1. Introduction

Several hundred varieties of sausages are produced worldwide with outstanding social and economic relevance. Each local variety within each sausage type (raw, scalded, cooked, or raw and fermented/ripened) reflects the availability of raw materials, the climate conditions of each geographical environment, the cultural and religious conditionings, and the ancestral manufacture knowledge transmitted through generations [

1,

2,

3,

4].

The addition of non-meat protein sources in food products is widely used because of it is capability of improving the product properties and reducing the production cost. Soy protein fractions are preferred because of their higher protein content and functional properties [

5]. The use of soy protein fractions in meat products is also widely applied for their properties such as water binding, fat binding, texture, and emulsification capability and providing improved economy with increasing yield [

5,

6]. Otherwise, soybeans are composed of proteins (35%), carbohydrates (31%), oil (17%), water (13%) and ash (4%). It is important to emphasize that the protein and lipid contents are the components of soybeans that are of greatest commercial interest [

7].

Adding soy to sausages can contribute to increasing the amount of protein as well as reducing fat. Thus, fermented sausages with healthier characteristics can be produced without quality loss by reducing fat from 15 to 10% and by adding 1% soy fiber [

8]. The addition of soy to salami is a legal action, sand the European Commission establishes regulations regarding food additives and ingredients allowed in processed meats like salami. Soy protein and its derivatives are among the approved food additives used in meat products, subject to EU regulations and labeling requirements [

9]. However, although it is allowed, the levels of soy must be determined. For this reason, the European Commission Regulation (EC) No 1333/2008 sets maximum levels for food additives, including soy-based additives, in various food categories. These maximum levels are based on safety assessments conducted by the European Food Safety Authority (EFSA) and aim to ensure consumer safety [

9]. Also limited to maximum values based on Regulation (EU) No 1169/2011 of the European Parliament and the Council on the provision of food information to consumers mandates clear labeling of allergens, including soy, on food products sold in the EU. This regulation requires food producers to list allergenic ingredients in the ingredient list and highlight them using a specific format (e.g., bold type, contrasting color) [

10].

On the other hand, food allergy is a serious health problem that affects between 3% and 5% of adults, and 8% of children [

11,

12]. Additionally, the statistics in developed countries show that up to 20% of people suffer from some kind of food sensitivity caused by the consumption of foodstuffs containing chemical, microbiological, or pharmacologically active contaminants. Soy is among the many allergens used in the production of salami. In research by many authors, it turns out that salami has soy content.

Fat is an important component of salami, which is reported to play a major role in the texture, juiciness, and flavor of comminuted meat products [

13]. Mammalian fat is usually higher in saturated than unsaturated fatty acids, but this also depends on the type of animal from which the fat is derived. Fat in sausages is reported to be as a reservoir for flavour compounds, and contributes to the texture and juiciness of the products [

14]. The absence of fat in beef sausages therefore contributes to the products becoming “dry and tough”, as described by some consumers. There is a need to find alternative fats that are less saturated but have the potential to improve the sensory qualities of beef sausages. In addition, the addition of soy to sausages can play the role of enriching the sausage with unsaturated fatty acids since mammalian fat contains more saturated fatty acids. For this reason, recent studies are focusing on increasing the unsaturated fatty acid contents of meat products, by substituting beef fat with non-beef fats in beef sausages [

15,

16,

17].

Modern laboratory methods for detecting the presence of soy in sausages typically involve advanced analytical techniques that can identify soy-derived components such as proteins, DNA, or specific compounds unique to soybeans. Polymerase Chain Reaction (PCR): PCR is a sensitive and specific method used to detect DNA sequences unique to soybeans. It can identify the presence of soy DNA in sausage samples. Authors Sónia Soares et al, [

18], used Quantitative detection of soybean in meat products by a TaqMan real-time PCR assay and they proposed a normalized real-time quantitative PCR assay to determine the addition of soybean to meat products. The method proved to be a powerful tool for the quantification of soybean protein (dry basis) in the range of 0.01% to 6%, being successfully in-house validated. Its application was effective in the analysis of several meat products, indicating 2% of non-compliance with the food allergen labelling legislation, and some inconsistencies when comparing the declared with estimated amounts of soybean. This work highlights the importance of efficient tools to assess labeling statements of meat products, avoiding fraudulent practices. The detection of soy in sausages through this laboratory method is also confirmed by the works of other authors [

19,

20,

21,

22,

23].

