6.1. Results from the 3D-CFD Simulation

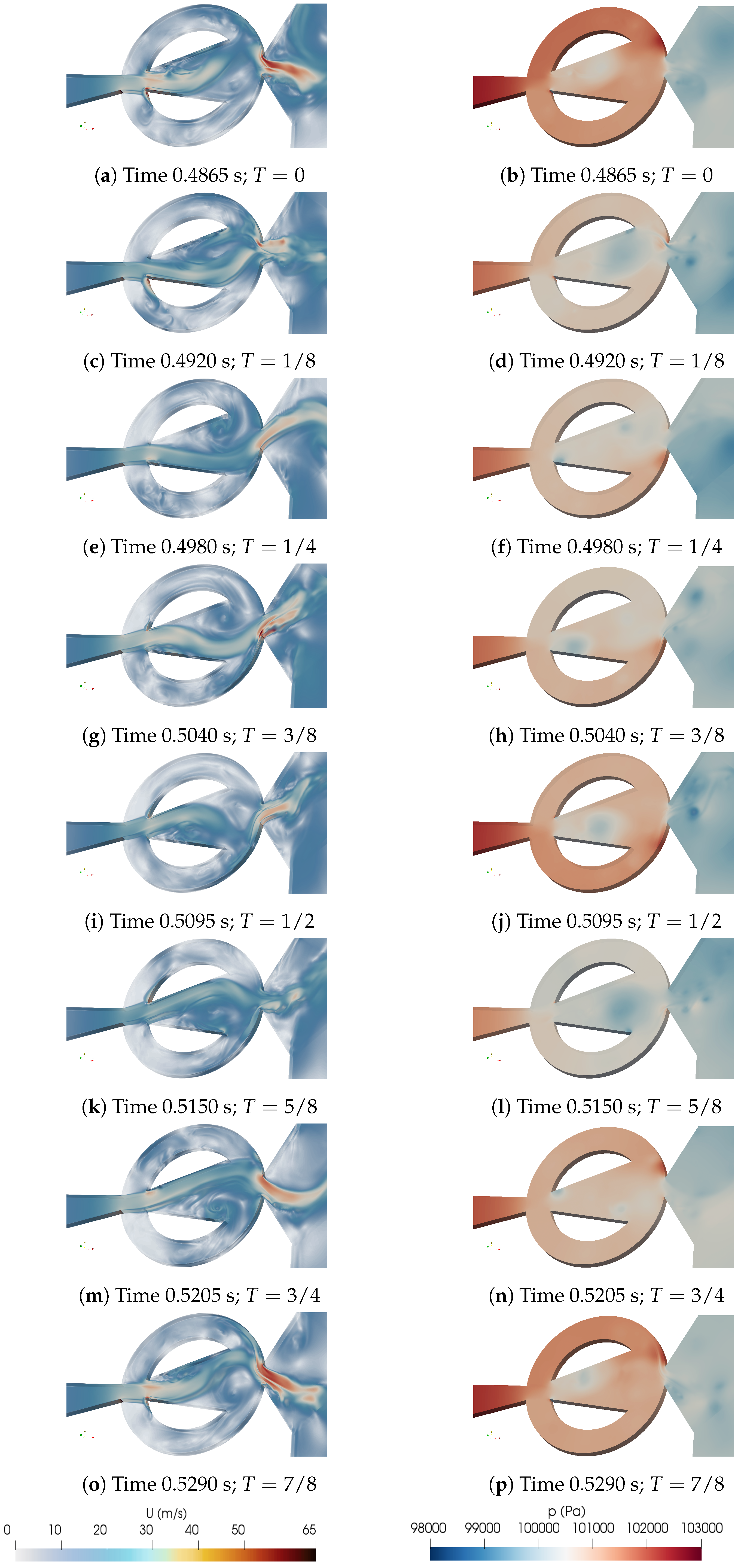

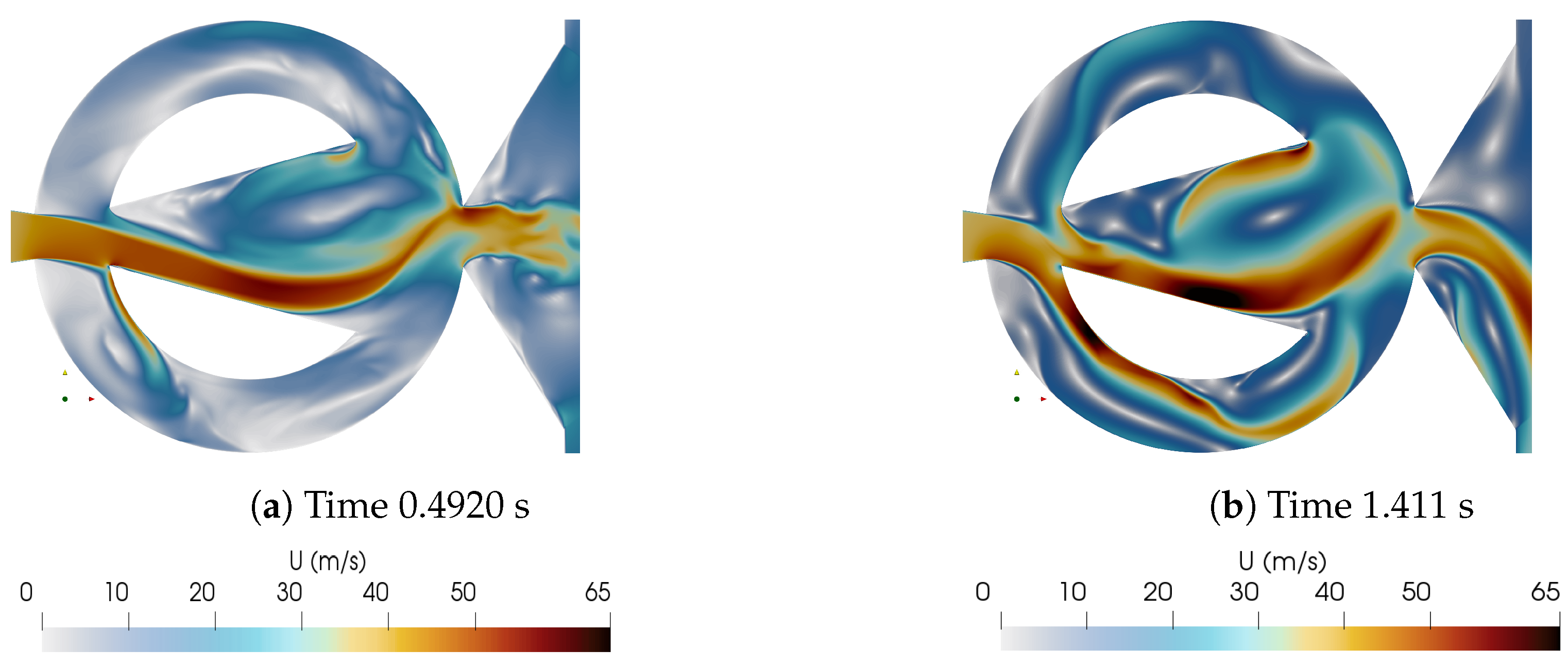

To start understanding the evolution of the jet inside the MC and at the FO outlet, we decided to divide a full oscillation cycle in eight equidistant time steps and present the corresponding velocity and pressure fields in

Figure 4. We have chosen the oscillation period to start at the instant at which the pressure at the MC upper converging wall is maximum, as clearly observed in

Figure 4b. At this instant (T = 0), the upper FC is pressurized and the jet inside the MC is being pushed downwards. At the next time step (T = 1/8) the jet inside the MC is about to reach its lower position, some reverse FC flow (flow going from the FC outlet towards the FC inlet) is observed at the lower FC,

Figure 4c, the pressure at the upper FC is slightly higher than at the lower one

Figure 4d. As we move forward to (T = 1/4), it is observed that the pressure at the MC lower converging wall starts rising and keeps rising until reaching (T = 1/2), see

Figure 4f, h, j. This stagnation pressure increase is due to the jet impinging on the MC lower converging wall as observed from

Figure 4e, g, i. In fact, and due to the pressure rise at the lower FC, the jet inside the MC starts moving upwards at time (T = 1/4) and keeps moving upwards until (T = 5/8), notice that at time (T = 3/4),

Figure 4n, the pressure at the MC upper converging wall is clearly much higher than the one at the MC lower converging wall, which pressurizes the upper FC and pushes the jet inside the MC downwards. This process will continue until reaching (T = 1/4) where the jet at the MC has reached its lower position and the lower FC is again beginning to be pressurized. It is interesting to note that the maximum velocity exiting the FO is obtained at the instants where the pressure at the MC upper and lower converging walls is around the respective maximum value, see

Figure 4a, b; o, p; g, h; and i, j.

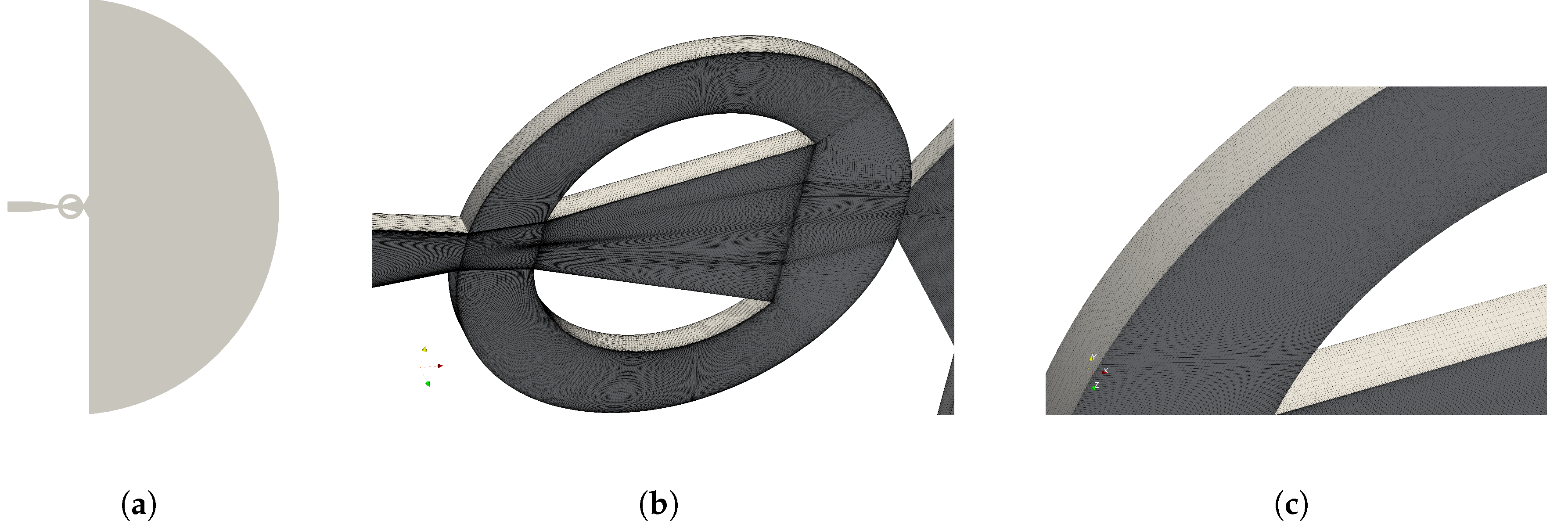

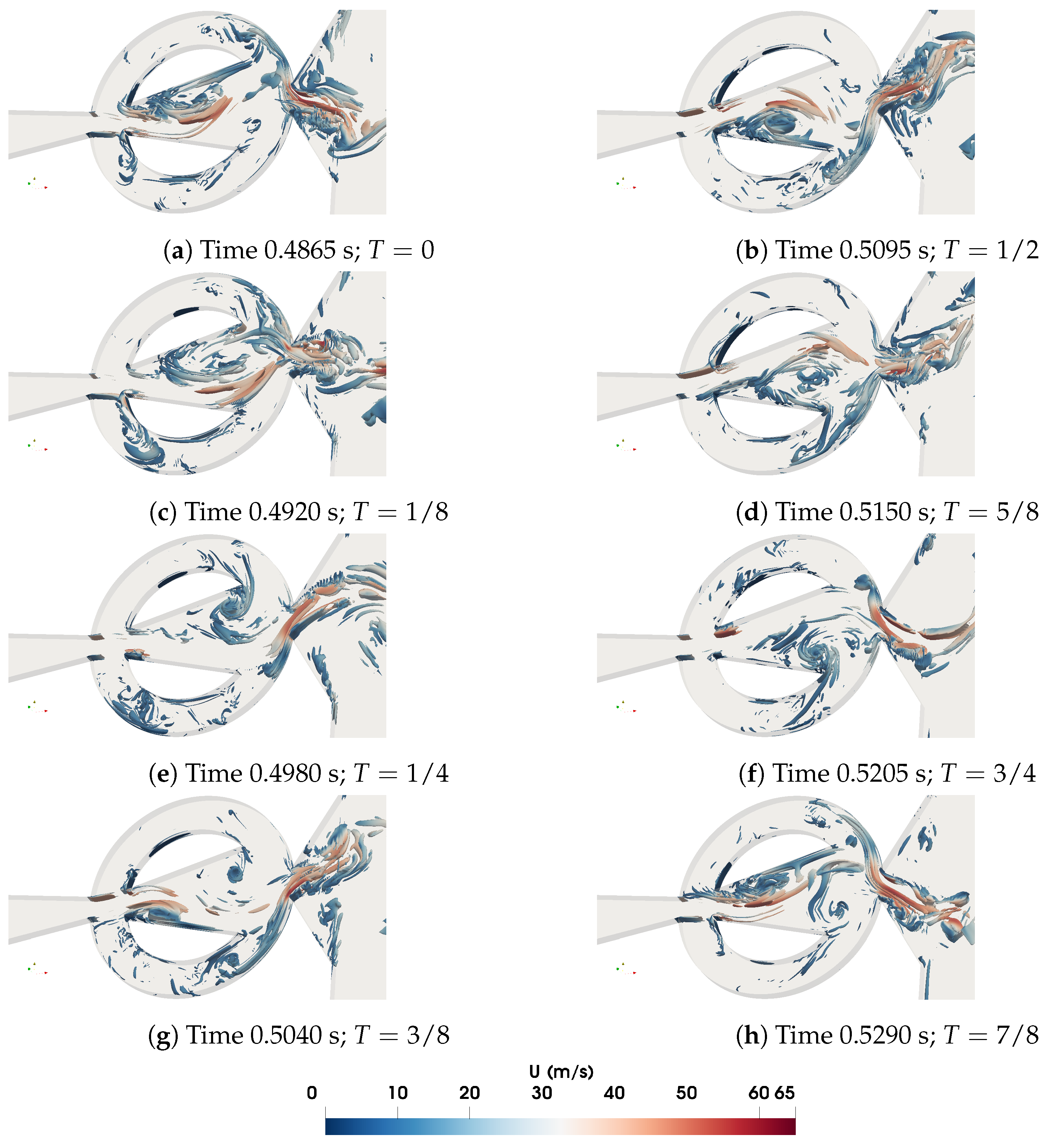

In order to further understand the FO internal 3D vortical structures formation, evolution and dimensions, the time averaged Q-criterion for a value of

is computed at each of the eight equidistant time steps we have divided the full oscillation period. Q-criterion is conventionally defined as the second invariant of the velocity gradient tensor, and it is empirically expressed as

. Where

is the rotation rate or vorticity tensor and S is the strain rate tensor. The iso-contours of the 3D structures are depicted in

Figure 5. When comparing

Figure 4a, c with

Figure 5a, c, the FC reverse flow can now be more clearly seen. In fact, the vortical structures forming alternatively on both sides of the MC are now clearly observed in all figures thanks to the Q-criterion plots. The flow entering and evolving inside the FCs is as well observed in great detail, see for example

Figure 5d, e, f, g. Of particular relevance is the evolution of the vortical structures associated to the jet exiting the FO. Such structures are mostly elongated flowing along the flow stream direction and breaking rather shortly downstream into smaller and more random structures. This effect is particularly relevant when willing to employ the FO to cool down a hot flat plate located perpendicularly in front of it, as in references [

10,

11,

12] for example, then it gives a hint of the downstream distance the plate should be located to maximize heat transfer.

