1. Introduction

Agriculture now plays a vital role in countries such as Ethiopia. Wheat and rice are significant crops and staple foods for millions of people, and they are farmed in many countries throughout the world, including ours. Harvesting crop is an important field operation involving the collection of prepared wheat and rice crops from the fields. The collecting operation involves cutting, laying, and gathering, transferring, and stacking the removed produce. Harvesting methods utilized include hand harvesting (traditional harvesting) and automated harvesting.

- I.

Traditional harvesting involves hand mowing using sickles. Crops are usually harvested manually. Major cereals, pulses, and oilseed crops are harvested with sickles, while tuber crops are reaped with a country plough or shovel. All of these traditional approaches are tedious and time-consuming.

- II.

Mechanical harvesting is a modern mowing approach that uses a machine. The timing of harvest is critical. During harvesting season, rainfall and storms are frequent, inflicting significant damage to standing crops. Rapid harvest allows for an additional day of field preparation as well as earlier planting of the next crop. Machines can help harvest crops at the correct stage of ripeness, reducing drudgery and operation time. Considering this, fanners are accepting improved harvesting gear, equipment, and combines.

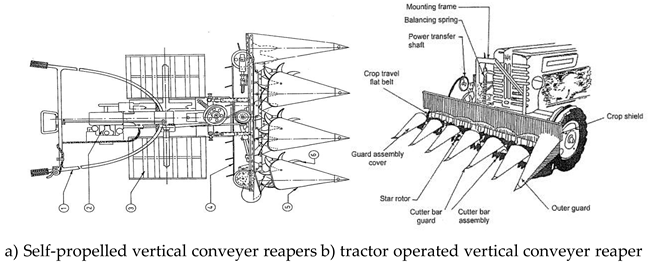

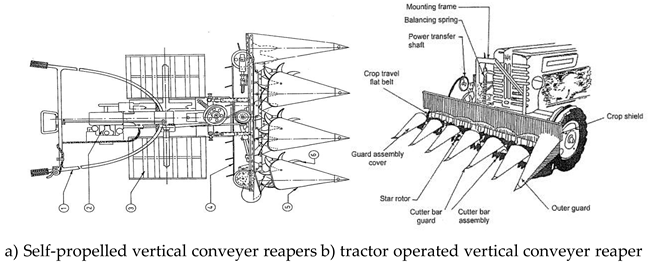

Mechanized agriculture is the process of deploying agricultural machinery to automate agricultural tasks, resulting in increased farm worker productivity. In modern times, powered machinery has replaced numerous jobs that were previously performed by manual labor or working animals such as oxen, horses, and mules. The history of agriculture includes numerous examples of tool use, such as the plow. Mechanization is the use of an intermediary device between the power source and the work. This intermediate device typically converts motion from rotary to linear or gives some sort mechanical advantage, including speed increase or decrease or leverage. Tractors, trucks, combine harvesters, airplanes (crop dusters), helicopters, and other vehicles are commonly used in modern mechanized agriculture. Until the eighteenth century, most grains were harvested using a sickle or scythe. In the nineteenth century, mechanized reapers were invented to chop and windrow grain for field drying. Reaper is a wheat and rice harvesting machine that reaps crops and gathers them manually. There are numerous kinds of horizontal conveyors reapers readily accessible, including manually driven, self-propelled, tractors front mounted, and self-propelled tying reaper. Reapers are used to harvest crops primarily at ground level. It consists of a crop-row divider, a cutter bar assembly, and feed and transporting equipment. Reapers are characterized based on crop conveyance, as follows:

1. Vertical conveying reaper windrower: This machine cuts crops, transports them vertically to one end, and evenly distributes them on the ground. There are three types of reaper-windrowers available: self-propelled walking, self-propelled riding, and tractor-mounted.

2. Horizontal transporting reapers include crop partitions, crop collection reel in, cutter bar, and horizontal conveyor belt. They cut the crop, transport it horizontally to one end, and drop it on the ground in a head-tail method. It’s compatible with wheat, rice, soybeans, and gram.

3. Bunch conveying reapers: - Identical to horizontal conveying reapers, but cut crop is collected upon a platform and discharged to the ground as a bunch using a hand lever.

4. Reaper binder: -This kind of reaper’s cutting machine can be either disc or cutter bar. After cutting, the crop is transported vertically to the binding mechanism and then released to the ground in the form of bundles. Reaper binders are appropriate for rice and wheat.

