1. Background

As a binder for Hot Mix Asphalt (HMA), the quality of asphalt significantly determines the performance of the flexible pavement that utilizes it. As a derivative of petroleum, the availability and quality of asphalt decrease over time due to the depletion of petroleum reserves. This reduction results in increased prices and difficulties in obtaining high-quality asphalt. To address these challenges, polymer asphalt and bio-asphalt have begun to be used. Bio-asphalt can serve as both an asphalt modifier and extender, and it can also rejuvenate aged asphalt (Bailey et al., 2010). Until the last decade, no research had successfully used bio-asphalt as a complete substitute for petroleum asphalt in HMA (Peralta et al., 2012).

The primary ingredients used to make bio-asphalt are plants. Various types of plants can be used, as most plant-based binders (bio-oils) contain components similar to conventional asphalt binders (hydrocarbons, aromatics, saturates, asphaltenes, etc.), as argued by Huang et al. (2012). However, the specific plants that can be used must undergo testing to ensure their chemical, rheological, and mechanical properties, as the properties of bio-asphalt can vary significantly depending on the type, composition of the materials used, and the manufacturing process (Williams et al., 2009).

Gopal (Gondorukem Asphalt) is a variant of bio-asphalt made using gondorukem (gum rosin) as the primary base material. The gondorukem used is derived from the distillation of the sap of the Merkusii pine tree and is then processed through esterification with the addition of melic and glycerol to produce rosin esters, identified in this article as GEG-90 and GEM-130. To create Gopal with properties similar to Pen 60 petroleum asphalt, as required by the 2018 Bina Marga Specifications Revision 2 (BM, 2018), a diluent oil in the form of crude palm oil (CPO) is added to each rosin ester at a specific dosage (Yamin et al., 2023), resulting in Gopal-GEG90 and Gopal-GEM130. To determine whether the produced Gopal can be used as an HMA binder like petroleum asphalt, its chemical, rheological, and mechanical properties need to be evaluated.

The aim of this study is to examine the chemical, rheological, and mechanical properties of Gopal-GEM130 and Gopal-GEG90 to assess their suitability as binders comparable to Pen 60 petroleum asphalt. The same tests were also conducted on Pen 60 petroleum asphalt, which served as a control for comparison against the chemical, rheological, and mechanical properties of Gopal-GEG90 and Gopal-GEM130.

2. Gondorukem

Gondorukem (gum rosin), also known as colophony, is obtained from pine resin (pine rosin) after the volatile fraction (turpentine) is removed through a distillation process. Gondorukem ranges in color from light to dark and does not dissolve in water but is soluble in various solvents such as alcohol, ether, acetone, benzene, and chloroform.

Gondorukem contains small acidic and neutral components, which are heavy molecules in the form of aldehydes, alcohols, esters, and hydrocarbons, structurally similar to rosin acid. Typically, rosin consists of approximately 10% neutral parts and 90% acidic elements (Mota et al., 2016). In gondorukem, the acidic elements primarily comprise two main groups of rosin acids: abietic acid (which includes abietic, levopimaric, palustric, neoabietic, dehydroabietic, and tetrahydroabietic acids) and pimaric acid (Mota et al., 2016). Rosin acids (abietic and pimaric) are tricyclic diterpenes (C20H30O2) with double bonds (Wiyono et al., 2006. Mota et al., 2016). Compounds with double bonds are easily oxidized, making rosin less stable and more prone to property changes due to heat (Mota et al., 2016).

Additionally, rosin generally contains 30-40% abietic acid. The content of abietic acid in rosin significantly affects its quality. Higher abietic acid content in rosin leads to faster crystallization, causing it to change from liquid to crystal form in a short time. Therefore, it is essential to minimize the abietic acid content in rosin. This minimization can be achieved through hydrogenation, dehydrogenation, isomerization, disproportionation, or esterification processes.

3. Gondorukem Esterification

Among the various processes used to minimize the abietic acid content in rosin, the most common and frequently employed method is esterification. This process occurs when acids and alcohols react under specific conditions to produce chemical compounds known as esters. Esterification involves the formation of organic compounds through chemical reactions between carboxylic acids or their derivatives and alcohols, typically occurring at temperatures ranging from 260 to 280°C, with or without the use of a catalyst (Mardiah et al., 2023). Esters are carboxylic acid derivatives with the general formula RCOOR, where R represents an alkyl group that can be either aliphatic or aromatic. The composition of the resulting ester depends on the types of carboxylic acids and alcohols used as reactants in the esterification process. Besides alcohol, esterification can also be achieved by adding other solutions such as glycerol, pentaerythritol, and ethylene glycol.