Figure 4.

Instantaneous velocity and pressure fields cut along a full oscillation period divided in 8 equi-spaced time steps. 3D baseline case (STD).

Figure 4.

Instantaneous velocity and pressure fields cut along a full oscillation period divided in 8 equi-spaced time steps. 3D baseline case (STD).

Figure 5.

Q criterion fields for a value of 2 × 106, shown along a full oscillation period divided in 8 equidistant time steps. 3D baseline case (STD).

Figure 5.

Q criterion fields for a value of 2 × 106, shown along a full oscillation period divided in 8 equidistant time steps. 3D baseline case (STD).

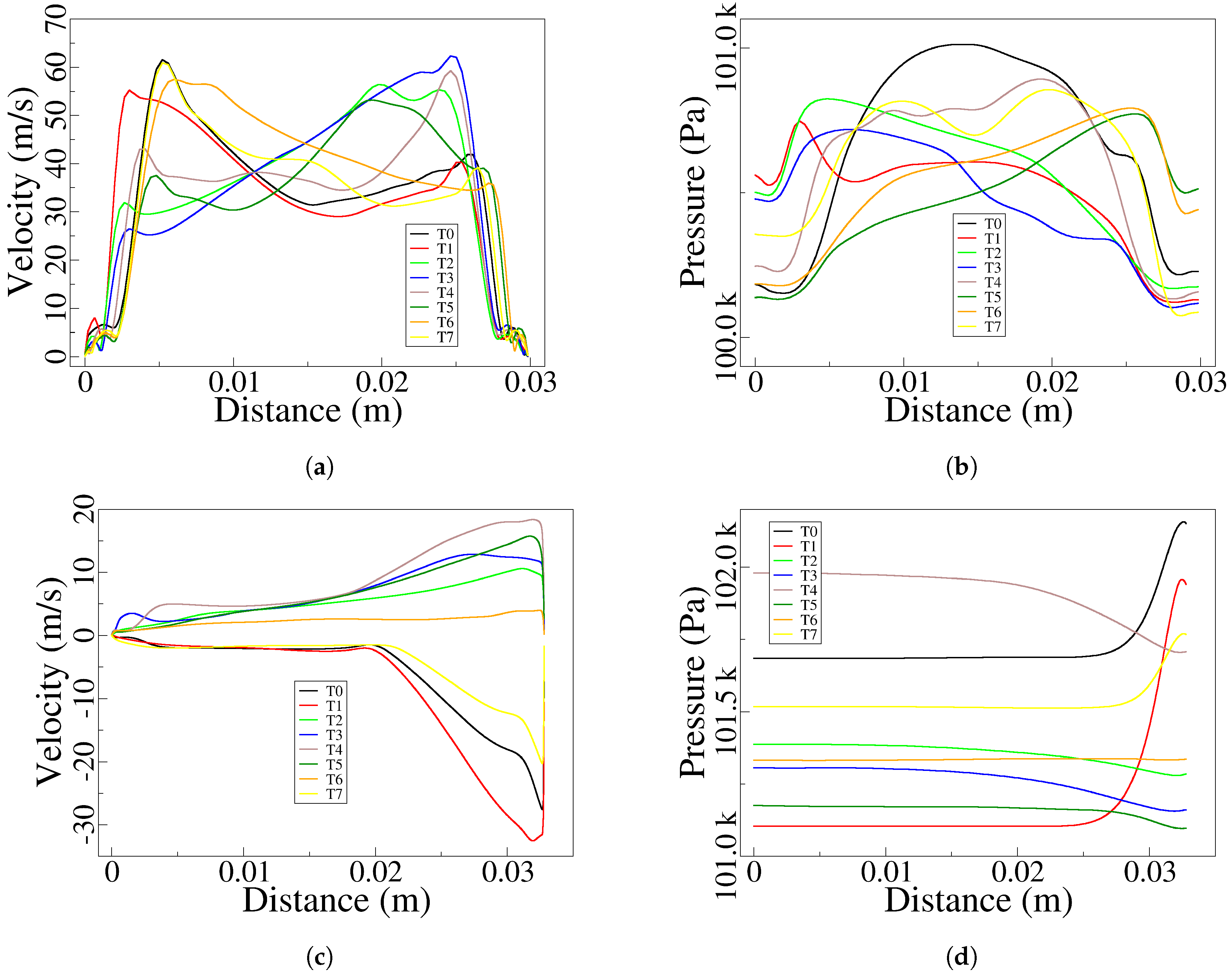

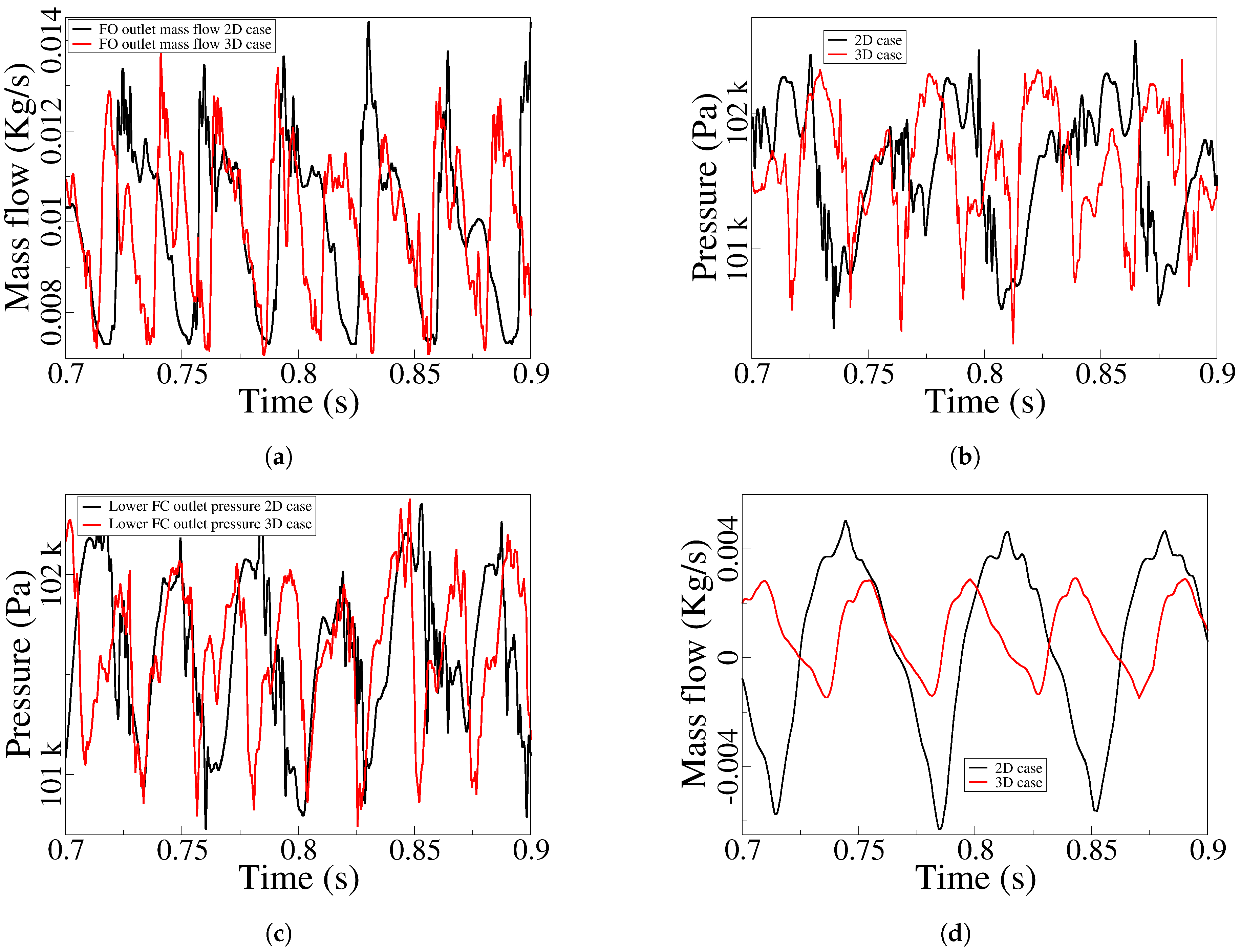

A more precise quantification of the instantaneous and spanwise averaged velocity and pressure fields measured at the FO outlet width and the lower FC outlet, is presented in

Figure 6. Each graph represents the corresponding magnitude obtained at each of the eight equidistant time steps an oscillation period was divided. The first thing to note is that the FO outlet maximum velocity is of about 60 m/s being its average of around 40 m/s,

Figure 6a. As expected, the maximum velocity flips from one side to the other along the FO outlet, every half oscillation period. Note that at times TO and T1,

Figure 6a, which correspond to the instants defined in

Figure 4a and

Figure 4c, respectively, the velocity peak is located on the left hand side of

Figure 6a, moving towards the right hand side at times, T2 to T5, respectively corresponding to

Figure 4e, g, i, k, and returning to the left hand side at times T6 and T7, which corresponds to

Figure 4m and

Figure 4o, respectively.

The pressure at the FO outlet width,

Figure 6b, oscillates around 100500 Pa and shows three different patterns. At T0, the jet exits the FO with rather a maximum velocity mostly concentrated on the upper side of the FO outlet, the MC outlet upper inclined wall is highly pressurized, but the pressure distribution along the FO outlet is rather uniform, showing a pronounce drop at the location where the fluid velocity is maximum, see

Figure 6a,b and

Figure 4a, b. At time T1, velocity and pressure maximum values are localized at the left hand side of the graph, the fact that the pressure field is moving towards the location where is the maximum velocity, precedes the flipping of the maximum velocity towards the opposite side of the FO outlet, which is happening in the next time step. At T2, the maximum velocity field has flipped towards the right hand side of

Figure 6a, while the maximum pressure field is well established on the left hand side, this situation is remaining for the next time step T3. At time step T4, the maximum velocity field is still observed at the right hand side of the graph, but the pressure field starts moving towards this same location, the situation is similar to the one observed at T0, although the maximum velocity location and pressure displacement were opposite. At instant T5, maximum velocity and pressure fields are located at the right hand side of the respective graphs, situation homologous to the one observed at T1, which was preceding the flipping of the maximum velocity location. As a matter of fact, the maximum velocity has moved toward the left at T6, while the max velocity position remains at the right side. Finally, at time T7, the maximum velocity position is the same as in the previous time step and the pressure field starts displacing from the right towards the left, situation homologous to the one described at time steps T0 and T4. It is interesting to note that, the respective maximum and minimum values for the velocity and pressure fields are generally appearing at opposite positions, the side where the velocity is maximum corresponds to a minimum pressure and vice-versa, which obeys to the energy equation under incompressible flow conditions, this situation changes at the instants where velocity flipping is about to happen.

Figure 6.

Instantaneous and spanwise averaged velocity and pressure fields measured at the Fluidic oscillator outlet width (a), (b), and at the lower feedback channel outlet (c), (d).

Figure 6.

Instantaneous and spanwise averaged velocity and pressure fields measured at the Fluidic oscillator outlet width (a), (b), and at the lower feedback channel outlet (c), (d).

When looking at the instantaneous velocity distribution along the lower FC outlet,

Figure 6c, it is clearly seen that the fluid flows in both FC directions. At T0, T1 and T7, which corresponds to the instants T = 0, T = 1/8 and T = 7/8 represented in

Figure 4a,

Figure 4c and

Figure 4o, respectively, there is reverse flow, (flow going from FC outlet towards FC inlet). The maximum reverse velocity is of about 30 m/s and it is localized rather at the right hand side of the FC outlet, as previously seen in

Figure 4a, c and o. For the rest of the time sub periods, the fluid flows towards the MC and the velocity is more uniformly distributed across the FC outlet, being the maximum value of about 18 m/s. The pressure field at the FC outlet,

Figure 6d, presents a considerable stability and follows the same trend as in the FO outlet, minimum pressure values are observed at the locations where the velocity is maximum, and vice-versa. In fact this behaviour is typical and obeys to the energy equation under incompressible flow conditions. Yet for the three time steps, T0, T1 and T7, where there is FC reverse flow, both, the pressure and velocity fields are having large values at the FC right hand side. For these three particular time steps, a large quantity of flow particles impinge on the MC lower wedge left hand side vertex, which raises the pressure in the vicinity of this corner, therefore explaining the unusual pressure rise.

