1. Introduction

Finger millet (Eleusine coracana) known as African millet, is an important cereal crop renowned for its nutritional benefits, especially in regions where it is a staple food. It is locally known as “

Dagussa” in Ethiopia and holds significant cultural, nutritional, and economic importance in the country’s agriculture and food systems. It is a resilient crop that thrives in diverse agroecological zones, contributing to food security and dietary diversity, particularly in rural communities [

2,

30]. It is rich in essential amino acids, dietary fiber, and minerals, making it a valuable dietary component for combating malnutrition and enhancing food security [

12,

27]. In recent years, there has been growing interest in utilizing finger millet not only for its nutritional qualities but also for its potential in fermented food products.

Fermentation is a traditional food processing technique that has been widely used to enhance the nutritional value, palatability, and shelf life of food products [

21]. During fermentation, complex biochemical reactions mediated by microbial communities lead to changes in the physicochemical properties of the substrate, resulting in alterations in texture, flavor, and nutrient availability [

24].

Finger millet flour is often used to prepare batters that undergo spontaneous or controlled fermentation. Fermentation of these batters not only modifies their sensory attributes but also enhances their nutritional quality through the breakdown of antinutritional factors such as phytates and tannins, and by increasing the bioavailability of minerals and vitamins [

24,

25]. Fermentation transforms the physicochemical properties of finger millet, enhancing its bioavailability of nutrients such as iron, calcium, and B vitamins, while reducing antinutritional factors like phytates [

2,

29]. Moreover, fermentation promotes the synthesis of bioactive compounds, such as antioxidants and peptides with potential health benefits [

12].

Despite the extensive traditional use and emerging scientific interest in fermented finger millet products, there remains a need to systematically investigate the influence of fermentation parameters, particularly fermentation time, on the physicochemical properties and microbial dynamics of finger millet flour batters. Understanding these dynamics is crucial for optimizing fermentation processes to enhance fermented finger millet products’ quality, safety, and health benefits [

20].

Recent studies have begun exploring metabolic activities during finger millet fermentation, highlighting the predominance of lactic acid bacteria and yeasts as key fermentative agents [

13,

28].These studies underscore the importance of microbial interactions and metabolic activities in shaping the final characteristics of fermented products. In this study, we aim to investigate how varying fermentation times influence finger millet flour batters of physicochemical properties.

2. Materials and Methods

2.1. Location of Study

The physicochemical properties of the studied crops were examined at the Melkassa Agricultural Research Center and Debre Zeit Agricultural Research Center.

2.2. Sample Collection and Preparation

Teff control, Axum, Meba, and

Padet finger millet varieties were collected from the Arsi Negele Agricultural Research Center, a Melkassa Agricultural Research Center subcenter. The finger millet varieties were grown in the 2022/2023 season. The collected samples were transported to the Melkassa Agricultural Research Center. The samples were cleaned and sorted to remove the stone, dust particles, and broken, undersized, and immature grains. About 2.5 kilograms of finger millet grains were taken from each variety and washed three to four times using tap water. Among this, 800 g of control

teff grains were sun-dried and served as control. The remaining cleaned and washed finger millet grains were soaked in a ratio of seeds to water of 1:3 for 24 hrs at room temperature. Then, the finger millet grains were milled using a miller (3010–019, USA) and sieved at 1 mm. The flour was packed using an airtight polyethylene bag and stored at room temperature [

8].

2.3. Preparation of Batter

The batter was mixed well by hand and allowed to ferment in an incubator at 30 0C for fingers millet batter was prepared separately by adding respective millet powder (10% w/w) to the fermented batter and mixing thoroughly. The fermentation was carried out for 24 to 72 hours in batters’ millet. The samples of fermented batter were drawn at every 4 h interval and subjected to physicochemical analysis. The samples collected at each interval were subjected to physicochemical analysis measurements of pH, titratable acidity, viscosity, and moisture content.

