1. Introduction

Agricultural intensification, population growth and climate change have put pressure on available water resources [

1]. The agricultural sector is the largest global consumer of freshwater in the world. According to the United Nations World Water Development Report 2020 [

2], croplands are responsible for 69% of water withdrawals. Therefore, there is an urgent need to adopt efficient irrigation systems to reduce water consumption in agriculture, mitigate climate change and improve farm profitability.

One way to solve this problem is to reduce inefficiencies in irrigation management. Automated drip irrigation systems are an innovative irrigation management tool that allows the continuous monitoring of soil moisture in real time, maintaining specified soil water levels so that the plant does not suffer stress and enabling adjusted harvests in terms of quality and quantity. Soil moisture is a key factor in the soil-plant-atmosphere water cycle and is a critical parameter for understanding soil water movement [

3]. Soil moisture sensors (SMSs) have long been used in agriculture for accurate irrigation scheduling [

4], as they measure soil moisture continuously, nondestructively and at different soil depths.

Soil moisture is the amount of water present in the soil pores and can be measured using direct methods (soil sampling) or indirect methods (soil moisture sensing). Direct methods such as gravimetric or volumetric techniques directly measure the moisture content present in the soil [

5]. The gravimetric method involves calculation of soil moisture according to the difference in weight between the soil in natural conditions and after being dried in an oven at 105°C to constant weight. The volumetric water content can be calculated by multiplying the gravimetric water content by the bulk soil density [

6]. While these methods are highly accurate and used to calibrate soil moisture sensors [

7,

8,

9,

10], they are destructive techniques which require a lot of labor to collect the samples and do not provide real-time monitoring of soil moisture.

Indirect methods of soil moisture measurement are based on measuring some soil characteristic in response to soil moisture changes. Such methods include the deployment of a variety of sensors that can be classified by the technology they use: neutron probes [

11], tensiometers [

12], gypsum blocks [

13], granular matrix sensors [

14], resistive probes [

15], time domain reflectometry (TDR) sensors [

16], frequency domain reflectometry (FDR) sensors [

17], time domain transmission (TDT) sensors and coaxial impedance dielectric reflectometry sensors ][

18]. Of the methods mentioned above, FDR and TDR sensors are the most widely used at present to estimate volumetric water content (ϴv) in the soil.

Conversion or calibration equations provided by manufacturers transform raw sensor measurements into ϴv [

19]. Typically, soil moisture sensors are calibrated under limited laboratory conditions, which are not always appropriate for field conditions. The values obtained by soil moisture sensors are affected by site characteristics (soil type and soil moisture), soil homogeneity, and the presence of stones and roots [

20,

21]. Sensor manufacturers provide generic equations for mineral and organic soils but acknowledge that SMSs are more accurate when soil-specific calibration equations are used [

22]. The performance of a given SMS can be increased by 2-3% if soil-specific calibration is performed [

23]. Therefore, to improve the accuracy and working range of a soil moisture sensor, it is essential to perform soil-specific calibration to match the particular plot conditions.

Currently, there is a wide variety of SMSs on the market, which means that farmers must have technical knowledge when choosing a suitable sensor for each soil type, land use and irrigation system used. This, coupled with the location, installation and adjustment of the sensor to a specific area, ensures the success of proper sensor-based decision making.

One of the objectives of the Life4Doñana project was to demonstrate and promote the adoption of an automatic on-demand irrigation system in strawberry cultivation in an intensive system under plastic. This automatic irrigation system was to increase irrigation efficiency, reduce water withdrawals and nutrient pollution in the area of influence of the Doñana National Park (Huelva, Spain). For this reason, it is necessary to identify the sensor that is best suited to the particular conditions of the study area.

The objective of this work is to evaluate the performance of six moisture sensors (HydraProbe, Teros 10, Teros 11, EnviroPro, CS616 and Drill&Drop) and three tensiometers (Irrometer RSU-C-34, Teros 32 and Teros 21) available on the market and to establish calibration equations for a typical sandy soil used for strawberry production in the Doñana National Park (Huelva, Spain). This objective was established as part of the LIFE4DOÑANA project to identify the sensors best suited to an on-demand automated irrigation system for the soil conditions and crop needs of the Doñana environment in order to obtain greater economic, productive and environmental benefits.

2. Materials and Methods

2.1. Moisture Sensor Description

- (a)

Impedance

The Stevens HydraProbe II sensor is based on a principle called coaxial dielectric impedance reflectometry. The HydraProbe operates at 50 MHz and measures real (Ꜫ) and imaginary (Ꜫ´) dielectric permittivities, helping to reduce measurement errors in the measurement caused by the effects of temperature, salinity and soil type. The raw signal outputs are five analog dc voltages which are used to calculate Ꜫ, Ꜫ´, bulk electrical conductivity, and temperature [

24]. The general calibration equation provided by the manufacturer is as follows:

- (b)

Frequency domain reflectometry (FDR)

FDR sensors are based on the resonance characteristic of RLC (resistor, inductor and capacitor) circuits in which a capacitor is formed by two electrodes and surrounding soil [

25]. These sensors measure the volumetric content indirectly through the apparent dielectric constant of the soil, but by measuring the time it takes to charge a capacitor that uses the soil as a dielectric. They are therefore also called capacitive sensors. They operate at frequencies between 10 and 100 MHz. The equations provided by the manufacturers for mineral soils of the different FDR sensors are as follows:

where RAW is the raw sensor output ; A, B and C are coefficients for a range of sand soil

- (c)

Time domain reflectometry (TDR)

The principle behind the TDR method is the determination of the velocity of propagation and return (or reflection) of an electromagnetic wave in a medium [

26]. The presence of water in the soil decreases the speed at which the electromagnetic wave travels, which allows the measurement of soil water content. The general calibration equation provided by the manufacturer for mineral soils is as follows:

The characteristics of the study sensors are shown in

Table 1.

2.2. Tensiometers

The main characteristics of the tensiometers are detailed in

Table 2.

2.3. Field Capacity, Permanent Wilting Point and Water Available to the Plant

To determine the field capacity (CC) of the soil, the permanent wilting point (PWP) in the soil and the water available to the plant (WAP), the HYPROP (UMS, München, Germany) method as described by Schindler et al. [

27] was used in combination with the WP4C dewpoint potentiometer (Decagon Devices, WA, USA).

An undisturbed soil sample was collected from one of the six pilot farms that form part of the LIFE4DOÑANA project in the area surrounding the Doñana Park, Spain). The selected farm on which the samples were taken was that with a soil texture closest to the mean and median of all the farms (latitude 37º 15´68.98´´N, longitude 6º 48´19.63´´W datum WGS8). Soil texture is sandy, with an average 84% sand content, 8% silt content and 8% clay content The sample was taken with a 250 cm³ stainless steel ring on 22 January 2021 at a depth of 0.2 m in the ridge under the plant. In the laboratory, the sample was taken to capillary saturation. The sample was then analyzed with HYPROP according to the manufacturer’s specifications [

28]. The HYPROP is a device that uses the simplified evaporation method [

29]. The procedure used by HYPROP is based on the direct measurement of the water potential in the soil by inserting small tensiometers into the sample while the moisture content of the sample is progressively evaporated. The HYPROP device works at suctions of between 0 and −85 kPa.

A sample of the disturbed soil was also taken from the same farm at 0.2 m for analysis with a WP4C dew point hygrometer that measures water potential pointwise over a range from -0.1 MPa to -300 MPa. For the WP4C system, samples were sieved and wetted to varying degrees [

30]. Combining the information obtained from Hyprop and WP4, values for CC, PWP and WAP were obtained using the HYPROP-FIT software (version 4.2.2, METER Group) adjusted to the Fredlung-Xing PDI model.

Table 3.

Parameters obtained with HYPROP+WP4C.

Table 3.

