Submitted:

06 September 2024

Posted:

09 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Results and Discussion

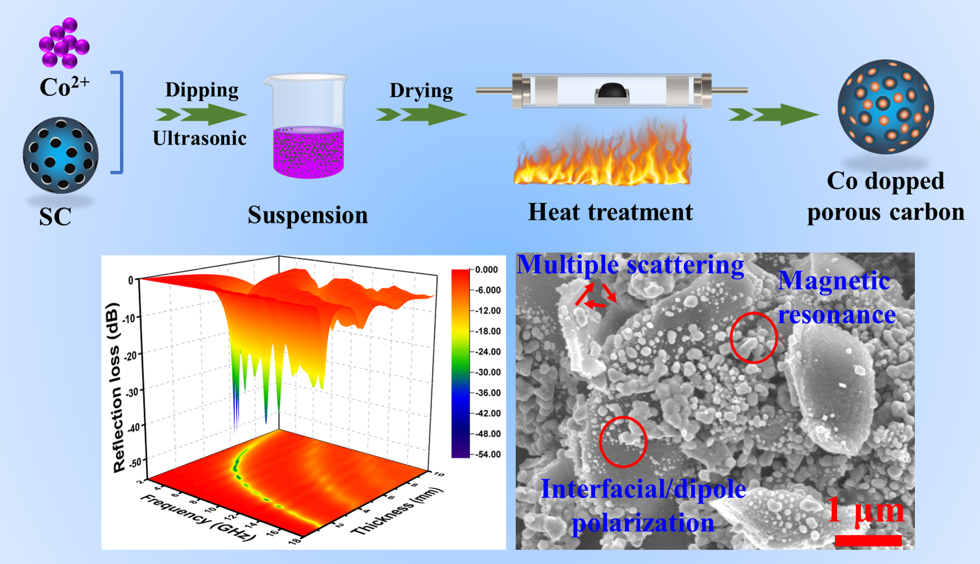