2.4. Determination of Physicochemical Properties of Finger Millet Batters

2.4.1. Functional Properties of Composite Flour

Water absorption capacity and oil absorption capacity were determined following the method of Abiodun et al, and while the method of Kusumayanti et al. was used to determine the swelling power and solubility index of the flours [

1,

16].

2.4.2. Water and Oil Absorption Capacity

A clean, pre weighed 20 mL centrifuge tube containing approximately 1. 000 g of flour was filled with 10 distilled water and stirred continuously for approximately one hour. The mixture was then centrifuge (90-1, electronic centrifuge, China) at 3000 rmp for fifteen minutes. Following centrifugation, the supernatant was carefully decanted and the tube containing the sediment was weighed again. The water and oil absorption capacity were calculated as mL of water absorbed per gram of flour.

where: WAC = water absorption capacity, W

1 =Weight of centrifuge tube and sample (g), W

2= weight of centrifuge tube and sediment (g) w= weight of dry sample (g)

2.4.3. Swelling Power and Water Solubility Index

The determination of swelling power and water solubility index were performed using the procedure outlined by [

9,

15]. A pre weighed centrifuge tube was filled with about 2.500 g of flour.30 mL of distilled water and the mixture was then weighed again. After agitating the mixture with a glass rod, it was cooked for ten minutes at 90 in water bath (GEMMYCOModel-YCW010, Taiwan). After cooling to ambient temperature, the mixtures were centrifuged for 10 minutes at 3000 rmp. Following centrifugation, the sediment was weighed and the supernatant was poured from it into an evaporating aluminum dish that had been previously weighed to ascertain its solid content. By evaporating the supernatant at 110 during the whole night, the weight of the dry particles was recovered (Thermostatic Drier, Model-202OA, China). Next, WSI and SP were determined using the following equations.

where: SP = Swelling power, WSI =water solubility index =weight of sediment (g) Wds =weight of dry supernatant(g), and Wo =weight of dry sample (g)

2.5. Determination of Viscosity of Batter

The viscosity of the fermented batter of finger millet flour (100 mL) at 20, 50, and 100 rpm was determined using a Viscometer (Brookfield, DV-E) fitted with two types of disc spindles S-62 and S-18. The readings were taken after 1 minute of revolution [

10] The appropriate disc spindle was selected so that the torque readings were not below 10% of the total scale. For all samples, the viscosity of the batter was determined right before baking by regulating the temperature with a water bath at 25 1°C.

2.6. Determination of pH Batter

The batter of finger millet flour (10 g) was mixed with 100 mL of distilled water and centrifuged at 3000 g for 20 min. The supernatant was separated to determine the pH using a pH meter. The pH of each fermented finger millet batter sample was tested directly using a glass digital pH meter according to [

4] standard procedure 981.12. The pH meter was calibrated using buffer solutions with pH values of 4.0 and 7.0. The pH meter electrode was then rinsed with distilled water, blotted with tissue paper, and dipped into each liquid sample beaker to determine the pH value.

2.7. Determination of Total Titratable Acidity

Ten (10) g of the finger millet batter was mixed with 100 mL of distilled water and titrated with 0.1 N NaOH to an end point pH of 8.2 using an auto-titrator (Titroline Alpha plus TA 20, S.I. GmbH, Mainz, of using). The volume of NaOH used for each titration was recorded and titratable acidity was expressed as % lactic acid Sadler et al., using the formula below:

where: V=Volume of 0.1 N NaOH used for sample titration; 0.009008=Factor equivalent in which 1ml of 0.1N NaOH =0.009008g C3H6O5; W=Weight in a gram of sample in the mixture.

3. Results and Discussion

3.1. Experimental Design and Data Analysis

The physicochemical properties of the samples were analyzed in duplicate was tested in triplicate. We used a Completely Randomized Design (CRD) for physicochemical data and a Randomized Complete Block Design (RCBD) for the experimental designs [

14] The physicochemical properties data were analyzed using analysis of variance (ANOVA) with JMP software version 13. Mean differences were assessed using Tukey’s Honestly Significant Differences (HSD) test (p < 0.05). The results were presented as means ± standard error.