Parameters obtained with HYPROP+WP4C.

| Parameter |

Soil water content |

| Field capacity |

12.40% |

| Permanent wilting point |

4.70% |

| Water available to the plant |

7.70% |

2.4. Laboratory Experiment

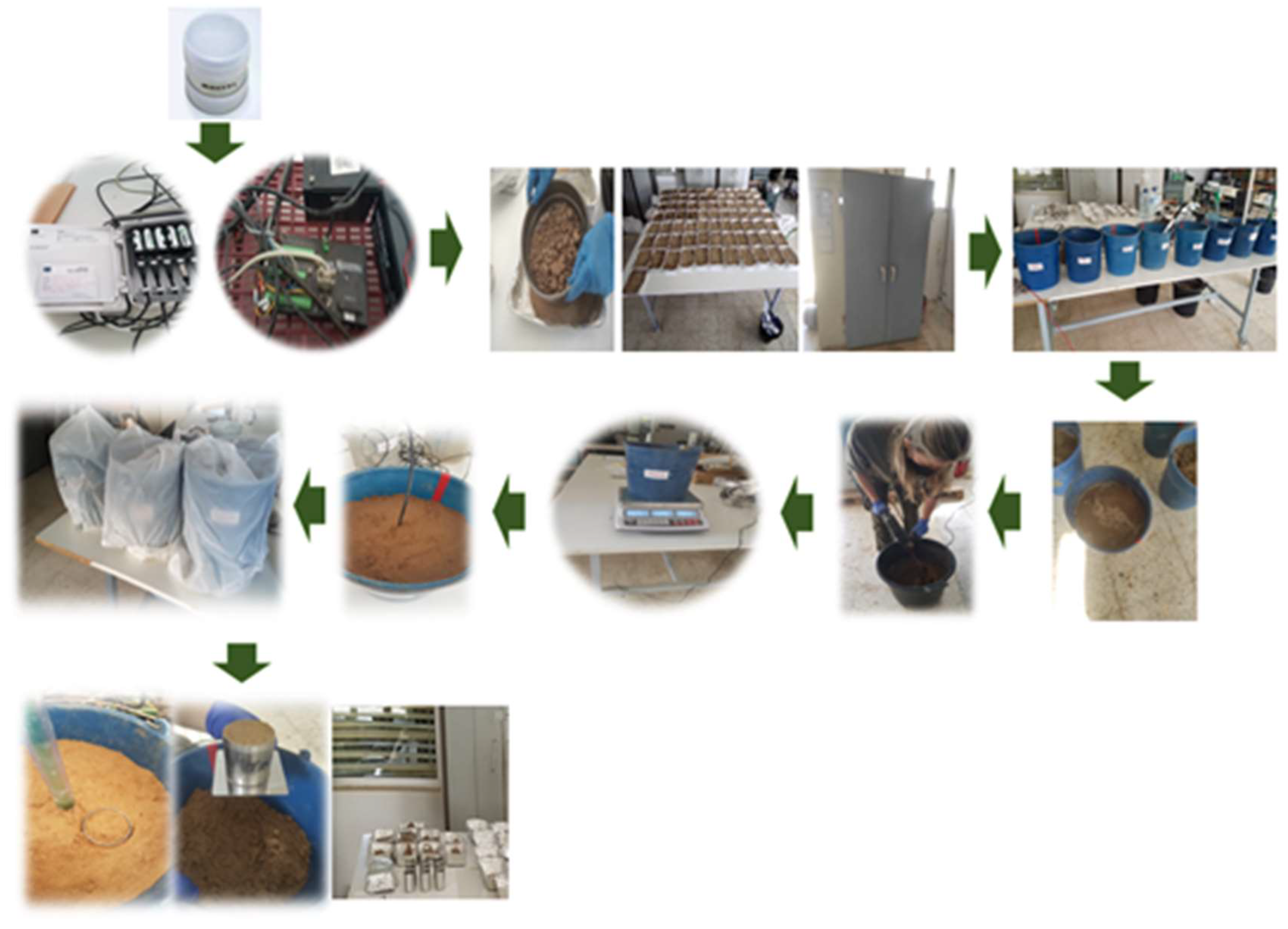

To determine the calibration curve for each of the sensors, 172 kg of soil were collected from the study plot. The process carried out was as follows:

Another soil sample was collected on 22 January, 2021 to determine the bulk density (ρa) of the study area. A cylinder of known volume (250 cm³) was used and dried in an oven at 105 ºC to constant weight (ρa=1.56 g/cm³) [

31].

The Irrometer, HydraProbe, EnviroPro, CS616 and Drill&Drop sensors were connected to a CR1000 datalogger (Campbell Scientific Inc., Logan, UT). The Teros 10, Teros 11, Teros 21 and Teros 32 sensors were connected to a ZL6 datalogger (METER Group, Inc. USA). The information stored in both dataloggers was downloaded daily.

The soil was then prepared to start the test. The soil was sieved (2-5 mm) and then put on aluminum trays and placed in an oven at 105 °C until a constant weight was reached to ensure a moisture content which we call zero.

Preparation of the containers in which the calibration process will be carried out. For all the sensors, a weight of 12 kg of processed soil was used, except for the CS616 sensor, which used a 9 kg container as the format of this sensor requires a different container.

A volume of water was added daily to the total soil (0%, 2%, 4%, 6%, 7%, 8%, 9%, 10%, 11%, 12% and 13%) until field capacity was reached.

The soil was then thoroughly mixed and left to stand for 24 hours so that the water was distributed by capillarity throughout the volume of soil.

The soil was then placed in the containers. Filling was carried out in such a way that a certain amount (weight) of soil occupied a certain volume of the container. For this purpose, the container was compacted as it was filled. In short, the aim was to guarantee a constant bulk density value close to that of the soil under natural conditions.

Subsequently, each of the containers was weighed.

The sensors were then inserted vertically into the soil and the readings recorded. The sensor was left until the following day to stabilize and 3 measurements were collected every 5 minutes. The containers and sensors were covered with plastic bags to prevent evaporation.

Simultaneously to the data acquisition from the sensors, the water content of the soil was determined at each water content level by volumetric analysis. For this, a small cylinder of known volume (98 cm³) was removed and placed on pre-weighed and numbered trays. The trays were then placed in an oven at 105°C and weighed daily until a constant weight was reached. At the end of the test, all the soil was returned to the original container (12 kg or 9 kg) where it was mixed outside the container by adding another quantity of water.

Figure 1.

Schematic diagram of the process to carry out sensor calibration.

Figure 1.

Schematic diagram of the process to carry out sensor calibration.

2.5. Statistical Analysis

Five statistical measures were computed to evaluate the accuracy and precision of the soil moisture sensors: the root mean square error (RMSE), the coefficient of determination (R²), the coefficient of variation (CV), the index of agreement (IA) and the mean bias error (MBE).

2.5.1. The Root Mean Square Error (RMSE)

The RMSE is a frequently used measure of the difference between the value predicted by a model and the “real” value actually observed. The RMSE represents the sample standard deviation of the differences between predicted and observed values [

32]. RMSE can be described by the following equation:

where N is the sample size, M is the measured (soil sample) value, and P is the predicted (sensor measurement) value. The units for the RMSE are volumetric water content (m³/m³).

2.5.2. Coefficient of Determination (R²)

The R² is used to evaluate how well a model explains or predicts future outcomes. The R² can be defined as the percentage of the response variable variation that is explained by a model. Its value is given as a percentage (0-100%). A model fits the data well if the differences between predicted and observed values are small. The value of the R² ranges between -1 and +1. The closer its value is to 1, the better the fit of the model to the variable we are trying to explain. Conversely, the closer to zero, the less well-fitted the model will be and, therefore, the less reliable it will be [

31].

The coefficient of determination is usually denoted as R², r², or R-square, referring to the squared value of the correlation coefficient, r. The r is calculated through the following equation:

where N is the sample size, M is the measured (soil sample) value, P is the predicted (sensor measurement) value, M‾ is the average measured value and P ̅ is the average predicted value.

2.5.3. The Index Of Agreement (IA)

The IA reflects the degree to which observations are correctly estimated by the model. This IA was propused by Willmott [

34], as defined in equation (9) [Willmott, 1981]. The IA varies between 0 (complete mismatch between the value estimated by the model and the observed value) and 1 (a perfect fit).

where N is the sample size, M is the measured (soil sample) value, P is the predicted (sensor measurement) value, M‾ is the average measured value.

