1. Introduction

Circular economy (CE) is a shift from the traditional linear economy model, focusing on closed-loop systems where resources are reused, recycled, and regenerated [

1,

2,

3]. The concept has gained considerable traction in recent years, with a growing body of literature exploring its application across various industries and niche markets [

1]. The CE model minimizes waste and reduces environmental impact by extending the lifecycle of products and materials used [

4,

5,

6]. When companies adopt sustainable practices and circular economy principles, risk assessment becomes essential for anticipating and preparing for uncertainties associated with these transitions [

7,

8]. Assessing risks associated with circular economy adoption, such as technological, financial, regulatory, and operational risks, allows companies to make informed decisions, allocate resources efficiently, and capture the full benefits of a circular model [

6,

9,

10,

11,

12,

13,

14]

.

The ability of companies to engage in sustainable practices and implement circular economy principles is a key aspect of their dynamic capabilities [

15]. Ref. [

16] classifies dynamic abilities into three tiers:

incremental (which focuses on consistent enhancement of the company’s resources),

renewing (which involves refining, adapting, and expanding resources), and

regenerative (which requires a fundamental shift in the company’s approach to resource change) [

15]. For instance, a risk assessment could identify potential risks in sourcing sustainable materials or transitioning to a circular supply chain, allowing the organization to develop strategies to mitigate these risks [

17,

18]. Several key studies highlight the benefits of circular economy practices, including cost savings, reduced environmental impact, and enhanced competitiveness [

2,

13,

14].

In industries like food and beverage, integrating circular economy principles can reduce costs [

19] , increase sustainability [

20], reduce food waste [

21,

22,

23], improve resource efficiency [

9,

24], develop closed-loop supply chains [

3,

25] and meet consumer demands for eco-friendly products [

25]. For example, breweries have implemented systems to recycle water and energy, while food manufacturers have developed methods to repurpose by-products into new products [

26,

27,

28]. However, implementing circular economy practices at the micro-level poses challenges, as companies must overcome barriers like lack of infrastructure, high upfront costs, and resistance to change [

6,

10,

14]. To address these barriers, risk assessment is crucial to identify potential risks and implement effective mitigation strategies [

19,

26,

29].

The whisky industry, known for its rich heritage and traditional production methods, faces unique challenges in adopting sustainable practices due to its resource-intensive nature [

4,

15,

28,

30]. This highly fragmented and competitive market, with over 3,500 independent whisky distilleries in 69 countries [

31,

32], was valued at

$69 billion in 2023, and is projected to grow at a compound annual growth rate (CAGR) of 6.9%, reaching

$123.65 billion by 2032 [

28]. As the global demand for whisky continues to grow, the industry must find innovative ways to minimize its environmental footprint and embrace the principles of a circular economy [

31,

33,

34,

35]. Through the implementation of sustainable practices and the embrace of circular economy principles, the whisky industry can lead the way in demonstrating how traditional industries can adapt and thrive in a more environmentally conscious world. Recent trends show distilleries outside of the traditional whisky-producing countries are pioneering innovative techniques, utilizing unique ingredients, and challenging conventional norms [

28], and creating new value chains can provide economic opportunities for the communities surrounding the whisky production facilities [

30]. Managing by-products in a way that aligns with circular economy principles, such as repurposing spent grains as animal feed or bioenergy production, has significantly enhanced the industry’s sustainability profile [

21,

36]

. Biorefineries can also utilize whisky by-products and waste to create various fuels, chemicals and materials [

33].

This research paper explores the application of the Analytical Hierarchy Process (AHP) model for risk assessment in whisky production, providing a framework for its implementation. This study aims to provide industry stakeholders with actionable insights into the most critical risk factors affecting 18 whisky distilleries in Europe. By prioritizing these risks, whisky producers can better allocate resources, manage potential challenges, and develop effective strategies for sustainable production. Ultimately, this research seeks to contribute to the broader discourse on sustainability in the food and beverage industry, demonstrating the applicability of the AHP model in a practical, industry-specific context.

1.1. Sustainable Whisky Production

There are many challenges facing sustainable whisky production. They span across various stages of production, from ingredient sourcing to water usage, energy consumption, distillation, product aging, packaging, and the generation of by-products such as spent grains and pot ale.

Climate change challenges. Whisky character is significantly influenced by geographical location and climate [

34]. An increase in global temperatures by 2˚C may result in yield losses of 46% for wheat and 31% for maize across the world, leading to supply chain disruptions and higher cost of raw material [

37] Temperature control during malting and kilning is crucial, but high ambient air temperatures can cause overheating, while additional moisture reduces the effectiveness of fermentation [

38]. Hot summer days can reduce cooling efficiency, requiring additional water to prevent the fermentation from failing [

37], or causing distillation to run slower and less frequently [

39]. The aging process of whisky and oak is influenced by temperature and pressure, with warm temperatures accelerating maturation and altering the whisky character due to aggressive interaction [

37].

Ingredient Sourcing and Agriculture. Whisky production relies on fertilizers and pesticides, causing soil and water pollution. To address these environmental challenges, the industry is shifting towards sustainable farming practices [

34]. However, sourcing key grain ingredients like barley, corn, rye, and wheat can be challenging due to the high water, land, and fertilizer requirements. Transitioning to organic or sustainably farmed grains can be costly and resource-intensive [

10,

40]. Organic barley can cost up to 50% more than conventionally grown barley [

34]. Additionally, supply chain disruptions due to weather conditions, pests, or crop diseases can affect availability, consistency and price of barley and wheat crops [

31,

41,

42].

Water usage. The whisky industry relies heavily on freshwater for various stages of production, including malting, mashing, distillation, and bottling [

34]. Distilleries generally use their own private water source, thus contributing to the unique flavor of the finished product [

37]. Water scarcity and droughts are known to force distilleries to halt production [

34,

38,

42]. Approximately

61 billion liters of water are annually used, with a majority imputed in the cooling process. It is a water-intensive product, where the production of

one liter of whiskey requires 46.9 liters of water [

42]. Considering both direct and indirect usage (e.g., water used for growing grains), the production of one liter of whiskey requires approximately 15,000 liters of water [

43]. Whisky production generates significant amounts of wastewater (20 liters of wastewater to 1 liter of whisky produced), which contains caustic soda, copper levels from copper stills, organic material and other contaminants [

34,

37]. Companies meet environmental standards by implementing water management strategies, treating discharged water and increasing water consumption efficiency using the 3Rs principle (Reduce, Reuse, Recycle), and by performing water footprint assessments throughout product life cycles [

4,

26].

Energy Consumption. Traditional distillation, a highly energy-intensive process reliant on fossil fuels, significantly increases greenhouse gas emissions due to its heavy heat input. Just the Scotch whisky industry in Scotland, with only 175 distilleries was reported to emit around 620,000 tonnes of CO2 annually as of 2024 [

34]. Significant upfront costs and technological advancements are needed to replace outdated equipment in the whisky production process or switch to renewable energy sources. Among the initiatives are increasing water conservation, employing renewable energy, and improving energy efficiency [

4,

15,

30,

34,

36].

Waste management. Whisky production generates by-products like spent grains and pot ale, which can be repurposed for animal feed or compost [

4,

22,

23,

30,

44,

45]. For example, the Scotch whisky industry produces around 500,000 tonnes of spent grains annually [

34]

. Companies have implemented anaerobic digestion to convert organic waste into biogas, reducing CO2 emissions by over 95% [

4,

28,

43]. Ref. [

34] reports that 90% of the industry’s waste is now recycled or reused, a significant improvement from previous years.

Aging and Storage. The flavor of whisky is developed through years of ageing in barrels, which presents unique sustainability challenges. The aging process requires large amounts of space and resources over many years, tying up significant capital and material. Whiskies are aged for various periods (minimum 3 years, and up to 30 years or more), making forecasts of demand in future periods subject to significant uncertainty [

46,

47].