3.2. Physicochemical Properties of Finger Millet Flour Batter

3.2.1. Functional Properties flour

Table 1 Presents the results of the functional properties of finger millet flours. water absorption capacity (WAC), water absorption index (WAI), oil absorption capacity (OAC), swelling power, bulk density, and dispersibility play significant roles in determining the usability of these flours in various food products.

The WAC and WAI values shows the ability of millet flours to retain moisture. In this study,

Quncho Teff and

Axum have similar WAC values (1.89 g/g), while

Meba has a slightly higher WAC (2.06 g/g). This suggests that Meba may be better suited for products that require higher moisture retention. The higher WAI values observed for

Quncho Teff (5.90 g/g) and

Meba (5.99 g/g) indicate enhanced hydration properties, which are crucial for dough formation and textural qualities in baked goods. [

22] reported WAC values for millet flours between 1.5 and 2.2 g/g, indicating similar moisture retention capabilities. [

22] also noted that higher WAI values improve dough quality, highlighting the significance of these properties in food applications.

OAC values vary significantly among millet varieties, with

Quncho Teff exhibiting the highest OAC (156.67%) and

Axum the lowest (100.00%). This variation is important as higher oil absorption can enhance flavor and texture in food products. OAC values reported in other studies vary from 90% to over 160%, depending on the specific variety and processing methods [

11]. According to these authors, emphasized the role of oil absorption in flavor release and texture enhancement, suggesting that the differences in OAC among millet varieties may be influenced by their lipid composition.

Swelling power is vital for determining the thickening and gelling properties of flours.

Axum demonstrates the highest swelling power (8.28%), indicating its potential for applications requiring thickening. Conversely,

Quncho Tef (7.66%) and

Meba (7.84%) show lower swelling power. Swelling power for millet flours has been documented between 6% and 10% in various cultivars [

7] aligning closely with observations. This finding aligns with [

7], who indicated that swelling power is influenced by the amylose content of starches in different cereals.

The bulk density values range from 0.73 g/mL (

Meba) to 0.81 g/mL (

Axum), suggesting that

Axum may be more suitable for products where lower density is desired, facilitating better mixing and incorporation. According [

15], bulk density values for millet flours typically range from 0.70 to 0.85 g/mL. This alignment with findings that the millet varieties studied have similar physical characteristics to those previously analyzed.

Dispersibility is an essential property for flours used in liquid formulations. The dispersibility values range from 75.83% (

Quncho Teff) to 78.33% (

Axum), indicating that

Axum has superior dispersibility. High dispersibility is vital for ensuring uniform distribution of flour in liquids, which is critical in products like soups and sauces [

15] reported dispersibility values for millet flours between 70% and 80%. This similarity confirms that the millet varieties analyzed in study demonstrate comparable dispersibility characteristics to those documented in the literature.

