2.2. Analysis of True Stress-True Strain Curve of U-50wt.%Zr Metal Fuel during Thermal Deformation

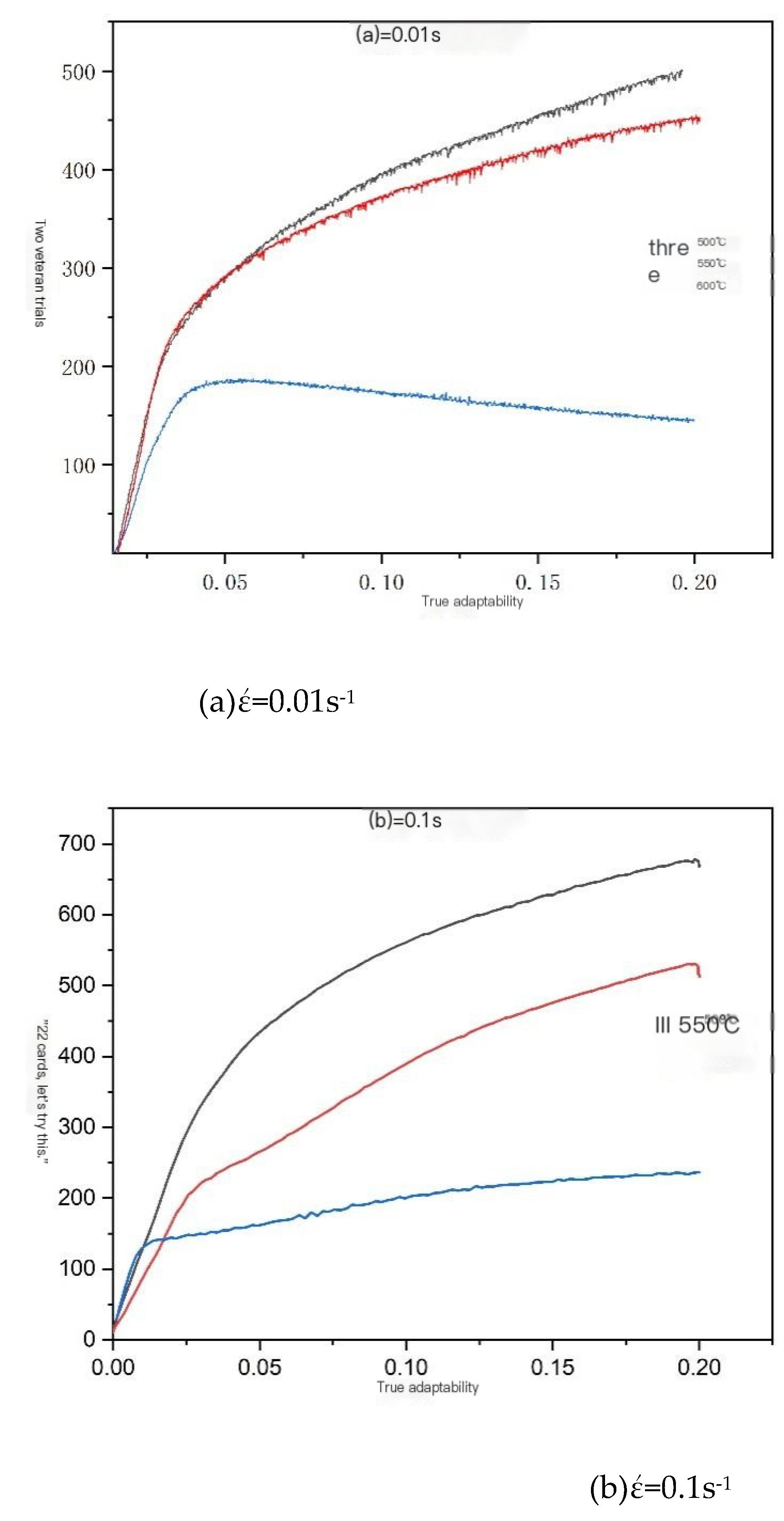

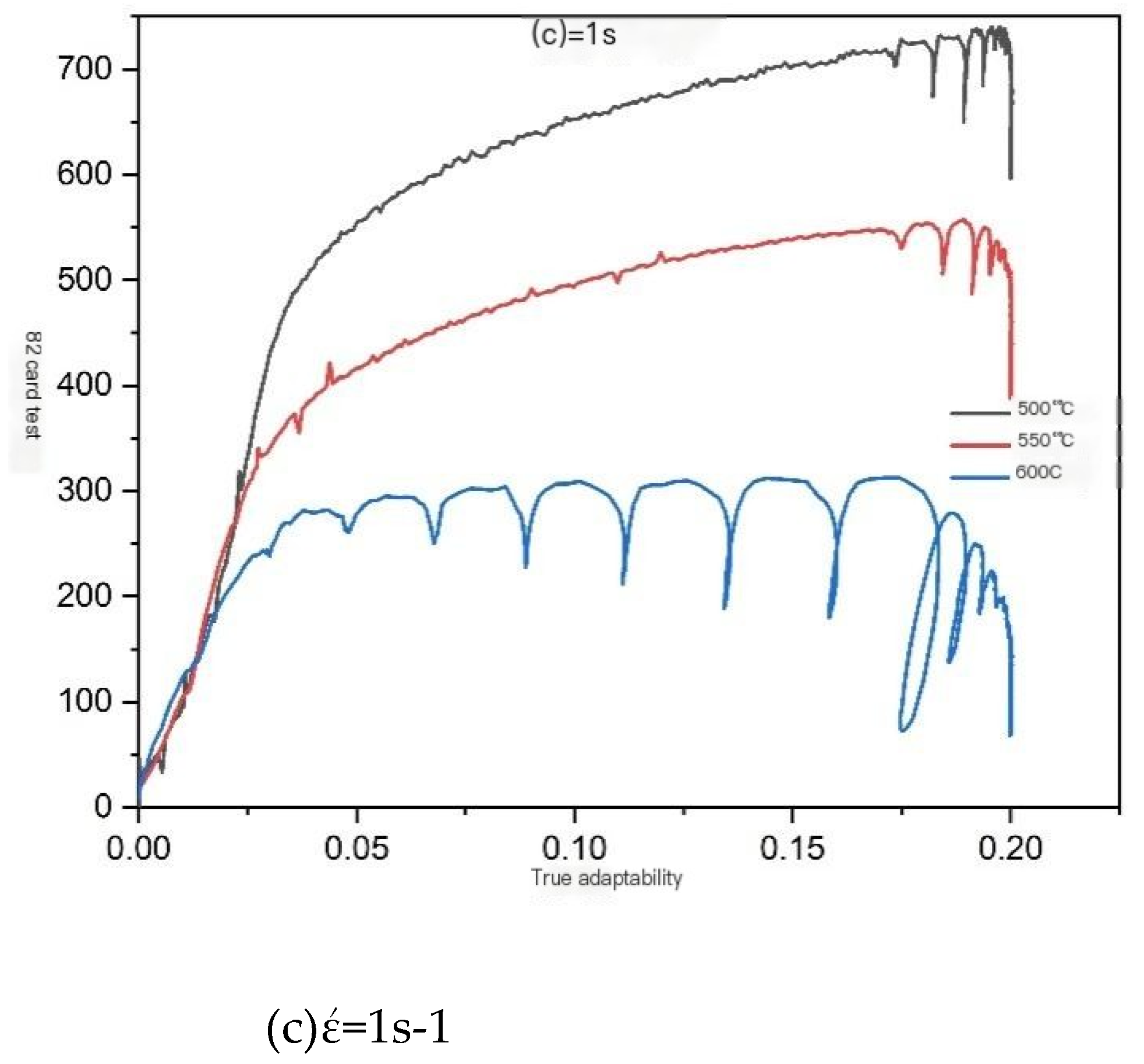

The true stress-true strain data obtained from the experiment were processed to obtain the true stress-true strain relationship curves at different temperatures under various strain rates, as shown in

