Submitted:

25 September 2024

Posted:

26 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

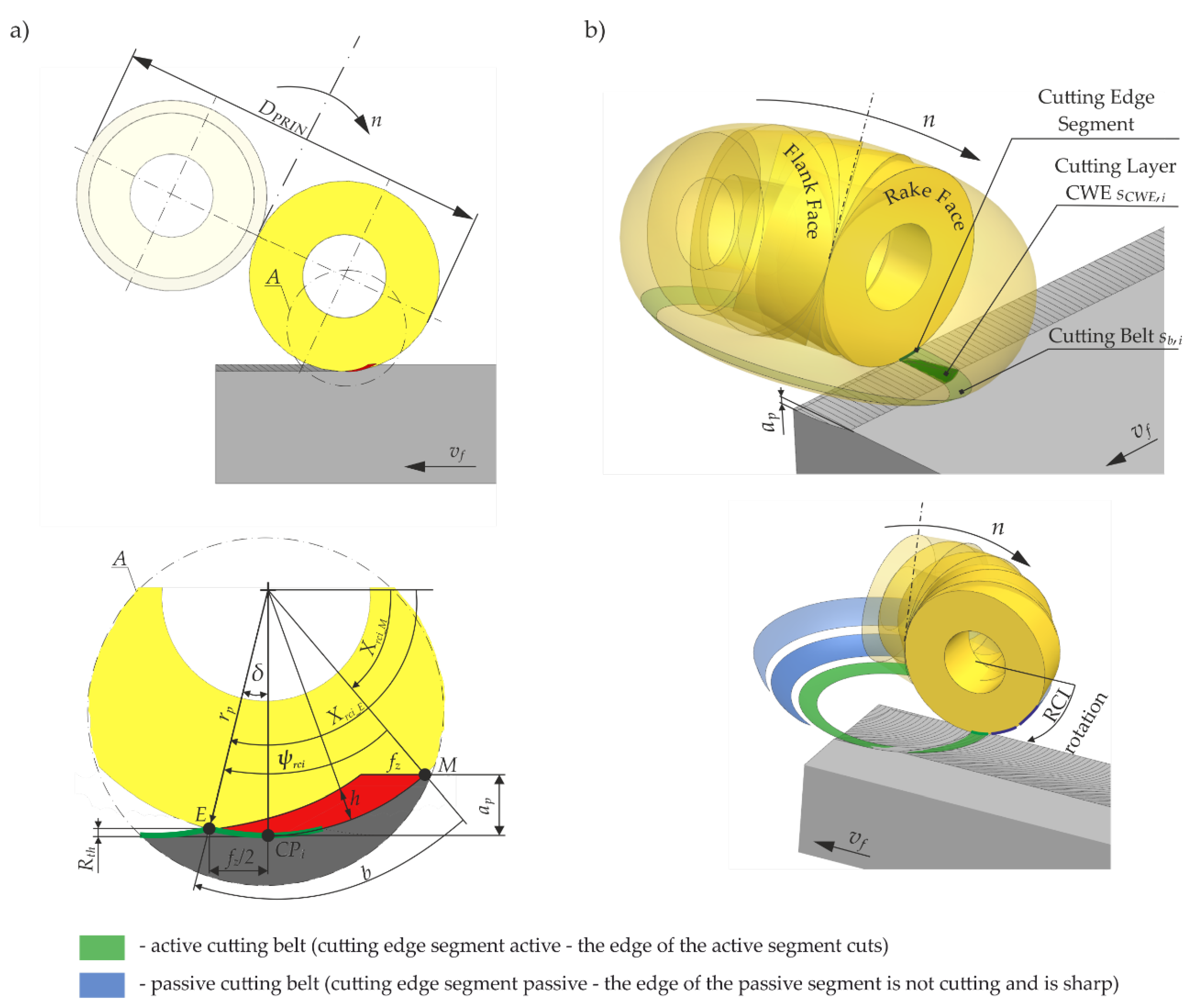

2. Fundamentals of the APofRCI Method, Taking into Account Torus Milling Cutter Cutting Blade Wear

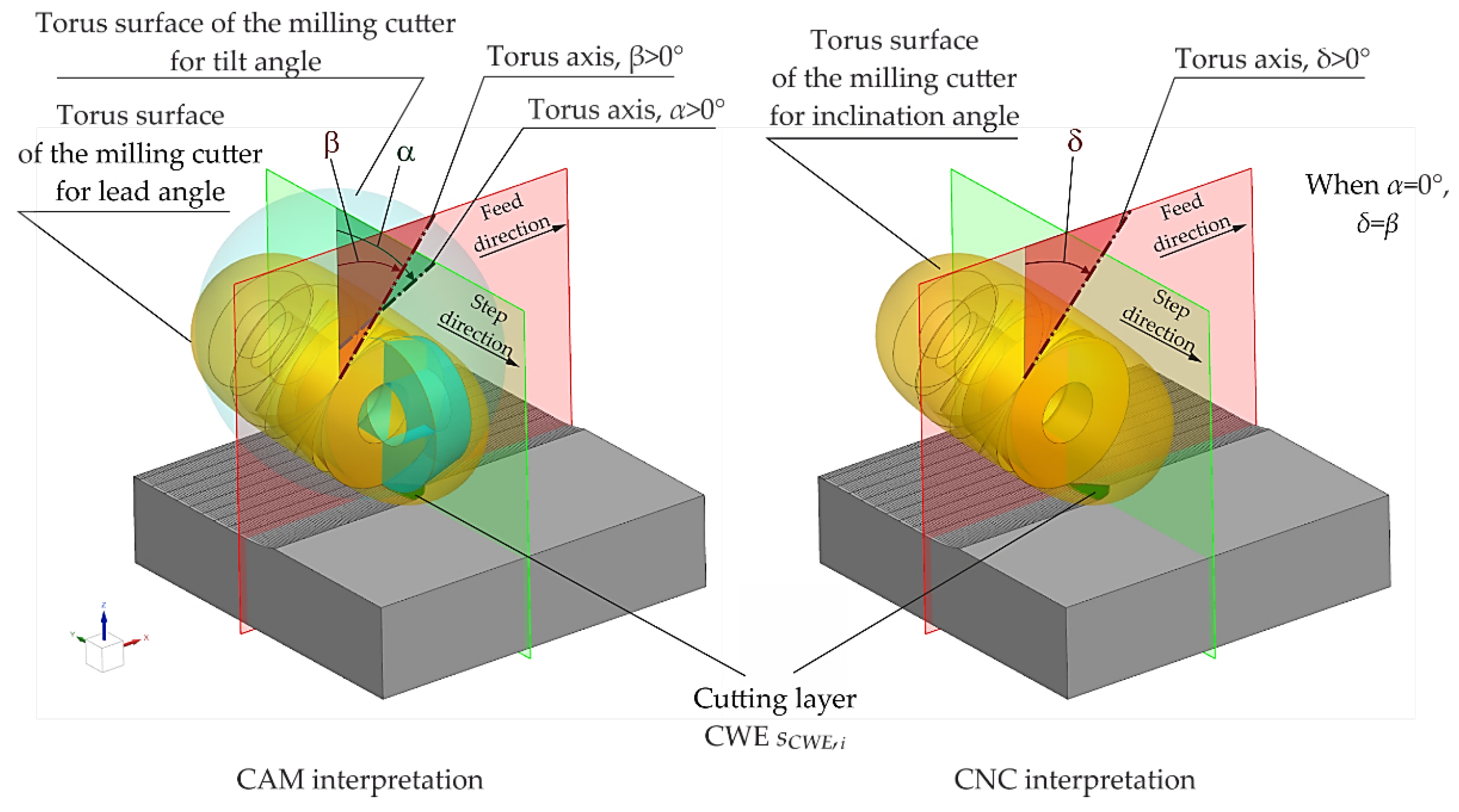

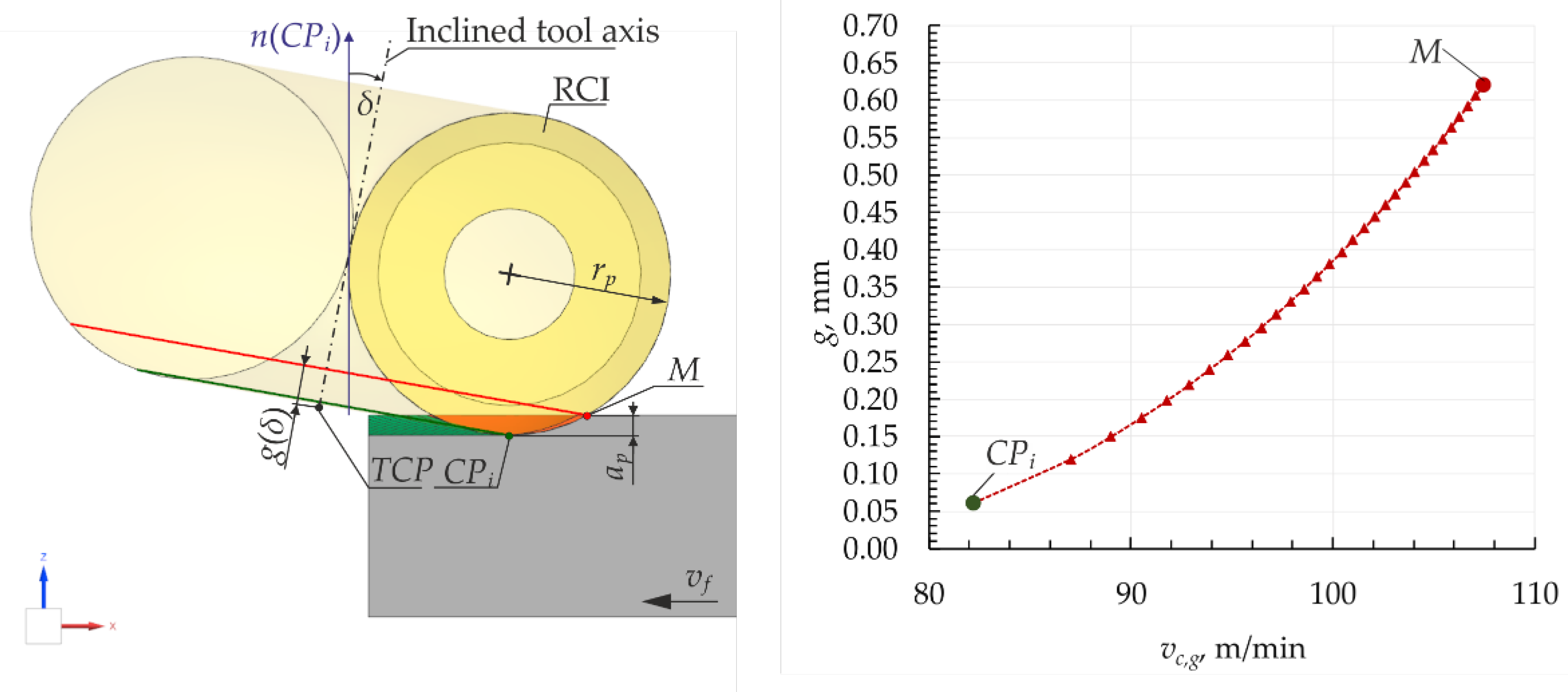

2.1. Definition of the Torus Milling Cutter Axis Orientation

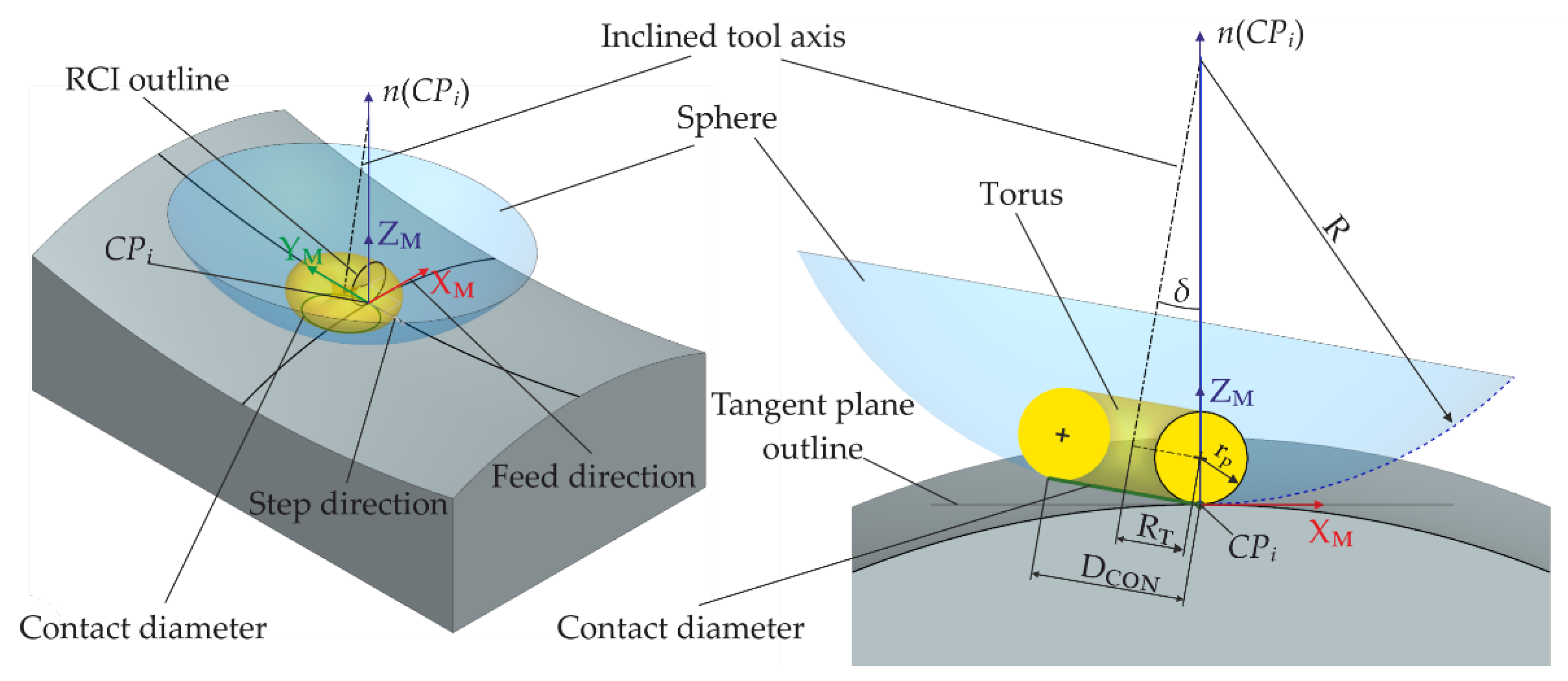

2.2. Characteristic of the Torus Milling Cutter

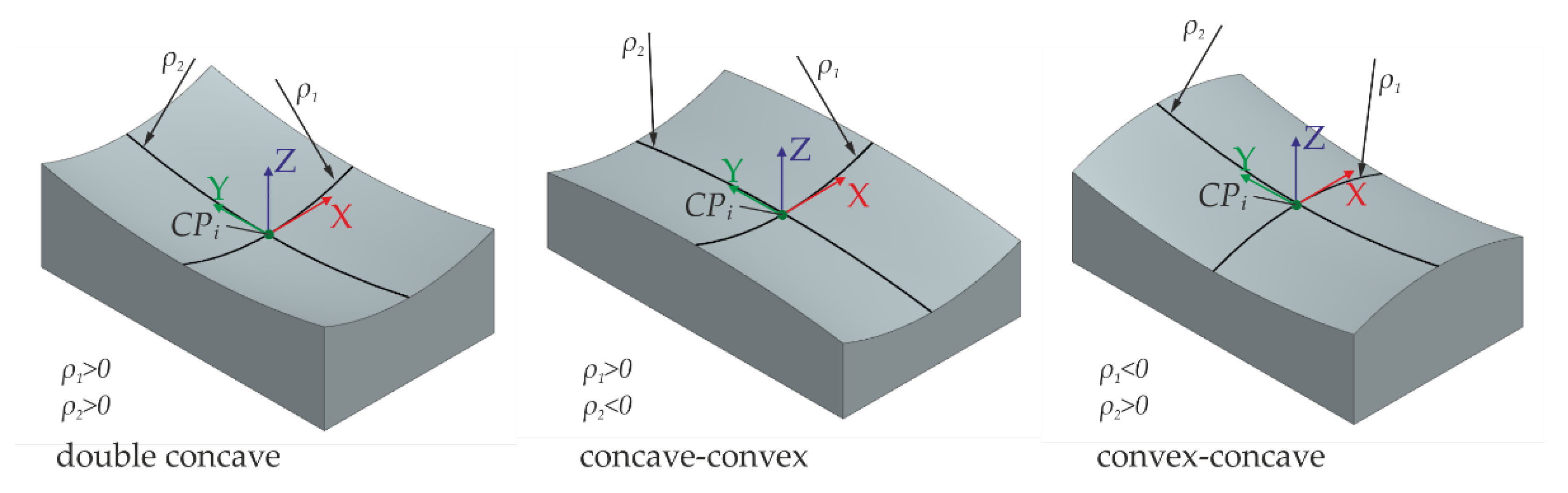

2.3. Method to Avoid Undercutting the Machined Surface

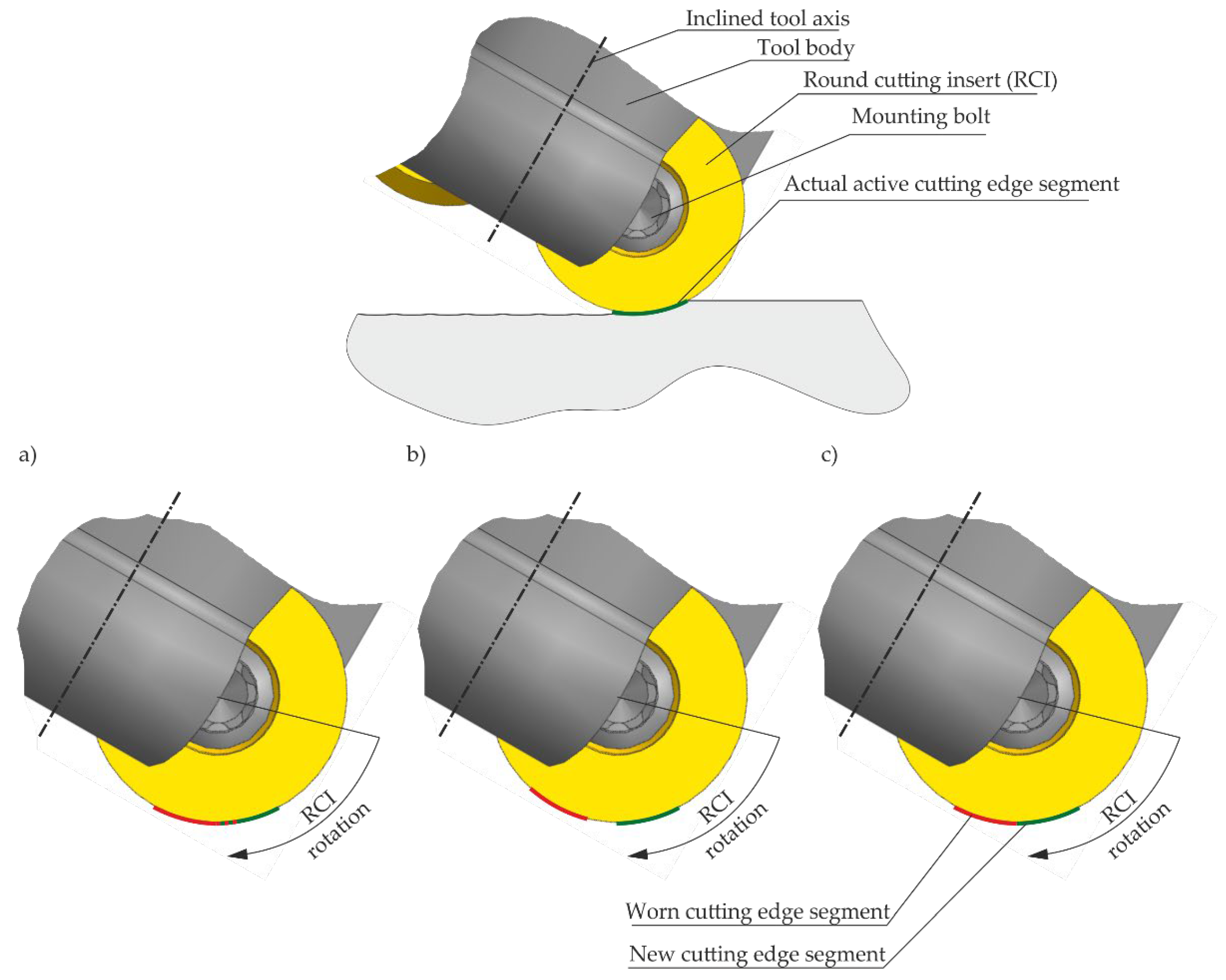

2.4. Active Cutting Edge Segment and Active Cutting Belt

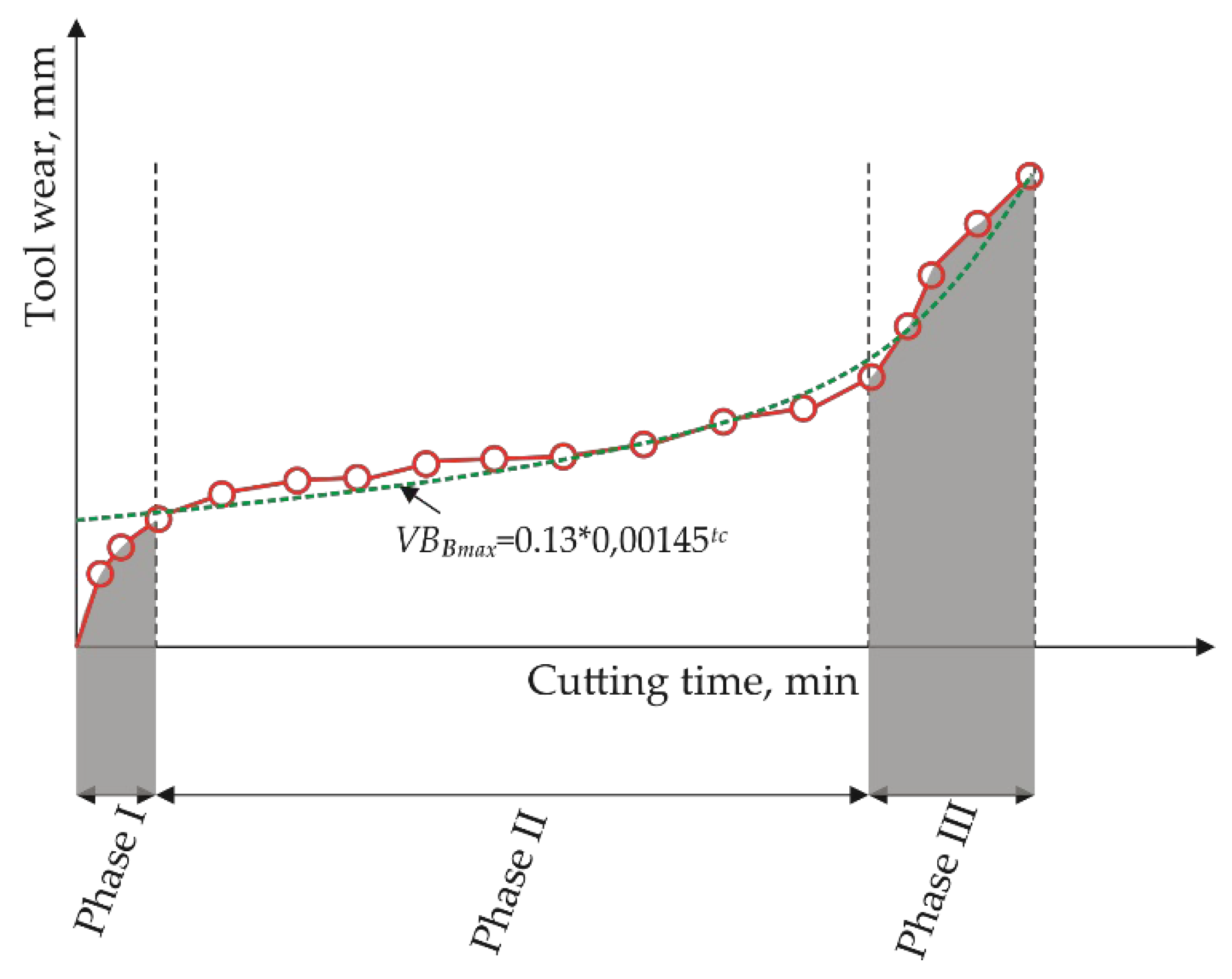