For gondorukem specifically, esterification aims to reduce its acidity, improve its thermal stability, and enhance its resistance to acids and bases (Mardiah et al., 2023). Because gondorukem contains abietic acid, esterification transforms it into rosin ester, which is more stable, has a higher softening point, and can be tailored to specific needs. Commonly used alcohols in gondorukem esterification include pentaerythritol, glycerol, methanol, alkyl groups, starch, and malic acid. The choice of alcohol depends on the desired properties of the resulting ester product (Ladero et al., 2011; Mardiah et al., 2023). Through the esterification process, gondorukem finds applications in various industries, including perfume, textile, and polymer manufacturing.

4. Crude Palm Oil

Crude Palm Oil (CPO) is the primary product derived from processing palm oil fruit. CPO is obtained through the extraction or pressing of the palm oil fruit flesh (mesocarp) and has not undergone refining. In contrast, palm kernel oil (PKO), which is also produced from processing palm fruit, does not contain beta carotene. CPO, on the other hand, is generally reddish due to its high beta carotene content (Agam et al., 2022). CPO's uses are diverse, spanning the food industry, cosmetics, chemical industry, and animal feed industry, among others. Yamin et al. (2023) utilized CPO as a material for producing bio-asphalt, referred to as Gopal (Gondorukem Asphalt).

According to Yamin et al. (2023), the quality of the CPO used significantly impacts the rheological characteristics of the resulting Gopal. Among the two main factors determining CPO quality—color and acidity level (Free Fatty Acid/FFA content)—the FFA content in CPO has a profound influence on the rheological properties of the produced Gopal. Conversely, the color of CPO does not negatively affect its quality. Their study on producing Gopal with varying FFA content in CPO concluded that only CPO with an FFA content above 30% is suitable for making Gopal.

5. Experimental Setup

Before use, the gondorukem utilized as the primary ingredient for making Gopal in this study undergoes esterification using either glycerol or melic acid. The esterification process yields rosin esters, which are coded as GEG90 (Gondorukem resulting from Glycerol Esterification, with a softening point of approximately 90°C) and GEM130 (Gondorukem resulting from Melic Esterification, with a softening point of approximately 130°C).

In the production of Gopal, the rosin esters GEG90 or GEM130 are first melted, after which CPO with a high Free Fatty Acid (FFA) content (>30%) is added. The weight-to-weight ratios (w/w) of GEG90 rosin ester to CPO and GEM130 rosin ester to CPO are 82.5:17.5 and 83.5:16.5, respectively. During mixing, continuous heating and stirring are performed until a homogeneous mixture is achieved, containing no solids. The resulting products are referred to as Gopal-GEG90 and Gopal-GEM130, respectively.

To achieve the objectives of this study, Gopal-GEG90 and Gopal-GEM130 were subjected to FTIR (Fourier Transform Infra-Red) and EDX (Energy Dispersive X-Ray) testing, along with rheological property assessments. These tests, including Dynamic Shear Rheometer (DSR) and Multiple Stress Creep Recovery (MSCR) tests, were conducted with reference to the value limits specified in the General Specifications for Bina Marga Revision 2 of 2017 (BM, 2017). All these tests were also performed on Pen 60 petroleum asphalt, which served as the comparison (control) in this study.