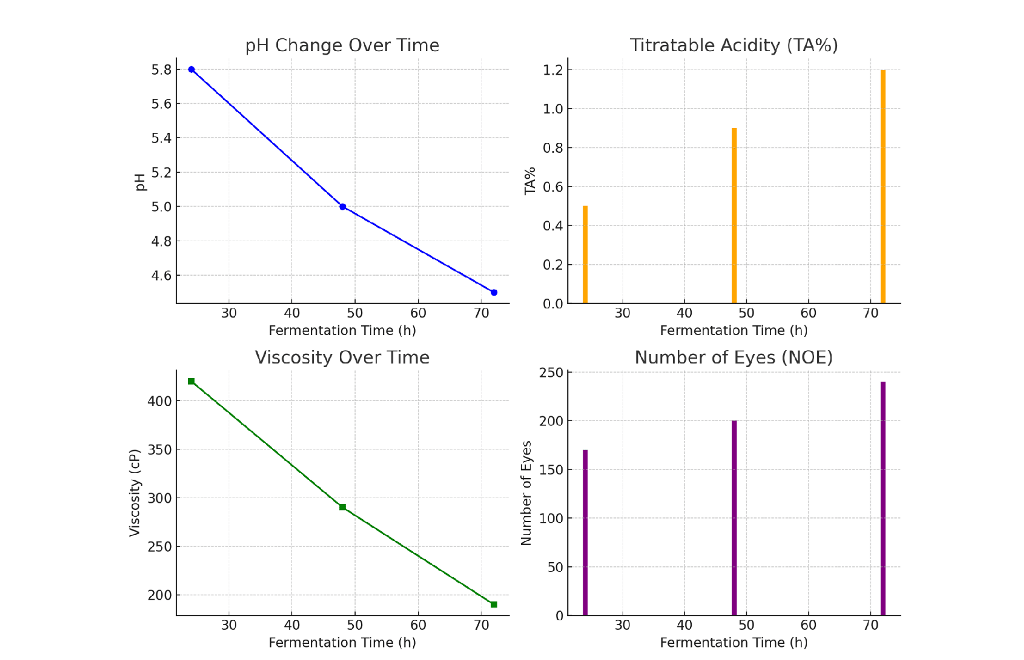

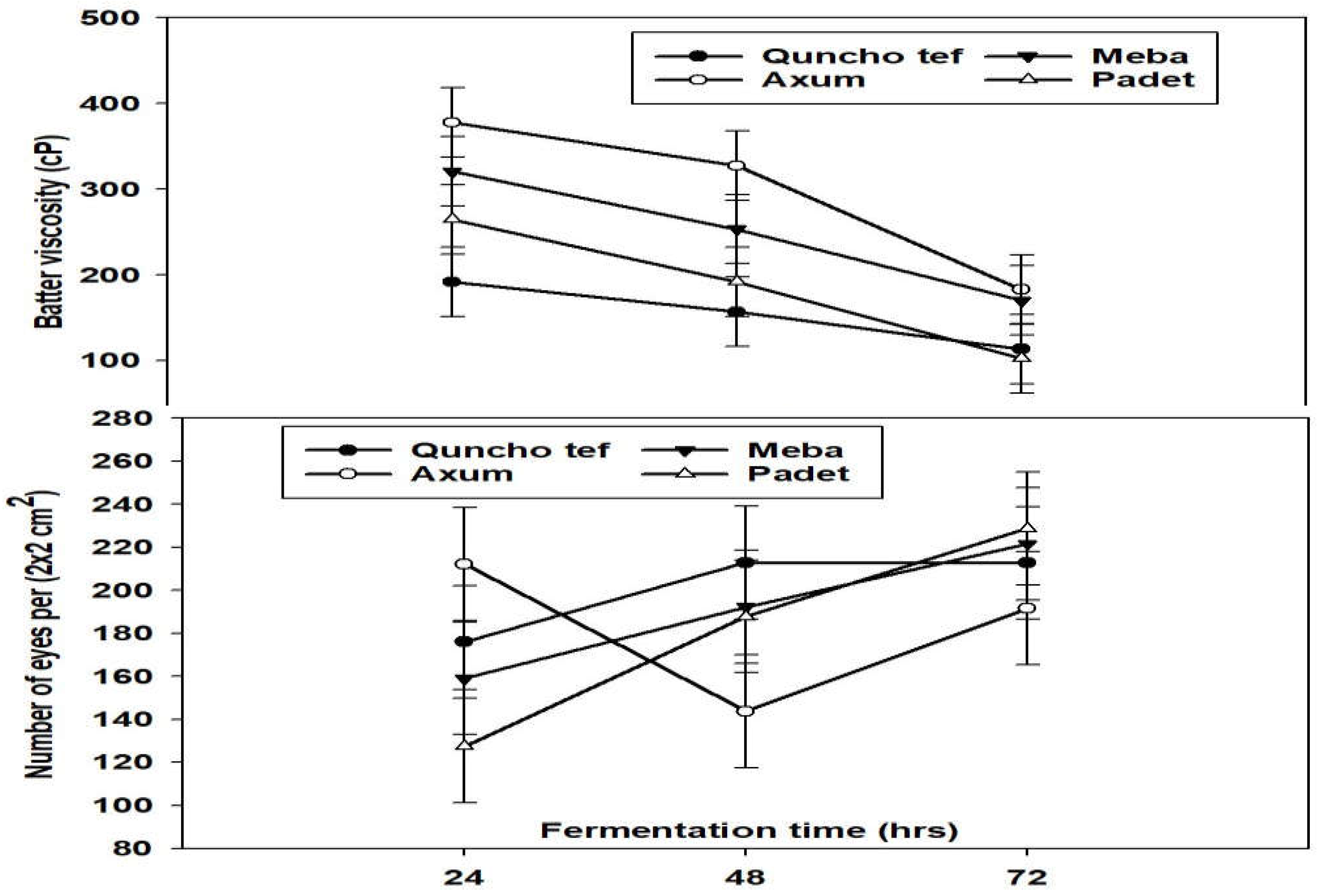

3.2.2. Viscosity

The viscosity of finger millet flour (

Padet,

Meba, Axum, and

Quncho Teff control) batter exhibited a significant decrease (p < 0.05) over the fermentation period of 24 to 72 h were indicated in

Figure 1. At 24 hours, the viscosities of the various millet flours ranged from 300 cP for Padet to 420 cP for

Quncho Teff. By 72 h, the viscosity of the

Padet variety decreased to 200 cP, while

Quncho Teff reached approximately 190 cP. This reduction in viscosity can be attributed to the enzymatic breakdown of complex carbohydrates into simpler sugars and the production of organic acids during fermentation, aligning with findings by [

19,

23,

26].

3.2.3. Number of Eyes (NOE)

As showed in

Figure 1, the number of eyes (a measure of porosity) in the

injera made from the different finger millet varieties generally increased over the fermentation time. The

Quncho Teff variety showed a steady increase in the number of eyes, from 170 to 240 eyes per 2x2 cm

2, indicating enhanced gas production and improved porosity during the fermentation process [

3,

31]. Similarly, the

Meba and

Padet varieties exhibited consistent increases in the number of eyes, from 180 to 220 and 150 to 210, respectively. This aligns with the notion that optimal fermentation conditions are crucial for maximizing the porosity of finger millet

injera [

31]. However, the

Axum variety exhibited an initial decrease followed by an increase in the number of eyes. This unique pattern could be attributed to variations in fermentation conditions or microbial activity, as [

3] suggested, highlighting the importance of carefully controlling the fermentation process. The varietal differences in the number of eyes can be influenced by factors such as the starch and protein composition of the finger millet [

5,

8].

