1. Introduction

Materials created and intended to function with biological systems are known as biomaterials. They might be bioactive materials that enter human tissue fast. Their biodegradability is good. They are frequently employed in the production of pharmaceuticals, tissue engineering, and human body components [

1,

2]. New and innovative technical developments like surface alterations, bio printing, nanotechnology, biodegradable materials, bioactive molecules, surface modification, and creation of new, eco-friendly materials and biomaterials all complement each other [

3,

4]. Green technology is used to generate eco-friendly biomaterials, or they can be derived from other biological sources. Many biomaterials have been explored and created as workable alternatives to conventional materials, and they have been successfully used in various biomedical domains. Applications for contact lens design in ophthalmology, wound healing, orthopedics, ligament and tendon restoration, and reproduction therapy for nerve generation are the primary uses [

5]. They are also widely used in non-biomedical fields. Filters and membranes, energy products, textiles, building materials, food packaging, sporting goods, cosmetics, and personal hygiene are examples of non-biomedical applications [

6,

7,

8].

Because of the expansion of the pharmaceutical sector and the focus on improving patient compliance, applications of specific biomaterials for biomedical use have grown significantly. Materials can be added to natural tissue or used as a therapeutic enhancement in medical devices. It might be simpler to rejuvenate bones, heart valves, cartilage, and other tissues when biological and synthetic materials produced from stem cells are combined [

9]. In order to do this, the damaged portion is either replaced or attempted to be reinstated, and materials that are immune to immunological rejection because to their genetic similarity to the patient are used. Most biomaterials are composed of metals, ceramics, and polymeric components [

10]. Polymeric materials can be utilized to temporarily substitute both soft and hard tissues, while metals and ceramics are typically used to replace hard tissue [

11].

Biomaterials can also be utilized in dental surgery and medication delivery. They can also be utilized for blood vessel prosthesis, artificial ligaments and tendons, bone plates, skin repair instruments, contact lenses, cochlear replacements, and bone cement [

12]. Biomaterials are man-made or naturally occurring synthetic materials that are used to make implants and other structures that replace lost or damaged biological structures and return them to their original form and function. Collagen, chitosan, alginate, cellulose, and gelatin are a few naturally occurring biomaterials [

13]. Synthetically produced biomaterials include metal, ceramics, composites, polymers, and hydrogels. Because of this, biomaterials are extending human lifespans and enhancing quality of life. The biomaterials sector has expanded rapidly to fulfill the needs of an aging population. Biomaterials are used in the construction of several body components, such as prosthetic heart valves, shoulder replacement implants, knee and elbow joints, ears, oriental structures, and hip joints. Various materials can be used to make implants, according on the requirements of the application. Metals, alloys, polymers, ceramics, and composite materials are the most commonly utilized biomaterials.

The pharmaceutical and medical industries are becoming more interested in sustainable biomaterials as a result of the intersection of environmental sustainability and healthcare advancement. The area of sustainable biomaterials and its applications in healthcare are examined in this review, with particular attention paid to the fundamentals of biomaterials, method of preparation of sustainable biomaterials, sustainability of biomaterials, natural biomaterials, synthetic biomaterials for renewable sources, and applications of biomaterials in pharmaceuticals, applications of biomaterials in medical devices cell toxicity of sustainable biomaterials, future prospective and challenges.

2. Fundamentals of Biomaterials

Biomaterials play a pivotal role in contemporary medical and pharmaceutical landscapes, serving as versatile substrates that interact seamlessly with biological systems to facilitate therapeutic interventions and medical device development. These materials, whether naturally occurring or synthetically engineered, are characterized by their inherent biocompatibility and ability to integrate with living tissues, thereby enabling a myriad of applications across diverse medical disciplines. The European Society for Biomaterials Consensus Conference-II has provided a comprehensive definition of biomaterials, emphasizing their role in interfacing with biological systems to support tissue replacement, treatment, or augmentation [

14]. Categorized based on their constituent materials and responsiveness to living tissues, biomaterials encompass a broad spectrum, including polymeric materials, ceramics, metals, and their composites. Moreover, biomaterials exhibit varying degrees of biodegradability, biomimicry, and biological activity, crucial attributes that determine their suitability for specific medical applications such as hand surgery, bone replacement, and nerve repair [

15,

16]. Advanced imaging techniques like Backscattered Electron Microscopy (BSEM) offer invaluable insights into the interaction dynamics between implanted biomaterials and bone tissue [

17]. By categorizing biomaterials based on their influence on bone apposition, BSEM aids in understanding the efficacy of biomaterial integration and tissue regeneration processes. Additionally, biomaterial design can be tailored to facilitate controlled interactions with living tissues, enabling therapeutic or diagnostic applications across a spectrum of medical conditions.

The versatility of biomaterials is exemplified by their widespread use in medical device fabrication, including heart valves, dental implants, vascular grafts, and artificial organs [

18]. These materials, ranging from biodegradable polymers to bioactive ceramics, offer distinct advantages in restoring or enhancing the function of deteriorating or damaged tissues. Furthermore, the advent of bio composite materials, reinforced with natural fibers or synthesized from animal-based sources, underscores the diverse array of biomaterial options available for biomedical applications [

19]. Organs and tissues that are failing or damaged can be replaced, or their functionality can be enhanced, with certain biomaterials. Because of their special physical, chemical, and biological characteristics, a wide range of materials, including some biodegradable polymeric materials, ceramic materials, metals and their alloys, biopolymers, composite materials, bio composite materials reinforced with natural fibers, and some other filler materials, are used as biomaterials [

20]. Classification of biomaterials into resorbable and non-resorbable categories further elucidates their temporal fate within the body. While resorbable materials undergo gradual degradation and absorption by bodily tissues, non-resorbable materials exhibit enduring stability, offering unique advantages in specific clinical contexts. Moreover, biomaterials can be classified based on their bioactivity, biocompatibility, and degradability, informing strategic selection and design considerations for targeted therapeutic interventions [

21].

The integration of cutting-edge technologies like bio printing, nanotechnology, and surface modifications augments the repertoire of biomaterials, fostering innovation in pharmaceutical and medical domains [

22]. Green technologies further contribute to the development of eco-friendly biomaterials sourced from renewable biological reservoirs, promoting sustainability in biomedical research and development. The exploration of sustainable biomaterials for pharmaceutical and medical applications underscores their transformative potential in shaping the future of healthcare delivery [

23]. With their diverse properties and applications, biomaterials continue to revolutionize therapeutic approaches, medical device fabrication, and drug delivery systems, thereby advancing the frontiers of modern medicine and enhancing patient care [

24,

25].

2. Method of Fabrication of Biomaterials

Conventional industrial methods are used in the production of biomaterials. Even with traditional manufacturing techniques like gas foaming, freeze drying, powder forming, solvent casting, solvent casting/particulate leaching, sol-gel method, electro spinning, and thermally induced phase separation, it can be challenging to control pore parameters and incorporate intricate architectural details while maintaining reproducibility [

26]. Tissue scaffolds cannot have uniformly sized pores that are fully interconnected by these standard procedures Furthermore, deviation during traditional fabrication techniques is nearly impossible to eliminate and can lead to the failure of created tissue constructs [

27].

Another technique is additive manufacturing techniques. Biomedical engineers have extensively investigated additive manufacturing (AM) technology for producing a range of bespoke goods for healthcare systems. Using the right 3D printing technique, the technology can be used to create anatomic models and medical implants that are particular to each patient [

28]. The selection of biopolymers and the transformation of reasonable AM are important factors in biomedical applications [

29]. For 3D printing, biopolymers should ideally have excellent shape fidelity, structural stability, printability, and processability in addition to precise and accurate polymer 3D plotting [

30]. The American Society for Testing and Materials' International classification system can be used to classify 3D bioprinting procedures (ASTM). Digital light processing (DLP), inkjet printing (IJP)/binder jetting (BJ), stereolithography (SLA), and extrusion-based printing (fused deposition modeling, or FDM) are the most widely used techniques for 3D bioprinting of sustainable polymeric materials [

2].

Polymeric biomolecules consist of long chains of monomeric components covalently bound together, called biopolymers. Unlike synthetic polymers, biopolymers have a unique three-dimensional structure due to their intricate molecular structure. The term "bio" indicates that the polymer will degrade naturally due to biological processes. Thus, biopolymers are biodegradable materials that are a compelling substitute for fossil-based polymers and could potentially tackle the most pressing concerns for the conservation of our planet [

31]. On the other hand, man-made synthetic polymers are composed of non-biodegradable petrochemicals. Oil has a limited supply, which seriously harms the environment on a worldwide scale. In contrast to synthetic polymers, which currently have a linear lifecycle that consumes fossil fuels as resources, converts them into polymers, builds things, and then discards them, biopolymers merge material design, manufacture, application, and disposal into a circular process.

3. Sustainability in Biomaterials

The field of biomaterials is rapidly evolving towards greater environmental responsibility. Traditional biomaterials often rely on non-renewable resources or generate plastic waste, posing significant environmental challenges. In contrast, sustainable biomaterials, derived from renewable sources like plant starches, bacterial cellulose, or chitosan from shrimp shells, offer a promising alternative with reduced environmental impact [

32]. Sustainability in biomaterials encompasses various aspects, including biodegradability, life cycle assessments, energy efficiency, and minimizing pollution throughout their lifecycle [

24]. By adhering to these principles, biomaterials can contribute to environmental stewardship while advancing medical and pharmaceutical applications. Efforts are underway to develop biomaterials that utilize renewable resources, such as proteins, to create novel materials with desirable properties [

33]. Alternative protein sources, including recombinant proteins and peptides, are being explored for their potential in biomaterial applications.

