Submitted:

24 September 2024

Posted:

25 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methods

2.1. Materials

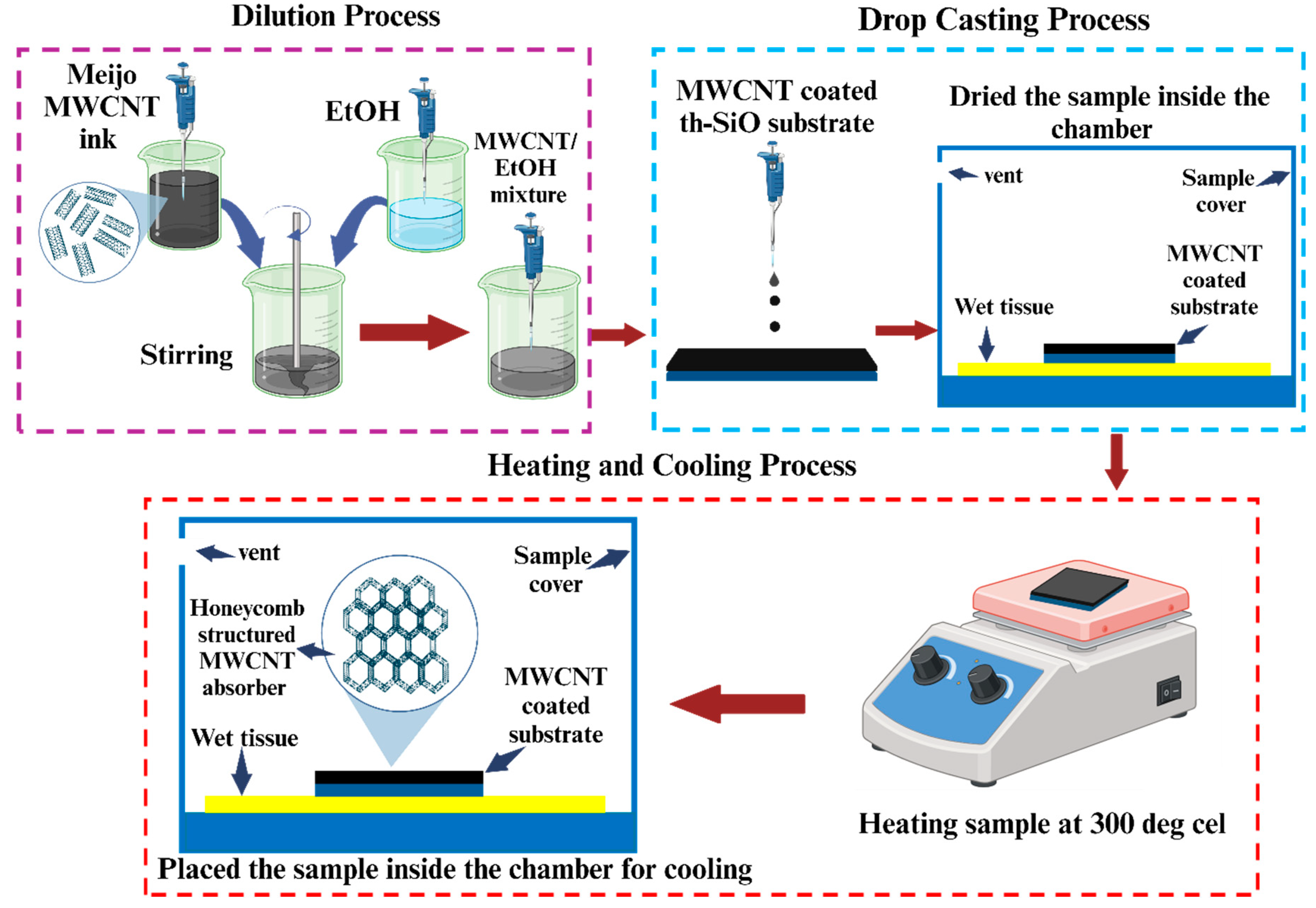

