Submitted:

26 September 2024

Posted:

29 September 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Methodology

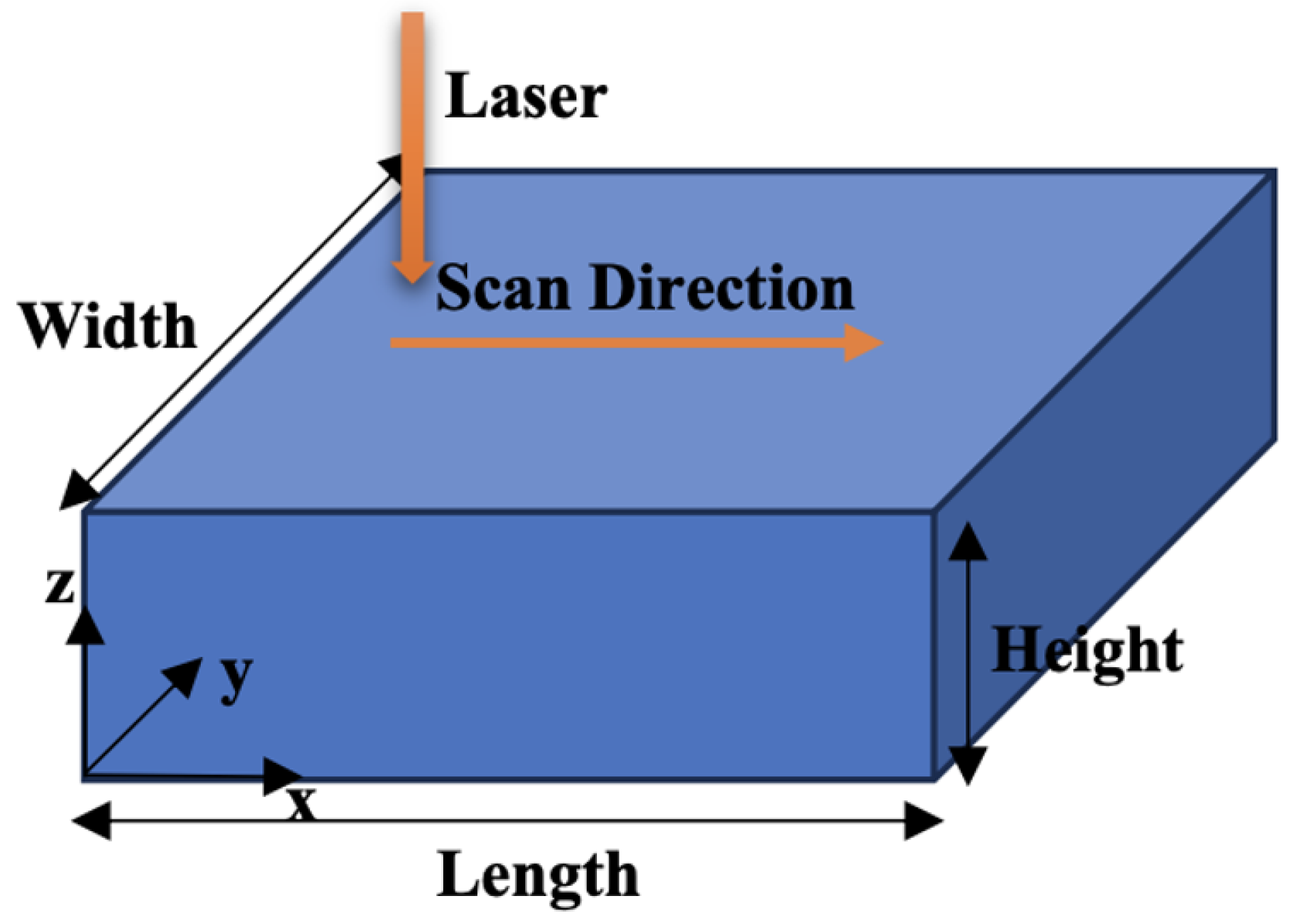

2.1. Thermal Model

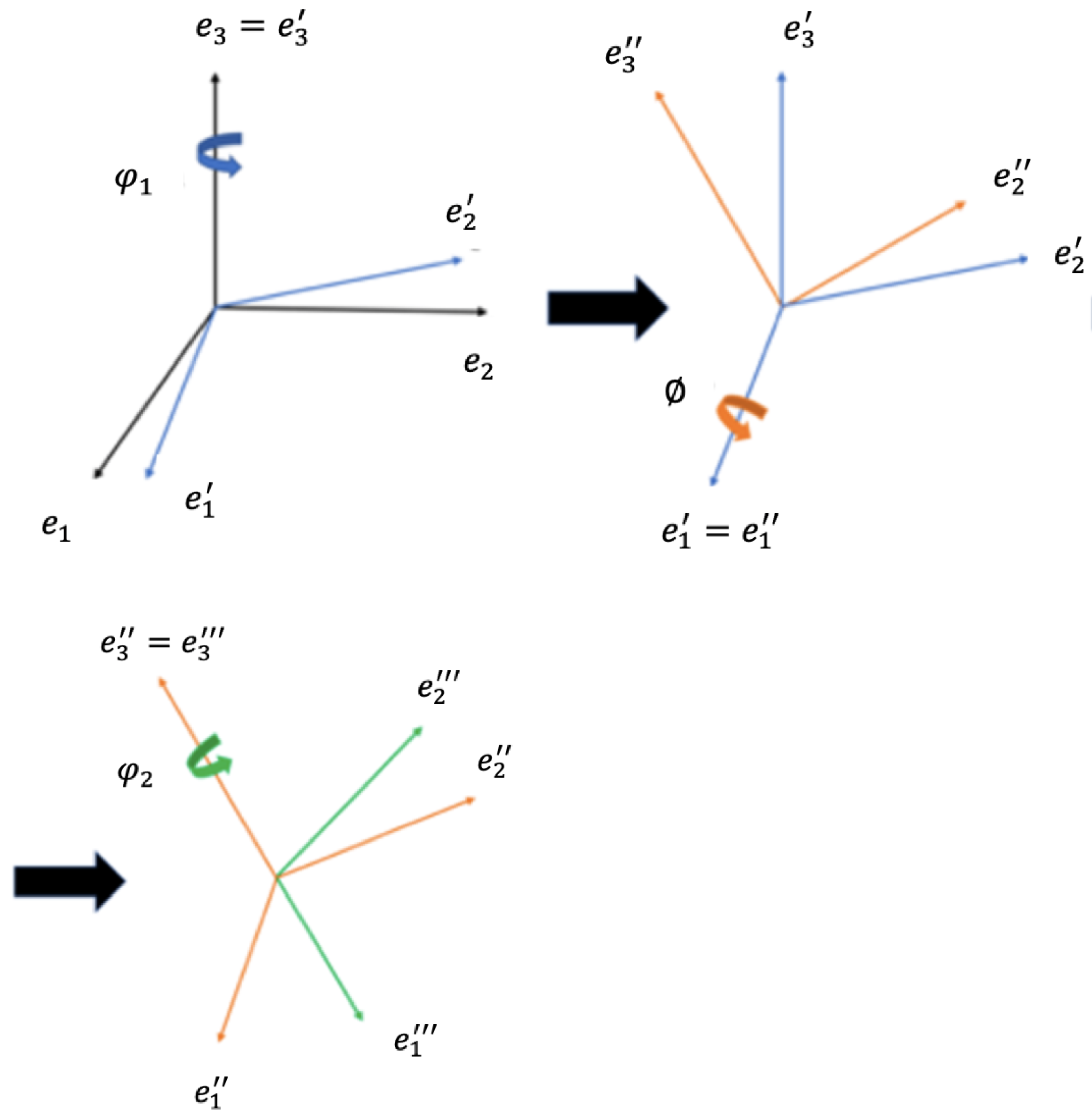

2.2. Single-Phase Texture Model

2.3. Multi-Phase Texture Model

3. Results and Discussion

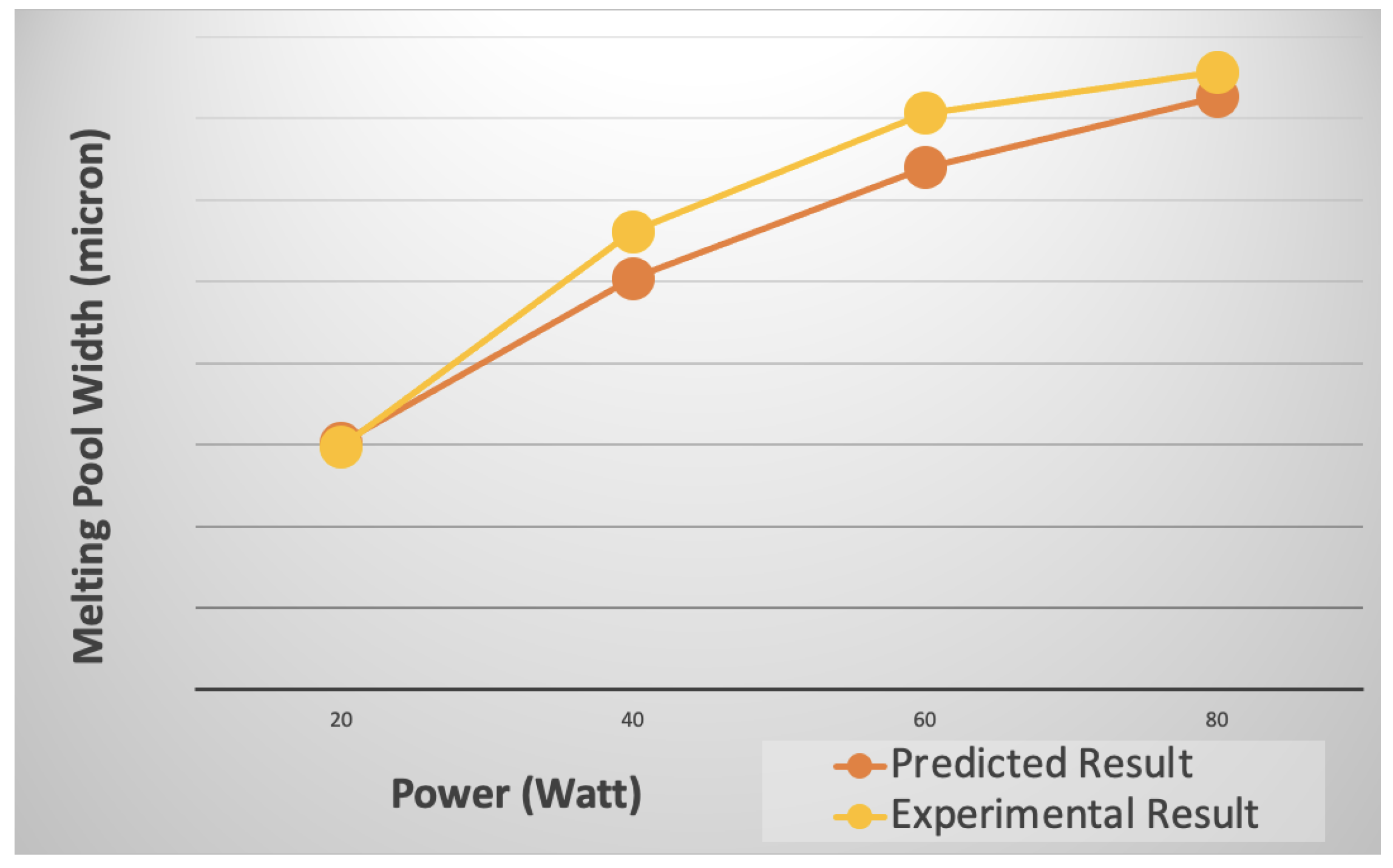

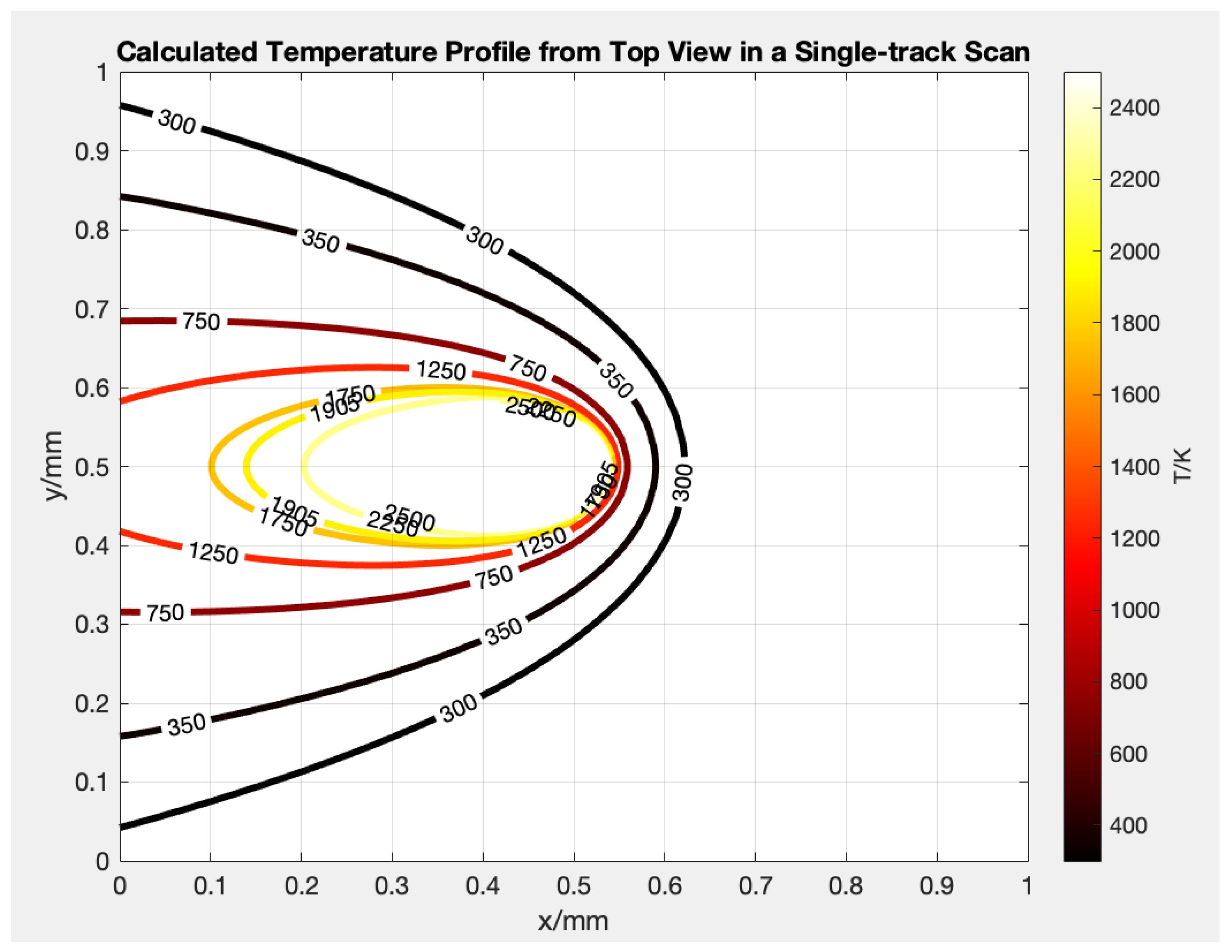

3.1. Thermal Model

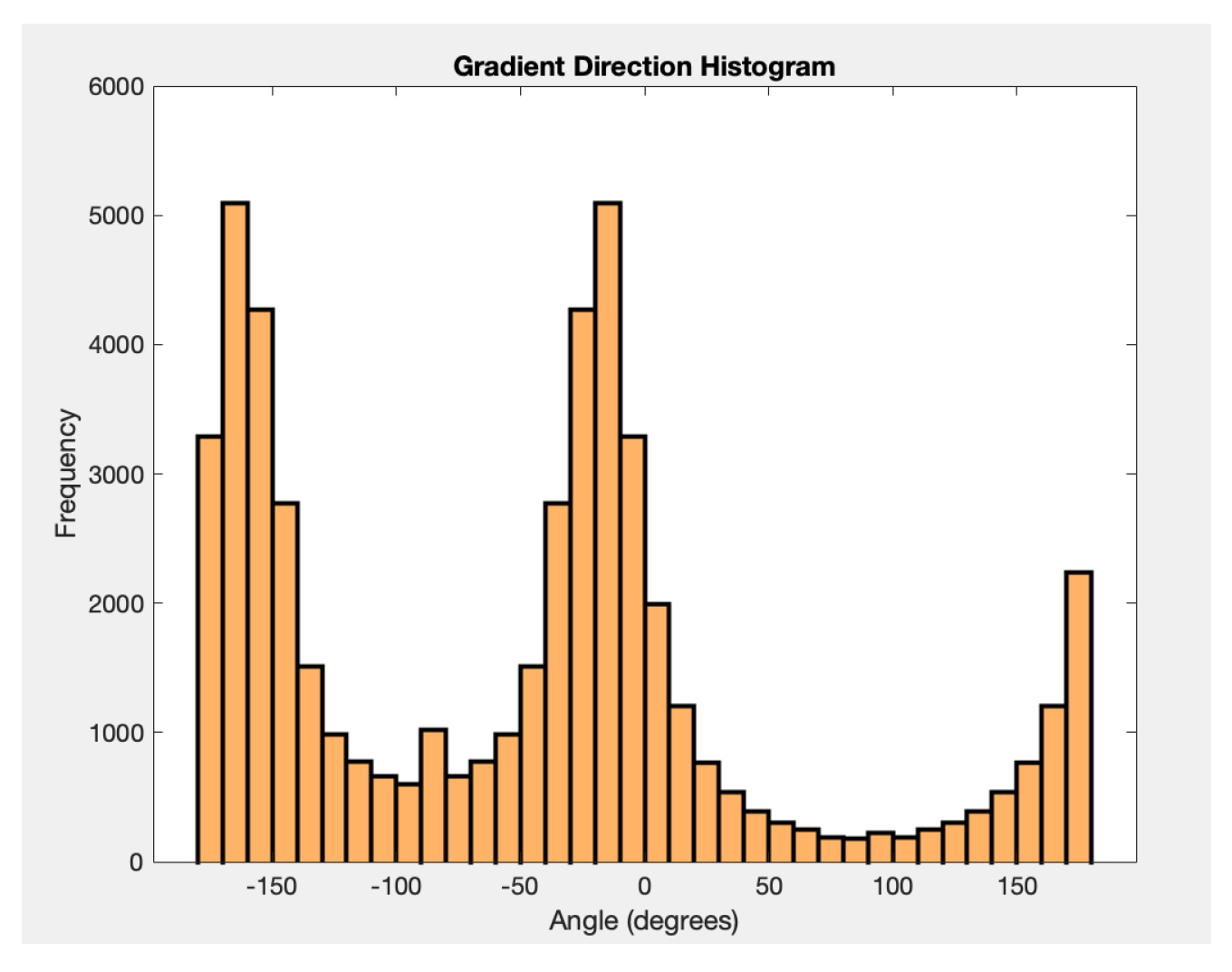

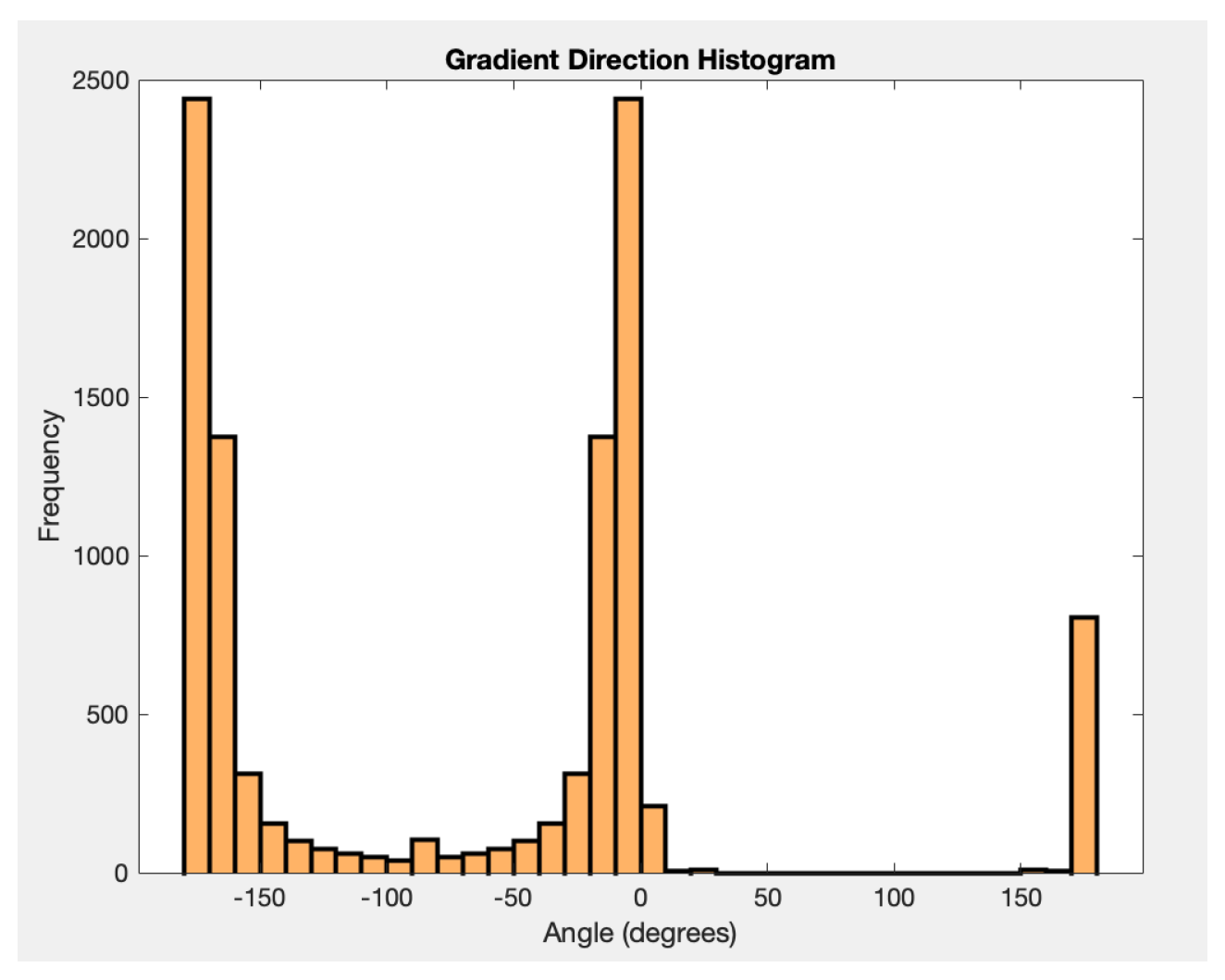

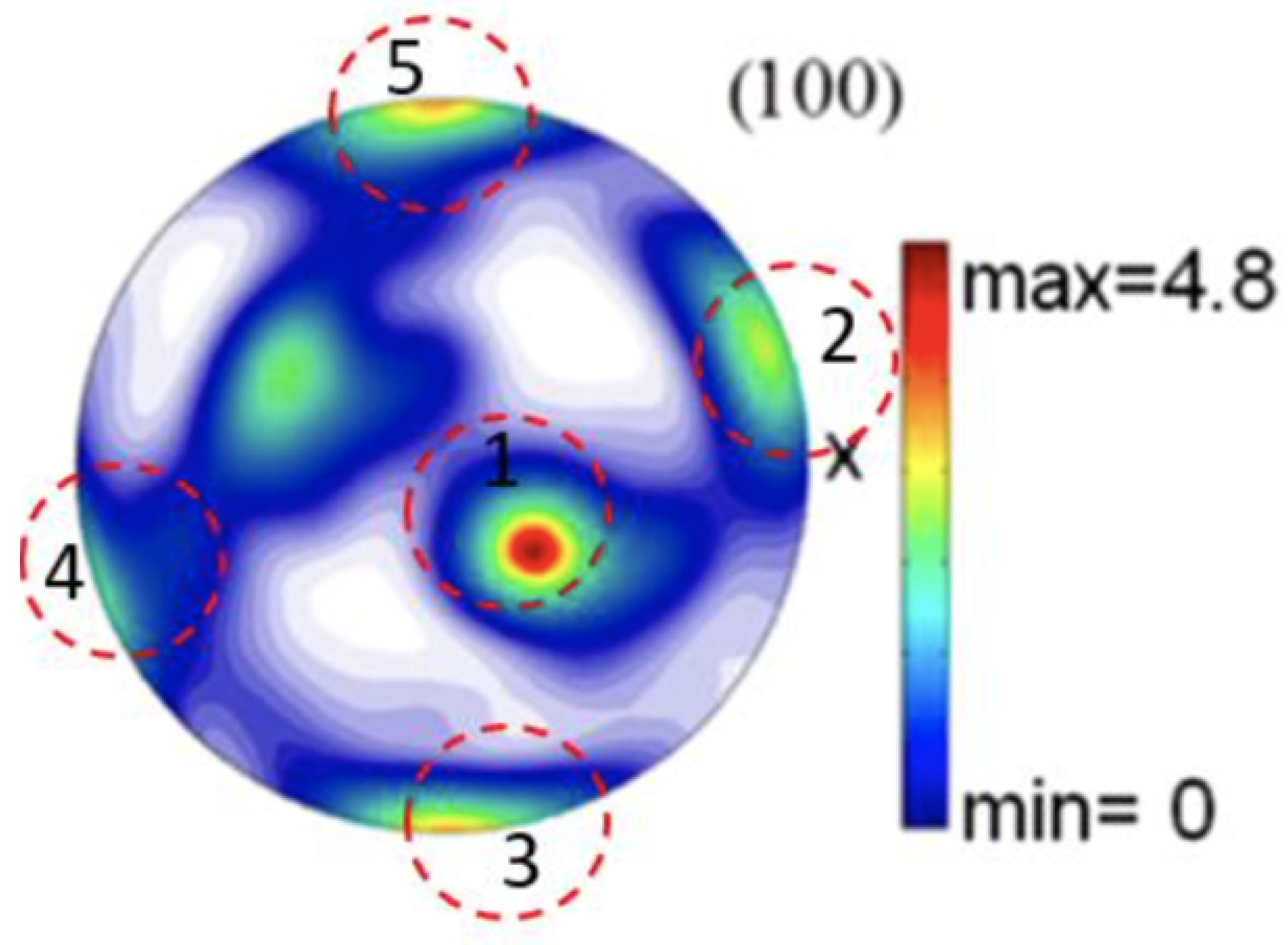

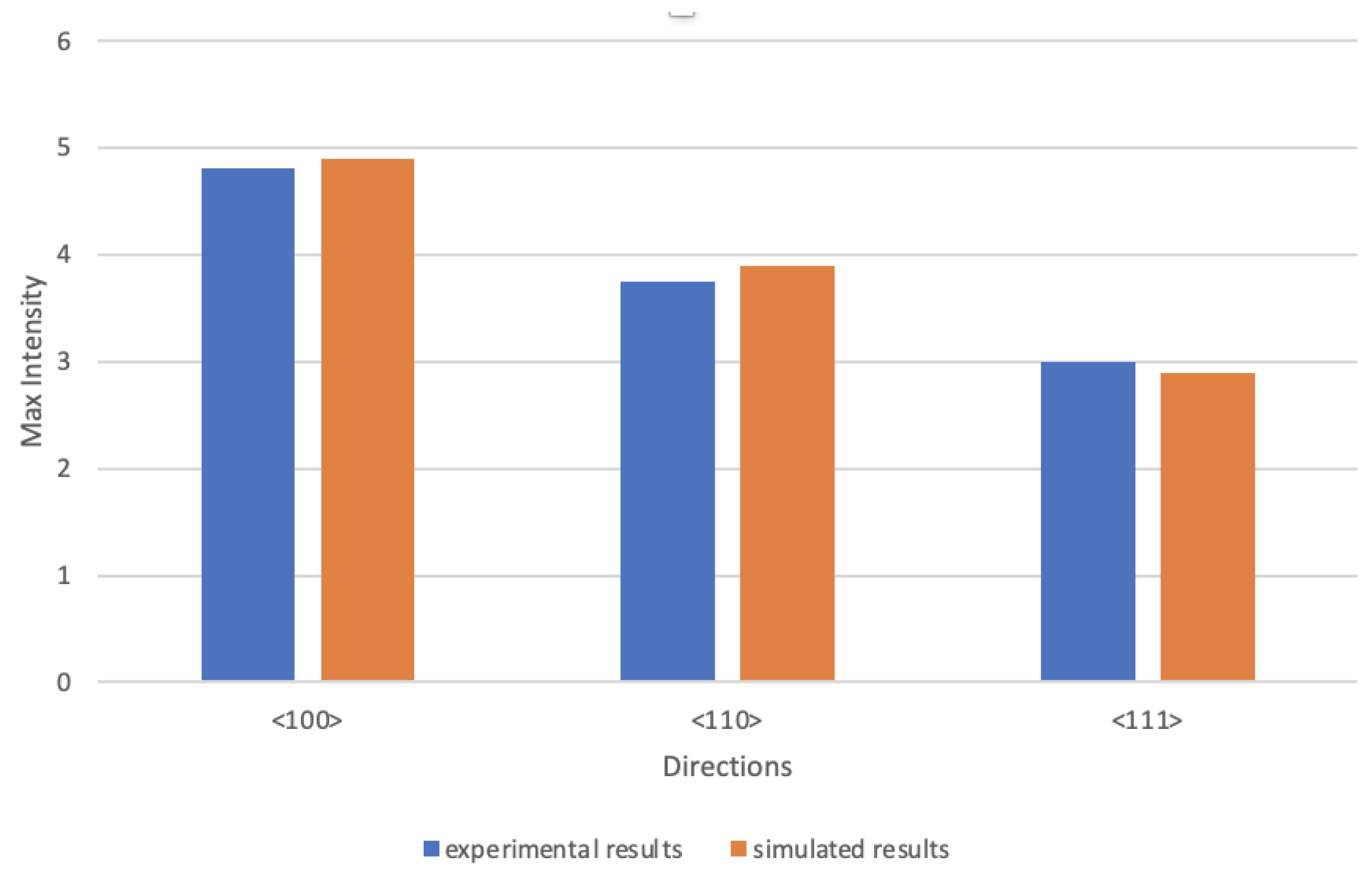

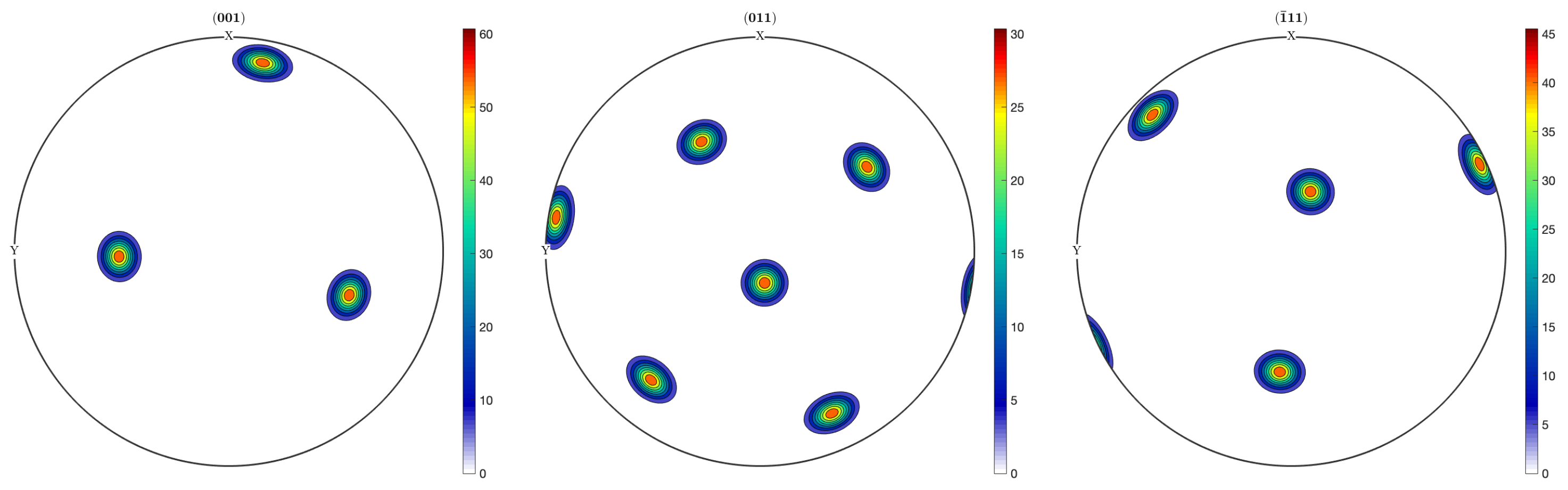

3.2. Single-Phase Texture Model

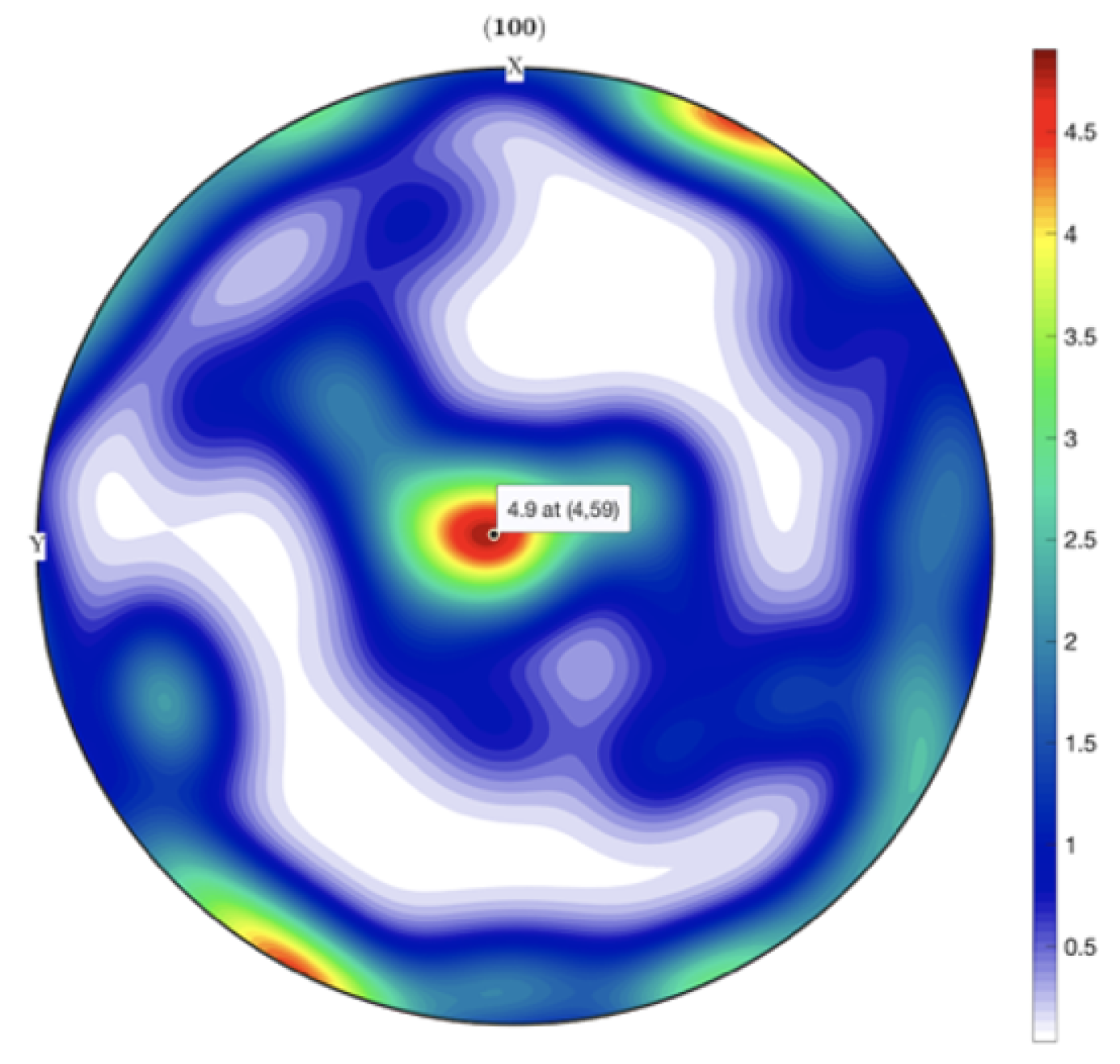

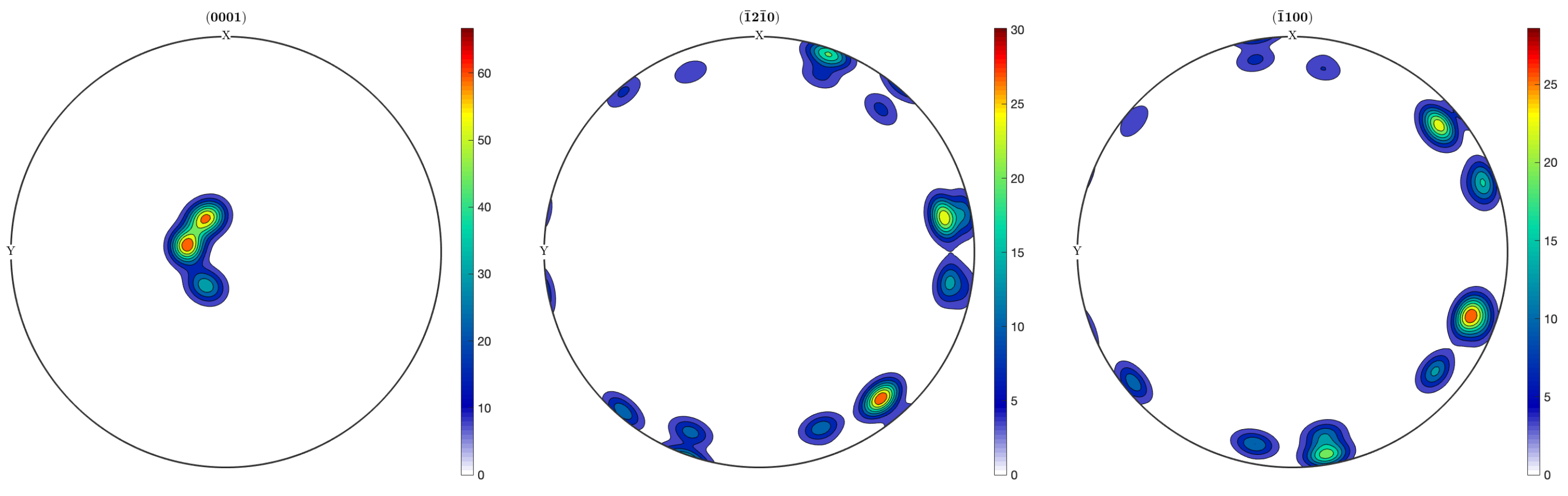

3.3. Multi-Phase Texture Model

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

Abbreviations

| LPBF | Laser powder bed fusion |

| CET | Columnar-to-equiaxed transition |

| FEM | Finite element method |

| AI | Artificial intelligence |