2. Literature Review

This chapter discusses previous research on the performance of harvesting operations, and how mechanization is critical to reducing harvesting costs, crop production costs, crop loss, turnaround time, weather risk, and increasing benefit through appropriate technology. Crop harvesting is a major aspect of agricultural mechanization; it is the act of removing mature crops from the field. The harvesting operation involves slicing, laying, gathering, transferring, and stacking the cut produce. Harvesting methods utilized include traditional and mechanical harvesting. Product development general design process steps for reaper harvester’s machine include planning, concept development, system-level design, detail design, testing and refining, and product ramp-up. In this step, the material properties are defined based on the design.

2.1. Design and Develop a Reaper for Harvesting

(Devani and Pandey , 1985) Devised and built a vertical conveyor belt windrower to harvest wheat crops. The study found that the field capacity for 1.6 m wider units was 0.269 ha/h, whereas for 2.09 m wide units it was 0.337 ha/h. The operating costs of tractor and power tiller models were 20 to 30% less compared to the traditional manual approach.

(El-Sahrigi et al. ,, 1992) Created a front-mounted reaper. The design features included a flat belt mechanism that conveys the crop to the side of the machines. a strengthened cutter bar star wheel assembly to reduce clogging, a bevel gear drive for power transmission, a strong frame, a header provide design that does not dig into the soil, and the ability to convert the flat belt conveyor drivers to chain without frame modification.

(J Prasad et al. ,, 2001-2002) Developed a self-propelled riding reaper windrower powered by a small diesel engine. In a test of four wheat crop varieties, the mean values of plant height, effective field capacity, fuel consumption, and total machine loss were 84.6 cm, 0.336 ha/h, 1.35 l/h, and 0.610%, correspondingly.

(D.N Sharma and S. Mukesh, 2010) Conducted research on the design of self-propelled vertical conveyer reapers and tractor-powered vertical conveyer reaper harvesting equipment.

2.2. Comparing Field Performance of Different Reaper Machines

(El-Sharabasy, 1997) Tested four different equipment (small combine harvester, power reaper, self-propelled mower, and rear mounted mower) in wheat and rice fields. He discovered the followings:-

The tiny combine harvester resulted in a minimum grain loss of 1.66%.

Self-propelled mowers showed the highest efficiency (78.04%).

Tractor powered reaping machines produced a maximum field efficiency of 1.64 fed/h. 4. Harvesting with a self-propelled lawnmower and thrashing with a stationary thresher resulted in a minimum energy of 25.38 wk./fed.

2.3. Evaluation of Reaper Machine Performance in the Field

(Ni Ni Aung, Win Pa Pa Myo, and Zaw Moe Htet, 2012) Analyzed the field effectiveness of a vertical conveyor paddy reaper. The reaper’s actual field capacity was 0.24 ha/hr, with a field efficiency of 92% and an average operating speed of 2.18 km/h.

(Mahrous, tested and evaluated rear mounted mower, 1995) Examined and assessed a horizontal flat conveyor belt to increase the efficiency of a rear-mounted mower. The mower was run on a wheat crop at forward speeds of 3, 4, 5, and 6 km/h. The created rear-mounted mower had a standard field capacity, field effectiveness, cutting efficiency, and cost needs of 1.18 fed/h.

According to ( Habib, Azzam and Khattab, 2001), the parameters affecting the cutting process include the cutting tool, machine characteristics, and plant material properties. They also mentioned the amount of energy consumed throughout the harvesting procedure.

According to (Sahar, Design of a harvester appropriate for Egyptian Agriculture, 1988), the usage of a large-scale machine is improper for the following reasons: - it requires extensive technical skill for operation and maintenance, as well as a significant investment. Low field efficiency occurs on small holdings, and straw losses are severe in irregularly furrowed soils. Small machines are suitable for small holdings with low capital requirements and limited technical operations and maintenance skills.

(Prof. P.B. Chavan, Prof. D.K. Patil, and Prof. D.S. Dhondge , 2015), 2015) Discovered that reapers tend to be selected based on the farmer’s land holding; the larger the agricultural holding, the tractor-operated vertical conveyer reaper is chosen; for medium-sized land holdings, self-propelled vertical conveyer reapers are preferred; and for small land holdings, manually operated vertical conveyor reapers are preferred.

(Manjunatha et al., 2008) Conducted a field performance evaluation of a vertical conveyor paddy reaper. The power reaper’s actual field capacity was 0.3 ha/hr, with a field efficiency of 73% and an average operating speed of 3.2 km/h. Mechanization of harvesting activities could help to minimize the cost of paddy production.

