1. Introduction

Shape memory polymer foams are a new class of intelligent polymer materials that have a porous structure and combine the characteristic features of conventional foams and shape memory polymers (SMPs) [

1,

2,

3,

4,

5]. The advantages of shape memory polymer foams are their lower specific weight and faster recovery compared to SMPs. Furthermore, by adding functional additives, additional functional properties of foams can be achieved, such as fire resistance, heat resistance, self-healing, etc. [

6,

7,

8,

9,

10].

Shape memory polymer foams are produced either on the basis of thermoplastic foams [

11,

12,

13,

14,

15] or on the basis of thermoset foams [

16,

17,

18,

19]. The commonly used thermoplastic foams are easy to process and recyclable, but have poorer mechanical properties, while thermoset foams have better thermomechanical properties, but are difficult to process due to the cross-linking of their macromolecular structure. There are also polymer foams, which are a combination of thermoplastics and thermosets. However, their properties depend in a complex way on the multi-level hierarchical structure that forms and are currently poorly understood [

20]. Nevertheless, the possibility of combining the advantages of thermoplastics and thermosets in a foamed polymer material is very promising.

The properties of polymer foams depend not only on the polymer material from which they are made, but also on the foaming process. The most environmentally friendly and therefore widely used process is foaming with supercritical carbon dioxide (sc-CO

2). However, the use of sc-CO

2 as physical foaming agent has a number of limitations. In particular, it is ineffective for thermoplastics with high melt viscosity but low thermal stability (polyvinyl chloride) or high processing temperatures close to the decomposition temperature (polycarbonate, poly(phenylene oxide)) [

11,

21]. The addition of other polymers or, more effectively, a low molecular weight plasticizer is often used to reduce the melt strength (or viscosity) so which the foaming process can be carried out at a lower temperature. However, the presence of plasticizers often carries the risk of reducing the mechanical strength and heat resistance of the resulting foams. In the case of thermosetting plastics, the curing and foaming processes must take place simultaneously. In this case, cell growth requires a suitable viscosity, but the viscosity of thermosets, which depends not only on the foaming temperature but also on the degree of pre-curing, rises close to the gel point in a very short time during the curing process [

22,

23,

24,

25]. Epoxy polymers and hard polyurethanes are the least suitable for CO

2 foaming. The question of how very lightweight thermoset foams with high performance can be produced using the sc-CO

2 foaming process is still an unsolved research problem.

The formation of shape memory foams requires two structural components, including a reversible switching phase and a permanent phase [

26]. This usually requires the creation of more complex systems consisting of phases responsible for the transition of the shape memory and phases responsible for the storage of the permanent/temporary shapes. However, in both thermoplastics and thermosets with more complex, e.g. two-phase or multi-phase structures, the interphase region can be a pathway for CO

2 escape or an obstacle to efficient foam expansion, as well as leading to the formation of undesirable open porosity. In such systems, attempts are made to separate the foaming and phase separation processes. Several strategies have been developed for this purpose. In the first strategy, called "foaming-reinforcing", a cellular structure is formed and then microphase separation is carried out in the resulting cell walls [

20]. The second strategy is a combination of preformed large-pored flexible foam and solid-liquid phase change materials by impregnation [

27,

28]. However, the search for alternative ways to produce shape memory foams with low weight and high performance is urgently needed.

Generally, the introduction of a light and strong filler, such as carbon nanotubes or carbon nanosheets, is used to increase the strength of polymer foams as well as to improve their foamability [

29,

30,

31,

32,

33,

34,

35,

36]. An effective improvement in their mechanical response and rheological behavior during extensional deformation is achieved by the formation of an effective interphase. However, the interphase layer formed between the polymer matrix and the filler, which is a network of physical entanglements, can also serve as a permanent phase to enable polymers with shape memory effect [

37,

38]. From this point of view, polymeric fillers seem to be the most promising as they exhibit stronger adhesion to the polymer matrix and do not require additional functionalization [

39]. Compared to polymer nanodroplets, polymer nanofibers form a higher phase continuity, which contributes to higher shape memory properties (shape fixation and shape recovery ratio) [

40]. Furthermore, the use of in-situ generated polymer nanofibers formed during the conversion of polymer nanoblends into polymer-polymer nanocomposites, also known as nanofibrillar composites [

41,

42,

43,

44], would allow the greatest impact in terms of forming an effective interphase layer, as they are characterized by a homogeneous distribution and high aspect ratio compared to ready-made polymer nanofibers [

45,

46,

47]. Polymer nanofibers can also form a physical network between themselves that can induce or enhance strain hardening behavior, also known as extensional thickening, during cell growth, facilitating the production of a closed-cell structure with a high expansion ratio and uniform cell distribution [

48]. To our knowledge, a few papers [

48,

49] have investigated the possibility of using in-situ generated polymer-polymer nanocomposites to form polymer foams. At the same time, the shape memory performance of such foams has not yet been investigated.

In this study, the possibility of forming polymer foam with shape memory by the sc-CO2 foaming process of polymer-polymer nanocomposites is demonstrated using the polylactide (PLA)/biosourced polyamide (PA) system as an example. The effects of the morphology of the minor polymer phase (droplet or fiber network) on the foam formation and shape memory performance were investigated.