A sustainable biomaterial has low environmental risk, is produced with ecologically acceptable methods, and comes from renewable resources that are farmed responsibly. Furthermore, it should be capable of being reused or recycled at the end of its intended use, promoting circularity and resource efficiency [

34]. The creation of sustainable biomaterials involves considering the entire material lifecycle, from sourcing to disposal. This includes assessing manufacturing processes for their environmental impact, as well as exploring opportunities for recycling or composting at the end of the material's life [

35]. Economic viability and societal advantages, such as job creation, cost savings, and supply chain resilience, are important evaluation factors for sustainability. A sustainable biomaterial must also fulfill legitimate societal needs to justify its ecological footprint. Overall, the growing interest in sustainable biomaterials reflects a global shift towards more environmentally responsible practices. By integrating renewable resources, reducing pollution, and promoting circularity, sustainable biomaterials have the potential to drive positive environmental outcomes while meeting the demands of diverse medical and pharmaceutical applications [

36].

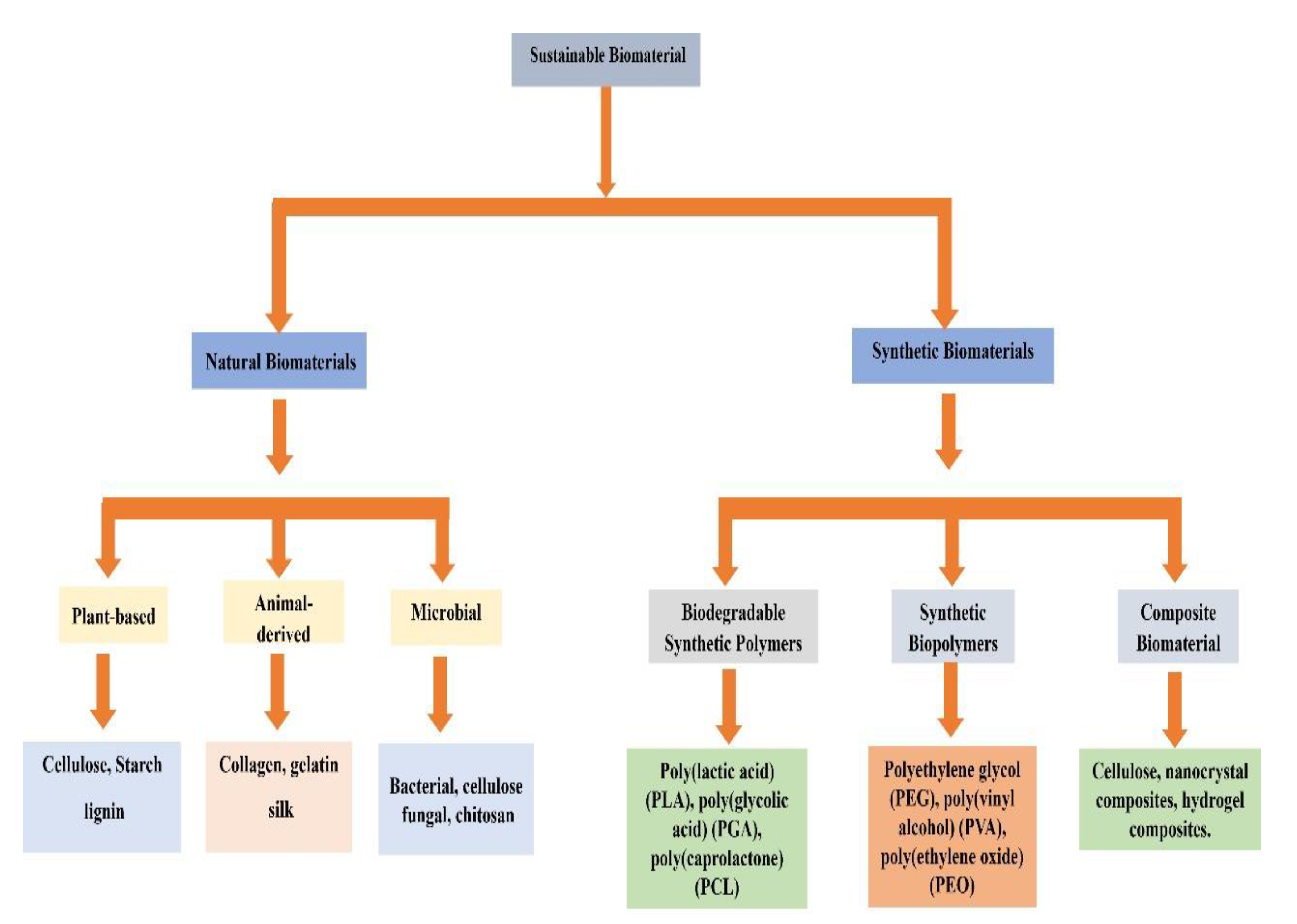

Figure 1 shows the classification of sustainable biomaterials.

4. Natural Biomaterials

Natural biomaterials, derived from the life cycles of organisms, offer versatile applications in healthcare. Ranging from bioinert to bioactive, they are increasingly recognized for their sophistication and suitability. Novel biomaterials research focuses on harnessing the abundant chemical options of natural biomaterials. Their non-immunogenicity, biocompatibility, and renewability make them desirable. Nature has evolved materials with biomimicry, mechanical strength, and biodegradability [

37]. From reptiles to avian waste, insects, and fish, various sources provide biomaterials like collagen, silk, and venom. Insects, with a million species, offer silk, fatty acids, and sericin. Arachnids, like spiders and scorpions, provide protein-rich biomaterials. Fish waste yields collagen, thrombin, and chondroitin sulfate. These biomaterials, essential for healthcare, emphasize sustainable sourcing and utilization [

38].

In essence, natural biomaterials, diverse in origin and properties, hold immense potential for sustainable healthcare solutions. Natural biomaterials, originating from microorganisms, plants, and marine sources, offer a diverse array of applications in healthcare. Microbial polysaccharides genetically engineered or naturally occurring, and plant-based biomaterials like cellulose, starch, and lignin are notable examples [

39]. Bodin et al. have explored the mechanical properties of biomaterials like bacterial nanocellulose (BNC) gel for applications in meniscal lesion treatment [

40]. Yang et al. investigated 3D bioprinting using natural polymers like sodium alginate and collagen for cartilage tissue engineering, demonstrating enhanced mechanical strength and cell adhesion [

41]. Similarly, Liu et al. developed porous scaffolds for bone repair using sodium alginate and collagen with promising stability and cell support [

42]. Marine polysaccharides like agarose, derived from red seaweed, serve as carriers for drug delivery systems due to their bioactivity and controllable chemical reactivity [

43]. Collagen, a widely used biomaterial, aids in wound healing by mimicking the dermal extracellular matrix [

44]. Chitosan derivatives demonstrate versatility in applications such as drug delivery, mucoadhesion, and wound healing [

45]. Fujita et al. investigated the efficacy of photo cross-linkable chitosan hydrogel in preventing prosthetic aortic graft infections, showing promising results in inhibiting graft infections [

46].The use of nanocellulose in lesion repair, as scaffolds to support cell culture, and in tissue repair and regeneration has advanced significantly in recent years. The

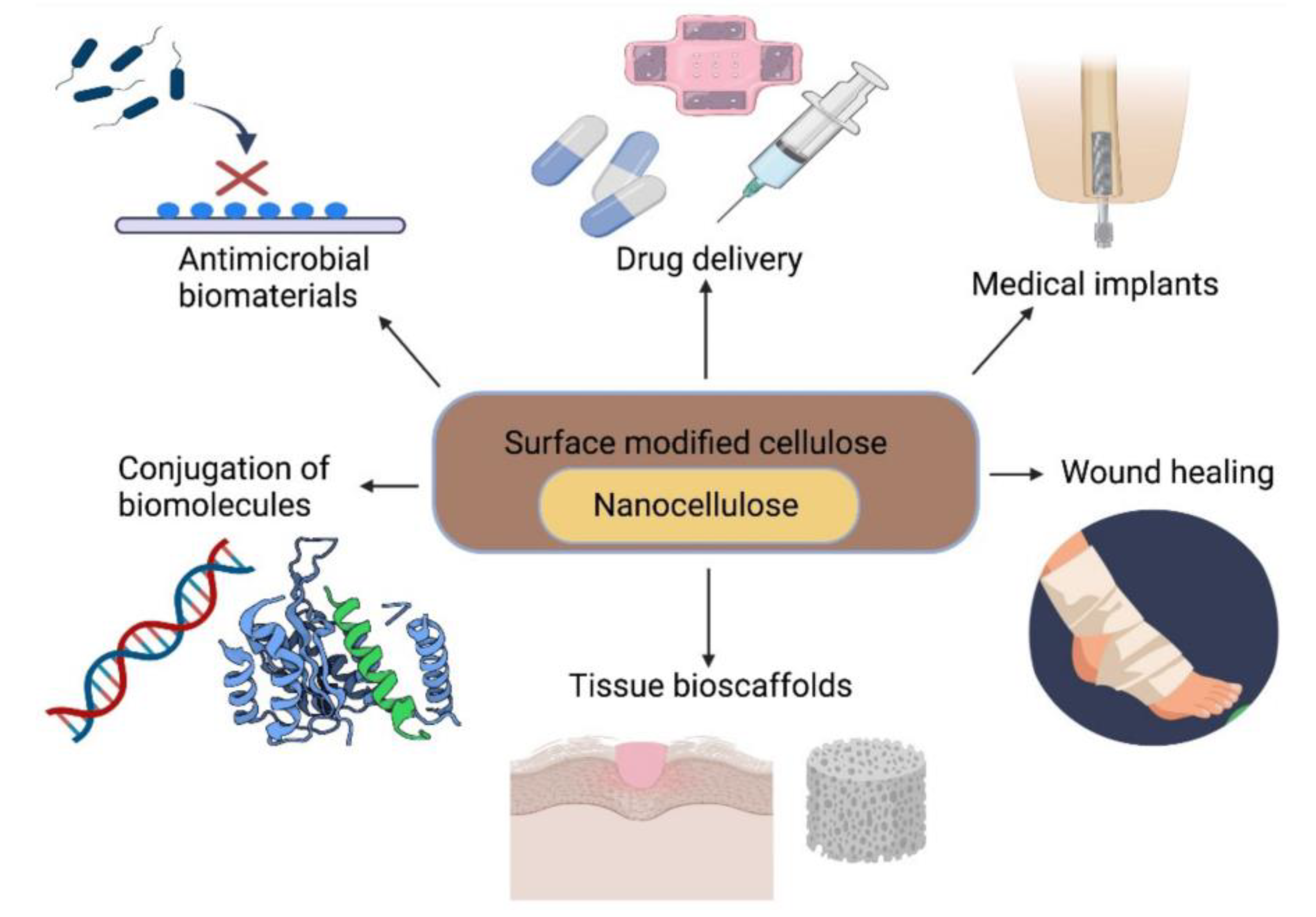

Figure 2 shows the uses of cellulose as a biomaterial.