6. Results and Discussion

6.1. Chemical Analysis

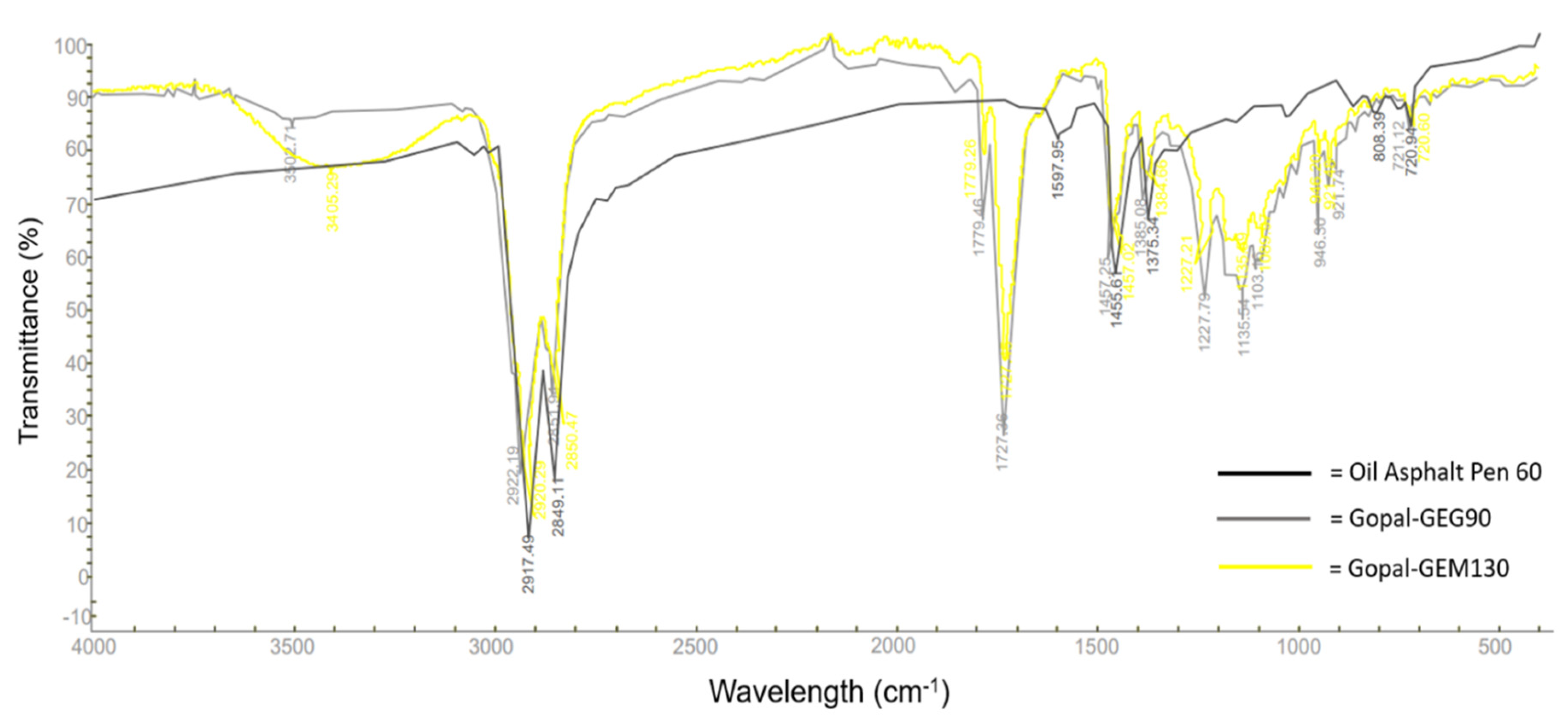

Figure 1 and

Table 1 present the results of FTIR and EDX testing conducted to identify the chemical groups and elements present in Gopal-GEG90 and Gopal-GEM130. The figure and table also include the test results for Pen 60 petroleum asphalt, which is used as a comparison (control) in this research.

From

Figure 1, it can be observed that Gopal-GEG90 has 13 spectrum peaks, Gopal-GEM130 has 13 spectrum peaks, and Pen 60 petroleum asphalt has 7 spectrum peaks. The transmission percentage (transmittance) of the spectrum peaks for each asphalt type occurs at the wavelengths provided in

Table 1. Several spectrum peaks at certain wavelengths produced by Pen 60 petroleum asphalt are also produced by Gopal-GEG90 and Gopal-GEM130. These shared peaks and chemical groups include:

A peak in the wave range of 650–910 cm-1 corresponding to the aromatic CH bend.

A peak in the wave range of 1370–1380 cm-1 corresponding to the aliphatic CH2 bend.

A peak in the wave range of 1440–1485 cm-1 corresponding to the aliphatic CH3 bend.

A peak in the wave range of 2850–3000 cm-1 corresponding to the aliphatic CH stretch.

One peak present in Pen 60 petroleum asphalt but absent in both Gopal-GEG90 and Gopal-GEM130 is the benzene ring stretch peak, located in the wave range of 1430–1650 cm-1. However, Gopal-GEG90 and Gopal-GEM130 have an additional peak that Pen 60 petroleum asphalt does not have, specifically in the wave range of 1000–1300 cm-1, which corresponds to the CO stretch peak.

Thus, it can be said that gondorukem-based bio-asphalt, in the forms of Gopal-GEG90 and Gopal-GEM130, has 86% of the same chemical groups as Pen 60 petroleum asphalt. However, Gopal-GEG90 and Gopal-GEM130 contain more light oil fractions, with peak wavelength spectra in the range of 900–1250 cm-1.

According to Huber and Dumesic (2016), there are hundred of comonents in bio-oil which used for producing bio-asphalt, and it is mainly composed of element of C, H, O,N and S but some bio oil contain trace amounts elements of Si, P, Ca and others. For Gopal, based on test results of the EDX on Gopal-GEG90 and Gopal-GEM130, as shown in

Table 2, it is evident that the elements in Gopal-GEG90 include C, O, Na, Mg, Al, Si, Ca, and Ti, with C and O being the primary elements. In contrast, Gopal-GEM130 contains elements such as C, O, Mg, Al, and Si, with C and O also being the primary elements. Three minor elements found in Gopal-GEG90 but absent in Gopal-GEM130 are Na, Ca, and Ti. Despite these differences in minor elements, the dominant elements in both types of Gopal are the same, namely C and O.