2.2. Preparation of MWCNTs Absorber

2.3. Optical Measurements

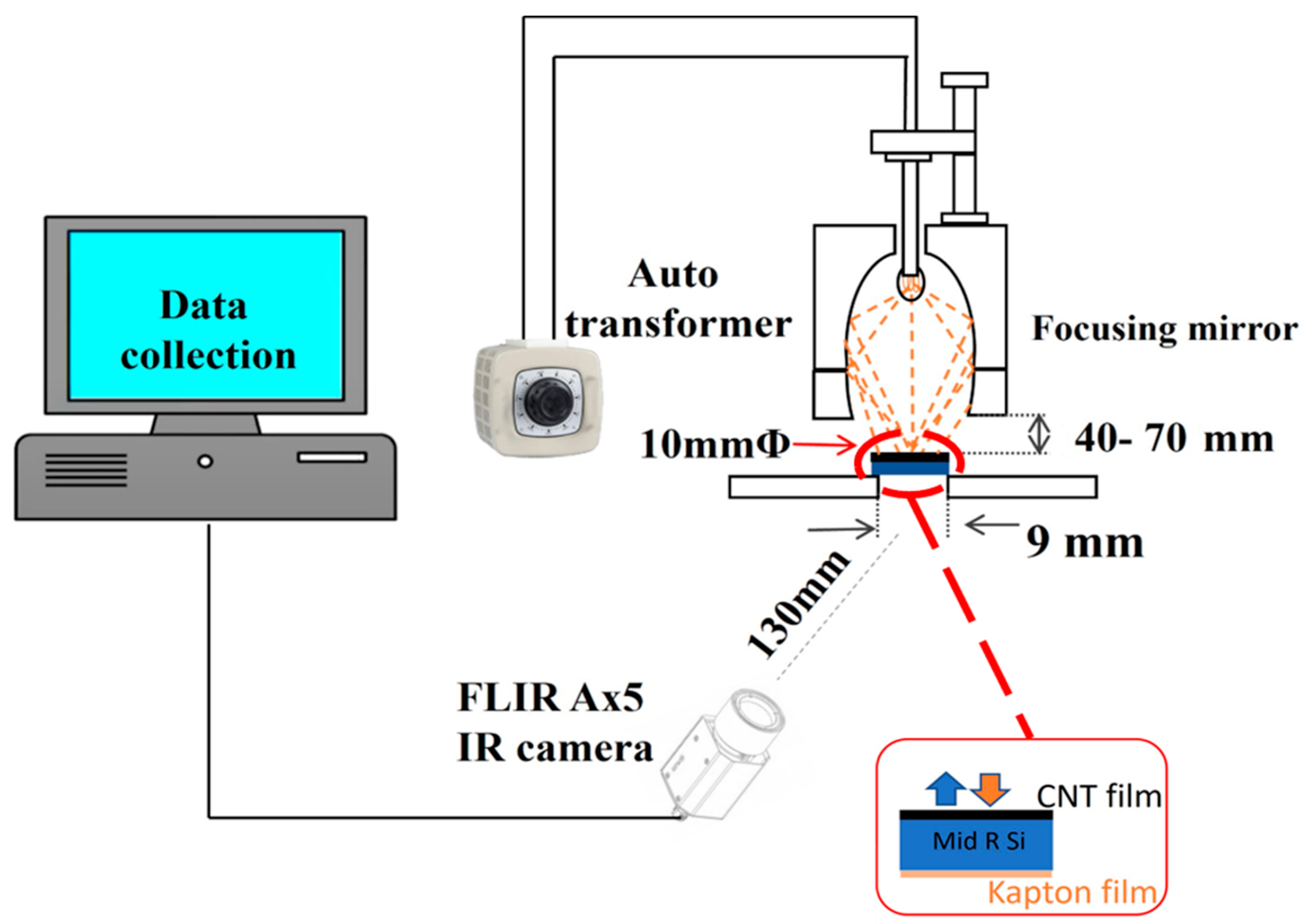

2.4. Thermal Measurements

3. Results and Discussion