2.5. The Torus Milling Cutter Wear and Life Model

3. Machining and Measurement Conditions

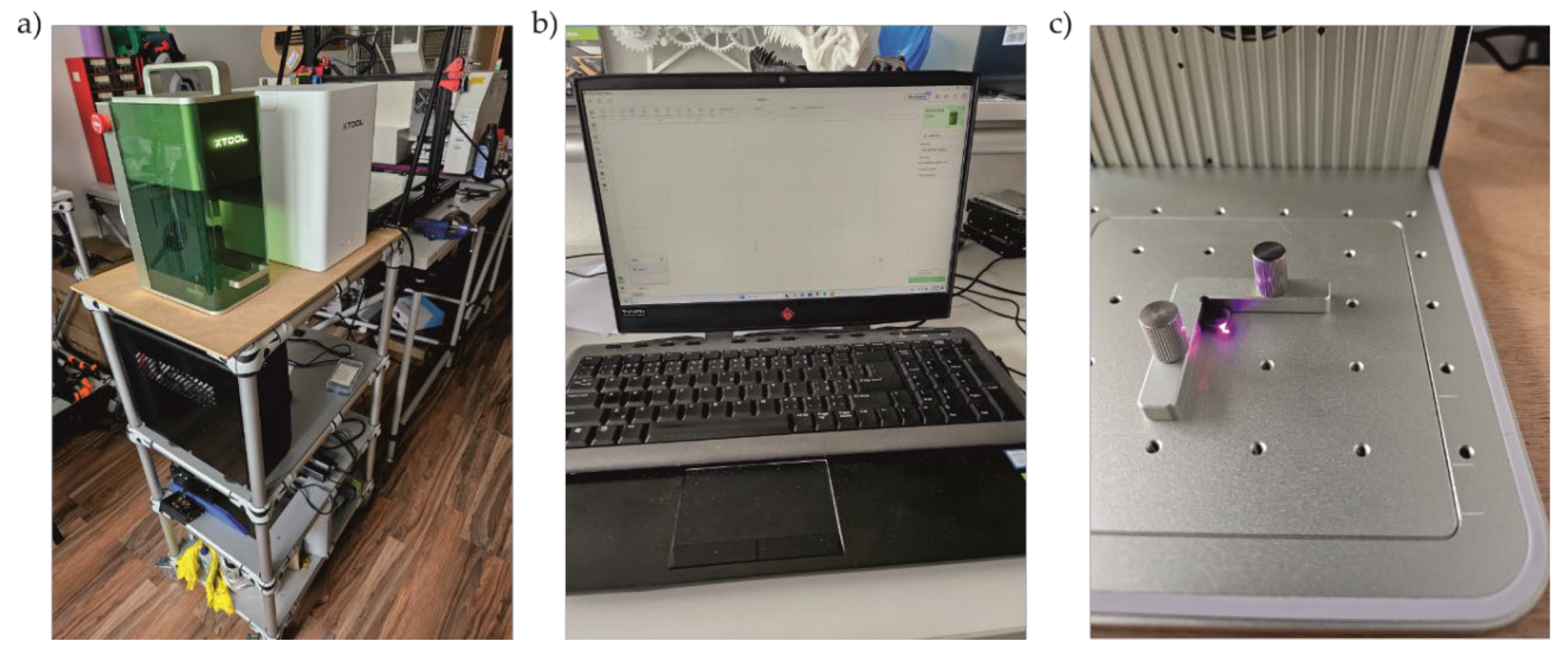

3.1. Materials, Tools and Machining Station

3.2. Tool Wear Modelling and Calibration

3.3. Measuring and Auxiliary Equipment

4. Results and Discussion

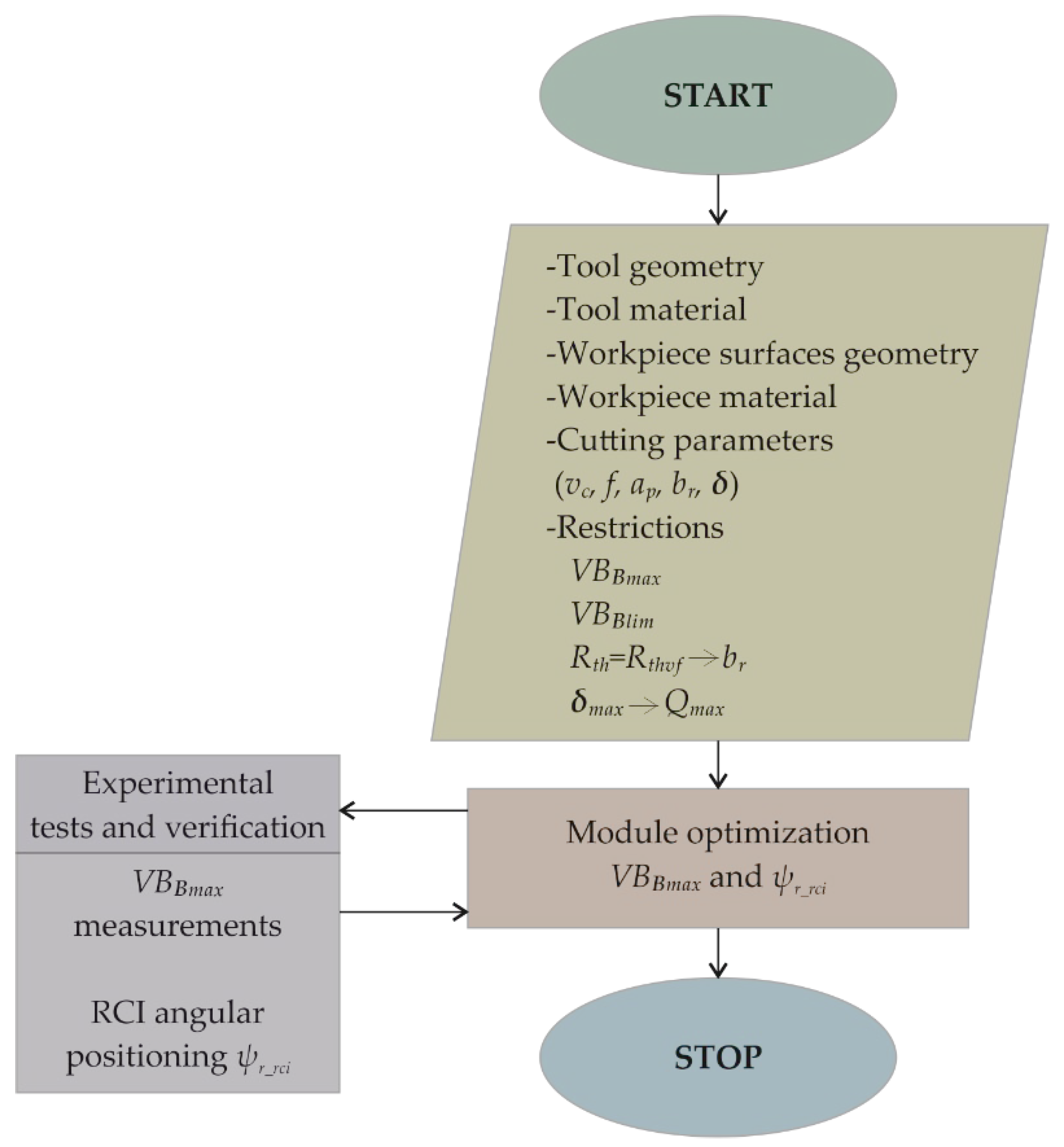

4.1. Procedure for Angular Positioning of the RCI of the Torus Milling Cutter

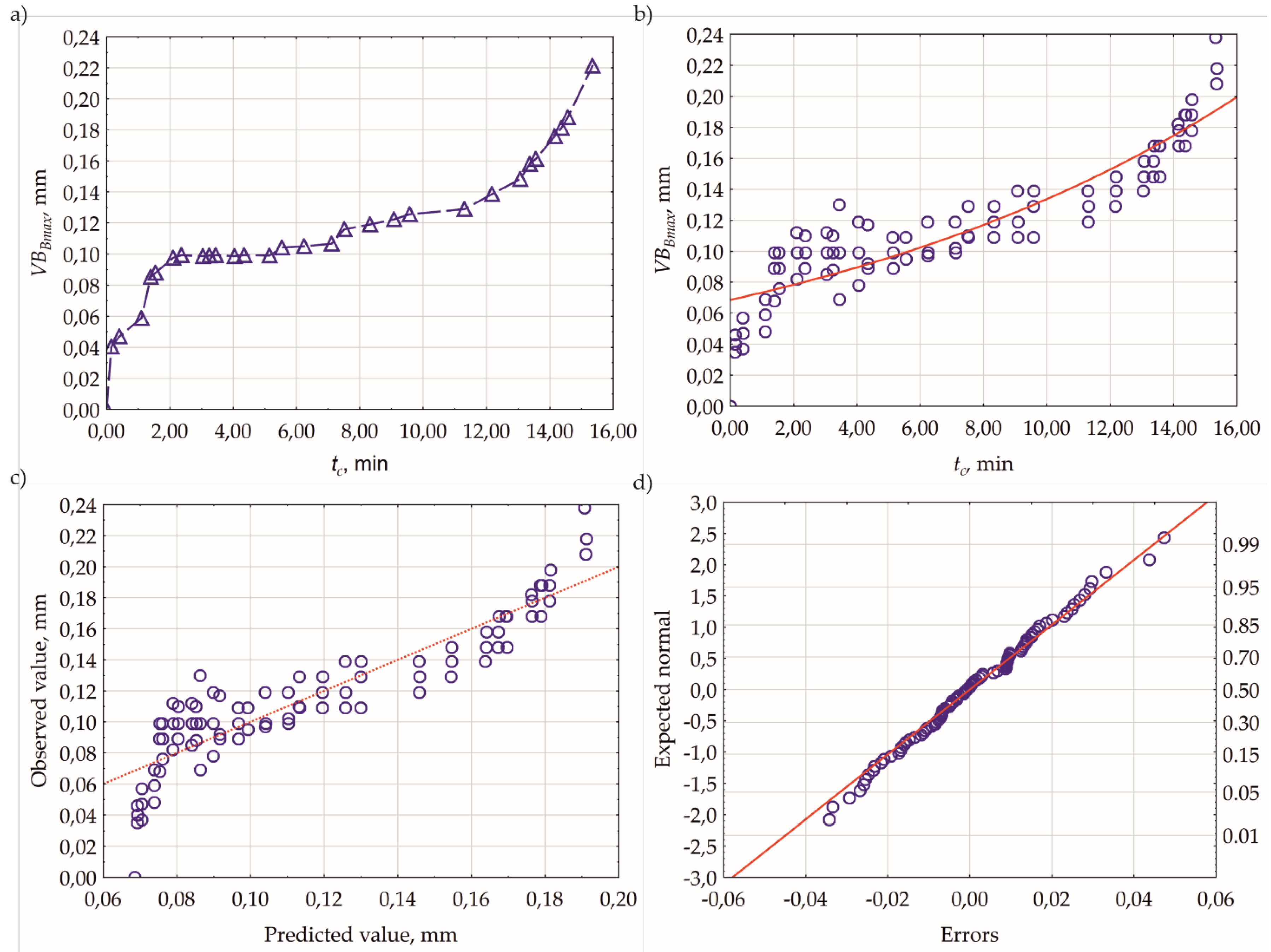

4.2. Tool Wear and Tool Life Models

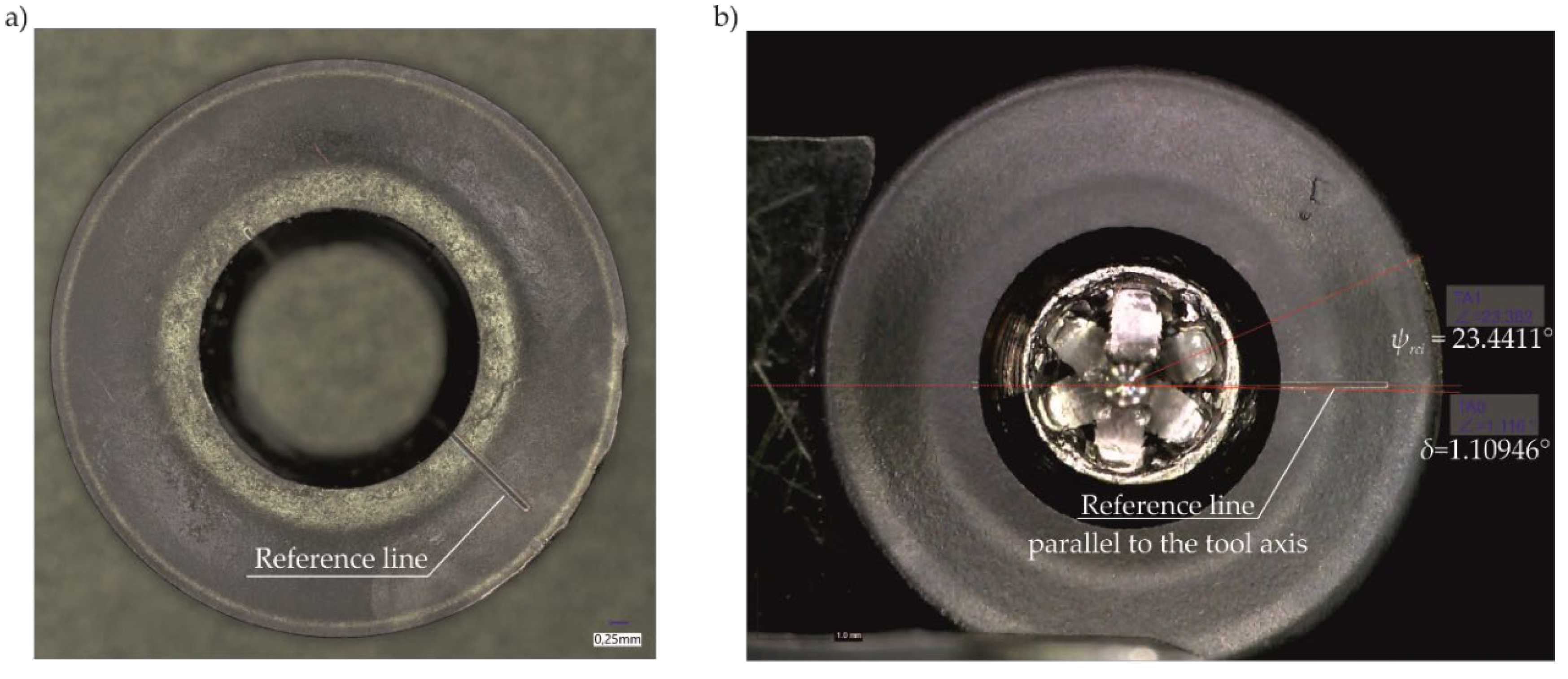

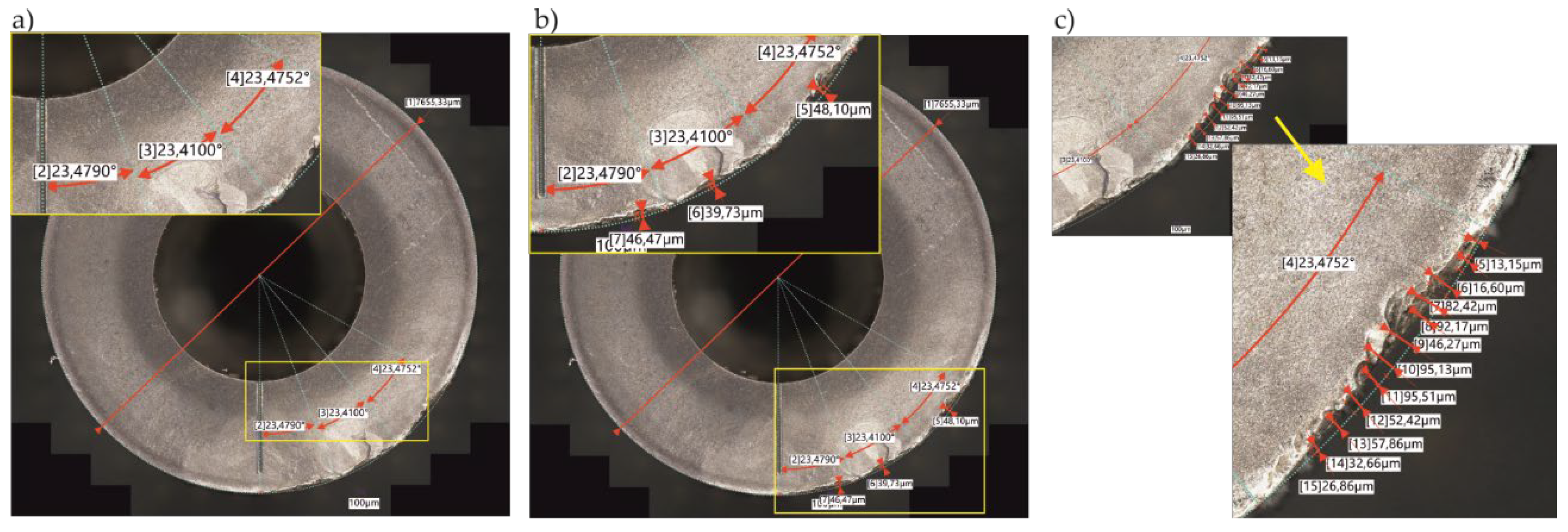

4.3. Measurements and APofRCI

5. Conclusions

- The adopted function approximating tool wear over its lifetime is adequate and provides 90% prediction accuracy;