Regulatory compliance. International production and safety standards, such as ISO 22000: 2018 -

Food Safety Management System [48,49,50], FSSC 22000: Food Safety System Certification [

48,

51], ISO 45001: 2018 -

Occupational Health and Safety Management System [52,53] or

OHSAS 18001: Occupational Health and Safety Assessment Series, ISO 14001:2015 -

Environmental Management Systems [54], and National Sanitation Laws are frequently adopted by whisky distilleries [

30]. Production facilities are certified and run in accordance with international energy management system standards (ISO 50001) [

55,

56]. ISO 22,000 integrates the principles of the

Hazard Analysis and Critical Control Points (HACCP) management system in which food safety is addressed through the analysis and control of biological, chemical, and physical hazards from raw material production, procurement, and handling, to manufacturing, distribution, and consumption of the finished product [

50]. Additionally, ISO 31000: 2018 -

Risk Management – Guidelines [57] and the ISO 31010:2019 -

Risk Management - Risk Assessment Techniques [

58]provide guidance on the selection and application of systematic techniques for risk assessment and risk management pertinent in food and beverage industry [

59].

The implementation of circular economy principles in the whisky production process entails a number of inherent risks that require careful consideration and analysis. Prior research has primarily focused on energy efficiency [

36], water management [

38], and waste valorization [

22,

30,

44]. To identify, assess, and prioritize possible risks, risk assessment models like the Life Cycle Assessment, Failure Mode and Effects Analysis, Environmental Risk Assessment, and Risk Matrix are crucial for sustainable practices in the whisky production industry [

59,

60]. Few studies comprehensively evaluate sustainability risks in whiskey production [

4,

31,

35,

44,

47]. The research aims to identify key risk factors from 18 European distilleries and develop a multi-criteria decision-making framework incorporating circular economy principles.

1.2. Analytical Hierarchy Process model used for Risk Assessment

One of the most crucial steps in the risk management process is accurately identifying potential sources of risk. Because risk criteria are determined based on an individual’s perspective and experience, they are subjective. Using a multi-criteria analysis framework such as the Analytical Hierarchy Process (AHP) model, which establishes the significance levels and consistency of the risk criteria, allows for a more objective risk assessment in complex settings for managing risk and uncertainty involving intuitive, rational, and even irrational aspects [

61,

62,

63].

In risk assessment, the most widely used multi-scale decision-making technique is the Analytic Hierarchy Process (AHP) [

60,

61,

62,

63,

64,

65]. Because of its adaptability, ease of computation, and integration with other strategies, it is the most popular and effective multi-criteria decision support method [

61]. The method relies on the judgment of experts (trained members) who must use pairwise comparisons between items. AHP increases precision because it reduces the variability between experts in terms of the evaluated criteria [

61,

62,

66]. This model lessens decision-making bias by utilizing the geometric average of each decision maker’s individual choice [

61,

66]. Thanks to AHP’s consistency ratio, experts who deviate greatly from the group can be removed or retrained [

62,

67] One of AHP’s most significant benefits is its ability to prioritize criteria and sub-criteria in a well-balanced hierarchical structure [

59,

60,

65]. Judgements are made between the criteria and the applicable alternatives using the 1-to-9 assessment scale, and comparison matrices are formed [

66,

68].

AHP model has been applied in risk assessment in many industries, including construction, forestry, agriculture, logistics, and occupational health and safety [

59,

60,

63,

64,

69,

70,

71,

72,

73]. Ref. [

74] used the method to analyze food safety risk criteria in Baltic fish and the AHP method to rank these risk criteria in order of importance. As a result of the investigation, it was discovered that there were clear variations in the recognition and understanding of certain risk factors. Ref.[

75], an AHP-based risk assessment model was created to assess agriculture supply chain framework. Ref. [

72] used AHP to rank the success factors in sustainable food supply chain management. In Ref. [

73] fuzzy AHP and fuzzy TOPSIS was used to evaluate quality and sustainability in bakeries’ production process. The authors have previously used AHP to perform sensory analysis of buckwheat and sorghum beers [

71]. However, there are no studies that we know of, that evaluate risks in the field of sustainable whisky production using AHP model.

2. Materials and Methods

This study utilizes a combined qualitative and quantitative research methodology.

2.1. Qualitative Analysis – Identify Common Risk Factors from Case Studies

The qualitative analysis identifies key risk factors in whisky manufacturing through literature and interviews with micro-distilleries. Selecting appropriate evaluation criteria is crucial for the risk assessment’s validity, with industry experts providing valuable insights from their practical experience. To make sure that the AHP model appropriately represents the company’s priorities and the state of the industry, this expert input is crucial [

66,

68,

76]

.

For the case studies, we chose to focus on whisky distilleries from continental Europe that were opened after 2000, which reduced the samples size to around 275 potential distilleries out of 580. Since European distilleries are mostly independently owned, very few information is available online. Our final case study pool consisted of 18 small distilleries that with a production capacity between 20,000 and 200,000 liters (

Table 1). Experts were selected from various areas of the whisky industry, including production, health and food safety, sustainability, regulatory affairs, and marketing, and were asked to brainstorm risks from workplace observations and work evaluations.

2.2. Quantitative Analysis – Using AHP Model to Assess Risks in Whisky Industry

The Analytic Hierarchy Process approach typically involves a hierarchical structure, pairwise comparisons, and a consistency evaluation to analyze complex decision-making problems. In this study, the implemented AHP model utilized data collected from 18 European whisky production facilities to examine the factors influencing sustainable whisky production and the adoption of circular economy principles.

