle on an uneven road; and Fa is the resistance due to acceleration of the vehicle.

where

is the road slope; m is the vehicle’s overall mass, g is the gravitational acceleration; ρ is the air density at room temperature; and δ is the vehicle’s rotational mass factor.

4.2.2. Vehicle Controller Unit Para Model

In the Sandian simulation testing, the vehicle controller VCU simulation model typically consists of several key components, each playing a crucial role in ensuring the system meets the expected performance and functionality [

24]. The main functions of the VCU model components are as follows:

Sensor Simulation Module: This module is responsible for simulating the input signals from various sensors within the vehicle system, such as speed and steering sensors. It provides real-time environmental data and ensures coordination between the sensors and the VCU.Actuator Simulation Module: This module simulates the actuators of the vehicle’s powertrain, such as the engine and brake actuators. It receives control commands from the VCU and simulates the actual behavior of these actuators. Communication Interface Module: This module simulates the communication process between the VCU and other vehicle systems, including the reception of sensor data and the transmission of control commands. It ensures normal communication between the VCU and the entire vehicle system.

The VCU digital twin simulation model is constructed as illustrated in

Figure 5.

By coordinating these components and implementing their functions, the VCU simulation model effectively simulates the behavior and performance of the entire vehicle system during HiL testing, thereby supporting system integration validation.

4.2.3. Motor Controller Unit Para Model

The main components and their functions of the MCU simulation model in the Sandian test are: a communication interface module to achieve data transmission, command exchange; a signal acquisition module to simulate the signal acquisition function in the MCU of the motor controller, including receiving feedback signals from sensors, such as speed, temperature, etc.; a control algorithm module to achieve speed control, torque control, position control, etc.; a PWM generator module to simulate PWM signal generation function for driving power semiconductor devices in the motor controller; a protection logic module: to achieve overcurrent protection, voltage protection, temperature protection, etc. of the controller to avoid damage to the controller. The PWM generation module simulates the PWM signal generation function, which is used to drive the power semiconductor devices in the motor controller; the Protection logic module: realises the controller’s over-current protection, over-voltage protection, over-temperature protection, etc., to avoid the controller from suffering from potential damages [

25].

The primary parameters of the motor model are determined by the slope of the operating environment, the vehicle’s mass, and the transmission efficiency of the power system [

26], as expressed by Equation:

where: Tm is the peak torque of the motor; grade is the climbing parameter set for the vehicle; i0 is the powertrain transmission ratio;

is the system efficiency.

The voltage equation of the permanent magnet motor based on rotor field orientation is obtained as follows:

where Rs, Ld, and Lq are the stator winding resistance, stator d-axis inductance, and stator q-axis inductance. Ψf is the magnetic chain of permanent magnets. ωr is the rotor electric angular velocity; id and iq are the d-axis and q-axis currents; and ud and uq are the d-axis and q-axis voltages, respectively.

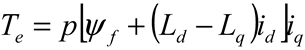

The motor torque formula is given by:

where p is the number of motor pole pairs.

Accordingly, the MCU digital twin simulation model is built as shown below.

Figure 6.

The simulation pare model of MCU.

Figure 6.

The simulation pare model of MCU.

4.2.4. Battery Management System Para Model

The main components and their functions of the battery management system simulation model in the hardware-in-the-loop test are listed: the communication interface module is responsible for simulating the communication process between the battery controller BMS and other vehicle systems; the data acquisition module realises the collection and monitoring of battery parameters such as voltage, current, temperature, etc.; the state estimation module simulates the state estimation algorithms in the battery controller BMS, which is used to estimate the battery’s residual capacity and health status, etc.; the protection control module simulates the protection functions in the battery controller BMS, including over-capacity protection, over-discharge protection, short-term protection, etc. information; the protection control module simulates the protection functions in the battery controller BMS, including overcharge protection, over-discharge protection, short circuit protection, etc. [

27].

The model of the battery addresses the mathematical relationship between the state of charge SOC of the battery and the characteristic parameters of the battery [

28]. This is shown in the following equation:

In these equations, SOCint is the initial state of charge; η is the Coulombic efficiency of the battery; Q is the capacity of the battery. Ut is the open-circuit voltage of the battery; Rt is the internal resistance of the battery; and Pbat is the output power of the battery.

The BMS digital twin simulation model is constructed as illustrated in the following figure.

Figure 7.

The simulation para model of BMS.

Figure 7.

The simulation para model of BMS.

5. Test Case Design of Sandian Platform

During the development of test cases for the digital twin simulation platform of the powertrain system, functional logic testing of typical scenarios and fault injection testing under severe conditions are designed to ensure that the parameters of the test cases align more closely with the predefined requirements established for the powertrain system. This design facilitates a scientific evaluation of the system’s functionality [

29]. Therefore, in response to the functional definitions provided by the R&D department, this chapter undertakes the development of functional requirement use cases based on relevant standards. Additionally, leveraging the technical knowledge and project experience of the project team members, targeted fault injection test cases are designed for both functional scenarios and extreme corner cases of the powertrain system.