Compared to Pen 60 petroleum asphalt (as shown in

Table 2), Gopal-GEG90 has a more similar element profile to Pen 60 than Gopal-GEM130. However, all three asphalts have the same dominant elements, C and O. Neither Gopal-GEG90 nor Gopal-GEM130 contains sulfur (S), indicating that both types of Gopal are less toxic than Pen 60 petroleum asphalt. Additionally, Gopal-GEM130 is less alkaline (positive) due to the absence of Na. Therefore, compared to Pen 60 petroleum asphalt, Gopal-GEM130 is less toxic and less alkaline, while Gopal-GEG90 is less toxic and more alkaline.

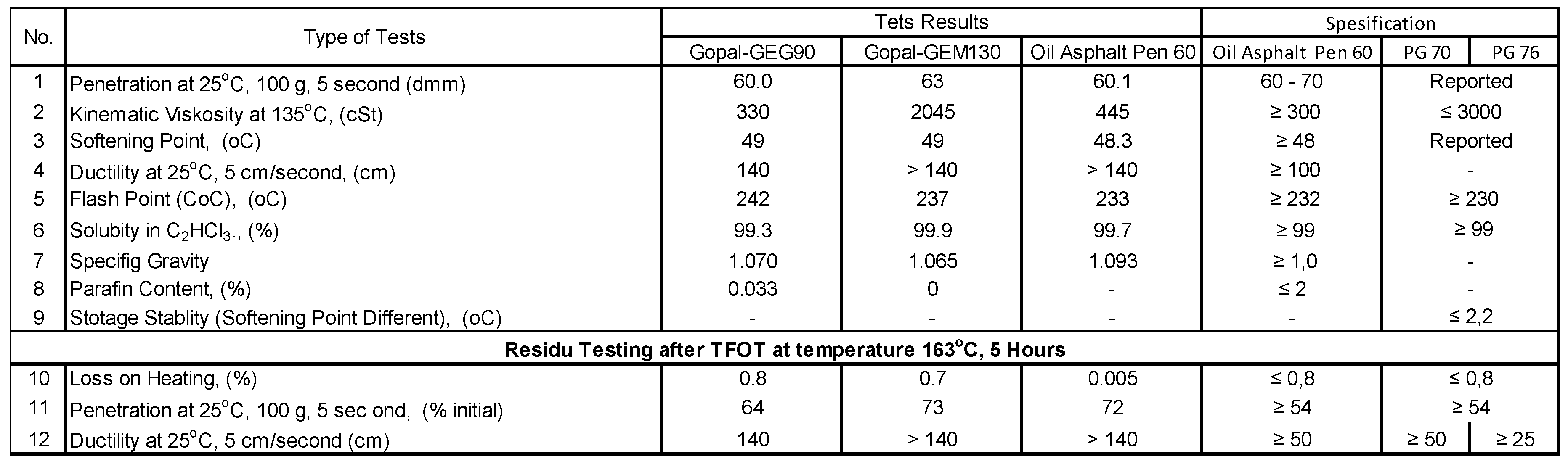

6.2. Rheological Analysis

Table 3 presents the rheological properties of Gopal-GEG90 and Gopal-GEM130, as well as those of Pen 60 petroleum asphalt, which is used as a comparison in this study. The table shows that Gopal-GEG90 and Gopal-GEM130 meet the requirements of the General Specifications for Bina Marga Rev-2 of 2017 (BM, 2017). Pen 60 petroleum asphalt, used as a control, also meets these requirements. Despite having relatively the same penetration value as Pen 60 petroleum asphalt, Gopal-GEG90 and Gopal-GEM130 exhibit a softening point (SP) value that is one degree higher.

In terms of viscosity, there are notable differences between the two types of Gopal. Gopal-GEG90, with a viscosity of 330 cSt, is thinner than Pen 60 petroleum asphalt (445 cSt), while Gopal-GEM130, with a viscosity of 2045 cSt, is much thicker than both Gopal-GEG90 and Pen 60 petroleum asphalt. Even after the Thin Film Oven Test (TFOT), Gopal-GEG90 remains ductile, with a ductility value above 140 cm. However, Gopal-GEG90 has lower aging resistance compared to Pen 60 petroleum asphalt, as indicated by its lower residual penetration value (64%) compared to Pen 60 petroleum asphalt (72%).

For Gopal-GEM130, the residual penetration value (73%) is relatively similar to Pen 60 petroleum asphalt. However, with a Loss on Heating (LoH) value of 0.7%, much higher than Pen 60 petroleum asphalt (0.005%), it can be concluded that Gopal-GEM130 also has lower aging resistance compared to Pen 60 petroleum asphalt.