Figure 6. It can be observed from the figure that the deformation temperature, strain rate, and true strain have a significant impact on the rheological stress of the sample. In the initial stage of thermal deformation, the rheological stress increases rapidly with the increase of true strain. During this deformation stage, as the true strain increases, dislocations proliferate rapidly, and a large number of dislocations entangle and accumulate with each other, leading to a significant increase in work hardening. Therefore, the work hardening mechanism is the main reason for the increase in rheological stress in the initial stage of thermal deformation—e.g., [

6,

7].

At the same strain rate, the peak stress decreases with increasing deformation temperature. The peak stress reaches a maximum of 740MPa at deformation temperatures of 500℃ and 550℃, while it is around 200MPa at 600℃. As shown in

Figure 6(a), the peak stress at a strain rate of 0.01 s-1 decreases by 10% at 550℃ compared to 500℃, and decreases by 59% at 600℃ compared to 550℃. As shown in

Figure 6(b), the peak stress at a strain rate of 0.1 s-1 decreases by 24% at 550℃ compared to 500℃, and decreases by 54% at 600℃ compared to 550℃. As shown in

Figure 6(c), the peak stress at a strain rate of 1 s-1 decreases by 25% at 550℃ compared to 500℃, and decreases by 44% at 600℃ compared to 550℃. From the above results, it can be seen that there is only a 50℃ difference between 550℃ and 600℃, but the peak stress difference is about 50%. Therefore, the U-50wt.%Zr metal-type fuel should undergo microstructural changes at 600℃.

Under the same deformation temperature, the peak stress increases with the increase of strain rate. At 500℃, the peak stress at a strain rate of 1s-1 increased by 48% compared to that at a strain rate of 0.01s-1. At 550℃, the peak stress at a strain rate of 1s-1 increased by 24% compared to that at a strain rate of 0.01s-1. At 600℃, the peak stress at a strain rate of 1s-1 increased by 68% compared to that at a strain rate of 0.01s-1. From the above results, it can be seen that the peak stress increases significantly with the increase of strain rate, mainly due to the sufficient time for dynamic recrystallization of U-50wt.%Zr metal fuel during thermal deformation, resulting in a significant decrease in peak stress at a strain rate of 0.01s-1 compared to that at strain rates of 0.1s-1 and 1s-1.

Based on the above analysis, it can be observed that the thermal deformation behavior of U-50wt.%Zr metal-type fuel at 600℃ with a strain rate of 0.01s-1 exhibits significant dynamic recrystallization. However, at 500℃ and 550℃ with higher strain rates, the dynamic recrystallization phenomenon is not evident, and the thermal deformation behavior is dominated by work hardening. Therefore, the true stress-strain curve of U-50wt.%Zr metal-type fuel can be divided into two types: one is the dynamic recrystallization type curve, as shown in the true stress-strain curves at different strain rates at 600℃ in the figure. Specifically, as the true strain increases, the flow stress gradually decreases until reaching a steady-state stress. This phenomenon weakens with an increase in strain rate. When the strain rate is 1s-1, the time of dynamic softening effect is shortened, and the stress curve exhibits severe fluctuations. The other type is the work hardening type curve, as shown in the true stress-strain curves at different strain rates at 500℃ and 550℃. The true stress increases with the increase of strain, showing an overall work hardening state without reaching steady-state flow.[

8,

9]