5.1. Functional Requirements Test Cases Design

According to industry testing guidelines, each function must have corresponding individual measurable requirements, with each measurable requirement linked to one or more specific test cases [

30]. Consequently, the functional definitions of the powertrain system are decomposed into measurable requirements, enabling the subsequent design of test cases using clear pass/fail criteria to verify the predefined requirements. Based on the project characteristics, the following methods are employed to design derived test cases for the powertrain system based on functional requirements:

① Equivalent partitioning

Test cases are crafted to cover all acceptable valid data and reject invalid partitions [

31]. For both valid and invalid data, equivalence classes are identified, considering specific parameters such as output values, internal values, and time-related values.

② Boundary value analysis

Boundary value analysis complements equivalence partitioning analysis. The behavior of the powertrain system at the boundary values of specific parameters is often more unpredictable than its behavior within the partitions, making it more likely to reveal undiscovered defects. Therefore, this technique is typically used as an extension of equivalence partitioning or other black-box testing design techniques [

32].

③ Assumption error

The assumed error analysis method employs structured thinking by listing potential defects or failures and designing tests aimed at triggering these defects or failures. This list is developed based on the experiences of the testers and their colleagues, along with the collection of data regarding typical defects and failure scenarios. It embodies the collective knowledge and experience of the team.

5.2. Fault Injection Test Case Design

Fault injection represents a reliability validation technique that involves injecting faults into a system through controlled experiments to observe its behavioral responses and coping mechanisms [

33]. During system development, the dependency of software components on other system entities regarding functional failures is analyzed using supervised execution in conjunction with simulation technology. The application of fault injection techniques in powertrain simulation testing enables testers to observe the safety response mechanisms of signal interactions between various components under fault-injection conditions within the simulation environment, facilitating an assessment of the powertrain system’s reliability.

The main significance of the design of functional requirements and fault injection use cases is to study the response of important functions of the powertrain in a hardware-in-the-loop test environment. By analysing the expected goals, the project team designed the use cases to cover the two major categories of component system fault injection testing and vehicle functional testing based on the separate open and closed loop debugging of VCU, MCU, and BMS and the digital twin testing strategy of multi-controller intermodulation. A total of 673 functional requirement test cases and 419 system fault injection test cases were designed. The test cases are executed for subsequent use cases to achieve full coverage of the test, which makes the system test focus evolve from purely functional to robustness, and facilitates the execution and optimisation of subsequent system regression tests.

6. Test Results

The hardwired configuration and connections of each controller are established according to the topology diagram defined by the actual vehicle model, while the signal transmission channels of the test cabinet and software modules are debugged. The digital twin testing platform is constructed as shown below.

Figure 8.

The physical drawing of the powertrain digital twin bench.

Figure 8.

The physical drawing of the powertrain digital twin bench.

During the testing of the three-electric system, strict environmental conditions are implemented. The temperature is maintained within a constant range of 10-45°C, and humidity is controlled between 40% and 60%. Additionally, anti-static measures are taken to protect circuit boards and components from electrostatic interference. The testing environment is also equipped with specialized power regulation devices and signal generators to ensure stable power supply and signal input conditions during hardware testing. By rigorously controlling environmental conditions, external factors affecting test results are effectively eliminated, ensuring the accuracy and reliability of the data collected.

According to the test requirements of the three power systems, the project has designed 673 test cases of functional requirements category, containing 13 items, up and down function, slow charging function, fast charging function, driving mode, inverter function, energy recovery, creep braking, intelligent replenishment, gear EPB, slow charging lockout, water cooling of batteries, battery thermal loss of control, and drive driving function; 419 test cases of system fault injection, containing 4 items of VCU, BMS, MCU and system class 4 items.

This chapter selects the power up/down and driving condition validations from the functional requirement test cases to assess the effectiveness of the digital twin three-electric system testing. Furthermore, typical voltage-related fault injection scenarios are selected to discuss the comparative advantages of three-electric simulation testing versus actual vehicle testing.