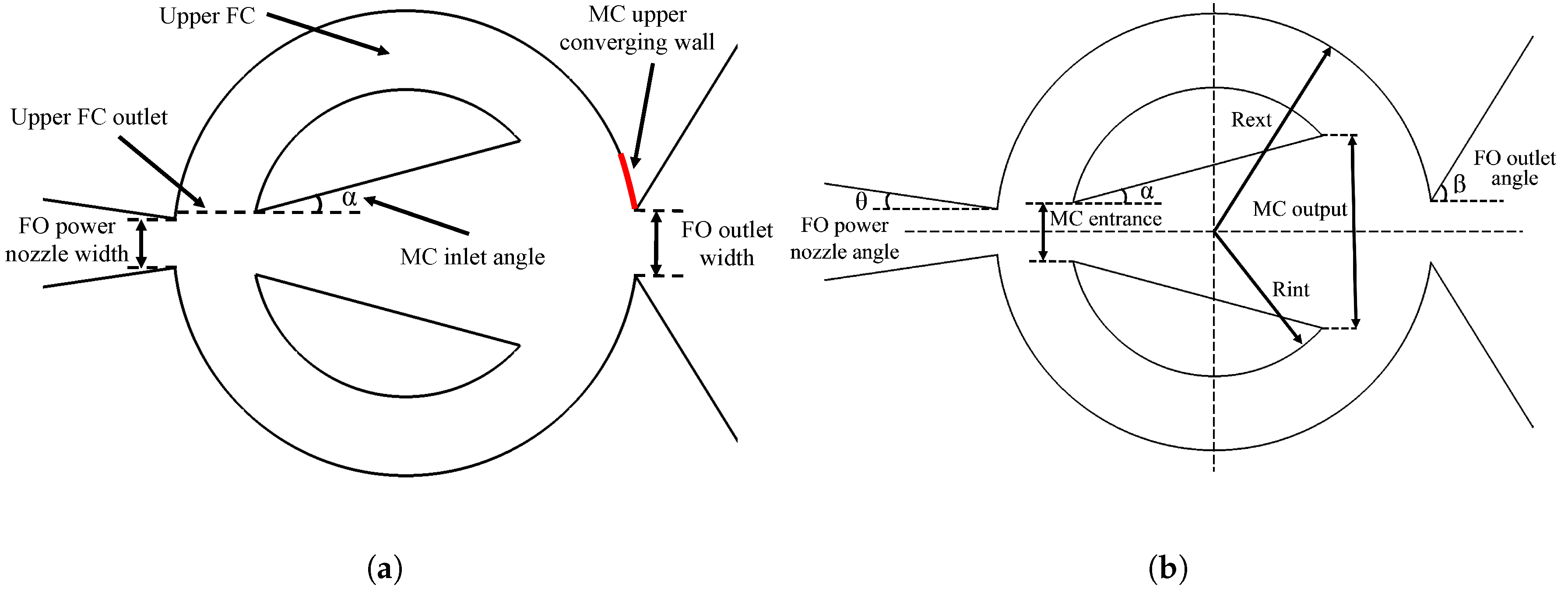

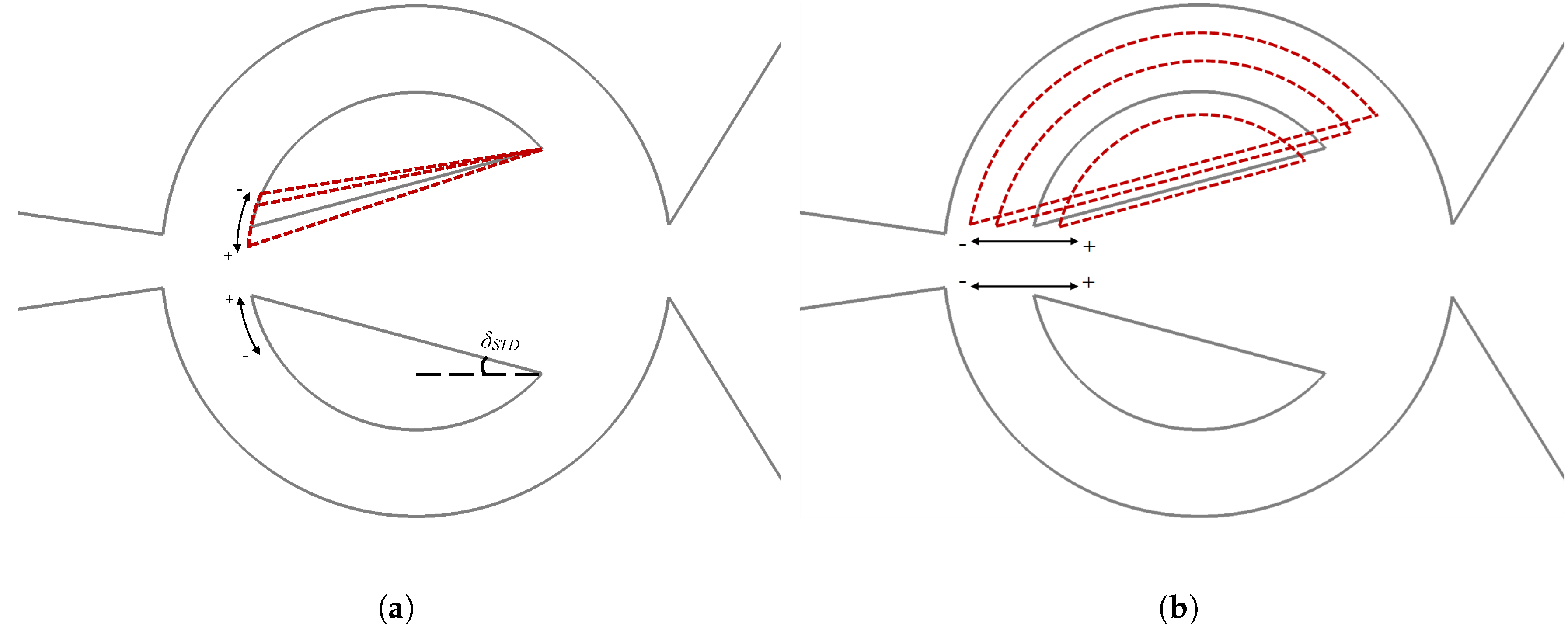

6.3. Mixing Chamber Angular Modifications (2D-CFD)

In the present sub-section, the effects of modifying the mixing chamber angle are introduced. To properly understand the following observations, the reader should recall the information presented in

Figure 3a and

Table 3. Note that all information presented in this sub-section was obtained through 2D-CFD simulations.