2.5.4. Mean Bias Error (MBE)

The MBE provides information on the nature of the error associated with the ϴv measured with the sensor with respect to the ϴv taken as the reference value. An MBE of zero implies that measured ϴv and reference ϴv are unbiased, while positive and negative values of MBE imply that measured ϴv is overestimating and underestimating reference ϴ

v, respectively [

35]. The smaller the absolute value, the better the sensor performance.

where N is the sample size, M is the measured (soil sample) value, and P is the predicted (sensor measurement) value.

2.5.5. The Coefficient of Variation (CV)

The CV was determined to estimate the efficiency of the studied sensors. The CV was calculated through the following equation:

where X ̅ represents the mean of the sensor readings, and SD represents the deviations of the values from their arithmetic mean.

3. Results and Discussion

3.1. Evaluation of Factory Calibrated Moisture Sensors

The soil water content (ϴv) values measured by the sensors were compared with the results obtained by volumetric determination in the laboratory.

Table 4 shows the performance evaluation of the different sensors calibrated with the manufacturer’s equation.

Accuracy is the ability of a sensor to estimate the true water content, while precision is an indication of the uniformity or repeatability of obtaining the same result [

36]. Sensors need to have high accuracy and high precision.

For sensor accuracy, we used the RMSE (equation 7) and the R² (equation 8) to check the quality of the fit.

Fares et al. [

36] described the different categories for interpreting RMSE values: good (RMSE ≤ 0.01 m³/m³), fair (0.01 ≤ RMSE ≤ 0.05 m³/m³), poor (0.05 ≤ RMSE ≤ 0.10 m³/m³) and very poor (RMSE ≥ 0.10 m³/m³) Dong et al. [

17] used the criterion of taking into account an R² > 0.65 to assess sensor accuracy. The most accurate sensors were the HydraProbe and Teros 10, which had the highest R² and lowest RMSE. The Teros 11, Drill&Drop and CS616 sensors showed a fair RMSE and the EnviroPro sensor a poor RMSE (RMSE =0.07 m³/m³). This indicates a need to improve the factory calibrations, especially for the EnviroProbe sensor.

To evaluate the precision, the IA, MBE and CV were calculated to compare the results obtained from the sensor with the volumetric method. The range of IA is between 0 and 1, with a value of 0 indicating no agreement between measured and predicted values. A value of 1 indicates perfect agreement between observed and predicted values (Eq.(9)) [

34]. Varble and Chavez [

37] set the criteria for MBE and RMSE to within ±0.02 m³mˉ³. Dong et al., [

17] evaluated the various sensors studied according to the following criteria: RMSE<0.035 m

3/m

3, IA>0.8 and MBE±0.02 m

3/m

3. The MBE values for the Teros 11, HydraProbe and CS616 sensors underestimated the volumetric water content by an average of 0.0003 m³/m³, 0.0092 m³/m³ and 0.0072 m³/m³, respectively, with an IA>0.94. In contrast, the Teros 10, EnviroPro and Drill&Drop sensors overestimated the volumetric water content by an average of 0.0101 m³/m³, 0.0574 m³/m³ and 0.0110 m³/m³, respectively. All probes have an MBE between ± 0.02 m³/m³ and IA>0.9, except the EnviroPro. The factory calibration of the EnviroPro was therefore not very accurate in the sandy soil (MBE = 0.057 m³/m³ and IA = 0.786). The CV ranged from 2.129% for CS616 to 18.785% for Drill&Drop. Differences in CV values may be due to the specific electronics of each sensor, oscillation frequency, probe geometry, and their sensitivity to soil heterogeneity and air gaps [

23].

3.2. Evaluation of Moisture Sensors Calibrated for Sandy Soils

Correction equations for the sensors were developed (

Table 5) based on the laboratory data. In terms of accuracy, the sensors had an R²>0.96 and the RMSE values ranged from 0.007 to 0.055 m³ mˉ³ (

Table 5). The Teros 10, Teros 11, EnviroPro and Drill&Drop had a good RMSE [

36]. The CS616 sensor also had an improved RMSE. However, the HydraProbe sensor had an increased RMSE in comparison to the factory equation.

In terms of precision, all sensors had increased IA and decreased MBE, except for the HydraProbe sensor which had a lower IA and a higher MBE. The CV was also lower for all sensors except the CS616 sensor. It can therefore be concluded that all sensors improved with the adjustments made to the factory calibration, except for the HydraProbe sensor which had a more accurate factory calibration for a sandy soil.