6.1. Functional Simulation Test

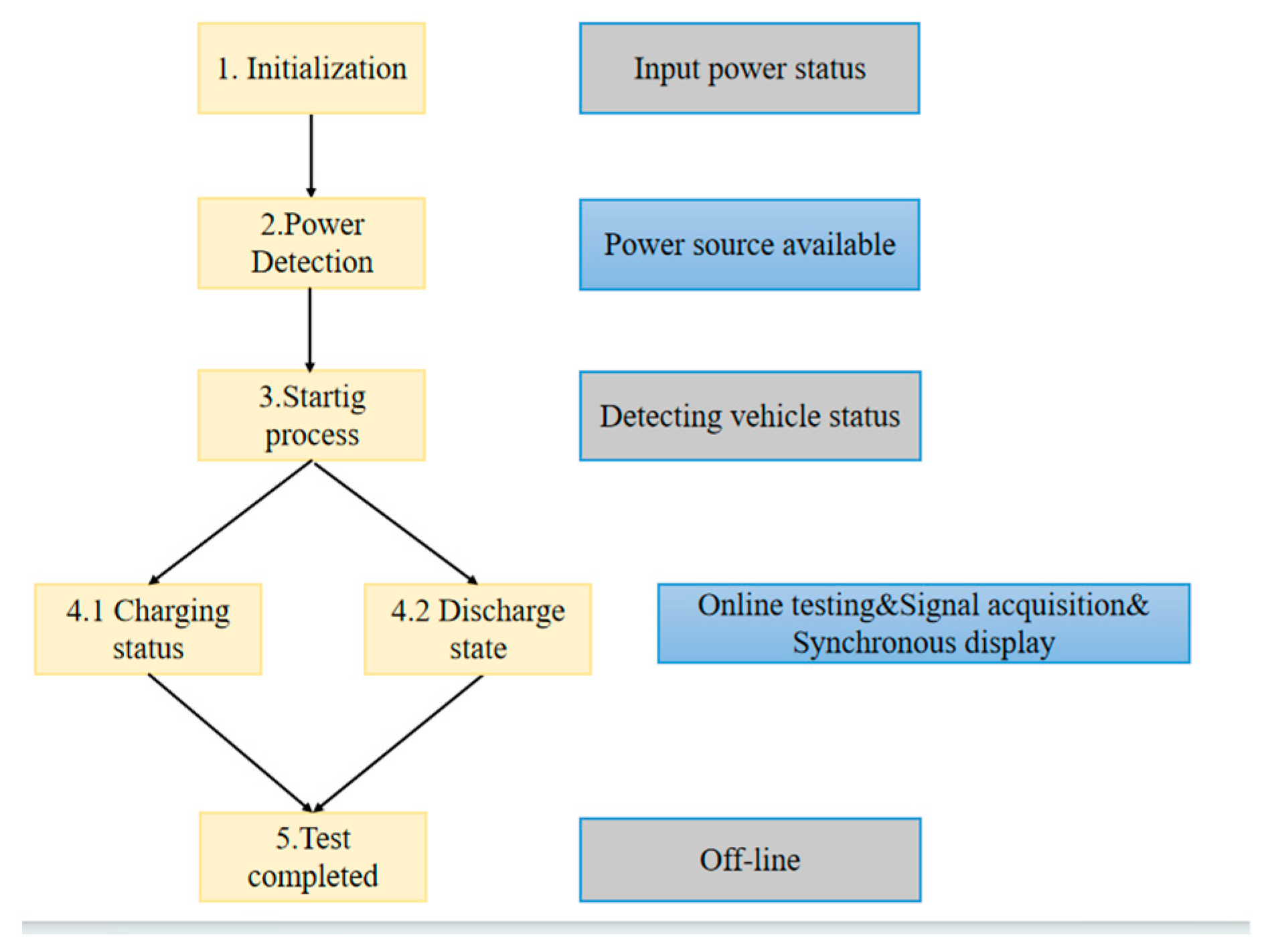

In the 13 sub-projects of the functional test, they all follow the five major steps of initialisation, power detection, start-up process, charge/discharge status, and test completion.

Figure 9.

Logical flow diagram of functional testing for the real vehicle.

Figure 9.

Logical flow diagram of functional testing for the real vehicle.