Gelatin micro particles have been extensively studied for drug delivery systems, showing potential in delivering anti-inflammatory, antibacterial, and antineoplastic drugs [

48].In dentistry, biomaterials like chitosan and gelatin are used for root canal infections and periodontal regeneration, respectively. Regenerative urology utilizes biomaterials for repairing urinary system segments and developing fully functional organs. Hyaluronic acid, a component of the brain's extracellular matrix, holds promise in central nerve system (CNS) regeneration medications. Silk, through silk grafts, has been explored for wound healing applications [

49]. Biomaterials with antioxidant properties, such as bioactive glass composite biomaterials, show potential in chronic wound healing. Hydrogel-based biomaterials like polyvinyl alcohol are also used for wound healing. Spider silk sutures demonstrate promising properties for flexor tendon repair. Calcium alginate hydrogel and hyaluronan-chitosan combinations exhibit potential in chronic wound treatment and neovascularization, respectively. Various biomaterials, including polyvinyl alcohol, mungbean starch, and cryogenics, show functional effects in drug delivery, cardiovascular implants, and diabetic wound healing [

50].

Natural biomaterials offer vast potential in healthcare applications, with ongoing research focusing on discovering new materials and exploring their physical, chemical, and biological properties to further advance medical treatments.

1. Synthetic Biomaterials from Renewable Resources

Renewable resource-based synthetic biomaterials offer a sustainable solution for various biological applications, serving as environmentally friendly alternatives to conventional biomaterials derived from finite resources like fossil fuels. By harnessing renewable sources such as plant-based polymers, sugars, and oils, researchers can reduce reliance on non-renewable materials and mitigate environmental harm caused by resource extraction and processing [

51]. One significant advantage of synthetic biomaterials derived from renewable resources is their biodegradability, which allows them to naturally decompose over time, reducing waste production and environmental pollution. Moreover, their production methods support environmental sustainability by minimizing energy consumption and carbon emissions [

52]. The characteristics of these biomaterials can be easily customized by researchers for use in tissue engineering, regenerative medicine, and drug delivery systems, among other biomedical applications. To get desired properties like mechanical strength, biocompatibility, and degradation rate, one can modify parameters like molecular weight, chemical composition, and cross-linking density [

53].

Polylactic acid (PLA), polyhydroxyalkanoates (PHAs), cellulose-based polymers, chitosan, polyglycolic acid (PGA), and starch-based polymers are examples of synthetic biomaterials derived from renewable resources [

54]. Because it is both biocompatible and biodegradable, chitosan which is produced by deacetylating the chitin present in crustacean exoskeletons—is frequently used in biomedical applications [

55]. Many polymer formulations based on chitosan have been developed for applications such as wound healing, medicine administration, and tissue engineering. Using methods such emulsion crosslinking, coacervation/precipitation, spray-drying, ionic gelation, and reverse micellar approaches, customized chitosan particulate systems have been developed. With their tunable mechanical properties, biodegradability, and biocompatibility, PHAs, aliphatic polyesters made by bacteria as carbon storage molecules, are well suited for use in biomedical applications. Polyhydroxybutyrate (PHB) and Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV), two types of PHAs, have been extensively studied for drug delivery, tissue engineering, and medical implant applications. [

56].

The biomedical industry has shown a great deal of interest in PLA, another flexible biodegradable polyester, because of its strong mechanical qualities, ease of production, and high biodegradability. Commercially produced through ring-opening polymerization of lactide, PLA conforms to renewable and sustainable development principles, as lactide is typically derived from carbohydrate fermentation. PLA-based biomaterials, such as Poly(L-lactic acid) (PLLA) and Poly(D,L-lactic acid) (PDLLA), have been developed for load-bearing applications like orthopedic fixation screws and drug delivery systems, respectively. Renewable resource-based synthetic biomaterials offer a promising avenue for sustainable biomedical applications, providing customizable properties and environmental benefits that align with the principles of renewable and sustainable development [

57].

2. Applications of Sustainable Biomaterials in Pharmaceutics

In pharmaceutical applications, sustainable biomaterials are essential, especially for drug delivery systems. These biomaterials make it possible to encapsulate pharmaceutical compounds and release them under regulated conditions, which increases treatment efficacy, decreases side effects, and prolongs release for chronic illnesses. Poly(lactic-co-glycolic acid) (PLGA), liposomes, alginate, chitosan, hyaluronic acid (HA), polyethylene glycol (PEG), cyclodextrins, dendrimers, PLA , and polymeric micelles are common biomaterials utilized in drug delivery systems [

58]. Enzymatic degradation of polymers is influenced by various factors, including chemical modifications, physicochemical characteristics, environmental conditions, and the presence of activators or inhibitors. For instance, Chen et al. studied the effects of acetylation on maize starch and its application in drug-release systems [

59]. Natural polymers have also gained attention in medicine, pharmacy, and cosmetics, with polymeric nanoparticles and hydrogels based on natural polymers being utilized for topical drug delivery and skin regeneration [

60,

61,

62].

Chitosan, which is obtained responsibly from crab shells, is a mucoadhesive, biodegradable, and biocompatible substance that is frequently used in pharmaceutical formulations. For example, Hussain et al. enhanced chitosan nanoparticles for hydrocortisone and hydroxytyrosol percutaneous co-delivery [

63]. In a similar vein, Md et al. created chitosan nanoparticles loaded with betamethasone to treat atopic dermatitis, showing improved efficacy above traditional formulations [

64]. Alginate gels have been utilized in tissue engineering, controlled drug delivery, and wound dressing applications because they are biocompatible and biodegradable [

65]. In order to provide cynaroside to patients with atopic dermatitis, Szekalska et al. developed an alginate-based hydrogel that showed encouraging results in lowering inflammation [

66]. Furthermore, Salehi et al. created an alginate-based hydrogel that was loaded with naringenin and showed antioxidant, antibacterial, and anti-inflammatory qualities to treat skin wounds [

67].

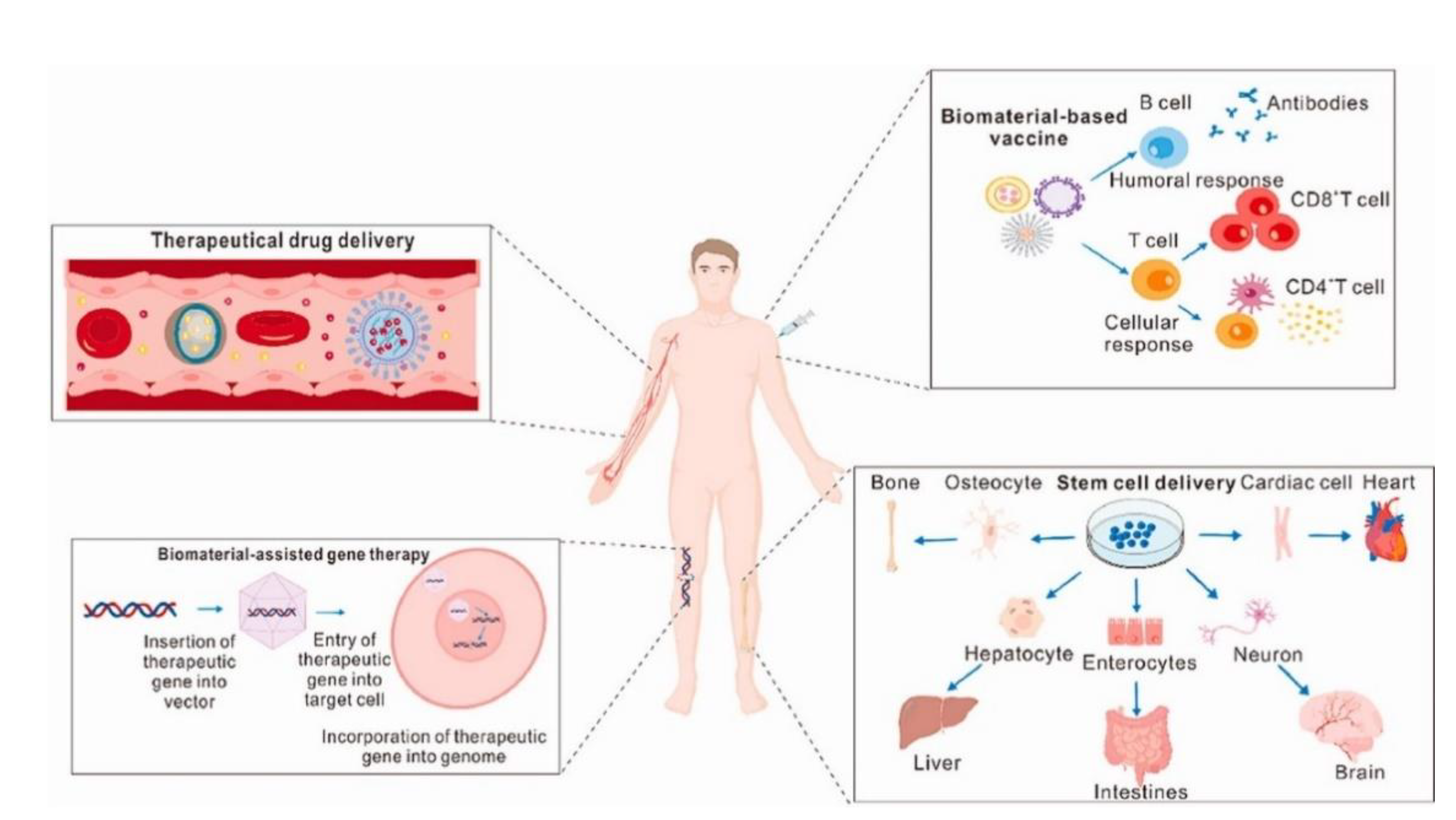

Figure 3 depicts A list of the most recent pre-clinical and clinical research on the use of biomaterials in biotherapy, encompassing gene therapy, stem cell therapy, medication administration, and vaccine development.