3.3. Validation of Moisture Sensors with Sandy Soil Calibration

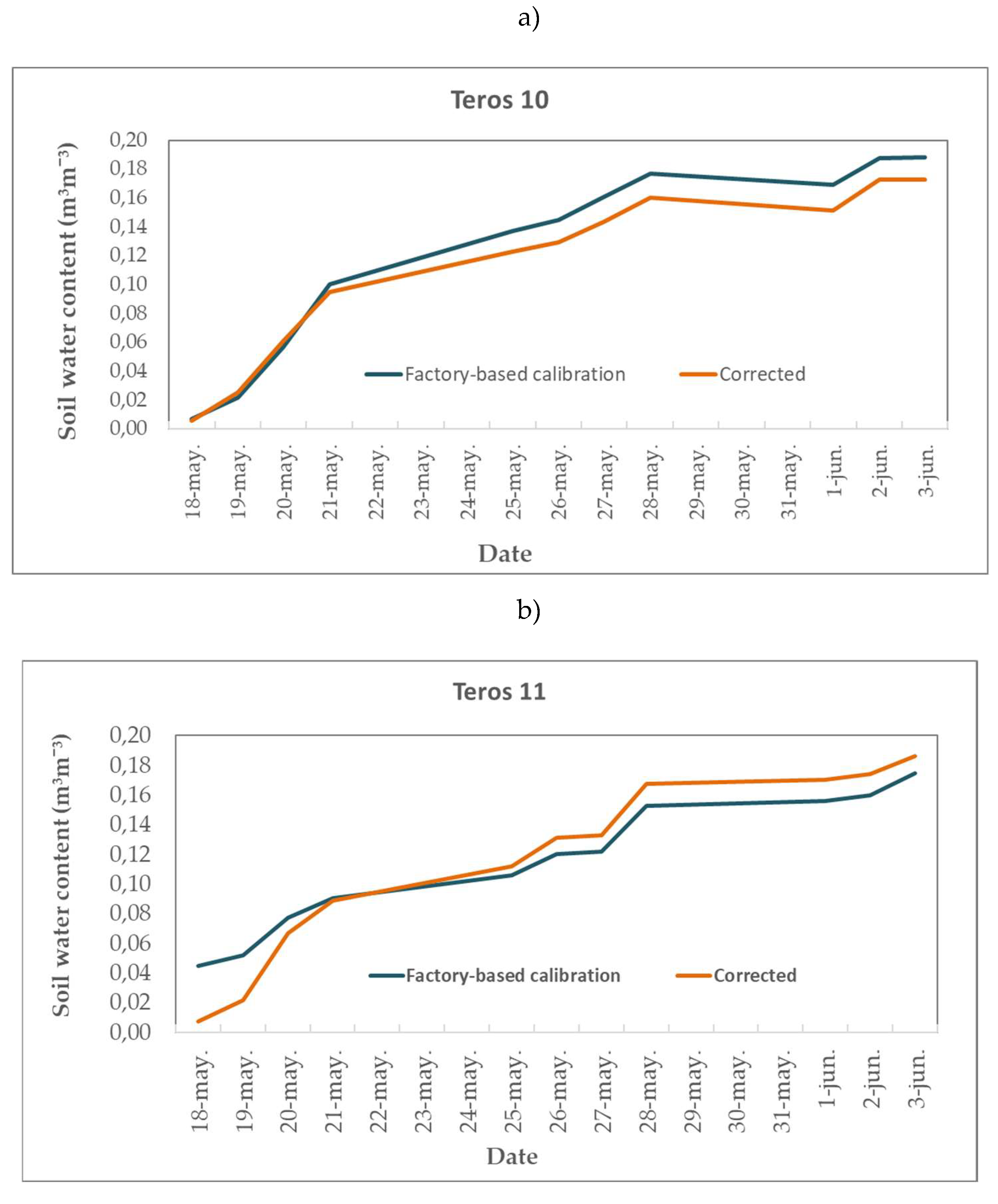

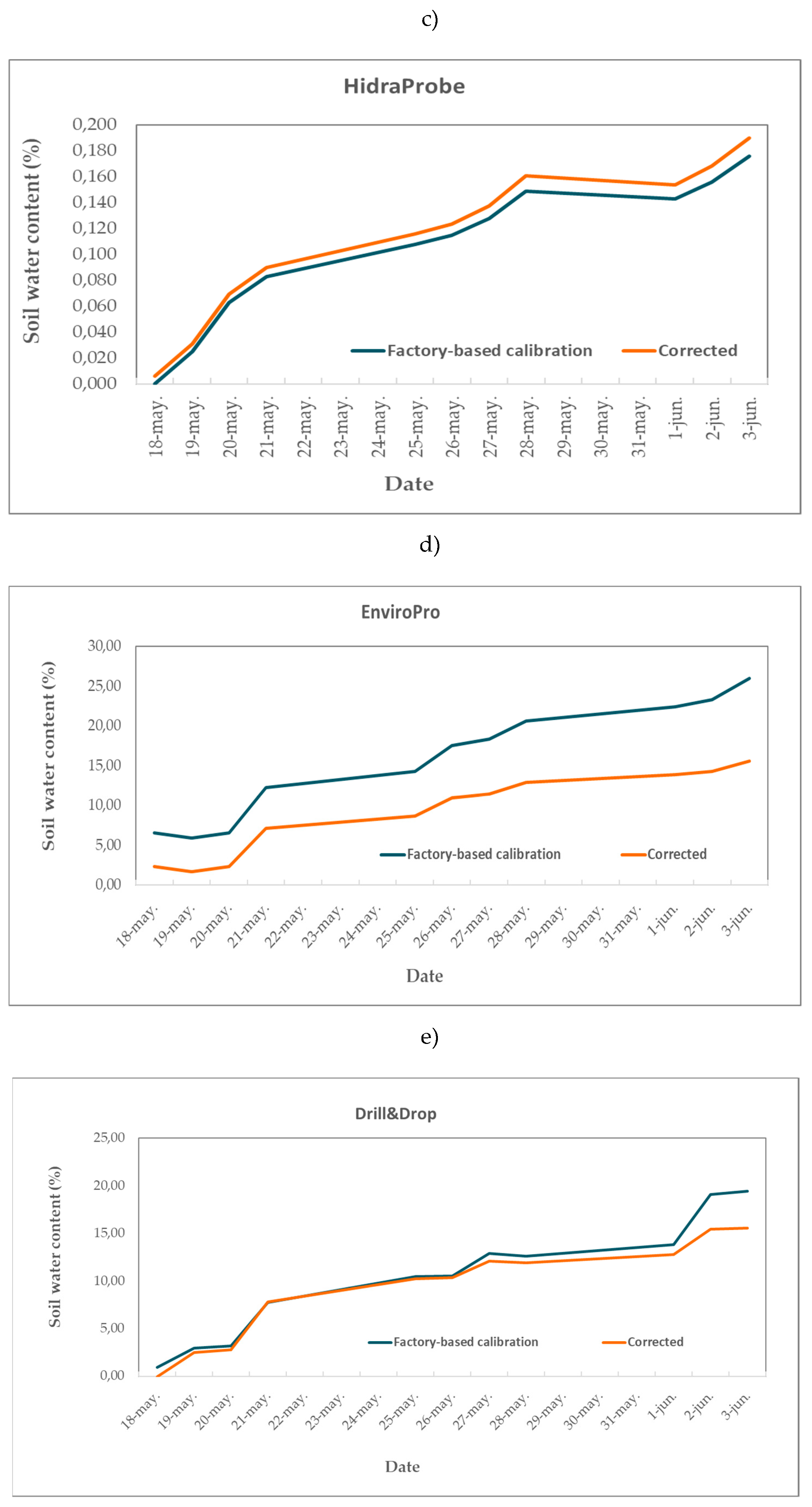

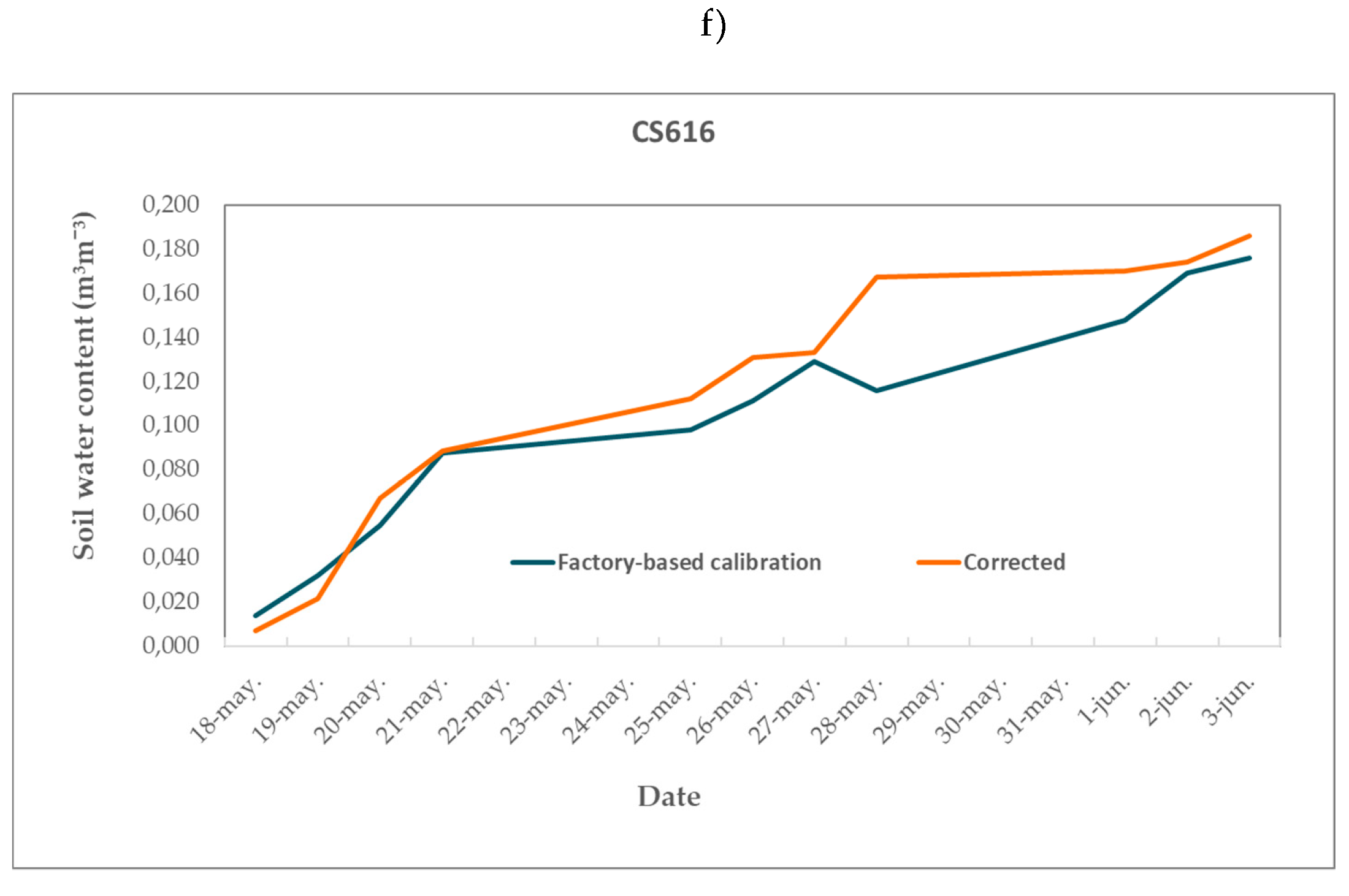

Figure 2 shows the comparisons of the factory calibration of all the soil moisture sensors with the corrected values for sandy soil throughout the calibration cycle period from 18 May to 3 June of 2021. As can be seen in the different figures, moisture evolution is compared according to the values given by the factory calibration recommended by the manufacturer for this type of soil and the values corrected with the calibration obtained during the sensor calibration work.