2. Results and Discussion

Cell Structure of PLA/PA Foams

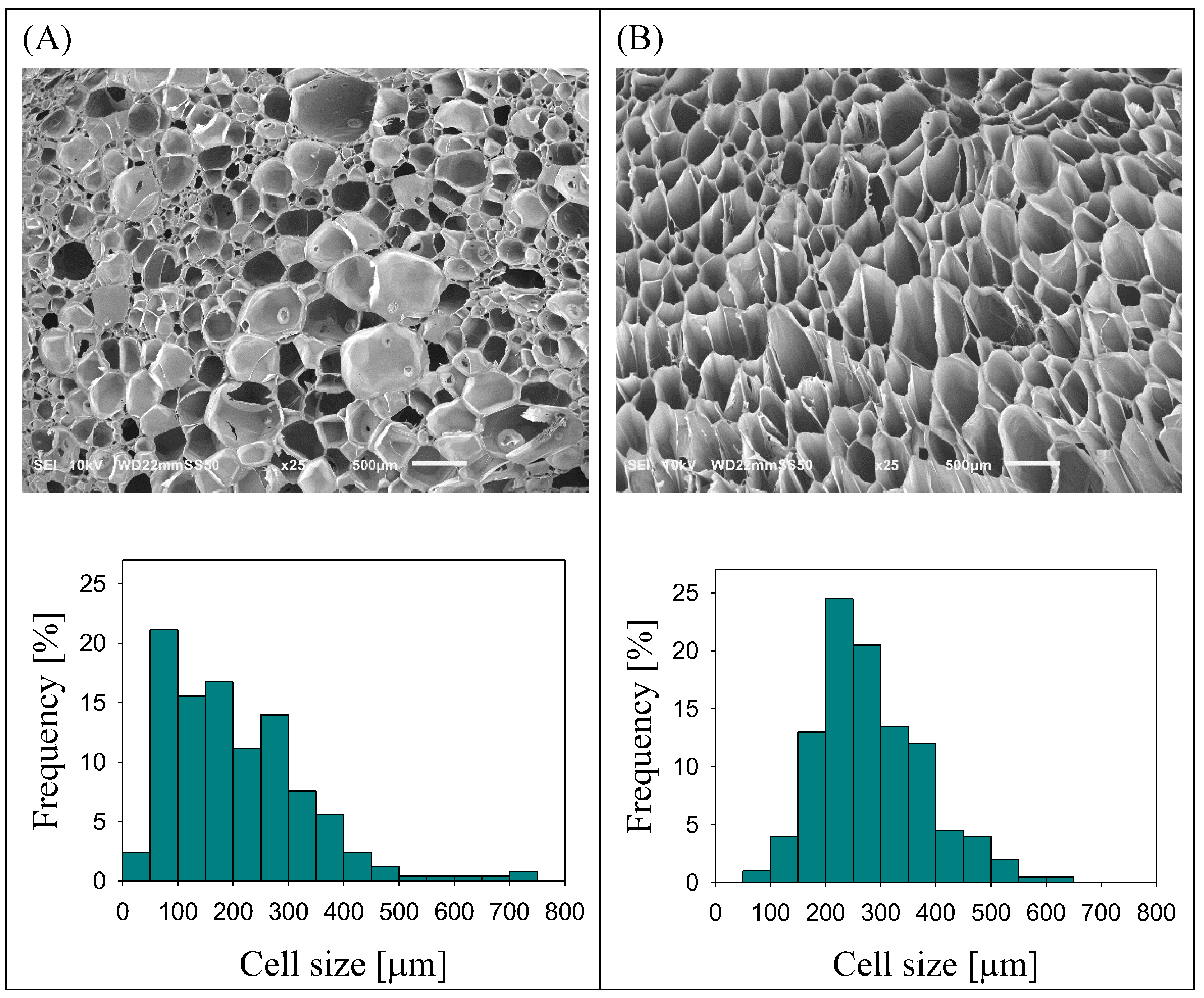

Figure 1A-B shows SEM images of the foamed PLA/PA nanoblends and in-situ generated nanocomposites with the corresponding cell size distribution diagrams. The foamed PLA/PA nanocomposite showed a homogeneous cell structure with an average cell size of 280 μm and a unimodal distribution. At the same time, the foamed PLA/PA nanoblend showed a more complex cell structure with a bimodal cell size distribution and the presence of large pores with an average cell size of 316 μm and small cells with an average pore size of 70 μm. The cell concentration is slightly higher in the foamed nanoblend than in the foamed nanocomposite: 1.78 ×10

6 cells/cm

3 and 0.88 ×10

6 cells/cm

3, respectively. However, the contribution of a large number of small pores located at the edge of the intersection of large pores to the obtained cell concentration value should be taken into account.

