1. Introduction

White pan bread, one of the most widely consumed bakery products, is made by fermenting and baking dough mixed with flour, water, salt, yeast, and butter as main ingredients. It is continuously gaining attention as a snack or meal replacement due to its mild sweetness and soft texture [

1]. As the demand for products that satisfy not only convenience and preference but also health benefits increases, a lot of research is being conducted for product development [

2]. The development and quality improvement of bakery products are largely achieved through the use of new ingredients, advancements in processes, and meeting social demands [

3]. Research on varying the ingredients of white pan bread includes studies on rice flour-added white bread made with different main ingredients such as flour, sugar, and water [

4], white bread made using yacon concentrate as a sugar substitute [

5], and bread made with different types of water [

6]. There is also active research on adding functional ingredients such as kelp powder [

7], black garlic extract [

8], and cacao nibs powder [

9]. Research on processes applying new machinery includes studies utilizing near-vacuum high-speed mixers and microwave ovens [

3,

10,

11]. In the case of bread-making research, studies on the physical properties and sensory quality characteristics of bread according to the addition of functional sub-ingredients are mainly conducted [

12], while research related to process application is hardly being conducted. The introduction of new equipment or innovative approaches in bread-making processes to meet the demands of consumers who want high-quality bread is expected to improve the physical properties of existing white pan bread and offer differentiation.

Bread is made through the processes of mixing, fermentation, and baking [

13], and each step significantly influences the final product. The mixing process involves evenly dispersing and hydrating all ingredients to form gluten. Wheat flour contains gliadin, which contributes to the viscosity and extensibility of the dough, and glutenin, which contributes to its elasticity. When water is added and physical force is applied through mixing, gluten with viscoelastic properties is formed. The network structure of gluten traps the carbon dioxide gas produced by yeast, allowing the dough to rise [

14,

15,

16]. Fermentation is a crucial process that greatly affects the product’s quality. During fermentation, the dough expands due to the carbon dioxide produced by yeast. The dough undergoes maturation through enzymatic activity, metabolite action, physical effects, and interactions between ingredients, making it softer and maximizing its gas retention capacity. Additionally, alcohol, organic acids, esters, and volatile compounds produced by yeast and lactic acid bacteria impart a unique flavor to the bread [

17]. The baking process is the final stage that determines the bread’s quality [

18]. During baking, carbon dioxide and alcohol produced during fermentation, along with the moisture in the dough, evaporate, reducing the product’s weight and increasing its volume. The heat denaturation of proteins and gelatinization of starch make digestion easier. Caramelization and the Maillard reaction occur, enhancing the product’s color and flavor [

19]. The bread-making process, even in the basic straight dough method, typically consists of 10 steps, making it highly complex with many considerations for each step.

High-voltage pulsed electric fields (PEF) technology is a method in which a high-voltage pulse is applied to food placed between two electrodes. Since it is processed for less than a few seconds at room temperature or a suitable temperature that does not cause thermal damage, the temperature of the food does not rapidly increase during process treatment. This allows the food to maintain its original taste, color, texture, nutrients, and efficacy [

20,

21]. PEF technology has been mainly applied to the sterilization of low-viscosity liquid foods such as fruit and vegetable juices since research on microbial inactivation began in the 1960s. Subsequently, research on the sterilization of high-viscosity liquid foods and solid foods has also been conducted. The scope of application in food has expanded beyond sterilization to include the extraction of pigments and beneficial components, pre-treatment for freezing or drying, changes in meat quality, and changes in starch properties [

22]. Aibara [

23] reported that the quality of bread improved with PEF treatment, demonstrating its potential applicability in the baking field. To date, most studies using PEF technology in the food industry have focused on sterilization. Research applying it to the baking field is still in its early stages, and in particular, research on the optimal treatment conditions that affect the quality characteristics of bread is scarce. This study aimed to find the optimal treatment time for using PEF technology in the production of white pan bread by measuring the quality properties of the dough and bread.

2. Materials and Methods

2.1. Materials

The materials used in the experiment were wheat flour (Samyang Co., Asan, Korea), sugar (CJ Cheiljedang Co., Incheon, Korea), salt (CJ Cheiljedang Co., Shinan, Korea), fresh yeast (Jenico Foods Co., Ltd., Pyeongtaek, Korea), defatted milk powder (Seoul Milk Co-Op., Yangju, Korea), improver (Puratos Korea Co., Ltd., Chungju, Korea), and shortening (Ottogi Co., Anyang, Korea). All materials were purchased as domestic products through an online mall.