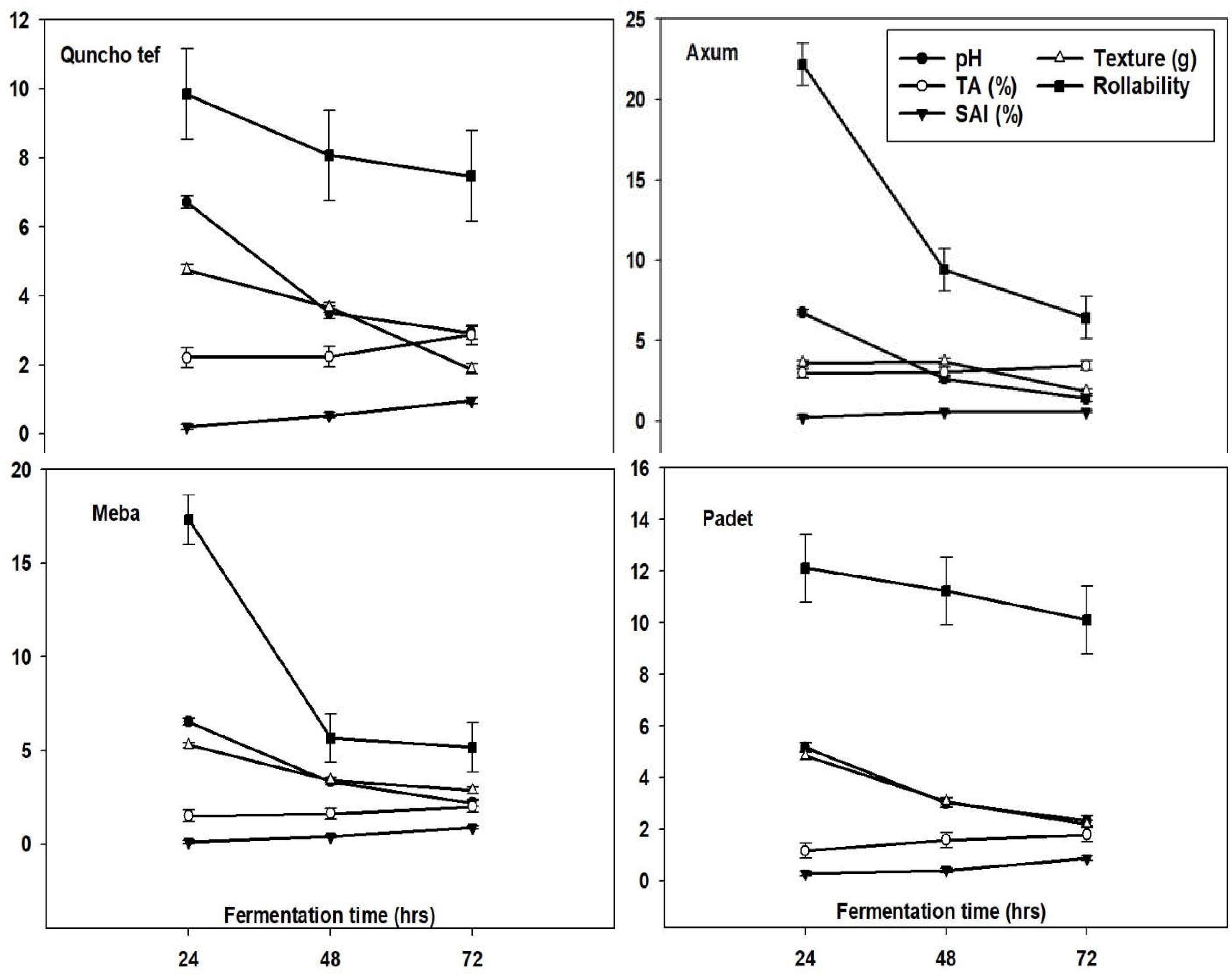

The physicochemical properties of different varieties of finger millets and control tef

injera were significantly

(p<0.05) varied except for the number of eyes and sauce absorption index (SAI) shown in

Figure 2. The highest titratable acidity TA (%), batter viscosity, and

injera rollability corresponding to the least pH and hardness were exhibited by the Axum finger millet variety. There was no significant difference between the Axum and Padet varieties regarding

injera texture and rollability. The

injera samples obtained from all finger millet varieties and tef control exhibited a similar number of eyes (NOE) and SAI, which implies that the newly released finger millet varieties have great potential in application for

injera making.