2.2.1. Step 1. Hierarchy Construction

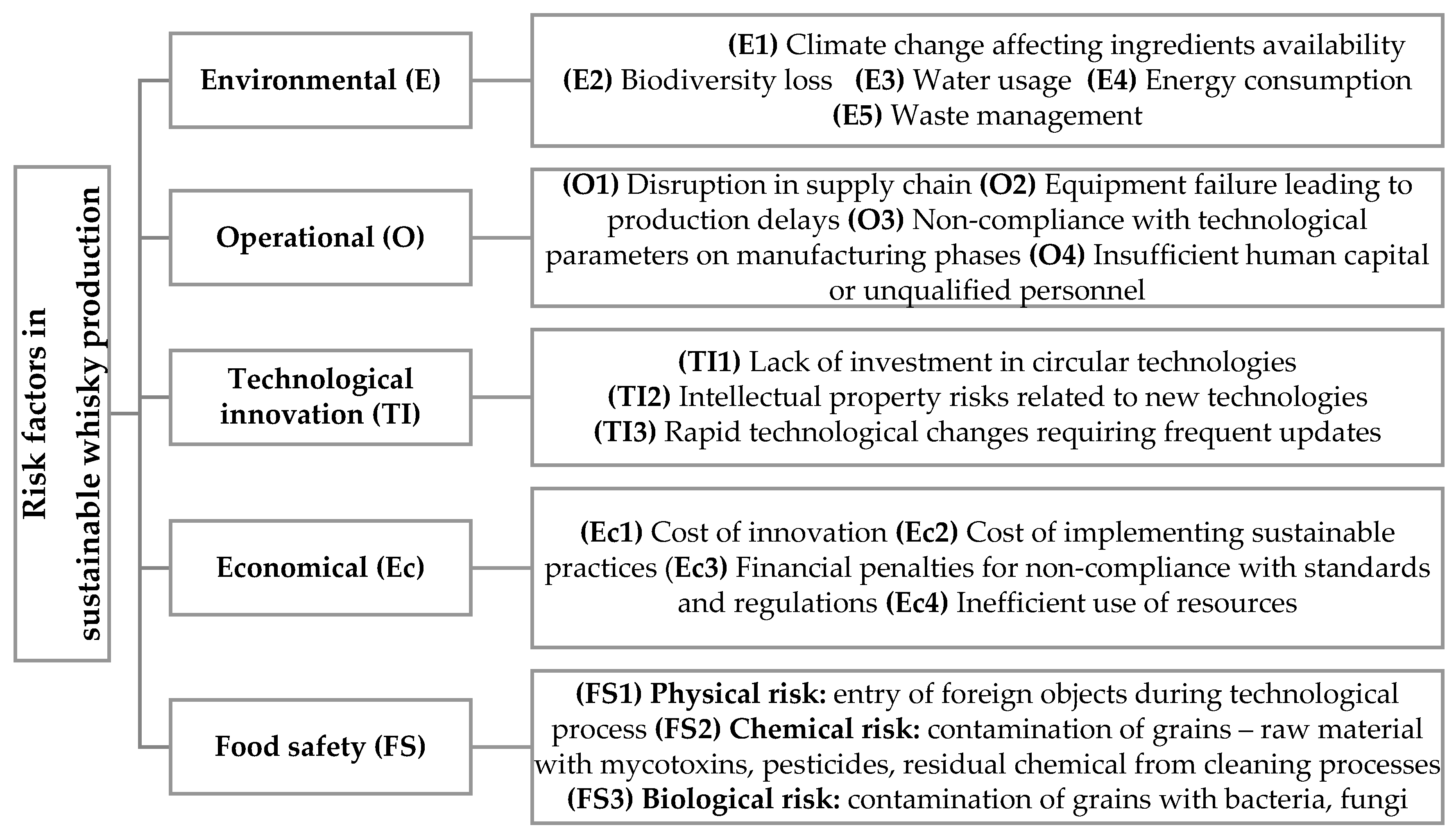

As a result of the qualitative analysis, it was determined that whisky distilleries are commonly exposed to 19 risk sub-criteria within 5 main risk groups:

environmental risks (5),

operational risks (4),

technological innovation risks (3),

food safety risks (3) and

economical risks (4) (

Figure 1). Utilizing the Analytic Hierarchy Process facilitates the examination of the importance and significance of each risk factor outlined in the hierarchical structure of

Figure 1, thereby revealing how these risks influence the sustainability of whisky production. The primary purpose of this hierarchical approach is to simplify the complex problem and enhance overall understanding of the underlying factors impacting the sustainability of whisky production [

61,

68].

A well-defined hierarchy ensures that the decision criteria and sub-criteria are appropriately decomposed, enhancing the model’s accuracy and reliability [

65]. The existing literature on Analytic Hierarchy Process applications does not specify a strict minimum sample size requirement. Typically, AHP studies have been conducted with a range of four to fifteen decision-makers [

61,

62,

71]. Furthermore, some studies have even included more than fifteen decision-makers in their AHP applications, demonstrating the flexibility of the method to accommodate a variety of sample sizes based on the research objectives and context [

60,

61,

64]

.

2.2.2. Step 2. Pairwise Comparison

At this stage, the relative importance of the main criteria and sub-criteria is determined by comparing them in pairs, based on the judgment of the decision maker. When comparing the criteria, the expert uses a pairwise comparison scale in

Table 2 containing the numerical values between 1 and 9 determined by Ref.[

66,

68], where:

Therefore, if the expert making the judgement considers a criterion to be strongly more important than another, it will receive a score of 5; and if it is less important, it receives a score of .

For a given set of

elements (criteria or alternatives), the pairwise comparisons are represented in an

matrix

, where:

with

for all i.

For instance, a pairwise comparison matrix

for

three criteria might look like:

where:

By aggregating the pairwise comparison matrices derived from the assessments provided by the whisky distillery experts using the geometric mean, a consolidated pairwise comparison matrix (A) is formed. This consolidated matrix can then be utilized to determine the significance or relative importance of each risk criterion under consideration. The resulting dimensional square matrix (

) is formed by arranging the compared criteria in the corresponding rows and columns [

66,

68]. The matrices can also be represented as:

where matrix A represents the pairwise comparisons of the criteria, and the dimension n corresponds to the number of criteria being evaluated.

When precise quantitative measurement is not feasible, it is essential to evaluate the consistency and reliability of the measurements. This is particularly important in cases where subjective assessments or expert judgments are used to determine the relative importance of different criteria or alternatives [

66,

76,

77]. The characteristic function of a matrix, particularly in the context of a pairwise comparison matrix, is a key mathematical tool used to compute the eigenvector corresponding to the maximum eigenvalue:

The eigenvectors of the matrix

are calculated as follows:

where w represents the eigenvector. Thus, the eigenvector corresponding to the maximum eigenvalue

is derived [

40,

41].

Various methods are used to determine the eigenvector and eigenvalue in Analytical Hierarchy Process research. In this study, the eigenvector and eigenvalue were calculated using the methodology outlined in Ref.[

66]. To prevent excessively large or small values in the comparison matrix from causing issues with this approach, matrix A is normalized. This is achieved by dividing each value in the comparison matrix by the sum of the column elements, resulting in the elements of the normalized pairwise comparison matrix. The normalized element

is calculated as:

Matrix normalization facilitates the calculations and enhances the comprehensibility of the value comparisons since all values are standardized within the range (0, 1) [

61,

66,

70]. To ensure that the results are consistent and can be readily interpreted, the elements of the eigenvector associated with the maximum eigenvalue are determined by calculating the average of the row elements in the normalized matrix A, as follows:

Maximum eigenvalue

is calculated as:

This approach generates reliable outcomes when there is substantial consistency in paired comparisons. The result represents an estimated value, and the more consistent the experts’ assessments, the more precise the outcome will be. If the comparison results are unsatisfactory, decision-makers must revisit and refine the paired comparison process to ensure the integrity and accuracy of the risk assessment, which is crucial for enabling the successful implementation of circular economy strategies [

64,

66].

2.2.3. Step 3. Checking the Consistency Ratio

Human judgments are often subject to inconsistencies. Checking the consistency of these judgments is crucial to ensure that the derived priorities or weights are meaningful and reliable. Thomas Saaty, the creator of this method, defined the consistency ratio as the ratio of consistency index to random index [

66,

68]. The random index presented in

Table 3 is calculated based on the number of criteria.

The Random Index depends on the size of the matrix. For n=1 or n=2, the RI is 0 because a matrix of size 1 or 2 is always consistent. As the matrix size increases, the RI values increase because the chances of inconsistency grow with more criteria.

The consistency index, which determines the acceptability of the consistency ratio for the comparison matrix A, is then calculated as [

66,

68,

76]:

The Consistency Index (CI) represents the average degree of inconsistency in the matrix based on the characteristic equation’s remaining solutions (see

Table 3 for details). To evaluate and reduce inconsistencies in the comparison matrix, the Consistency Ratio (CR) is calculated using the formula from Ref. [

66,

68,

76].

where RI (Random Index) is a predefined value that varies according to the size of the matrix.

The Consistency Ratio (CR) indicates how consistent the expert judgments are. A CR value of 0.10 or less is considered acceptable, meaning the level of inconsistency in the comparisons is within an acceptable range [

68,

76].

3. Results

The study involved 36 experts from 18 whisky distilleries who were asked to evaluate and rate the risk criteria in the hierarchy on a scale of one to nine, based on their expertise and experience. These experts assessed the various risk factors associated with the circular economy model, such as supply chain disruptions, resource availability, and environmental compliance. The final comparison matrix for the main risk criteria was then constructed by calculating the geometric means of the data collected from these experts. The appropriate mathematical equation was used to generate the resulting matrix, which provided a comprehensive risk assessment framework for the circular economy.