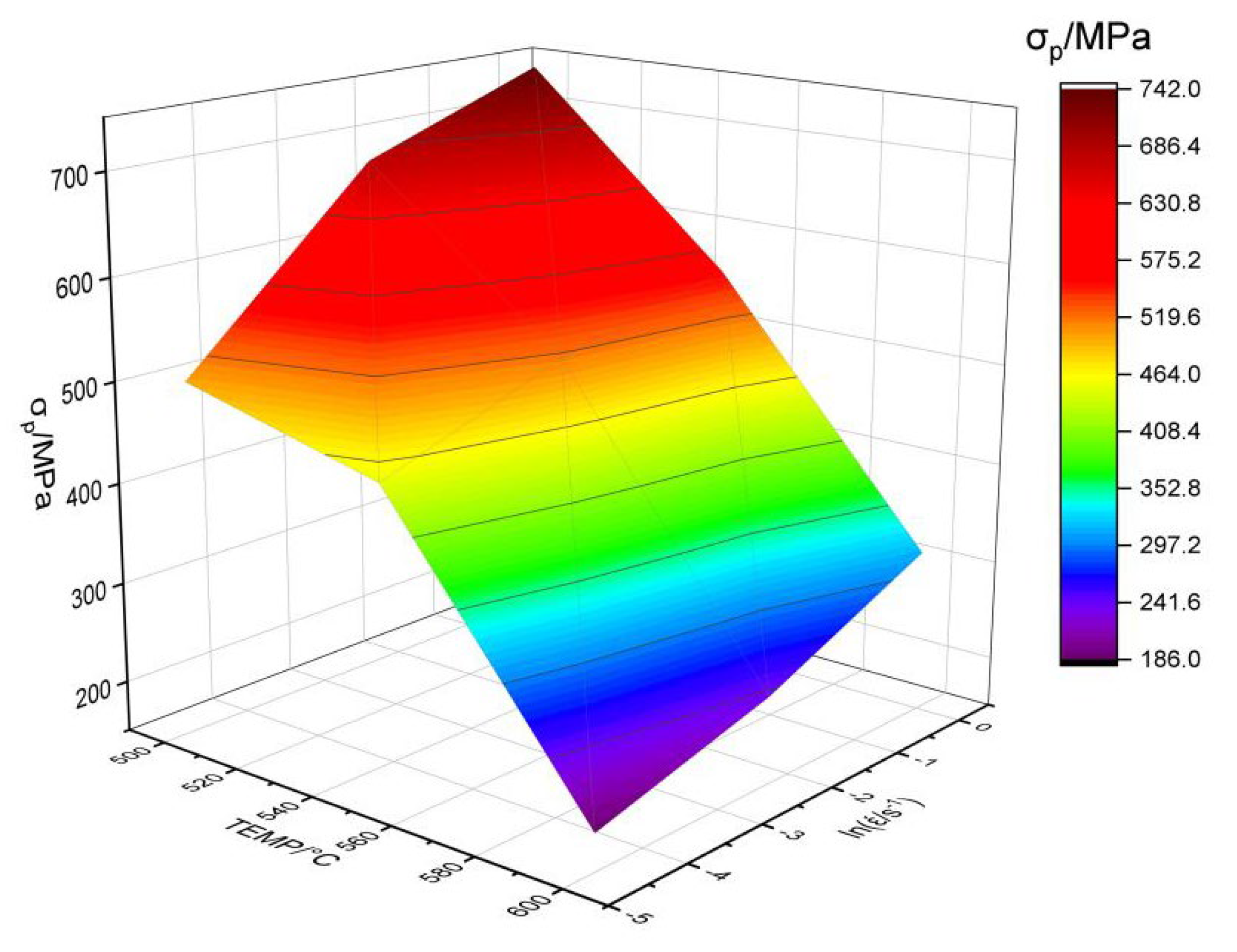

Figure 7 illustrates the 3D peak stress diagram of U-50wt.%Zr metal fuel under various deformation conditions. It can be observed that the peak stress decreases with increasing temperature and decreases with decreasing strain rate.