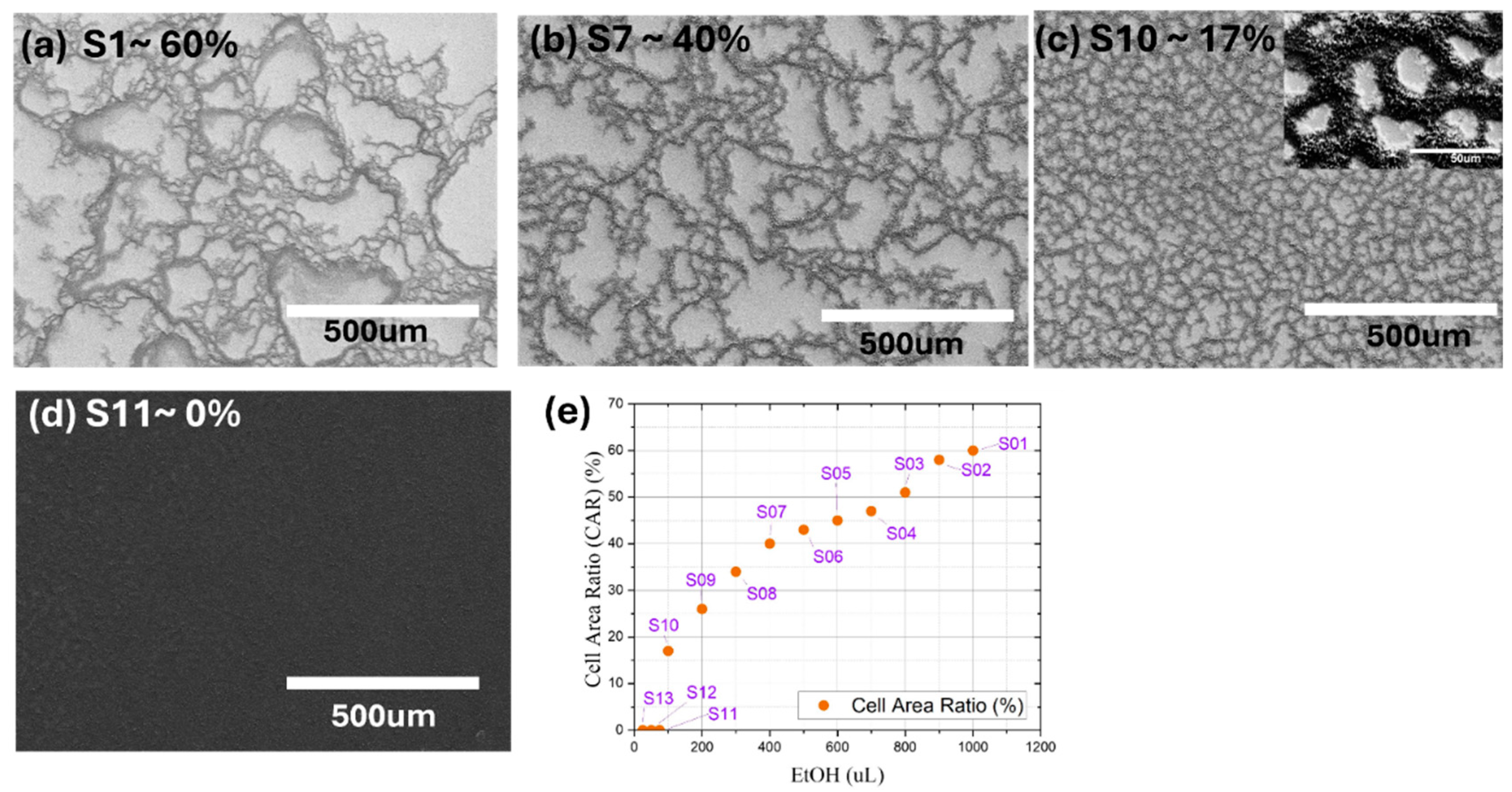

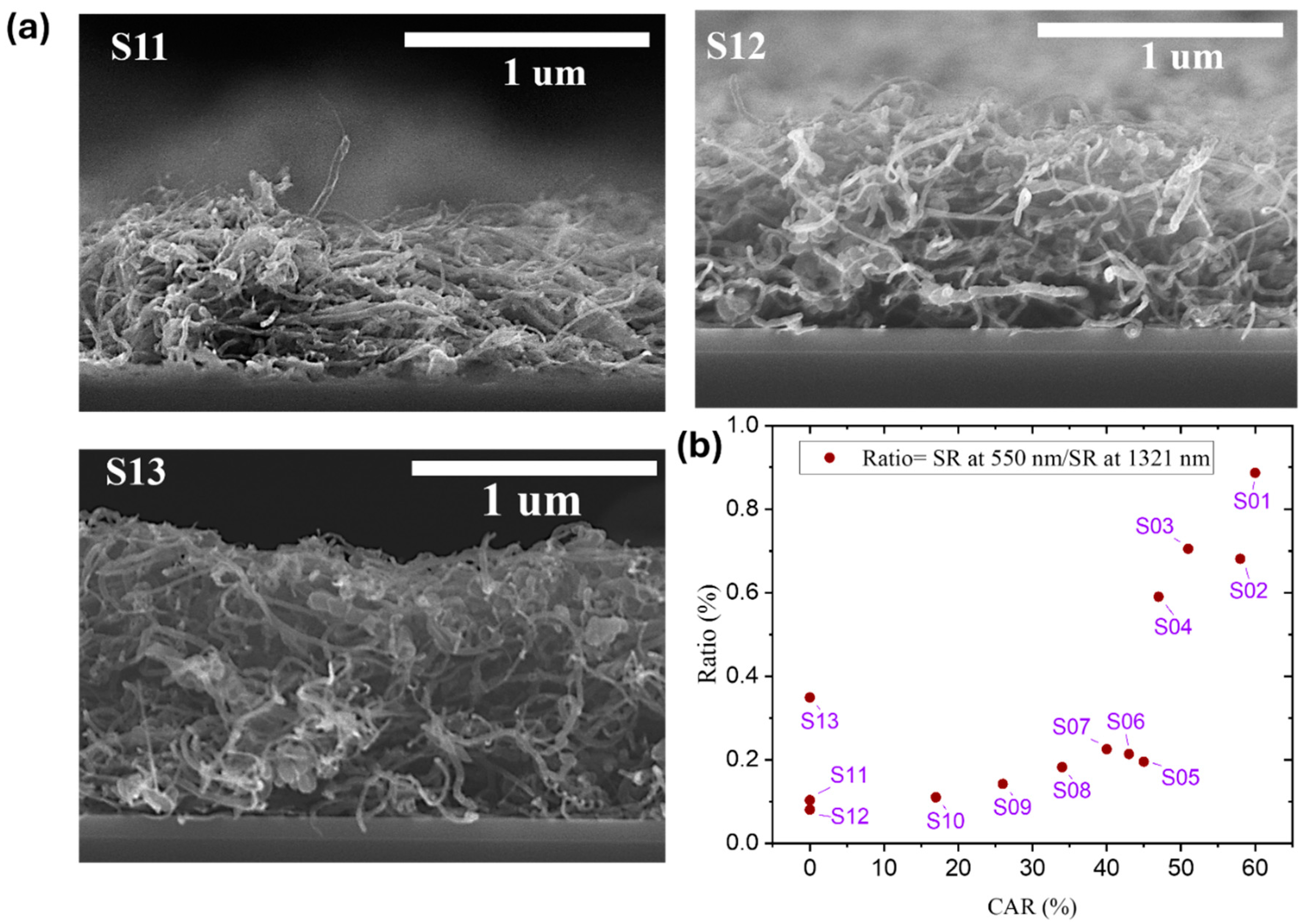

3.1. Cell Area Analysis

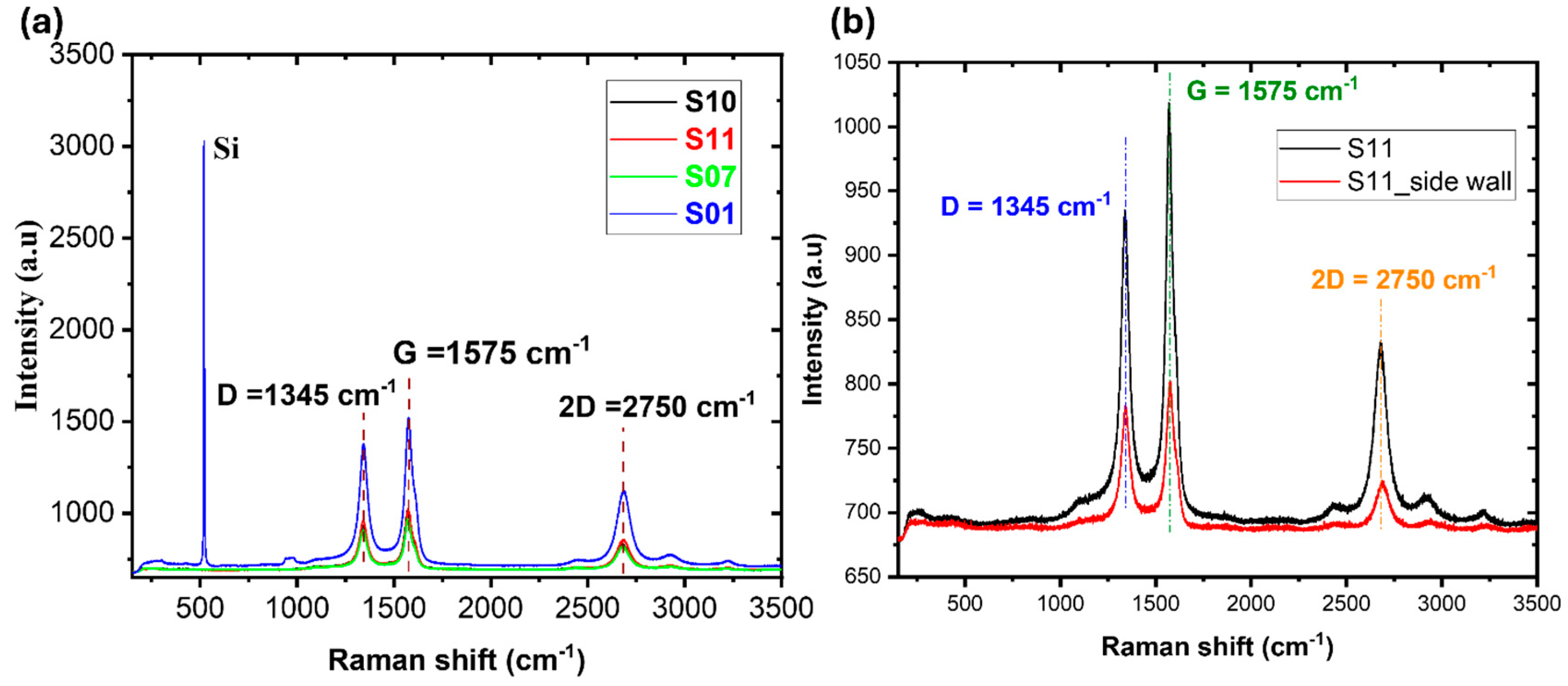