2.2. High-Voltage Pulsed Electric Fields System and Treatment Method

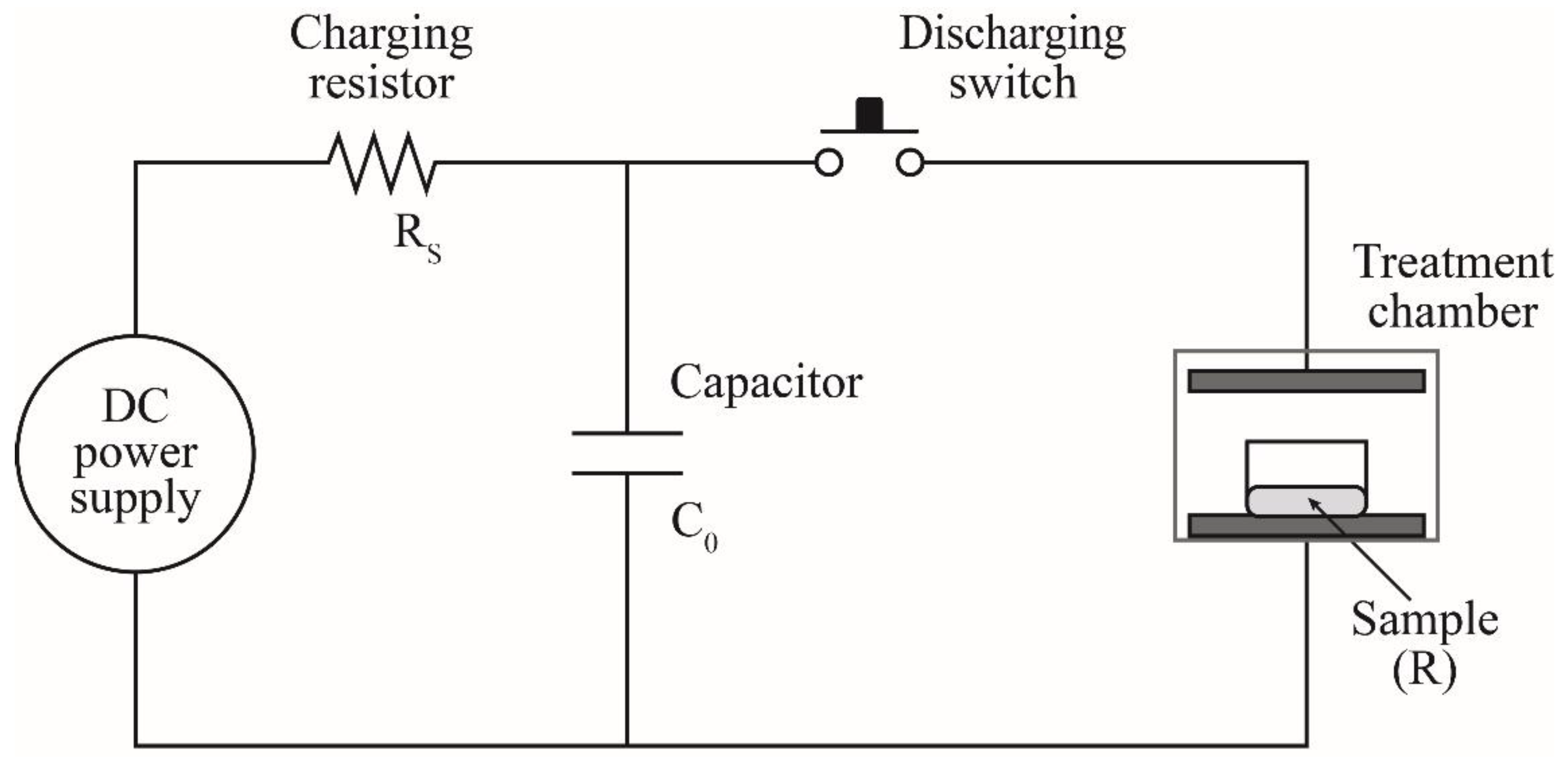

The high-voltage pulsed electric field system (Smart PS, Dong A High Tech. Co., Ltd., Busan, Korea) used in the experiment was designed and manufactured for laboratory use. Its overall configuration and schematic diagram are shown in