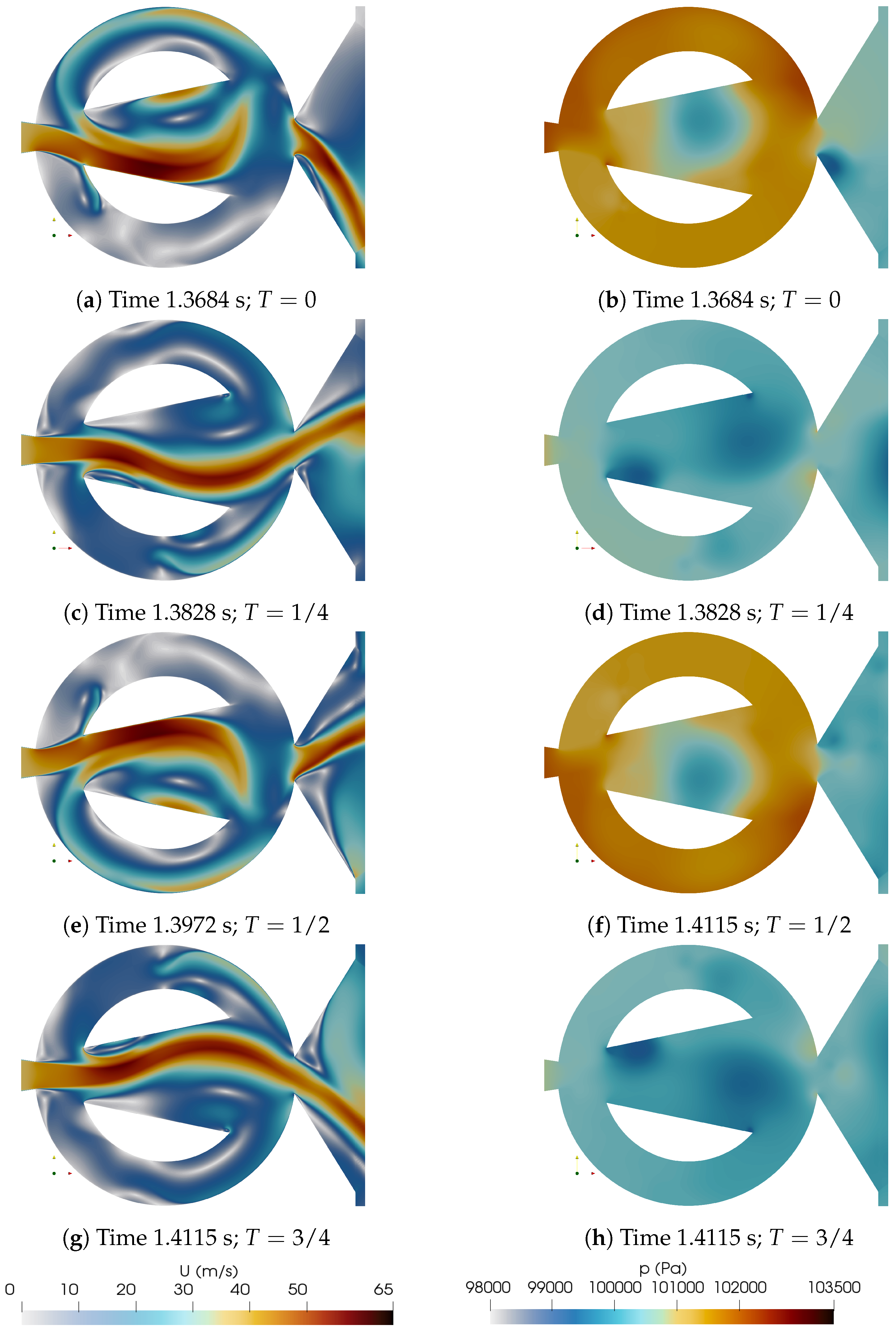

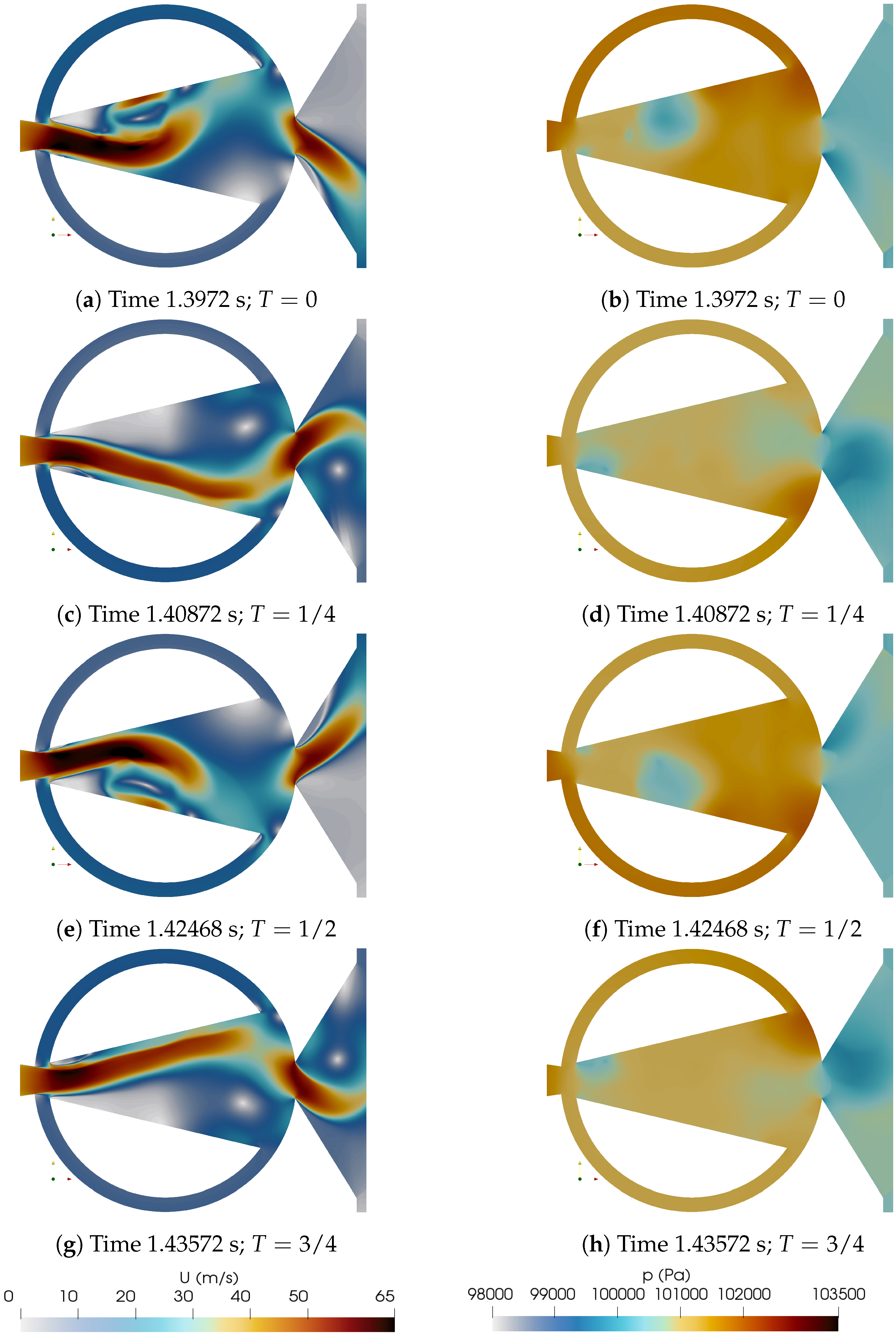

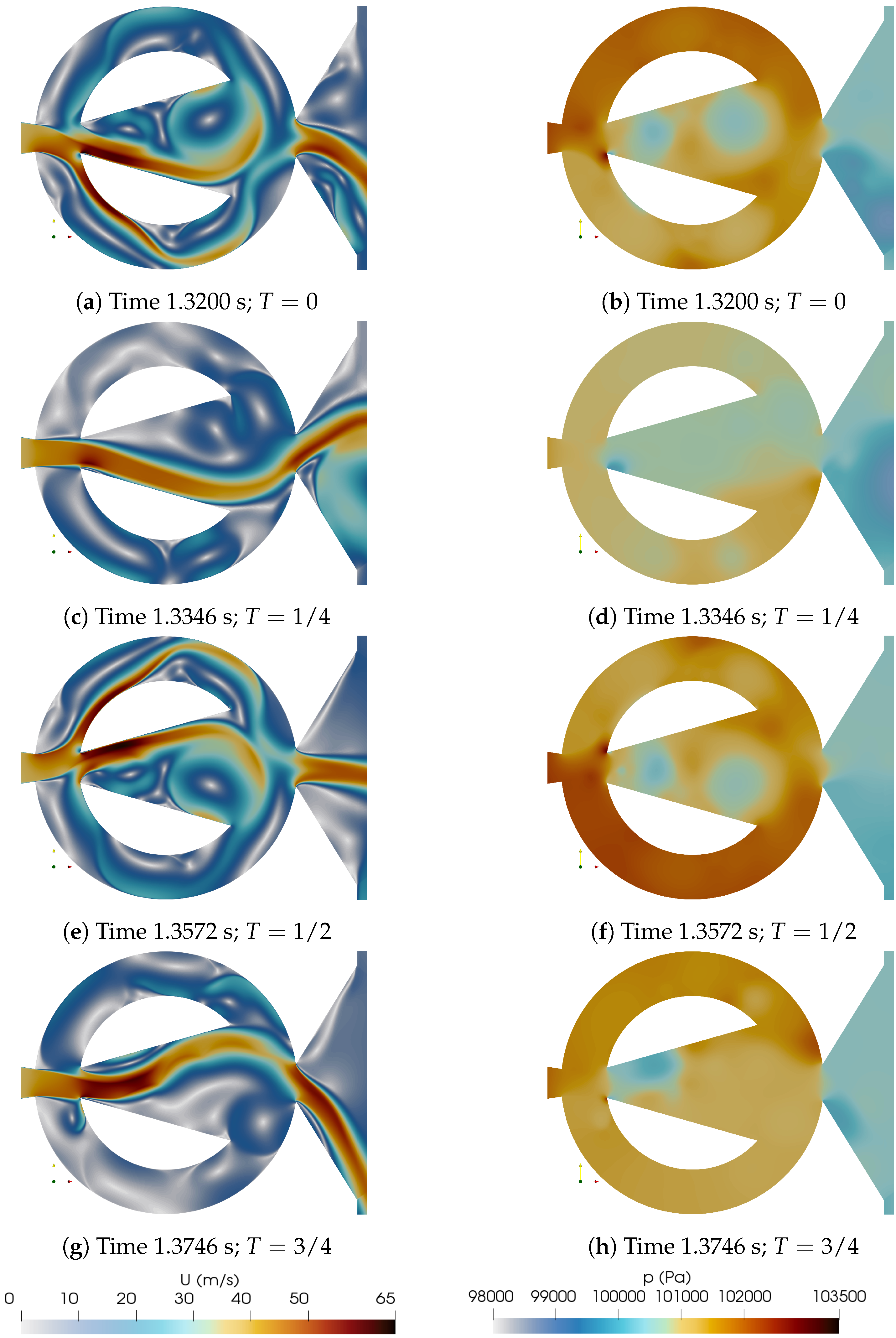

Figure 9 and

Figure 10, respectively introduce the velocity and pressure fields for the maximum

(Entrance 1) and minimum

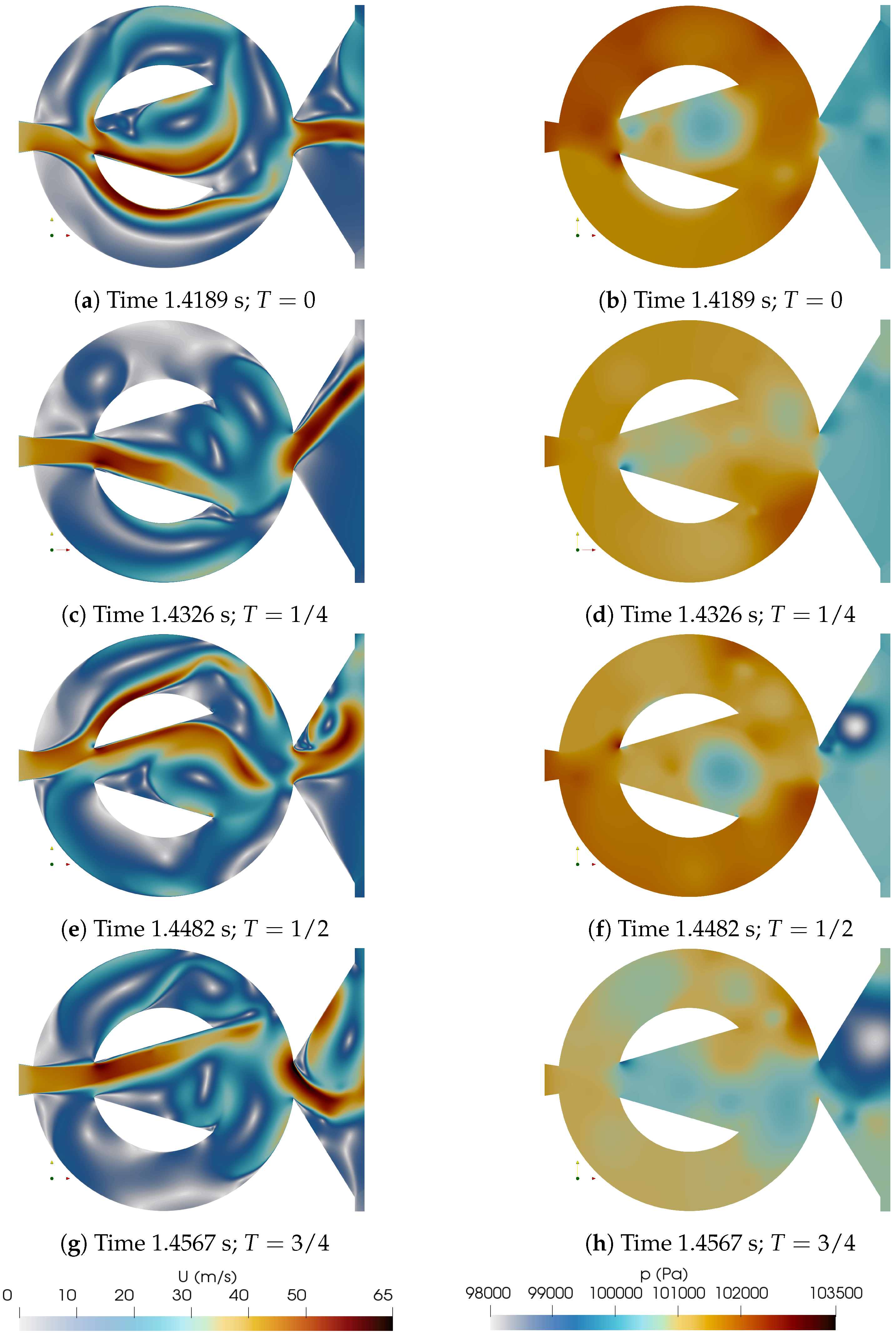

(Entrance 4), studied. In both figures the oscillation period is divided in four equidistant time steps. The initial time T = 0, is taken at the instant at which the stagnation pressure at the MC upper converging wall is about its maximum, see

Figure 9 and

Figure 10b, the jet inside the MC is moving downwards then the upper FC is pressurized. At this particular instant, a large FC reverse flow is observed for the configuration

,

Figure 9a, but a considerably smaller reverse flow is seen for the configuration

,

Figure 10a. In the next time step T = 1/4,

Figure 9 and

Figure 10c, d, the jet inside the MC has reached its down-most position and has started to move upwards, the lower FC is beginning to be pressurized, reaching its maximum pressure at T = 1/2,

Figure 9 and

Figure 10f. The maximum reverse flow is now observed at the upper FC, but just for the

configuration,

Figure 9e, then just a minor reverse flow is observed for

,

Figure 10e. It is relevant to note the stagnation pressure points appearing alternatively at the MC upper and lower wedges left hand side vertices,

Figure 9b, f, which are created by the jet entering the MC and partly impinging at these vertices. These stagnation pressure points are not observed in

Figure 10. Finally, at T = 3/4, the jet inside the MC is already moving downwards due to the upper FC pressure increase generated by the MC jet impinging at the MC upper converging wall, see the red area in this particular location. The comparison of the vortical structures forming inside the MC and in the FCs of

Figure 9 and

Figure 10, serve to further understand the differences between these two FO configurations.

Four videos characterizing the velocity and pressure fields for the maximum and minimum MC internal angles studied are presented in Appendix.

Figure 10.

Instantaneous velocity and pressure fields along a full oscillation period divided in four equidistant time steps. . Entrance 4.

Figure 10.

Instantaneous velocity and pressure fields along a full oscillation period divided in four equidistant time steps. . Entrance 4.