2.3. Microstructural Analysis of U-50wt.%Zr Metal-Type Fuel

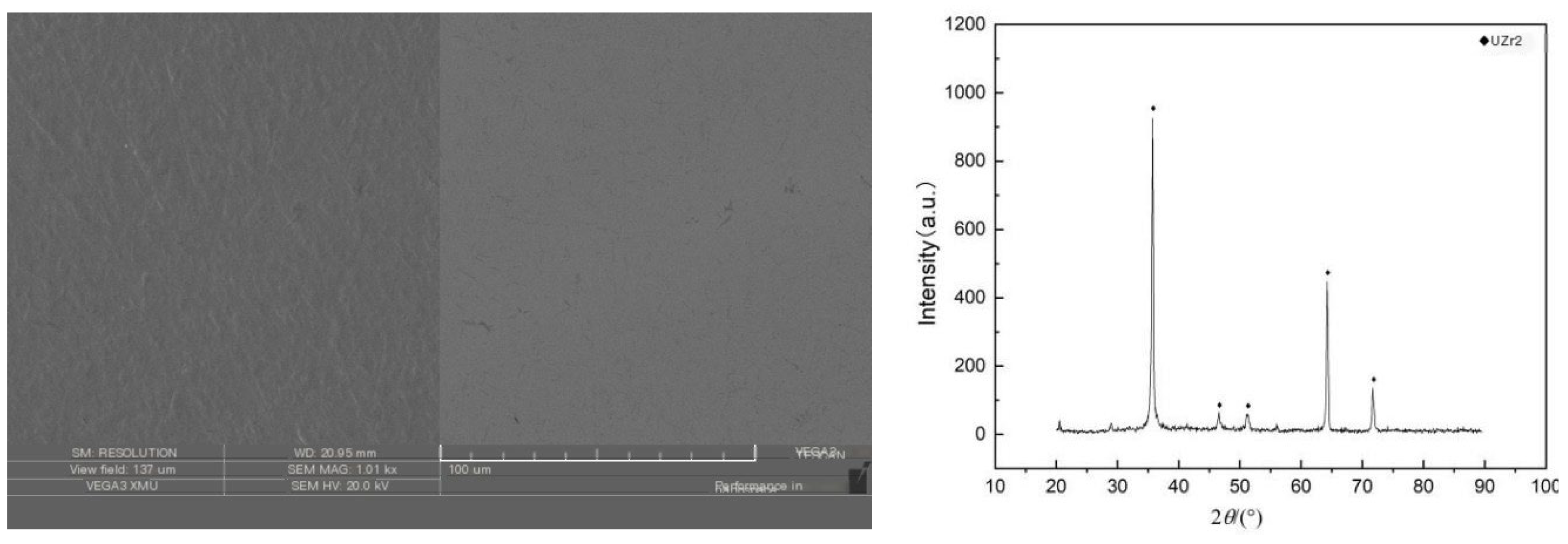

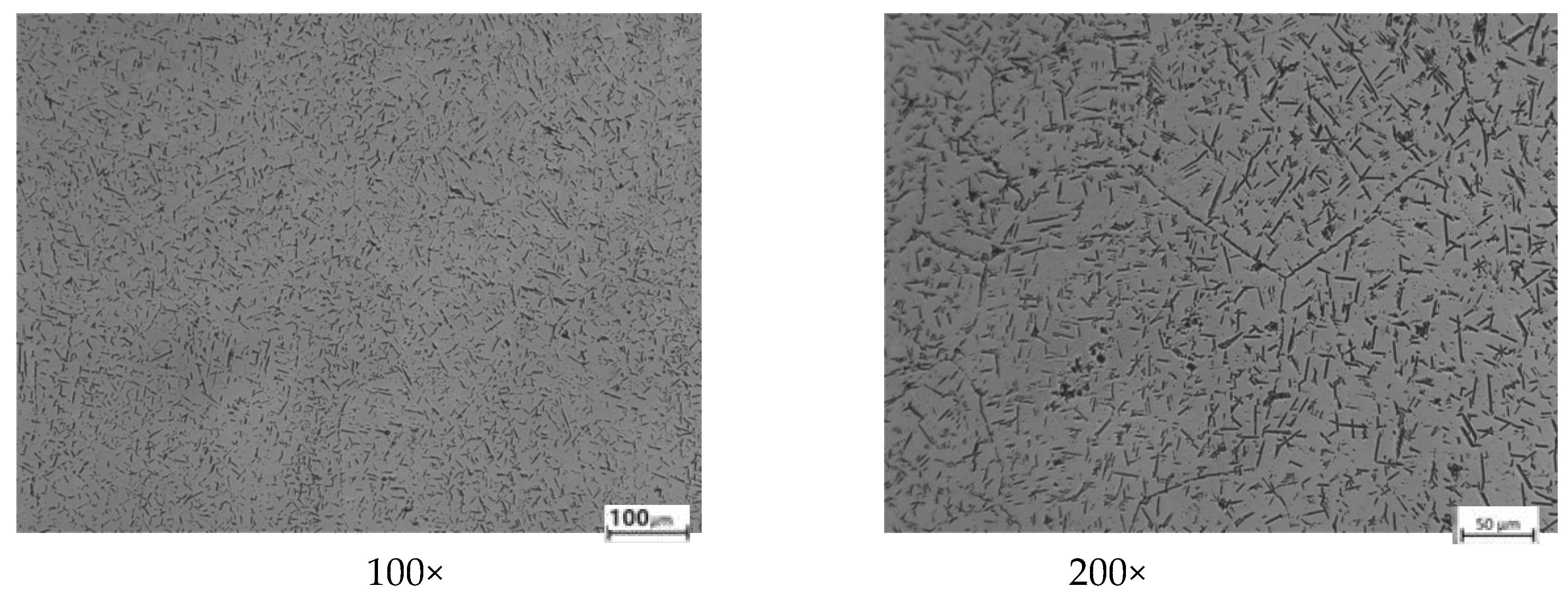

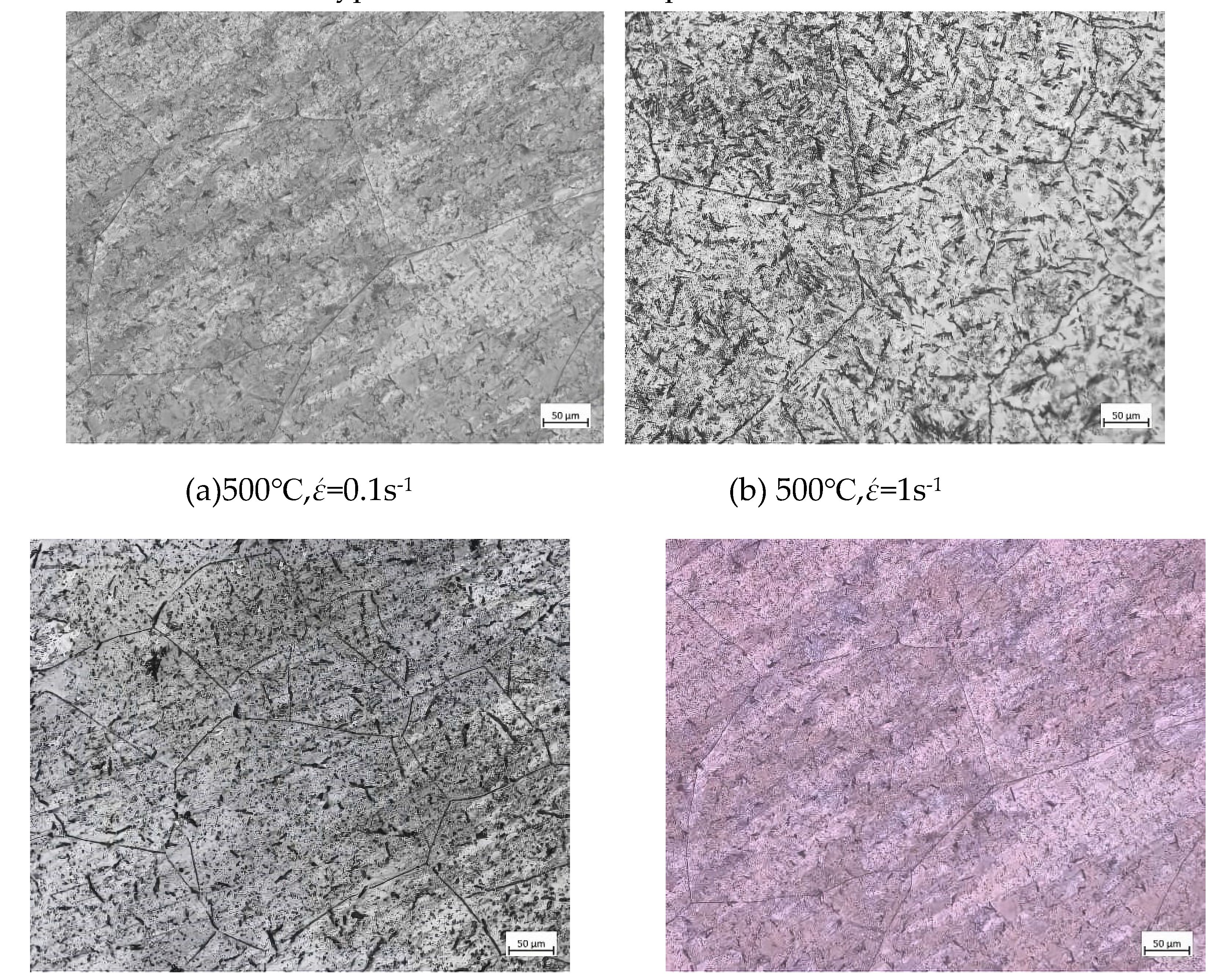

Metallographic examination was conducted on the cross-section of the deformed area of the thermally compressed sample. The results are shown in

Figure 8. It was observed from the figure that under the same strain rate conditions, the thermal deformation temperature had an impact on its metallographic microstructure. At strain rates of 0.1s-1 and 1s-1, the grain size changes were not significant at 500℃ and 550℃, with grain sizes around 250μm. At 600℃, the grain size reached 493μm, indicating grain growth after thermal deformation at this temperature. As the strain rate increased, there were no significant changes in the shape and structure of the grain boundaries and grains of U-50wt.%Zr metal-type fuel at the same temperature.