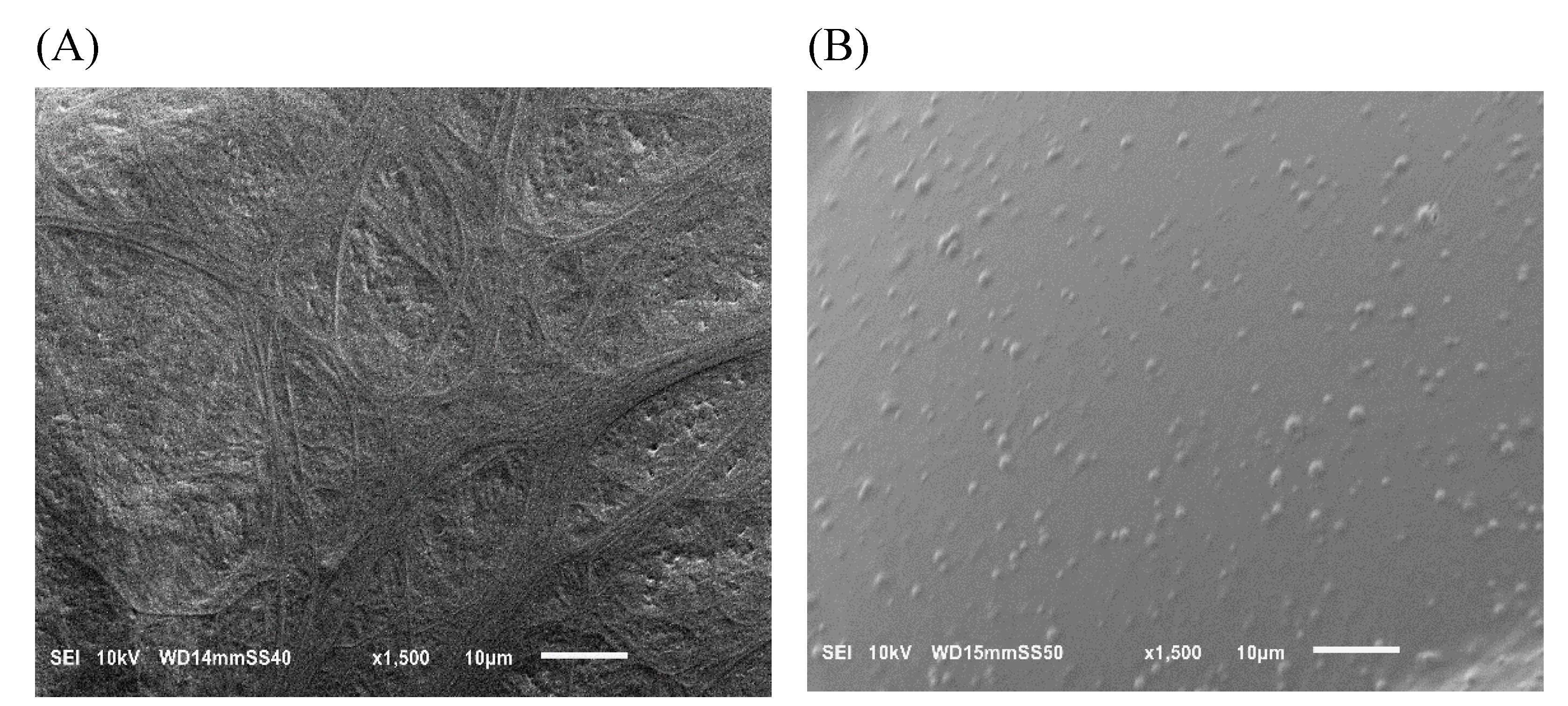

Figure 2А clearly shows the presence of a large number of PA nanofibers in the PLA cell walls (also seen in

Figure S1 and

Figure S2 in the

supplementary materials). In addition, the PA nanofibers form a spatial network with many physical entanglements. In contrast, in the case of the nanoblends, the PLA cell walls contain inclusions of nanodroplets that are homogeneously distributed in the polymer matrix but do not form additional physical bonds (

Figure 2B). As mentioned in [

48], the entangled network of polymer nanofibers appears to play a crucial role in reinforcing the growing cells. First, the polymer nanofibers localized in the cell walls induce strain hardening (

Figure S3 in the

supplementary materials), which in turn prevents the cells from breaking during expansion. As a result, the phenomenon of coalescence was suppressed in PLA/PA nanocomposite foams. The coalescence of growing cells during sc-CO

2 foaming of the PLA/PA blend leads to the generation of foams with a much lower concentration of large cells. Secondly, the entanglements between the polymer nanofibers appear to act as a local confinement for the further expansion of the growing cells. Moreover, the network of PA nanofibers favors efficient stress distribution during cell formation, which contributes to the formation of cells with more uniform size.

Mechanical Properties of PLA/PA Foams

The mechanical properties of nanoblend and nanocomposite foams are closely related to their cellular microstructure, including cell density and size, wall thickness and surface defects, as well as the morphology of nanoparticles.