According to Equation (1) the following matrix was formed:

To create the pairwise comparison matrix normalized according to Equation (6), each element

from matrix

A was divided by the sum of the elements in the corresponding column. The following normalized pairwise comparison matrix was obtained:

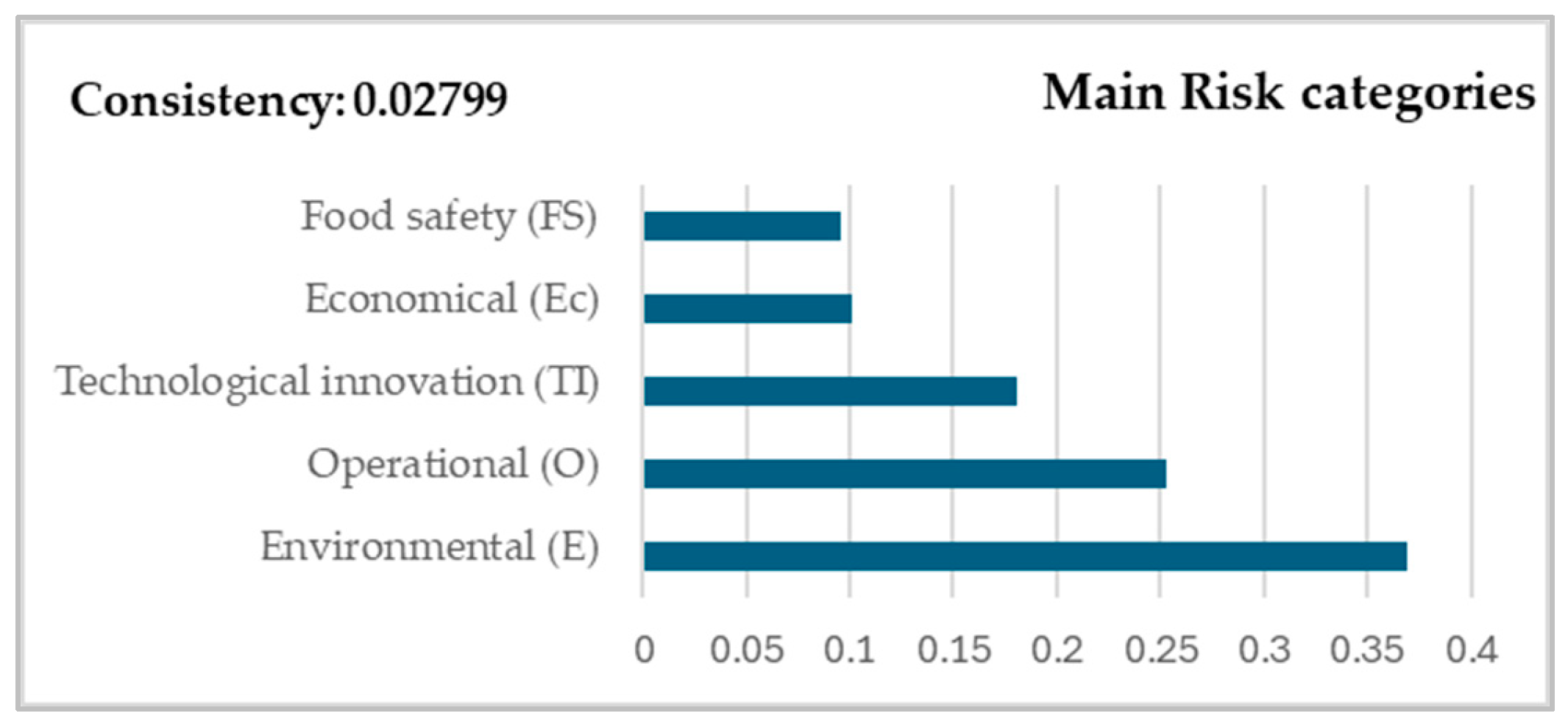

The weight coefficients and consistency ratios of the main criteria were calculated by averaging the row elements of the normalized matrix A, according to the principle of Equation (7) and Equation (9). As shown in

Figure 2, the key risk criteria were identified as environmental risk (0.369), operational risk (0.253), technological innovation risk (0.181), economical risk (0.101), and food safety risk (0.096), based on their relative priorities. This finding aligns with the conclusions of a similar prior study, which emphasizes the importance of considering these risk factors for ensuring the long-term viability and minimizing the negative environmental impacts of a circular economy.

A priority weight of 0.369 suggests that environmental risk accounts for approximately 37% of the total importance assigned to all criteria. This high weighting reflects the emphasis placed on mitigating environmental impacts, particularly in contexts where sustainability and environmental stewardship are paramount, such as in a circular economy. Following at 25%, operational risk is critical in ensuring that the day-to-day functions of an organization or system are managed efficiently and that potential disruptions are minimized. The results show a moderate level of concern regarding the risks associated with the adoption of new technologies and innovations for the distilleries opened after 2000s. Economic and food safety risks are perceived as less significant within the given context for European whisky distilleries.

The maximum eigenvalue (= 5.126) calculated from Equation (9) was placed in Equation (10), and the consistency index value (CI=0.031) was calculated. The random index value given for the 5 parameters from Table (3) was taken as (RI=1.11), the CI and RI values were placed in the relevant positions in Equation (10) and calculated: CR=0.028). Since the consistency ratio was less than the 10% limit value (CR=0.028<0.1), it was decided that the comparisons of the experts were deemed consistent.

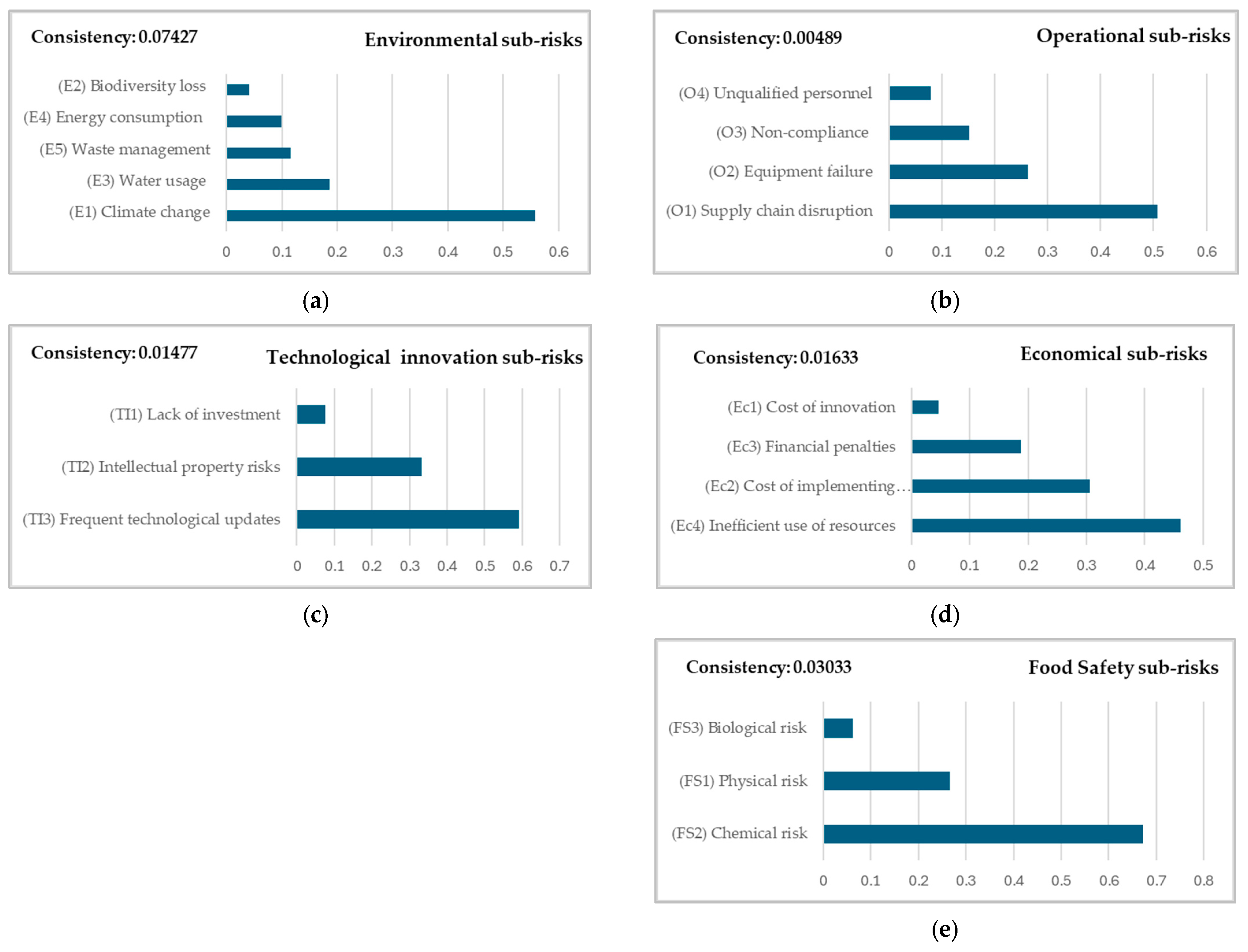

The same procedure was applied to determine the prioritization and weight of sub-criteria on each main risk category. As seen in