| BCC | Body-centered cubic |

| HCP | Hexagonal tightly packed |

| P | Laser power |

| T | Temperature |

| Laser absorption coefficient | |

| x, y, z | Coordinates |

| V | Laser scanning velocity |

| R | The distance between the source of heat and the analysis point |

| K | Thermal conductivity |

| , , | Coordinates of the heat source |

| Thermal diffusivity | |

| Room temperature | |

| c | Heat capacity |

| Density | |

| Heat of conduction | |

| Heat of convection | |

| Heat of radiation | |

| A | Each heat sink’s area on the surface of the melt pool |

| Powder thermal conductivity | |

| T | Temperature change |

| h | Heat convection coefficient |

| Radiation emissivity | |

| Stefan-Boltzmann constant | |

| Thermal gradient vector | |

| Solidification rate | |

| The angle formed by the growth and scanning directions | |

| n | Exponent |

| ∅ | Certain value in Hunt’s model |

| The exact texture vector of the seed crystal that yields the maximum value of | |

| PX | Polycrystal base |

| Number of possible seed crystals | |

| Melting temperature | |

| Bulk thermal conductivity | |

| nn, kk | Columnar/equiaxed transition coefficient |

| X, Y, Z | Coordinate axis |

| GX, GY | The X and Y directions’ components of the thermal gradient vector |

| Angle between the X and Y components of the thermal gradient |

References

- Zhu, S.; Yu, T.; Xu, T.; Chen, H.; Dustdar, S.; Gigan, S.; Gunduz, D.; Hossain, E.; Jin, Y.; Lin, F.; et al. Intelligent computing: The latest advances, challenges, and future. Intelligent Computing 2023, 2, 0006. [CrossRef]

- Newton, I. Philosophiæ Naturalis Principia Mathematica. 1687.

- NSTC Subcommittee on Advanced Manufacturing, N.S.; Council, T. NATIONAL STRATEGY FOR ADVANCED MANUFACTURING. Technical report, Office of Science and Technology Policy, 2022.

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Žídek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589. [CrossRef]