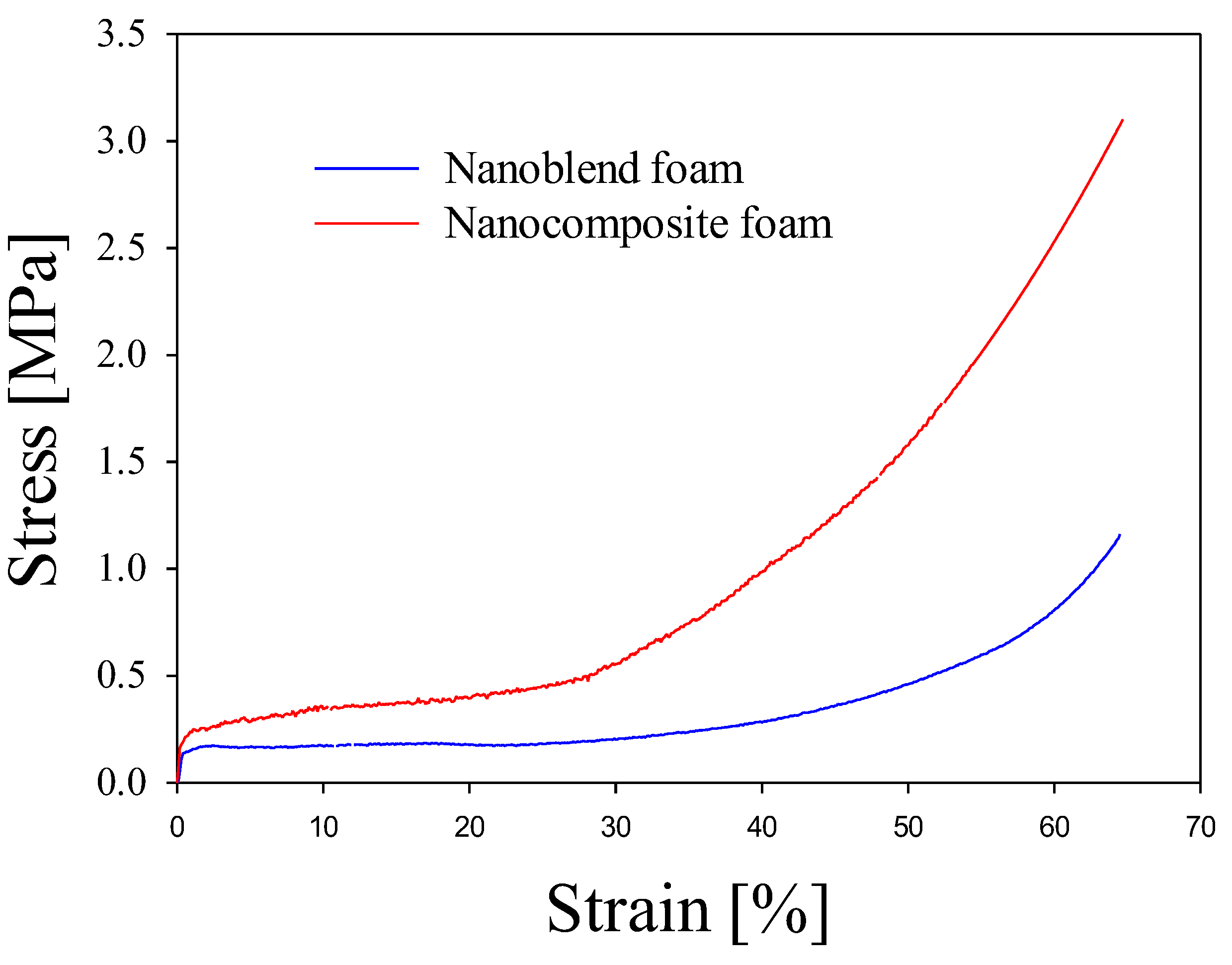

Figure 3 shows the compression behavior of the foams. Both foams respond initially with elastic response reaching the level of 0.2 MPa. The modulae for both foams are different: 0.278 MPa for nanoblend foam and 0.466 MPa for nanocomposite foam. With farther compression the nanocomposite foam responds with significantly larger stress 0.35-0.35 MPa while nanoblend foam is much softer, at the level of 0.2-0.25 MPa. With further compression both foams respond with evident strain hardening, with nanocomposite foam responding with approximately twice the stress for nanoblend foam. This is probably due to the stronger reinforcing effect of the PLA matrix caused by the presence of PA nanofibers compared to PA nanodroplets. The influence of the cell structure can also be observed. Cell walls, ribs at junctions of cells and cell corners are having the major influence on the mechanical properties of a foam. They all are stronger and fortified by PA nanofibers in the case of nanocomposite foam than for nanoblend foam resulting in higher modulus and higher strength. In addition, a more uniform distribution of pore sizes should contribute to better overall mechanical properties (compare

Figure 1A,B). It should be noted that some defective wall surfaces were formed in the nanoblend foams and the wall thickness was slightly less than the wall thickness in the nanocomposite foams, which also contributed to the strength of the foams.

Shape Memory Properties of PLA/PA Foams

In PLA/PA polymer system, the amorphous phase of PLA can be selected as the switching elements, while the crystalline phases of PA and PLA/PA interphase serve as the permanent elements. The amorphous phase of PA can potentially be a switching element, but its low volume content does not allow efficient accumulation of elastic energy to realise the shape memory effect. The glass transition temperature of PLA, 60 °C, was chosen as the programming temperature for the shape memory effect.