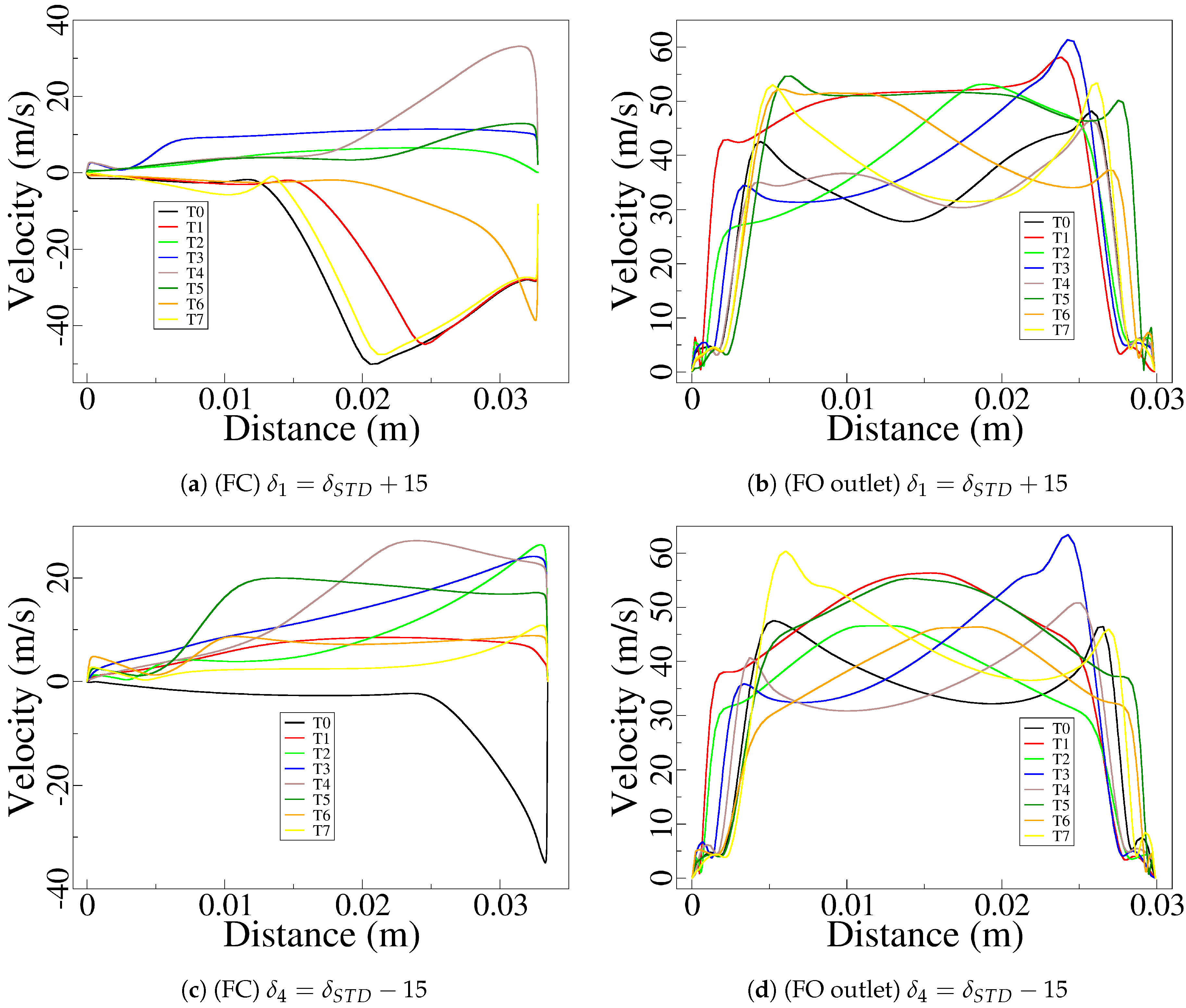

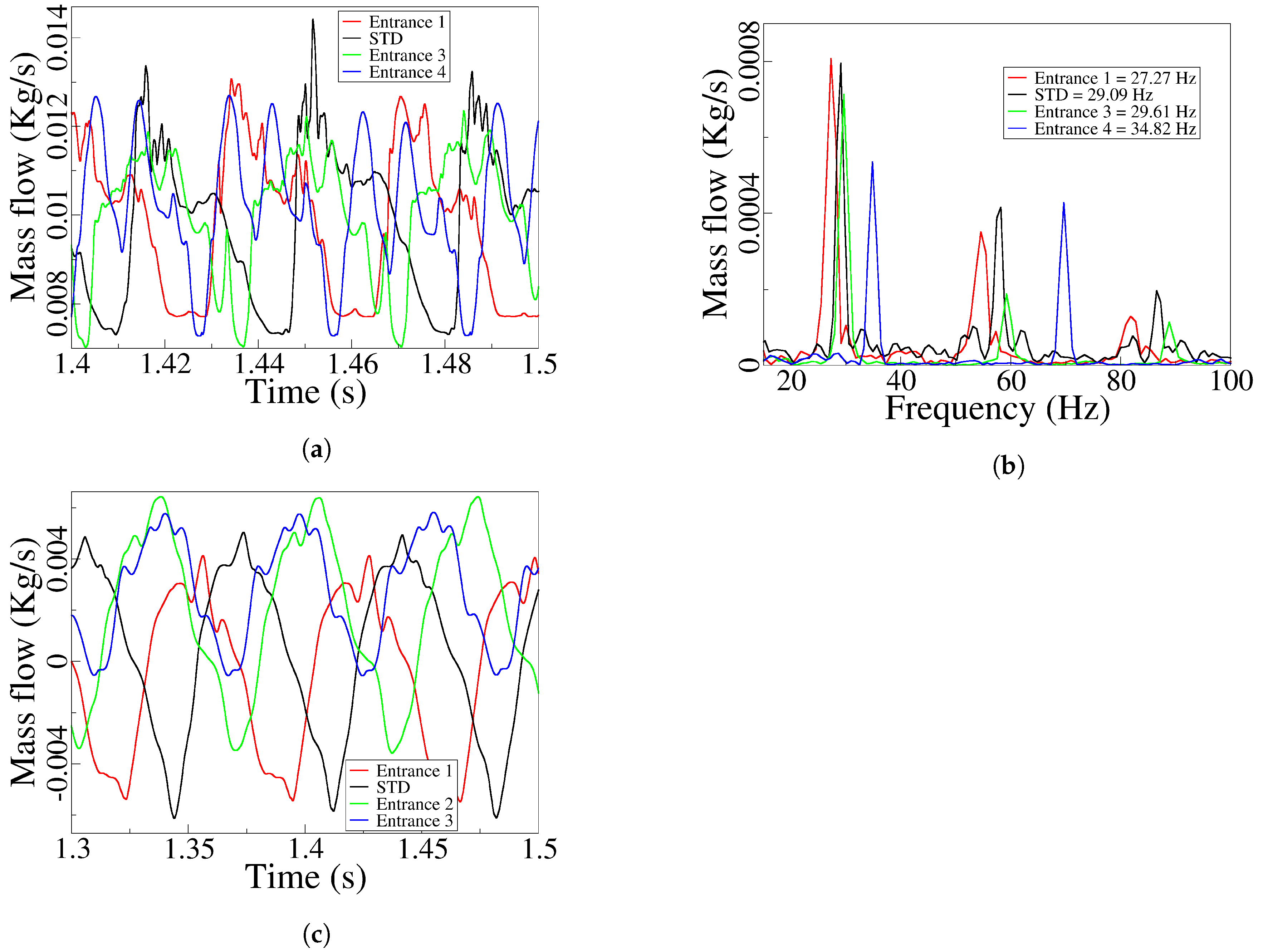

The instantaneous velocity distributions measured at the FO outlet and at the FC lower outlet are presented in

Figure 11, where the results from the maximum

(Entrance 1) and minimum

(Entrance 4), mixing chamber inclination angles are compared. The respective oscillation cycles are divided in eighth equidistant time steps, the first one T0 corresponding to the initial time presented in

Figure 9 and

Figure 10. When looking at the FO outlet velocity distributions,

Figure 11b, d, and comparing them with the ones obtained from the baseline case 3D simulations presented in

Figure 6a, it can be concluded that the three graphs show very similar results, the maximum and average velocities are almost identical, around 60 m/s and 40 m/s, respectively. The maximum velocity peaks appear alternatively at both sides of the FO outlet, and despite the fact the pressure field graphs are not presented in

Figure 11, it can be stated that, the relation between the pressure and velocity fields show the same trend described when introducing

Figure 6, which obeys to the energy equation.

The comparison of the 2D instantaneous velocity distributions at the FC lower outlet, for

,

Figure 11a,

,

Figure 11c, and the baseline 3D results,

Figure 6c, it clearly shows the existence of FC reverse flow in all three cases. As previously observed, the FC reverse flow decreases with the MC inlet angle decrease, in fact for the smallest inlet angle evaluated, the maximum reverse flow velocity magnitude is about 35 m/s and appears for a very small fraction of time, about 1/8 of the oscillation cycle, note that such velocity magnitude is about 50 m/s for the maximum MC angle considered and reverse flow exists for half oscillation cycle. The comparison of the reverse flow from the baseline case 3D results with the 2D one gathered from the maximum and minimum MC angles evaluated, shows that the 2D-CFD results overestimate the maximum reverse flow velocity, but the time period at which reverse flow exists is quite properly determined. Note that the for the 3D baseline case the existence of reverse flow last about 3/8 of the oscillation period, which is between the time for the maximum MC angle, 50% of the cycle, and the minimum FC angle, 1/8 of the oscillation period. As already observed in the 3D baseline case simulations, for the 2D ones presented in

Figure 11a, c, the velocity distribution associated to the fluid coming from the FC outlets and entering the MC is much more uniform than the reverse flow one, being the maximum velocities associated also smaller.

Figure 11.

Feedback channel and fluidic oscillator outlet instantaneous velocity profiles at eighth equi-distant time steps taken along a full oscillation cycle. Feedback channel lower outlet velocity profiles, case (a), and case (c). Fluidic oscillator outlet velocity profiles, case (b), and case (d).

Figure 11.

Feedback channel and fluidic oscillator outlet instantaneous velocity profiles at eighth equi-distant time steps taken along a full oscillation cycle. Feedback channel lower outlet velocity profiles, case (a), and case (c). Fluidic oscillator outlet velocity profiles, case (b), and case (d).

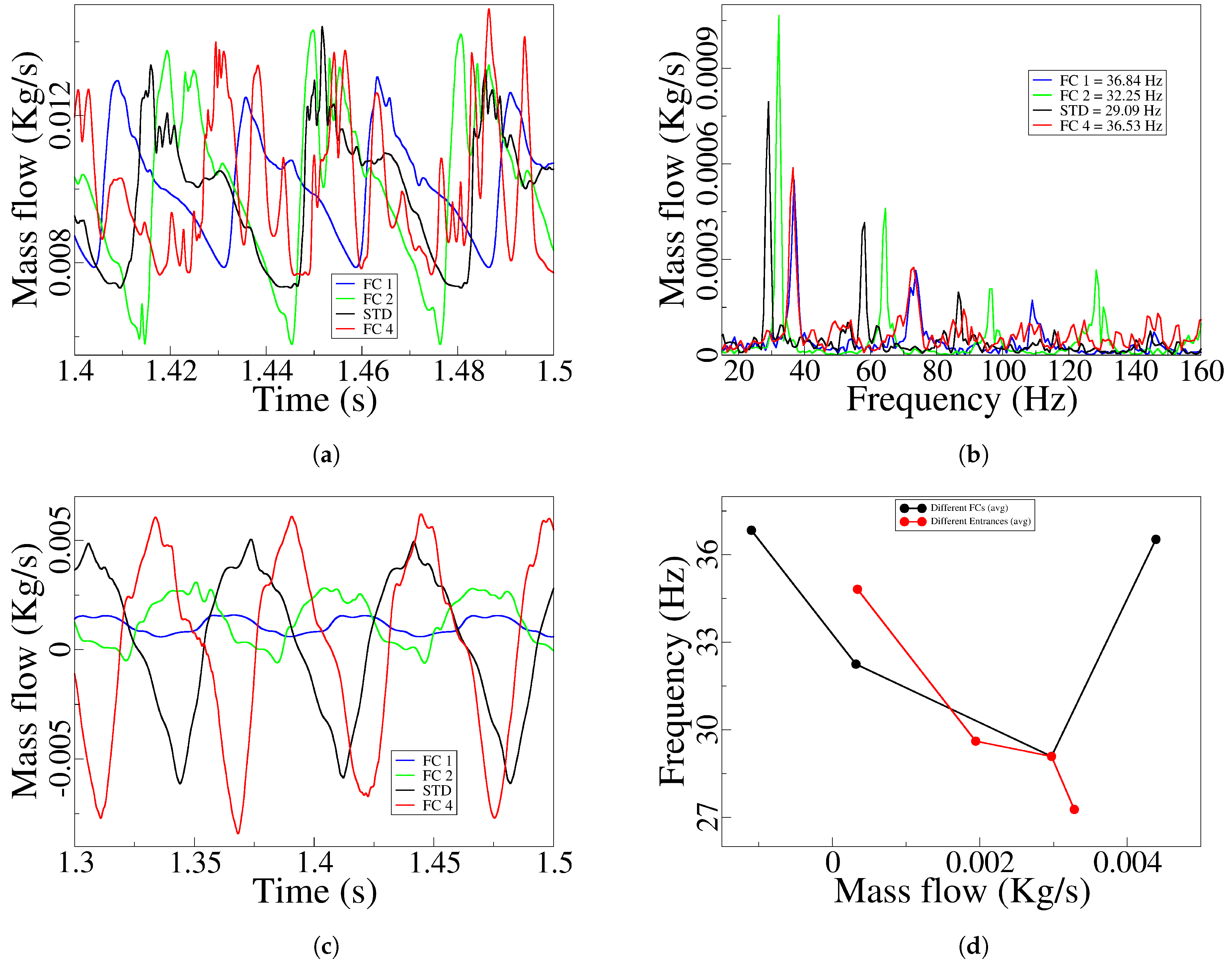

Until this point, we have studied the main generic effects of the flow inside the MC, at the FO outlet and the FC outlet, for the Entrance 1 and Entrance 4 configurations. From now on, the analysis of the four MC angular configurations is presented and discussed. For the four MC angles studied, the FO outlet mass flow dynamics and their corresponding frequency is presented in

Figure 12. As expected, the average mass flow remains constant for all the four MC angles considered, the peak to peak amplitude tends to decrease with the MC internal angle decrease, a maximum variation of about 18%

is observed between the maximum an minimum amplitudes evaluated,

Figure 12a. In reality, the main effect on the MC angular modification is observed when evaluating the FO outlet jet oscillation frequency, then it keeps increasing with the MC inlet angle decrease (MC entrance width increase),

Figure 12b. For entrance 1,

, the FO frequency is of 27.27 Hz and increases to 34.82 Hz when entrance 4,

, is considered. It must as well be highlighted that as the internal angle decreases the FC reverse flow also decreases

Figure 12c, therefore the FO outlet frequency increase can as well be associated to the FC reverse flow decrease. And this also applies when comparing the 3D and 2D simulations in

Figure 8, where for the same internal dimensions the 3D case was generating higher frequencies than the 2D one, being the 3D FC reverse flow much smaller than the two dimensional case one.