3.1. Self-Prosperous Riding Reapers Machine Design

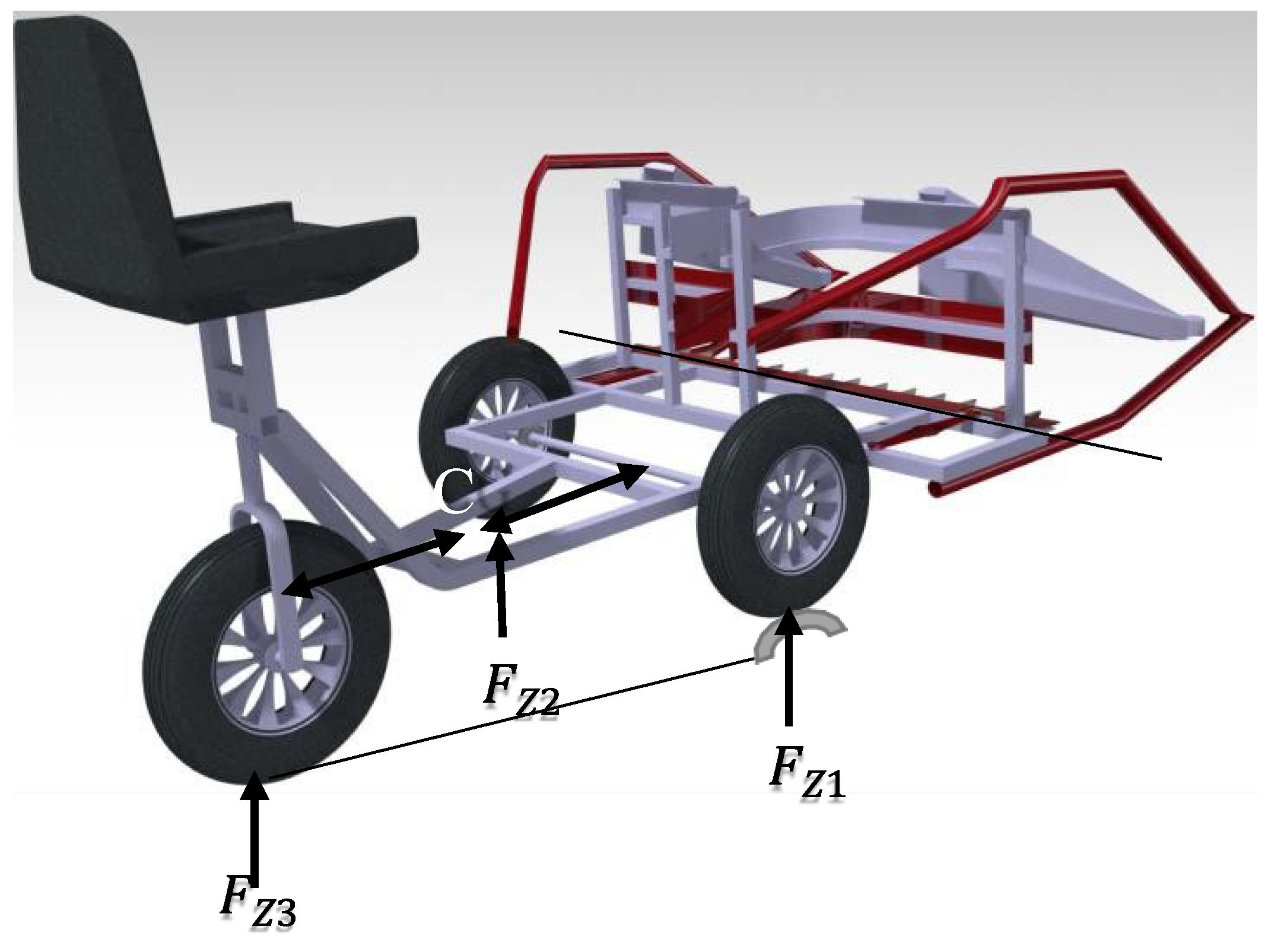

A Reapers Harvesting Machine is stressed by loads that are usually determined by the dynamic interaction of the stimulation and the Reaper. During the early stages of design, the data available for the Reaper and its subsystems may be insufficient to describe such dynamic interactions. Even in this phase, a study of the loads is required to identify a basic design. In the subsequent stage, a dynamic condition check is performed, yielding a more refined design. Based on these considerations, the purpose of the next paragraph is to depict various load circumstances that will be useful in the initial design of structural body components. The Reapers Harvesting Machine, parked on a flat road and carrying the greatest payload feasible, is not in an extreme load condition. Nonetheless, flat road parking is interesting since the other requirements can be found by calculating the variances in relation to this example. Given the mass and the position of the center of gravity, the vertical loads acting on the front and rear axles are simply as follows: Machine mass (m) = 250 kg, p = 2m, a = 0.35m and b = 0.65m.