The Teros 10 sensor (

Figure 2a) shows similar behavior in the factory equation and the corrected equation under conditions of low soil moisture content. Above a soil moisture content of 0.10 m³/m³ there is an overestimation of the soil moisture values with the factory equation. This overestimation is similar between the values 0.14 m³/m³ and 0.18 m³/m³. Walker et al. [

38] obtained similar results in a loam soil, where soil moisture sensor readings showed a good approximation to the values obtained by gravimetry except under conditions of high soil moisture content.

In the case of Teros 11 (

Figure 2b), in contrast to Teros 10 there is an overestimation of the moisture values obtained with the factory equation at low moisture values between 0 m³/m³ and 0.04 m³/m³. Above these values, the two moisture curves are very similar, except for water contents close to saturation where the moisture values obtained with the factory equation underestimate the values obtained with the corrected equation.

From the factory equations of the Teros 10 and Teros 11 sensors (

Figure 2a,b) it can be seen that there is a certain delay in the reading of the sensors when working with relatively low moisture content (almost dry soil). Initially, the Teros 10 sensor had a reading close to 0 m³/m³ with dry soil and the Teros 11 a reading of 0.04 m³/m³. When assessing the performance of the Teros family of sensors, it is important to note that the sensors have the same shape and operate at the same frequency. The main differences between the two sensors are that the Teros 11 sensor provides information on the temperature variable and the volume of measurement is larger (1,010 cm³). These errors between readings obtained using the factory equation of one type of sensor and another may be due to the measurement volume [

32].

For the HydraProbe sensors (

Figure 2c), the soil moisture values obtained using the factory equation underestimated the moisture values obtained using the corrected equation. This discrepancy between one equation and the other is proportional for all moisture values. Better results in correlation indices were not always obtained when sensors were calibrated (

Table 5), which could be due to possible errors in sample handling, limitations of instrument operation in low moisture conditions or even the presence of preferential pathways in the containers used.

The largest differences between the factory values and the corrected values are observed in the case of the EnviroPro probe (

Figure 2d). In the case of the EnviroPro, in contrast to the HydraProbe, the factory values overestimate the actual soil moisture values obtained with the corrected equation. When the sandy soil is dry, the difference between the values obtained from the factory equation and the corrected equation is about 36%. When the sandy soil is wet, the difference between the values obtained using the two equations is much greater, around 60%. The installation technique of the soil moisture sensor plays a major role in sensor performance. Installation must be done with care, as the soil moisture sensor only measures a small volume of soil surrounding the sensor. It is essential that there is good contact between the sensor and the ground to avoid creating an air gap that can disturb the measurement [

38,

39,

40]. Other authors have indicated that factors such as soil temperature and salinity can influence sensor readings [

17] indicated that temperature fluctuations in soil are minimized as soil depth increases. In the case of the Drill&Drop sensor (

Figure 2e), the sensor readings are similar to the values obtained with the corrected equation, except that there is an overestimation of the values obtained with the factory equation for soil moisture values close to saturation.

Finally, for the CS616 sensor (

Figure 2f), when the soil is dry, the soil moisture values obtained from the factory equation and the corrected equation are similar. Around 25 May 2021, the soil moisture values obtained with the corrected equation overestimate the factory equation. This overestimation of the corrected equation values increases with increasing soil water content. Overall, the corrected equation for the CS616 sensor improved the accuracy of the sensor readings under high moisture conditions in a sandy soil field. Dong et al. [

17] obtained similar results when evaluating the corrected equation for the CS616 sensor in a sandy soil field.