Figure 1. The main components of the system consist of a power supply unit, the pulse generator, and a treatment chamber. The power supply unit boosts and rectifies the 220V AC input power through a high-voltage transformer to generate a maximum of 65 kV DC power. The pulse generator is composed of a pulse-forming network that determines the shape and length of the pulse, and a switch that instantaneously discharges the charged high voltage. The pulse-forming network consists of a capacitor and a discharge delay inductor. The treatment chamber is made of polycarbonate material, which has insulation and transparency properties, allowing the interior of the chamber to be observed during treatment. The internal electrode is installed in the form of parallel plates, and the distance between the electrodes can be adjusted by a handle connected to the upper electrode, allowing the desired intensity of the electric field to be formed. The external size of the treatment chamber is 480×390×365 mm, and the size of the electrodes is 400×370×5 mm. The maximum voltage of the device is <65 kV, the frequency is <30 Hz, the pulse width is 100 μs, and the operating time is <1 h. The bread dough samples were placed in a heat-resistant glass container measuring 220×190×135 mm (width×depth×height). The dough height was adjusted to a uniform 5 cm to ensure a consistent electric field. The distance between the electrodes was set to 20 cm, and the container holding the bread dough was placed in the center of the lower electrode. The device was then configured with the desired voltage, frequency, pulse width, and treatment time for bread dough processing. The electric field intensity was calculated by dividing the applied voltage by the distance between the electrodes [

24]. The experiments were conducted at an indoor temperature of 15℃. The applied electric field intensity was set at 1.5 kV/cm, 2.0 kV/cm, 2.5 kV/cm, and 3.0 kV/cm, and the treatment time was set at 20 minutes based on preliminary experiments. The frequency and pulse width were fixed at 10 Hz and 100 μs, respectively, for all experiments.

2.3. Making of White Pan Bread

The bread dough's ingredient ratio was determined based on the bread formulation ratio for the baking technology specialist certification exam administered by the Korea Industrial Training Corporation. The bread dough was prepared using the straight dough method, referring to AACC method 10-10A [

25]. The material ratios are shown in

Table 1. All ingredients except shortening were placed in a vertical mixer (SP-800A, Spar Food Machinery Mfg. Co., Ltd., Taichung, Taiwan) and mixed for 2 minutes in the first stage. Shortening was then added during the clean-up stage, and mixing continued for an additional 4 minutes in the second stage to complete the dough. The final dough temperature was adjusted to 27±1℃ using a water bath, and the finished dough was placed in a glass container with its surface wrapped. The glass container with the dough was then placed in a processing container, and PEF treatment was performed according to each experimental condition. After PEF treatment, the dough was placed in a proofing machine (SMP-1010, Daehung Softmill Co., Ltd., Gwangju, Korea) set to 27℃ and 80% relative humidity for 1 hour, which included both PEF treatment and fermentation times. After the first fermentation, the dough was divided into 210 g portions, rounded, and covered with plastic wrap for 15 minutes of intermediate proofing at room temperature (20℃). The dough was then shaped into a one-loaf form, panned into a bread pan measuring 155×75×65 mm, and proofed for a second time for 40 minutes at 35℃ and 85% relative humidity until the dough rose 1 cm above the pan. The proofed dough was baked in a preheated oven (DHO2-21, Daehung Softmill Co.) at 180℃ on top and 190℃ on bottom for 20 minutes. After baking, the bread was cooled at room temperature (20℃) for 1 hour and then stored in a sealed polyethylene zipper bag for use in the experiment.

2.4. Fermentation Expansion Rate

After treatment with the control group and high-voltage pulsed electric field, the dough was weighed into 20 g portions, rounded, and placed in a 100 mL measuring cylinder with the top surface pressed flat. The cylinder was then placed in a fermentation chamber (Daehung Softmill Co., Ltd.). The expansion volume of the dough was measured every 15 minutes from 0 to 60 minutes under the first fermentation conditions (27°C and 80% relative humidity), and from 60 to 90 minutes under the second fermentation conditions (35°C and 85% relative humidity). The expansion rate was calculated as the ratio of the dough expansion volume at each fermentation time to the initial volume. The calculation formula is as follows.

Fermentation Expansion Rate (%) =

V0 : Volume of dough at t=m (mL)

Vt : Volume of dough during fermentation at t (mL)

2.5. Weight, Volume, Specific Volume, Oven Spring, and Baking Loss

The bread's weight was measured using a digital scale (MW II-3000N, CAS, Yangju, Korea) one hour after it had cooled to room temperature following baking. The volume was measured using the displacement method [

26]. A container large enough to hold the bread was filled with rice and leveled off. The excess rice was removed by cutting it flush with the top of the container. Bread and additional rice were added to the container until it was full. The remaining rice was then measured with a measuring cylinder to calculate the bread's volume. Specific volume was calculated by dividing the volume of the bread by its weight (mL/g). The oven spring was determined by measuring the height difference between the center of the unbaked dough and the center of the baked bread using a vernier height gauge (BD514-300, Bluetec. Shanghai, China). The baking loss was calculated using the weight of the dough before baking and the weight of the bread after baking.

Baking Loss Rate (%) =

Wd : Weight of dough before baking (g)

Wb : Weight of bread (g)

2.6. Moisture Content

The moisture content of the bread was measured by removing the crust, blending a 2 g sample in a hand blender (MR5550MFP, Braun GmbH, Wroclaw, Poland) at level 12 for 30 seconds, and weighing the sample before drying it to a constant weight at 105℃ using a moisture analyzer (MA35M-000230V1, Sartorius AG, Göttingen, Germany).