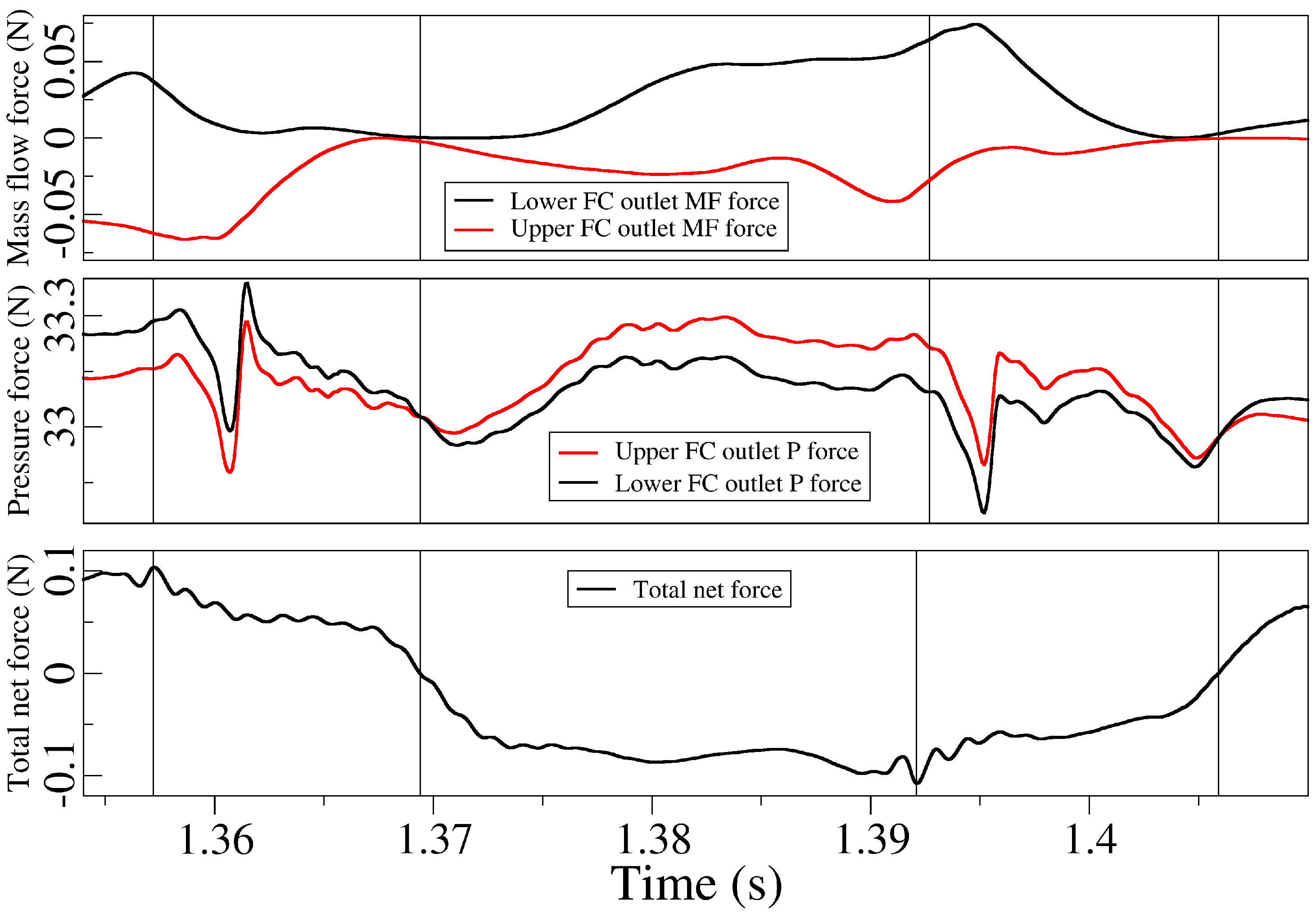

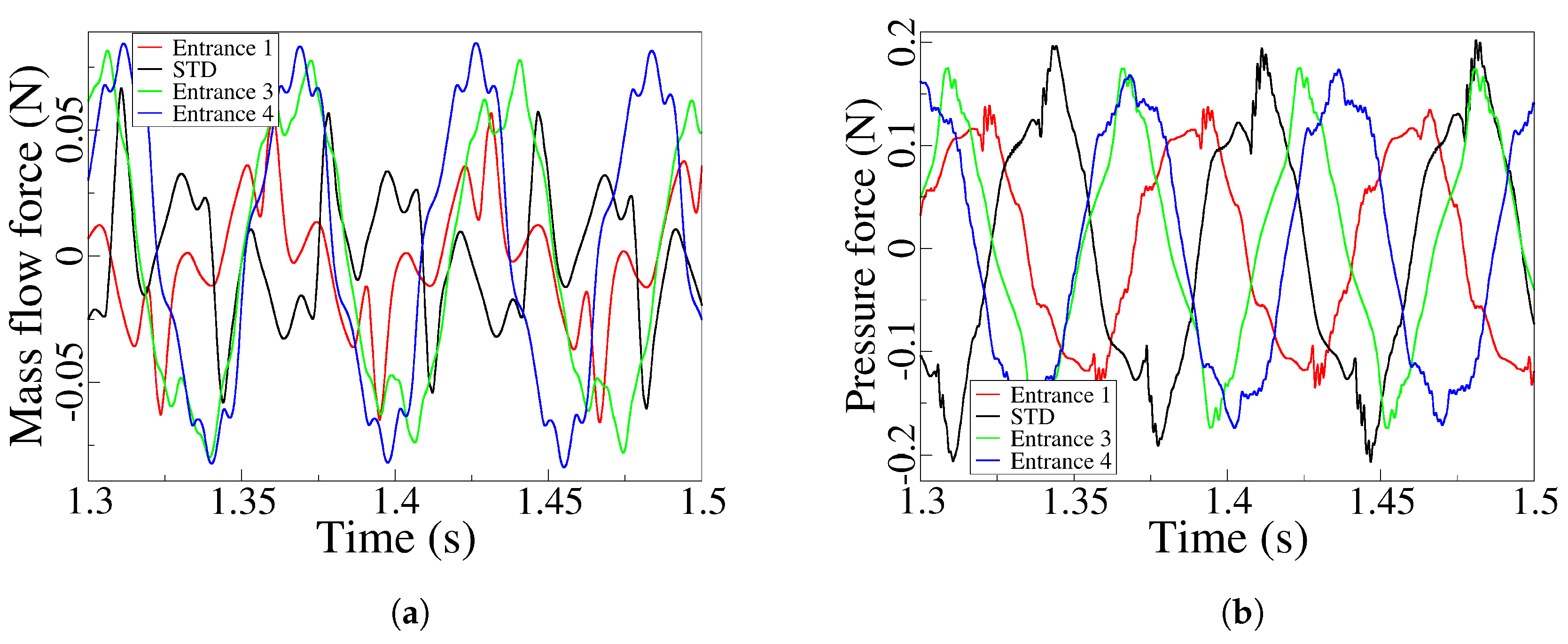

One of the key points when willing to understand the performance of any FO is the study of the origin of the self-sustained oscillations. In order to start understanding the time dependent forces acting on the jet as it enters the MC,

Figure 13 introduces for the four MC inlet angles studied, the unsteady net mass flow and pressure forces acting on the jet and considering both FC outlets. Which corresponds to the instantaneous application of the first and second terms of Figure

16 on both FC outlets. The first thing to notice is that, the maximum mass flow forces magnitude is about 35% of the pressure forces one.

The peak to peak amplitude of the net mass flow forces increases with the MC inlet angle decrease. The same happens for the net pressure forces although it appears that for the STD case the peak to peak amplitude is slightly larger than for the rest of the cases, note as well that for Entrance 3 and Entrance 4 cases, the unsteady pressure amplitude remains the same. The increase of the net mass flow forces magnitude is directly linked with the increase of the FC mass flow measured at the FC outlet, while the pressure force is mostly connected to the dynamic stagnation pressure increase measured at the MC outlet converging walls, which in turn depends on the jet inside the MC impinging on such converging walls. Therefore a higher peak to peak amplitude it indicates that the jet is impinging more perpendicularly to the MC converging walls, rising the pressure along the corresponding FC. When comparing the pressure and mass flow forces from

Figure 13a, b, it is observed a phase lag between both parameters. It seams the mass flow forces actuate about 0.02 seconds after the pressure ones. This delay is likely to be the time needed for the mass flow to travel from the FC inlet to the FC outlet.

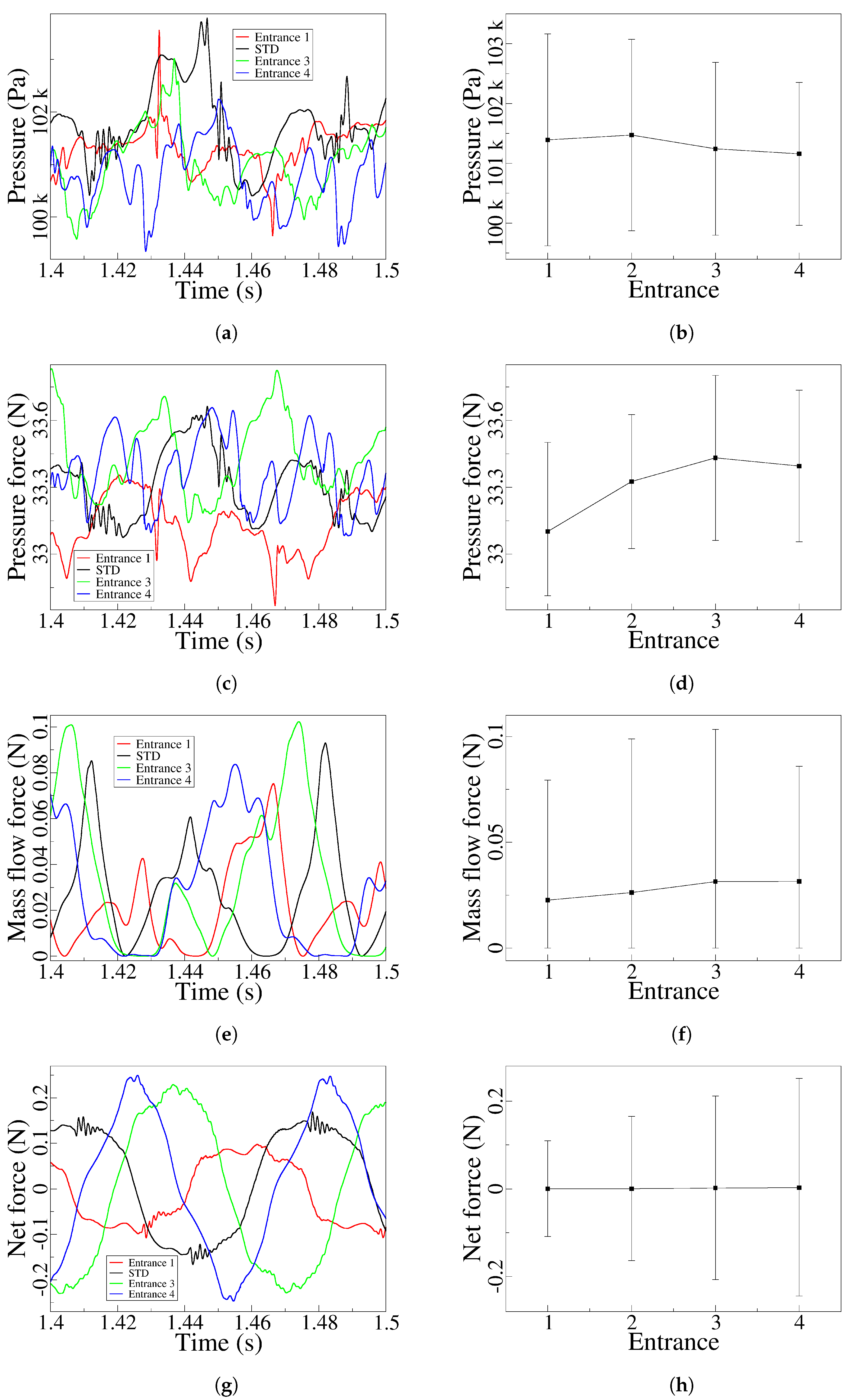

The left hand side column of

Figure 14, respectively represents for the four different MC angular positions evaluated, the stagnation pressure unsteady value measured at the MC lower converging wall, the time dependent pressure and mass flow forces measured at the lower FC outlet, and the instantaneous net force evaluated on both FC outlets. The graphs introduced on the right hand side column, characterize the time averaged and peak to peak amplitude of the respective time dependent values introduced on the left hand side column. Perhaps the first thing to point out is that, there is no a direct link between the stagnation pressure variations measured at the MC lower converging walls and the rest of the parameters, as previously noted in [

1] for different Reynolds numbers. In reality, we must consider that when modifying the MC internal angle, we are modifying the MC entrance width as well as the FCs outlet width, also the FC length is being modified. This combined effect is what makes

Figure 14 particularly difficult to follow. When analyzing the stagnation pressure evolution at the MC lower converging wall,

Figure 14a, b, it is observed that its time averaged value as well as the peak to peak amplitude, tends to decrease with the MC internal angle decrease, compare Entrance 1 and Entrance 4 results. But this trend is not followed by the pressure forces measured at the lower FC outlet,

Figure 14c, d, since the time averaged value of such pressure forces initially grow and finally suffer a small decrease. This evolution is mostly due to the FC outlet area variation generated when going from Entrance 1 to entrance 4, then the initial FC outlet area increase appearing between Entrance 1 and 2, is slightly smaller between Entrance 2 and Entrance 3, becoming almost negligible between Entrance 3 and 4. In fact, the pressure force decrease observed in Entrance 4,

Figure 14c, d, is due to the time averaged stagnation pressure decrease observed at the MC lower converging wall,

Figure 14a, b. From the analysis of the mass flow forces acting on the lower FC outlet,

Figure 14e, f, it can as well be observed the change of tendency between Entrance 3 and 4.

The time averaged as well as the peak to peak amplitude keeps growing from Entrance 1 to Entrance 3, mostly due to the FC outlet area increase, the averaged value suffers a negligible variation when moving from Entrance 3 to Entrance 4 and the peak to peak amplitude decreases. The peak to peak values are related with the maximum/minimum FC mass flow values presented in

Figure 12c, the higher the peak values the higher the mass flow forces amplitude. From the observation of

Figure 14c and e, it is clear that pressure forces on a FC outlet are over two orders of magnitude higher than the mass flow forces, which makes the jet oscillations particularly depended on pressure variations. The overall resulting forces acting on the jet as it enters the MC are introduced in

Figure 14g, h. The peak to peak amplitude of these forces increase as the MC angle decreases. Note that, although the time averaged stagnation pressure at the MC converging wall decreases when moving from Entrance 2 to Entrance 3 and Entrance 4,

Figure 14b, the maximum overall forces on the jet keep increasing.