2. Materials and Methods

2.1. Sampling

In total, 63 samples, 42 industrial and 21 traditional sausages were collected either from the market or the production site. Collection was carried without taking into consideration whether the soy has been declared on the label. Each sample containing 250 g was divided into two parts for molecular and chemistry testing. Samples were kept at 4° C until further testing.

2.2. Real-Time PCR for the Detection of Soya DNA

DNA extraction was performed using the DNeasy® mericon® Food Kit (QIAGEN, Cat. 69514), according to the manufacturer’s standard protocol, using 200 mg of sample as a starting material. For the purpose of quantification, the Allergen RM 800 reference material (Hygiene, former Biotecon) was extracted simultaneously with samples. Real-time PCR for the detection and quantification of soya DNA was performed in all samples as well as reference material by using commercially available kits (foodproof® Soya detection kit and foodproof®). The amplification was carried out according to the manufacturer's instructions. All reactions were performed on the QuantStudio 5 Real-Time PCR system (Applied Biosystems™, USA), with the following thermal profile: pre-incubation step at 37 °C for 4 minutes, initial denaturation at 95 °C for 10 minutes, and 50 amplification cycles with denaturation at 95 °C for 5 seconds and annealing at 60 °C for 60 seconds. Data were collected on the FAM channel for soy and the VIC channel for internal control.

2.3. Gas Chromatography-Flame Ionization Detector (GC/FID)

Analytical determination has been done using MIX FAME-s fatty acid standard. Procedure is

based on base-catalysed transesterification of fatty acids, forming methyl esters (FAME-s) and modified from Frank et al. (2002) (Trbovic et al., 2017; Guntarti et al., 2019; Pop et al., 2010). The following chemicals were used: Hexane 99.9% from Honeywell Riedel-de-Haën™, Methanol 99.9% CHROMASOLV™ from Honeywell Riedel-de-Haën™, Ethyl acetate 99.7% CHROMASOLV™ Honeywell Riedel-de-Haën™, Sodium Methylate from Merk and Supelco® 37 Component FAME Mix Sigma-Aldrich® as a certified reference material (CRM) in accordance with ISO 17034 and ISO/IEC 17025.

2.3.1. Extraction Procedure and Derivatization of Fatty Acids

Samples were homogenised with Velp Scientifica™ OV5 homogenizer. After homogenization, 500 mg of sample were placed into 15 ml conical tubes and mixed with 5 ml of hexane (99.9%). After vortexing for 1 minute, 1 ml of sodium methoxide in 5.4M methanol was added and mixed for 1 minute by vortexing. Esterification was performed at room temperature. Afterwards, 1 ml of solution was transferred into a 2 ml microcentrifuge tube. Samples were analysed within an hour after esterification. Determination of FAMEs was performed by Agilent 5975C inert XL Triple Axis MSD with 7890 GC gas-liquid chromatography equipped with an inert electron ionisation (EI) source and a capillary DB-Fast FAME chromatographic column (30 m x 250 m x 0.25 m).

Table 1.

The operational set-up of GC-MS (9).

Table 1.

The operational set-up of GC-MS (9).

| Column |

DB-Fast FAME 30m x 250um x 0.25um 40to 250/260C |

| Run Time |

21 min |

| Post run |

0 min |

| Equilibration Time |

1min |

| Max Temb |

280°C |

| Column conditions |

50C, 0.5min 220C; 30C/min 194C 3.5min. 5C/min 240C 3min |

| Syringe |

10ml |

| Injection volume |

1.0 µL |

| Front inlet N2 |

Split 250C, 13 Psi |

| Total flow |

64.412ml/min |

| Septum purge flow |

3ml/min |

2.4. Statistical Analysis

The difference in means between groups was calculated by the ANOVA test in Analysis Tool Pak Excel. The correlation factor between ct values in real-time PCR for soy DNA with each fatty acid content was calculated by the correlation analysis tool, Analysis Tool Pak Excel.