2.7. Color

The color of the bread was measured using a colorimeter (CM-5, Konica Minolta Sensing INC., Osaka, Japan) based on the Hunter system. Slices of bread with a thickness of 1 cm were taken from the center, and the lightness (L), redness (a), and yellowness (b) were measured. The values for the standard white plate were L=96.50, a=-0.10, b=-0.32. The total color difference (ΔE), which represents the color change due to PEF treatment, was calculated using the following formula where L0, a0, b0 are the color values of the control group, and L1, a1, b1 are the color values of the treated group.

2.8. Texture Profile Analysis

The texture of the bread was measured using Texture Profile Analysis (TPA). The central part of the bread was cut into a 2x2x2 cm cube and analyzed using a texture analyzer (TA-XT Express, Stable Micro Systems Ltd., Godalming, UK) to measure the following parameters: hardness, springiness, cohesiveness, chewiness, and resilience. The measurement conditions were as follows: pre-test speed 2.0 mm/s, test speed 1.0 mm/s, post-test speed 5.0 mm/s, and distance 10.0 mm.

2.9. Statistical Analysis

All experimental results were measured in triplicate, and the mean and standard deviation were calculated using SPSS (IBM Version 26, SPSS Inc., Chicago, IL, USA). Independent sample t-tests were conducted to compare the control and treatment groups, while one-way ANOVA was used to analyze quality characteristics according to the storage period. Significance was tested at the p<0.05 level using Duncan's multiple range test.

3. Results and Discussion

3.1. Physical Characteristics of Bread Dough and White Pan Bread by High-Voltage Pulsed Electric Fields Treatment

3.1.1. Fermentation Expansion Rate of Bread Dough

The fermentation expansion rate of bread dough is shown in

Table 2. Gas generation during dough fermentation is influenced by factors such as the amount and type of yeast, sugar, and salt. In addition, enzyme activity, dough temperature, pH, and damaged starch content also affect gas production. During dough fermentation, these factors not only act individually but also interact in complex ways to generate gas [

27,

28]. In the sample treated with PEF for 10 min, there was no significant difference between the control and the treated sample after 15 min of fermentation. However, from 30 min of fermentation onwards, the treated sample expanded rapidly, showing significantly higher expansion rates at 30, 45, 75, and 90 min of fermentation. At the end of fermentation (90 min), the control group increased by 226.35±26.79% compared to the start of fermentation, while the treated group increased by 281.67±15.28%, showing a large difference. However, there was no significant difference the two samples treated with PEF for 20 min. In the sample treated with PEF for 30 min, the expansion rate of the treatment group began to increase from 30 min after fermentation and was significantly higher from 45 to 75 min. A higher fermentation expansion rate is expected to shorten the fermentation time, which is considered a desirable outcome in the bread-making process [

29]. Considering the treatment time and fermentation expansion rate, PEF treatment for 10 min seems to be appropriate.

3.1.2. Weight, Volume, Specific Volume, Oven Spring, Baking Loss Rate, and Moisture Content

The result of measuring weight, volume, specific volume, oven spring, and baking loss rate after PEF treatment are shown in

Table 3. The weight was significantly higher compared to the control group when treated for 10 min, and it decreased as the treatment time increased. The volume and specific volume were significantly higher than the control group when treated for 30 min, and they showed a tendency to increase as the treatment time increased. Although there was no significant difference in oven spring, the treated group showed lower values. The baking loss rate was significantly lower when treated for 10 min and tended to increase as the treatment time increased. Generally, the baking loss rate is determined by the amount of moisture evaporation from the dough during the baking process. Moisture evaporation can either be promoted or suppressed depending on the dough characteristics, which affects pore formation, structural changes, and the product's shelf life [

30,

31]. In studies by Aibara et al. [

23] and Esaki et al. [

32], it was reported that PEF treatment reduced moisture loss in bread dough, leading to a lower baking loss rate, which is similar to the results of this experiment. It is thought that PEF treatment for 10 min at an electric field strength of 2 kV/cm played a role in suppressing moisture evaporation from the dough. Comparing the results based on treatment time, it was confirmed that with 10 min of treatment, the weight was significantly higher, and the baking loss rate was lower. At 30 min, the volume and specific volume were significantly higher.