6.4. Feedback Channel Dimensional Modifications (2D-CFD)

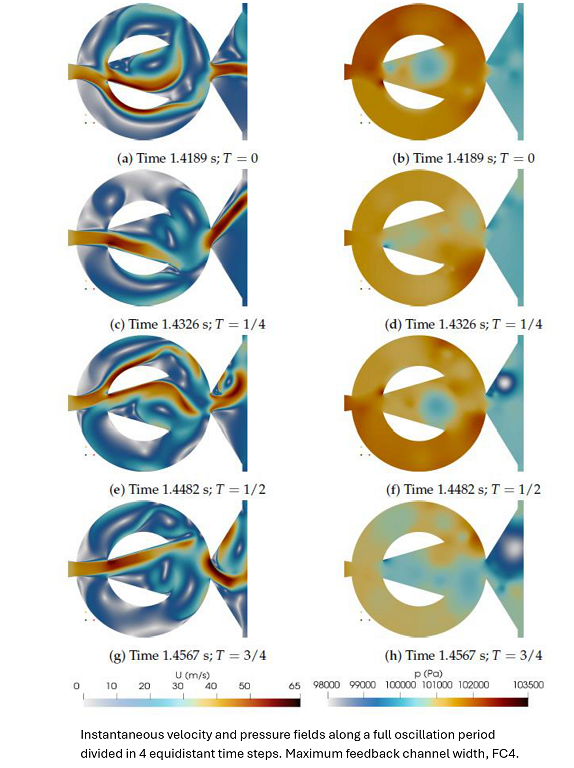

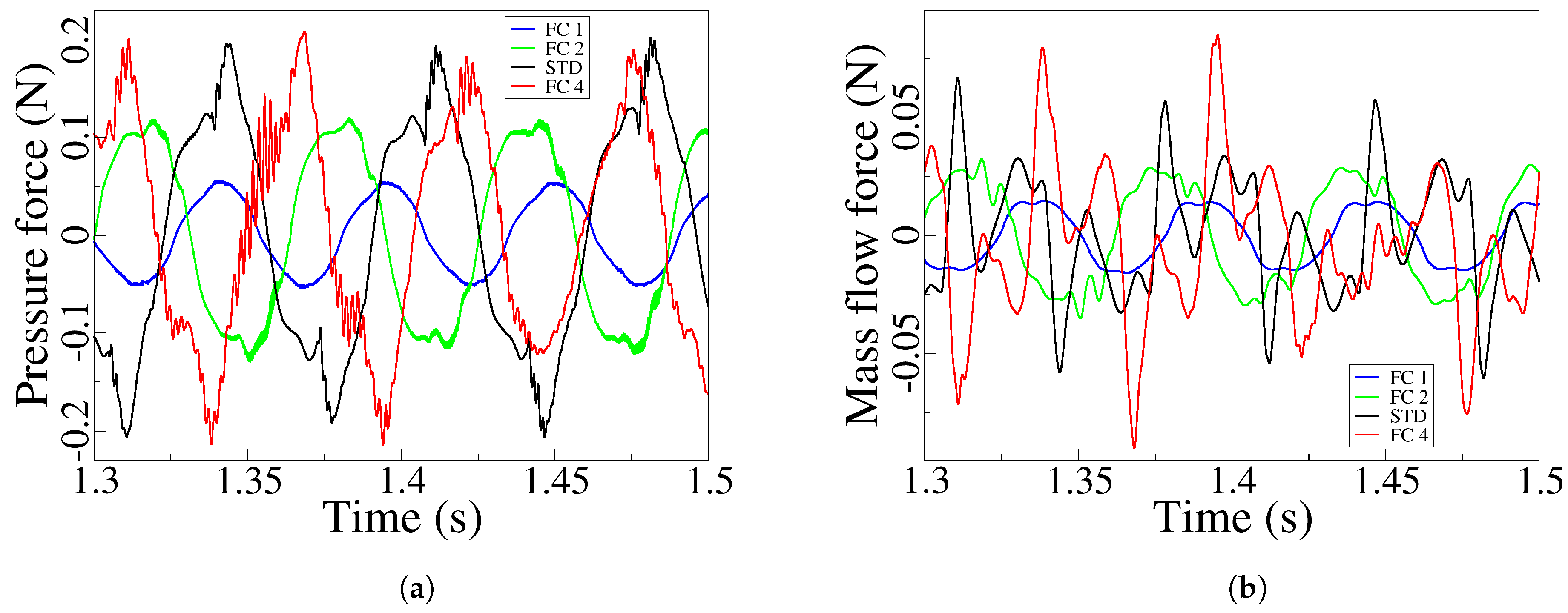

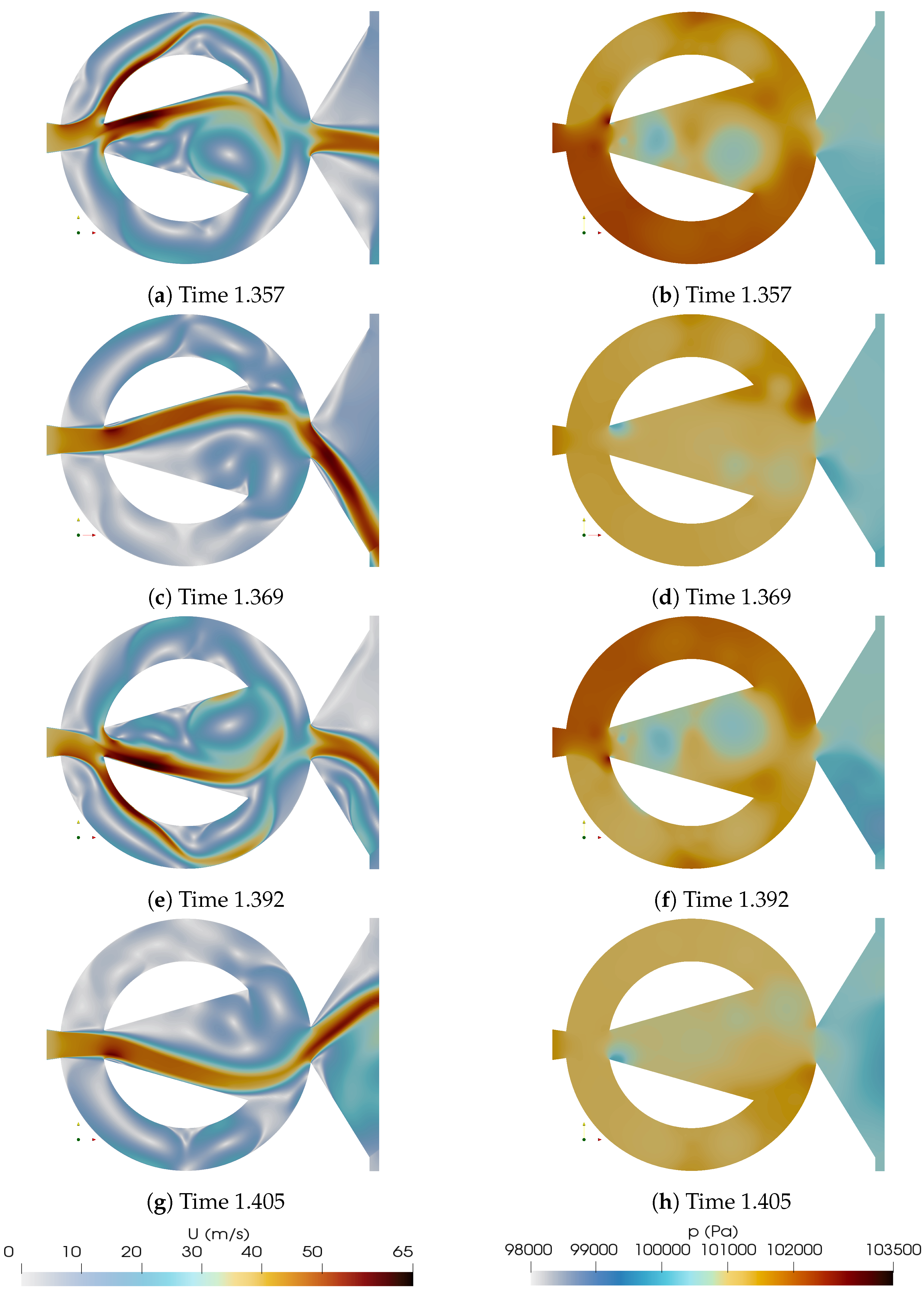

Pressure and velocity fields for the minimum FC1 and maximum FC4 feedback channel widths evaluated are presented in

Figure 15 and

Figure 16, respectively. In both figures, the respective oscillation cycle is divided in four equidistant time steps. The first thing that catch the eye is that for the smallest FC width there is no FC reverse flow, while a large reverse flow is observed in the FC4 case, in fact for this case, large flow in both FC directions is clearly observed. The jet inside the MC in FC1 is more uniform, the fluid follows the long MC internal walls. On the other hand a considerable random movement of the jet inside the MC is observed in FC4, the wide FC width favours such randomness. Pressure fields are very similar in both cases, but due to the major stability of the jet for case FC1, the periodic vortical structures forming inside the MC are much smoothly defined in this particular case. Four videos presenting the velocity and pressure fields for the minimum and maximum FC widths evaluated are provided in Appendix.

The major flow stability observed in the FC1 velocity fields, is further noted when evaluating the net pressure and mass flow forces acting on the jet as it enters the MC,

Figure 17a, b, respectively. See that the net pressure force curve for the FC1 case is much smoother than the rest of the curves, see as well that the peak to peak amplitude is the smallest one from the four cases evaluated, such amplitude grows with the FC width, although for the largest FC width, FC4, is becoming much more random. Clearly for the maximum FC width studied, the degree of freedom of jet inside the MC is too large, generating a higher degree of oscillation randomness observed in the scattered pressure curve. Similar conclusions are obtained when evaluating the net mass flow forces acting on the jet at the FC outlets, the peak to peak amplitude grows with the FC width and suffer a considerable increase at FC4, increasing as well the randomness associated. Regardless of the FC width studied, the net mass flow forces are about 1/3 of the corresponding pressure ones.

The FO and FC outlet mass flows for the four FC widths studied are presented in

Figure 18a, c, respectively. Focusing on the FC mass flow, it can clearly be seen that for the FC1 case, there is no reverse flow, a small amount of fluid is always flowing from the feedback channels towards the mixing chamber, notice as well the small peak to peak amplitude associated. As the FC width increases to FC2, there is an almost negligible FC reverse flow, being the peak to peak amplitude slightly higher than in the FC1 case. A further increase of the FC width to FC3 and FC4, generates a drastic increase of the feedback channel reverse flow as well as its peak to peak amplitude, the FC reverse mass flow maximum value being higher than the direct FC one. When observing the variations of the FO outlet mass flow,

Figure 18a, it is seen that the oscillation amplitude keeps growing with the FC width. In fact, the oscillation amplitude considerably grows when comparing the FC1 and FC2 cases, but a further increase of the FC width to FC3 = STD slightly reduces the amplitude, such FO outlet mass flow peak to peak amplitude remains rather similar for the FC4 and FC3 cases, yet the randomness associated to the oscillations for the FC4 case (maximum FC width studied), is considerably higher than for the rest of the FC widths studied. Note that a higher FO outlet mass flow peak to peak amplitude, involves a higher swept angle of the jet at the oscillator outlet. Regarding the FO outlet mass flow oscillating frequency,

Figure 18b, the frequency tends to decrease with the FC width increase. Yet, for the maximum FC width studied, FC4, there is a sudden increase of frequency, note that for this particular case the FO outlet mass flow peak to peak amplitude suffered a decrease while increasing its randomness, very likely due to the large degree of freedom associated to the jet inside the MC.

Figure 15.

Instantaneous velocity and pressure fields along a full oscillation period divided in 4 equidistant time steps. Minimum feedback channel width, FC1.

Figure 15.

Instantaneous velocity and pressure fields along a full oscillation period divided in 4 equidistant time steps. Minimum feedback channel width, FC1.

Figure 16.

Instantaneous velocity and pressure fields along a full oscillation period divided in 4 equidistant time steps. Maximum feedback channel width, FC4.

Figure 16.

Instantaneous velocity and pressure fields along a full oscillation period divided in 4 equidistant time steps. Maximum feedback channel width, FC4.

Figure 17.

Feedback channel outlet net pressure forces (a) and net mass flow forces (b), as a function of the different Feedback channel widths evaluated.

Figure 17.

Feedback channel outlet net pressure forces (a) and net mass flow forces (b), as a function of the different Feedback channel widths evaluated.

At this point it is interesting to recall the work done by [

15,

27,

36] among others, then they emphasized the effect of the FO outlet frequency with the variation of the MC entrance and outlet widths, as well as the FO outlet width. In fact in [

36] they highlighted the ratios (FO outlet width/MC entrance width) and the (MC entrance width/FO power nozzle) as two of the relations which were having a particular relevant effect on the FO dynamic performance. Based on the 2D-CFD simulations presented in

Section 6.3, we have studied the FO outlet mass flow frequency in (Hz) as a function of the (FO outlet width/MC entrance width) =

, the relation being

, the coefficient of determination was of (

), equation showing a small decrease in frequency as a function of the (FOo/MCe) ratio increase. We also studied the FO outlet mass flow frequency (Hz) as a function of the (MC entrance width/FO power nozzle) =

, obtaining the relation

, the coefficient of determination being (

). Showing that the FO outlet frequency tends to increase with the

ratio increase. In order to find out an equation which summarizes the FO outlet mass flow frequency as a function of the dimensional modifications presented in

Section 6.3 and

Section 6.4, we decided to link the FO frequency with the time averaged reverse FC outlet mass flow, and we noticed that the trend is the same as the one observed for different MC internal angles variation and it is also the same observed when comparing the 3D with the 2D simulations. This is, as the time averaged FC reverse flow increases the FO outlet frequency decreases. This information is summarized in

Figure 18d, note that regardless of the dimensional modification considered the frequency decreases with the FC time averaged reverse mass flow increase, with the exception of the maximum FC width studied. See that, the FC reverse mass flow is taken as positive in

Figure 18d. For this particular case there was a pretty random oscillation of the main jet inside the MC. When considering all the results obtained in the 2D-CFD simulations, with the exception of the point characterizing the maximum FC width case, the FO outlet mass flow frequency can be estimated as a function of the FC time averaged reverse mass flow, according to the equation:

,

being the time averaged FC reverse mass flow, which is taken as positive. The coefficient of determination was (

). We can conclude saying that, for the present FO configuration, the evaluation of the FC reverse mass flow allows to estimate the FO outlet frequency.

Figure 18.

Fluidic Oscillator outlet mass flow (a), its associated frequency (b), and the lower feedback channel outlet mass flow (c), as a function of the different Feedback channel widths evaluated. Fluidic oscillator outlet mass flow frequency as a function of the Feedback channel time averaged reverse mass flow (d).

Figure 18.

Fluidic Oscillator outlet mass flow (a), its associated frequency (b), and the lower feedback channel outlet mass flow (c), as a function of the different Feedback channel widths evaluated. Fluidic oscillator outlet mass flow frequency as a function of the Feedback channel time averaged reverse mass flow (d).

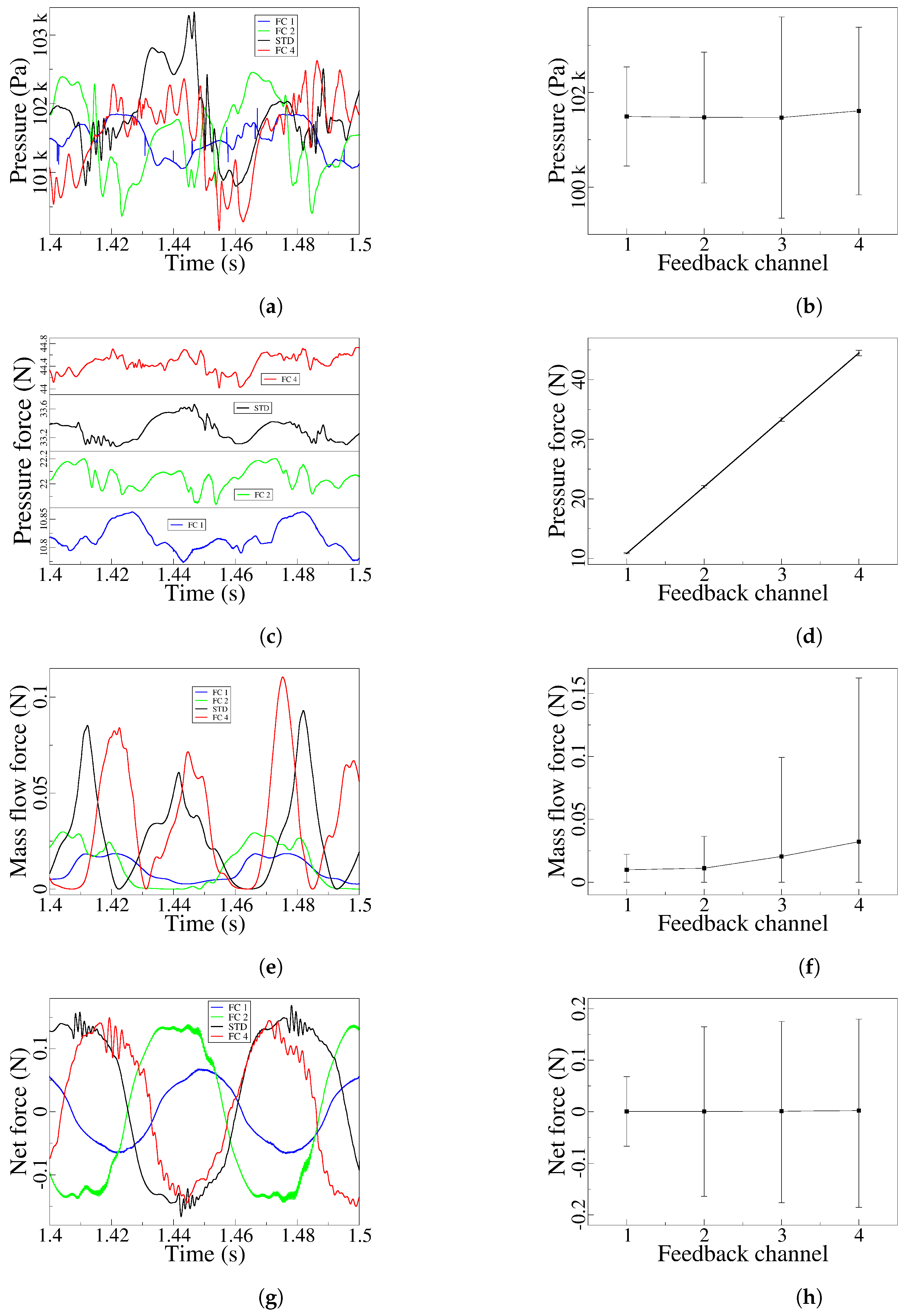

For the four FC widths evaluated, the time dependent stagnation pressure at the MC lower converging wall, its time averaged value and peak to peak amplitude is respectively presented in