- Merchant, A.; Batzner, S.; Schoenholz, S.S.; Aykol, M.; Cheon, G.; Cubuk, E.D. Scaling deep learning for materials discovery. Nature 2023, 624, 80 – 85. [CrossRef]

- Szymanski, N.J.; Rendy, B.; Fei, Y.; Kumar, R.E.; He, T.; Milsted, D.; McDermott, M.J.; Gallant, M.; Cubuk, E.D.; Merchant, A.; et al. An autonomous laboratory for the accelerated synthesis of novel materials. Nature 2023, 624, 86 – 91. [CrossRef]

- Schwab, K. The fourth industrial revolution: What it means, how to respond. 2016.

- Gibson, I.; Rosen, D.W.; Stucker, B.E.; Khorasani, M. Additive Manufacturing Technologies. 2021.

- Wohlers, T.T.; Gornet, T.J.; Mostow, N.; Campbell, I.; Diegel, O.; Kowen, J.; Huff, R.; Stucker, B.E.; Fidan, I.; Doukas, A.; et al. History of Additive Manufacturing. SSRN Electronic Journal 2023. [CrossRef]

- Carr, T.; Chewning, E.; Doheny, M.; Madgavkar, A.; Padhi, A.; Tingley, A. Delivering the US manufacturing renaissance. Technical report, McKinsey’s Operations Practice and the McKinsey Global Institute, 2022.