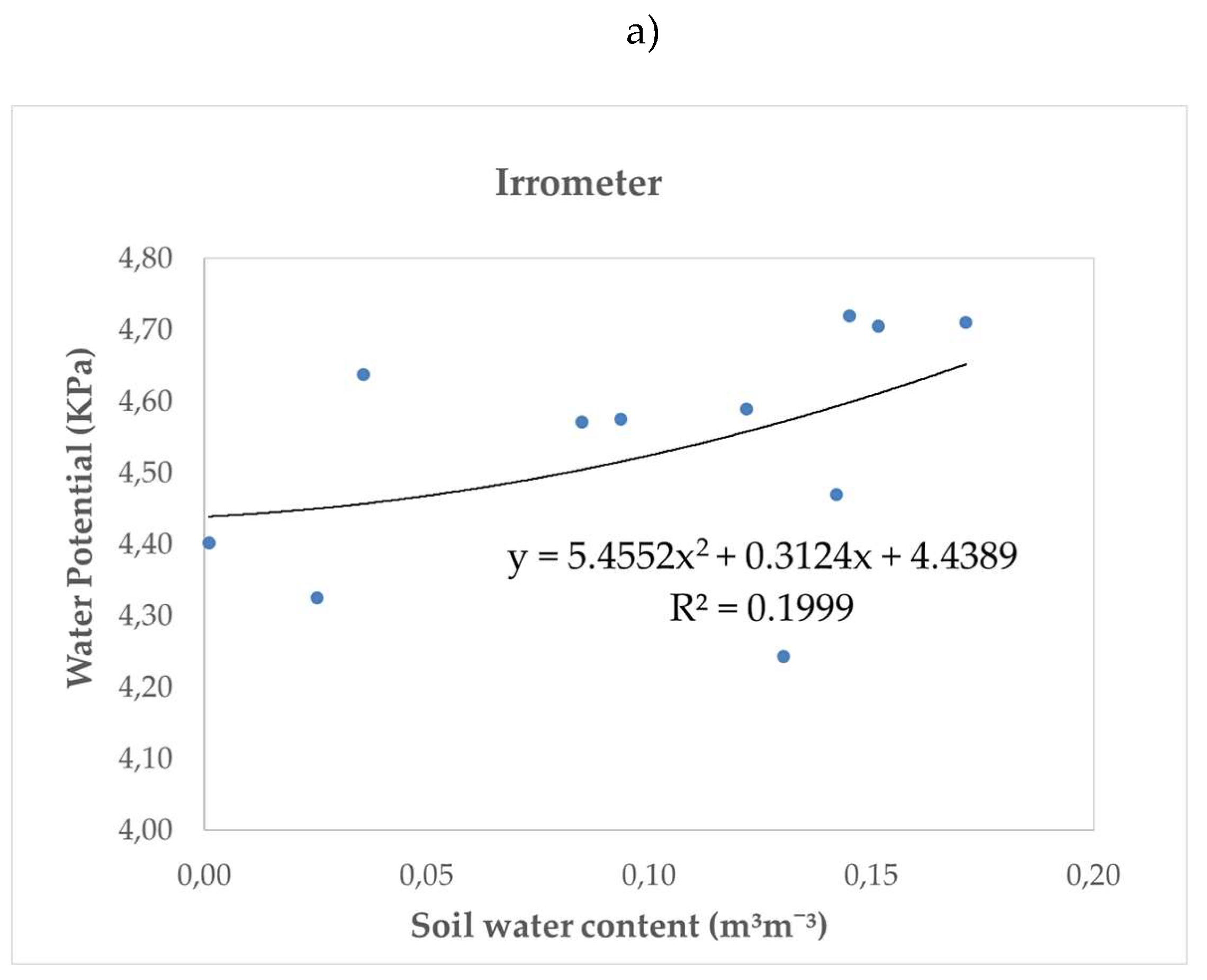

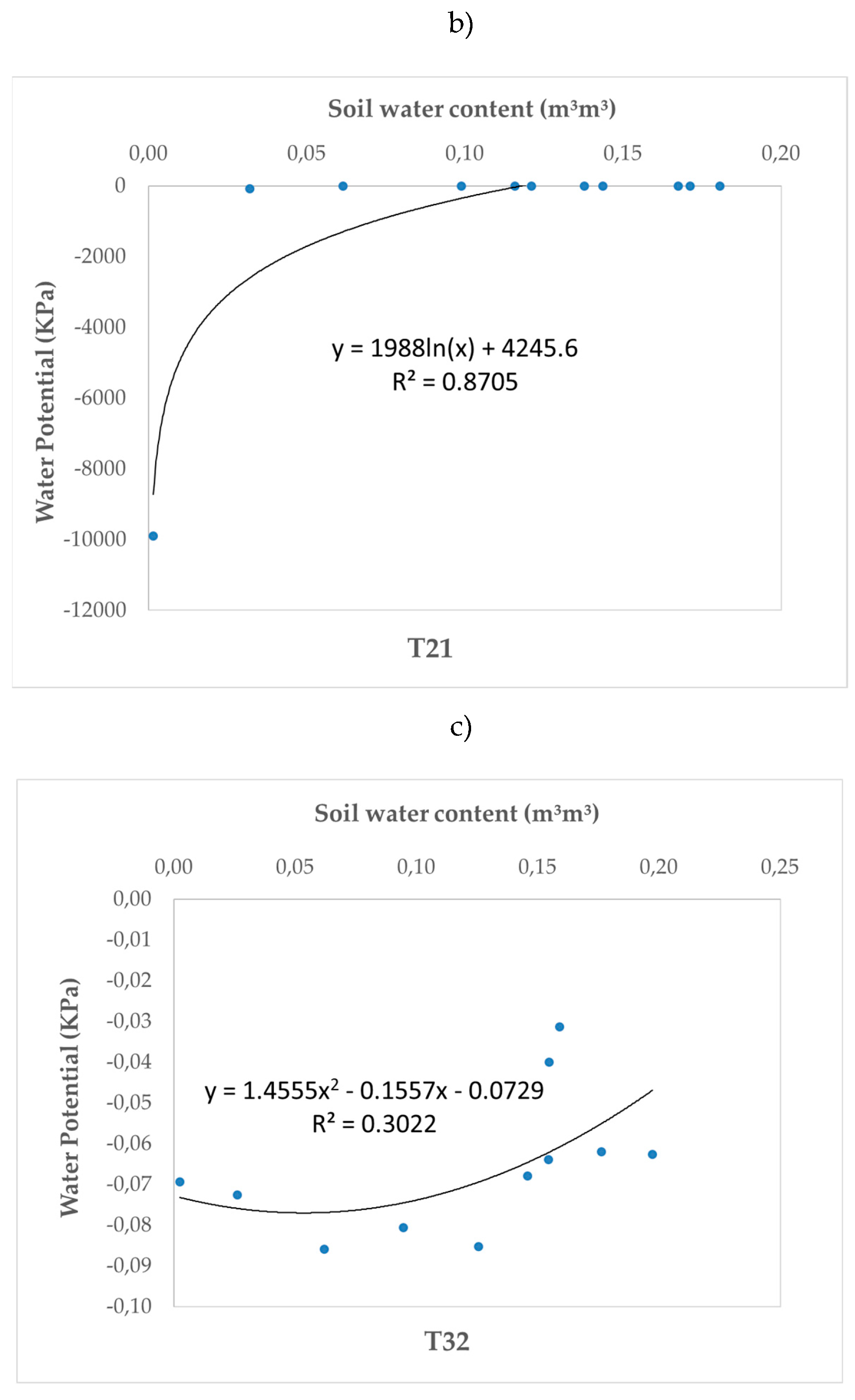

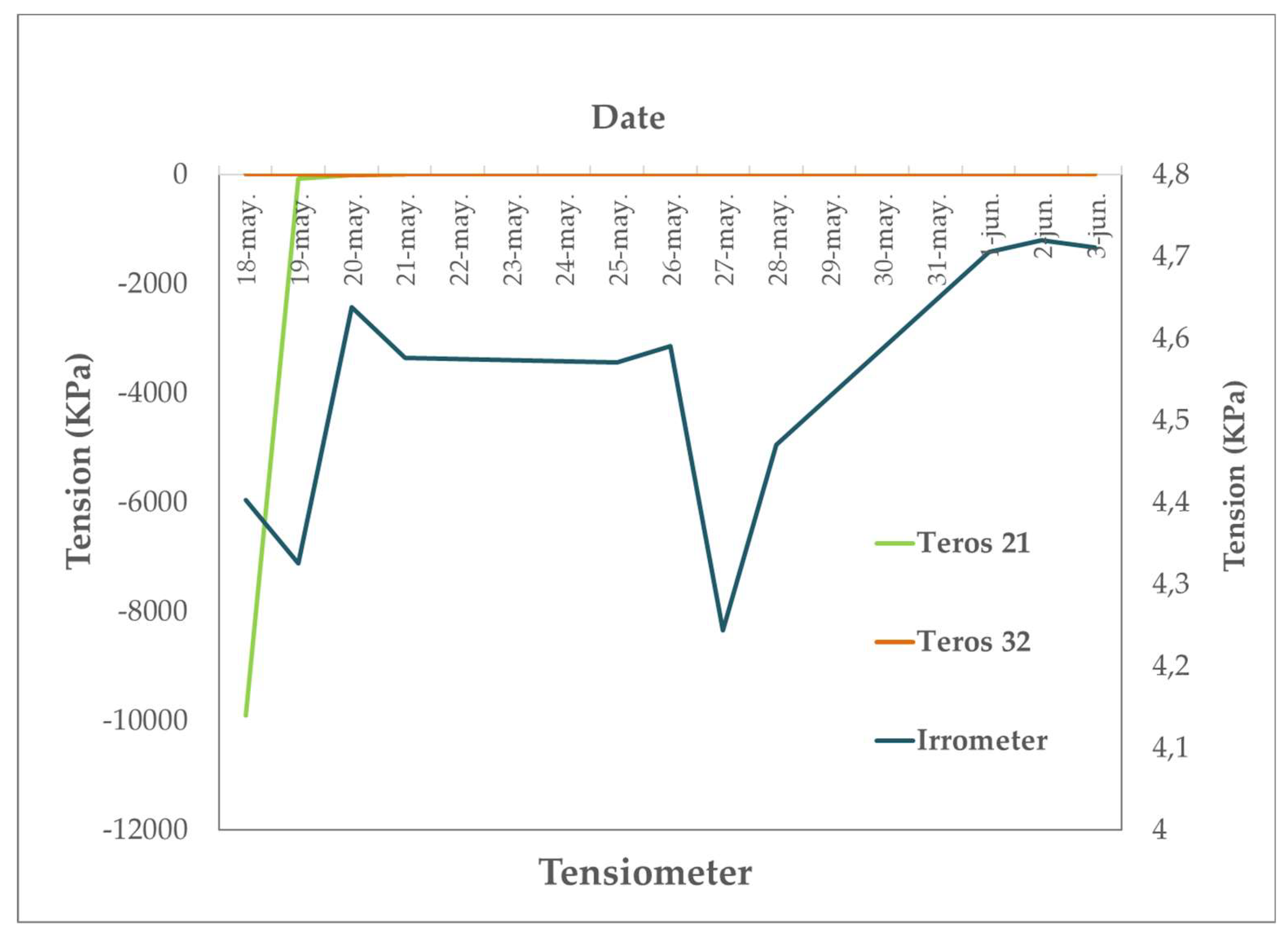

3.4. Tensiometers

Figure 3 shows the characteristic curve obtained with the tensiometer values and the volumetric water content in the soil. Dong et al. [

17] indicated that a sensor was accurate when R²>0.65. The highest R² was obtained with the Teros 21 sensor. In contrast, the Irrometer and Teros 32 tensiometers obtained very low R² values. Tensiometers measure the soil water potential, which is a quantity directly related to the movement of water in the soil-plant-atmosphere system. These sensors have been used by many researchers to adjust irrigation scheduling [

43,

44]. However, tensiometers require constant maintenance to avoid or correct cavitation problems and poor contact between the porous capsule and the soil [

44,

45]. The Teros 21 sensor does not require maintenance, but both the Irrometer and the Teros 32 do. In addition, in the case of the Teros 32 sensor, the sensor must be maintained with deionized water. With regard to installation, the Teros 32 sensor must be installed at the correct angle, which is 45º according to the manufacturer’s specifications. In this work, it was observed that tensiometers require a longer stabilization time in the measurement than sensors that measure the water content in the soil. In this case, the tensiometer that took the longest time to stabilize was the Teros 32.