Figure 19a, b. As FC width increases, the peak to peak amplitude oscillation grows until reaching the maximum FC width, where the amplitude decreases and the oscillation becomes more random due to the large freedom the MC internal jet is having under these conditions. In

Figure 19c, d, it is shown the time dependent force, its time averaged value and the associated peak to peak amplitude at the FC lower outlet due to the fluid pressure and for the four FC widths considered. The force appears to be linearly increasing with the FC width, but in reality such linearly increase is due to the FC width increase, then the average pressure at the MC converging walls is suffering a minor variation for the different FCs considered. Pressure force peak to peak amplitude also grows with the FC width. It is relevant to highlight that specially for the FC4 case, the pressure force curve is particularly scattered which obeys to the highly random fluctuations associated to this maximum FC width. The evaluation of the time dependent mass flow force, its time averaged and peak to peak amplitude at the FC lower outlet is shown in

Figure 19e, f. The mass flow force follows the same trend as the FC lower outlet mass flow

Figure 18c, the mass flow force average value and peak to peak amplitude, grows with the FC width. The time dependent overall force acting on the jet as in enters the MC as well as its peak to peak amplitude is introduced in

Figure 19g, h. The amplitude considerably grows when going from FC1 to FC2, but remains rather constant for the rest of the FC widths evaluated. Note as well that for the FC4 case the net force curve is particularly scattered, following the trend shown by the time dependent stagnation pressure measured at the MC lower converging wall,

Figure 19a.

6.5. Forces Assessment Acting on the Jet at the Mixing Chamber Entrance

To illustrate the effect of the forces acting on the jet as it enters the mixing chamber, we have chosen two cases, the minimum FC width case, FC1, and the Entrance 1 one, where the angle was

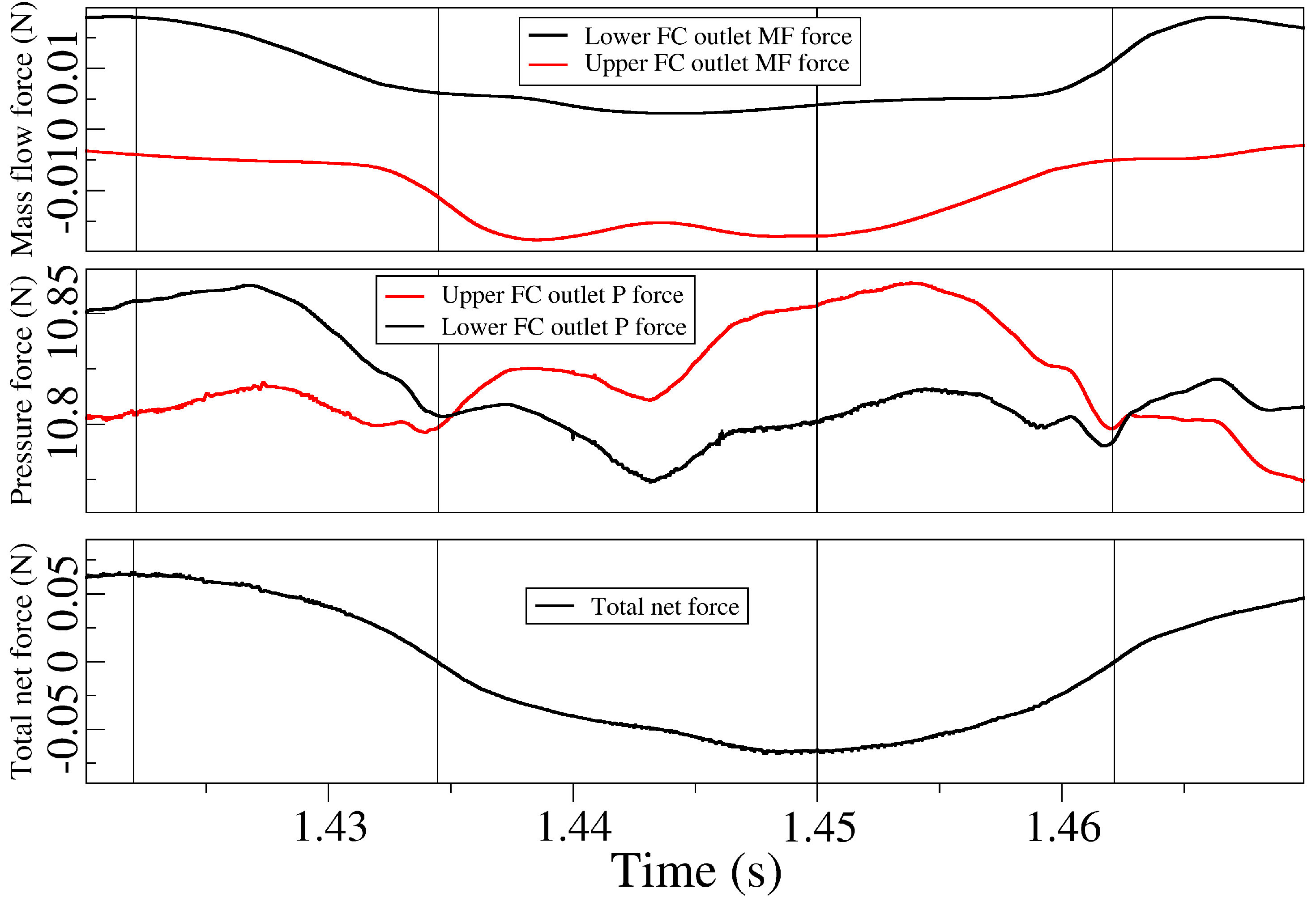

. We have chosen these two cases because they properly clarify the variations of the unsteady force curves when there is no FC reverse flow and when there is a large FC reverse flow. For the smallest FC width, FC1,

Figure 20 introduces for over half an oscillation cycle, the unsteady forces acting on the feedback channels outlets. The upper graph, represents the mass flow forces acting over the jet on each FC outlet. The central graph characterizes the pressure forces acting on the same FC outlets, for convenience the pressure force acting on the upper FC outlet was represented as positive. The lower graph introduces the overall forces acting on the jet as it enters the MC. The same information, but for the Entrance 1 case, characterized by

is presented in

Figure 21.

Regardless of the case studied, the mass flow forces at the lower FC outlet always push the jet upwards, these forces always push the jet downwards on the upper FC outlet. The mass flow forces for the Entrance 1 case, due to the larger FC mass flow associated, are about five times larger than the ones observed in the FC1 case. When comparing the pressure forces from

Figure 20 and

Figure 21, it is seen that for the FC1 case, the curves oscillate rather smoothly, while the periodic-like oscillation observed in the Entrance 1 case, has associated a ripple superimposed to the pressure curves. This pressure ripple is observed in all cases where large FC reverse flow exist. As a consequence, this pressure ripple is as well observed in the total net force curve presented at the bottom of

Figure 21, see that this curve is rather smooth in

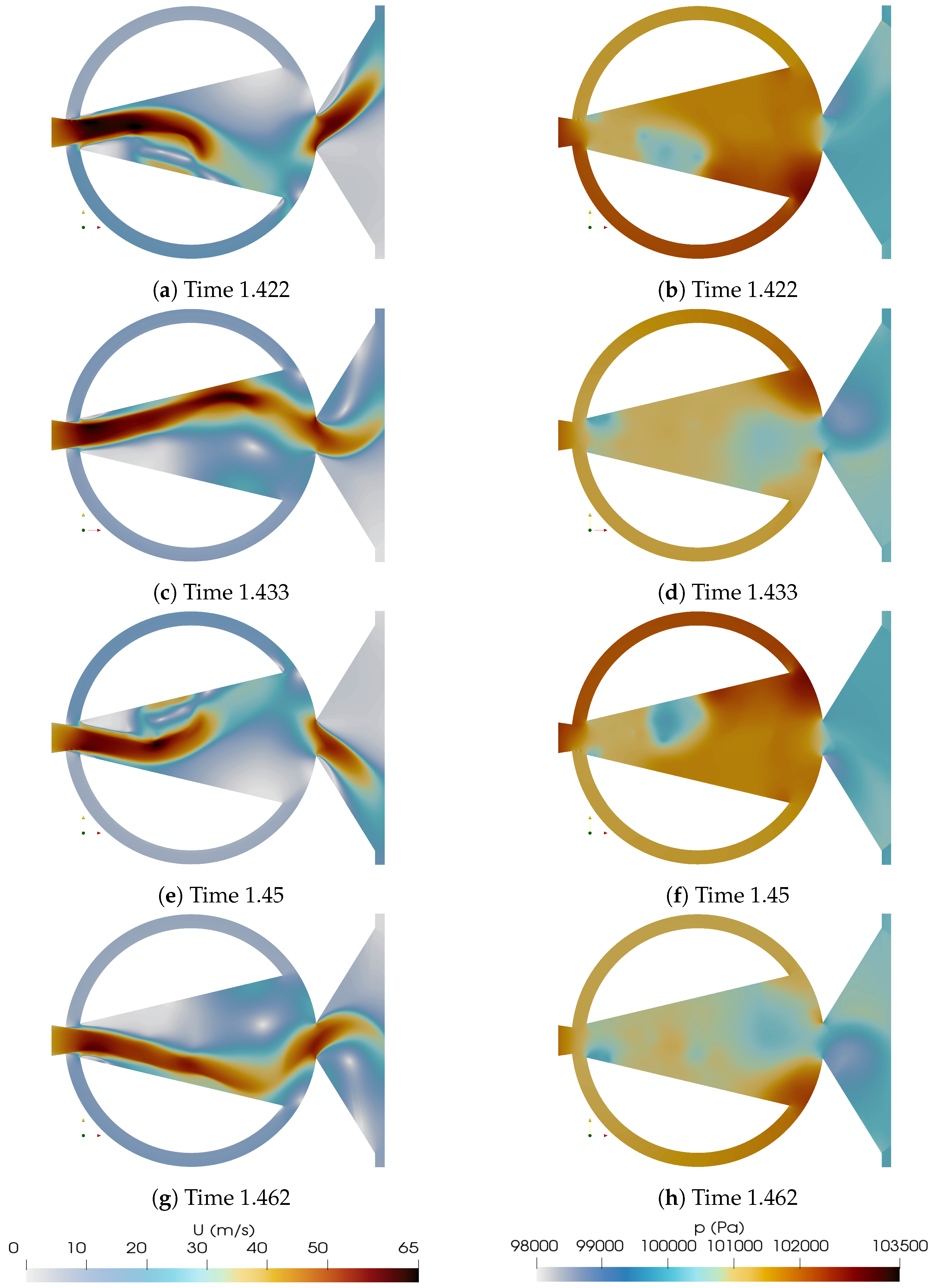

Figure 20. Note as well that pressure forces are always several orders of magnitude higher than mass flow ones, therefore indicating that smaller variations of pressure fields generate large forces on the jet. To understand the origin of the pressure ripple it is necessary to compare the velocity and pressure fields in the FO, see

Figure 22 and

Figure 23, with the pressure forces acting on the jet. At time 1.357 s,

Figure 23a,b, the lower FC is pressurized the jet is being pushed upwards, the pressure forces on the lower FC outlet are higher than the ones at the upper one as shown in

Figure 21. At this instant a large FC reverse flow is observed at the upper FC. Few milliseconds later, at about 1.36 s, see

Figure 21, the upper FC reverse flow is meeting the MC central jet at the MC upper converging wall (upper FC inlet), at this instant the pressure oscillations are particularly large and keep decreasing as the MC jet reaches its upmost position and starts moving downwards, see for example

Figure 23c,d and the corresponding pressure force curves in

Figure 21 at time around 1.37 s. In fact, from this time and until around 1.405 s, the pressure force at the upper FC outlet is pushing the jet downwards, see the stagnation point at the upper MC converging wall,

Figure 23d and the pressurization of the upper FC in

Figure 23f. Note as well that the upper FC pressure force is higher than the lower one,

Figure 21. See as well that, from time 1.392 s and until 1.405 s, the pressure forces have associated a considerable ripple, then the main jet at the MC and the lower FC reverse flow are going to meet at the MC outlet lower converging wall. The exact time the two jets meet is likely to be the instant at which the pressure curves suffer a drop, 1.395 s for the lower FC and 1.361 s for the upper one, see

Figure 21.

Figure 21.

Unsteady mass flow and pressure forces measured at both feedback channel outlets and the overall forces acting on the jet; about half of a cycle is presented here. Case Entrance 1, .

Figure 21.

Unsteady mass flow and pressure forces measured at both feedback channel outlets and the overall forces acting on the jet; about half of a cycle is presented here. Case Entrance 1, .

Finally, from the comparison of

Figure 22 and

Figure 23, it can be concluded that despite the fact that the upper and lower feedback channels are alternatively being pressurized, the no existence of FC reverse flow in the FC1 case, brings a major stability of the jet in the MC, generating smoother force curves, see

Figure 20. Note that this major smoothness was already observed in the stagnation pressure curve previously introduced in

Figure 19a.

Figure 22.

Velocity and pressure fields at different time steps along a half oscillation period. Smallest FC width, FC1.

Figure 22.

Velocity and pressure fields at different time steps along a half oscillation period. Smallest FC width, FC1.

Figure 23.

Velocity and pressure fields at different time steps along a half oscillation period. Case Entrance 1, .

Figure 23.

Velocity and pressure fields at different time steps along a half oscillation period. Case Entrance 1, .