3. Results and Discussion

3.1. The Presence of Soy DNA in Industrial and Traditional Sausages

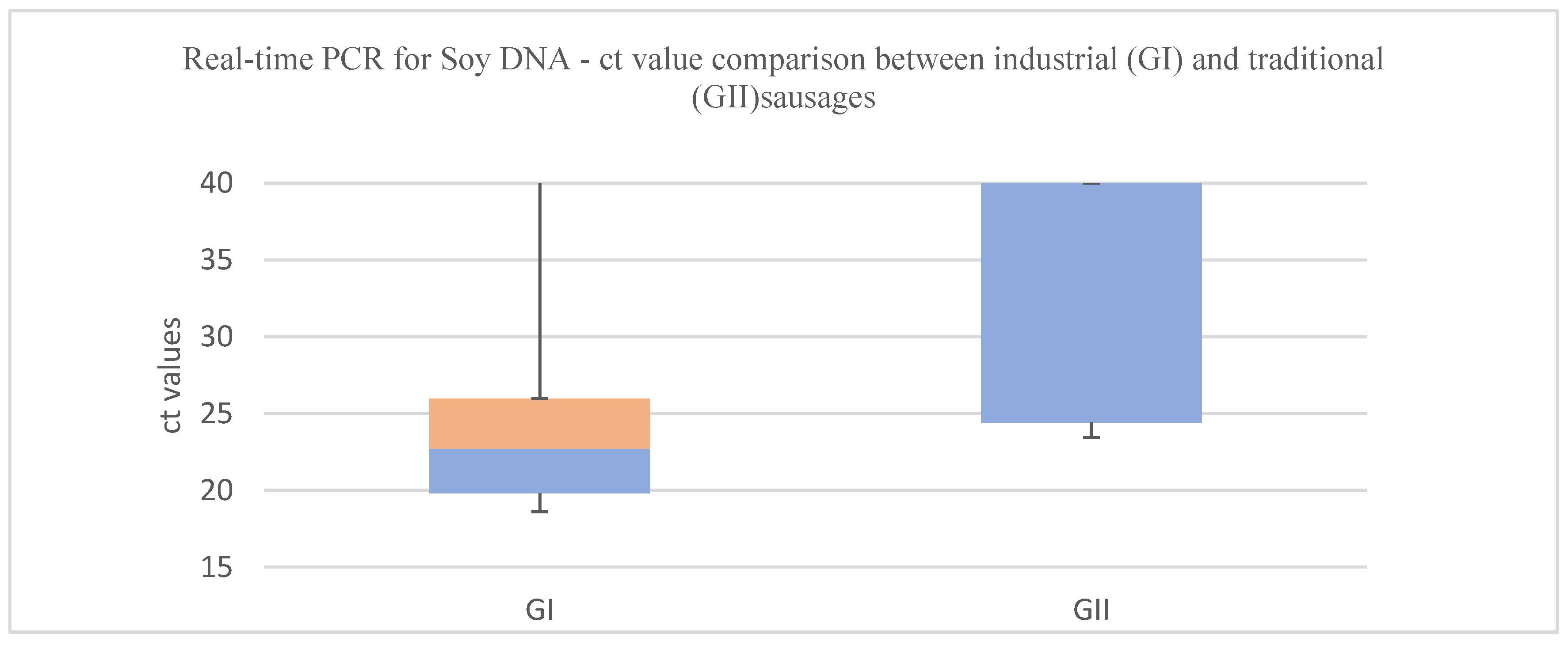

63 samples were tested for the presence of soy DNA by real-time PCR, and 54 out of 63 samples were positive for soy DNA. 41 out of 42 industrial sausage samples were positive for soya DNA, with an average ct value of 22.60 and a standard deviation (SD) of 4.288, whereas 13 out of 21 traditional sausage samples were positive for soya DNA, with a mean ct value of 23.36 and a standard deviation (SD) of 4.56. For a suitable statistical calculation, negative samples were adjusted to the value of the last ct = 40. There was a statistically significant difference of means between industrial sausage and traditional sausage, p<0.001 based on ct values (ANOVA test).

Figure 1.

Real-time PCR for soy DNA. Ct value comparison between industrial (GI) and traditional (GII) sausages.

Figure 1.