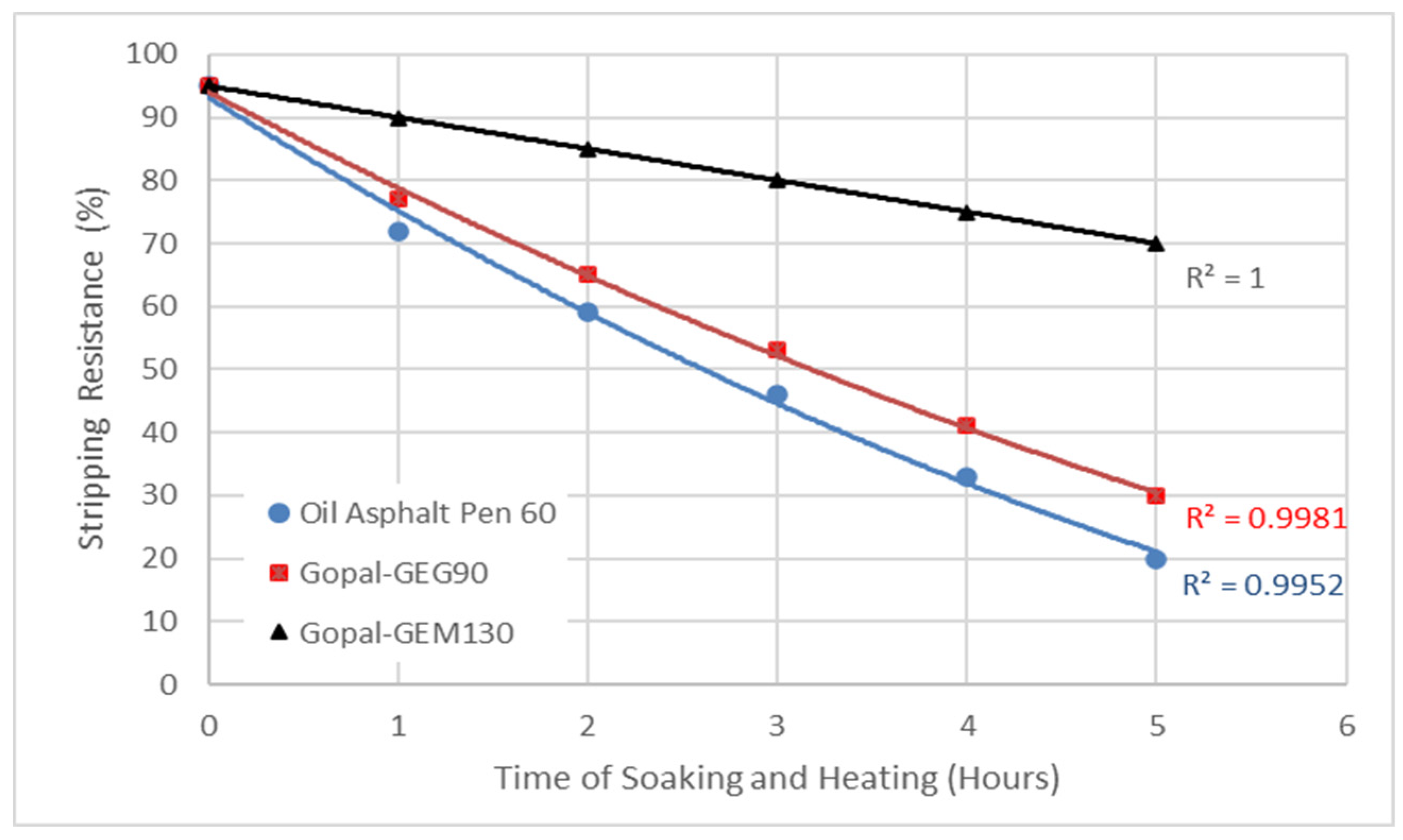

The advantage of Gopal-GEG90 and Gopal-GEM130 is their resistance to water. From the results of the boiling test shown in

Figure 2, it can be seen that the level of peeling and the rate at which Gopal-GEM130 peels from the aggregate surface is much lower compared to Gopal-GEG90 and Pen 60 petroleum asphalt. Therefore, it can be concluded that Gopal-GEM130 has significantly better stripping resistance than both Gopal-GEG90 and Pen 60 petroleum asphalt. Additionally, Gopal-GEG90 has slightly better stripping resistance than Pen 60 petroleum asphalt. These facts in line which have shown by Zhao et al., (2014) and Djumari et al., (2016) where as water stability of bio-asphlat mixture is better than ordinarry (petroleum) asphalt mixture but contrast with Zhenggi at al., (2022) where their research conclude those bio-asphalt mixtures all inferior to the ordinarry asphalt mixture.