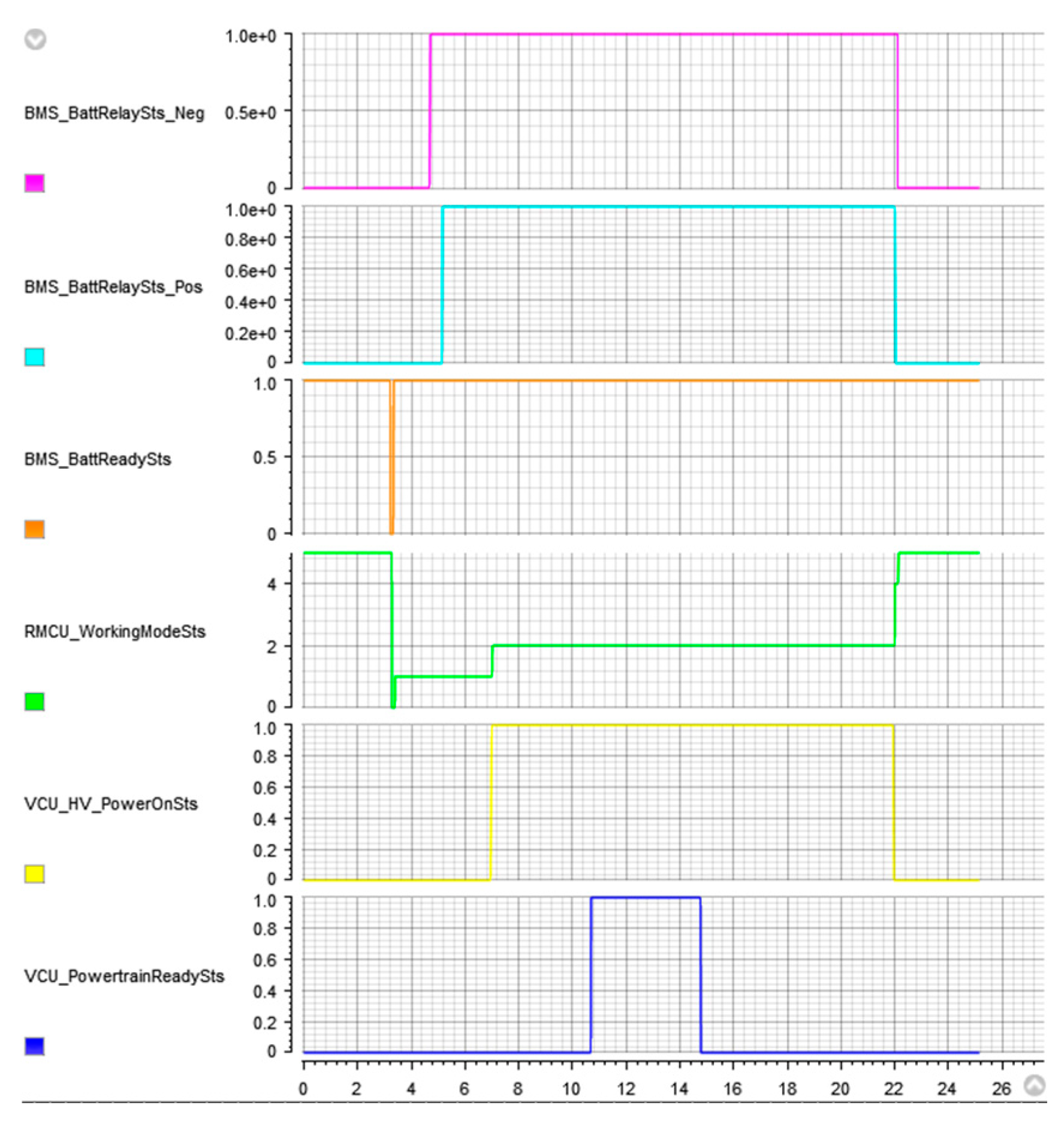

Based on the principles of multi-controller participation, typical power up/down conditions of the powertrain system are tested using the digital twin platform.

Figure 10.

Key signal timing diagram of power Up/Down conditions.

Figure 10.

Key signal timing diagram of power Up/Down conditions.

As shown in the figure, during the power-up process of the powertrain system, the status flag signals of the BMS and MCU, specifically BMS_BattReadySts and RMCUWorkingModSts, transition from their initial default states (1 and 5, respectively) to the high-voltage standby state (0) at the 3.5-second mark. After 1.8 seconds in the high-voltage standby state, the BMS indicates the statuses of the main negative relay (BMS_BattRelay_Neg) and main positive relay (BMS_BattRelay_Pos), which switch from open (0) to closed (1), marking the completion of high-voltage power supply to the system. Once the VCU confirms the high-voltage power supply completion feedback from the BMS and MCU, it issues a command (VCU_HV_PowerOnSts = 1), which changes the motor status signal (RMCUWorkingModSts) from the high-voltage standby state (value 1) to the operational state (value 2). Subsequently, provided that there are no faults in the feedback from each controller, the VCU transitions the powertrain system to the ready state (VCU_PowertrainReady = 1).

At the power-down moment, the powertrain system first changes from the ready state to power down (VCU_PowertrainReady = 0). Then, at the 22-second mark, the VCU issues a high-voltage power down command (VCU_HV_PowerOnSts = 0), resulting in the disconnection of the main positive and negative relays of the battery. The status flag signals of the BMS and MCU (BMS_BattReadySts and RMCUWorkingModSts) revert to their initial default states. The three-electric testing platform successfully completes the testing of power up/down conditions.