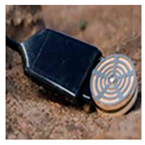

The soil water potential during the period from 18 May to 3 June can be seen in

Figure 4. The values obtained with the Irrometer tensiometer range from 4.24 kPa to 4.37 kPa when the soil is dry to 4.71 KPa when the soil is fully saturated. Thus, there is minimal variation between the two values making it difficult to use this type of sensor for automatic irrigation scheduling. The same is true for the Teros 32 sensor, with the measuring range between -0.03 to -0.07 KPa. This range of values makes it very difficult to identify when the soil is dry or wet. With respect to the Teros 21 tensiometer, a change of water movement in the soil from -9990 KPa to -0.07 KPa is detected between 18/05/2021 and 19/05/2021, when the soil is practically dry. After 19/05/2021, the Teros 21 sensor detects no change in soil moisture. So, when the soil acquires a small percentage of moisture, these changes are not reflected in the sensor.

Table 6 provides a comparison of different commercial sensors based on the following variables: accuracy, experience of the consortium of companies participating in the LIFE4DOÑANA project with the sensor, expected robustness/warranty, ease of installation, price, measurement volume, measurement stabilization, and sensor-soil contact area. Each of the variables, depending on the sensor, was given a score from 0 to 100. The most accurate sensors were the Teros 10, as it had a higher R² and lower RMSE (

Table 4). The consortium of companies had previously worked with the following sensors: Teros 10, Teros 11, HydraProbe, Drill&drop, CS616 and Irrometer. In contrast, they had no experience with the EnviroPro, Teros 21 and Teros 32 sensors. They wanted to reduce the number of sensors to be tested in this trial by using those that they had previously tested in other works, and which apparently worked well. The EnviroPro, Teros 21 and Teros 32 sensors were incorporated into this study because they wanted to expand the options of modular sensors and tensiometers. In terms of robustness, the sensors that appeared to be the most robust were the modular ones, as they were completely encapsulated by a PVC housing that protected them. The CS616 sensor had two fairly long stainless steel rods. These sensors had the drawback that if the soil was too compact or if there was an obstacle such as a stone the rods were very prone to bending, hence providing an erroneous measurement value. In the case of the Irrometer and Teros 32 sensor, excessive care must be taken with the porous capsule as it can easily break. The sensors that presented the least difficulty in installation were the Teros 10, Teros 11, HydraProbe and Teros 21. Normally these types of sensors are installed with a barrier at the desired depth, avoiding the formation of preferential pathways in the soil and ensuring that the sensor-soil contact area is adequate. In modular sensors and the Irrometer sensor, it is important to place the sensor correctly in the container to obtain a correct reading, avoiding any movement in the containers as this can cause changes in the sensor-soil contact area, thereby affecting the recorded measurement. Any air pockets or excessive compaction around the sensor may influence the measurements taken and it is therefore important to avoid creating preferential water passage channels between the sensor and the soil volume in contact with it. The Teros 32 sensor requires more specialized labor for proper installation as, during the installation process, it is necessary to make sure that the angle formed with the soil is correct (45º as specified in the manual) and a certain level of maintenance is required (it must be filled with distilled water). In terms of price, the cheapest sensors were the Teros 10 and the CS616. Typically, the use of more durable and accurate components contributes to a higher sensor acquisition cost [

46]. Compared to other sensors, the Teros 10 sensor provides us with fairly accurate information at a relatively low acquisition cost. The sensor with the largest measurement volume was the Teros 11, which measures at a single depth. However, if using modular sensors that measure the water content in the soil at different depths, the EnviroPro has the largest measurement volume. The time it took for the sensor to take reliable measurements from the time it was installed (stabilization of the measurement) was very fast for sensors that measure soil water content. However, the tensiometers needed some time to stabilize the measurement from the moment they were installed. The Teros 32 sensor needed about 3.5 h to take reliable measurements from installation, the Teros 21 about 3 h and the Irrometer about 2 h.

With regard to the sensor-soil contact area, proper placement and stabilization within the container are crucial for the modular sensors to obtain accurate readings. Movement or displacement of the sensor can lead to variations in the sensor-soil contact area, which in turn affects the recorded measurements. Air pockets can disrupt the uniformity of soil contact, leading to inaccurate measurements. The soil must be carefully compacted around the sensor to ensure good contact without being overly compressed, which could alter its natural properties. Excessive compaction carried out around the sensor can affect the soil's physical properties and thus the sensor readings. The aim should be for a natural compaction level similar to that of the surrounding soil environment.

5. Conclusions

This study highlights the importance of selecting sensors based on specific needs such as accuracy, cost, robustness, and ease of installation. Proper calibration and maintenance practices are essential to ensure reliable soil moisture measurements.

Accuracy and cost: The Teros 10 and CS616 sensors were the most cost-effective options while still providing reasonably accurate measurements. The Teros 10 sensor, in particular, offered high accuracy at a relatively low acquisition cost.

Measurement volume: the Teros 11 had the largest measurement volume for a single depth sensor. Among the modular sensors, the EnviroPro measured the largest volume of soil water content at various depths.

Stabilization time: Sensors measuring soil water content stabilized quickly after installation. In contrast, tensiometers required a longer stabilization period.

Sensor-soil contact: Proper placement and stabilization of sensors are crucial for accurate readings. Movement or displacement can cause variations in the sensor-soil contact area, leading to inaccurate measurements. Careful compaction around the sensor is necessary to avoid air pockets and ensure good contact without altering the soil's natural properties.

Ease of installation and robustness: The Teros 10, Teros 11, and HydraProbe sensors were the easiest to install. Modular sensors were deemed the most robust due to their encapsulated design, while the CS616 sensor’s stainless steel rods posed challenges in compact or obstacle-laden soils.

Sensor maintenance: Tensiometers, such as the Teros 21, require minimal maintenance compared to others like the Irrometer and Teros 32, which need constant attention to avoid cavitation and ensure proper contact between the porous capsule and soil.

Author Contributions

S.M. (70%) literature review; investigation; planning and execution of experimental work; processing of data; discussion of results and writing of paper. C.M. (15%) planning of experimental work and discussion of results. C.C (15%) revision of the paper. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the LIFE4DOÑANA project (LIFE19ENV/ES/000701) which has received funding from the European Union's LIFE program.

Institutional Review Board Statement

Not applicable.

Acknowledgments

Sébastien Guéry LIFE4DOÑANA project coordinator.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Oduor, B. O., Campo-Bescós, M. Á., Lana-Renault, N., Echarri, A. A., & Casalí, J. (2022). Evaluation of the impact of changing from rainfed to irrigated agriculture in a mediterranean watershed in Spain. Agriculture, 13(1), 106.

- Hídricos, R. (2020). Agua y Cambio climático. Unesco.

- Dong, Y., Miller, S., & Kelley, L. (2020). Performance evaluation of soil moisture sensors in coarse-and fine-textured Michigan agricultural soils. Agriculture, 10(12), 598.

- Antonucci, F., Pallottino, F., Costa, C., Rimatori, V., Giorgi, S., Papetti, P., & Menesatti, P. (2011). Development of a rapid soil water content detection technique using active infrared thermal methods for in-field applications. Sensors, 11(11), 10114-10128.

- Pahuja, R. (2022). Development of semi-automatic recalibration system and curve-fit models for smart soil moisture sensor. Measurement, 203, 111907.

- Songara, J. C., & Patel, J. N. (2022). Calibration and comparison of various sensors for soil moisture measurement. Measurement, 197, 111301.

- Cardenas-Lailhacar, B.; Dukes, M.D. Precision of soil moisture sensor irrigation controllers under field conditions. Agric. Water Manag. 2010, 97, 666–672.

- Sakaki, T.; Limsuwat, A.; Smits, K.M.; Illangasekare, T.H. Empirical two-point α -mixing model for calibrating the ECH2 O EC-5 soil moisture sensor in sands. Water Resour. Res. 2008, 44, 181–186.