6.3. Mechanical Analysis

Mechanical testing is conducted to determine the rutting factor (G*/sinδ) and fatigue factor (Gsinδ) of asphalt. G/sinδ is a factor used in the SHRP to assess the potential for rutting in asphalt (Bahia and Davies, 1995). According to the General Specifications for Bina Marga (BM, 2017), the required rutting factor for fresh asphalt and aged asphalt via RTFO (Rolling Thin Film Oven Test) and PAV (Pavement Aging Vessel) is the same as in the Superpave Specifications: 1.0 kPa for fresh asphalt and 2.20 kPa for aged asphalt. The fatigue factor (Gsinδ) indicates asphalt's resistance to cracking. Similar to the rutting factor, the General Specifications for Bina Marga (BM, 2017) specify that the fatigue factor should not exceed 5000 kPa, as required in the Superpave Specifications. A lower Gsinδ value indicates better fatigue resistance (Yusoff et al., 2013).

The rutting and fatigue factors of asphalt are determined through Dynamic Shear Rheometer (DSR) testing. To simulate real-world conditions where asphalt becomes stiffer over time due to short-term and long-term aging, DSR tests are performed not only on fresh asphalt but also on aged asphalt via RTFO (RTFO-aged) and PAV (PAV-aged). RTFO-aged specimens are also tested using Multiple Stress Creep Recovery (MSCR) to determine the percentage of recovery after stress removal (MSCR Test). The DSR test results for Gopal, Pen 60 petroleum asphalt, and the MSCR test results are provided in

Table 4,

Table 5, and

Table 6, respectively.

Table 4.

Rutting Factors of Gopal and Pen 60 Oil Asphalt.

Table 4.

Rutting Factors of Gopal and Pen 60 Oil Asphalt.

| Parameter |

G*/sin δ (kPa) |

| Test Samples |

| Original Binder |

After RTFOT |

| Gopal |

Oil Asphalt Pen 60 |

Gopal |

Oil Asphalt Pen 60 |

| GEG90 |

GEM130 |

GEG90 |

GEM130 |

| Temperature (°C) |

64 |

1,099 |

2,114 |

1,379 |

2,499 |

3,279 |

2,267 |

| 70 |

0.486 (Fail) |

1,024 |

0.642 (Fail) |

1,020 (Fail) |

1,436 (Fail) |

1,038 (Fail) |

| 76 |

- |

0.494 (Fail) |

- |

- |

- |

- |

| P.G |

|

70 |

64 |

|

64 |

64 |

| Specification |

≥ 1,000 kPa |

≥ 2,200 kPa |

From

Table 4, it can be seen that, when fresh, Gopal-GEG90 and Pen 60 petroleum asphalt fall into the same PG class, namely PG 64. However, Gopal-GEG90 ages faster than Pen 60 petroleum asphalt, as indicated by the larger difference in the rutting factor after RTFO aging compared to its original condition 1.4 for Gopal-GEG90 versus 0.9 for Pen 60 petroleum asphalt). This is because the main ingredient for gopal is rosin, which according to Solten et al., (1989) in Moha et al., (2016) rosin oxidation is started by the initiation step, i.e. heat, UV radiation, shear stress or impurities, free radicals are formed and accelerate the degradation by a complex mechanism. Despite this, Gopal-GEG90 has slightly better rutting resistance than Pen 60 petroleum asphalt.

Gopal-GEM130, which is initially classified as PG70 when fresh, also ages faster than Pen 60 petroleum asphalt, with the same reason as Gopal-GEG90, but at a slower rate than Gopal-GEG90. The rutting resistance of Gopal-GEM130 is better than that of Gopal-GEG90 and significantly better than Pen 60 petroleum asphalt. However, due to short-term aging, the PG classification of Gopal-GEM130 decreases by one level to PG 64.

Table 5 presents the fatigue factor of Gopal and Pen 60 petroleum asphalt. From this table, it is evident that, due to long-term aging (PAV), Gopal-GEG90 becomes more brittle compared to Pen 60 and Gopal-GEM130 petroleum asphalt. At the same temperature (31°C), the fatigue factor value of Gopal-GEG90 is significantly higher than that of Pen 60 petroleum asphalt and Gopal-GEM130, exceeding the required value (≤ 5000 kPa). This indicates that Gopal-GEG90 exhibits lower fatigue resistance compared to Pen 60 and Gopal-GEM130 petroleum asphalt.

For Gopal-GEM130, at a temperature of 25°C, the fatigue factor exceeds the required value. In contrast, at this temperature, the fatigue factor of Pen 60 petroleum asphalt remains well within acceptable limits, indicating very good fatigue resistance. Consequently, it can be concluded that Pen 60 petroleum asphalt demonstrates superior fatigue resistance compared to Gopal-GEM130, and particularly compared to Gopal-GEG90.