Figure 3.

Parking on a curb sufficient in height to lift one wheel off the ground, leaving the automobile supported by only three wheels.

Figure 3.

Parking on a curb sufficient in height to lift one wheel off the ground, leaving the automobile supported by only three wheels.

4. Results and Discussion

The talks in this study will focus on the impact of harvesting technologies on total grain losses, cutting efficiency, field capacity and efficiency, energy consumption, and total cost. The prerequisites for harvesting wheat crops. The mechanization of self-prosperous riding reapers machine operation is critical to improving field capacity, field efficiency, and cutting efficiency by reducing manual work and the difficulty of gathering crops or forming bundles of goods. During crop harvesting, the cutting unit collects the harvest crop from both the left and right sides and pushes it to the machine’s middle position to feed dropping or releasing to the ground in the form of bundles. The machine is powered by a 5 kW, single cylinder, water-cooled diesel engine with a rated engine speed of 970rpm. The Reaper machine frame structure was devised and developed using the crop binding mechanism.

4.1. Principle of Self-Prospered Reapers Harvesting Machine

The working width of the reaper machine is 120 cm, the length is 200 cm, and the machine height is 100 cm. The crop is transported vertically to the binding machinery by the finger conveyor before being delivered to the ground in bundles. During crop harvesting, the cutting unit takes the harvest crop from both the left and right sides and pushes it to the machine’s central position for dropping the bundles. The machine is powered by a 5 kW, 4 cylinder, water-cooled diesel engine with a rated engine speed of 970rpm. It has a reciprocating cutter bar with a cutting width of around 120 cm that is powered by the diesel engine, which also provides two driving wheels for the front pneumatic wheels. Other systems include brakes, steering, mechanism, and power transmission, and an operator seat is offered to make the machine ride able.

5. Conclusion

Harvesting is one of the more time-consuming and labor-intensive agricultural processes. Self-propelled riding reapers machines can be used successfully for speedy and cost-effective harvesting of wheat and rice crops, as well as to alleviate peak labor shortages during harvest. The machine can be controlled by a single person. The frame along with the other components of the reaper machine are built of angle iron, square bar, flat bar, and pipe. The materials include both standard and manufactured components that are used in the machine mentioned above. Working width of the reaper machine. 120 cm and the total length of the reaper machines are 200 cm and 125 cm, respectively. The cut crop material was bundled by the gathering equipment and left on the field. During crop harvesting, the cutting unit collects the harvest crop from both the left and right sides and pushes it to the device’s middle position for dropping or releasing to the ground in the form of bundles. The machine is powered by a 5 kW, single cylinder, water-cooled diesel engine with a rated engine speed of 970rpm. This self-propelled reaper moves at a forward speed of 2.54 m/s. The field capacity is 0.306 ha/hour, respectively. The needed manpower for harvesting one hectare of wheat and rice reaper harvesting field operation is two man-hours per ha. The amount of fuel required to completely fill the tank after harvesting the plot was measured to determine the amount of fuel consumed for reaping the test plot, which was 1.17 l/h. Before beginning the harvesting process in the test plot, the reaper’s fuel tank was filled to full capacity.

References

- Sahar (1988) “Design of a harvester appropriate for Egyptian Agriculture” IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684, p-ISSN: 2320- 334X, Volume 12, Issue 3 Ver. I page (15-16).

- Harerimana Leonce and D.C Saraswat (2005) “Comparative Study of Performance and Economics of Self Propelled Combine Harvester with Other Harvesting and Threshing Methods on Paddy” Journal of Emerging Trends in Engineering and Applied Sciences (JETEAS) 6(6):377- 382 (ISSN: 2141-7016) page. (378-379).

- Devani. R. S. and M. M. Pandey (1985)” Design, development and evaluation of vertical conveyor reaper windrower” Indian Journal of Agricultural Sciences 55(8): 543-547. page (4-5).

- parad, Nabi Bagh and Bersia (2002)” Tractor mounted vertical conveyor reaper windrower” published by coordination cell AICRP on farm implements and machinery central institute of agricultural engineering Bhopal-462 038. page (4-8).

- N sharma; S. mukesh (2008 and 2010). “farm machinery design principles and problems” agricultural book first edition and second edition publisher Indian research press, ISBN108183601421. page (822-872).

- Prashant L Agrawal, Sahil Shaileshbhai Patel and Shivanshu Rajesh Bhai Parmar (2016) “Design and Simulation of Manual Rack and Pinion Steering System” IJSART - Volume 2 Issue 7 –JULY 2016 ISSN [ONLINE]: 2395-1052. Page. (1-3).