Figure 3:

(a) The sub-criteria with the highest environmental risk were determined to be climate change affecting ingredients availability (0.558), and water usage (0.186), while the lowest environmental risk was biodiversity risk (0.041). Waste management (0.116) and energy consumption (0.098) are very closely ranked. These findings explain the extensive focus in research literature to developing new technological alternatives that mitigate these risks. The CR value of 0.074 (the highest among to other risk categories results from this study) implies that the prioritization may change, depending on the unique context under which certain distilleries may operate.

(b)In the operational risk class, supply chain disruption (0.507) is perceived to hold highest impact towards sustainable whisky production, followed by equipment failure leading to production delays (0.263), and non-compliance with technological parameters during manufacturing phases (0.152). Based on the experts’ experience, unqualified personnel (0.078) had the lowest perceived contribution to operational risk. The consistency ration CR of 0.004 indicates excellent consensus on the impact and priority of the sub-risks that were assessed.

(c) The weights of the sub-criteria in the technological innovation risk category have been determined to be frequent technological updates (0.591) and intellectual property risks related to new technologies (0.333). Since the distilleries that participated in this study are built after 2000s, majority of them rely on newer technology and adhere to ISO guidelines. Therefore, the sub-risk lack of investment in circular technologies (0.075) is ranked relatively low for the selected target group. However, there are many frequent technological advances that can be adopted to address water usage, waste management and other environmental risks. The intellectual property implication of such solutions are often the driving factors of successful marketing strategies that satisfy customer preferences for reduced carbon footprint technologies, increase brand awareness of being sustainable and help distilleries gain competitive advantage. The consistency ration CR of 0.014 indicates consensus on the impact and priority of the sub-risks that were assessed.

(d) In the economic risk class, inefficient use of resources (0.461) is by far the most important sub-criteria impacting sustainable whisky production, closely followed by the cost of implementing sustainable practices (0.305) and financial penalties for non-compliance with standards and regulations (0.187). The cost of innovation (0.046) is ranked lower than other economic sub-criteria, since the sample population have less of an innovation and technological gap to address compared to traditional whisky distilleries that, for example, would need to buy equipment to modernize their production facilities. The consistency ration CR of 0.016 indicates consensus on the impact and priority of the sub-risks that were assessed.

The main food safety risk associated with sustainable whisky production are chemical risks (0.671) such as contamination of grains – raw material with mycotoxins, pesticides, residual chemical from cleaning processes, followed by physical risks (0.265) – entry of foreign objects during technological process and biological risks (0.063) –contamination of grains with bacteria, fungi, etc. Biological risk has the lowest weight because of the nature of alcoholic beverage production, as the pathogenic microorganisms cannot survive the high alcohol content (min. 40% alc. vol.) present in whiskies . The consistency ration CR of 0.030 indicates consensus on the impact and priority of the sub-risks that were assessed.

By comparing all sub-risks associated with each risk factor in pairs, the local weight (LW) coefficients for each sub-criterion were found, which allowed for the determination of the significance order of each sub-criterion. The calculation of global weight (GW) involved multiplying the local weight (LW) of each sub-risk by the relevant main risk criterion’s local weight [

61]

. To ascertain the importance ranks of the sub-criteria shown in

Table 4, the global weight values of each sub-criteria were listed.

As seen in

Table 4 above, the five most important sub-risk criteria that new whisky distilleries are exposed to are: climate change affecting ingredients availability, supply chain disruptions, frequent technological updates, water usage and equipment failure leading to production delays.

To prioritize the sub-risk criteria within the main risk criteria, the

, CI and CR values of each main risk criteria class were calculated in separate AHP applications. The consistency was assessed by comparing the CR value with the limit value of 0.1 (

Table 5). Since all risk criteria had CR values less than 0.1, the decisions made for each expert were consistent.

4. Discussion

The application of the Analytic Hierarchy Process model in this study provides a structured and insightful examination of the risk landscape for new whisky distilleries established in Europe after the 2000s. The results underscore the significance of systematically prioritizing risks to enhance sustainable production and operational efficiency. Circular economy principles emphasize the importance of resource efficiency, waste reduction, and sustainable practices across all sectors. The study’s findings have several notable implications that align with and expand upon existing research, offering new perspectives on risk management in the whisky distillery industry.

Firstly, with a weight coefficient of 0.369, environmental risk was found to be the most important category. This result is consistent with the larger body of research on sustainability in the beverage sector, where environmental issues like waste management, water use, and climate change are increasingly recognized as major obstacles. Climate change’s impact on ingredient availability is prioritized at 0.558, indicating a growing understanding of the direct effects that these changes can have on the supply chain and ingredient quality. This result is in line with earlier research that highlights how susceptible agricultural inputs are to climatic variability and emphasizes the necessity of creative risk-reduction tactics. Furthermore, the focus on waste management and water use draws attention to persistent worries about resource efficiency, a recurring theme in sustainability research. According to these findings, distilleries should put an emphasis on environmental stewardship and implement cutting-edge technologies to effectively reduce these risks. By doing so, they will be able to meet consumer demand for environmentally friendly products and global sustainability goals.

Operational risks are the second most important risk category (0.253), with the most important sub-risks being supply chain disruptions (0.507) and equipment failure (0.263). These results validate earlier studies that show equipment reliability and supply chain resilience as essential components for continuous production in manufacturing industries. With the recent global supply chain challenges brought on by the COVID-19 pandemic, it is especially noteworthy that supply chain disruptions have been given such high priority. This indicates that in order to minimize any disruptions, new distilleries should invest in strong supply chain management plans and backup plans. Furthermore, research emphasizing the value of maintaining operational continuity and minimizing downtime to maximize production efficiency and cut costs is consistent with the focus on equipment failure. Expert agreement, as demonstrated by the low consistency ratio (CR=0.004), further supports the validity of these results and points to a broad consensus regarding the operational difficulties distilleries face.

Significant weights assigned to frequent technological updates (0.591) and intellectual property risks (0.333) highlight the importance of

technological innovation risks (0.181). The swift advancement of technology and the requirement for distilleries to consistently innovate to stay ahead of the competition are both reflected in this finding. Since many new distilleries rely on contemporary machinery and technologies, it is suggested that keeping up with technological developments should be a top priority due to the emphasis on frequent updates. This is especially important given how the whisky industry is going digital, automated, and using data analytics. Innovations that give a competitive advantage must be protected, as the significance of intellectual property risks emphasizes. These observations are consistent with the body of knowledge regarding the contribution of technological innovation to improved market differentiation and operational efficiency [[

29]. While sustainability is a priority, the weight given to the lack of investment in circular technologies (0.075) is relatively low, suggesting that the immediate focus is still on utilizing current technological capabilities rather than making significant investments in new circular technologies.

The study also identifies significant economic risks (0.101) are a notable concern, especially in relation to resource waste (0.461) and the expense of adopting sustainable practices (0.305). These results are in line with earlier studies that have highlighted the financial difficulties in implementing sustainable practices, particularly for new players in the market who might have severe funding shortages. Given the high ranking of inefficient resource use, distilleries should concentrate on streamlining their processes to reduce waste and increase resource efficiency, as this is essential to preserving their competitiveness and cost-effectiveness. This outcome is also consistent with more general economic trends, which call for striking a balance between sustainability and financial viability. Experts generally agree on these economic issues, as evidenced by the consistency ratio (CR=0.016), which highlights the necessity for distilleries to develop cost-effective sustainability strategies.