Hydrogels based on dextran have shown potential in tissue regeneration and wound healing, as demonstrated by studies conducted by Ribeiro et al. and Sun et al.[

69]. Silk fibroin-based hydrogels have also been investigated for wound healing applications, with Li et al.[

70] and Dong et al. reported their efficacy in preventing hypertrophic scars and delivering antibiotics, respectively [

71]. Collagen, a ubiquitous extracellular protein, holds promise in wound healing due to its ability to promote tissue ingrowth. Oryan et al. developed a collagen-based hydrogel bandage containing probiotics, which accelerated wound healing in burn injuries [

72]. Similarly, Yoon et al. formulated a gelatin-based hydrogel loaded with chemotactic cytokines for the treatment of diabetic wounds, demonstrating improved wound healing compared to conventional treatments [

73].In addition to natural polymers, synthetic polymers like PLA, PLGA, and PGA are widely used in drug delivery systems due to their mechanical properties and biodegradability. These synthetic polymers have been instrumental in vaccine development, including mRNA vaccines like the COVID-19 vaccine, where lipid nanoparticles are used to deliver delicate mRNA molecules into cells.

Overall, biomaterials have revolutionized drug delivery and pharmaceutical applications, offered targeted and sustained release of medications while minimized adverse effects. From cancer treatment to tissue engineering, biomaterials have diversified applications across various medical fields, promising advancements in patient care and treatment outcomes[

74,

75,

76].

Table 1 depicts some biomaterials used in pharmaceuticals, their sources, and applications.

8. Applications of Sustainable Biomaterials in Medical devices

Numerous potential medicinal applications for biopolymers exist, such as cell proliferation, adhesion, anchoring, suturing, covering, occlusion, isolation, and tissue guidance. The growing recognition of biomaterials' potential stemming from the need for improved, tissue-targeted implantable devices has focused emphasis on multimodal scaffolds with unique shapes and physical-chemical characteristics [

94]. Because these scaffolds combine diverse topographies not often observed in each material, they exhibit multifunctional or multimodal properties that increase their potential value in regenerative medical approaches. The development of three-dimensional templates and artificial extracellular matrix (ECM) habitats for tissue regeneration are important goals for polymers [

95]. It is possible to create biopolymers synthetically or using natural materials [

96]. Because natural polymers are more biodegradable and do not cause cytotoxicity, they are a great substitute for synthetic materials that are frequently employed. They are created through the chain-growth polymerization of activated monomers, which are commonly created inside of cells during metabolic activities and are catalyzed by enzymes. They mimic soft tissues and are derived from natural sources. Hyaluronic acid, cellulose, fibrin gels, agarose/alginate, collagen, gelatin, and dextran are some of the components that fall within this group. The enhanced mechanical characteristics and in vitro findings demonstrated that these innovative biodegradable stents can be utilized for the treatment of cardiac patients experiencing occlusion of the coronary arteries as shown in

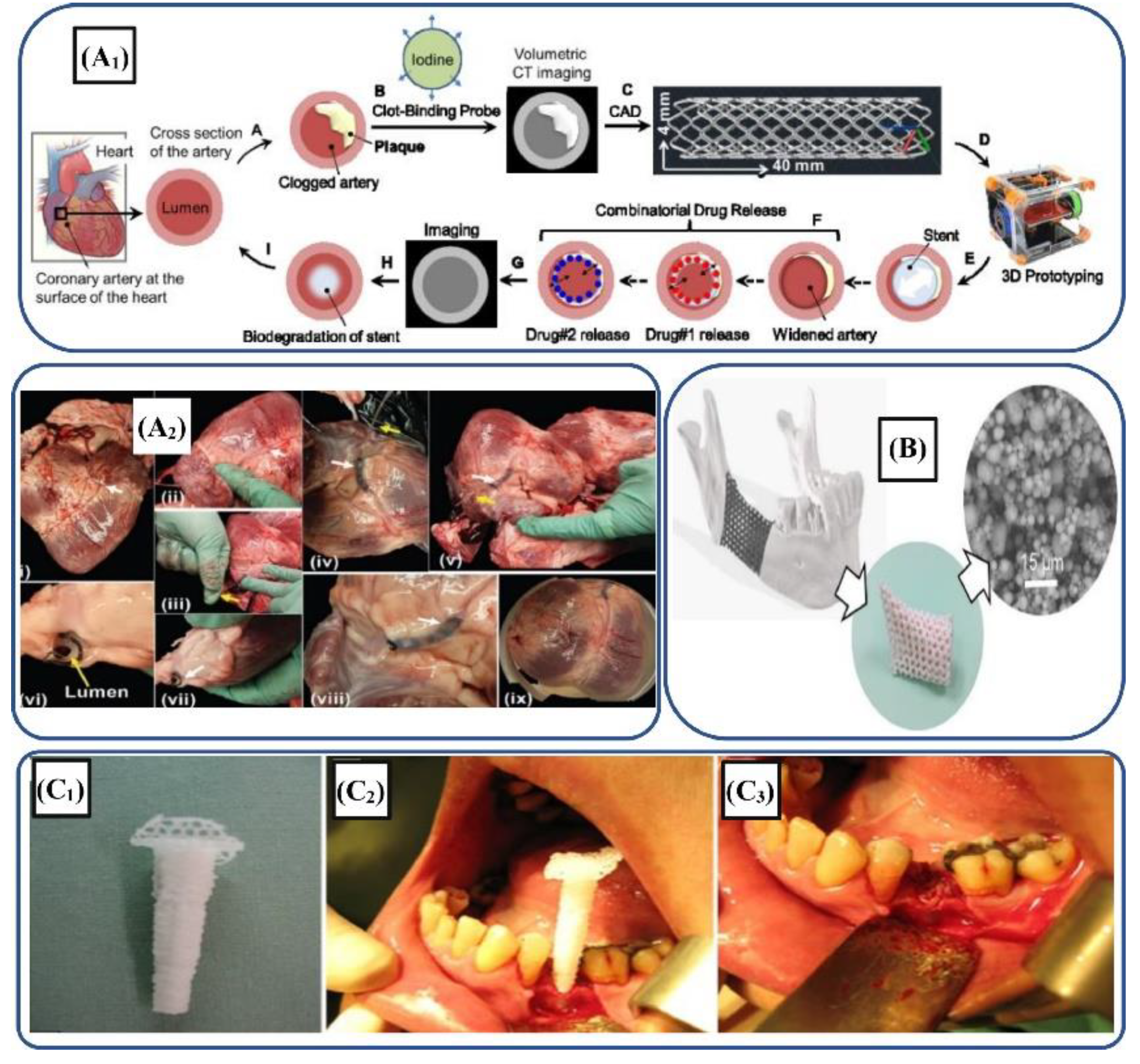

Figure 4.

In regenerative medicine, natural polymers are frequently utilized; however, they must be cleansed prior to implantation in order to prevent foreign body reactions. The drug delivery method uses biodegradable polymers, which may be eliminated by the body and do not require surgery to remove once the pharmaceuticals are discharged. Biopolymers have been used in many well-known biomedical applications, including artificial hearts, breast implants, intraocular lenses, soft-tissue replacement, bone cement, dialyzers, liver, pancreas, bladder, kidney, coatings for pharmaceutical tablets and capsules, cardiac assist devices, implantable pumps, pacemakers, encapsulations, artificial blood vessels, joint replacements, artificial skin, dentistry, drug delivery, and targeting tumor or inflammatory sites [

87,

100,

101,

102].