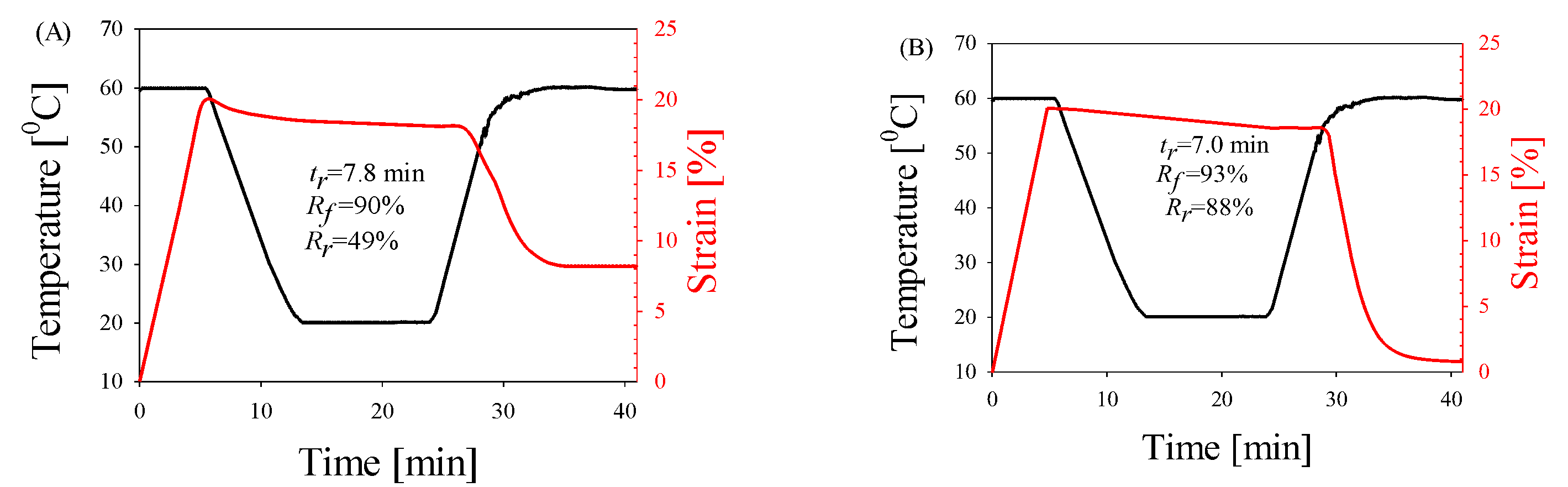

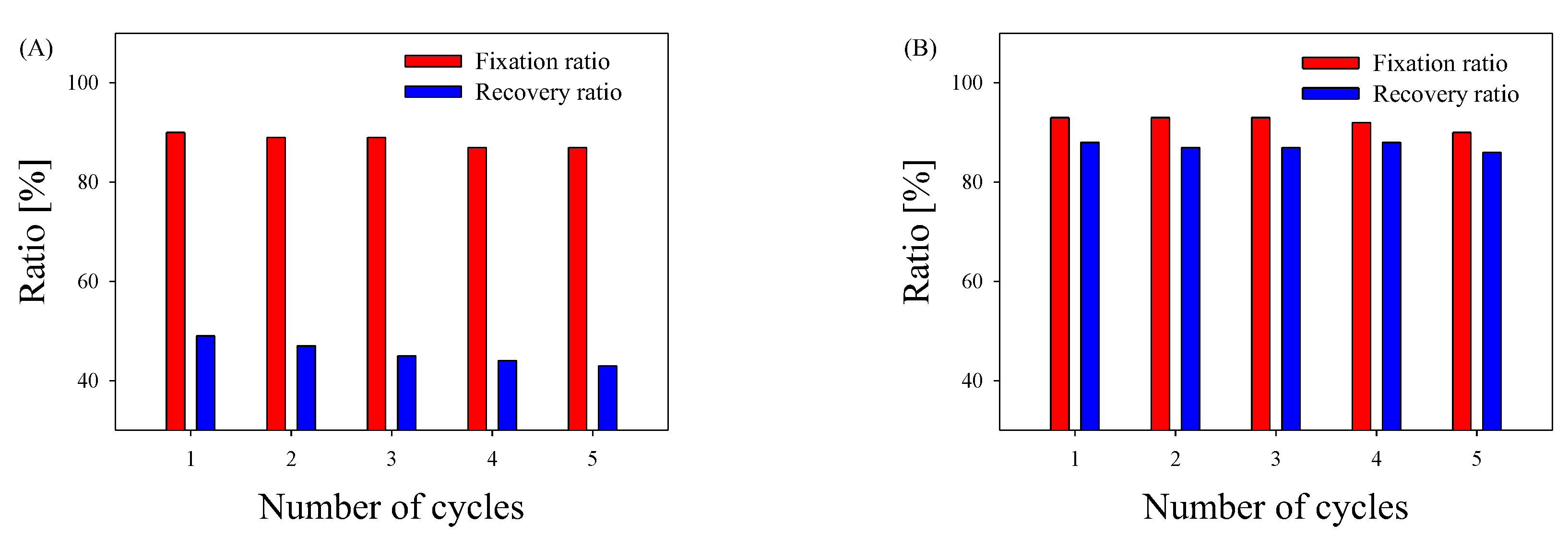

Figure 4 shows typical stress-strain-temperature curves as a function of time for nanoblend and nanocomposite foams. The transition temperature was set at 60 °C, with an overall strain of 20 %. As can be seen, both nanoblend and nanocomposite foams exhibit relatively high shape fixation ratios, namely 90 and 93 % respectively. At the same time, the shape recovery ratios differ significantly from each other, being 88% for nanocomposite foam and only 49% for nanoblend foam. The shape recovery times are similar but slightly shorter for the nanocomposite foam (7.0 minutes for nanocomposite foam vs. 7.8 minutes for nanoblend foam).

In [

50,

51] it was found that the expansion ratio of the foam (directly proportional to the cell concentration) and the cell size both, they affect the memory performance. In particular, when the expansion ratio of the foam is increased, the shape fixation ratio increases and the shape recovery ratio decreases. At the same time, when the cell size of the foam is reduced, the shape fixation ratio decreases and the shape recovery ratio increases. In the systems studied, reducing the large cell size actually led to an increase in the recovery ratio, and nanocomposite foams with a lower cell concentration showed a higher recovery ratio. The shape fixation ratio was practically independent of the cell microstructure parameters. It can be assumed that the cell structure had no decisive influence on the properties of the shape memory effect of the foams studied. In this case, the morphology of the polymer-polymer system from which the foam was produced had a greater influence. The presence of entangled PA nanofibers acting as permanent elements contributed to a more efficient accumulation of elastic deformation and to a significantly lower irreversible deformation in switching PLA elements compared to PA nanodroplets as permanent elements. It is also noteworthy that deterioration of shape memory properties during cycling (shape fixation and shape recovery ratios) was practically absent in the nanocomposite foams, while it was observed in the nanoblend foams (

Figure 5). The latter could also be related to the presence of an entangled nanofibril network in the foam walls, which effectively redistributes the load during shape memory effect programming and shape recovery.

3. Materials and Methods

3.1. Materials

A commercially available grade of polylactide, PLA 4060D, was purchased from NatureWorks LLC and used as the matrix. This grade of PLA is biodegradable, has a density of 1.24 g cm-3 and a molecular weight of 120,000 g mol-1. It has a glass transition temperature of 61 °C. A fully bio-based polyamide (PA) with the trade name Vestamid Terra DS from Evonik Industries was used to produce the composite materials. The monomers for the synthesis of this type are obtained from castor oil. The melting point of PA is 200 °C and its equilibrium melting temperature is 238 °C.

3.2. Sample Preparation

Blends and in-situ generated nanocomposites of PLA/PA were prepared according to the procedure we have already described [

52]. To produce the blend PLA/PA (95/5), 5 wt.% PA was melt blended with PLA (both components were dried for 8 h at 60 °C) in a twin-screw extruder, whereby the temperature zones were progressively adjusted from 200 °C to 230 °C. The blend was also produced in a single-screw extruder. The mixture was also processed in a single-screw extruder with a temperature gradient from 230 °C (feed zone) to 175 °C (slit nozzle). A co-rotating twin-screw extruder 2x20/40D EHP (Zamak Mercator) operating at 120 rpm was used for processing. After fibril formation, the tapes were extruded using a single-screw extruder (PlastiCorder PLV 151, Brabender; D = 19.5 mm, L/D = 25 and 20 rpm), which was equipped with a 12 mm wide, 0.8 mm thick and 100 mm long slit die. The slit die process pressure of the slit nozzle was 20.1 MPa.

3.3. Foaming Process

Before initiating the foaming process, the as-prepared blend and in-situ generated composites were hot-pressed in a hydraulic press using a steel template in the form of rectangular plates with dimensions of 8×5 cm in length and width and a thickness of 1 mm. Further, round discs with a diameter of 20 mm were cut from the plates and used for foaming. The foams of PLA/PA blends and composites were produced in a high-pressure stainless steel autoclave reactor using a batch foaming process. The reactor vessel was preheated to 100 °C. The samples were filled into an aluminium pan and loaded into the reactor vessel (50 ml). The reactor vessel was then filled with dry ice and sealed. The foaming temperature was set to 150°C for the PLA/PA blend and 155°C for the PLA/PA composite samples. The CO2 dissolution pressure was maintained at 13 MPa and the soaking time was 60 minutes for all the samples. The autoclave was gradually cooled to 120°C for the blends and 130°C for the composites, and then the pressure was quickly released (~1 second) via the vents in the autoclave chamber. The foamed samples were immediately quenched with dry ice and stored for analysis. This experimental procedure was repeated several times for each composition of the samples.