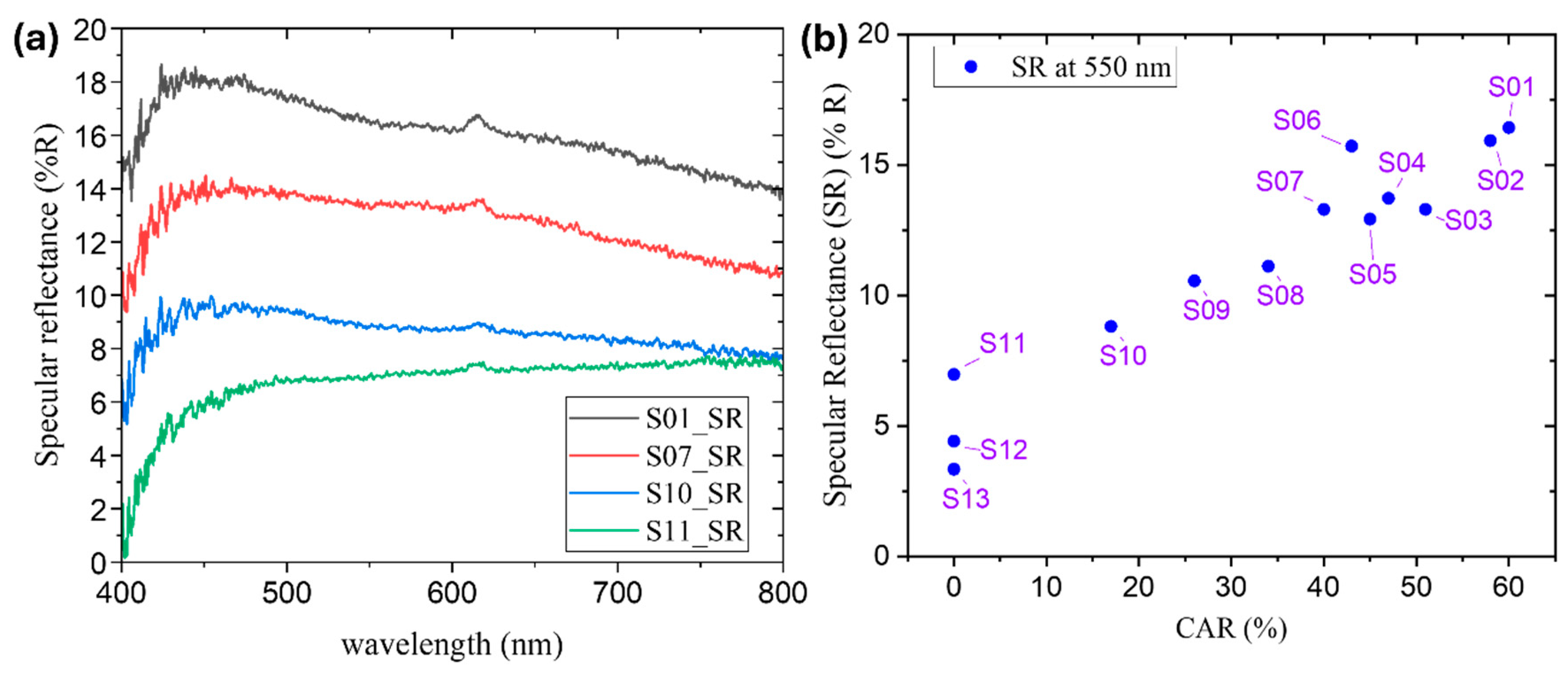

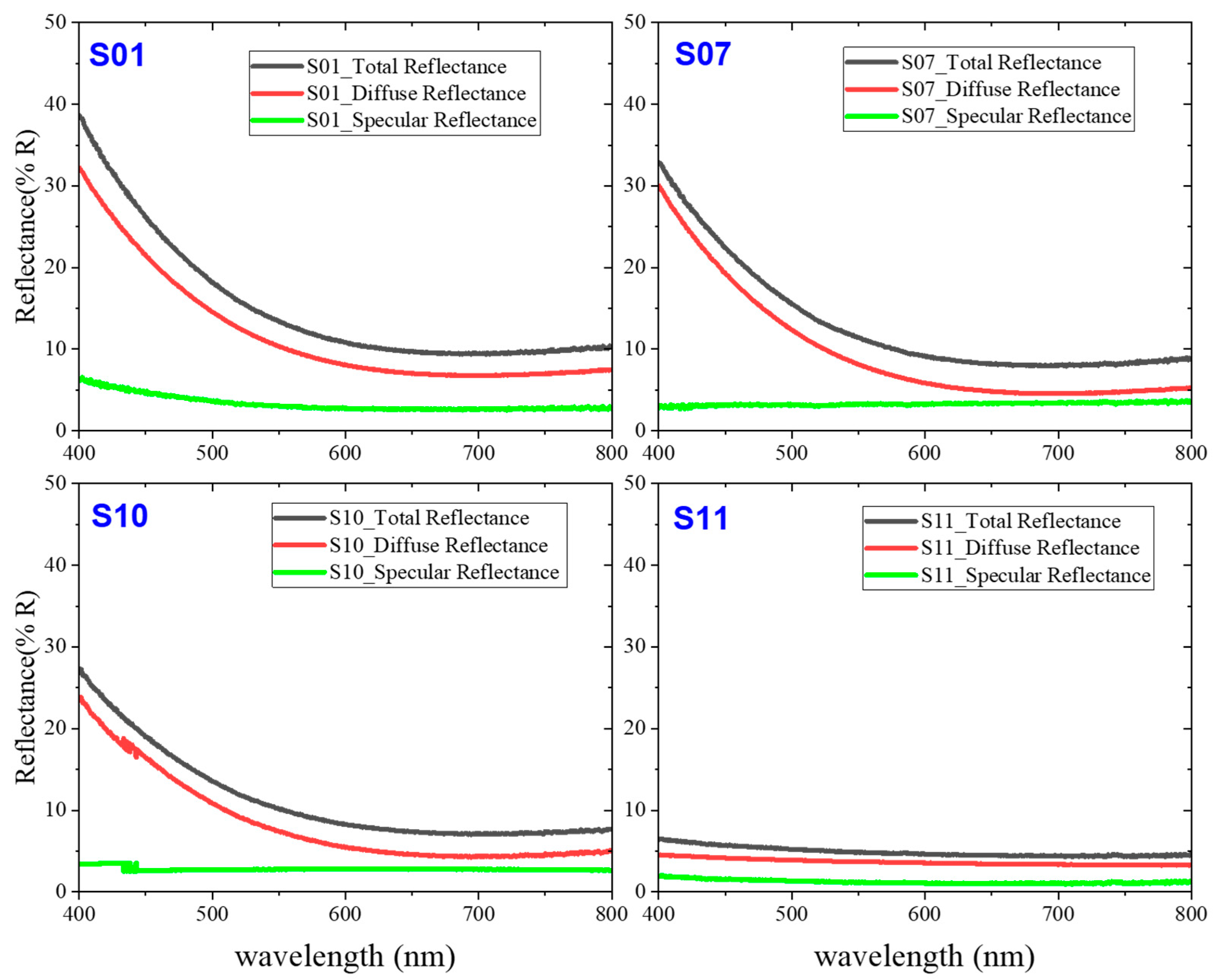

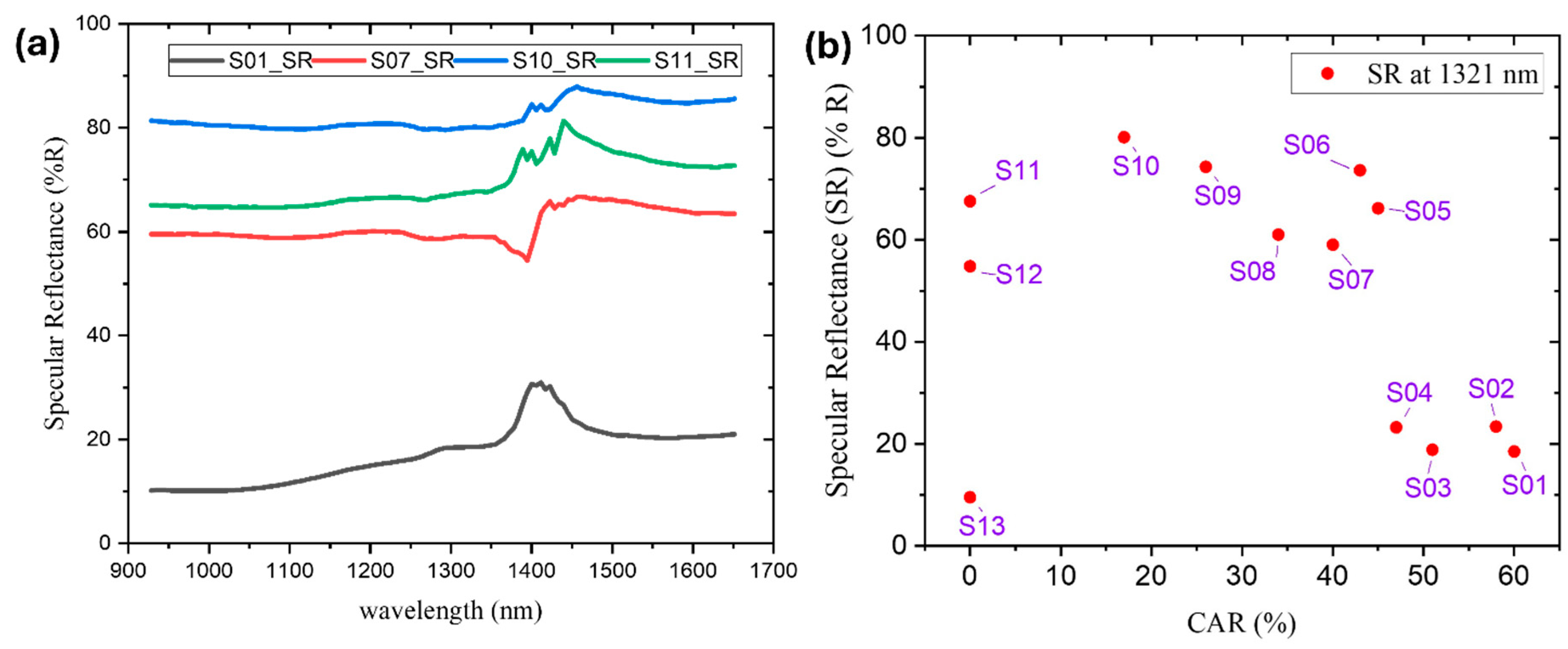

3.2. Optical Analysis

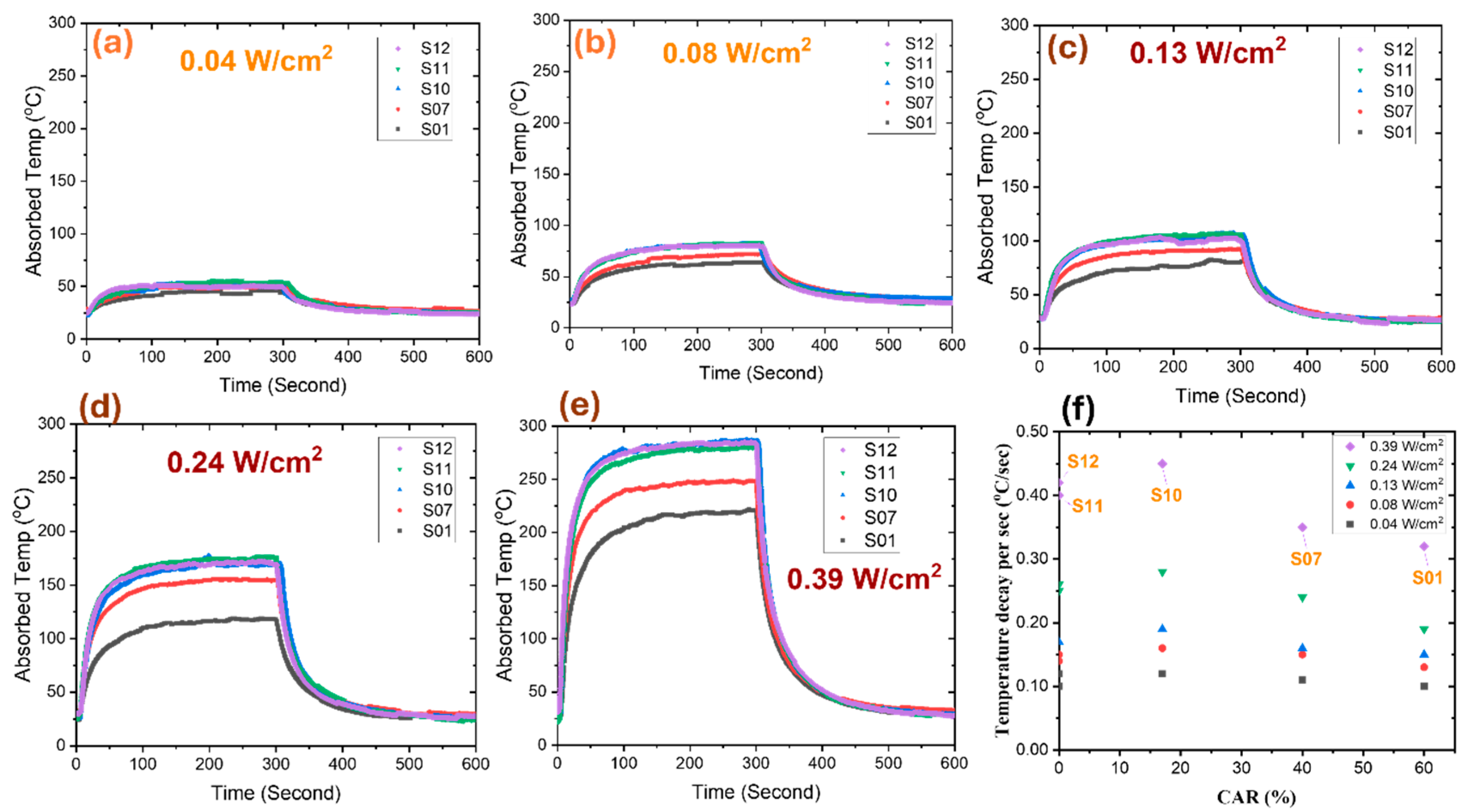