Real-time PCR for soy DNA. Ct value comparison between industrial (GI) and traditional (GII) sausages.

The high proportion of positive samples (85.7%) indicates that the majority of sausage products in the sample set contain soy. This suggests that soy is commonly used as an ingredient or additive in sausage production in Kosovo. The widespread use of soy might be due to its cost-effectiveness, functional properties (such as water retention and texture improvement), or as a protein extender. The high incidence of soy presence might reflect economic strategies employed by producers to reduce costs while maintaining product quality. Similar results for the presence and values of soy in sausages can also be found in research by other authors. Thus, during the investigation of the presence of soya proteins in 131 meat product samples such as salamis or sausages from the Czech Republic market, were detected in 84% of the investigated samples without any declaration on the package of the product [

24].; A survey of 38 Turkish processed meat products found only six samples to be negative for the presence of soybeans. In 32 (84%) positive samples, 13 (34%) contained levels of soy above 0.1% [

25].

The research findings indicating that 41 out of 42 industrial sausage samples (97.6%) and 13 out of 21 traditional sausage samples (61.9%) tested positive for the presence of soy in Kosovo provide significant insights into the practices and trends within the sausage production industry. The nearly ubiquitous presence of soy in industrial sausages suggests that soy is a standard ingredient in the production process of these products. Industrial manufacturers likely use soy for its functional properties, such as improving texture, water retention, and protein content, as well as for economic reasons. Soy is cost-effective compared to meat, allowing producers to reduce production costs while maintaining product quality.

The finding that 61.9% of traditional sausage samples contain soy indicates a significant, though not universal, use of soy in traditional sausage production. This may reflect variations in traditional recipes or the adoption of cost-saving measures by some traditional sausage producers. The lower prevalence compared to industrial sausages suggests that some traditional producers may adhere more closely to historical recipes that do not include soy. The lower prevalence of soy in traditional sausages may reflect cultural preferences and traditional methods of sausage-making that rely more heavily on meat. Traditional producers may prioritize maintaining authenticity and flavor profiles consistent with historical practices, which could limit the use of soy as an ingredient.

The use of real-time PCR in detecting soy DNA is a reliable and sensitive method, capable of identifying even trace amounts of soy. The high detection rate in this study underscores the method's effectiveness and reliability in food testing and allergen detection.

3.2. The Prevalence and Levels of the Presence of Soy DNA in Industrial and Traditional Sausages

Allergen RM-800 standard (Hygiene, former Biotecon) has been used to quantify the allergens in the sausages. To date, there are no official permitted levels of soy in the food. It is considered an allergen. Overall, 19 out of 63 samples had less than 10 ppm of soy. 9 samples had between 11 and 100 ppm, 11 samples between 101 and 1000 ppm, and 25 samples > 1001 ppm (higher levels above the quantification range). From the GI (industrial sausages), 35 samples (85.3%) exceeded a threshold of 10 ppm, where 5 samples had between 11 and 100 ppm, 11 samples had between 101 and 1000 ppm, and 20 samples had > 1001 ppm. On the other hand, 12 out of 21 traditional sausages (GII) exceeded a threshold of 10 ppm; 4 samples had between 11 and 100 ppm; 3 samples had between 101 and 1000 ppm; and 5 samples had > 1001 ppm (

Table 2).

Table 2.

Soy content comparison between GI and GII.

Table 2.

Soy content comparison between GI and GII.

| Soy content |

GI (industrial sausages) |

GII (traditional sausages) |

| < 10 ppm |

6 (14.63%) |

9 (42.90%) |

| 11 to 100 ppm |

5 (12.2%) |

4 (19.05%) |

| 101 to 1000 ppm |

11 (26.83%) |

3 (14.28%) |

| >1001 ppm |

20 (48.7%) |

5 (23.81%) |

The high prevalence of soy in industrial sausages (85.3%) highlights the common practice of using soy as an ingredient. The distribution of soy levels shows a significant number of samples (20) with very high soy content (>1001 ppm). This suggests that soy is being used not just as a minor additive but potentially as a major component in some products. The presence of soy at such high levels can be attributed to its cost-effectiveness, functional properties (e.g., emulsification, moisture retention), and its role as a meat extender. This practice helps manufacturers reduce costs while maintaining product characteristics.