3.4. Apparatus and Experimental Techniques

The structure of the foams was analyzed by scanning electron microscopy (SEM) using a JEOL JSM 6010 LV/LA microscope. The internal structure of the samples was visualized by cutting at liquid nitrogen temperature. The cell size and cell concentration of foams were determined from SEM images. The number of cells (N

0) per unit volume (cm

3) of the foamed samples was calculated using the following formula

where n is the number of cells and A is the area (cm

2) of the SEM micrograph. The foaming expansion ratio (

) is the ratio of the density of the solid sample (

ρ0) to the density of the foamed sample (

ρf) and is given as follows,

Uniaxial extension tests on samples were conducted using an extensional viscosity fixture (EVF) attached to the ARES rheometer. Rectangular specimens, measuring 18 × 10 × 0.7 mm³, were either prepared by hot compression molding at 200°C in a standard mold (for blend) or cut from extruded tapes (for composite). These specimens were stretched uniaxially at 160°C with constant Hencky strain rates of 0.05 and 0.5 sec⁻¹. The temperature was adjusted to ensure that the elastic force of the minor phase was strong enough to counteract the plastic flow of the molten matrix. At higher temperatures, the effect of nanofibers would be masked due to the dominant plasticity of the major phase. The tensile stress growth coefficient, η+E (t, εH), as a function of strain time (t) at a given Hencky strain rate (εH), was recorded.

Thermally-activated shape memory characterization of foamed samples was conducted using Q800 DMA instrument with the film tension clamp under controlled strain and controlled force modes. The dual shape memory properties were enforced by primary strain deformation of 20% applied at 60 °C. The strain was then kept constant. The strain was then held constant while the sample was cooled to room temperature and then released. To observe the memory effect, the samples were heated to 62 °C for 30 minutes to recover the shape.

The shape fixity Rf and the shape recovery Rr ratios were calculated using the following equations: Rf=(εun/εmax)×100%; Rr=((εun−εfin)/εmax)×100%, where εun is the strain after cooling and unloading, εmax is the strain obtained before the constant loading was released, and εfin is the strain obtained after heating in the step of recovery.

The mechanical properties of the foamed samples were tested under plane-strain compression using the Instron 5582 tensile testing machine. The test temperature was 25 °C. The specimen was compressed at a rate of 5% of the initial thickness per minute. The specimens had a rectangular shape with a size of 8x4x3 mm.

4. Conclusions

The concept of in-situ generated polymer-polymer nanocomposites was applied to the production of shape memory polymer foams. In-situ generated polymer nanofibers are characterized by a high degree of dispersion in the polymer matrix and an associated high specific surface area, which significantly improves the adhesion between the phases in polymer-polymer systems. Furthermore, in-situ generated polymer fibers are able to form entangled nanofiber structures due to the end-to-end coalescence process. In-situ generated nanofibers not only have a positive effect on the foaming behavior by ensuring the formation of a homogeneous, closed cell structure with uniform cell size distribution, but also on the improvement of mechanical properties and shape memory. The effects achieved are due to the formation of an effective interphase adhesion between major and minor polymer phases. Using the PLA/PA system as an example, it is shown that the foam produced on the basis of an in-situ generated polymer-polymer nanocomposite has excellent shape memory properties (shape fixation of 93 % and recovery of 88 %), which are significantly higher than that of the foam based on a polymer-polymer nanoblend (shape fixation of 90 % and recovery of 49 %). In addition, nanocomposite foams have higher mechanical properties (modulus of elasticity of 0.466 MPa, yield stress of 0.24 MPa) compared to nanoblend foams (modulus of elasticity of 0.278 MPa, yield stress of 0.15 MPa).

Supplementary Materials

The following supporting information can be downloaded at the website of this paper posted on Preprints.org, Figure S1: Time-dependence of the tensile stress growth coefficient, η+E (t, εH), for PLA/PA nanoblend and in situ generated nanocomposite; Figure S2 SEM images of cross-section surfaces of foams of PLA/PA nanoblends; Figure S3 SEM images of cross-section surfaces of foams of PLA/PA in-situ generated nanocomposites.

Author Contributions

Conceptualization, A.G.; methodology, D.E., R.H., V.B., I.V., J.M.; software, D.E., R.H., V.B.; validation, D.E., R.H., V.B; formal analysis, D.E., R.H., V.B. and I.V.; investigation, D.E., R.H., V.B.; resources, J.M.; data curation, D.E., R.H., V.B; writing—original draft preparation, I.V.; writing—review and editing, D.E., R.H, V.B., J.M., A.G.; visualization, D.E., R.H.; supervision, A.G.; project administration, A.G.; funding acquisition, A.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Science Centre (Poland) under the grant UMO-2021/41/B/ST8/04036.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to acknowledge the Centre of Molecular and Macromolecular Studies of the Polish Academy of Sciences (CMMS-PAS) for the research facilities provided.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lee, S. T.; Park, C. B.; Ramesh, N. S. Polymeric Foams: Science and Technology, 1st ed.; CRC Press: Boca Raton, FL, 2006. [Google Scholar]

- Mills, N. Polymer Foams Handbook: Engineering and Biomechanics Applications and Design Guide; Butterworth-Heinemann: Burlington, MA, 2007. [Google Scholar]

- Leng, J. S.; Lan, X.; Liu, Y. J.; Du, S. Y. Shape-memory polymers and their composites: stimulus methods and applications. Prog. Mater. Sci. 56, 2011, 1077–1135.

- Hager, M.D.; Bode, S.; Weber, C.; Schubert, U.S. Shape memory polymers: past, present and future developments. Prog. Polym. Sci. 2015, 49–50, 3–33. [Google Scholar] [CrossRef]

- Santo, L. Shape memory polymer foams. Prog. Aerosp. Sci. 2016, 81, 60–65. [Google Scholar] [CrossRef]

- Zhao, G.; Wang, H.; You, J.; Xing, H.; Xue, J.; Jiang, Z.; Tang, T. Superlight flame-retardant poly(aryl ether ketone)/polyurea nanocomposite foam with excellent solvent-resistance and shape memory performance. Compos. Commun. 2024, 48, 101946. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Varyukhin, V.N.; Voznyak, Y.V. Electrical properties of carbon containing epoxy compositions under shape memory effect realization. Compos. Part A 2005, 36, 65–70. [Google Scholar] [CrossRef]

- Chen, J.; Jiang, W.; Zeng, Z.; Sun, D.; Qi, X.; Yang, J.; Wang, Y. Multifunctional shape memory foam composites integrated with tunable electromagnetic interference shielding and sensing. Chem. Eng. J. 2023, 466, 143373. [Google Scholar] [CrossRef]