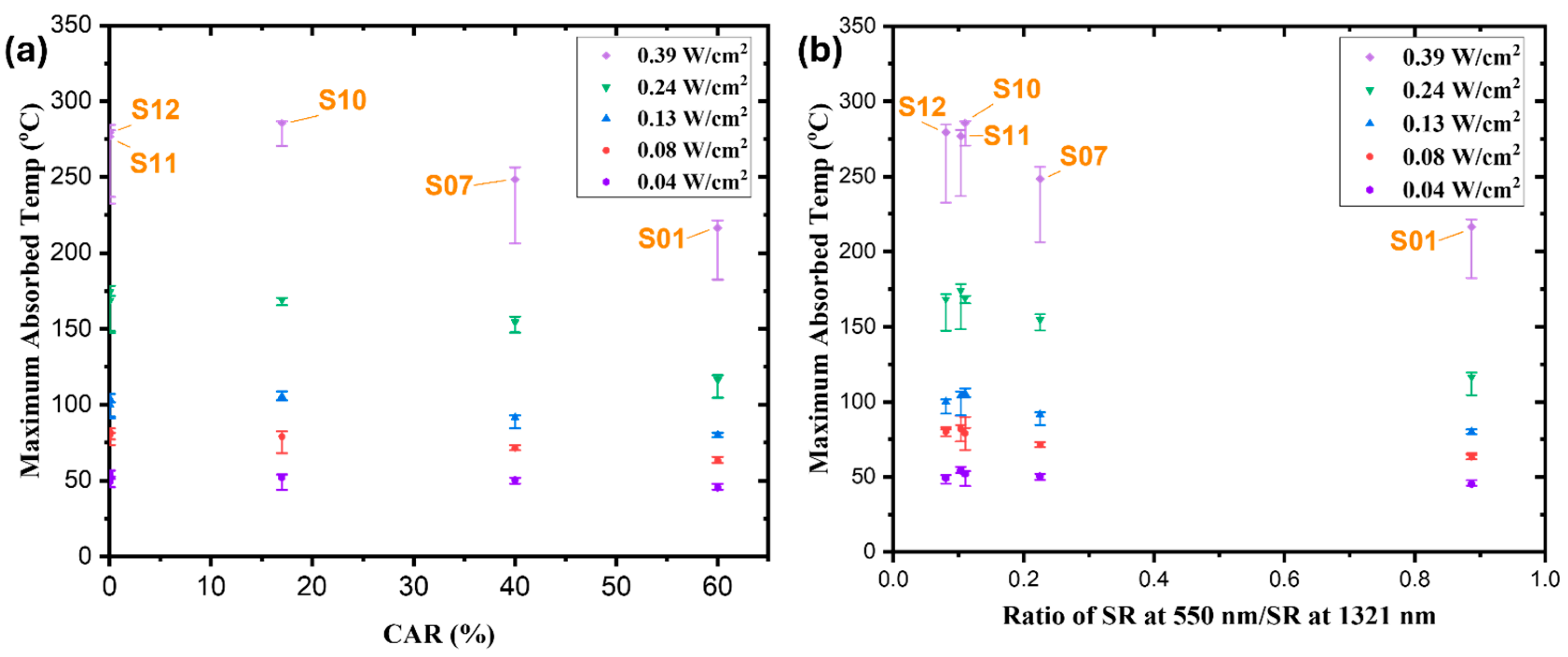

3.3. Thermal Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- W. Zhou et al., “High-Performance Freshwater Harvesting System by Coupling Solar Desalination and Fog Collection with Hierarchical Porous Microneedle Arrays,” Adv Funct Mater, vol. 32, no. 28, Jul. 2022. [CrossRef]