- Conner, B.P.; Manogharan, G.P.; Martof, A.N.; Rodomsky, L.M.; Rodomsky, C.M.; Jordan, D.C.; Limperos, J.W. Making sense of 3-D printing: Creating a map of additive manufacturing products and services. Additive manufacturing 2014, 1, 64–76. [CrossRef]

- Ngo, T.D.; Kashani, A.R.; Imbalzano, G.; Nguyen, K.T.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Composites Part B: Engineering 2018.

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of selective laser melting: Materials and applications. Applied physics reviews 2015, 2. [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.P.; van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and mechanical properties. Journal of Alloys and Compounds 2012, 541, 177–185. [CrossRef]

- dong Gu, D.; Shi, X.; Poprawe, R.; Bourell, D.L.; Setchi, R.; Zhu, J. Material-structure-performance integrated laser-metal additive manufacturing. Science 2021, 372.

- Hirsch, J.; Al-Samman, T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications. Acta Materialia 2013, 61, 818–843. [CrossRef]

- Margulies, L.; Winther, G.; Poulsen, H.F. In Situ Measurement of Grain Rotation During Deformation of Polycrystals. Science 2001, 291, 2392 – 2394. [CrossRef]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Van Humbeeck, J.; Kruth, J.P. A study of the microstructural evolution during selective laser melting of Ti–6Al–4V. Acta materialia 2010, 58, 3303–3312. [CrossRef]

- Azizi, H.; Ebrahimi, A.; Ofori-Opoku, N.; Greenwood, M.; Provatas, N.; Mohammadi, M. Characterizing the microstructural effect of build direction during solidification of laser-powder bed fusion of Al-Si alloys in the dilute limit: A phase-field study. Acta Materialia 2021, 214, 116983. [CrossRef]

- Klemens, P. Heat balance and flow conditions for electron beam and laser welding. Journal of Applied physics 1976, 47, 2165–2174. [CrossRef]

- Cline, H.; Anthony, T. Heat treating and melting material with a scanning laser or electron beam. Journal of Applied Physics 1977, 48, 3895–3900. [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A new finite element model for welding heat sources. Metallurgical transactions B 1984, 15, 299–305. [CrossRef]

- Hunt, J.D. Steady state columnar and equiaxed growth of dendrites and eutectic. Materials science and engineering 1984, 65, 75–83. [CrossRef]

- Gäumann, M.; Henry, S.; Cléton, F.; Wagnière, J.D.; Kurz, W. Epitaxial laser metal forming: analysis of microstructure formation. Materials Science and Engineering: A 1999, 271, 232–241. [CrossRef]

- Gäumann, M.; Bezencon, C.; Canalis, P.; Kurz, W. Single-crystal laser deposition of superalloys: processing–microstructure maps. Acta materialia 2001, 49, 1051–1062. [CrossRef]

- Gockel, J.; Beuth, J. Understanding Ti-6Al-4V microstructure control in additive manufacturing via process maps. In Proceedings of the 2013 International Solid Freeform Fabrication Symposium. University of Texas at Austin, 2013.