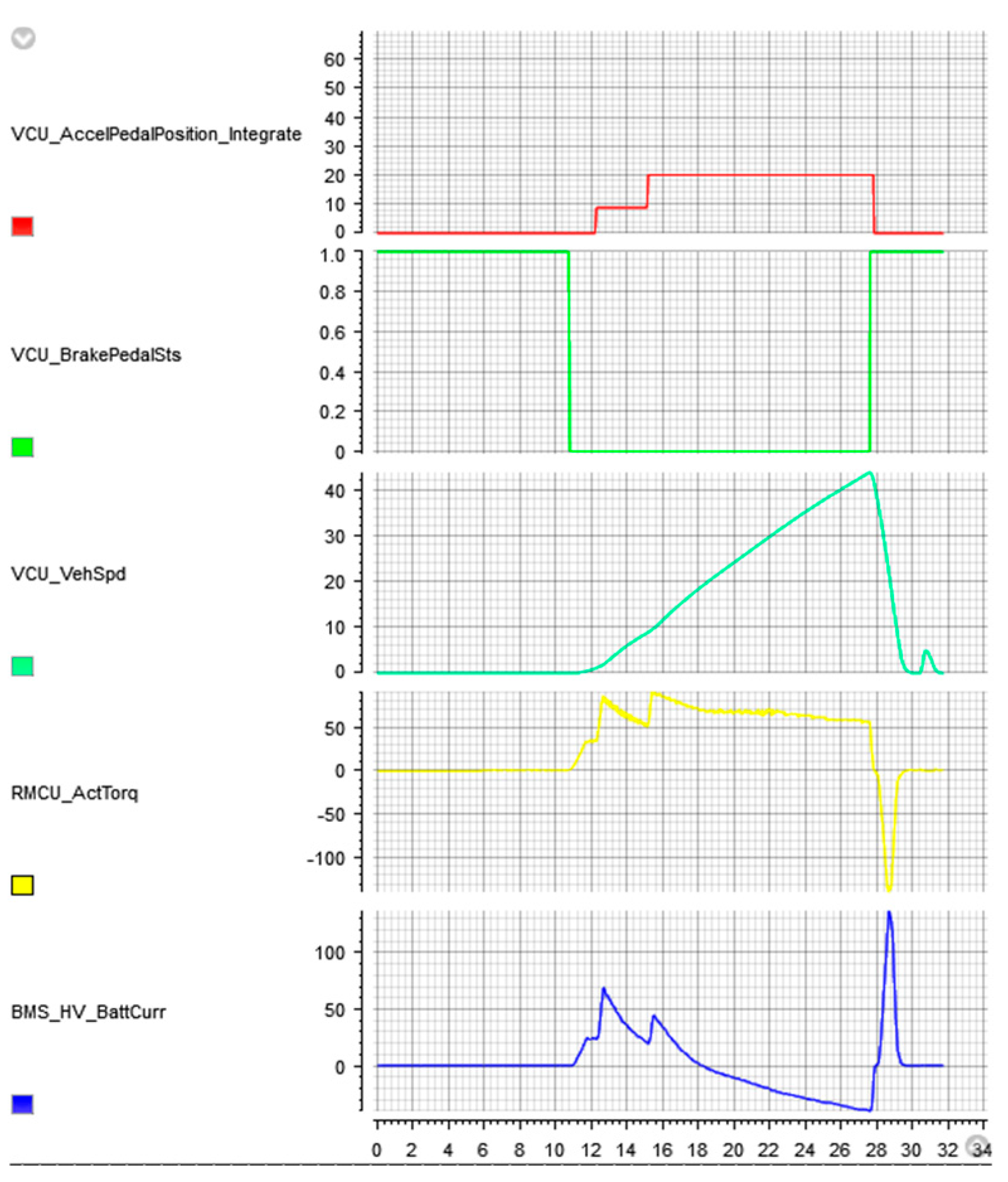

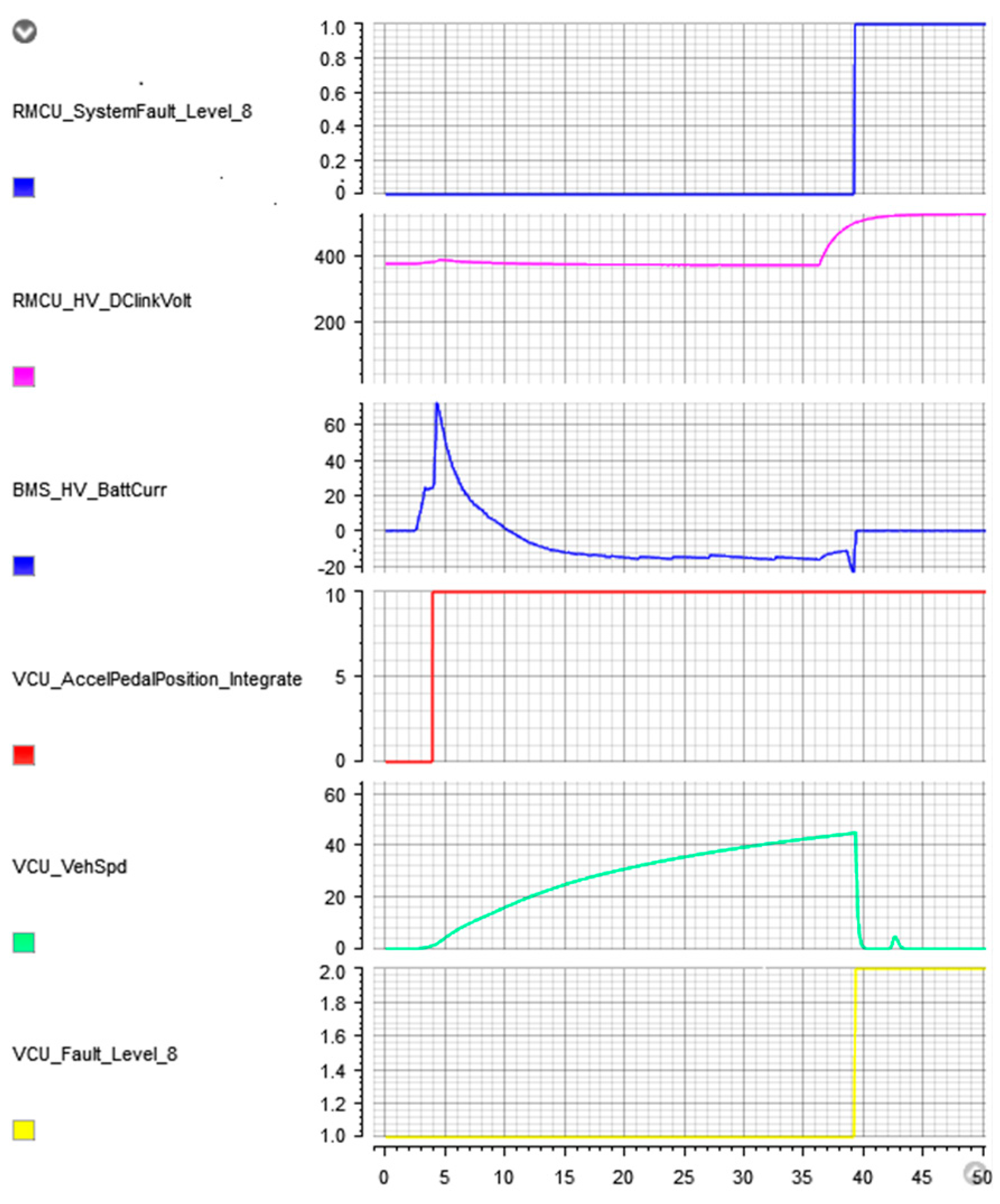

Figure 11.