Table 5.

Fatigue Gopal Factors and Pen 60 Oil Asphalt.

Table 5.

Fatigue Gopal Factors and Pen 60 Oil Asphalt.

| Parameter. |

G*Sin δ (kPa) |

| Test Samples |

| After PAV |

| Gopal |

Oil Asphalt Pen 60 |

| GEG90 |

GEM130 |

| Temperature (°C) |

31 |

9397 (Fail) |

1887 |

1783 |

| 28 |

- |

3294 |

2663 |

| 25 |

- |

6223 (Fail) |

3790 |

| 22 |

- |

- |

5156 (Fair) |

| AASHTO M-320 Specifications (2023) |

≤ 5000 kPa |

The ability of the asphalt to recover after load (stress) removal is an essential aspect of its performance.

Table 6 illustrates that the Jnr diff values for Gopal-GEG90, Gopal-GEM130, and Pen 60 petroleum asphalt are all below 75%. However, when examining the Jnr3.2 values, it is evident that Jnr3.2 for Gopal-GEG90 is higher than that for Pen 60 petroleum asphalt. This suggests that Gopal-GEG90 exhibits a greater degree of permanent deformation under stress compared to Pen 60 petroleum asphalt. In contrast, Gopal-GEM130, with a lower Jnr3.2 value than Pen 60 petroleum asphalt, indicates superior deformation resistance.

Therefore, although Gopal-GEM130 and Gopal-GEG90 are classified within the same Performance Grade (PG) as Pen 60 petroleum asphalt (PG 64[S]), Gopal-GEM130 exhibits superior deformation resistance, while Gopal-GEG90 demonstrates inferior deformation resistance relative to Pen 60 petroleum asphalt. These findings substantiate the empirical test results (rheological properties), affirming that Gopal-GEM130 possesses enhanced properties, whereas Gopal-GEG90 shows diminished properties compared to Pen 60 petroleum asphalt, which is utilized as the control in this study.

Table 6.

MSCR Gopal Test Results and Pen 60 Oil Asphalt.

Table 6.

MSCR Gopal Test Results and Pen 60 Oil Asphalt.

| Parameter |

Jnr3.2 (kPa-1) |

Jnr diff (%) |

| After RTFOT Test Samples |

| Gopal |

Oil Asphalt Pen 60 |

Gopal |

Oil Asphalt Pen 60 |

| GEG90 |

GEM130 |

GEG90 |

GEM130 |

|

| Temperature (°C) |

64 |

4,235 |

3,211 |

3.94 |

3.4 |

9.8 |

10.2 |

| Performance Grade (PG) |

64S |

64S |

64S |

Pass |

Pass |

Pass |

| Traffic Levels |

Standard (S) |

Max. 4.5 kPa-1 |

Max. 75% |

| Heavy (H) |

Max. 2.0 kPa-1 |

Max. 75% |

| Very Heavy (V) |

Max. 1.0 kPa-1 |

Max. 75% |

| Extremely Heavy (E) |

Max. 0.5 kPa-1 |

Max. 75% |

4. Conclusions and Suggestions

4.1. Conclusions

The conclusions drawn from this study are as follows, the chemical groups of Gopal-GEG90 and Gopal-GEM130 exhibit an 86% similarity with those of Pen 60 petroleum asphalt. Compared to Pen 60 petroleum asphalt, Gopal-GEM130 is less toxic and less alkaline, while Gopal-GEG90 is less toxic but more alkaline. Both Gopal-GEG90 and Gopal-GEM130 fall within the same classification grade of asphalt as Pen 60 petroleum asphalt. Gopal-GEG90 demonstrates slightly better stripping resistance and lower aging resistance. In contrast, Gopal-GEM130 exhibits much better stripping resistance but also lower aging resistance than Pen 60 petroleum asphalt. In terms of performance classification, both Gopal-GEG90 and Gopal-GEM130 are categorized in the same performance grade as Pen 60 petroleum asphalt, namely PG 64(S). The rutting resistance of Gopal-GEG90 is slightly better than Pen 60 petroleum asphalt but inferior to Gopal-GEM130, and it ages faster than both. Additionally, Gopal-GEG90 ages faster and has lower fatigue resistance compared to both Pen 60 and Gopal-GEM130 petroleum asphalt. Gopal-GEM130, on the other hand, exhibits significantly better rutting resistance than Pen 60 petroleum asphalt but has lower fatigue resistance and ages faster than Pen 60 petroleum asphalt.

4.2. Suggestions

While Gopal exhibits chemical group similarities to petroleum asphalt, demonstrates comparable rheological properties, and falls within the same performance grade, its viability as a substitute binder for petroleum asphalt in hot mix asphalt has not been definitively established. Therefore, it is essential to conduct additional rigorous evaluations to determine the performance of Gopal as an asphalt binder. These evaluations should encompass both comprehensive laboratory analyses and extensive field trials to thoroughly assess its suitability and effectiveness in practical applications.