- Basak, A.; Das, S. Epitaxy and microstructure evolution in metal additive manufacturing. Annual Review of Materials Research 2016, 46, 125–149. [CrossRef]

- Liu, J.; To, A.C. Quantitative texture prediction of epitaxial columnar grains in additive manufacturing using selective laser melting. Additive Manufacturing 2017, 16, 58–64. [CrossRef]

- Chadwick, A.F.; Voorhees, P.W. The development of grain structure during additive manufacturing. Acta Materialia 2021, p. 116862.

- Chadwick, A.F.; Voorhees, P.W. The Effects of Melt Pool Geometry and Scan Strategy on Microstructure Development During Additive Manufacturing. IOP Conference Series: Materials Science and Engineering 2023, 1274. [CrossRef]

- Elahi, S.M.; Tavakoli, R.; Boukellal, A.K.; Isensee, T.; Romero, I.; Tourret, D. Multiscale simulation of powder-bed fusion processing of metallic alloys. Computational Materials Science 2022. [CrossRef]

- Zhang, J.; Chadwick, A.F.; Chopp, D.L.; Voorhees, P.W. Phase field modeling with large driving forces. npj Computational Materials 2023, 9, 1–9. [CrossRef]

- Huang, W.; Wang, W.; Ning, J.; Garmestani, H.; Liang, S.Y. Analytical Model of Quantitative Texture Prediction Considering Heat Transfer Based on Single-Phase Material in Laser Powder Bed Fusion. Journal of Manufacturing and Materials Processing 2024. [CrossRef]

- Ning, J.; Mirkoohi, E.; Dong, Y.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of 3D temperature distribution in selective laser melting of Ti-6Al-4V considering part boundary conditions. Journal of Manufacturing Processes 2019. [CrossRef]

- Carslaw, H.S.; Jaeger, J.C. Conduction of Heat in Solids. 1952.

- Bunge, H.J. Texture analysis in materials science: mathematical methods; 2013.

- Kobryn, P.A.; Semiatin, S.L. Microstructure and texture evolution during solidification processing of Ti–6Al–4V. Journal of Materials Processing Technology 2003, 135, 330–339. [CrossRef]

- Welsch, G.; Boyer, R.; Collings, E. Materials properties handbook: titanium alloys; 1993.

- Takajo, S.; Tomida, T.; Caspi, E.N.; Pesach, A.; Tiferet, E.; Vogel, S.C. Property Improvement of Additively Manufactured Ti64 by Heat Treatment Characterized by In Situ High Temperature EBSD and Neutron Diffraction. Metals 2021. [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. On the Texture Formation of Selective Laser Melted Ti-6Al-4V. Metallurgical and Materials Transactions A 2014, 45, 2863–2872. [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.; Zhang, W.; Todd, I. The Origin of Microstructural Diversity, Texture, and Mechanical Properties in Electron Beam Melted Ti-6Al-4V. Metallurgical and Materials Transactions A 2010, 41, 3422–3434. [CrossRef]

- Glavicic, M.G.; Kobryn, P.A.; Bieler, T.R.; Semiatin, S.L. An automated method to determine the orientation of the high-temperature beta phase from measured EBSD data for the low-temperature alpha-phase in Ti–6Al–4V. Materials Science and Engineering A-structural Materials Properties Microstructure and Processing 2003, 351, 258–264. [CrossRef]

- Wang, S.; Aindow, M.; Starink, M.J. Effect of self-accommodation on α/α boundary populations in pure titanium. Acta Materialia 2003, 51, 2485–2503. [CrossRef]

- Shi, R.; Wang, Y. Variant selection during α precipitation in Ti–6Al–4V under the influence of local stress – A simulation study. Acta Materialia 2013, 61, 6006–6024. [CrossRef]

- Chen, W.; Boehlert, C.J. The elevated-temperature fatigue behavior of boron-modified Ti-6Al-4V(wt.%) castings. Materials Science and Engineering A-structural Materials Properties Microstructure and Processing 2008, 494, 132–138. [CrossRef]

- Yang, Y.; Knol, M.F.; van Keulen, A.; Ayas, C. A semi-analytical thermal modelling approach for selective laser melting. Additive manufacturing 2018, 21, 284–297. [CrossRef]

- Gusarov, A.V.; Yadroitsev, I.; Bertrand, P.; Smurov, I.Y. Model of Radiation and Heat Transfer in Laser-Powder Interaction Zone at Selective Laser Melting. Journal of Heat Transfer-transactions of The Asme 2009, 131, 072101. [CrossRef]

- Boyer, R.R.; Welsch, G.; Collings, E.W. Materials Properties Handbook: Titanium Alloys. 1994.

- Yadroitsev, I.; Yadroitsava, I. Evaluation of residual stress in stainless steel 316L and Ti6Al4V samples produced by selective laser melting. Virtual and Physical Prototyping 2015, 10, 67 – 76. [CrossRef]

- Fu, C.H.; Guo, Y.B. Three-Dimensional Temperature Gradient Mechanism in Selective Laser Melting of Ti-6Al-4V. Journal of Manufacturing Science and Engineering-transactions of The Asme 2014, 136, 061004. [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C.J. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Materials Science and Engineering A-structural Materials Properties Microstructure and Processing 2014, 616, 1–11. [CrossRef]

- Muiruri, A.M.; Maringa, M.; du Preez, W.B. Crystallographic Texture Analysis of As-Built and Heat-Treated Ti6Al4V (ELI) Produced by Direct Metal Laser Sintering. Crystals 2020. [CrossRef]

- Hadadzadeh, A.; Hadadzadeh, A.; Amirkhiz, B.S.; Li, J.Y.; Mohammadi, M. Columnar to equiaxed transition during direct metal laser sintering of AlSi10Mg alloy: Effect of building direction. Additive Manufacturing 2018. [CrossRef]

| Properties of Material | Value | Unit |

| Surrounding Temperature () | 20 | °C |

| Melting Temperature () | 1655 | °C |

| Density () | 4428 | |

| Bulk Thermal Conductivity () | 5-35 | |

| Powder Thermal Conductivity () | 0.21 | |

| Heat Capacity (C) | 500-800 | |

| Heat Convection Coefficient (h) | 24 | |

| Radiation Emissivity () | 0.9 | 1 |

| Stefan-Boltzmann Constant () | ||

| CET (nn) | 3.2 | 1 |

| CET (kk) | 1 |

| Construct Parameters | Value |

| Layers | 10 |

| Seeds | 100 |

| Sections | 1000 |

| Grains | 20 |

| Track | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).