Lastly, the risks to food safety (0.096) are emphasized, with the most important sub-risk being chemical risks (0.671), which include contamination from pesticides and mycotoxins. This research emphasizes how crucial it is to uphold strict food safety regulations in the whisky industry, especially as consumers grow more conscious of these concerns. The natural antimicrobial qualities of alcohol, which lessen the possibility of bacterial contamination, are consistent with the lower ranking of biological risks (0.063). These findings are consistent with earlier research emphasizing the need for strict quality control procedures to avoid contamination and guarantee product safety. The industry’s recognition of the significance of food safety is reflected in the moderate consistency ratio (CR=0.030), which indicates a reasonable level of agreement among experts.

The study assesses commonly found risks for new whisky distilleries in Europe, emphasizing environmental sustainability, operational resilience, technological innovation, economic efficiency, and food safety. It contributes to sustainable practices and offers insights for future research, using the AHP model for decision-making.

4.1. Limitations of the AHP Research

The AHP model used in a study for decision-making in new distilleries in Europe has several limitations, including potential expert bias and subjectivity, inability to fully capture the dynamic nature of the industry, limited scope of risk factors considered, and limited applicability to distilleries in other regions or time periods. The study focuses on a predefined set of main risk categories and sub-criteria, potentially overlooking other relevant factors that could impact new distilleries. For example, social and cultural factors, brand reputation, or market competition might also play a significant role but were not included in the analysis. Additionally, the model assumes a static decision environment, which may not accurately reflect the evolving market conditions, technological advancements, and regulatory landscapes. The conclusions may not apply directly to older distilleries or those in other regions with different operating environments and regulatory requirements because they are specific to new distilleries in Europe built after the 2000s.

4.2. Recommendations for Future Research

To address these limitations and build on the current findings, future research should expand the AHP model’s scope to include social factors, market dynamics, and brand-related risks to better understand the challenges faced by distilleries. Longitudinal studies could track changes in risk priorities over time, while integrating AHP with other decision-making models and risk assessment models could improve its ability to handle interdependencies. Expanding the geographic scope could provide a global perspective on risks in the whisky industry. Exploring the impact of emerging technologies like artificial intelligence, blockchain, and Internet of Things (IoT) on risk management could provide valuable insights. Additionally, conducting case studies at specific distillery could further validate the model’s applicability in real-world settings.

By addressing these areas, future research can further refine the AHP model, enhance its applicability, and provide valuable guidance for new distilleries navigating the complex landscape of risk management.

5. Conclusions

This study shows how the Analytic Hierarchy Process (AHP) model can be used effectively to assess risks in the production of sustainable whisky, especially when distilleries implement the circular economy. The AHP model offers a strong framework for determining, ranking, and prioritizing the different risk factors that new whisky distilleries in Europe must contend with by combining qualitative and quantitative data. Thirteen sub-criteria and five primary risk criteria—environmental, operational, technological innovation, economic, and food safety risks—were identified by the analysis, which involved thirty-six experts from eighteen small European distilleries. The findings show that operational risks like supply chain disruptions and technological innovation risks, such as the requirement for frequent technological advancements, are second most important for sustainable whisky production, after environmental risks, particularly those pertaining to climate change and water usage.

The results emphasize how critical it is to approach risk management methodically in a way that is consistent with sustainable practices and the ideas of the circular economy. The AHP model’s reliability is validated in this context by the experts’ consistent judgments, as evidenced by the low consistency ratios (CR < 0.1) across all risk categories. By offering a thorough framework for risk assessment, the study adds to the larger conversation on sustainability in the food and beverage sector. This framework can help whisky producers make more informed strategic decisions and improve their ability to effectively manage risks.

The study acknowledges limitations in its application of the AHP model, including reliance on expert judgments and its static nature. Future research should include social, cultural, and market dynamics, longitudinal studies, and the impact of emerging technologies on risk management. This will enhance the applicability of the model and offer valuable insights for sustainable whisky production and risk management.

6. Patents

Not applicable.

Author Contributions

“Conceptualization, D.D and A.C.; methodology, D.D and A.D.; software, D.D.; validation, A.C., A.D. and C.E.N.; formal analysis, D.D and A.C.; investigation, D.D.; resources, D.D.; data curation, D.D.; writing—original draft preparation, D.D.; writing—review and editing, A.C., C.E.N and A.D; visualization, D.D.; supervision, C.E.N and A.D. All authors have read and agreed to the published version of the manuscript.”

Funding

This research received no external funding

Data Availability Statement

Data available on request.

Acknowledgments

We would like to express our thanks to the panel of industry experts and to the anonymous reviewers who have contributed to improve this article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Dabija, D.; Năstase, C. Exploring the Evolution of Sustainability Paradigms: From Linear to Circular Economy Models. Proceedings of the International Conference on Business Excellence 2024, 18, 754–769. [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy – A New Sustainability Paradigm? J Clean Prod 2017, 143, 757–768. [CrossRef]

- MahmoumGonbadi, A.; Genovese, A.; Sgalambro, A. Closed-Loop Supply Chain Design for the Transition towards a Circular Economy: A Systematic Literature Review of Methods, Applications and Current Gaps. J Clean Prod 2021, 323, 129101. [CrossRef]

- Duffy, C.; Styles, D.; Schestak, I.; Macgregor, K.; Jack, F.; Henn, D.; Black, K.; Iannetta, P.P.M. Optimising Sustainability: Circular Pathways for Scotch Whisky Distillery Co-Products. J Clean Prod 2023, 395. [CrossRef]

- Onat, N.C.; Kucukvar, M.; Halog, A.; Cloutier, S. Systems Thinking for Life Cycle Sustainability Assessment: A Review of Recent Developments, Applications, and Future Perspectives. Sustainability (Switzerland) 2017, 9.

- Dieckmann, E.; Sheldrick, L.; Tennant, M.; Myers, R.; Cheeseman, C. Analysis of Barriers to Transitioning from a Linear to a Circular Economy for End of Life Materials: A Case Study for Waste Feathers. Sustainability (Switzerland) 2020, 12. [CrossRef]

- Wang, Z.; Luo, P.; Zha, X.; Xu, C.; Kang, S.; Zhou, M.; Nover, D.; Wang, Y. Overview Assessment of Risk Evaluation and Treatment Technologies for Heavy Metal Pollution of Water and Soil. J Clean Prod 2022, 379. [CrossRef]

- Awan, U.; Sroufe, R. Sustainability in the Circular Economy: Insights and Dynamics of Designing Circular Business Models. Applied Sciences (Switzerland) 2022, 12. [CrossRef]

- Golinska-dawson, P.; Werner-lewandowska, K.; Kosacka-olejnik, M. Responsible Resource Management in Remanufactur-Ing—Framework for Qualitative Assessment in Small and Medium-sized Enterprises. Resources 2021, 10, 1–17. [CrossRef]

- Gedam, V. V.; Raut, R.D.; Lopes de Sousa Jabbour, A.B.; Tanksale, A.N.; Narkhede, B.E. Circular Economy Practices in a Developing Economy: Barriers to Be Defeated. J Clean Prod 2021, 311. [CrossRef]

- Dey, P.K.; Malesios, C.; Chowdhury, S.; Saha, K.; Budhwar, P.; De, D. Adoption of Circular Economy Practices in Small and Medium-Sized Enterprises: Evidence from Europe. Int J Prod Econ 2022, 248. [CrossRef]

- Walzberg, J.; Lonca, G.; Hanes, R.J.; Eberle, A.L.; Carpenter, A.; Heath, G.A. Do We Need a New Sustainability Assessment Method for the Circular Economy? A Critical Literature Review. Frontiers in Sustainability 2020, 1.