- The tool life model developed is essentially based on the cutting blade working angle parameter. This makes it possible to predict tool life for different machining conditions and for individual instantaneous positions of the cutting edge in relation to the workpiece surface (3D analysis), which is the subject of further work;

- The developed procedure for angular positioning and measurement enables the entire cutting edge of the blade to be fully utilised, so that the total lifespan of the tool as an assembly is significantly extended;

- The proposed solution also allows measurement and analysis of wear mechanisms, which significantly extends the possibilities of angular positioning of the RCI, taking into account its macro- and micro- geometric.

Author Contributions

Data Availability Statement

Conflicts of Interest

References

- Sun, D.; Ding, J.; Zheng, C.; Huang, W. Angular Misalignment Calibration Method for Ultra-short Baseline Positioning System Based on Matrix Decomposition. IET Radar, Sonar & Navigation 2019, 13, 456–463. [CrossRef]

- Gao, W.; Kim, S.W.; Bosse, H.; Haitjema, H.; Chen, Y.L.; Lu, X.D.; Knapp, W.; Weckenmann, A.; Estler, W.T.; Kunzmann, H. Measurement Technologies for Precision Positioning. CIRP Annals 2015, 64, 773–796. [CrossRef]

- Ivanov, V.; Botko, F.; Dehtiarov, I.; Kočiško, M.; Evtuhov, A.; Pavlenko, I.; Trojanowska, J. Development of Flexible Fixtures with Incomplete Locating: Connecting Rods Machining Case Study. Machines 2022, 10, 493. [CrossRef]

- Brillinger, M.; Wuwer, M.; Abdul Hadi, M.; Haas, F. Energy Prediction for CNC Machining with Machine Learning. CIRP Journal of Manufacturing Science and Technology 2021, 35, 715–723. [CrossRef]

- Ramos-Fernández, J.C.; López-Morales, V.; Márquez-Vera, M.A.; Pérez, J.M.X.; Suarez-Cansino, J. Neuro-Fuzzy Modelling and Stable PD Controller for Angular Position in Steering Systems. Int.J Automot. Technol. 2021, 22, 1495–1503. [CrossRef]