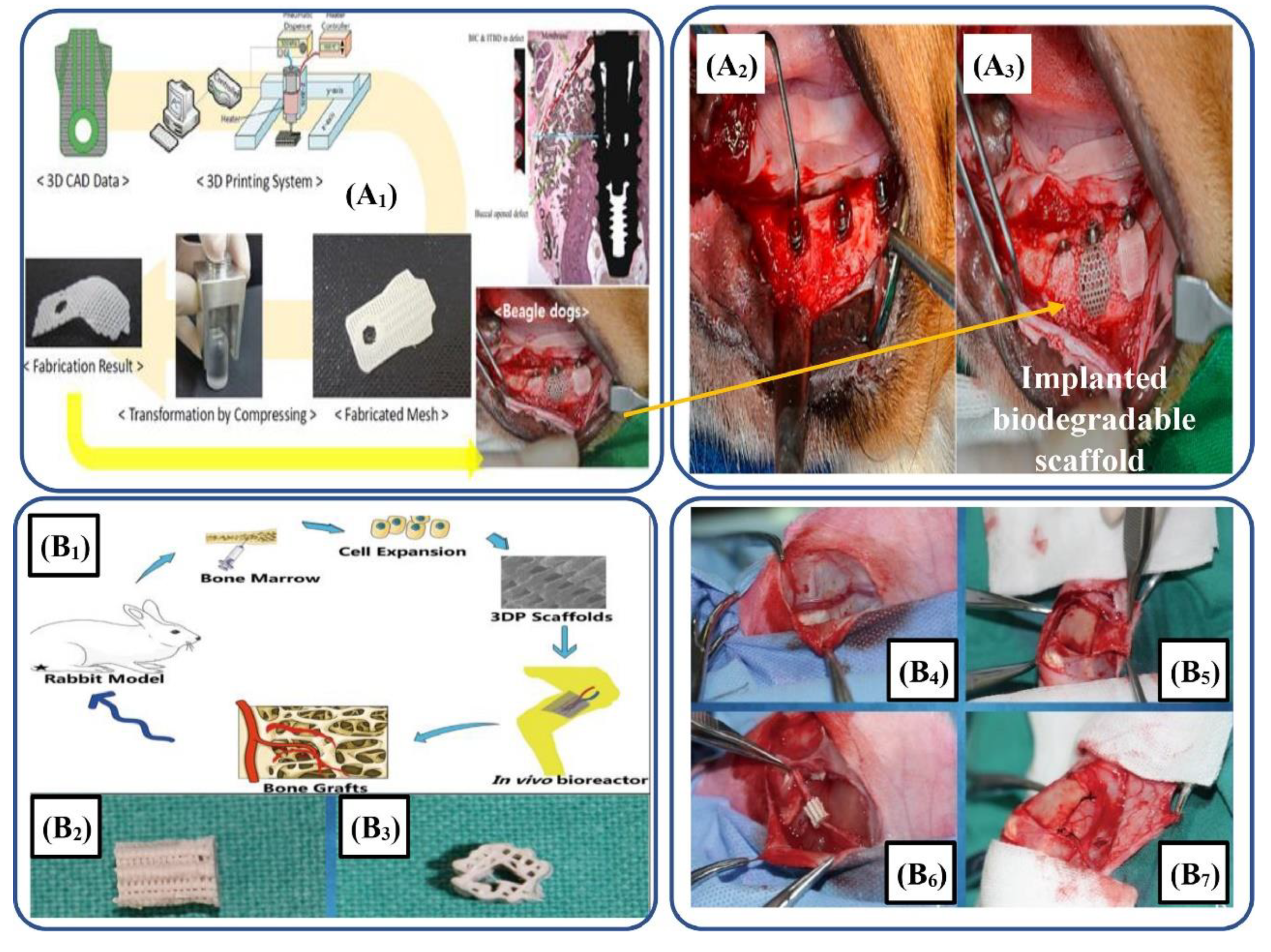

Figure 5 show the step-by-step process that the authors used to create 3D-printed scaffolds using Fused Deposition Modeling (FDM) for bone regeneration and dog tooth osteointegration based on PLGA/PCL/β-TCP-based scaffolds.

PHAs can be utilized in biomedical applications in place of petrochemical polymers because they degrade naturally.

Table 2 shows some biomaterials used in the medical field, their sources, and applications.

8. Cell Toxicity of Sustainable Biomaterials

The cytotoxicity of biomaterials can be assessed using a number of commonly used techniques, including the agar diffusion test, direct contact test/colony formation assay, neutral red absorption assay, and y-MTT (3-[4,5-dimethyl2-thiazolyl]-2,5-diphenyl tetrazolium bromide) assay. Several detrimental impacts of biomaterials have already been studied with the MTT test. A polyhydroxyalkanoate (PHA), poly(hydroxybutyrate-co-hydroxy hexanoate) (PHBHHx), was shown to be cytotoxic to L929 murine fibroblast cells by Yang et al [

126]. The MTT test was used to measure the number of viable L929 cells that were adhered to and cultured on polymer surfaces. The technique known as neutral red uptake (NRU) has also been widely utilized to assess the cytotoxicity of biomaterials and gauge cell viability. MG-63 osteoblast-like cells were tested with cement extracts, and Ciapetti et al.[

127] used NRU to confirm this. Utilizing NRU has the advantage of not being influenced by sporadic microbial contamination, which can cause an overestimation of cell viability.

Based on the morphological changes in the cells, the direct contact test can be used to assess the cytotoxicity of biomaterials, according to ISO10993-5. Typically, this assay uses fibroblast cells. Lee et al.[

128] developed a novel method to modify bovine pericardium (BP) by directly coupling heparin, aiming for cardiovascular bioprosthetic applications. Their study showed reduced cytotoxicity in vitro and decreased calcium deposition in vivo on heparin-treated BP compared to untreated and GA-treated samples, indicating improved biocompatibility. This suggests the potential of heparinized BP as a sustainable biomaterial for cardiovascular implants. According to reports, the most practical and sensitive cytotoxicity test is the colony-forming assay. The Agar Diffusion Assay is carried out according to ISO10993-5 guidelines. Cytotoxicity is synonymous with cell death, the mechanisms of which have been extensively studied. There are two primary categories of cell death. like apoptosis and necrosis [

129].

10. Future Perspectives and Challenges

Creating environmentally and economically viable methods for the large-scale production of minerals, chemicals, and fuels is the problem of the twenty-first century [

130]. In light of their potential uses, a few selected examples of bio-derived materials, such as carbonaceous materials and biocompatible nano-composites created from natural sources, show the promise of these materials [

131]. There are numerous different applications in these examples. The best course of action in this situation is to use cheap, renewable precursors like waste and biomass to generate well-defined, controllable nanostructures [

132]. In some circumstances, it may be difficult to accurately control the characteristics of the It can occasionally be challenging to precisely regulate the characteristics of the synthesized biomaterials due to factors like the complexity of the starting material, the existence of contaminants, etc. However, these issues have occasionally been rectified, depending on the biomaterial production method and/or the selected future utilization [

130]. In other scenarios, advanced materials with high-end applications, like electrodes in energy storage devices (fuel cells, batteries, etc.), where specific physical properties like conductivity, flexibility, transparency, and mechanical strength are needed, can be synthesized by forming Nano composites or by adding an extra substrate or starting material (like graphene) [

133]. These biomaterials with specific compositions and porosities may be used as super capacitor cell electrodes or as CO2 sequestration adsorbents. In conclusion, a complete comprehension of the structure and content of the foundational material is necessary for any future advancements in the field of sustainable biomaterials for a variety of applications.

Although sustainable biomaterials present a number of obstacles, they also provide intriguing solutions for a range of biomedical and pharmacological applications [

130]. The creation of sustainable biomaterials with qualities on par with or superior to those of conventional materials while maintaining performance and safety is a major issue. Regulatory criteria and standards for the use of sustainable biomaterials in pharmaceutical and biomedical applications, as well as ensuring their scalability and cost-effectiveness, continue to be obstacles. Furthermore, removing obstacles pertaining to perception, education, and awareness is necessary to achieve broad acceptance and adoption of sustainable biomaterials within the pharmaceutical sector and biomedical community [

134]. Moreover, the biocompatibility of sustainable biomaterials is crucial, as certain materials may elicit cytotoxic responses in living cells. Achieving a balance between biocompatibility and material functionality is essential to prevent adverse effects on cell viability and function. Understanding the mechanisms underlying the cytotoxicity of sustainable biomaterials and developing effective strategies to mitigate these effects are ongoing challenges in the field [

135]. Furthermore, standardized methods for assessing cell toxicity of sustainable biomaterials need to be established to ensure accurate and reproducible results across studies. Despite these challenges, continued research efforts are focused on addressing these issues to unlock the full potential of sustainable biomaterials in biomedicine and pharmaceuticals [

130].

11. Conclusion

In conclusion, biomaterials stand at the forefront of contemporary medical and pharmaceutical landscapes, offering versatile substrates that seamlessly interact with biological systems to enable therapeutic interventions and medical device development. Categorized based on their constituent materials and responsiveness to living tissues, biomaterials encompass a broad spectrum, including polymeric materials, ceramics, metals, and composites. They exhibit varying degrees of biodegradability, biomimicry, and biological activity, crucial for their suitability across diverse medical disciplines. The widespread use of biomaterials in medical device fabrication, including heart valves, dental implants, vascular grafts, and artificial organs, underscores their versatility and importance. Advanced imaging techniques such as BSEM provide crucial insights into biomaterial integration and tissue regeneration processes.

Moreover, the field of biomaterials is transitioning towards greater environmental responsibility, with a focus on sustainability. Sustainable biomaterials, derived from renewable sources, offer promising alternatives, addressing environmental concerns and promoting circularity in biomedical research and development. Natural biomaterials, derived from organisms' life cycles, and synthetic biomaterials from renewable resources provide sustainable solutions for various biological applications. However, challenges remain, including the development of sustainable biomaterials with properties comparable to traditional materials, scalability, cost-effectiveness, regulatory requirements, and addressing cytotoxicity concerns. Standardized methods for assessing cell toxicity of sustainable biomaterials are essential for accurate and reproducible results across studies. In summary, biomaterials continue to revolutionize healthcare delivery, offering targeted and sustained release of medications, advancing medical device fabrication, and contributing to regenerative medicine. With ongoing research focused on sustainability and eco-friendly practices, biomaterials hold immense promise in shaping the future of medicine and pharmaceuticals, driving positive environmental outcomes, and enhancing patient care.

Ethical consideration

Not applicable

Funding

The authors reported there is no funding associated with the work featured in this article.

Data availability statement

The data analyzed in this study were sourced from publicly available articles in the open literature. All references to the data used, including article titles, authors, and publication sources, are provided in the reference list of this article. Readers and researchers interested in accessing the raw data can refer to the original publications cited herein for retrieval from the respective sources.

Acknowledgments

We would like to convey our special thanks to the research house of the institution.

Abbreviations

| BSEM |

Backscattered Electron Microscopy |

| AM |

Additive Manufacturing |

| PLA |

Polylactic Acid |

| PHAs |

Polyhydroxyalkanoates |

| PGA |

Polyglycolic Acid |

| PHB |

Polyhydroxybutyrate |

| PHBV |

Poly(3-hydroxybutyrate-co-3-hydroxyvalerate |

| PLLA |

Poly(L-lactic acid) |

| PDLLA |

Poly(D,L- lactic acid) |

| PLGA |

Poly(lactic –co-glycolic acid) |

| PEG |

Polyethylene glycol |

| ECM |

Extracellular Matrix |

| NRU |

Neutral Red Uptake |

| MTT |

(3-[4,5-dimethyl2-thiazolyl]-2,5-diphenyl tetrazolium bromide |

References

- Rezvani Ghomi E, Khalili S, Nouri Khorasani S, Esmaeely Neisiany R, Ramakrishna S: Wound dressings: Current advances and future directions. J Appl Polym Sci. 2019, 136:47738. [CrossRef]

- Al Rashid A, Khan SA, G. Al-Ghamdi S, Koç M: Additive manufacturing of polymer nanocomposites: Needs and challenges in materials, processes, and applications. J Mater Res Technol. 2021, 14:910–41. [CrossRef]

- Tümer EH, Erbil HY. Extrusion-Based 3D Printing Applications of PLA Composites: A Review. Coatings. 2021; 11(4):390. [CrossRef]