- Kirchherr, J.; Yang, N.H.N.; Schulze-Spüntrup, F.; Heerink, M.J.; Hartley, K. Conceptualizing the Circular Economy (Revisited): An Analysis of 221 Definitions. Resour Conserv Recycl 2023, 194.

- Kirchherr, J.; Piscicelli, L.; Bour, R.; Kostense-Smit, E.; Muller, J.; Huibrechtse-Truijens, A.; Hekkert, M. Barriers to the Circular Economy: Evidence From the European Union (EU). Ecological Economics 2018, 150, 264–272. [CrossRef]

- MacKenzie, N.G.; Perchard, A.; Mackay, D.; Burt, G. Unlocking Dynamic Capabilities in the Scotch Whisky Industry, 1945–Present. Bus Hist 2022. [CrossRef]

- Ambrosini, V.; Bowman, C.; Collier, N. Dynamic Capabilities: An Exploration of How Firms Renew Their Resource Base. British Journal of Management 2009, 20. [CrossRef]

- Gennari, F. The Transition towards a Circular Economy. A Framework for SMEs. Journal of Management and Governance 2023, 27, 1423–1457. [CrossRef]

- Schulte, J.; Villamil, C.; Hallstedt, S.I. Strategic Sustainability Risk Management in Product Development Companies: Key Aspects and Conceptual Approach. Sustainability (Switzerland) 2020, 12, 1–20. [CrossRef]

- Bigdeloo, M.; Teymourian, T.; Kowsari, E.; Ramakrishna, S.; Ehsani, A. Sustainability and Circular Economy of Food Wastes: Waste Reduction Strategies, Higher Recycling Methods, and Improved Valorization. Materials Circular Economy 2021, 3. [CrossRef]

- De Pascale, A.; Di Vita, G.; Giannetto, C.; Ioppolo, G.; Lanfranchi, M.; Limosani, M.; Szopik-Depczyńska, K. The Circular Economy Implementation at the European Union Level. Past, Present and Future. J Clean Prod 2023, 423.

- Weber, C.T.; Trierweiler, L.F.; Trierweiler, J.O. Food Waste Biorefinery Advocating Circular Economy: Bioethanol and Distilled Beverage from Sweet Potato. J Clean Prod 2020, 268. [CrossRef]

- Chetrariu, A.; Dabija, A. Spent Grain: A Functional Ingredient for Food Applications. Foods 2023, 12.

- Chetrariu, A.; Dabija, A. Brewer’s Spent Grains: Possibilities of Valorization, a Review. Applied Sciences (Switzerland) 2020, 10.

- Klein, S.P.; Liszt-Rohlf, V.; Spieth, P. Value-based Bricolage: Resource Mobilization in the Circular Economy. J Ind Ecol 2023, 27, 1476–1487. [CrossRef]

- Arijeniwa, V.F.; Akinsemolu, A.A.; Chukwugozie, D.C.; Onawo, U.G.; Ochulor, C.E.; Nwauzoma, U.M.; Kawino, D.A.; Onyeaka, H. Closing the Loop: A Framework for Tackling Single-Use Plastic Waste in the Food and Beverage Industry through Circular Economy- a Review. J Environ Manage 2024, 359. [CrossRef]

- Schestak, I.; Styles, D.; Black, K.; Williams, A.P. Circular Use of Feed By-Products from Alcohol Production Mitigates Water Scarcity. Sustain Prod Consum 2022, 30, 158–170. [CrossRef]

- Yu, T.; Kowalski, M.P.; Shackelford, L.T.; Brooks, D.C.; Ennis, J.M. Using Web3 Technologies to Represent Personalized Consumer Taste Preferences in Whiskies. Food Qual Prefer 2024, 118. [CrossRef]

- Mordor Intelligence (2024). Whiskey Market Size & Share Analysis - Growth Trends & Forecasts (2024 - 2029) Available online: https://www.mordorintelligence.com/industry-reports/whisky-market accessed 08.08.2024.

- Urbinati, A.; Shams Esfandabadi, Z.; Messeni Petruzzelli, A. Assessing the Interplay between Open Innovation and Sustainability-Oriented Innovation: A Systematic Literature Review and a Research Agenda. Business Ethics, the Environment & Responsibility 2023, 32, 1078–1095. [CrossRef]

- Edwards, C.; McNerney, C.C.; Lawton, L.A.; Palmer, J.; Macgregor, K.; Jack, F.; Cockburn, P.; Plummer, A.; Lovegrove, A.; Wood, A. Recoverable Resources from Pot Ale & Spent Wash from Scotch Whisky Production. Resour Conserv Recycl 2022, 179. [CrossRef]

- Page, I.B. Why Do Distilleries Produce Multiple Ages of Whisky? Journal of Wine Economics 2019, 14, 26–47. [CrossRef]

- The Whisky Yardvark (2024). Distilleries Available online: https://www.thewhiskyardvark.com/distilleries accessed 08.08.2024.

- Ubando, A.T.; Felix, C.B.; Chen, W.-H. Biorefineries in Circular Bioeconomy: A Comprehensive Review. Bioresour Technol 2020, 299, 122585. [CrossRef]

- Scotch Whisky Association (2024). Insights Available online: https://www.scotch-whisky.org.uk/insights accessed 08.08.2024.

- Bower, J. Scotch Whisky: History, Heritage and the Stock Cycle. Beverages 2016, 2. [CrossRef]

- Olanrewaju, F.O.; Andrews, G.E.; Phylaktou, H.N.; Li, H.; Smith, S.; Maxfield, J.D.; Wakeman, R. Renewable Energy from Whisky Distillery By-Products. Chem Eng Trans 2023, 105, 211–216. [CrossRef]

- Roberts, C.; Maslin, M. How Might Climate Change Impact Scotch Whisky Production in the next 50-100 Years?; 2021;

- Bringhurst, T.; Brosnan, J.; Russell, I.; Stewart, G. Water: An Essential Raw Material for Whisk(e)y Production. In Whisky; Elsevier, 2014; pp. 291–298.

- Nicol, D.A. Batch Distillation. In Whisky; Elsevier, 2014; pp. 155–178.

- Pecchioli, B.; Moroz, D. Do Geographical Appellations Provide Useful Quality Signals? The Case of Scotch Single Malt Whiskies. Econ Model 2023, 124. [CrossRef]

- Harkness, C.; Semenov, M.A.; Areal, F.; Senapati, N.; Trnka, M.; Balek, J.; Bishop, J. Adverse Weather Conditions for UK Wheat Production under Climate Change. Agric For Meteorol 2020, 282–283. [CrossRef]

- Mcgrane, S.J.; Allan, G.J.; Roy, G. Water as an Economic Resource and the Impacts of Climate Change on the Hydrosphere, Regional Economies and Scotland;

- Maximize Market Research(2024). Whiskey Market: Global Industry Analysis by Market Share, Trend, Size, Competitive Landscape, Regional Outlook and Forecast (2024-2030). Available online: https://www.maximizemarketresearch.com/market-report/global-whiskey-market/27265/ accessed on 08.08.2024.