- Kaščak, J.; Gašpár, Š.; Paško, J.; Husár, J.; Knapčíková, L. Polylactic Acid and Its Cellulose Based Composite as a Significant Tool for the Production of Optimized Models Modified for Additive Manufacturing. Sustainability 2021, 13, 1256. [CrossRef]

- Abdul Hadi, M.; Brillinger, M.; Wuwer, M.; Schmid, J.; Trabesinger, S.; Jäger, M.; Haas, F. Sustainable Peak Power Smoothing and Energy-Efficient Machining Process Thorough Analysis of High-Frequency Data. Journal of Cleaner Production 2021, 318, 128548. [CrossRef]

- Abdul Hadi, M.; Kraus, D.; Kajmakovic, A.; Suschnigg, J.; Guiza, O.; Gashi, M.; Sopidis, G.; Vukovic, M.; Milenkovic, K.; Haslgruebler, M.; et al. Towards Flexible and Cognitive Production—Addressing the Production Challenges. Applied Sciences 2022, 12, 8696. [CrossRef]

- Visan, D.A.; Lita, I.; Cioc, I.B. Wireless Control System for Angular Positioning Applications. In Proceedings of the 2013 IEEE 19th International Symposium for Design and Technology in Electronic Packaging (SIITME); IEEE: Galati, Romania, October 2013; pp. 103–106.

- Adamczak, M.; Kolinski, A.; Trojanowska, J.; Husár, J. Digitalization Trend and Its Influence on the Development of the Operational Process in Production Companies. Applied Sciences 2023, 13, 1393. [CrossRef]

- Hrehova, S. Description of Using Different Software Tools to Analyze the Selected Process. In Proceedings of the 2019 20th International Carpathian Control Conference (ICCC); IEEE: Krakow-Wieliczka, Poland, May 2019; pp. 1–5.