- Arif ZU, Khalid MY, Noroozi R, et al.: Additive manufacturing of sustainable biomaterials for biomedical applications. Asian J Pharm Sci. 2023, 18:100812. [CrossRef]

- Huang Z, Shao G, Li L: Micro/nano functional devices fabricated by additive manufacturing. Prog Mater Sci. 2023, 131:101020. [CrossRef]

- Zhang Y, Lim CT, Ramakrishna S, Huang Z-M: Recent development of polymer nanofibers for biomedical and biotechnological applications. J Mater Sci Mater Med. 2005, 16:933–46. [CrossRef]

- Alizadeh-Osgouei M, Li Y, Wen C: A comprehensive review of biodegradable synthetic polymer-ceramic composites and their manufacture for biomedical applications. Bioact Mater. 2019, 4:22–36. [CrossRef]

- Azuraini MJ, Vigneswari S, Huong K-H, Khairul WM, H.P.S. AK, Ramakrishna S, Amirul A-AA. Surface Modification of Sponge-like Porous Poly(3-hydroxybutyrate-co-4-hydroxybutyrate)/Gelatine Blend Scaffolds for Potential Biomedical Applications. Polymers. 2022; 14(9):1710. [CrossRef]

- Qiu S, Zhou Y, Waterhouse GIN, Gong R, Xie J, Zhang K, Xu J: Optimizing interfacial adhesion in PBAT/PLA nanocomposite for biodegradable packaging films. Food Chem. 2021, 334:127487. [CrossRef]

- 10. Giubilini A, Bondioli F, Messori M, Nyström G, Siqueira G. Advantages of Additive Manufacturing for Biomedical Applications of Polyhydroxyalkanoates. Bioengineering. 2021; 8(2):29. [CrossRef]

- Abbasian M, Massoumi B, Mohammad-Rezaei R, Samadian H, Jaymand M: Scaffolding polymeric biomaterials: Are naturally occurring biological macromolecules more appropriate for tissue engineering? Int J Biol Macromol. 2019, 134:673–94. [CrossRef]

- Mohanty AK, Wu F, Mincheva R, et al.: Sustainable polymers. Nat Rev Methods Primer. 2022, 2:.

- Biswas MC, Jony B, Nandy PK, et al.: Recent Advancement of Biopolymers and Their Potential Biomedical Applications. J Polym Environ. 2022, 30:51–74. [CrossRef]

- Naderi H, Matin MM, Bahrami AR: Review paper: critical issues in tissue engineering: biomaterials, cell sources, angiogenesis, and drug delivery systems. J Biomater Appl. 2011, 26:383–417. [CrossRef]

- Campoccia D, Montanaro L, Arciola CR: A review of the biomaterials technologies for infection-resistant surfaces. Biomaterials. 2013, 34:8533–54. [CrossRef]

- Pradhan D, Sukla LB: Thin film of Yttria stabilised zirconia on NiO using vacuum cold spraying process for solid oxide fuel cell. Int J Nano Biomater. 2017, 7:38. [CrossRef]

- Abraham AK, G SV: Materials, design and manufacturing technologies for orthopaedic biomaterials: A review. Trends Biomater Artif Organs. 2015, 29:258–61.

- Stoddart A, Cleave V: The evolution of biomaterials. Nat Mater. 2009, 8:444–5. [CrossRef]

- Parker JB, Griffin MF, Spielman AF, Wan DC, Longaker MT: Exploring the Overlooked Roles and Mechanisms of Fibroblasts in the Foreign Body Response. Adv Wound Care. 2023, 12:85–96. [CrossRef]

- Sheikh Z, Najeeb S, Khurshid Z, Verma V, Rashid H, Glogauer M: Biodegradable Materials for Bone Repair and Tissue Engineering Applications. Materials. 2015, 8:5744–94. [CrossRef]

- Zybutz MD, Laurell L, Rapoport DA, Rutger Persson G: Treatment of intrabony defects with resorbable materials, non-resorbable materials and flap debridement. J Clin Periodontol. 2000, 27:169–78. [CrossRef]

- Sheikh Z, Najeeb S, Khurshid Z, Verma V, Rashid H, Glogauer M. Biodegradable Materials for Bone Repair and Tissue Engineering Applications. Materials. 2015; 8(9):5744-5794. [CrossRef]

- Prakasam M, Locs J, Salma-Ancane K, Loca D, Largeteau A, Berzina-Cimdina L. Biodegradable Materials and Metallic Implants-A Review. J Funct Biomater. 2017 Sep 26;8(4):44. [CrossRef]

- Biswal T, BadJena SK, Pradhan D: Sustainable biomaterials and their applications: A short review. Mater Today Proc. 2020, 30:274–82. [CrossRef]

- Sathiyavimal S, Vasantharaj S, LewisOscar F, Selvaraj R, Brindhadevi K, Pugazhendhi A: Natural organic and inorganic–hydroxyapatite biopolymer composite for biomedical applications. Prog Org Coat. 2020, 147:105858. [CrossRef]

- Huang Z-M, Zhang Y-Z, Kotaki M, Ramakrishna S: A review on polymer nanofibers by electrospinning and their applications in nanocomposites. Compos Sci Technol. 2003, 63:2223–53. [CrossRef]

- Roshandel M, Dorkoosh F: Cardiac tissue engineering, biomaterial scaffolds, and their fabrication techniques. Polym Adv Technol. 2021, 32:2290–305. [CrossRef]

- Mani MP, Sadia M, Jaganathan SK, et al.: A review on 3D printing in tissue engineering applications. J Polym Eng. 2022, 42:243–65. [CrossRef]

- Zhang C, Li Y, Kang W, Liu X, Wang Q: Current advances and future perspectives of additive manufacturing for functional polymeric materials and devices. SusMat. 2021, 1:127–47. [CrossRef]

- Udayakumar GP, Muthusamy S, Selvaganesh B, et al.: Biopolymers and composites: Properties, characterization and their applications in food, medical and pharmaceutical industries. J Environ Chem Eng. 2021, 9:105322. [CrossRef]

- Visco A, Scolaro C, Facchin M, Brahimi S, Belhamdi H, Gatto V, Beghetto V: Agri-Food Wastes for Bioplastics: European Prospective on Possible Applications in Their Second Life for a Circular Economy. Polymers. 2022, 14:2752. [CrossRef]

- Agnieray H, Glasson JL, Chen Q, Kaur M, Domigan LJ: Recent developments in sustainably sourced protein-based biomaterials. Biochem Soc Trans. 2021, 49:953–64. [CrossRef]

- Lefèvre T, Auger M: Spider silk inspired materials and sustainability: perspective. Mater Technol. 2016, 1–16. [CrossRef]

- Pesode P, Barve S, Wankhede SV, Ahmad A: Sustainable Materials and Technologies for Biomedical Applications. Adv Mater Sci Eng. 2023, 2023:e6682892. [CrossRef]

- Moshood TD, Nawanir G, Mahmud F, Mohamad F, Ahmad MH, AbdulGhani A: Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr Res Green Sustain Chem. 2022, 5:100273. [CrossRef]

- López-Castro LF, Solano-Charris EL. Integrating Resilience and Sustainability Criteria in the Supply Chain Network Design. A Systematic Literature Review. Sustainability. 2021; 13(19):10925. [CrossRef]

- Troy E, Tilbury MA, Power AM, Wall JG: Nature-Based Biomaterials and Their Application in Biomedicine. Polymers. 2021, 13:3321. [CrossRef]

- Bhat S, Kumar A: Biomaterials and bioengineering tomorrow’s healthcare. Biomatter. 2013, 3:e24717. [CrossRef]

- Liu S, Yu J-M, Gan Y-C, et al.: Biomimetic natural biomaterials for tissue engineering and regenerative medicine: new biosynthesis methods, recent advances, and emerging applications. Mil Med Res. 2023, 10:16. [CrossRef]

- Bodin A, Concaro S, Brittberg M, Gatenholm P: Bacterial cellulose as a potential meniscus implant. J Tissue Eng Regen Med. 2007, 1:406–8. [CrossRef]

- Yang X, Lu Z, Wu H, Li W, Zheng L, Zhao J: Collagen-alginate as bioink for three-dimensional (3D) cell printing based cartilage tissue engineering. Mater Sci Eng C. 2018, 83:195–201. [CrossRef]

- Liu S, Huang D, Hu Y, et al.: Sodium alginate/collagen composite multiscale porous scaffolds containing poly(ε-caprolactone) microspheres fabricated based on additive manufacturing technology. RSC Adv. 10:39241–50. [CrossRef]

- Zarrintaj P, Manouchehri S, Ahmadi Z, Saeb MR, Urbanska AM, Kaplan DL, Mozafari M: Agarose-based biomaterials for tissue engineering. Carbohydr Polym. 2018, 187:66–84. [CrossRef]

- Davison-Kotler E, Marshall WS, García-Gareta E: Sources of Collagen for Biomaterials in Skin Wound Healing. Bioengineering. 2019, 6:56. [CrossRef]

- Kato Y, Onishi H, Machida Y: Application of Chitin and Chitosan Derivatives in the Pharmaceutical Field. Curr Pharm Biotechnol. 4:303–9.