- Li, G.; Xu, T. Thermomechanical characterization of shape memory polymer−based self-healing syntactic foam sealant for expansion joints. ASCE J. Transp. Eng. 2011, 137, 805–814. [Google Scholar] [CrossRef]

- Wang, J.; Luo, J.; Kunkel, R.; Saha, M.; Bohnstedt, B.N.; Lee, C.H.; Liu, Y. Development of shape memory polymer nanocomposite foam for treatment of intracranial aneurysms. Mater. Lett. 2019, 250, 38–41. [Google Scholar] [CrossRef]

- Park, C.B.; Zhai, W. Special section "fabrication and properties of engineering plastic foams". Adv. Eng. Mater. 2022, 24, 2200172. [Google Scholar]

- Guo, H.; Kumar, V. Solid-state poly(methyl methacrylate) (PMMA) nanofoams. Part I: low-temperature CO2 sorption, diffusion, and the depression in PMMA glass transition. Polymer 2015, 57, 157–163. [Google Scholar] [CrossRef]

- You, J.; Xing, H.; Xue, J.; Jiang, Z.; Tang, T. Preparation of rigid cross-linked PVC foam with excellent thermal insulation through adding high-reflectivity IR opacifier. Compos. Sci. Technol. 2021, 203, 108566. [Google Scholar] [CrossRef]

- Zhang, F. , Zhou, T. , Liu, Y. et al. Microwave synthesis and actuation of shape memory polycaprolactone foams with high speed. Sci. Rep. 2015, 5, 11152. [Google Scholar]

- Chen, XL; Huang, QG. Significantly tunable foaming behavior of blowing agent for the polyethylene foam resin with a unique designed blowing agent system. ACS Omega 2024, 9, 5798–5808. [Google Scholar] [CrossRef]

- Di Prima, M. A.; Lesniewski, M.; Gall, K.; McDowell, D.L.; Sanderson, T.; Campbell, D. Thermomechanical behavior of epoxy shape memory polymer foams. Smart Mater. Struct. 2007, 16, 2330–2340. [Google Scholar] [CrossRef]

- Fan, J.; Li, G. High enthalpy storage thermoset network with giant stress and energy output in rubbery state. Nat. Commun. 2018, 9, 642. [Google Scholar] [CrossRef]

- Abedin, R.; Feng, X.; Pojman Jr., J.; Ibekwe, S.; Mensah, P.; Warner, I.; Li, G. A Thermoset shape memory polymer-based syntactic foam with flame retardancy and 3D printability. ACS Appl. Polym. Mater. 2022, 4, 1183–1195. [Google Scholar] [CrossRef]

- Feng, X.; Fan, J.; Li, A.; Li, G. Biobased tannic acid cross-linked epoxy thermosets with hierarchical molecular structure and tunable properties: damping, shape memory, and recyclability. ACS Sustainable Chem. Eng. 2020, 8, 874–883. [Google Scholar] [CrossRef]

- You, J.; Jiang, Z.; Jiang, H.; Qiu, J.; Li, M.; Xing, H.; Xue, J.; Tang, T. A “Plasticizing-foaming-reinforcing” approach for creating thermally insulating PVC/polyurea blend foams with shape memory function. Chem. Eng. J. 2022, 450, 138071. [Google Scholar] [CrossRef]

- Akrami, H.; Park, C.B. Advanced polycarbonate foam: enhancing foamability and mechanical properties with toughened polycarbonate using nanofibrillation method and crosslinked rubbery EPDM networks. J. Manuf. Proc. 2024, 127, 340–348. [Google Scholar] [CrossRef]

- Ling, Y.; Yao, S.; Chen, Y.; Hu, D.D.; Xi, Z.; Zhao, L. Synergetic effect between curing reaction and CO2 diffusion for microcellular epoxy foam preparation in supercritical CO2. J. Supercrit. Fluids 2022, 180, 105424. [Google Scholar] [CrossRef]

- Yang, Z.; Liu, T.; Hu, D.; Xu, Z.; Zhao, L. Foaming window for preparation of microcellular rigid polyurethanes using supercritical carbon dioxide as blowing agent. J. Supercrit. Fluids 2019, 147, 254–262. [Google Scholar] [CrossRef]

- Brondi, C.; Di Caprio, M.R. , Scherillo, G.; Di Maio, E.; Mosciatti, T.; Cavalca, S.; Parenti, V.; Corti, M.; Iannace, S. Thermosetting polyurethane foams by physical blowing agents: chasing the synthesis reaction with the pressure. J. Supercrit. Fluids 2019, 154, 104630. [Google Scholar] [CrossRef]

- Yang,Z. ; Hu, D.; Liu, T.; Xu, Z.; Zhao, L. Strategy for preparation of microcellular rigid polyurethane foams with uniform fine cells and high expansion ratio using supercritical CO2 as blowing agent. J. Supercrit. Fluids 2019, 153, 104601.

- Hager, M. D.; Bode, S.; Weber, C.; Schubert, U. S. Shape memory polymers: Past, present and future developments. Prog. Polym. Sci. 2015; 49-50, 3–33. [Google Scholar]

- Shi, T.; Liu, H.; Wang, X. Multi-stimuli-responsive shape memory flexible composites based on magnetic melamine/polydopamine/phosphorene complex foams and polyethylene glycol. Compos. Part A 2024, 181, 108117. [Google Scholar] [CrossRef]

- Marotta, A.; Lama, G.C.; Ambrogi, V.; Cerruti, P.; Giamberini, M.; Gentile, G. Shape memory behavior of liquid-crystalline elastomer/graphene oxide nanocomposites. Compos. Sci. Technol. 2018, 159, 251–258. [Google Scholar] [CrossRef]

- Gong, P.J.; Buahom, P.; Tran, M.-P.; Saniei, M.; Park, C.B.; Potschke, P. Heat transfer in microcellular polystyrene/multi-walled carbon nanotube nanocomposite foams, Carbon 2015, 93, 819–829.