Key signal timing diagram of driving and braking conditions.

Figure 11.

Key signal timing diagram of driving and braking conditions.

The above diagram illustrates the signal timing for the driving and braking conditions of the powertrain system. As seen in the figure, at the 11-second mark, when the VCU-related signals indicate that the accelerator pedal position (VCU_AccelPedalPosition = 0) and brake pedal switch (VCU_BrakePedalSts = 0) are released, the vehicle begins to accelerate due to the creep functionality, causing the vehicle speed signal (VCU_VehSpd) to gradually increase. At the 13-second and 15.5-second marks, the driver operates the accelerator pedal position, increasing it from 0 to 10% and then to 20%. Consequently, the torque feedback from the MCU (RMCU_ActTorq) begins to increase non-linearly, with the BMS working current (BMS_HV_BattCurr) peaking at 60A.

At the 27.8-second mark in the figure, the driver depresses the brake pedal, resulting in (VCU_BrakePedalSts = 1). The vehicle speed signal (VCU_VehSpd) decreases from 42 km/h as the system initiates energy recovery, with the MCU feedback torque (RMCU_ActTorq) becoming negative and outputting negative torque. The BMS working current (BMS_HV_BattCurr) also becomes negative, with a peak negative value of -46A, ultimately reducing the vehicle speed to zero. Thus, the testing of the driving and braking conditions of the three-electric system is completed.

In summary, the recorded parameters from the above tests indicate that the functional logic processes of the digital twin simulation technology and the actual vehicle testing align effectively, demonstrating the validity of the digital twin model. Multiple condition parameters are set as required, enhancing the efficiency of functional testing.

6.2. Functional Requirements Test Cases Design

To achieve comprehensive testing of the powertrain system within the scope of fault injection, it is necessary to inject signals that surpass predefined system setpoints. By observing the responses of various controllers to these disturbances, the fault response mechanisms of the powertrain system can be evaluated. However, during actual vehicle testing, the voltage levels at which the drive motor and battery pack operate normally range from 320 to 425 V, significantly exceeding the human safety voltage range of 0 to 36 V. Executing such test cases on actual vehicles poses uncertainties, such as high voltage leakage, which could endanger the safety of testing personnel.

As a result, this chapter employs a digital twin testing platform to execute the test cases, injecting over-voltage faults into the motor bus voltage during the execution of environmental test cases. The variations in the test result signals are illustrated in the following figure.

As shown in the figure, when the driver presses the accelerator pedal (VCU_AccelPedalPosition = 10), the vehicle speed signal (VCU_VehSpd) begins to increase from zero. At the 36.6-second mark, the software ControlDesk is used to forcibly alter the MCU bus voltage signal (RMCU_HV_DClinkVolt) from the normal range of 375 V to an abnormal range of 525 V. This action prompts the MCU to report a level 8 fault at the 39.1-second mark (RMCU_SystemFault_Level_8 = 1). Consequently, the VCU_Fault_Level_8 also transitions to 1, causing the system to command the vehicle to decelerate to zero. The BMS working current (BMS_HV_BattCurr) gradually decreases to zero. The changes in signal behavior align with the predefined fault response mechanisms.

Figure 12.

Key signals Timing diagram of typical fault injection working condition.

Figure 12.

Key signals Timing diagram of typical fault injection working condition.

6.3. Discussion

The multi-controller coordination Hardware-in-the-Loop test bench, based on digital twin technology, allows the simulation of routine driver operations or key signals from controllers as inputs. This setup facilitates the observation of characteristic signal flow and transmission among various controllers, effectively simulating the signal interaction processes between different controllers within the powertrain system.

In the context of functional testing for electric vehicle powertrain systems, the digital twin testing platform encompasses several components, including wiring harness design (signal classification and harness production), open-loop testing (building the open-loop model, establishing the open-loop testing interface, and testing input/output signals), closed-loop testing (integrating the digital twin model in a closed loop), and functional debugging. This testing platform can execute functional test cases identical to those performed on actual vehicles while enhancing testing efficiency without compromising test effectiveness.

In the realm of voltage and current-related fault injection scenarios, direct execution of tests on actual vehicles poses safety risks for personnel. The use of a digital twin three-electric test bench effectively mitigates these risks, demonstrating significant advantages in simulation testing.

7. Conclusions

7.1. Current Status

1. The digital twin testing technology effectively inherits the characteristic of high flexibility in parameter settings from software testing. Due to its capability to efficiently simulate the working environment required by controllers, it is applied in the early development and testing of powertrain systems prior to the prototype manufacturing phase. This technological approach aligns organically with the rapidly evolving demands of the new energy industry and is gradually becoming a focal point for researchers involved in the functional development of electric vehicle powertrains.

2. Variations in vehicle models and configurations lead to insufficient coverage in functional testing during powertrain development. This paper establishes a digital twin simulation model based on multi-controller joint debugging theory, which accurately simulates the signal interaction processes among different controllers within the powertrain system. It effectively characterizes the intrinsic relationships and computational logic governing signal transmission, thereby becoming a significant driver for product development within enterprises.