The lower prevalence of soy in traditional sausages (57.1%) compared to industrial sausages suggests a more varied approach to soy usage. Traditional sausage producers may be less reliant on soy, possibly due to adherence to traditional recipes or consumer expectations. The fact that 5 traditional samples exceeded 1001 ppm indicates that some traditional producers also heavily rely on soy. This might be driven by similar economic reasons or attempts to improve texture and yield.

Overall, the GI had an average concentration of 12555 ppm, whereas the GII had an average concentration of 3650 ppm. This is a clear indication that industrial sausages are more likely to contain a larger amount of soy compared to traditional sausages. However, the ANOVA test failed to show statistical significance (p = 0.43). The soy content of each sample is shown in the supplementary material, Table S1. These results indicate that soya could be used extensively in industrial sausages and could be one of the factors contributing to the difference in price between industrial and traditional sausages.

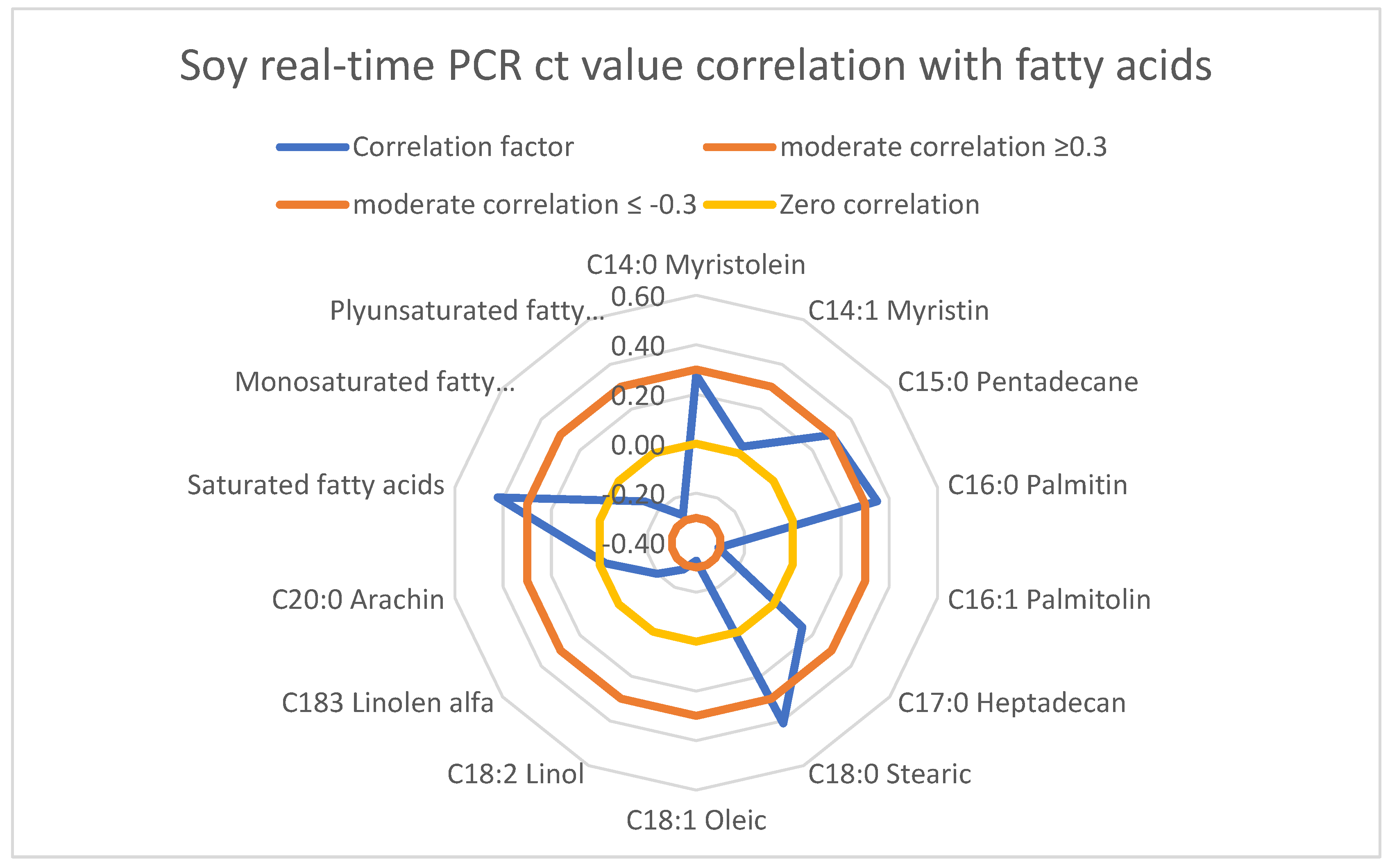

3.3. Concentration of Soya and Fatty Acid Profile

Furthermore, the concentration of soy in the sausage is reflected in the fatty acid profile. We investigated the correlation between ct values in real-time PCR for soy DNA with each fatty acid content. There is a moderate correlation of soy DNA ct values with C16:0 palmitin (decrease), C18:0 stearic acid (decrease), C18:1 oleic acid (increase), and overall saturated fatty acids (decrease). (

Figure 2).

The correlations between the amounts of soybean DNA in sausages and the fatty acid profile are as follows:

There is a moderate negative correlation between soy DNA ct values and the content of C16:0 Palmitic Acid. This suggests that as the amount of soy in the sausage increases, the content of palmitic acid decreases. Similarly, a moderate negative correlation is observed between soy DNA ct values and C18:0 Stearic Acid content. This indicates a reduction in stearic acid levels with higher soy content in sausages. The overall content of saturated fatty acids decreases as soy content increases, reflecting the specific trends observed for palmitic and stearic acids. Soy products typically contain lower levels of saturated fatty acids compared to animal fats. Soy oil, for example, has a higher proportion of unsaturated fatty acids. This substitution of animal fat with soy-derived ingredients in sausage formulations likely leads to a reduction in saturated fatty acids such as palmitic and stearic acids. The decrease in palmitic and stearic acids can be beneficial from a health perspective, as high levels of saturated fats are associated with an increased risk of cardiovascular diseases.