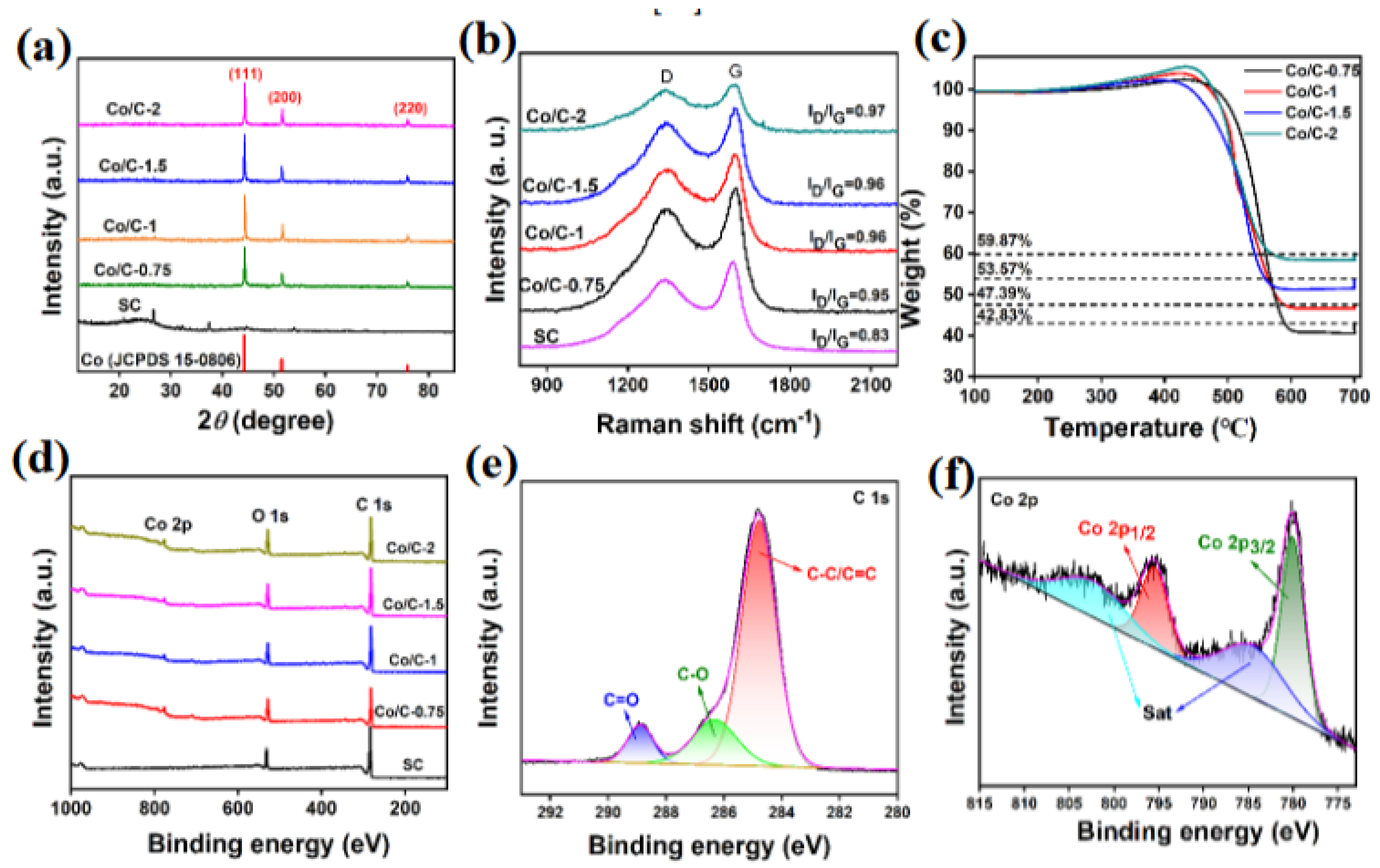

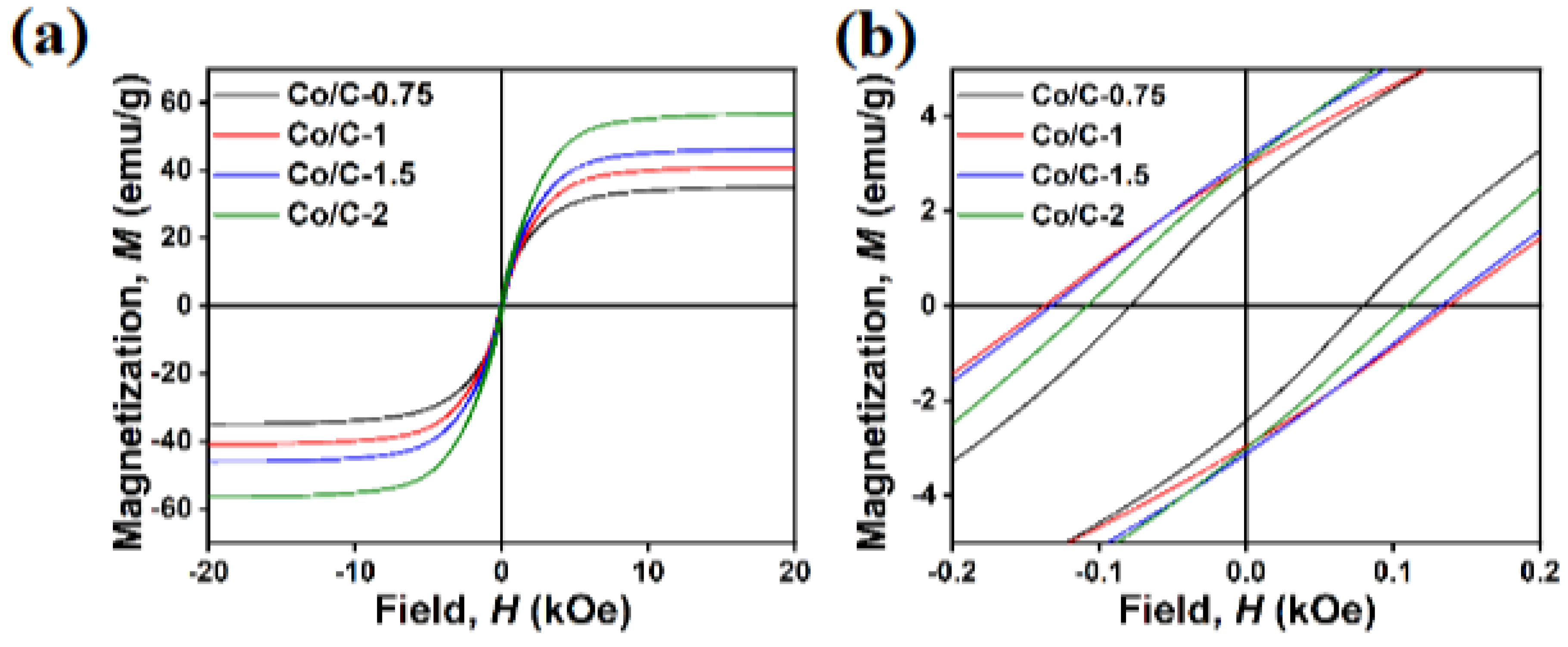

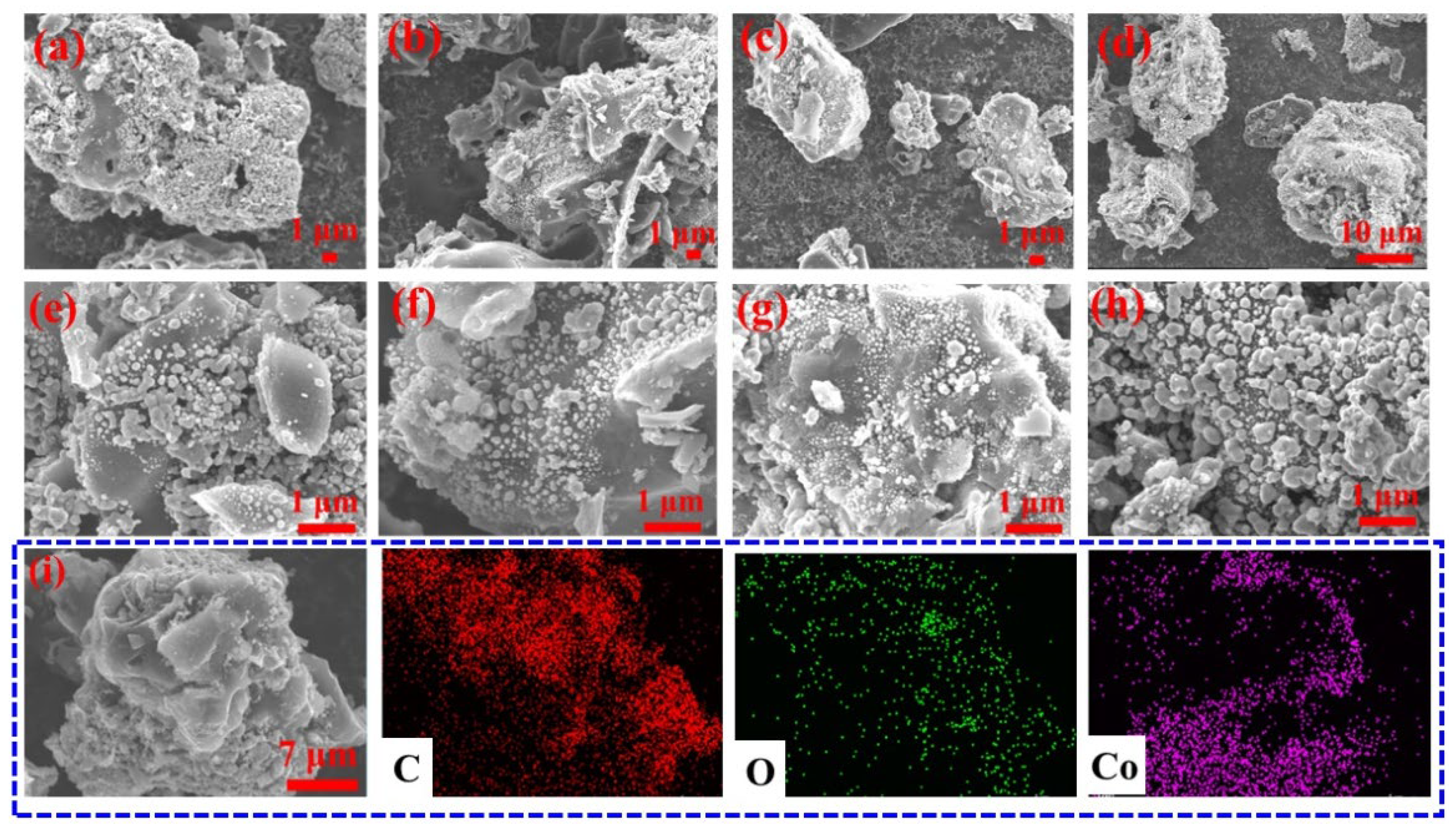

2.1. Morphology and Structure

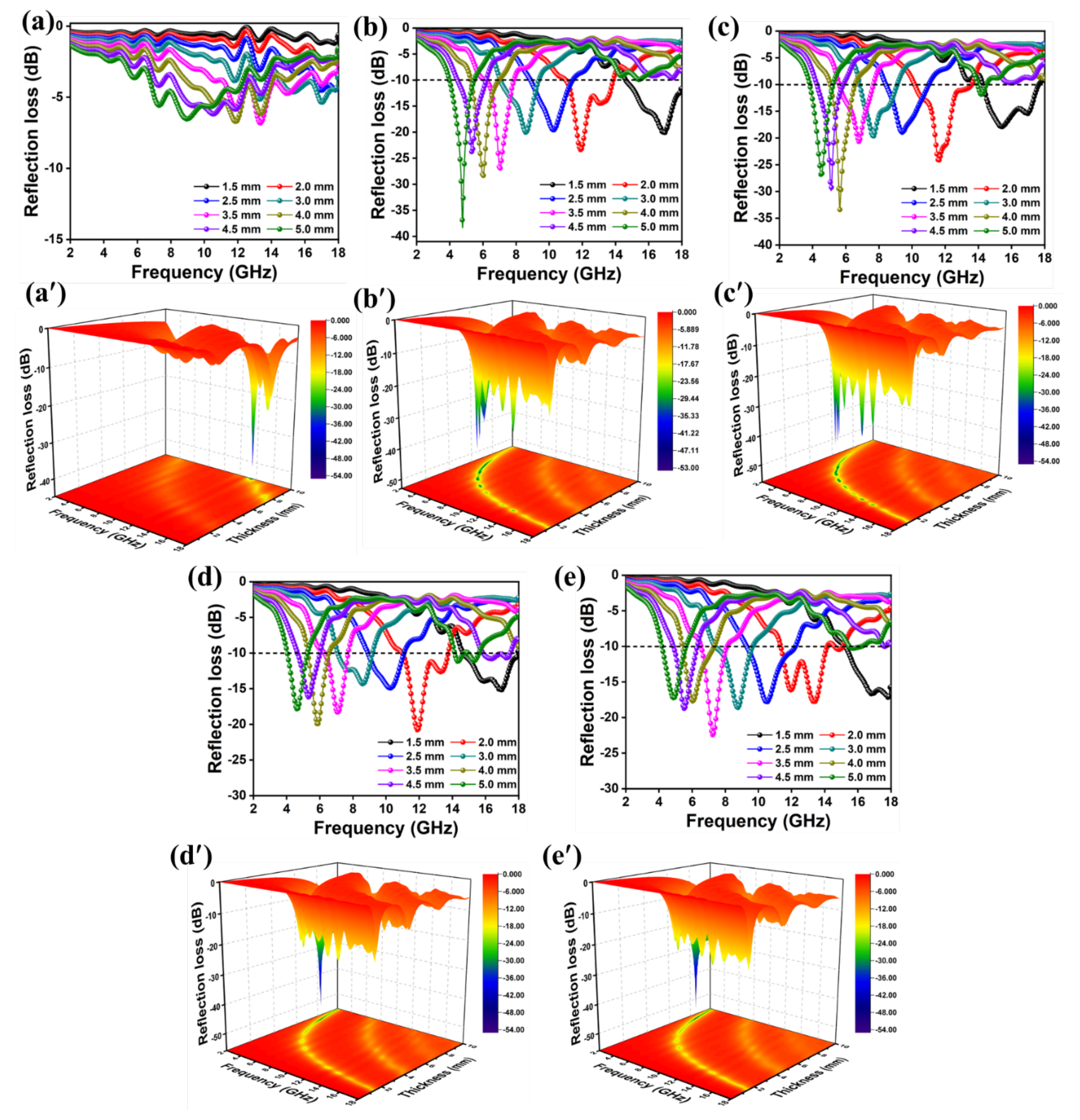