- Hu, L.; Zhang, F.; Luo, L.; Wang, L.; Liu, Y.; Leng, J. Design and preparation of shape memory phenol–formaldehyde foam composites with excellent thermal stability and mechanical properties. Compos. Part A 2023, 174, 107738. [Google Scholar] [CrossRef]

- Zhao, J.C.; Wang, G.L.; Wang, C.D.; Park, C.B. Ultra-lightweight, super thermal insulation and strong PP/CNT microcellular foams. Compos. Sci. Technol. 2020, 191, 108084. [Google Scholar] [CrossRef]

- Gong, P.J.; Wang, G.L.; Tran, M.-P.; Buahom, P.; Zhai, S.; Li, G.X.; Park, C.B. Advanced bimodal polystyrene/multi-walled carbon nanotube nanocomposite foams for thermal insulation. Carbon 2017, 120, 1–10. [Google Scholar] [CrossRef]

- Yan, D.X.; Xu, L.; Chen, C.; Tang, J.H.; Ji, X.; Li, Z.M. Enhanced mechanical and thermal properties of rigid polyurethane foam composites containing graphene nanosheets and carbon nanotubes. Polym. Int. 2012, 61, 1107–1114. [Google Scholar] [CrossRef]

- Meng, H. P.; Li, G. Q. A review of stimuli-responsive shape memory polymer composites. Polymer 2013, 54, 2199–2221. [Google Scholar] [CrossRef]

- Jamil, H.; Faizan, M.; Adeel, M.; Jesionowski, T.; Boczkaj, G.; Balciunaite, A. Recent advances in polymer nanocomposites: unveiling the frontier of shape memory and self-healing properties—a comprehensive review. Molecules 2024, 29, 1267. [Google Scholar] [CrossRef]

- Bakshi, M. S.; Kattimani, S. Study of mechanical and dynamic mechanical behavior of halloysite nanotube-reinforced multiscale syntactic foam. J. Appl. Polym. Sci. 2021, 138, 49855. [Google Scholar] [CrossRef]

- Vozniak, I.; Beloshenko, V.; Vozniak, A.; Zaïri, F.; Galeski, A.; Rozanski, A. Interfaces generation via severe plastic deformation – a new way to multiple shape memory polymer composites. Polymer 2023, 267, 125653. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, Y.; Liu, X.; Yin, B.; Yang, M. Fabrication of poly(ε-caprolactone) (PCL)/poly(propylene carbonate) (PPC)/ethylene-a-octene block copolymer (OBC) triple shape memory blends with cycling performance by constructing a co-continuous phase morphology. Polym. Int. 2020, 69, 702–711. [Google Scholar] [CrossRef]

- Huang, Z.M.; Zhang, Y.Z.; Kotaki, M.; Ramakrishna, S. A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos. Sci. Technol. 2003, 63, 2223–2253. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Zaïri, F. In situ generation of green hybrid nanofibrillar polymer-polymer composites—a novel approach to the triple shape memory polymer formation. Polymers 2021, 13, 1900. [Google Scholar] [CrossRef]

- Voznyak, Yu.; Morawiec, J.; Galeski, A. Ductility of polylactide composites reinforced with poly(butylene succinate) nanofibers. Compos. Part A 2016, 90, 218–224. [Google Scholar] [CrossRef]

- Kelnar, I.; Fortelný, I.; Kaprálková, L.; Angelov, B.; Nevoralová, M. Effect of layered silicates on fibril formation and properties of PCL/PLA microfibrillar composites. J. Appl. Polym. Sci. 2016, 133, 43061. [Google Scholar] [CrossRef]

- Fakirov, S. In situ nano- and microfibrillar polymer-polymer composites: The concept of micro- or nanofibrils reinforced polymerpolymer composites. In Synthetic Polymer-Polymer Composites; D. Bhattacharyya, S. Fakirov, S., Ed.; Hanser Publications: Munich, Germany, 2012; pp. 353–400. [Google Scholar]

- Xie, L.; Xu, H.; Niu, B.; Ji, X.; Chen, J.; Li, Z.M.; Hsiao, B.S.; Zhong, G.J. Unprecedented access to strong and ductile poly (lactic acid) by introducing in situ nanofibrillar poly (butylene succinate) for green packaging. Biomacromolecules 2014, 15, 4054–4064. [Google Scholar] [CrossRef]

- Vozniak, I.; Hosseinnezhad, R.; Morawiec, J.; Galeski, A. Nanofibrillar green composites of polylactide/polyhydroxyalkanoate produced in situ due to shear induced crystallization. Polymers 2019, 11, 1811. [Google Scholar] [CrossRef]

- Vozniak, I.; Hosseinnezhad, R.; Morawiec, J.; Galeski, A. Microstructural evolution of poly(-caprolactone), its immiscible blend, and in situ generated nanocomposites. Polymers 2020, 12, 2587. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A.; Dutkiewicz, S. In situ generation of sustainable PLA-based nanocomposites by shear induced crystallization of nanofibrillar inclusions. RSC Adv. 2019, 9, 30370. [Google Scholar] [CrossRef] [PubMed]

- Jurczuk, K.; Galeski, A.; Morawiec, J. Effect of poly(tetrafluoroethylene) nanofibers on foaming behavior of linear and branched polypropylenes. Eur. Polym. J. 2017, 88, 171–182. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Wang, G.; Zhao, H.; Lin, J.; Zhao, G.; Park, C.B. Strong and super thermally insulating in-situ nanofibrillar PLA/PET composite foam fabricated by high-pressure microcellular injection molding. Chem. Eng. J. 2020, 390, 124520. [Google Scholar] [CrossRef]

- Sauter, T.; Kratz, K.; Lendlein, A. Pore-size distribution controls shape-memory properties on the macro- and microscale of polymeric foams. Macromol. Chem. Phys. 2013, 214, 1184–1188. [Google Scholar] [CrossRef]

- Gong, Z.; Chen, Y.; Yuan, J.; Zhao, L.; Hu, D. Shape memory temperature-tunable poly(butylene adipate-coterephthalate)/polylactic acid foams prepared by supercritical CO2 foaming. ACS Sustainable Chem. Eng. 2024, 12, 12064–12075. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A. Nanofibrillar green composites of polylactide/polyamide produced in situ due to shear induced crystallization. Compos. Commun. 2020, 22, 100512. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).