3.3.4. Correlation of Physicochemical Properties

The different physicochemical properties of batter and

injera were significantly (p<0.05) varying over the fermentation time shown in

Figure 2. The batter pH and viscosity as well as

injera hardness and rollability exhibited significantly

(p<0.05) decreasing trends over the fermentation time (24-72 hr); which corresponded to increasing levels of TA (although not statically significant), NOE, SAI

(p<0.05). The decreasing pH with increasing NOE and SAI was also evidenced by a significant negative correlation (r = -0.4496 and -0.3737, respectively. The decreasing pH is due to the formation of lactic acid by lactic acid bacteria, which resulted in thinning of the batter (reduced viscosity) and softer

injera. The increased NOE and SAI levels signify better desirability of injera as the increased NOE and SAI made it better interact with the sauce and get softer and palatable. The decreasing pH can be attributed to lactic acid production by lactic acid bacteria, which in turn, thins the batter (reducing viscosity) and softens the injera, enhancing its palatability [

13].

4. Conclusions

The fermentation time significantly influences the physicochemical properties and microbial dynamics of finger millet flour batter, enhancing the quality of injera. Findings include a decrease in pH, an increase in titratable acidity, and a reduction in viscosity over time, which collectively improve the batter’s texture and sensory attributes. The Axum variety exhibited the most favorable changes, highlighting its potential for optimal fermentation results. The research supports the adoption of 24-hour fermented finger millet flour in food production, promoting nutritious and culturally relevant food products while enhancing dietary diversity and food security.

References

- Abiodun, O. A., Akinoso, R., & Oluoti, O. J. (2014). Changes in functional and pasting properties of trifoliate yam flour during storage. Journal of Applied Sciences and Environmental Management, 18(2), 337-340. [CrossRef]

- Alemayehu, A., Hailu, G., & Ayalew, A. (2021). Nutritional and health benefits of finger millet (Eleusine coracana): A review. Food Science & Nutrition, 9(5), 2351-2361. [CrossRef]

- Asrat, Y., Elias, A., Gashe, B. A., & Nega, T. (2019). Effect of fermentation time on the physicochemical and sensory properties of injera prepared from tef (Eragrostis tef) and finger millet (Eleusine coracana) blends. Food Science & Nutrition, 7(6), 2110-2119. [CrossRef]

- Bhaskarachary, K., & Reddy, V. R. (2019). Nutritional and functional properties of whole grain finger millet (Eleusine coracana) flour. Journal of Food Science and Technology, 56(6), 2955-2963. [CrossRef]

- Bultosa, G., Abebe, W., Shumey, D., & Schulz-Schroeder, G. (2022). Functional properties and in vitro antioxidant activities of finger millet (Eleusine coracana) flour and its protein isolate. Food Chemistry, 366, 130653. [CrossRef]

- Chandrasekar, A., & Reddy, V. R. (2020). Potential of finger millet in food and nutrition security:A review. Food Reviews International, 36(5), 1-18. [CrossRef]

- Chavan, U. D., et al. (2018). “Functional properties of millets: A review.” Journal of Food Science and Technology, 55(8), 3095-3104.

- Gebremariam, M. M., Zarnkow, M., & Becker, T. (2021). Tef (Eragrostis tef) as a raw material for malting, brewing, and manufacturing of gluten-free foods and beverages: A review. Journal of Food Science and Technology, 58(2), 387-402. [CrossRef]

- Hassan, A.B., Ahmed, I.A., Osman, N.M., Eltayeb, M.M., Osman, G., & Babiker, E.E. (2006). Effect of processing treatments followed by fermentation on protein content and digestibility of pearl millet (Pennisetum typhoideum) cultivars. Pakistan Journal of Nutrition, 5(1), 86-89. Google Scholar.

- Hassan, A.N., Frank, J.F., Farmer, M.A. (2006). Observation of bacterial exopolysaccharide in dairy products using cryo-scanning electron microscopy. Letters in Applied Microbiology, 40(3), 215-221.

- Haug, W. (2011). Oil absorption and its impact on food texture. Food Chemistry, 126(3), 1041-1045.

- Holla, S. (2021). Fermentation of finger millet (Eleusine coracana) flour: A review on nutritional, microbiological, and technological aspects. Food Reviews International, 1-24.