- P. G. Struchalin, D. M. Kuzmenkov, V. S. Yunin, X. Wang, Y. He, and B. V. Balakin, “Hybrid Nanofluid in a Direct Absorption Solar Collector: Magnetite vs. Carbon Nanotubes Compete for Thermal Performance,” Energies (Basel), vol. 15, no. 5, Mar. 2022. [CrossRef]

- X. Liu et al., “Biomass-based phase change material gels demonstrating solar-thermal conversion and thermal energy storage for thermoelectric power generation and personal thermal management,” Solar Energy, vol. 239, pp. 307–318, Jun. 2022. [CrossRef]

- J. R. Werber, C. O. Osuji, and M. Elimelech, “Materials for next-generation desalination and water purification membranes,” Apr. 05, 2016, Nature Publishing Group. [CrossRef]

- F. Ren et al., “Hydrophilicity regulation of carbon nanotubes as phase-change materials for thermal energy storage,” Journal of Materials Research and Technology, vol. 30, pp. 1482–1489, May 2024. 20 May. [CrossRef]

- J. Zhang, C. Wang, J. Shi, D. Wei, H. Zhao, and C. Ma, “Solar Selective Absorber for Emerging Sustainable Applications,” Advanced Energy and Sustainability Research, vol. 3, no. 3, p. 2100195, Mar. 2022. [CrossRef]

- S. Yamashita, “Nonlinear optics in carbon nanotube, graphene, and related 2D materials,” APL Photonics, vol. 4, no. 3, Mar. 2019. [CrossRef]

- D. J. Yang, S. G. Wang, Q. Zhang, P. J. Sellin, and G. Chen, “Thermal and electrical transport in multi-walled carbon nanotubes,” Physics Letters, Section A: General, Atomic and Solid State Physics, vol. 329, no. 3, pp. 207–213, Aug. 2004. [CrossRef]

- J.-P. Salvetat et al., “Mechanical properties of carbon nanotubes,” Appl. Phys. A, vol. 69, pp. 255–260, 1999. [CrossRef]

- S. Iijima, “Helical microtubules of graphitic carbon,” Nature, vol. 354, no. 6348, pp. 56–58, Nov. 1991. [CrossRef]

- J. Lehman, C. Yung, N. Tomlin, D. Conklin, and M. Stephens, “Carbon nanotube-based black coatings,” Appl Phys Rev, vol. 5, no. 1, Mar. 2018. [CrossRef]

- P. V. Mane, R. M. Rego, P. L. Yap, D. Losic, and M. D. Kurkuri, “Unveiling cutting-edge advances in high surface area porous materials for the efficient removal of toxic metal ions from water,” Dec. 01, 2024, Elsevier Ltd. [CrossRef]

- T. Zheng et al., “Self-assembled multi-layered hexagonal-like MWCNTs/MnF2/CoO nanocomposite with enhanced electromagnetic wave absorption,” Carbon N Y, vol. 186, pp. 262–272, Jan. 2022. [CrossRef]

- A. Kumar Sharma, P. Kumar Jain, R. Vyas, V. Mathur, and V. Kumar Jain, “Study of thermal stability and dielectric behavior of PANI/MWCNT nanocomposite,” in Materials Today: Proceedings, Elsevier Ltd, Sep. 2021, pp. 1259–1262. [CrossRef]

- Y. Vinetsky, J. Jambu, D. Mandler, and S. Magdassi, “Cnt-based solar thermal coatings: Absorptance vs. emittance,” Coatings, vol. 10, no. 11, pp. 1–12, Nov. 2020. [CrossRef]

- T. Yang, H. T. Yang, H. Lin, K. Te Lin, and B. Jia, “Carbon-based absorbers for solar evaporation: Steam generation and beyond,” Sep. 01, 2020, Elsevier B.V. [CrossRef]

- Y. Jin et al., “Spray coating of a perfect absorber based on carbon nanotube multiscale composites,” Carbon N Y, vol. 178, pp. 616–624, Jun. 2021. [CrossRef]

- X. Liu, Z. Liu, D. Devadutta Mishra, Z. Chen, J. Zhao, and C. Hu, “Evaporation rate far beyond the input solar energy limit enabled by introducing convective flow,” Chemical Engineering Journal, vol. 429, Feb. 2022. [CrossRef]

- R. J. Pan et al., “Peak-like three-dimensional CoFe2O4/carbon nanotube decorated bamboo fabrics for simultaneous solar-thermal evaporation of water and photocatalytic degradation of bisphenol A,” J Mater Sci Technol, vol. 179, pp. 40–49, Apr. 2024. [CrossRef]

- M. Yu et al., “Preparation of ultra-black film with good resistance to wiping based on a typical forest structure,” Prog Org Coat, vol. 195, Oct. 2024. [CrossRef]

- P. M. Martinez, V. A. Pozdin, A. Papadimitratos, W. Holmes, F. Hassanipour, and A. A. Zakhidov, “Dual use of carbon nanotube selective coatings in evacuated tube solar collectors,” Carbon N Y, vol. 119, pp. 133–141, Aug. 2017. [CrossRef]

- J. Udorn, A. Hatta, and H. Furuta, “Carbon nanotube (CNT) honeycomb cell area-dependent optical reflectance,” Nanomaterials, vol. 6, no. 11, Nov. 2016. [CrossRef]