In the case of the PEF 10 min treated sample, the moisture content of the treated group was 42.03±0.70%, which was 6.06% higher than the moisture content of the control group, 39.63±0.51%. For the sample treated for 20 min, although there was no significant difference between the control and treated groups, the treated group showed a higher value. In the sample treated for 30 min, the treated group showed a value 3.32% higher than the control group. Generally, bread with a soft and moist texture is considered fresh [

33], and moisture content is one of the most influential factors affecting the texture of fresh bread [

34]. During the storage period, bread quality gradually deteriorates due to staling, resulting in reduced palatability. However, according to Sych et al. [

35], higher initial moisture content can reduce the staling of bread. In the study by He and Hoseney [

36], it was also reported that the higher the moisture content, the slower the rate at which the bread's hardness increased, resulting in lower final hardness. In the study by Aibara and Esaki [

37], it was found that high-voltage pulsed electric field treatment affects the moisture content of bread and enhances its moisture retention capacity. It is expected that treating the dough with an electric field strength of 2 kV/cm for 10 min would increase the initial moisture content, delay the staling of bread, and extend its shelf life.

3.1.3. Color

In terms of color attributes, lightness (L), redness (a), and yellowness (b) did not show significant differences with 10 min of treatment, but the treated groups showed lower values in the 20 min and 30 min treatments (

Table 4). In particular, the redness and yellowness values were significantly lower in the 20 min treatment. The ΔE value, which indicates the color difference between the control and treated groups, was largest with 20 min treatment, but there was no significant difference depending on the treatment time. According to the study by Nimeroff [

38], based on the National Bureau of Standards (NBS) units, the 10 min and 30 min treatment samples showed a slight difference (0.5-1.5), while the 20 min treatment sample showed a noticeable difference (1.5-3.-0). Regardless of the treatment time, the color difference due to the high-voltage pulsed electric field treatment was considered to be insignificant.

3.1.4. Texture Profile Analysis

The texture profile analysis of bread according to the treatment time of high-voltage pulsed electric fields is shown in

Table 5. Hardness indicates firmness, with higher values meaning greater firmness, which is one of the most characteristic changes in bread staling. It shows a good correlation with sensory evaluation scores, so if the hardness is high, consumers are more likely to perceive the bread as stale [

39,

40]. Hardness showed lower values than the control regardless of the treatment time, and in particular, the 20 min treatment showed the most significant difference from the control, but it was the highest among the treated groups. In the study of Aibara et al. [

23], when bread was made after treating the dough with a high-voltage pulsed electric field, the hardness of the bread showed a lower value, showing similar results to this experiment. Springiness is related to the freshness of bread, and the higher the value, the more preferred it is [

41]. There was no significant difference in springiness between the treated samples, and the 20 min and 30 min treated samples showed slightly higher values than the control, but there was no significant difference. Cohesiveness is an indicator of the strength of internal bonds, and the higher the cohesiveness of bread, the more desirable it is because it forms a lump rather than being finely broken when chewed, and it reduces damage due to physical shocks such as packaging and transportation [

42,

43]. Cohesiveness was slightly higher in the 10 min treatment than in the 20- and 30 min treatments, but the differences were not statistically significant. Compared to the untreated group, it was slightly higher in the 20- and 30 min treated samples, but there was no significant difference. Chewiness generally shows a similar trend to hardness, and in this experiment, as in the results of hardness, the control group showed higher value the than the treated group, and the 20 min treated group showed the greatest difference, but there was no significant difference. Resilience refers to the ability of the bread to recover to its original shape after being pressed and generally contributes to the good quality of bread [

44]. In this experiment, there were no differences in resilience based on treatment time, but the 20 min treated group showed a significant difference from the control.

3.2. Changes of Moisture Content and Texture Profile Analysis of PEF-treated Bread During Storage Period

3.2.1. Changes of Moisture Contents During Storage Period

The moisture content of white pan bread made after high-voltage pulsed electric field treatment during storage is shown in

Table 6. Regardless of treatment time, the moisture content of the samples showed a significant decrease as the storage days increased. The samples treated for 10 min maintained a significantly higher moisture content during the storage period. On the day of production, the moisture content of the control group was 39.63±0.51%, and the moisture content of the treated group was 42.03±0.70%, showing a significant difference of 6.06% higher in the treated group compared to the control. On days 1 and 2 of storage, the treated group showed higher values by about 2%, and on the last day of storage, it showed a higher value by 3.48%. In the case of the 20 min treatment, there was no significant difference between the control and treated samples, showing similar values. For the 30 min treatment, the value of the treated group was significantly higher than that of the control by 3.32% on the day of production, but there was no difference after that. Generally, bread with a soft and moist texture is evaluated as fresh [

33], and moisture content is one of the factors affecting the texture of fresh bread [

34]. During storage, the quality of bread gradually deteriorates due to staling, resulting in a decrease in palatability, but Sych et al. [

35] reported that a higher initial moisture content can reduce the extent of staling. He and Hoseney [

36] also found that the higher the moisture content, the slower the rate of increase in bread hardness, and the final hardness was lower. On the other hand, according to Salinas and Puppo [

45], the changes in bread hardness and moisture content during the storage period did not show a direct relationship, and in this experiment, the hardness did not decrease as much as the moisture content increased. In the study by Aibara and Esaki [

37], it was reported that high-voltage pulsed electric field treatment affects the moisture content of bread and enhances its moisture retention ability. At an electric field strength of 2 kV/cm and a treatment time of 10 min, not only was the initial moisture content high, but it also maintained a significantly higher moisture content than the control during the 3-day storage period.