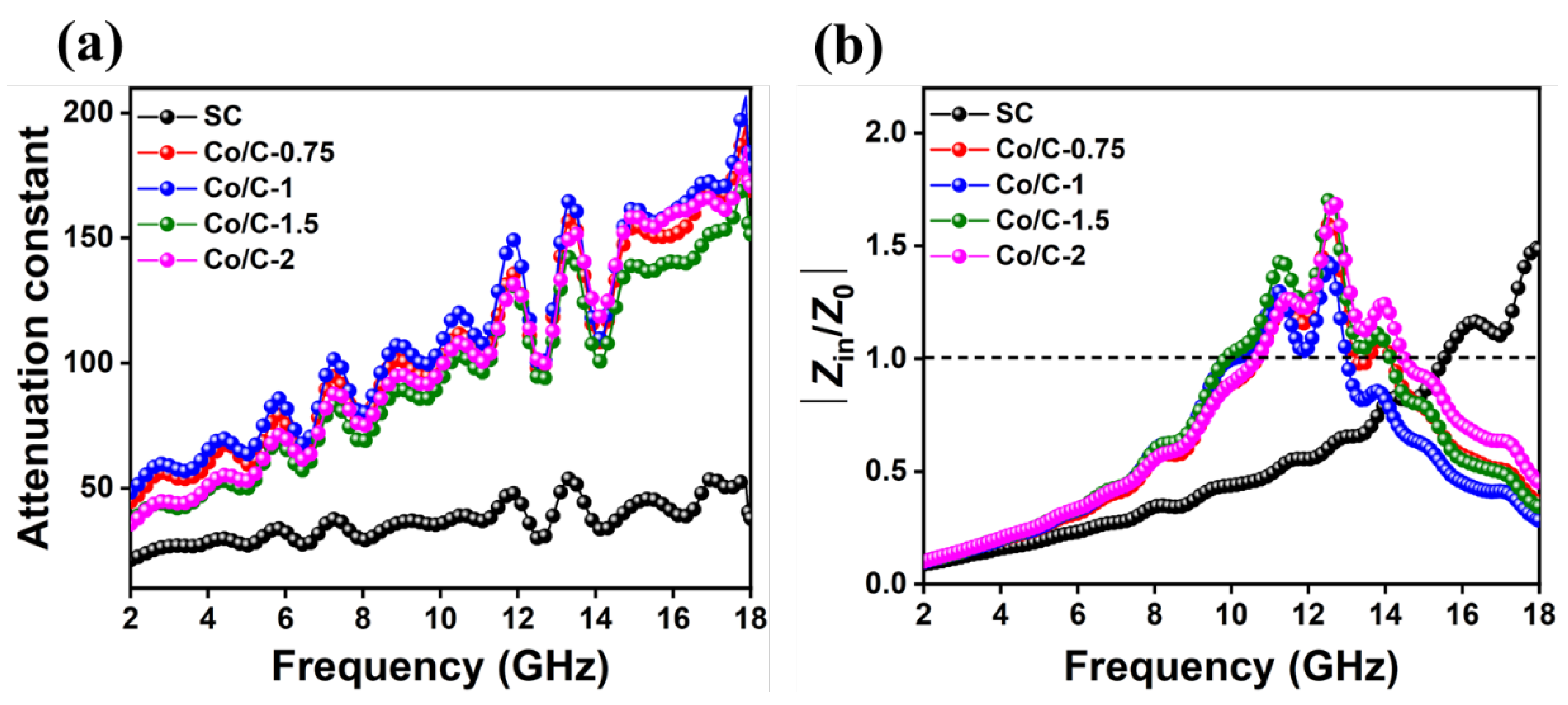

2.2. Microwave Absorption Performance

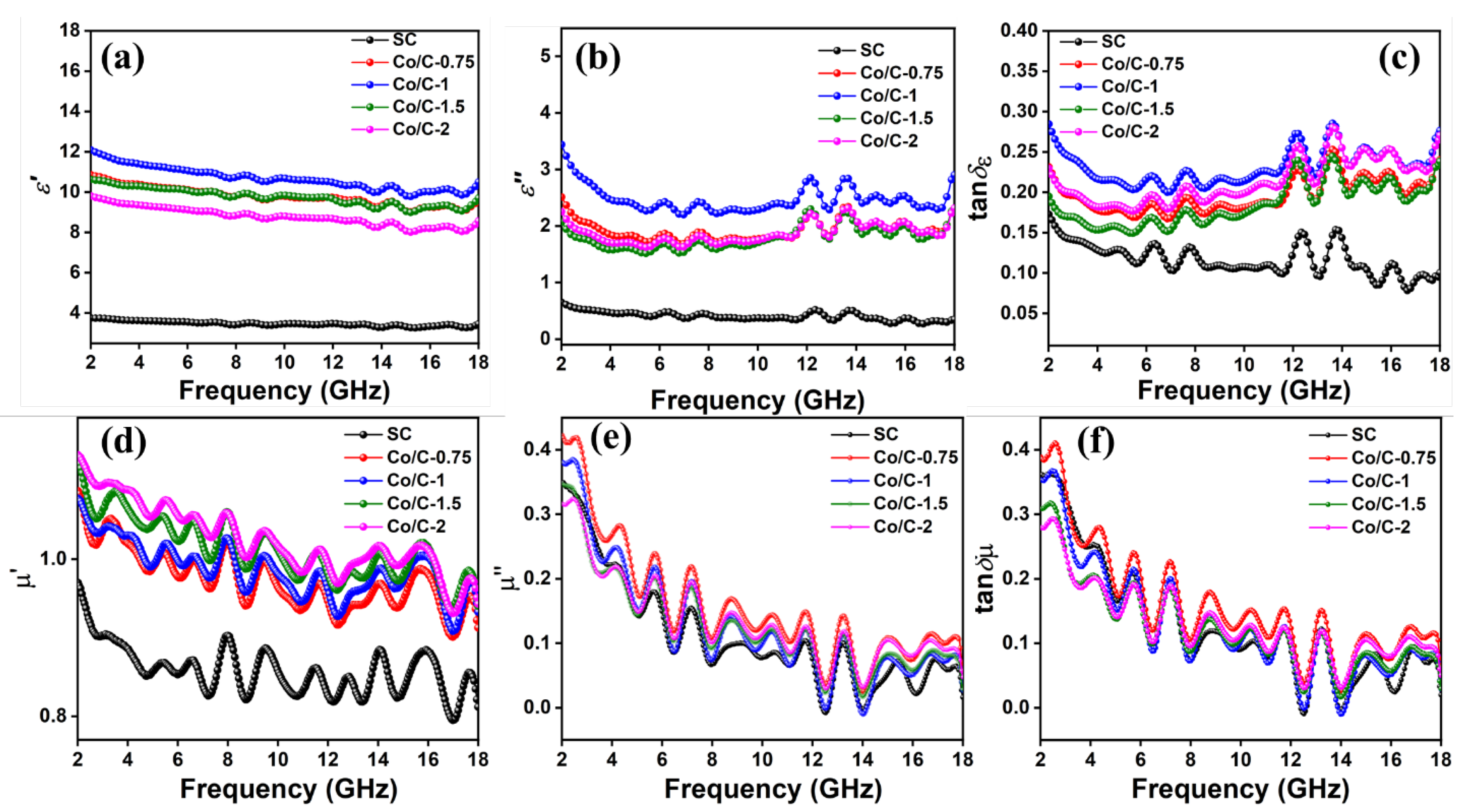

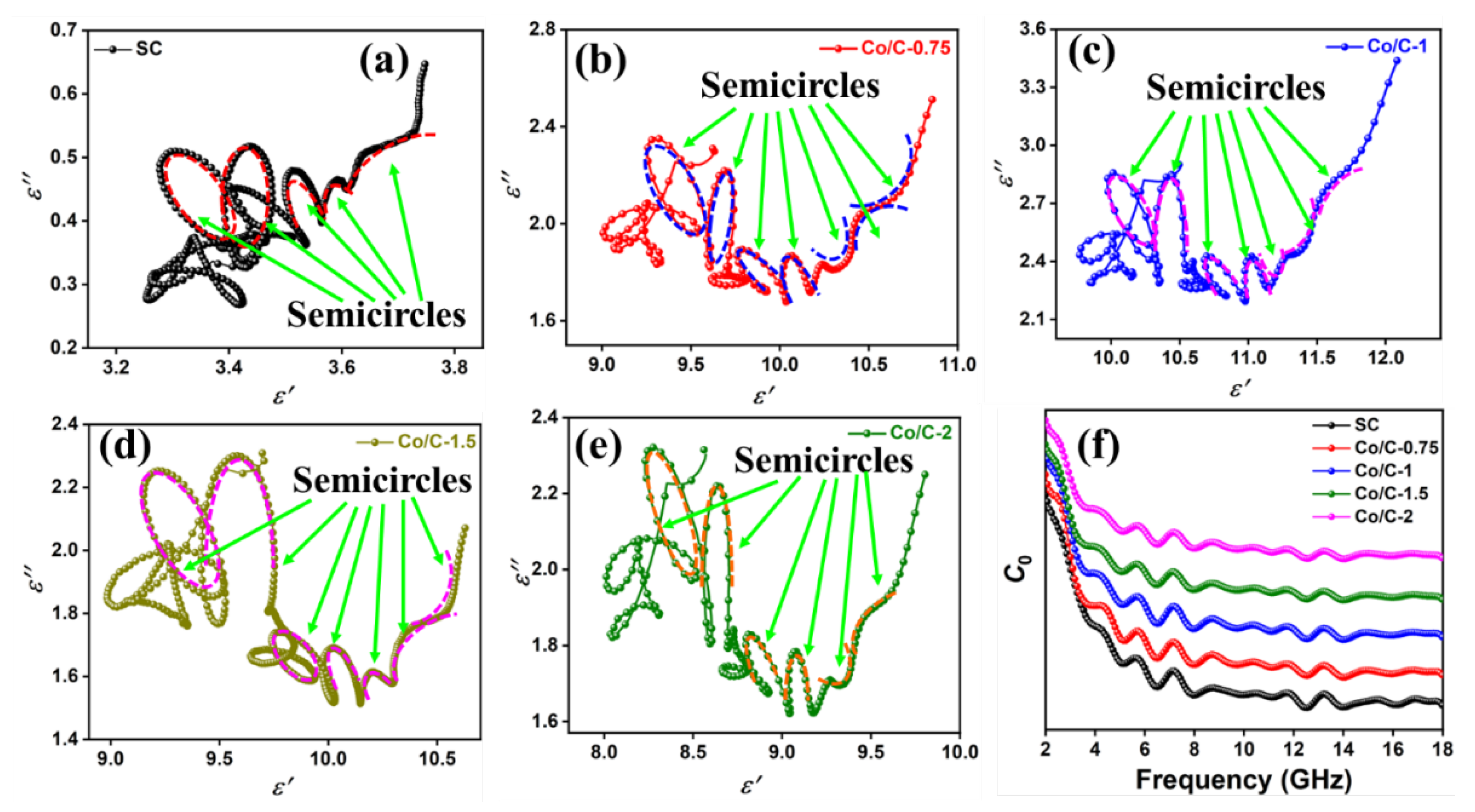