- Holla, S., Shobana, S., & Muralidharan, K. (2021). Fermentation of finger millet (Eleusine coracana) flour: A review on nutritional, microbiological, and technological aspects. Food Reviews International, 1-24. [CrossRef]

- Karanja, S. M., & Tanga, C. M. (2019). The role of fermentation in enhancing the nutritional quality of food: A review. Journal of Food Science and Technology, 56(6), 2904-2915. [CrossRef]

- Kaur, A., & Singh, B. (2020). Nutritional and functional properties of fermented finger millet (Eleusine coracana) products: A review. Journal of Food Science and Technology, 57(5), 1887-1897. [CrossRef]

- Kusumayanti, H., Handayani, N. A., & Santosa, H. (2015). Swelling power and water solubility of cassava and sweet potatoes flour. Procedia Environmental Sciences, 23, 164-167. [CrossRef]

- Lei, V., Arneborg, N., & Jespersen, L. (2006). The release and activity of potential probiotic lactic acid bacteria and Saccharomyces cerevisiae strains in fermented maize slurry. International Journal of Food Microbiology, 110(3), 216-225.

- Lei, V., Friis, H., & Michaelsen, K.F. (2006). Spontaneously fermented millet product as a natural probiotic treatment for diarrhea in young children: an intervention study in northern Ghana. International Journal of Food Microbiology, 110(3), 246-253. [CrossRef]

- Lule, V. K., Naz, F., Gat, Y., Vyas, P., Pophaly, S. D., & Tomar, S. K. (2022). Finger millet-based fermented foods: Technological aspects, health benefits, and prospects. Food Chemistry, 369, 130903. [CrossRef]

- Murevanhema, Yvonne M, (2021): “Effects of fermentation on physicochemical properties and consumer acceptability of finger millet-based beverages.” Foods 10.4 (2021): 815. [CrossRef]

- Pandey, K. R. (2020). Fermentation technology for value-added food products: A review with special reference to indigenous fermented foods. Critical Reviews in Food Science and Nutrition, 60(20), 3462-3484. [CrossRef]

- Ragaee, S., et al. (2006). “Functional properties of millet flours and their use in bakery products.” Cereal Chemistry, 83(1), 26-32.

- Rakesh, M., & Nair, B. M. (2020). Nutritional and health benefits of millet: A review. Journal of Food Science and Technology, 57(12), 5145-5152. [CrossRef]

- Ranadheera, C. S. (2014). Bacteriocin production by lactic acid bacteria isolated from fermented foods and beverages: A review. Frontiers in Microbiology, 5, 1-19.

- Sanz-Penella, J. M., & de la Hera, E. (2012). Influence of fermentation conditions on antioxidant activities, phytates, and phenolic acids in whole-wheat sourdoughs. Food Chemistry, 131(1), 141-148. [CrossRef]

- Shimelis, E. A., & Rakshit, S. K. (2020). Effect of processing on antinutrients and in vitro protein digestibility of finger millet (Eleusine coracana L.). Food Chemistry, 315, 126238. [CrossRef]

- Shobana, S., & Muralidharan, K. (2021). Development of functional foods from finger millet flour: A review. Journal of Food Science and Technology, 58(1), 1-10. [CrossRef]

- Shobana, S., & Muralidharan, K. (2021). Finger millet (Eleusine coracana): A review of its nutritional properties, processing, and plausible health benefits. Food Research International, 140, 109973. [CrossRef]

- Tilahun, M., Shobana, S., & Mulugeta, H. (2019). The role of fermentation in improving the nutritional quality of finger millet. Journal of Food Science and Technology, 315, 126238. [CrossRef]

- Woldegiorgis et al., 2020: Emnet Tadesse Woldegiorgis, Irina Turner, and Abraham Brahima edited a book titled Decolonization of Higher Education in Africa: Perspectives from Hybrid Knowledge Production.

- Yetneberk, S., de Kock, H. L., & Rooney, L. W. (2021). Effects of sorghum type and malting on injera quality. Journal of Cereal Science, 99, 103188. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).