3.2.2. Change of Texture Profile Analysis During Storage Period

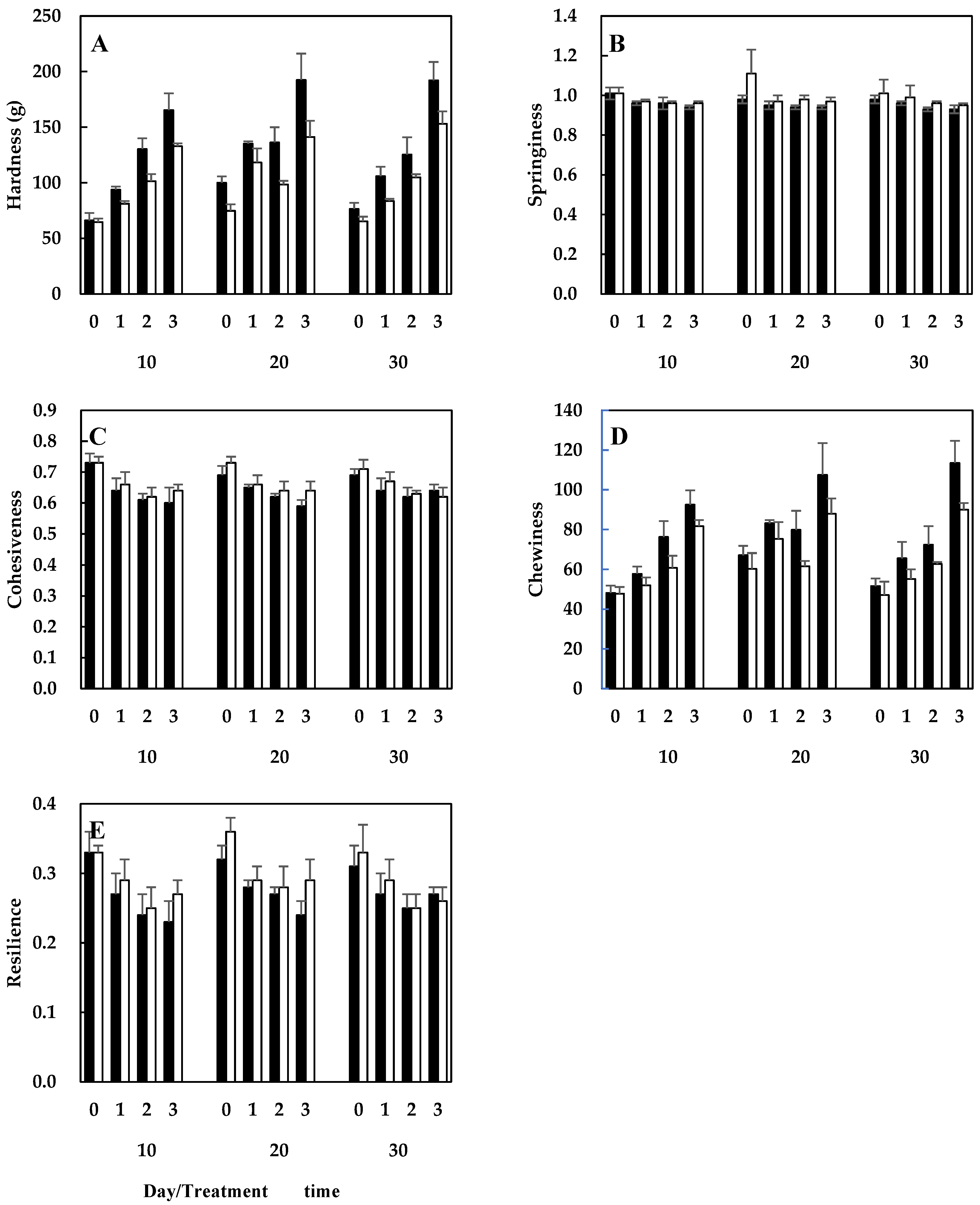

The texture properties of white pan bread after high-voltage pulsed electric field treatment during storage are shown in