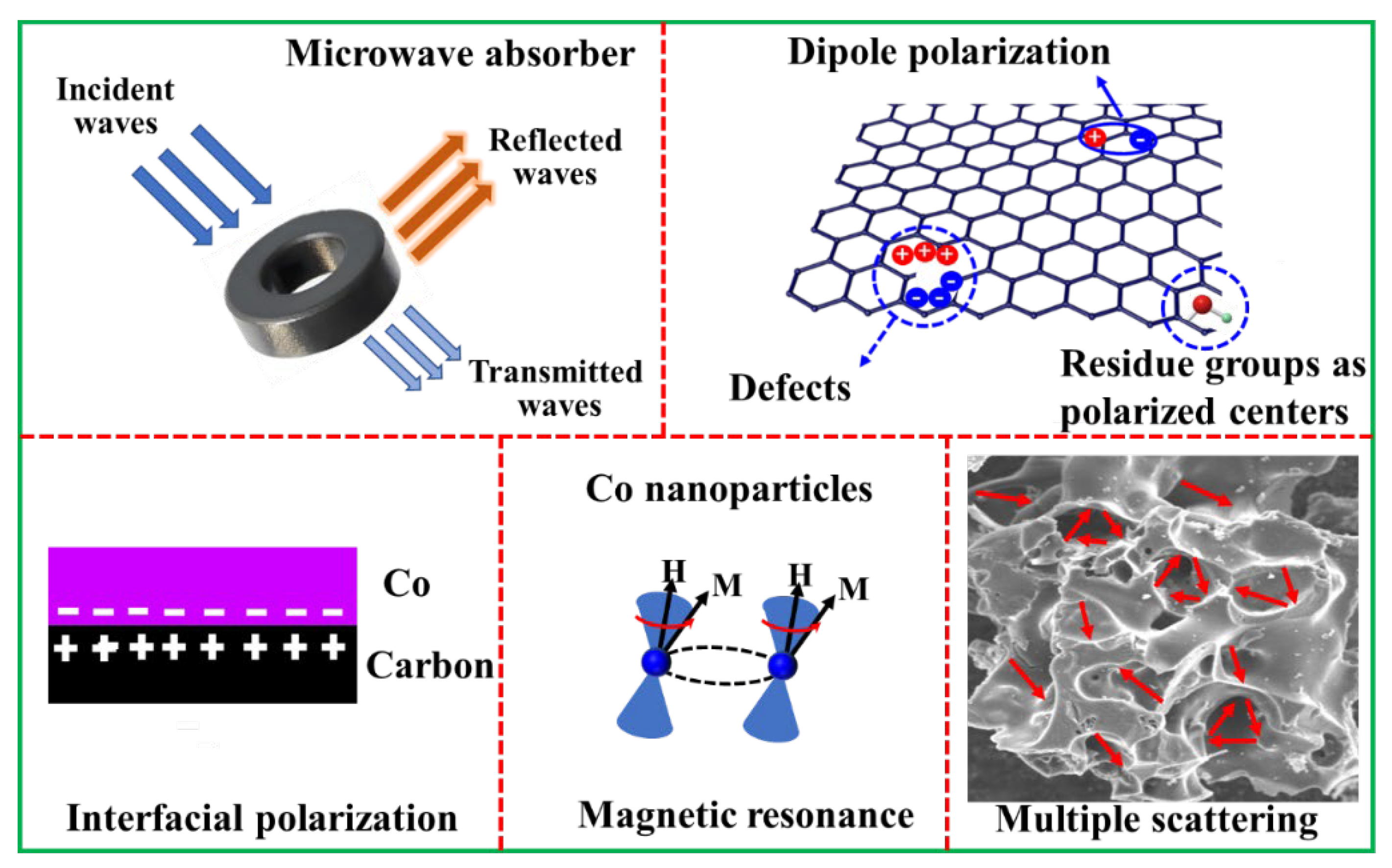

2.3. Microwave Absorption Mechanism

3. Materials and Methods

3.1. Materials

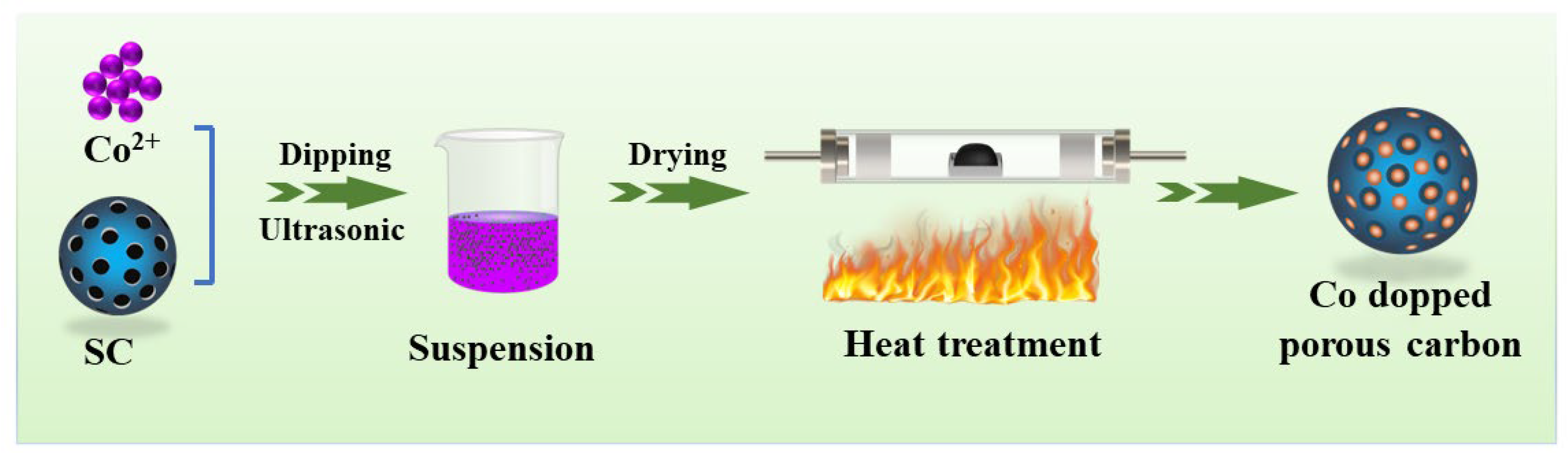

3.2. Preparation of Hierarchical Porous Co/C Absorbers

3.3. Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guan, H.; Wang, Q.; Wu, X.; Pang, J.; Jiang, Z.; Chen, G.; Dong, C.; Wang, L.; Gong, C. Biomass derived porous carbon (BPC) and their composites as lightweight and efficient microwave absorption materials. Compos. Pt. B-Eng. 2021, 207. [Google Scholar] [CrossRef]