Conversely, there is a moderate positive correlation between soy DNA ct values and oleic acid content. This implies that as the soy content increases, the level of oleic acid also increases. Oleic acid is a monounsaturated fatty acid predominantly found in plant oils, including soy oil. The increase in oleic acid content with higher soy levels is consistent with the fatty acid profile of soy, which is rich in oleic acid. Oleic acid is considered heart-healthy and can help reduce bad cholesterol levels, providing a potential health benefit when soy replaces animal fat in sausages.

Correlation and Real-Time PCR ct Values: The ct (cycle threshold) value in real-time PCR indicates the cycle number at which the fluorescence of the PCR product crosses a threshold, reflecting the amount of target DNA present. Lower ct values indicate higher amounts of soy DNA. A moderate correlation between ct values and fatty acid content suggests a significant but not exclusive influence of soy on the fatty acid profile, indicating other factors may also play a role in determining the fatty acid composition of the sausages.

In the present study, it is unclear to what extent the fatty acid profile is influenced by other ingredients. However, an increase in oleic acid and a decrease in stearic and overall saturated fatty acids are expected.

3.4. The Means of Each Fatty Acid between GI (Industrial Sausages) and GII (Traditional Sausages) by Using the ANOVA Test

Here we also investigated the differences in means of each fatty acid between GI (industrial sausages) and GII (traditional sausages) by using the ANOVA test. There is a significant difference in means between groups of most fatty acids, except C14:0 Myristin, C18:1 Oleic, and C20:0 Arachin acids, as well as monosaturated fats (

Table 3).

The differences in means of each fatty acid between GI (industrial sausages) and GII (traditional sausages) by using the ANOVA are as follows:

Decrease in C16:0 Palmitic Acid and C18:0 Stearic Acid: These are major saturated fatty acids found in animal fats. Their decrease in sausages with higher soy content can be attributed to the substitution of animal fats with soy-based ingredients, which are naturally lower in these saturated fatty acids. Lower levels of saturated fats such as palmitic and stearic acids can be beneficial for cardiovascular health. Saturated fats are linked to increased levels of LDL cholesterol, which is a risk factor for heart disease. Thus, reducing these fats through the inclusion of soy can improve the nutritional profile of the sausages.