Figure 2. Hardness tended to increase in both the control and treated groups during the storage regardless of treatment time, but the treated groups showed significantly lower values. For the 10 min treatment, the control and treated groups were similar on the day of production, but the values in treated groups were significantly lower from day 1 to day 3 of storage. In the case of the 20 min and 30 min treatments, the treated groups showed significantly lower values than the control group throughout the storage period. Comparing the rate of change in hardness according to the treatment time, the rate of change was highest in the 20 min treatment on the day of production, followed by 30 min and 10 min, and there was no significant difference between the treatment groups on the first day of storage (data not shown). On day 2 of storage, the rate of change showed lower values in the order of 20 min, 10 min, and 30 min. On day 3 of storage, there was no significant difference between the treatment groups, with a reduction of 19.27% for the 10 min treatment, 26.42% for the 20 min treatment, and 20.18% for the 30 min treatment. Springiness tended to decrease during storage, and the treated groups showed higher springiness regardless of treatment time. In the 10 min treatment, the treated group showed significantly higher springiness than the control group on the last day of storage. In the case of the 20 min treatment, the treated group maintained higher values throughout the storage period and showed significantly higher

values on days 2 and 3 of storage. For the 30 min treatment, the treated group showed higher values than the control groups during the storage period. Cohesiveness significantly decreased as storage days increased in both the control and treated groups. Regardless of treatment time, cohesiveness was generally higher in all treated groups than in the control group, but most did not show a significant difference, and cohesiveness was relatively high in the 10 min and 20 min treatments. Chewiness showed a similar trend to hardness. It showed a significant increase during storage, and all treated groups exhibited lower values than the control group. In the 10 min treatment, the treated group showed significantly lower values from day 1 to day 3 of storage, except for the day of production. In the case of the 20 min treatment, it was significantly lower than the control group from day 2 to day 3 of storage, and in the case of the 30 min treatment, it showed significantly lower values on day 1 and 3 of storage. Resilience showed a significant decrease during storage in both the control and treated groups, with the treated groups showing higher values overall. In the 10 min treatment, the treated groups showed higher values on the 3-day of storage. For the 20 min treatment, significantly higher values were observed on the day of production and day 3 of storage. In the case of the 30 min treatment, no significant differences were observed. The resilience of the treated groups on the last day of storage at 10 min and 20 min treatment time showed a large difference, being about 20% higher than the control group.

4. Conclusions

In the bakery industry, which is experiencing increased market size and competition due to rising demand and consumption of bread, product differentiation and quality improvement are essential for securing a competitive edge. High-voltage pulsed electric field (PEF) technology, primarily used for microbial inactivation, is now being explored for broader applications in food processing, such as drying, extraction, and starch modification. This study aimed to determine the optimal PEF treatment time for improving bread quality. For this purpose, PEF treatment was applied to bread dough at an electric field strength of 2 kV/cm, a frequency of 10 Hz, and a pulse width of 100 μs, varying the treatment time to 10, 20, and 30 min. After the PEF treatment, the fermentation expansion rate, weight, volume, specific volume, oven spring, baking loss rate, moisture content and texture profile analysis during storage were measured. The dough's fermentation expansion rate was significantly higher in the 10 min treatment group throughout most of the fermentation period, showing a significant difference from the control group. Bread made with the 10 min treated dough also exhibited higher weight, volume, specific volume, and moisture content, along with lower oven spring and baking loss rate. During storage, the 10 min treated samples maintained significantly higher moisture content, while the 20 and 30 min treated samples showed no significant difference. In terms of texture, the treated samples had lower hardness and chewiness, but higher springiness, cohesiveness, and resilience compared to the control group.

This study investigated the effect of different PEF treatment times on dough and bread quality, but it has limitations due to the narrow and limited range of treatment conditions. Additionally, the equipment used in the experiment was a small, laboratory-scale device. Further research is needed to consider various aspects, such as equipment specifications and processing environment, for practical application in the bakery industry.

Author Contributions

Conceptualization, DY Kim, and JK Shin; methodology, DY Kim, and JK Shin; software, GM Lee, DY Kim, and JK Shin; validation, GM Lee, and JK Shin; formal analysis, GM Lee, DY Kim, and JK Shin; investigation, DY Kim, and JK Shin; data curation, GM Lee, DY Kim, and JK Shin; writing—original draft preparation, GM Lee, DY Kim, and JK Shin; writing—review and editing, GM Lee, and JK Shin; visualization GM Lee, and JK Shin; supervision, JK Shin; project administration, GM Lee, DY Kim and JK Shin; funding acquisition, JK Shin. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Korea Institute of Planning and Evaluation for Technology in Food, Agriculture and Forestry (IPET) through High Value-added Food Technology Development Program, funded by Ministry of Agriculture, Food and Rural Affairs (MAFRA) 322018-4.