- Lv, H.; Yang, Z.; Pan, H.; Wu, R. Electromagnetic absorption materials: Current progress and new frontiers. Prog. Mater. Sci. 2022, 127. [Google Scholar] [CrossRef]

- Zhao, H.; Cheng, Y.; Liu, W.; Yang, L.; Zhang, B.; Wang, L.P.; Ji, G.; Xu, Z.J. Biomass-Derived Porous Carbon-Based Nanostructures for Microwave Absorption. Nano-Micro Lett. 2019, 11. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Gu, W.; Wang, G.; Zheng, J.; Pei, C.; Fan, F.; Ji, G. Sustainable wood-based composites for microwave absorption and electromagnetic interference shielding. J. Mater. Chem. A 2020, 8, 24267–24283. [Google Scholar] [CrossRef]

- Li, W.; Liu, Y.; Guo, F.; Du, Y.; Chen, Y. Self-assembly sandwich-like Fe, Co, or Ni nanoparticles/reduced graphene oxide composites with excellent microwave absorption performance. Appl. Surf. Sci. 2021, 562. [Google Scholar] [CrossRef]

- Qu, Z.; Wang, Y.; Wang, W.; Yu, D. Robust magnetic and electromagnetic wave absorption performance of reduced graphene oxide loaded magnetic metal nanoparticle composites. Adv. Powder Technol. 2021, 32, 194–203. [Google Scholar] [CrossRef]

- Lu, X.; Li, X.; Zhu, W.; Xu, H. Construction of embedded heterostructures in biomass-derived carbon frameworks for enhancing electromagnetic wave absorption. Carbon 2022, 191, 600–609. [Google Scholar] [CrossRef]

- Yang, W.; Yan, L.; Jiang, B.; Wang, P. Crumpled nitrogen-doped porous carbon nanosheets derived from petroleum pitch for high-performance and flexible electromagnetic wave absorption. Ind. Eng. Chem. Res. 2022, 61, 2799–2808. [Google Scholar] [CrossRef]

- Wang, H.; Meng, F.; Li, J.; Li, T.; Chen, Z.; Luo, H.; Zhou, Z. Carbonized Design of Hierarchical Porous Carbon/Fe3O4@Fe Derived from Loofah Sponge to Achieve Tunable High-Performance Microwave Absorption. ACS Sustain. Chem. Eng. 2018, 6, 11801–11810. [Google Scholar] [CrossRef]

- Wu, Z.; Tian, K.; Huang, T.; Hu, W.; Xie, F. ; Wei Hu; Xie, F. Hierarchically porous carbons derived from biomasses with excellent microwave absorption performance. ACS Appl. Mater. Interfaces 2018, 10, 11108–11115. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Li, Q.; Rong Zhang, Y.; Zhao, Y.; Wang, J. Fabrication of flexible thermoplastic polyurethane/coal hydrogasification semi-coke composites with low rGO content for high-performance microwave absorption. ACS Appl. Electron. Mater. 2022, 4, 5941–5952. [Google Scholar] [CrossRef]

- Zhang, D.; He, W.; Quan, G.; Wang, Y.; Su, Y.; Lei, L.; Du, Y.; Hong, Y.; Wang, S.; Tang, Y.; Zhang, W.; Chen, Y. Sterculia lychnophora seed-derived porous carbon@CoFe2O4 composites with efficient microwave absorption performance. Appl. Surf. Sci. 2023, 607. [Google Scholar] [CrossRef]

- Zhou, C.; Wang, X.; Luo, H.; Deng, L.; Wang, S.; Wei, S.; Zheng, Y.; Jia, Q.; Liu, J. Interfacial design of sandwich-like CoFe@Ti3C2Tx composites as high efficient microwave absorption materials. Appl. Surf. Sci. 2019, 494, 540–550. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, P.; Liang, B.; Wan, G.-S. Carbon nanotubes decorated Co/C from ZIF-67/melamine as high efficient microwave absorbing material. Carbon 2023, 202, 66–75. [Google Scholar] [CrossRef]

- Quan, B.; Xu, G.; Gu, W.; Sheng, J.; Ji, G. Cobalt nanoparticles embedded nitrogen-doped porous graphitized carbon composites with enhanced microwave absorption performance. J. Colloid Interface Sci. 2019, 533, 297–303. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, B.; Lv, H. Low-dimensional cobalt doped carbon composite towards wideband electromagnetic dissipation. Nano Res. 2023, 16, 70–79. [Google Scholar] [CrossRef]

- Liu, Q.; Zhang, D.; Fan, T. Electromagnetic wave absorption properties of porous carbon/Co nanocomposites. Appl. Phys. Lett. 2008, 93, 013110. [Google Scholar] [CrossRef]

- Jing Yan, Y.H. Chen Chen, Xudong Liu, Hui Liu, The 3D CoNi alloy particles embedded in N-doped porous carbon foams for high-performance microwave absorbers. Carbon 2019, 152, 545–555. [Google Scholar]

- Wang, L.; Du, Z.; Bai, X.; Lin, Y. Constructing macroporous C/Co composites with tunable interfacial polarization toward ultra-broadband microwave absorption. J. Colloid Interface Sci. 2021, 591, 76–84. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, J.; Jin, H.; Dong, Y. Facile synthesis of Co-embedded porous spherical carbon composites derived from Co3O4/ZIF-8 compounds for broadband microwave absorption. Compos. Sci. Technol. 2020, 195, 108206. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, H.-B.; Wu, X.; Deng, Z. Nanolayered Cobalt@Carbon Hybrids Derived from Metal−Organic Frameworks for Microwave Absorption. ACS Appl. Nano Mater. 2019, 2, 2325–2335. [Google Scholar] [CrossRef]