- Habib, Azzam and Khattab (2001): “A theoretical analysis of the Free-cutting process of plant materials”1St International Conference for Manufacturing Agricultural Equipment and Machinery. 9th Conference of Misr Society of Agric. Eng. Page. (2).

- Manjunatha (2008)” field performance evaluation of vertical conveyor paddy reaper” International Journal of Agricultural Engineering | Volume 6| Issue 2| | 394–397).

- Mahrous (1995). “tested and evaluated rear mounted mower” M. Sc. Thesis. Agricultural Engineering. Dept., Faculty of Agric., Zagazig Univ. Egypt. Page. (2 & 4).

- Prof. P.B. Chavan, Prof. D.K. Patil and Prof. D.S. Dhondge (2015)” design and development of manual operated reaper” (IOSR Journal of Mechanical and Civil Engineering (IOSR-JMCE) e-ISSN: 2278-1684, p-ISSN: 2320-334X, Volume 12, Issue 3 Ver. I (May. - Jun. 2015), PP 15-22). Page. (15-18). [CrossRef]

- Ni Ni Aung, Win Pa Pa Myo and Zaw Moe Htet (2012)” Field Performance Evaluation of a Power Reaper for Rice Harvesting” International Journal of Science, Engineering and Technology Research (IJSETR) Volume 1, Issue 1. Page. (2-4).

- Duraga (2003) “Cold formed structural hollow section and profiles” fourth edition Onesteel publications trading PLS Limited ABN. Issue 4.2 BC0050. page (28 and 43).

- R.S. KHURMI and J.K. GUPTA (2005) “text book of Machine Design” S.I. units B.E. / B. Tech., U.P.S.C. (Eng. Services); Eurasia publishing house (PVT.) LTD. ram nagar, new delhi- 110 055. page (509–557,677-775, 820–884 and 996–1020).

- Aouad, G., Hinks, J., Sheath, D., Cooper, R., Kagioglou, M. and Sexton, M. (1997)” generic design and construction process protocol”; submitted to ITCon - Electronic Journal of Information Technology in Construction, http://itcon.org, page (10 and 54).

- Karl Ulrich and Steven (1994)” Product design and development” university of Pennsylvania, Massachusetts Institute of Technology. ISBN 1259297136. page (57 and 110).

- D. Eppinger, Steven and Karl Ulrich [2016]” Product design and development” sixth edition, university of Pennsylvania, Massachusetts Institute of Technology. page (2).

- Datt, P. and Prasad, J. (1999)” Development and evaluation of self-propelled vertical conveyor reaper for safflower crop”. Journal of the institution of Engineers (India), volume 79, pt AG/2, pp 45-47. page (2,6-7).

- Awady (1978)” Tractor and farm machinery. Text book, Faculty of Agriculture” Ain- Shams University. Pp: 164-167. page (3-5).

- Roozenburg, N. and Eekels, J. Utrecht: lemma (1995)” product Design fundamental and method” university of Michigan publisher Wiler. ISBN 0471943517.

- Devani. R. S. and M. M. Pandey (1985)” Performance evaluation of vertical conveyor reaper windrower” Karnataka Journal of Agricultural Sciences 9(1): 102-105. page (3).

- El-Sahrigi, A.F; A.S. Haman and Y. F. Sharobeem (1992)” Development of tractor front mounted reaper windrower”. Agricultural Engineering 14 (1): 50-67. page (1-5).

- Awady, M. N. (1978)” Tractor and farm machinery. Text book”: Faculty of Agriculture, Ain-Shams University. Pp: 164-167. page (2-4).

- R.K. Rajput. (2007)” manufacturing technology text book” manufacturing process book. page (2-5).

- R.S. Khurmi and J.K. Gupia (2010)” manufacturing process text book” workshop technology published by s. Chand and Co Ltd. publisher. ISBN 10:81219309928. page (17 -60 and 110-123).

- Richard G. Budynas and J. Keith Nisbett (2011)” Shigley’s mechanical engineering design” ninth edition Published by McGraw-Hill, a business unit of The McGraw-Hill Companies, Inc., 1221 Avenue of the Americas. page (359-409, 517-569 and 143-231).

- R.S. KHURMI and J.K. GUPTA (2005)” Theory of Machines” Section ‘B’ Of A.M.I.E. Eurasia publishing house (PVT.) LTD. Ram nagar, new delhi-110 055. page (24 – 71,94-118 and 143- 231).

- Lorenzo Morello, Lorenzo Rosti Rossini, Giuseppe Pia and Andrea Tonoli [2011] “The Automotive Body” volume II System Design page (21 - 167). [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).