- S. Hong, Y. Shi, R. Li, C. Zhang, Y. Jin, and P. Wang, “Nature-Inspired, 3D Origami Solar Steam Generator toward Near Full Utilization of Solar Energy,” ACS Appl Mater Interfaces, vol. 10, no. 34, pp. 28517–28524, Aug. 2018. [CrossRef]

- F. Kiani, F. Sterl, T. V. Tsoulos, K. Weber, H. Giessen, and G. Tagliabue, “Ultra-broadband and omnidirectional perfect absorber based on copper nanowire/carbon nanotube hierarchical structure,” ACS Photonics, vol. 7, no. 2, pp. 366–374, Feb. 2020. [CrossRef]

- V. Ghai, H. Singh, and P. K. Agnihotri, “Structure Dependent Broadband Optical Absorption in Carbon Nanotubes,” ACS Applied Optical Materials, vol. 1, no. 1, pp. 252–260, Jan. 2023. [CrossRef]

- A. Pander, T. Onishi, A. Hatta, and H. Furuta, “Fabrication of Self-Assembling Carbon Nanotube Forest Fishnet Metamaterials,” Nanomaterials, vol. 12, no. 3, Feb. 2022. [CrossRef]

- Y. Huang, L. Zhu, Q. Huang, and Z. C. He, “Effect of carbon nanotubes and TiN nanoparticles on light absorption property of nanostructured carbon-based coatings fabricated by high-voltage electrostatic spraying technique,” Opt Mater (Amst), vol. 150, Apr. 2024. [CrossRef]

- J. Jiang, H. Jiang, Y. Xu, M. Chen, and L. Ai, “Janus Co@C/NCNT photothermal membrane with multiple optical absorption for highly efficient solar water evaporation and wastewater purification,” Colloids Surf A Physicochem Eng Asp, vol. 647, Aug. 2022. [CrossRef]

- M. He, H. Liu, L. Wang, X. Qin, and J. Yu, “One-step fabrication of a stretchable and anti-oil-fouling nanofiber membrane for solar steam generation,” Mater Chem Front, vol. 5, no. 9, pp. 3673–3680, May 2021. 20 May. [CrossRef]

- M. Jin et al., “Hierarchically Designed Three-Dimensional Composite Structure on a Cellulose-Based Solar Steam Generator,” ACS Appl Mater Interfaces, vol. 14, no. 10, pp. 12284–12294, Mar. 2022. [CrossRef]

- Q. Li et al., “Porous Ni/CNTs composite membrane as solar absorber for highly efficient solar steam generation,” Solar Energy Materials and Solar Cells, vol. 243, Aug. 2022. [CrossRef]

- S. Zhang et al., “Multiscale Preparation of Graphene Oxide/Carbon Nanotube-Based Membrane Evaporators by a Spray Method for Efficient Solar Steam Generation,” ACS Appl Nano Mater, May 2022. 20 May. [CrossRef]

- D. Wang et al., “Hanging Photothermal Fabric Based on Polyaniline/Carbon Nanotubes for Efficient Solar Water Evaporation,” ACS Omega, vol. 8, no. 47, pp. 44659–44666, Nov. 2023. [CrossRef]

- T. Saleh et al., “Transforming carbon nanotube forest from darkest absorber to reflective mirror,” Appl Phys Lett, vol. 101, no. 6, Aug. 2012. [CrossRef]

- Z. Han, Z. Jiao, S. Niu, and L. Ren, “Ascendant bioinspired antireflective materials: Opportunities and challenges coexist,” Jun. 01, 2019, Elsevier Ltd. [CrossRef]

- Y. Qiu, M. Lee, J. Chen, and Q. Zhang, “Effect of light intensity on solar-driven interfacial steam generation,” Dec. 28, 2021, Royal Society of Chemistry. [CrossRef]

- S. Islam and H. Furuta, “Recent Development of Carbon-Nanotube-Based Solar Heat Absorption Devices and Their Application,” Nov. 01, 2022, MDPI. [CrossRef]

- M. Zhang, S. Inoue, and Y. Matsumura, “Difference in Gas-Sensing behavior of Multi-walled carbon Nanotube-Paper-Based gas sensor to polar and non-Polar organic solvents,” Chem Phys Lett, vol. 798, Jul. 2022. [CrossRef]

- M. Łojkowski, A. Chlanda, E. Choińska, and W. Swieszkowski, “Water vapor induced self-assembly of islands/honeycomb structure by secondary phase separation in polystyrene solution with bimodal molecular weight distribution,” Sci Rep, vol. 11, no. 1, Dec. 2021. [CrossRef]

- J. A. Maroto, V. Pérez-Mũuzuri, and M. S. Romero-Cano, “Introductory analysis of Bénard-Marangoni convection,” Eur J Phys, vol. 28, no. 2, pp. 311–320, Mar. 2007. [CrossRef]

- B. D. Wood, J. S. Dyer, V. A. Thurgood, N. A. Tomlin, J. H. Lehman, and T.-C. Shen, “Optical reflection and absorption of carbon nanotube forest films on substrates,” J Appl Phys, vol. 118, no. 1, p. 013106, Jul. 2015. [CrossRef]

- K. Nomura, Y. Sawada, H. Nishimori, A. Hatta, and H. Furuta, “Basic Research on CNT Structures for the Solar Water Heater Applications,” JSAP Annual Meetings Extended Abstracts, vol. 2021.1, p. 2790, 2021. [CrossRef]

- B. Kumanek and D. Janas, “Thermal conductivity of carbon nanotube networks: A review,” May 30, 2019, Springer New York LLC. 30 May. [CrossRef]

- V. Herrera, “Reconciling global aspirations and local realities: Challenges facing the Sustainable Development Goals for water and sanitation,” World Dev, vol. 118, pp. 106–117, Jun. 2019. [CrossRef]

- N. Manoj Kumar, S. S. Chopra, A. A. Chand, R. M. Elavarasan, and G. M. Shafiullah, “Hybrid renewable energy microgrid for a residential community: A techno-economic and environmental perspective in the context of the SDG7,” Sustainability (Switzerland), vol. 12, no. 10, May 2020. 20 May. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).