- Fujita M, Kinoshita M, Ishihara M, et al.: Inhibition of vascular prosthetic graft infection using a photocrosslinkable chitosan hydrogel. J Surg Res. 2004, 121:135–40. [CrossRef]

- 47. Alexandru Mihai Grumezescu, Valentina Grumezescu; Materials for Biomedical Engineering: Bioactive Materials, Properties, and Applications - 1st Edition | Elsevier Shop. Accessed: March 26, 2024. [Google Scholar]

- Elzoghby AO: Gelatin-based nanoparticles as drug and gene delivery systems: Reviewing three decades of research. J Controlled Release. 2013, 172:1075–91. [CrossRef]

- Husain S, Al-Samadani KH, Najeeb S, Zafar MS, Khurshid Z, Zohaib S, Qasim SB: Chitosan Biomaterials for Current and Potential Dental Applications. Materials. 2017, 10:602. [CrossRef]

- Fadilah NIM, Phang SJ, Kamaruzaman N, et al.: Antioxidant Biomaterials in Cutaneous Wound Healing and Tissue Regeneration: A Critical Review. Antioxidants. 2023, 12:787. [CrossRef]

- Kumar Gupta G, De S, Franco A, Balu AM, Luque R: Sustainable Biomaterials: Current Trends, Challenges and Applications. Molecules. 2015, 21:48. [CrossRef]

- Moshood TD, Nawanir G, Mahmud F, Mohamad F, Ahmad MH, AbdulGhani A: Sustainability of biodegradable plastics: New problem or solution to solve the global plastic pollution? Curr Res Green Sustain Chem. 2022, 5:100273. [CrossRef]

- Hou W, Miyazaki S, Takada M, Komai T: Sustained release of indomethacin from chitosan granules. Chem Pharm Bull (Tokyo). 1985, 33:3986–92. [CrossRef]

- Dash M, Chiellini F, Ottenbrite RM, Chiellini E: Chitosan—A versatile semi-synthetic polymer in biomedical applications. Prog Polym Sci. 2011, 36:981–1014. [CrossRef]

- Zhang Y, Zhang M: Microstructural and mechanical characterization of chitosan scaffolds reinforced by calcium phosphates. J Non-Cryst Solids. 2001, 282:159–64. [CrossRef]

- Peng T, Gibula P, Yao K, Goosen MFA: Role of polymers in improving the results of stenting in coronary arteries. Biomaterials. 1996, 17:685–94. [CrossRef]

- Kılıçay E, Demirbilek M, Türk M, Güven E, Hazer B, Denkbas EB: Preparation and characterization of poly(3-hydroxybutyrate-co-3-hydroxyhexanoate) (PHBHHX) based nanoparticles for targeted cancer therapy. Eur J Pharm Sci. 2011, 44:310–20. [CrossRef]

- Chen L, Li X, Li L, Guo S: Acetylated starch-based biodegradable materials with potential biomedical applications as drug delivery systems. Curr Appl Phys. 2007, 7:e90–3. [CrossRef]

- Chen L, Li X, Li L, Guo S: Acetylated starch-based biodegradable materials with potential biomedical applications as drug delivery systems. Curr Appl Phys. 2007, 7:e90–3. [CrossRef]

- Park S-B, Lih E, Park K-S, Joung YK, Han DK: Biopolymer-based functional composites for medical applications. Prog Polym Sci. 2017, 68:77–105. [CrossRef]

- Caldas M, Santos AC, Veiga F, Rebelo R, Reis RL, Correlo VM: Melanin nanoparticles as a promising tool for biomedical applications – a review. Acta Biomater. 2020, 105:26–43. [CrossRef]

- Freitas AAR, Ribeiro AJ, Santos AC, et al.: Sterculia striata gum as a potential oral delivery system for protein drugs. Int J Biol Macromol. 2020, 164:1683–92. [CrossRef]

- Hussain Z, Katas H, Mohd Amin MCI, Kumolosasi E, Buang F, Sahudin S: Self-assembled polymeric nanoparticles for percutaneous co-delivery of hydrocortisone/hydroxytyrosol: An ex vivo and in vivo study using an NC/Nga mouse model. Int J Pharm. 2013, 444:109–19. [CrossRef]

- Md S, Kuldeep Singh JKA, Waqas M, et al.: Nanoencapsulation of betamethasone valerate using high pressure homogenization-solvent evaporation technique: optimization of formulation and process parameters for efficient dermal targeting. Drug Dev Ind Pharm. 2019, 45:323–32. [CrossRef]

- Dadashzadeh A, Imani R, Moghassemi S, Omidfar K, Abolfathi N: Study of hybrid alginate/gelatin hydrogel-incorporated niosomal Aloe vera capable of sustained release of Aloe vera as potential skin wound dressing. Polym Bull. 2020, 77:387–403. [CrossRef]

- Szekalska M, Sosnowska K, Tomczykowa M, Winnicka K, Kasacka I, Tomczyk M: In vivo anti-inflammatory and anti-allergic activities of cynaroside evaluated by using hydrogel formulations. Biomed Pharmacother. 2020, 121:109681. [CrossRef]

- Salehi M, Ehterami A, Farzamfar S, Vaez A, Ebrahimi-Barough S: Accelerating healing of excisional wound with alginate hydrogel containing naringenin in rat model. Drug Deliv Transl Res. 2021, 11:142–53. [CrossRef]

- Han X, Alu A, Liu H, Shi Y, Wei X, Cai L, Wei Y: Biomaterial-assisted biotherapy: A brief review of biomaterials used in drug delivery, vaccine development, gene therapy, and stem cell therapy. Bioact Mater. 2022, 17:29–48. [CrossRef]

- Sun G, Zhang X, Shen Y-I, et al.: Dextran hydrogel scaffolds enhance angiogenic responses and promote complete skin regeneration during burn wound healing. Proc Natl Acad Sci. 2011, 108:20976–81. [CrossRef]

- Li Z, Song J, Zhang J, et al.: Topical application of silk fibroin-based hydrogel in preventing hypertrophic scars. Colloids Surf B Biointerfaces. 2020, 186:110735. [CrossRef]

- Dong M, Mao Y, Zhao Z, Zhang J, Zhu L, Chen L, Cao L: Novel fabrication of antibiotic containing multifunctional silk fibroin injectable hydrogel dressing to enhance bactericidal action and wound healing efficiency on burn wound: In vitro and in vivo evaluations. Int Wound J. 2021, 19:679–91. [CrossRef]

- Oryan A, Jalili M, Kamali A, Nikahval B: The concurrent use of probiotic microorganism and collagen hydrogel/scaffold enhances burn wound healing: An in vivo evaluation. Burns. 2018, 44:1775–86. [CrossRef]

- Yoon DS, Lee Y, Ryu HA, et al.: Cell recruiting chemokine-loaded sprayable gelatin hydrogel dressings for diabetic wound healing. Acta Biomater. 2016, 38:59–68. [CrossRef]

- Pawar V, Maske P, Khan A, Ghosh A, Keshari R, Bhatt M, Srivastava R: Responsive Nanostructure for Targeted Drug Delivery. J Nanotheranostics. 2023, 4:55–85. [CrossRef]

- Malhotra N, Joshi M, Dey S, Sahoo R, Verma S, Asish K: Recent trends in chronic pain medicine. Indian J Anaesth. 2023, 67:123–9. [CrossRef]

- Gu X, Carroll Turpin MA, Romero-Ortega MI: Biomaterials and Regenerative Medicine in Pain Management. Curr Pain Headache Rep. 2022, 26:533–41. [CrossRef]

- Makadia HK, Siegel SJ. Poly Lactic-co-Glycolic Acid (PLGA) as Biodegradable Controlled Drug Delivery Carrier. Polymers. 2011; 3(3):1377-1397. [CrossRef]

- Trucillo P, Campardelli R, Reverchon E. Liposomes: From Bangham to Supercritical Fluids. Processes. 2020; 8(9):1022. [CrossRef]

- Tønnesen HH, Karlsen J: Alginate in drug delivery systems. Drug Dev Ind Pharm. 2002, 28:621–30. [CrossRef]

- Tao F, Ma S, Tao H, et al.: Chitosan-based drug delivery systems: From synthesis strategy to osteomyelitis treatment – A review. Carbohydr Polym. 2021, 251:117063. [CrossRef]

- How KN, Yap WH, Lim CLH, Goh BH, Lai ZW: Hyaluronic Acid-Mediated Drug Delivery System Targeting for Inflammatory Skin Diseases: A Mini Review. Front Pharmacol. 2020, 11. [CrossRef]

- Sun S, Cui Y, Yuan B, et al.: Drug delivery systems based on polyethylene glycol hydrogels for enhanced bone regeneration. Front Bioeng Biotechnol. 2023, 11:1117647. [CrossRef]

- Haimhoffer Á, Rusznyák Á, Réti-Nagy K, et al.: Cyclodextrins in Drug Delivery Systems and Their Effects on Biological Barriers. Sci Pharm. 2019, 87:33. [CrossRef]

- Wang J, Li B, Qiu L, Qiao X, Yang H: Dendrimer-based drug delivery systems: history, challenges, and latest developments. J Biol Eng. 2022, 16:18. [CrossRef]

- Rancan F, Papakostas D, Hadam S, et al.: Investigation of Polylactic Acid (PLA) Nanoparticles as Drug Delivery Systems for Local Dermatotherapy. Pharm Res. 2009, 26:2027–36. [CrossRef]

- Chaudhuri A, Ramesh K, Kumar DN, Dehari D, Singh S, Kumar D, Agrawal AK: Polymeric micelles: A novel drug delivery system for the treatment of breast cancer. J Drug Deliv Sci Technol. 2022, 77:103886. [CrossRef]

- Pattanashetti NA, Heggannavar GB, Kariduraganavar MY: Smart Biopolymers and their Biomedical Applications. Procedia Manuf. 2017, 12:263–79. [CrossRef]

- Bello AB, Kim D, Kim D, Park H, Lee S-H: Engineering and Functionalization of Gelatin Biomaterials: From Cell Culture to Medical Applications. Tissue Eng Part B Rev. 2020, 26:164–80. [CrossRef]

- Wachol-Drewek Z, Pfeiffer M, Scholl E: Comparative investigation of drug delivery of collagen implants saturated in antibiotic solutions and a sponge containing gentamicin. Biomaterials. 1996, 17:1733–8. [CrossRef]

- Tenchov R, Bird R, Curtze AE, Zhou Q: Lipid Nanoparticles─From Liposomes to mRNA Vaccine Delivery, a Landscape of Research Diversity and Advancement. ACS Nano. 2021, 15:16982–7015. [CrossRef]

- Patel N, Davis Z, Hofmann C, Vlasak J, Loughney JW, DePhillips P, Mukherjee M: Development and Characterization of an In Vitro Cell-Based Assay to Predict Potency of mRNA–LNP-Based Vaccines. Vaccines. 2023, 11:1224. [CrossRef]

- Liang Z, Zhu H, Wang X, et al.: Adjuvants for Coronavirus Vaccines. Front Immunol. 2020, 11:. [CrossRef]