- Jin, H.; Wang, J.; Yang, S.; Wu, Q. ZIF-67-derived micron-sized cobalt-doped porous carbon-based microwave absorbers with g-C3N4 as template. Ceram. Int. 2021, 47, 11506–11513. [Google Scholar] [CrossRef]

- Sun, Q.; Li, J.; Zhang, H.; He, X.; Wu, B.; Wang, J.; Mahmood, N.; Jian, X. The MOFs/COFs-derivant decorating FeSiAl coupling magnetic and electrical losses for enhanced microwave absorption. Appl. Surf. Sci. 2024, 651. [Google Scholar] [CrossRef]

- Liang, J.; Chen, J.; Shen, H.; Hu, K.; Zhao, B.; Kong, J. Hollow porous bowl-like nitrogen-doped cobalt/carbon nanocomposites with enhanced electromagnetic wave absorption. Chem. Mat. 2021, 33, 1789–1798. [Google Scholar] [CrossRef]

- Fu, M.; Yu, H.; Chen, W. Construction of Co3O4 porous rod/graphene heterostructures toward strong and broadband microwave absorption applications. Appl. Surf. Sci. 2023, 622. [Google Scholar] [CrossRef]

- Li, C.; Sui, J.; Zhang, Z.; Jiang, X. Microwave-assisted synthesis of tremella-like NiCo/C composites for efficient broadband electromagnetic wave absorption at 2–40 GHz. Chem. Eng. J. 2019, 375, 122017. [Google Scholar] [CrossRef]

- Wu, N.; Liu, C.; Xu, D.; Liu, J. Ultrathin high-performance electromagnetic wave absorbers with facilely fabricated hierarchical porous Co/C crabapples. J. Mater. Chem. C 2019, 7, 1659. [Google Scholar] [CrossRef]

- Huang, Y.; Tian, K.; Zhang, C.; Wang, J. Lightweight and efficient luffa sponge carbon/Co composites with adjustable electromagnetic wave absorption properties. J. Colloid Interface Sci. 2023, 652, 1138–1147. [Google Scholar] [CrossRef]

- Wang, X.; Guan, Y.; Zhang, R.; Zhang, R. Facile synthesis of cobalt nanoparticles embedded in a rod-like porous carbon matrix with excellent electromagnetic wave absorption performance. Ceram. Int. 2021, 47, 643–653. [Google Scholar] [CrossRef]

- Li, Y.; Li, X.; Kang, M.; Zhao, Y.; Li, Q.; Wang, J. Fabrication of flexible waterborne polyurethane/Fe-doped residual carbon from coal hydrogasification semi-coke composites for high-performance microwave absorption. Compos. Pt. A-Appl. Sci. Manuf. 2023, 174. [Google Scholar] [CrossRef]

- Li, P.; Ailijiang, N.; Cao, X.; Lei, T.; Liang, P.; Zhang, X.; Huang, X.; Teng, J. Pretreatment of coal gasification wastewater by adsorption using activated carbons and activated coke. Colloid Surf. A-Physicochem. Eng. Asp. 2015, 482, 177–183. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, Y.; Zhang, T.; Tang, J.; Xu, Y.; Zhang, J. Effect of Operational Variables on the Hydrogasification of Inner Mongolian Lignite Semicoke. Energy Fuels 2013, 27, 4589–4597. [Google Scholar] [CrossRef]

- Ding, X.K.; Zhang, T.K.; Zhang, Y.F.; Xu, Y.; Zhang, G.J. Hydrogasification of Low-Oxygen Semi-Coke to Produce Methane by Consuming Less Hydrogen. Appl. Mech. Mater. 2013, 316-317, 124–127. [Google Scholar] [CrossRef]

- Gao, F.; Li, Y.; Mao, L.; Wang, Y.; Zhu, B.; Liang, L.; Li, G.; Zhang, R. Facile synthesis of Co/SC microwave absorbents by recycling coal hydrogasification residue. Mater. Lett. 2022, 308. [Google Scholar] [CrossRef]

- Gao, S.; Chen, L.; Zhang, Y.; Shan, J. Fe nanoparticles decorated in residual carbon from coal gasification fine slag as an ultra-thin wideband microwave absorber. Compos. Sci. Technol. 2021, 213. [Google Scholar] [CrossRef]

- Ferrari, A.; Robertson, J. Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev. B 2000, 61, 14095. [Google Scholar] [CrossRef]

- Deng, X.; Gao, S.; Liu, Y.; Bao, Y.; Zhu, Y.; Fu, Y. Cellular-like sericin-derived carbon decorated reduced graphene oxide for tunable microwave absorption. Appl. Surf. Sci. 2022, 599. [Google Scholar] [CrossRef]

- Cui, J.; Wang, X.; Huang, L. Environmentally friendly bark-derived Co-Doped porous carbon composites for microwave absorption. Carbon 2022, 187, 115–125. [Google Scholar] [CrossRef]

- Cai, Y.; Cheng, Y.; Wang, Z.; Baoshan, Z. Facile and scalable preparation of ultralight cobalt@graphene aerogel microspheres with strong and wide bandwidth microwave absorption. Chem. Eng. J. 2023, 141102. [Google Scholar] [CrossRef]

- Wang, B.; Ji, Y.; Mu, C.; Huo, Y.; Xiang, J.; Nie, A.; Xue, T.; Zhai, K.; Liu, Z.; Wen, F. Well-controlled Core-shell structures based on Fe3O4 nanospheres coated by polyaniline for highly efficient microwave absorption. Appl. Surf. Sci. 2022, 591. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, X.; Huang, J.; Chen, S.; Zhang, Y. Enhanced microwave absorption of biomass carbon/nickel/polypyrrole (C/Ni/PPy) ternary composites through the synergistic effects. J. Alloy. Compd. 2021, 890, 161887. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).