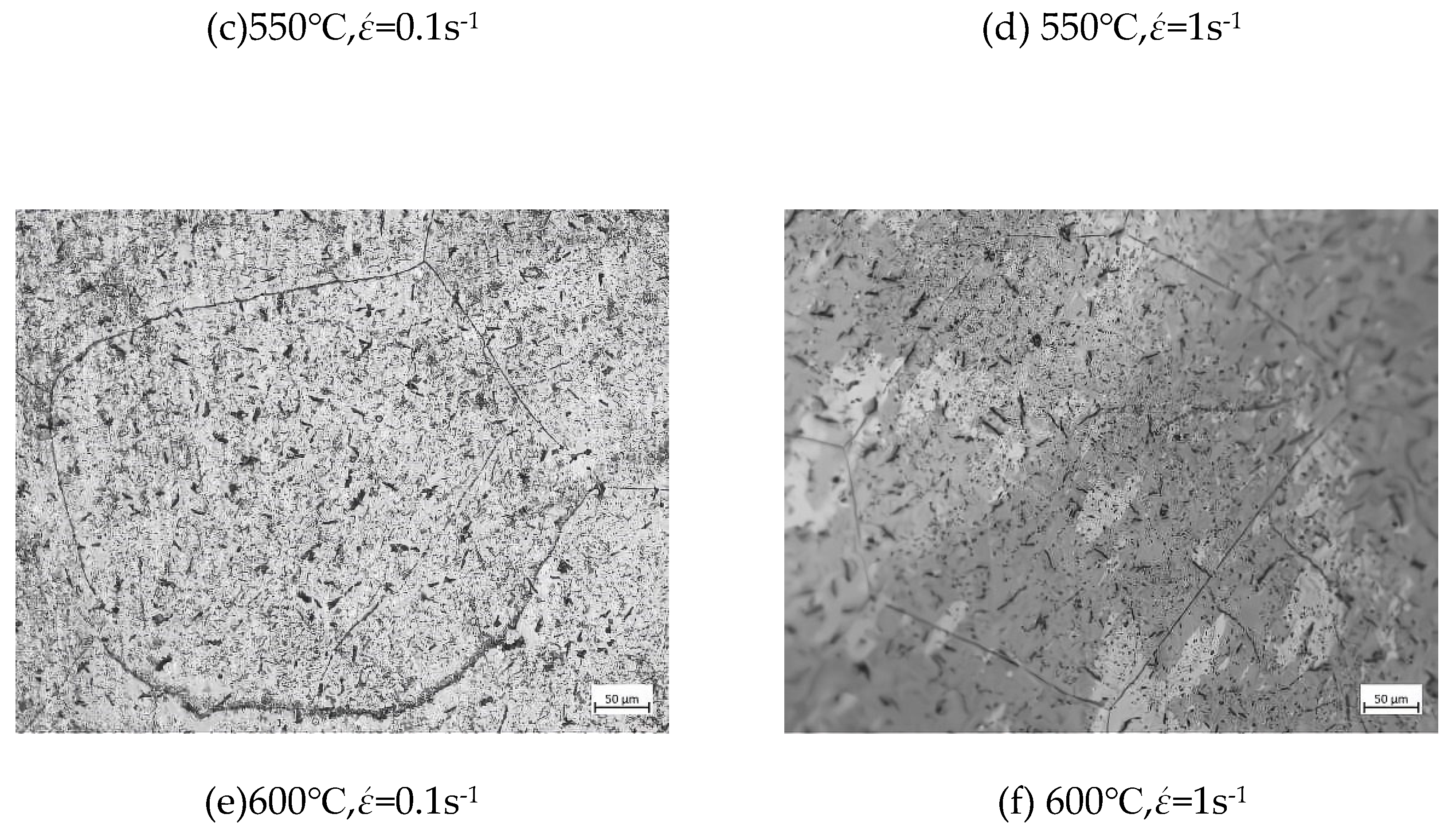

The samples after the experiment were subjected to X-ray diffraction testing, and their phases were identified through a database. The phase results of U-50wt.%Zr metal-type fuel subjected to compression experiments at different strain rates and temperatures are shown in

Figure 9. After thermal deformation, the U-50wt.%Zr metal-type fuel maintains the UZr

2 phase, which is known as the δ phase according to the phase diagram —e.g., [

10]. After thermal deformation at 500℃, 550℃, and 600℃, the U-50wt.%Zr metal-type fuel is in the δ-UZr

2 phase.

2.4. Construction of Arrhenius Constitutive Equation for U-50wt.%Zr Metal-Type Fuel

Based on the results of the hot deformation test, the relationship between peak stress, strain rate, and temperature of U-50wt.%Zr metal-type fuel was fitted using the Arrhenius equation. The study focused on the relationship between temperature, deformation rate, and deformation resistance of U-50wt.%Zr metal-type fuel within a strain rate range of 0.01~1s-1 —e.g., [

11,

12,

13,

14].

In the formula:

represents the strain rate, s-1;

is a constant;

is a

function related to ;

denotes the activation energy for thermal deformation, J/mol; represents the

gas constant, which is 8.314J/(mol·K);

stands for the thermodynamic temperature, K; and

represents the peak stress, MPa.

In the formula

,

,

, and are constants, where

Taking the natural logarithm on both sides of equation (1), we can obtain equations (3), (4), and (5) after rearranging.

Where , and are constants.