Increase in C18:1 Oleic Acid: This is a monounsaturated fatty acid commonly found in plant oils, including soy oil. The increase in oleic acid with higher soy content reflects the fatty acid composition of soy, which is rich in oleic acid. Oleic acid is considered heart-healthy as it can help reduce LDL cholesterol and increase HDL cholesterol. This shift towards higher oleic acid content makes the sausages potentially more beneficial for heart health.

Decrease in Overall Saturated Fatty Acids: The reduction in overall saturated fatty acids aligns with the decreases observed in palmitic and stearic acids. This is consistent with the replacement of animal fats by soy-based ingredients. The overall decrease in saturated fats and the increase in monounsaturated fats like oleic acid enhance the nutritional quality of the sausages. This is desirable from a public health perspective, given the current dietary guidelines recommending the reduction of saturated fat intake.

4. Conclusions

The research highlights the significant presence of soy in both industrial and traditional sausages in Kosovo, with higher levels predominantly found in industrial products. These findings have important implications for regulatory compliance, consumer safety, and industry practices. Ensuring accurate labeling and enhancing regulatory oversight are critical steps to address these issues, protect consumer health, and maintain trust in food products.

The moderate correlations observed between real-time PCR ct values for soy DNA and fatty acid profiles indicate significant changes in the fatty acid composition of sausages with increased soy content. Specifically, the decrease in palmitic and stearic acids and the increase in oleic acid reflect the fatty acid profile of soy, offering potential health benefits by improving the nutritional quality of sausages. These findings underscore the importance of considering both nutritional and sensory aspects when incorporating soy into sausage formulations.

Author Contributions

Conceptualization, X.B. and D.M.; methodology, D.M. and A.C.; formal analysis, D.M., V.G.Z. and M.SH.Z..; investigation, D.M., A.C.; writing—original draft preparation, D.M. and X.B.; review and editing, D.B. and Z.H.M; supervision, D.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

N/A.

Acknowledgments

The authors would like to thank the staff of the chemistry and molecular biology laboratory of the Kosovo Food and Veterinary Laboratory.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lebert, I., Leroy, S. and Talon, R., 2007. Microorganisms in traditional fermented meats –Chapter 11. Book Editor(s): Fidel Toldrá.

- Talon, R., Lebert, I., Lebert, A., Leroy, S., Garriga, M., Aymerich, T., Drosinos, E. H., Zanardi, E., Ianieri, A., Fraqueza, M.J., Patarata, L., Laukova, A. Traditional dry-fermented sausages are produced in small-scale processing units in Mediterranean countries and Slovakia. 1: Microbial ecosystems of processing environments, Meat Sci. 2007 Dec;77(4):570-9. [CrossRef]

- Roseiro, L. C., Gomes, A. and Santos, C. Influence of processing in the prevalence of polycyclic aromatic hydrocarbons in a Portuguese traditional meat product. Food and Chemical Toxicology, 2011, 49, 1340–1345. [CrossRef]

- Santos, C., Gomes, A. and Roseiro, L. C. Polycyclic aromatic hydrocarbons incidence in Portuguese traditional smoked meat products. Food and Chemical Toxicology, 2011, 49, 2343–2347. [CrossRef]

- Kurt, Ş., Kılınççeker, O. The efects of cereal and legume fours on the quality characteristics of beef patties. Kafkas Univ Vet Fak Derg, 2012, 18, 725- 730. [CrossRef]

- Belloque, J., Garcia, M.C., Torre, M., Marina, M.L. Analysis of soyabean proteins in meat products: A review. Crit Rev Food Sci, 2002, 42, 507-532. [CrossRef]

- Norman, AG., 1978. Soybean Physiology, Agronomy, and Utilization. 1st ed. Academic Press, New York, 1978.

- Paulo Cezar Bastianello Campagnol, Bibiana Alves Dos Santos, Roger Wagner, Nelcindo Nascimento Terra; The Effect of Soy Fiber Addition on the Quality of Fermented Sausages at Low-Fat Content; February 2013, Journal of Food Quality 36(1):41-50. [CrossRef]

- European Commission. (2008). "Regulation (EC) No 1333/2008 of the European Parliament and of the Council of 16 December 2008 on food additives. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32008R1333.