- Coranic, T.; Mascenik, J. Experimental Measurement of Dynamic Characteristics of Structural Units. Processes 2023, 11, 3333. [CrossRef]

- Jurko, J.; Miškiv-Pavlík, M.; Hladký, V.; Lazorík, P.; Michalík, P.; Petruška, I. Measurement of the Machined Surface Diameter by a Laser Triangulation Sensor and Optimalization of Turning Conditions Based on the Diameter Deviation and Tool Wear by GRA and ANOVA. Applied Sciences 2022, 12, 5266. [CrossRef]

- Jurko, J.; Miškiv-Pavlík, M.; Husár, J.; Michalik, P. Turned Surface Monitoring Using a Confocal Sensor and the Tool Wear Process Optimization. Processes 2022, 10, 2599. [CrossRef]

- Tran, C.-S.; Hsieh, T.-H.; Jywe, W.-Y. Laser R-Test for Angular Positioning Calibration and Compensation of the Five-Axis Machine Tools. Applied Sciences 2021, 11, 9507. [CrossRef]

- Yi-Tsung, L.; Kuang-Chao, F. A Novel Method of Angular Positioning Error Analysis of Rotary Stages Based on the Abbe Principle. Proceedings of the Institution of Mechanical Engineers 2018, Part B: Journal of Engineering Manufacture, 1885–1892. [CrossRef]

- Kanno, Y.; Sato, Y. Linear and Angular Position Sensing for Two- Degrees-of-Freedom Motor. International Journal on Smart Sensing and Intelligent Systems 2014, 7, 1–6. [CrossRef]

- Chen, H.; Jiang, B.; Lin, H.; Zhang, S.; Shi, Z.; Song, H.; Sun, Y. Calibration Method for Angular Positioning Deviation of a High-Precision Rotary Table Based on the Laser Tracer Multi-Station Measurement System. Applied Sciences 2019, 9, 3417. [CrossRef]

- Gietler, H.; Stetco, C.; Zangl, H. Scalable Retrofit Angular Position Sensor System. In Proceedings of the 2020 IEEE International Instrumentation and Measurement Technology Conference (I2MTC); IEEE: Dubrovnik, Croatia, May 2020; pp. 1–6.

- Sridharan, M.; Dhandapani, S. Real Time Embedded System Development for Missile Angular Position Acquisition through Image Processing. CSIT 2020, 8, 257–261. [CrossRef]

- Diakov, D.; Komarski, D. Micro-Positioning Module for Angular Orientation Position of the Axis of Rotation Analysis. In Proceedings of the 2021 XXXI International Scientific Symposium Metrology and Metrology Assurance (MMA); IEEE: Sozopol, Bulgaria, September 7 2021; pp. 1–6.

- Luo, M.; Luo, H.; Zhang, D.; Tang, K. Improving Tool Life in Multi-Axis Milling of Ni-Based Superalloy with Ball-End Cutter Based on the Active Cutting Edge Shift Strategy. Journal of Materials Processing Technology 2018, 252, 105–115. [CrossRef]

- Winczek, J.; Gucwa, M.; Mičian, M.; Koňár, R.; Parzych, S. The Evaluation of the Wear Mechanism of High-Carbon Hardfacing Layers. Archives of Metallurgy and Materials 2019, 1111–1115. [CrossRef]

- Vandzura, R.; Simkulet, V.; Gelatko, M.; Hatala, M.; Mitalova, Z. Effect of Hardening Temperature on Maraging Steel Samples Prepared by Direct Metal Laser Sintering Process. Machines 2023, 11, 351. [CrossRef]

- Mičian, M.; Winczek, J.; Gucwa, M.; Koňár, R.; Málek, M.; Postawa, P. Investigation of Welds and Heat Affected Zones in Weld Surfacing Steel Plates Taking into Account the Bead Sequence. Materials 2020, 13, 5666. [CrossRef]

- Marciniak, K. Influence of Surface Shape on Admissible Tool Positions in 5-Axis Face Milling. Computer-Aided Design 1987, 19, 233–236. [CrossRef]

- Lazoglu, I.; Liang, S.Y. Modeling of Ball-End Milling Forces With Cutter Axis Inclination. Journal of Manufacturing Science and Engineering 2000, 122, 3–11. [CrossRef]

- Knapčíková, L.; Dupláková, D.; Radchenko, S.; Hatala, M. Rheological Behavior Modelling of Composite Materials Used in Engineering Industry. 6.

- Pavlenko, I.; Piteľ, J.; Ivanov, V.; Berladir, K.; Mižáková, J.; Kolos, V.; Trojanowska, J. Using Regression Analysis for Automated Material Selection in Smart Manufacturing. Mathematics 2022, 10, 1888. [CrossRef]

- Altintas, Y. Manufacturing Automation. Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design; Second Edition.; Cambridge University Press: University of British Columbia, 2012; ISBN 978-0-521-17247-9.

- Kita, Y.; Furuike, H.; Kakino, Y.; Nakagawa, H.; Hirogaki, T. Basic Study of Ball End Milling on Hardened Steel. Journal of Materials Processing Technology 2001, 111, 240–243. [CrossRef]

| Inclination angle δ [°] |

Work angle of cutting blade ψr_rci [°] |

Distance between toolpaths br [mm] |

Axial depth of cut ap [mm] |

Feed per tooth fz [mm/z] |

Cutting speed (at p. CPi) vc [m/min] |

Criterion Rth=Rthvf [mm] |

Criterion VBBlim [mm] |

|---|---|---|---|---|---|---|---|

| 1.10946 | 23.4411 | 1.6 | 0.3 | 0.1549 | 71 | 0.0015 | 0.2 |

| Test No. | Cutting speed (at p. CPi) vc [m/min] |

Feed rate f [mm/rev] |

Measured tool life Tt [min] |

|---|---|---|---|

| 1 | 40 | 0.4 | 84 |

| 2 | 140 | 0.4 | 0.97 |

| 3 | 140 | 0.2 | 3.7 |

| Laser set | Movement accuracy [mm] | Repeat positioning accuracy [mm] |

Up to working speed [mm/s] |

|---|---|---|---|

| 2W 1064 nm |

0.00199 | 0.000248 | 84 |

| Microscope | Keyence VHX 7000 |

| Lens | ZS-20 with 20-200x zoom |

| Shooting mode | 4K 3D HDR scanning mode with glare reduction |

| Magnification | merging images at 100X zoom |

| Room temperature | 22 °C |

| Humidity | 55% |

| Sum of squares | Degrees of freedom | Mean square | F-value | p-value | R | |

|---|---|---|---|---|---|---|

| Regression | 1.3271 | 2.0 | 0.6635 | 1867.4383 | 0.0000 | 0.90 |

| Residual | 0.0305 | 86 | 0.0003 | |||

| Total | 1.3577 | 88 | ||||

| Adjusted grand total | 0.1675 | 87 | ||||

| Regression of the adjusted total | 1.3271 | 2.0 | 0.6635 | 344.5687 | 0.0000 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).