3. To accommodate the stringent compression of development cycles in powertrain systems, digital twin three-electric simulation testing technology exhibits the same accuracy in functional testing as actual vehicle testing and demonstrates superior advantages in fault injection scenarios. This technology serves as an effective evaluation method for the logical development of critical controller components in electric vehicles, contributing to the ongoing advancement of electric vehicles towards safer and more reliable outcomes.

7.2. Prospects

Future research opportunities include the following:

① When evaluating the performance of powertrain systems, future studies should prioritize bridging the gaps and differences between laboratory simulations and actual vehicle testing. The first step involves optimizing the scalability of the digital twin paramodel. For example, while the current model primarily focuses on longitudinal dynamics, it should also consider lateral dynamics and the impacts of other systems on the powertrain.

② Development of large artificial intelligence models aimed at specific scenarios is necessary to enhance the sensitivity of powertrain systems to environmental changes. Utilizing digital twin (DT) technology and leveraging collected vast datasets of operational conditions—such as those caused by rain, snow, wind, frost, or extreme temperatures—will enable the assessment of vehicle performance under various conditions, ultimately optimizing electric vehicle powertrain performance and accurately predicting lifespan.

③ One of the typical advantages of the digital twin Sandian testing technology is its efficiency. Future execution methods should evolve toward automation, beginning with the input of requirement documents. The testing platform should automatically provide a comprehensive set of automated testing services, including the automatic generation of test cases, configuration of test programs, execution of tests, recording of test data, and report writing. This evolution will not only significantly enhance testing efficiency but also reduce occurrences of inefficient work practices.

Author Contributions

Conceptualization, Chong Li, Yong You and Jianmei Lei; methodology, Chong Li, Yong You and Jianmei Lei; software, Chong Li, and Yong You; validation, Chong Li, Yong You and Liangyi Yang; formal analysis, Chong Li and Liangyi Yang; investigation, Chong Li, Yong You and Liangyi Yang; funding, Wei Xu; data curation, Chong Li and Wei Xu; writing—original draft preparation, Yong You and Chong Li; writing—review and editing, Chong Li.

Funding

This study was funded by the Research on Testing and Evaluation of Electronic and Electrical Architecture and Application Technology of Vehicle Integration of the 2021 National Key Research and Development Program Project (grant number: 2021YFB2500904).

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

Thank you to Zhou Jian from Shanghai Technical University for providing detailed and feasible ways to present images and tables in this paper. Also, gratitude to Zhou Jun from Chery Automobile Co., Ltd., for providing valuable insights for the writing of this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bhatti, G.; Mohan, H.; Raja Singh, R. Towards the future of smart electric vehicles: Digital twin technology. Renewable and Sustainable Energy Reviews 2021, 141. [CrossRef]

- Miraftabzadeh, S.M.; Longo, M.; Di Martino, A.; Saldarini, A.; Faranda, R.S. Exploring the Synergy of Artificial Intelligence in Energy Storage Systems for Electric Vehicles. Electronics 2024, 13. [CrossRef]

- Narimani, M.; Emami, S.A.; Banazadeh, A.; Modarresi, A. A unified thermal management framework for electric vehicles: Design and test bench implementation. Applied Thermal Engineering 2024, 248. [CrossRef]

- Ma, J.; Zhou, Y.; Lian, J. Comparative assessment and improvement of the powertrain supplied by hybrid energy source in fuel cell vehicles. Sustainable Energy Technologies and Assessments 2024, 65. [CrossRef]

- Liu, X.; Zhao, F.; Hao, H.; Liu, Z. Comparative analysis for different vehicle powertrains in terms of energy-saving potential and cost-effectiveness in China. Energy 2023, 276. [CrossRef]

- LIU Fawang, CAO Jianyong, ZHANG Zhiqiang, XU Xiaoqing, CHEN Zhen. A Scenario-Based “Three-Pillar” Safety Testing and Assessment Method for Intelligent and Connected Vehicles. Chinese Journal of Automotive Engineering 2023, 13(01). [CrossRef]

- Chen, Y. Research on collaborative innovation of key common technologies in new energy vehicle industry based on digital twin technology. Energy Reports 2022, 8, 15399-15407. [CrossRef]

- Frederico Ferreiraa, Vasco Amarala, Fernando Brito e Abreu.Digital twinning for smart restoration of classic cars. In Proceedings of the 5th International Conference on Industry 4.0 and Smart Manufacturing, Caparica, Portugal, 24 May 2023.

- Demetrious T. Kutzke, James B. Carter, Benjamin T. Hartman. Subsystem selection for digital twin development: A case study on an unmanned underwater vehicle. Ocean Engineering 2021, 223. [CrossRef]

- Zhao Shulian, Lai Fei, Li Keqiang, Chen Tao. Research on Intelligent Vehicle Test Method Based on Digital Twin Technology. Automotive Engineering 2023, 45(1) 42-51. [CrossRef]

- 11. Zhang Shiyuan. Research and Implementation of a Digital Twin System for Automatic Driving Testing. Master, Changan University, Xian, China, 3 June 2023.