- Chetrariu, A.; Dabija, A. Spent Grain from Malt Whisky: Assessment of the Phenolic Compounds. Molecules 2021, 26. [CrossRef]

- Klein, O.; Nier, S.; Tamásy, C. Towards a Circular Bioeconomy? Pathways and Spatialities of Agri-Food Waste Valorisation. Tijdschrift voor Economische en Sociale Geografie 2022, 113, 194–210. [CrossRef]

- Jahandideh, H.; McCardle, K.; Tang, C.; Fahimnia, B. Capacity Allocation for Producing Age-Based Products. Decision Sciences 2023, 54, 473–493. [CrossRef]

- Fromentin, V.; Pecchioli, B.; Moroz, D. Time-Varying Causality among Whisky, Wine, and Equity Markets. Financ Res Lett 2024, 63. [CrossRef]

- Bomba, M.Ya.; Susol, N.Ya. Main Requirements for Food Safety Management Systems under International Standards: BRC, IFS, FSSC 22000, ISO 22000, Global GAP, SQF. Scientific Messenger of LNU of Veterinary Medicine and Biotechnologies 2020, 22, 18–25. [CrossRef]

- Zimon, D.; Madzik, P.; Domingues, P. Development of Key Processes along the Supply Chain by Implementing the ISO 22000 Standard. Sustainability (Switzerland) 2020, 12. [CrossRef]

- Mamalis, S.; Kafetzopoulos, D.P.; Aggelopoulos, S. The New Food Safety Standard ISO 22000. Assessment, Comparison and Correlation with HACCP and ISO 9000:2000. The Practical Implementation in Victual Business Paper Prepared for Presentation at the 113 Th EAAE Seminar “A Resilient European Food Industry and Food Chain in a Challenging World; 2009;

- Condrea, E.; Constantinescu, G.; Stanciu, A.C.; Constandache, M. PARTICULARITIES OF FSSC 22000-FOOD SAFETY MANAGEMENT SYSTEM; 2015; Vol. 16;.

- Darabont, D.C.; Antonov, A.E.; Bejinariu, C. Key Elements on Implementing an Occupational Health and Safety Management System Using ISO 45001 Standard;

- Darabont, D.-C.; Moraru, R.I.; Antonov, A.E.; Bejinariu, C. 7 Th International Multidisciplinary Symposium “SUSTAINABLE DEVELOPMENT THROUGH QUALITY AND INNOVATION IN ENGINEERING AND RESEARCH” Managing New and Emerging Risks in the Context of ISO 45001 Standard;

- Tarí, J.J.; Molina-Azorín, J.F.; Heras, I. Benefits of the ISO 9001 and ISO 14001 Standards: A Literature Review. Journal of Industrial Engineering and Management 2012, 5, 297–322.

- Rampasso, I.S.; Filho, G.P.M.; Anholon, R.; de Araujo, R.A.; Lima, G.B.A.; Zotes, L.P.; Filho, W.L. Challenges Presented in the Implementation of Sustainable Energy Management via ISO 50001:2011. Sustainability (Switzerland) 2019, 11.

- Fuchs, H.; Aghajanzadeh, A.; Therkelsen, P. Identification of Drivers, Benefits, and Challenges of ISO 50001 through Case Study Content Analysis. Energy Policy 2020, 142. [CrossRef]

- Parviainen, T.; Goerlandt, F.; Helle, I.; Haapasaari, P.; Kuikka, S. Implementing Bayesian Networks for ISO 31000:2018-Based Maritime Oil Spill Risk Management: State-of-Art, Implementation Benefits and Challenges, and Future Research Directions. J Environ Manage 2021, 278. [CrossRef]

- Sine, M.M.; Maria, E. Analisis Manajemen Risiko Pada Penerapan Sistem Informasi Pembangunan Daerah (SIPD) Menggunakan IEC/ISO 31010:2019. Building of Informatics, Technology and Science (BITS) 2022, 4. [CrossRef]

- Kokangül, A.; Polat, U.; Dağsuyu, C. A New Approximation for Risk Assessment Using the AHP and Fine Kinney Methodologies. Saf Sci 2017, 91, 24–32. [CrossRef]

- Božanić, D.; Tešić, D.; Komazec, N.; Marinković, D.; Puška, A. Interval Fuzzy AHP Method in Risk Assessment. Reports in Mechanical Engineering 2023, 4, 131–140. [CrossRef]

- Unver, S.; Ergenc, I. Safety Risk Identification and Prioritize of Forest Logging Activities Using Analytic Hierarchy Process (AHP). Alexandria Engineering Journal 2021, 60, 1591–1599. [CrossRef]

- Gheorghita, R.E.; Lupaescu, A.V.; Gâtlan, A.M.; Dabija, D.; Lobiuc, A.; Iatcu, O.C.; Buculei, A.; Andriesi, A.; Dabija, A. Biopolymers-Based Macrogels with Applications in the Food Industry: Capsules with Berry Juice for Functional Food Products. Gels 2024, 10. [CrossRef]

- Xu, L.; Kumar, D.T.; Shankar, K.M.; Kannan, D.; Chen, G. Analyzing Criteria and Sub-Criteria for the Corporate Social Responsibility-Based Supplier Selection Process Using AHP. International Journal of Advanced Manufacturing Technology 2013, 68, 907–916. [CrossRef]

- Ioan Ban, A.; Iuliana Ban, O.; Bogdan, V.; Sabau Popa, D.C.; Tuse, D. Performance Evaluation Model of Romanian Manufacturing Listed Companies by Fuzzy Ahp and Topsis. Technological and Economic Development of Economy 2020, 26, 808–836. [CrossRef]

- Canco, I.; Kruja, D.; Iancu, T. Ahp, a Reliable Method for Quality Decision Making: A Case Study in Business. Sustainability (Switzerland) 2021, 13. [CrossRef]

- Saaty, T.L. Correction to: Some Mathematical Concepts of the Analytic Hierarchy Process (Behaviormetrika, (1991), 18, 29, (1-9), 10.2333/Bhmk.18.29_1). Behaviormetrika 2021, 48, 193–194.

- Vivek, K.; Subbarao, & K. V; Routray, W.; Kamini, & N.R.; Dash, K.K. Application of Fuzzy Logic in Sensory Evaluation of Food Products: A Comprehensive Study. 1947. [CrossRef]

- Saaty, T.L. The Analytic Hierarchy and Analytic Network Processes for the Measurement of Intangible Criteria and for Decision-Making. In; 2016; pp. 363–419.

- Ayyildiz, E.; Gumus, A.T. Pythagorean Fuzzy AHP Based Risk Assessment Methodology for Hazardous Material Transportation: An Application in Istanbul.. [CrossRef]

- Zuraidi, S.N.F.; Rahman, M.A.A.; Akasah, Z.A. A Study of Using AHP Method to Evaluate the Criteria and Attribute of Defects in Heritage Building. In Proceedings of the E3S Web of Conferences; EDP Sciences, November 26 2018; Vol. 65.

- Dabija, A.; Ciocan, M.E.; Chetrariu, A.; Dabija, D. RESEARCH ON THE USE OF THE AHP METHOD IN THE SENSORY ANALYSIS OF BUCKWHEAT AND SORGHUM BEER; 2023; Vol. 24;.

- Kumar Sharma, Y.; Kumar Yadav, A.; Kumar Mangla, S.; Patil, P.P. Ranking the Success Factors to Improve Safety and Security in Sustainable Food Supply Chain Management Using Fuzzy AHP; 2018; Vol. 5;.

- Serpa, N.P.; Silva, D.J.C. da; Wegner, R. da S.; Stertz, E. da S.; Teixeira, C.S.; Lopes, L.F.D. Quality and Sustainability in the Production Process: A Study of Bakeries Using an Integrated Multi-Criteria Method Based on Fuzzy AHP and Fuzzy TOPSIS. Environmental Quality Management 2023, 32, 251–262. [CrossRef]

- Ali, B.M.; Andersson, M.G.; van den Borne, B.H.P.; Focker, M.; van der Fels-Klerx, H.J. Multi-Criteria Decision Analysis in Food Safety Risk Management: The Case of Dioxins in Baltic Fish. Foods 2022, 11. [CrossRef]

- Yazdani, M.; Gonzalez, E.D.R.S.; Chatterjee, P. A Multi-Criteria Decision-Making Framework for Agriculture Supply Chain Risk Management under a Circular Economy Context. Management Decision 2019, 59, 1801–1826. [CrossRef]

- Agapie, A. CONSISTENCY IN THE CONTEXT OF AHP: HALF FRIEND, HALF FOE; 2014;

- Pino, M.E.M.; Ordoñez, F.R.R.; Ysa, R.A.S.; Llanos, D.M.J.; Cruz, M.M.T.; Calderón, B.A.C. Role of Expert in Validation of Information Collection Instruments for Business Purposes. International Journal of Professional Business Review 2023, 8, e03122. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).