- Kinzli, K.; Manana, N.; Oad, R. Comparison of Laboratory and Field Calibration of a Soil-Moisture Capacitance Probe for Various Soils. J. Irrig. Drain. Eng. 2012, 138, 310–321.

- Stevanato, L.; Baroni, G.; Cohen, Y.; Fontana, C.L.; Gatto, S.; Lunardon, M.; Marinello, F.; Moretto, S.; Morselli, L. A Novel Cosmic-Ray Neutron Sensor for Soil Moisture Estimation over Large Areas. Agriculture 2019, 9, 202.

- Kodikara, J., Rajeev, P., Chan, D., & Gallage, C. (2014). Soil moisture monitoring at the field scale using neutron probe. Canadian Geotechnical Journal, 51(3), 332-345.

- Richards, L. A., & Gardner, W. (1936). Tensiometers for Measuring the Capillary Tension of Soil Water 1. Agronomy Journal, 28(5), 352-358.

- Dela, B. F. (2001). Measurement of soil moisture using gypsum blocks. SBI forlag.

- Eldredge, E. P., Shock, C. C., & Stieber, T. D. (1993). Calibration of granular matrix sensors for irrigation management. Agronomy Journal, 85(6), 1228-1232.

- Kalita, H., Palaparthy, V. S., Baghini, M. S., & Aslam, M. (2016). Graphene quantum dot soil moisture sensor. Sensors and Actuators B: Chemical, 233, 582-590.

- Jones, S. B., Wraith, J. M., & Or, D. (2002). Time domain reflectometry measurement principles and applications. Hydrological Processes, 16(1), 141-153.

- Dong, Y., Miller, S., & Kelley, L. (2020). Performance evaluation of soil moisture sensors in coarse-and fine-textured Michigan agricultural soils. Agriculture, 10(12), 598.

- Francisca, F. M., & Montoro, M. A. (2012). Measuring the dielectric properties of soil–organic mixtures using coaxial impedance dielectric reflectometry. Journal of Applied Geophysics, 80, 101-109.

- Singh, J. (2017). Performance Assessment of Electromagnetic Soil Water Sensors in Different Soil Textural, Temperature, and Salinity Conditions.

- Andrade, P., Aguera, J., Upadhyaya, S., Jenkins, B., Rosa, U., & Josiah, M. (1998). Evaluation of a dielectric-based moisture and salinity sensor for in-situ applications. In 2001 ASAE Annual Meeting (p. 1). American Society of Agricultural and Biological Engineers.

- Mittelbach, H., Lehner, I., & Seneviratne, S. I. (2012). Comparison of four soil moisture sensor types under field conditions in Switzerland. Journal of Hydrology, 430, 39-49.

- Spelman, D., Kinzli, K. D., & Kunberger, T. (2013). Calibration of the 10HS soil moisture sensor for southwest Florida agricultural soils. Journal of Irrigation and Drainage Engineering, 139(12), 965-971.

- Vaz, C. M., Jones, S., Meding, M., & Tuller, M. (2013). Evaluation of standard calibration functions for eight electromagnetic soil moisture sensors. Vadose Zone Journal, 12(2), vzj2012-0160.

- Seyfried, M. S., & Grant, L. E. (2007). Temperature effects on soil dielectric properties measured at 50 MHz. Vadose Zone Journal, 6(4), 759-765.

- Visconti, F., & de Paz, J. M. (2016). Electrical conductivity measurements in agriculture: The assessment of soil salinity. New trends and developments in metrology, 1, 99-126.

- Paltineanu, I. C., & Starr, J. L. (1997). Real-time soil water dynamics using multisensor capacitance probes: Laboratory calibration. Soil Science Society of America Journal, 61(6), 1576-1585.

- Schindler, U., Durner, W., Von Unold, G., Mueller, L., & Wieland, R. (2010). The evaporation method: Extending the measurement range of soil hydraulic properties using the air-entry pressure of the ceramic cup. Journal of plant nutrition and soil science, 173(4), 563-572.

- UMS. (2015). Manual HYPROP, Version 2015-01.

- Schindler, U.; Müller, L. Soil hydraulic functions of international soils measured with the Extended Evaporation Method (EEM)and the HYPROP device. Open Data J. Agric. Res. 2017 ,3, 10–16.

- Campbell, G.S., Smith, D.M. and Teare, B.L. 2007. Application of a dew point method to obtain the soil water characteristic. Experimental Unsaturated Soil Mechanics.

- Blake, GR & KH Hartge. 1986. Bulk Density. In: A Klute (ed). Methods of soil analysis. Part 1. Physical and Mineralogical Methods. Pp. 363-375. Am. Soc. Agron. and Soil Sci. Soc. Am., Madison, Wisconsin, USA.

- Bogena, H.R.; Huisman, J.A.; Oberdörster, C.; Vereecken, H. Evaluation of a low-cost soil water content sensor for wireless network applications. J. Hydrol. 2007, 344, 32–42.

- Matula, S., Báťková, K., & Legese, W. L. (2016). Laboratory performance of five selected soil moisture sensors applying factory and own calibration equations for two soil media of different bulk density and salinity levels. Sensors, 16(11), 1912.

- Willmott, C. J. (1981). On the validation of models. Physical Geography, 2(2), 184-194.

- Sharma, K., Irmak, S., Kukal, M. S., Vuran, M. C., Jhala, A. J., & Qiao, X. (2021). Evaluation of soil moisture sensing technologies in silt loam and loamy sand soils: Assessment of performance, temperature sensitivity, and site-And sensor-specific calibration functions. Transactions of the ASABE, 64(4), 1123-1139.

- Fares, A., Abbas, F., Maria, D., & Mair, A. (2011). Improved calibration functions of three capacitance probes for the measurement of soil moisture in tropical soils. Sensors, 11, 4858-4874.

- Varble, J. L., & Chávez, J. L. (2011). Performance evaluation and calibration of soil water content and potential sensors for agricultural soils in eastern Colorado. Agricultural water management, 101(1), 93-106.

- Walker, J. P., Willgoose, G. R., & Kalma, J. D. (2004). In situ measurement of soil moisture: a comparison of techniques. Journal of Hydrology, 293(1-4), 85-99.

- Evett, S. R., Heng, L. K., Moutonnet, P., & Nguyen, M. L. (2008). Field estimation of soil water content: A practical guide to methods, instrumentation, and sensor technology. IAEA: Vienna.

- Robinson, P. W., Villegas-Amtmann, S., & Costa, D. P. (2009). Field validation of an inexpensive time-depth recorder. Marine Mammal Science, 25(1).

- Kinzli, K. D., Manana, N., & Oad, R. (2012). Comparison of laboratory and field calibration of a soil-moisture capacitance probe for various soils. Journal of Irrigation and Drainage Engineering, 138(4), 310-321.

- Nagahage, E. A. A. D., Nagahage, I. S. P., & Fujino, T. (2019). Calibration and validation of a low-cost capacitive moisture sensor to integrate the automated soil moisture monitoring system. Agriculture, 9(7), 141.

- Dobriyal, P., Qureshi, A., Badola, R., & Hussain, S. A. (2012). A review of the methods available for estimating soil moisture and its implications for water resource management. Journal of Hydrology, 458, 110-117.

- da Silva, T. J. A., Bonfim-Silva, E. M., Pacheco, A. B., Duarte, T. F., de Freitas Sousa, H. H., & José, J. V. (2018). Evaluation of various soil moisture sensors in four different soil types. Applied Engineering in Agriculture, 34(6), 963-971.

- Marković, M., Matoša Kočar, M., Barač, Ž., Turalija, A., Atılgan, A., Jug, D., & Ravlić, M. (2024). Field Performance Evaluation of Low-Cost Soil Moisture Sensors in Irrigated Orchard. Agriculture, 14(8), 1239.

- Schwamback, D., Persson, M., Berndtsson, R., Bertotto, L. E., Kobayashi, A. N. A., & Wendland, E. C. (2023). Automated low-cost soil moisture sensors: trade-off between cost and accuracy. Sensors, 23(5), 2451.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).