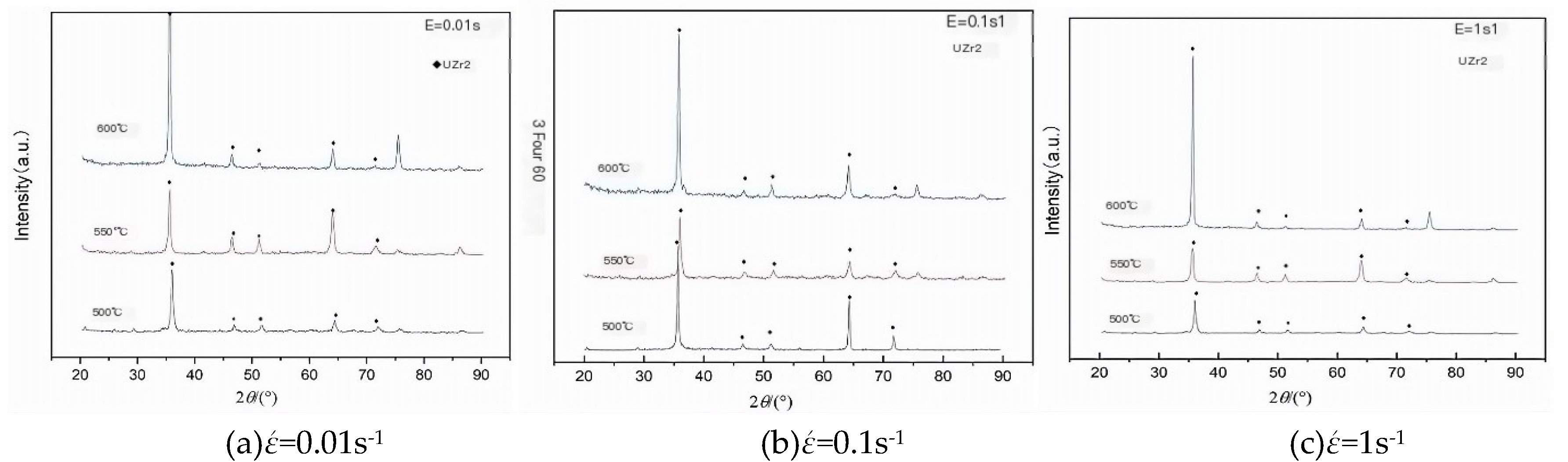

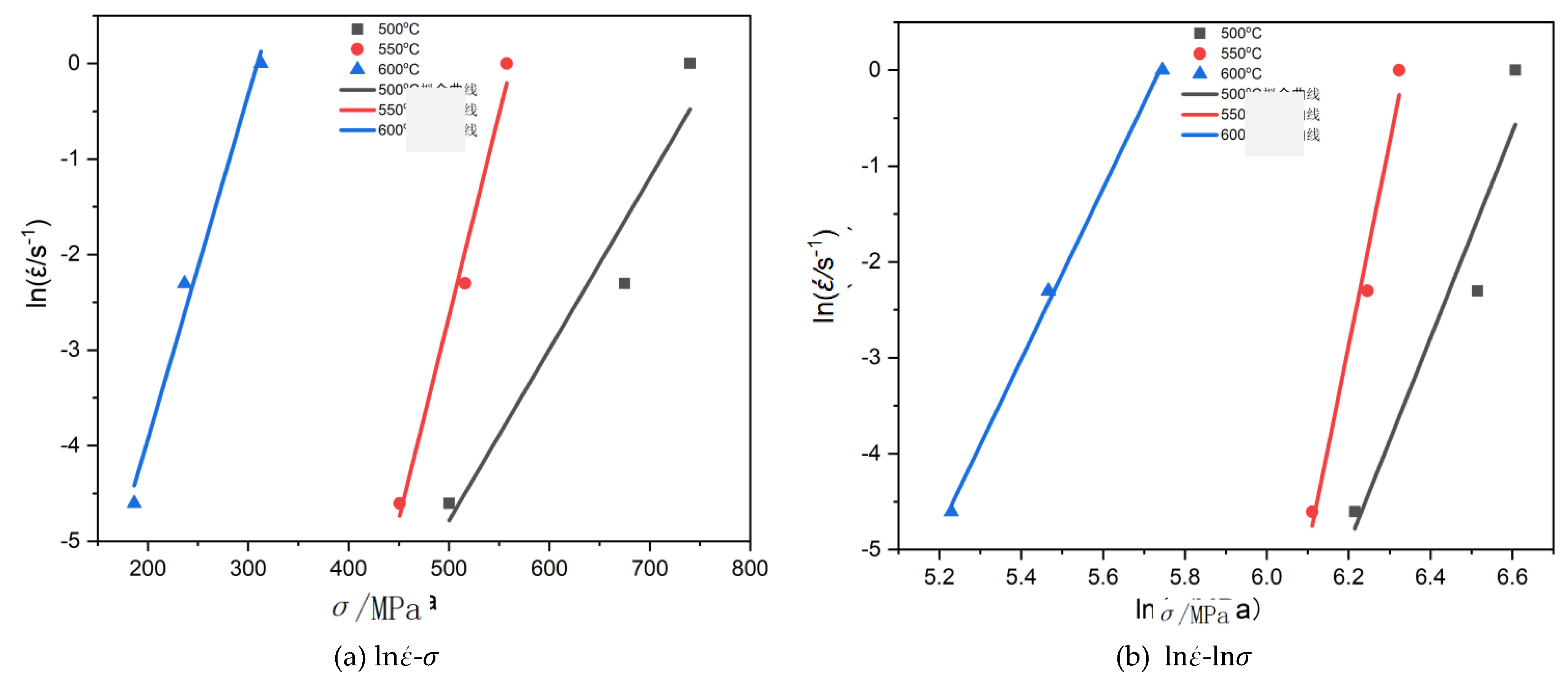

Assuming that the peak stress, strain rate, and temperature have

minimal influence on the activation energy of thermal deformation and remain constant

, it can be observed from equations (3) and (4) that if we use

and

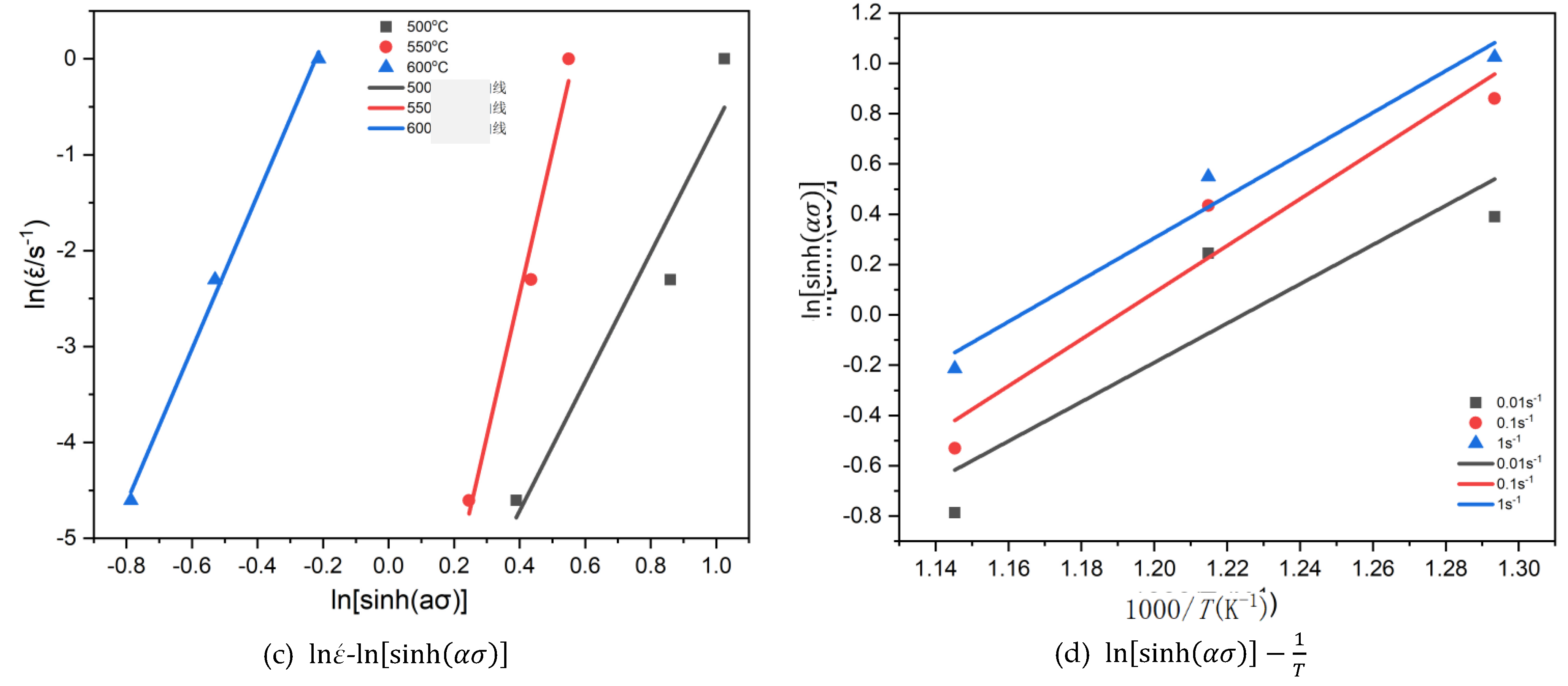

as the horizontal coordinates and as the vertical coordinate for fitting, and employ the least squares method for linear regression to determine the slope of the straight line, we can obtain and. As shown in

Figure 10(a,b), by calculating the average values of the slopes of the fitted straight lines, we obtain

13.6035,

0.03215, and

0.00236. Substituting the values of into equation (5) and performing a linear fitting, as shown in

Figure 10(c). Zener and Hollomon proposed a

parametric equation that can be used to represent the relationship between the strain rate and temperature during high-temperature plastic deformation of materials, as shown in equation (6). [

15]

Taking the natural logarithm of both sides of equation (6) and rearranging, we obtain equation (7).

From equation (7), it can be observed that under a constant strain rate

, a linear fit can be applied to

, with the slope representing the

value of. Through further calculations, the thermal deformation activation energy can be determined. The slope of the straight line in

Figure 10(d)

is, and its average value is 9.8638. The average slope of the three fitted straight lines is 8.4734, and the thermal deformation activation energy is calculated to be 694.9 kJ/mol.

Taking the natural logarithm of both sides of equation (6) and rearranging, we can obtain equation (8).