- JIANG Nanyu, WU Dongmei, DU Changqing, XIONG Jianchang. HIL Modeling and Testing of Pure Electric Vehicle Based on dSPACE. Automation & Instrumentation 2021,36(3):70-75. [CrossRef]

- Hang Yawei, Han Dong. Research on Controller Fault Injection and AutomatedTesting Technology Based on HIL. Mechatronics, 2022, 06: 58-64.

- Liu Jiangbo, Yang Fasong, Sun Tao. Vehicle Multi-ECU Hardware-in-the-Loop Test and Analysis. Agricultural Equipment,2018 56(8):88-92. [CrossRef]

- Tao fei, Liu Weilan, Zhang Meng. Five-dimension digital twin model and its ten applications. Computer Integrated Manufacturing Systems, 2019, 25(01): 1-18.

- Soeiro, L.G.G.; Filho, B.J.C. Vehicle Power System Modeling and Integration in Hardware-in-the-Loop (HIL) Simulations. Machines 2023, 11. [CrossRef]

- Xiao, M.; Chen, L.; Feng, H.; Peng, Z.; Long, Q. Sustainable and robust route planning scheme for smart city public transport based on multi-objective optimization: Digital twin model. Sustainable Energy Technologies and Assessments 2024, 65. [CrossRef]

- Kasri, A.; Ouari, K.; Belkhier, Y.; Oubelaid, A.; Bajaj, M.; Berhanu Tuka, M. Real-time and hardware in the loop validation of electric vehicle performance: Robust nonlinear predictive speed and currents control based on space vector modulation for PMSM. Results in Engineering 2024, 22. [CrossRef]

- Lanqi Zhou, Dongpo Yang , Xiaohua Zeng, Xuanming Zhang, Dafeng Song. Multi-objective real-time energy management for series–parallel hybrid electric vehicles considering battery life. Energy Conversion and Management, 2023, 290,11734. [CrossRef]

- Vladislav Dygaloa, Andrey Kellerb, Aleksey Shcherbin. Principles of application of virtual and physical simulation technology in production of digital twin of active vehicle safety systems. In Proceedings of the XIV International Conference 2020 SPbGASU, Moscow, Russia, 5 June 2020. [CrossRef]

- Xu Zhe. Simulation of Virtual-real Hybrid Traffic Scene Based on Digital Twin. Master, Changan University, Xian, China, 26 May 2023.

- Shi, J.; Wang, X.; Zhang, Z.; Zhang, C.; Chen, J. Optimization of energy flow in thermal management of electric vehicles based on real vehicle testing and digital twin simulation. Case Studies in Thermal Engineering, 2024, 60. [CrossRef]

- Xie, Y.; Li, Y.; Zhao, Z.; Dong, H.; Wang, S.; Liu, J.; Guan, J.; Duan, X. Microsimulation of electric vehicle energy consumption and driving range. Applied Energy 2020, 267. [CrossRef]

- Chen, Z.; Wu, S.; Shen, S.; Liu, Y.; Guo, F.; Zhang, Y. Co-optimization of velocity planning and energy management for autonomous plug-in hybrid electric vehicles in urban driving scenarios. Energy 2023, 263. [CrossRef]

- Huang, Z.; Wen, X.; Zhu, J.; Feng, Z. Research on fault location of DC line in UHV converter station based on digital twin technology. Measurement: Sensors 2024, 33. [CrossRef]

- HUANG Yanwei, XIONG Shaohua. An Internal Model Control-Based Observer for Current Loops in Permanent Magnet Synchronous Motor. Proceedings of the CSEE, 2016, 36(11): 3070-3075. [CrossRef]

- Weidong Fang, Yihan Guo, Ji Zhang. Generative Adversarial Network-Based Voltage Fault Diagnosis for Electric Vehicles under Unbalanced Data. Electronics, 2024, vol. 13, pp. 3131-3149. [CrossRef]

- Li, W.; Cai, D.; Wu, S.; Zhang, G.; Zhang, F. A multi-purpose battery energy storage system using digital twin technology. International Journal of Electrical Power & Energy Systems 2024, 157. [CrossRef]

- ZHAO Linhui, LUO Quan, LIU Zhiyuan. Study on test case generation and integration testing method for vehicle electronic control unit. Harbin Institution Technology, 2018 46(4): 48-53. [CrossRef]

- Rajković, P.; Aleksić, D.; Djordjević, A.; Janković, D. Hybrid Software Deployment Strategy for Complex Industrial Systems. Electronics 2022, 11. [CrossRef]

- Zhou Wenshuai, Zhu Yu, Zhao Xiangmo, Wang Runmin, Xu Zhigang. Vehicle Cut-in Test Case Generation Methods for Testing of Autonomous Driving on Highway. Automobile Technology 2021(1): 11-18. [CrossRef]

- RAN Yiming, ZHANG Yadong, RAO Chang, JIANG Lei. An Automatic Generation Method of Safety Test Cases for Dangerous Scenarios of Urban Rail Transit FAO System. Railway Standard Design 2024 69:1-12. [CrossRef]

- Ferlini, F.; Viel, F.; Seman, L.O.; Pettenghi, H.; Bezerra, E.A.; Leithardt, V.R.Q. A Methodology for Accelerating FPGA Fault Injection Campaign Using ICAP. Electronics 2023, 12. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).