- Elmowafy E, Abdal-Hay A, Skouras A, Tiboni M, Casettari L, Guarino V: Polyhydroxyalkanoate (PHA): applications in drug delivery and tissue engineering. Expert Rev Med Devices. 2019, 16:467–82. [CrossRef]

- Chaikof EL, Matthew H, Kohn J, Mikos AG, Prestwich GD, Yip CM: Biomaterials and Scaffolds in Reparative Medicine. Ann N Y Acad Sci. 2002, 961:96–105. [CrossRef]

- Song W, Lima AC, Mano JF: Bioinspired methodology to fabricate hydrogel spheres for multi-applications using superhydrophobic substrates. Soft Matter. 2010, 6:5868–71. [CrossRef]

- Hassan N, Verdinelli V, Ruso JM, Messina PV: Assessing structure and dynamics of fibrinogen films on silicon nanofibers: towards hemocompatibility devices. Soft Matter. 2012, 8:6582–92. [CrossRef]

- Misra SK, Ostadhossein F, Babu R, et al.: 3D-Printed Multidrug-Eluting Stent from Graphene-Nanoplatelet-Doped Biodegradable Polymer Composite. Adv Healthc Mater. 2017, 6:1700008. [CrossRef]

- Dienel KEG, Van Bochove B, Seppälä JV: Additive Manufacturing of Bioactive Poly(trimethylene carbonate)/β-Tricalcium Phosphate Composites for Bone Regeneration. Biomacromolecules. 2020, 21:366–75. [CrossRef]

- Goh BT, Teh LY, Tan DBP, Zhang Z, Teoh SH: Novel 3 D polycaprolactone scaffold for ridge preservation – a pilot randomised controlled clinical trial. Clin Oral Implants Res. 2015, 26:271–7. [CrossRef]

- Reddy N, Reddy R, Jiang Q: Crosslinking biopolymers for biomedical applications. Trends Biotechnol. 2015, 33:362–9. [CrossRef]

- Wróblewska-Krepsztul J, Rydzkowski T, Michalska-Pożoga I, Thakur VK: Biopolymers for Biomedical and Pharmaceutical Applications: Recent Advances and Overview of Alginate Electrospinning. Nanomaterials. 2019, 9:404. [CrossRef]

- Gagliardi A, Giuliano E, Venkateswararao E, Fresta M, Bulotta S, Awasthi V, Cosco D: Biodegradable Polymeric Nanoparticles for Drug Delivery to Solid Tumors. Front Pharmacol. 2021, 12:601626. [CrossRef]

- Shim J-H, Won J-Y, Sung S-J, Lim D-H, Yun W-S, Jeon Y-C, Huh J-B. Comparative Efficacies of a 3D-Printed PCL/PLGA/β-TCP Membrane and a Titanium Membrane for Guided Bone Regeneration in Beagle Dogs. Polymers. 2015; 7(10):2061-2077. [CrossRef]

- Zhang H, Mao X, Zhao D, et al.: Three dimensional printed polylactic acid-hydroxyapatite composite scaffolds for prefabricating vascularized tissue engineered bone: An in vivo bioreactor model. Sci Rep. 2017, 7:15255. [CrossRef]

- Tripathi D, Rastogi K, Tyagi P, et al.: Comparative Analysis of Collagen and Chitosan-based Dressing for Haemostatic and Wound Healing Application. AAPS PharmSciTech. 2021, 22:76. [CrossRef]

- Álvarez-Castillo E, Aguilar JM, Bengoechea C, López-Castejón ML, Guerrero A: Rheology and Water Absorption Properties of Alginate–Soy Protein Composites. Polymers. 2021, 13:1807. [CrossRef]

- Jensen G, Holloway JL, Stabenfeldt SE: Hyaluronic Acid Biomaterials for Central Nervous System Regenerative Medicine. Cells. 2020, 9:2113. [CrossRef]

- Nelson DW, Gilbert RJ: Extracellular matrix-mimetic hydrogels for treating neural tissue injury: a focus on fibrin, hyaluronic acid, and elastin-like polypeptide hydrogels. Adv Healthc Mater. 2021, 10:e2101329. [CrossRef]

- Grabska-Zielińska S, Sionkowska A: How to Improve Physico-Chemical Properties of Silk Fibroin Materials for Biomedical Applications?—Blending and Cross-Linking of Silk Fibroin—A Review. Materials. 2021, 14:1510. [CrossRef]

- Mahmood A, Patel D, Hickson B, DesRochers J, Hu X: Recent Progress in Biopolymer-Based Hydrogel Materials for Biomedical Applications. Int J Mol Sci. 2022, 23:1415. [CrossRef]

- Khaliq T, Sohail M, Minhas MU, et al.: Self-crosslinked chitosan/κ-carrageenan-based biomimetic membranes to combat diabetic burn wound infections. Int J Biol Macromol. 2022, 197:157–68. [CrossRef]

- Klavert J, van der Eerden BCJ: Fibronectin in Fracture Healing: Biological Mechanisms and Regenerative Avenues. Front Bioeng Biotechnol. 2021, 9:663357. [CrossRef]

- Microbial Polyhydroxyalkanoates Granules: An Approach Targeting Biopolymer for Medical Applications and Developing Bone Scaffolds - PMC. Accessed: , 2024. 14 March.

- Sarangthem V, Singh TD, Dinda AK: Emerging Role of Elastin-Like Polypeptides in Regenerative Medicine. Adv Wound Care. 2021, 10:257–69. [CrossRef]

- Sellappan LK, Anandhavelu S, Doble M, Perumal G, Jeon J-H, Vikraman D, Kim H-S: Biopolymer film fabrication for skin mimetic tissue regenerative wound dressing applications. Int J Polym Mater Polym Biomater. 2022, 71:196–207. [CrossRef]

- Varma K, Gopi S: Chapter 7 - Biopolymers and their role in medicinal and pharmaceutical applications. In: Thomas S, Gopi S, Amalraj A, eds. Biopolymers and their Industrial Applications. Elsevier; 2021. 175–91. [CrossRef]

- Mao J, Zhao L, De Yao K, Shang Q, Yang G, Cao Y. Study of novel chitosan-gelatin artificial skin in vitro. J Biomed Mater Res A. 2003 Feb 1;64(2):301-8. [CrossRef]

- Little CJ, Bawolin NK, Chen X: Mechanical Properties of Natural Cartilage and Tissue-Engineered Constructs. Tissue Eng Part B Rev. 2011, 17:213–27. [CrossRef]

- Kulinets I: 1 - Biomaterials and their applications in medicine. In: Amato SF, Ezzell RM, eds. Regulatory Affairs for Biomaterials and Medical Devices. Woodhead Publishing; 2015. 1–10. [CrossRef]

- Deng M, Kumbar SG, Wan Y, Toti US, Allcock HR, Laurencin CT: Polyphosphazene polymers for tissue engineering: an analysis of material synthesis, characterization and applications. Soft Matter. 2010, 6:3119–32. [CrossRef]

- Schatzlein, AG. Non-viral vectors in cancer gene therapy: principles and progress. Anticancer Drugs. 2001 Apr;12(4):275-304. [CrossRef]

- Kumar N, Langer RS, Domb AJ: Polyanhydrides: an overview. Adv Drug Deliv Rev. 2002, 54:889–910. [CrossRef]

- Leong KW, Kost J, Mathiowitz E, Langer R: Polyanhydrides for controlled release of bioactive agents. Biomaterials. 1986, 7:364–71. [CrossRef]

- Torres MP, Determan AS, Anderson GL, Mallapragada SK, Narasimhan B: Amphiphilic polyanhydrides for protein stabilization and release. Biomaterials. 2007, 28:108–16. [CrossRef]

- Varma K, Gopi S: Biopolymers and their role in medicinal and pharmaceutical applications. In: Biopolymers and their Industrial Applications. Elsevier; 2021. 175–91. [CrossRef]

- Yang X, Zhao K, Chen G-Q: Effect of surface treatment on the biocompatibility of microbial polyhydroxyalkanoates. Biomaterials. 2002, 23:1391–7. [CrossRef]

- Ciapetti G, Granchi D, Savarino L, Cenni E, Magrini E, Baldini N, Giunti A: In vitro testing of the potential for orthopedic bone cements to cause apoptosis of osteoblast-like cells. Biomaterials. 2002, 23:617–27. [CrossRef]

- Lee WK, Park KD, Keun Han D, Suh H, Park J-C, Kim YH: Heparinized bovine pericardium as a novel cardiovascular bioprosthesis. Biomaterials. 2000, 21:2323–30. [CrossRef]

- Rundén-Pran E, Mariussen E, El Yamani N, Elje E, Longhin EM, Dusinska M: The colony forming efficiency assay for toxicity testing of nanomaterials—Modifications for higher-throughput. Front Toxicol. 2022, 4:983316. [CrossRef]

- Kumar Gupta G, De S, Franco A, Balu AM, Luque R: Sustainable Biomaterials: Current Trends, Challenges and Applications. Molecules. 2015, 21:48. [CrossRef]

- Dutta V, Verma R, Gopalkrishnan C, Yuan M-H, Batoo KM, Jayavel R, Chauhan A, Lin K-YA, Balasubramani R, Ghotekar S. Bio-Inspired Synthesis of Carbon-Based Nanomaterials and Their Potential Environmental Applications: A State-of-the-Art Review. Inorganics, 1: 10(10).

- Nongbet A, Mishra AK, Mohanta YK, et al.: Nanofertilizers: A Smart and Sustainable Attribute to Modern Agriculture. Plants. 2022, 11:2587. [CrossRef]

- Xiang Y, Xin L, Hu J, Li C, Qi J, Hou Y, Wei X. Advances in the Applications of Graphene-Based Nanocomposites in Clean Energy Materials. Crystals. 2021; 11(1):47.

- R R, Philip E, Madhavan A, et al.: Advanced biomaterials for sustainable applications in the food industry: Updates and challenges. Environ Pollut. 2021, 283:117071. [CrossRef]

- Huzum B, Puha B, Necoara RM, et al.: Biocompatibility assessment of biomaterials used in orthopedic devices: An overview (Review). Exp Ther Med. 2021, 22:1315. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).