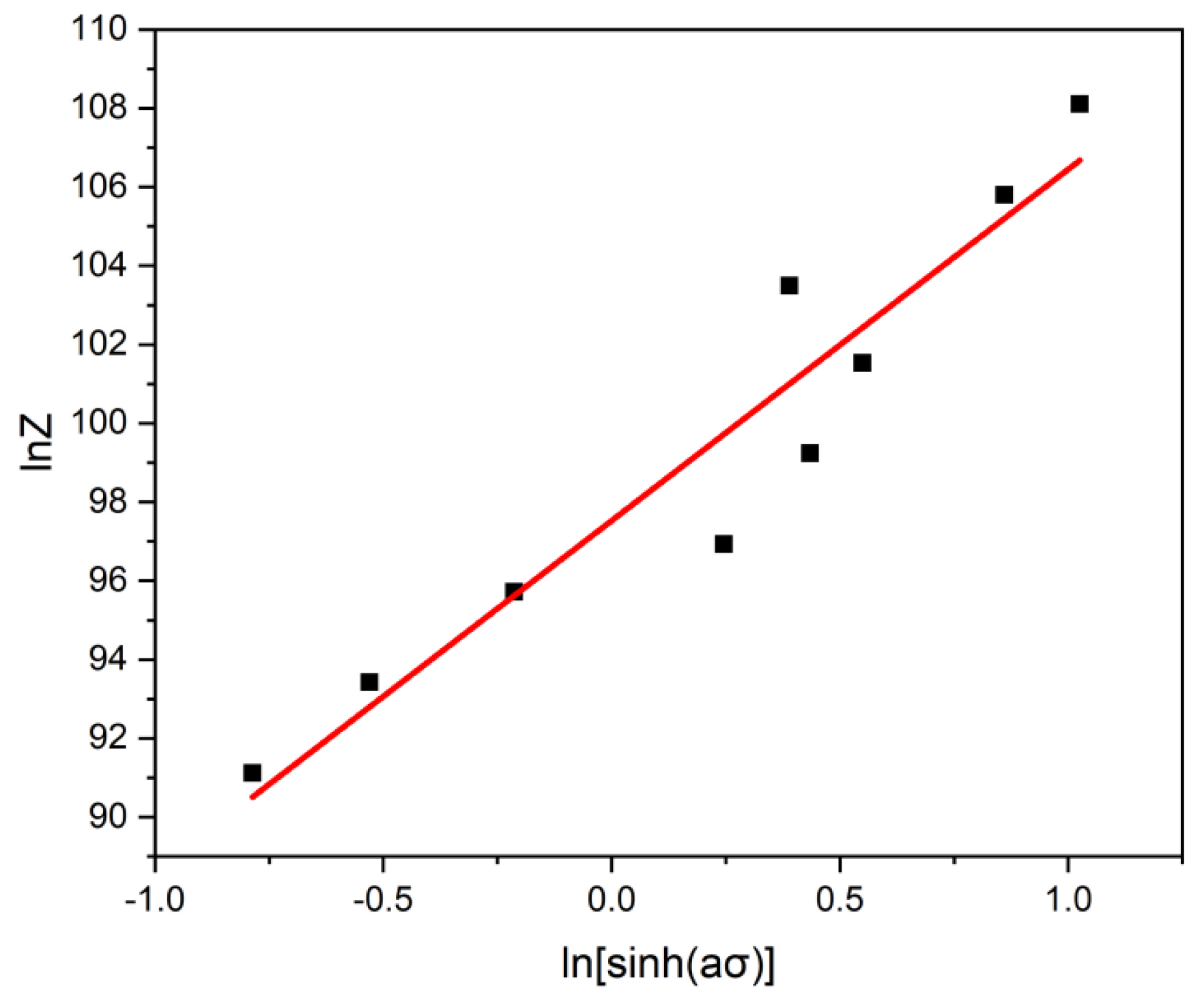

Substitute the corresponding strain rate, temperature, and thermal deformation activation energy into equation (6) to calculate the corresponding values, and then perform fitting. The slope of the fitted line is , and the intercept of the line with the vertical axis is .

The slope

of the fitted straight line in

Figure 11 is 8.9236, with an intercept of 97.527 and a

fitted value of 8.9236. The

calculated value is 2.267×10^42.

By

substituting

,

,

and into formula (1), we can obtain the constitutive equation (9) for U-50wt.%Zr metal-type fuel.

By varying (9), we can obtain the relationship between peak stress, temperature, and strain rate (10).