References

- AASHTO, (2023), Performance-Graded Asphalt Binders, AASHTO M-320, The Americans Association of State Highways and Transportation Officials, USA.

- Agam Muarif*, Rizka Mulyawan, Marisa Fitria, (2022), Analisis Kualitas Crude Palm Oil (CPO) Berdasarkan Kinerja Vacuum Dryer di PKS Koperasi Primajasa, Jornal Inovasi Teknik Kimia. Vol. 7, No.1, Fakultas Teknik Universitas Wahid Hasyim, Semarang, Indonesia.

- Bahia, HU, Davies, R.., (1995), Factors Controlling The Effect Of Crumb Rubber On Critical Properties of Asphalt Binders (With Discussion). Journal of the Association of Asphalt Paving Technologists.

- Bailey, HK and Phillips, P., 2010. Asphalt Rejuvenation, United States Patent Application Publications No. US 2010/0034586 A1.

- B.M., (2017), Specification General Build Clan Rev-2, Directoral General Build Clan (BM), Ministry Work General And Housing area People (PUPR), Indonesia.

- Djumari, Yamin, M.A.D., Nasution, M. F., et al., (2016), Design and Properties of Renewable Bioasphalt for Flexible Pavement. Sustainable Civil Engineering Structures and Costruction Materials. [CrossRef]

- Huang, S.C., Salomon, D. and Haddock, J.E., (2012), Work-shop Introduction , Transportation Research Circular E-C165, p. 1, Transportation Research Board, Washington, D.C.

- Huber, G.W., Dumesic, J.A., (2006), An overview of aqueous-phase catalytic processes for production of hydrogen and alkanesin a biorefinery. Catalysis Today 111. [CrossRef]

- Ladero, M., de Gracia, M., Tamayo, J.J., de Ahumada, IL; Trujillo, F., Garcia-Ochoa, F., (2011), Kinetic modelling of the esterification of rosin and glycerol: Application to industrial operation. Chem. Eng. Journal. [CrossRef]

- Mardiah Mardiah, Tjokorde Valmiki Samadhi, Winny Wulandari, Aqsha Aqsha, Yohanes Andre Situmorang and Antonius Indarto, (2023), Recent Progress on Catalytic of Rosin Esterification Using Different Agents of Reactant, AgriEngineering, MDPI. [CrossRef]

- Mota, R.F.G. Bordado, J.C.M. Goncalves, J.F.D., (2016), Increase of Rosin Ester Shelf Life: Improvement of Oxidative Stability, University of Lisbon.

- Peralta, J., Raouf, M.A., Tang, S., & Williams, R.C. (2012) Bio-renewable asphalt modifiers and asphalt substitutes. In Sustainable bioenergy and bioproducts (pp. 89-115). Springer, London.

- Soltes, E. J. and D. F. Zinkel, (1989), Naval Stores: Production, Chemistry and Utilization, in Chemistry of rosin, Pulp Chemical Association, New York, U.S.A.

- Williams, R. C., Satrio, J., Rover, M., Brown, R. C., & Teng, S. (2009). Utilization of fractionated bio oil in asphalt. In 88th annual meeting of the Transportation Research Board, Washington, D.C.

- Yamin R. Anwar, Laely FH, Zuni AN Dani Hamdani, (2023), Towards Artificial Asphalt in Indonesia, The 13 th I International Conference on Geotechnique, Construction Materials and Environment, GEOMATE, Tsu City, May – Japan.

- Yusoff, NIM, Jakarni, FM, Nguyen, VH, Hainin, MR and Airey, GD 2013. Modelling the rheological properties of bituminous binders using mathematical equations. Construction and Building Materials, 40,174-188. [CrossRef]

- Wiyono B., S. Tachibana, D. Tinambunan, (2006), Chemical Composition of Indonesian Pinus merkusii Turpentine Oils, Gum Oleoresins and Rosins from Sumatra and Java. Pakistan J. Bio. Sci. 9(1). Pakistan Journal of Biological Sciences, Vol. 9. Pakistan. [CrossRef]

- Zhao, S., Huang, B., Shu, X. et al., (2014), Laboratory Investigation of Biochar-modified Asphalt Mixture. In Transportation Research Board 93rd, Annual Meeting, Washington, D.C.

- Zhenggi, Z., Ying, F., Jianhua, Y., and Xinjun, L., (2022), A Comprehensive Review of Bio-oil, Bio-binder and Bio-asphalt materials: Their Source, Composition, Preparation and Preformance, ScinenceDirect, Journal of Traffic and Transportation Engineering, Chang’an University. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).