- European Commission. (2011). "Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the provision of food information to consumers.". Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32011R1169.

- Blom, W.M., Michelsen-Huisman, A.D., van Os-Medendorp, H., van Duijn, G., de Zeeuw-Brouwer M.L., Versluis, A., Castenmiller, JM., Noteborn H., Kruizinga, A., Knulst, A., Houben, G. Accidental food allergy reactions: Products and undeclared ingredients. J Allergy Clin Immunol 2018; 142: 865-875. [CrossRef]

- Parker, C.H., Khuda, S.E., Pereira, M., Ross, MM., Fu, TJ., Fan, X., Wu, Y., Williams, K., DeVries, J., Pulvermacher, B., Bedford, B., Zhang, X., Jackson., L. Multi-allergen quantitation and the impact of thermal treatment in industry-processed baked goods by ELISA and liquid chromatography-tandem mass spectrometry. J Agric Food Chem. 2015, 63: 10669-10680. [CrossRef]

- Crehan, C.M., Hughes, E., Troy, D.J., Buckley, D.J. Effects of fat level and Maltodextrin on the functional properties of frankfurters formulated with 5, 12 and 30% fat. Meat Sci. 2000, 55, 463-469. [CrossRef]

- Troutt, E.S., Hunt, M.C., Johnson, D.E., Claus, J.R., Kanstner, C.L., Kropf, D.H., Stroda, S. Chemical, Physical and Sensory Characterization of Ground Beef Containing 5 to 30 Percent Fat. J. Food Sci. 1992, 57, 25-29. [CrossRef]

- Martín, D., Ruiz, J., Kivikari, R., Puolanne, E. Partial replacement of pork fat by conjugated linoleic acid and/or olive oil in liver pâtés: Effect on physico-chemical characteristics and oxidative stability. Meat Sci. 2008, 80, 496–504. [CrossRef]

- Teye, M., Teye, G.A., Odoi, F.N.A. The potential of soya oil and egg-yolk as sources of fat in beef sausages. Scientific Journal of Animal Science 2012, 1(3) 81-89.

- Panea, B., Ripoll, G. Substituting fat with soy in low-salt dry fermented sausages. NFS Journal, 2021, 22, 1-5. [CrossRef]

- Soares, S., Amaral, J.S., Oliveira, M.B.P.P., Mafra, I. Quantitative detection of soybean in meat products by a TaqMan real-time PCR assay. Meat Sci, 2014 Sep;98(1):41-6. [CrossRef]

- Muratoğlu, K., Yilmaz-Eker, F., Ozgen-Arun, O. PCR detection of Soy Protein in ready to Eat Meat Doners. Kafkas Universitesi Veteriner Fakultesi Dergisi, 2016, 22(4): 557-560. 5.

- Kim, J.H., Song, J.Y., Hong, Y., Kim, H.Y. Monitoring of genetically modified soybean events in sausage products in South Korea. Food Control, 2016, 67:63-67. [CrossRef]

- Kesmen, Z., Sahin, F., Yetim, H. PCR assay for the identification of animal species in cooked sausages. Meat Science, 2007, 77 (4): 649-653. [CrossRef]

- Guntarti, A., Ahda, M., Kusbandari, A. Determining fatty acids and halal authentication of sausage. Food Research, 2020, 4 (2): 495 – 499. [CrossRef]

- Pereira, N.R., Tarley, C.R.T., Matsushita, M., de Souza, N.E. Proximate Composition and Fatty Acid Profile in Brazilian Poultry Sausages. Journal of Food Composition and Analysis. 2000, 13, 915:920. [CrossRef]

- Renčová, E., Tremlová, B. ELISA for Detection of Soya Proteins in Meat Products. Acta Veterinaria Brno, 2009, 78(4):667-671. [CrossRef]

- Ulca, P., Balta, H., Senyuva, H.Z. A survey of the use of soy in processed Turkish meat products and detection of genetic modification. Food Additives and Contaminants: Part B Surveillance, 2014, 7 (4) :261-6. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).