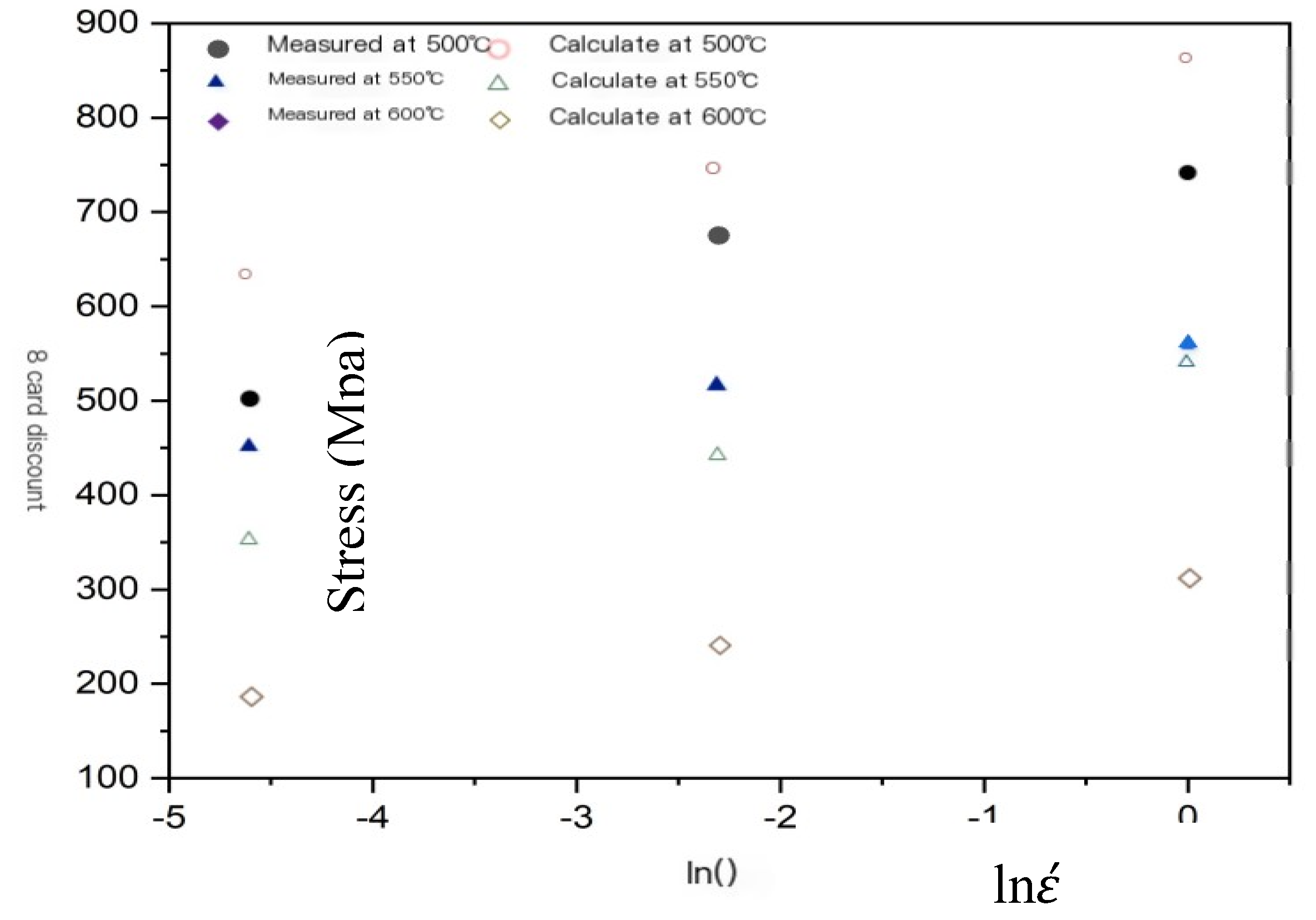

To verify the accuracy of the constitutive equation, the experimental results obtained under different temperatures and strain rates were substituted into equation (10) to theoretically calculate the peak stress. The calculated theoretical values were then compared with the measured peak stresses.

The theoretical and measured values of peak stress in

Figure 12 are relatively close, indicating that the constitutive equation can effectively describe the relationship between temperature, deformation rate, and deformation resistance of U-50wt.%Zr metal-type fuel within the temperature range of 500℃~600℃ and strain rate range of 0.01s

-1~1s

-1.

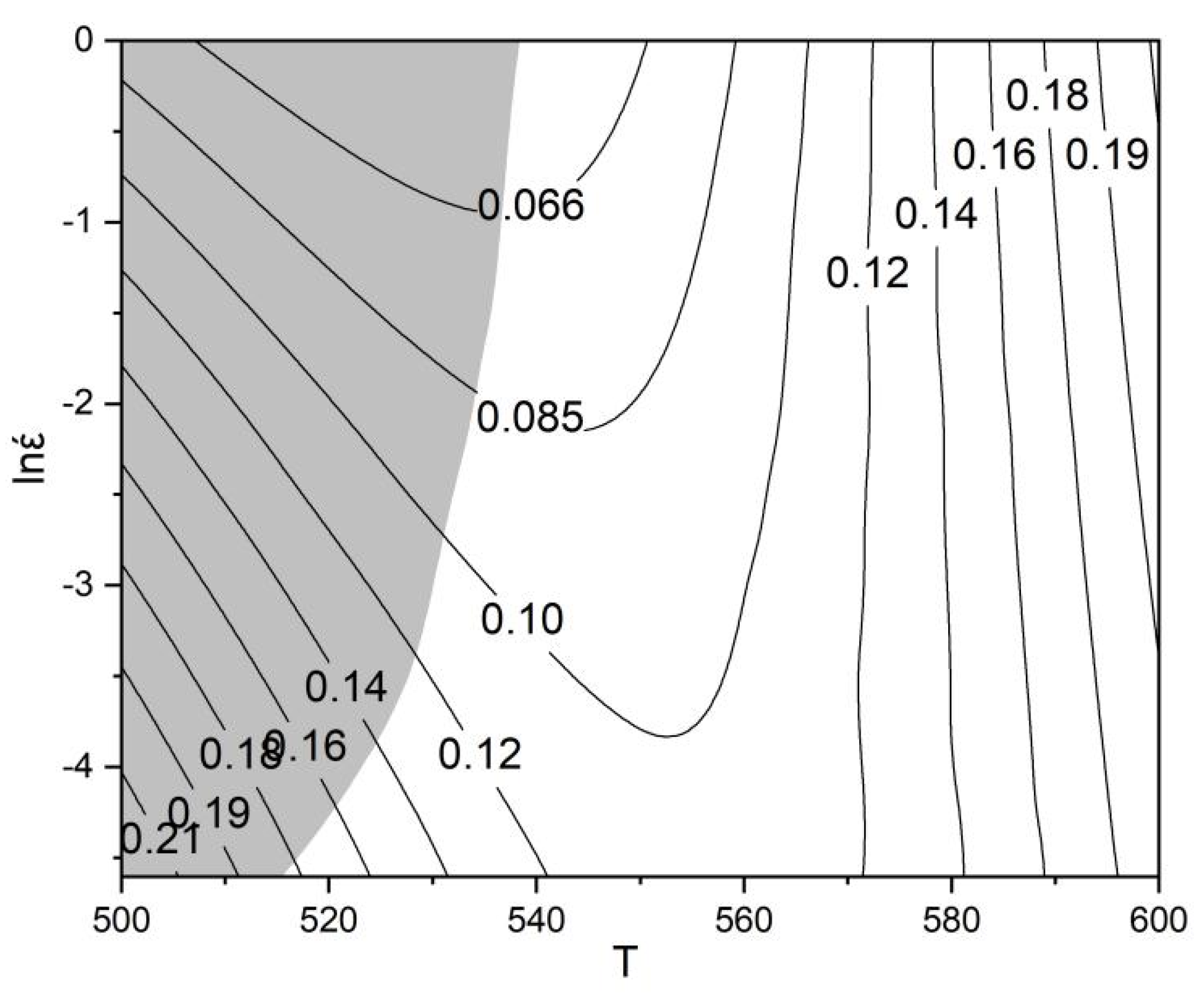

2.5. Establishment of Hot Working Diagram

This article utilizes the DMM dynamic material model [

16] to process experimental data from the Gleeble3800 thermal simulator, constructing a thermal processing diagram for U-50wt.%Zr metal-type fuel. During thermal deformation of the material, the total energy

can be calculated using equation (11).

In the formula: represents the energy consumed by plastic deformation (dissipation); represents the energy consumed by structural changes (dissipation).

During the deformation process of materials, the deformation stress and strain rate follow a power-law relationship, with the exponent being the strain rate sensitivity coefficient, which can be calculated using equation (12).

Calculate

using formulas (13) and (14).

When

=1, the dissipation state of material thermal deformation is optimal,

reaching its maximum value, as shown in

equation (15).

The energy dissipation efficiency of microstructural changes in materials during hot deformation can be calculated using equation (16).

The instability of U-50wt.%Zr metal fuel during thermal deformation can be judged using criterion (17).

Using Origin, power dissipation diagrams and instability diagrams were plotted after arranging the data in a matrix

. These diagrams were then superimposed to establish a thermal processing diagram for U-50wt.%Zr metal-type fuel.

Figure 13 shows the thermal processing diagram for U-50wt.%Zr metal-type fuel, where the contour lines represent the power dissipation factor. The gray area indicates the processing instability zone, while the white area represents the zone suitable for pressure processing. In the white zone, a higher power dissipation factor is beneficial for thermal pressure processing.