Data Availability Statement

This data presented in this study are available on request from the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jung, J.Y.; Kim, W.J.; Chung, H.J. Quality characteristics of bread added with germinated soybean powder. J. Korean Soc. Food Sci. Nutr. 2006, 35, 1260–1266. [Google Scholar]

- Lee, M.H. Quality characteristics of white pan bread added mate (Ilex paraguariensis) leaf powder. Culi. Sci. & Hos. Res. 2018, 24, 145–155. [Google Scholar]

- Lee, K.S. 2012. Development of baking technology and analysis of domestic and international bakery market and trends. Food Sci. Ind. 2012, 45, 16–20. [Google Scholar]

- Choi, I.D. Substitution of rice flour on bread-making properties. Korean J. Food Preserv. 2010, 17, 667–673. [Google Scholar]

- Lee, G.H.; Kim, W.M.; Kim, M.K. Quality characteristic changes during storage of bread prepared by addition of yacon concentrates as sugar substitute. J. Korean Soc. Food Cult. 2013, 28, 107–113. [Google Scholar] [CrossRef]

- Kim, Y.A.; Ko, J.Y.; Yoo, S.R.; Jang, SJ.; Kang, SH.; Han, DW.; Kim, SH.; Seo, JH. Quality characteristics of white pan bread with different water types. Culi. Sci. & Hos. Res. 2018, 24, 104–112. [Google Scholar]

- Kwon, E.A.; Chang, M.J.; Kim, S.H. Quality characteristics of bread containing Laminaria powder. J. Korean Soc. Food Sci. Nutr. 2003, 32, 406–412. [Google Scholar]

- Yang, S.M.; Shin, J.H.; Kang, M.J.; Kim, S.H.; Sung, N.J. Quality characteristics of bread with added black garlic extract. Korean J. Food Cook. Sci. 2010, 26, 503–510. [Google Scholar]

- Yoo, Y.S.; Lee, M.H. Quality characteristics and antioxidant of pan-bread prepared with cacao nibs powder. Culi. Sci. & Hos. Res. 2020, 26, 84–96. [Google Scholar]

- Cauvain, S.P.; Young, L.S. The Chorleywood Bread Process; Woodhead Publishing: Cambridge, UK,, 2006; pp. 6–16. [Google Scholar]

- Park, S.J.; An, H.L.; Lee, K.S. Quality characteristics of pan bread depending on the time of microwave irradiation time. J. East Asian Soc. Diet. Life. 2010, 20, 423–432. [Google Scholar]

- Choi, K.B.; Kim, H.S.; Kim, S.O.; Ryu, H.S.; Lyu, E.S. Quality characteristics of steamed bread with repeated fermentation processes. J. Korean Soc. Food Sci. Nutr. 2011, 40, 593–598. [Google Scholar] [CrossRef]

- Hoseney, R.C. Bread baking. Cereal Foods World 1994, 39, 180–183. [Google Scholar]

- MacRitchie, F. Evaluation of contributions from wheat protein fractions to dough mixing and breadmaking. J. Cereal Sci. 1987, 6, 259–268. [Google Scholar] [CrossRef]

- Wrigley, C.W.; Bekes, F. Glutenin-protein formation during the continuum from anthesis to processing. Cereal Foods World 1999, 44, 562–565. [Google Scholar]

- Chae, D. Description and point of each process: Mixing of bread (dough). In Bakery; Korea Bakers Association: Seoul, Korea, 2002; Volume 412, pp. 184–187. [Google Scholar]

- Kim, S.; Cho, N.; Kim, Y.; Yoon, S.; Lee, J.; Chung, S.; Chae, D. Baking Science; Bncworld: Seoul, Korea, 2009; pp. 99-120, 152-156. [Google Scholar]

- Kim, S.C.; Cho, S.I.; Chun, J.G. Neural network modeling for bread baking process. Korean J. Food Sci. Technol. 1995, 27, 525–531. [Google Scholar]

- Chae, D. Description and point of each process: Baking. In Bakery; Korea Bakers Association: Seoul, Korea, 2003; Volume 417, pp. 173–175. [Google Scholar]

- Dunn, J. Pulsed light and pulsed electric field for foods and eggs. Poult. Sci. 1996, 75, 1133–1136. [Google Scholar] [CrossRef]

- Barbosa-Cánovas, G.V.; Pierson, M.D.; Zhang, Q.H.; Schaffner, D.W. Pulsed electric fields. J. Food Sci. 2000, 65, 65–79. [Google Scholar] [CrossRef]

- Shin, J.K. Commercial pasteurization of foods using high voltage pulsed electric fields treatment. Food Sci. Ind. 2020, 53, 284–294. [Google Scholar]

- Aibara, S.; Hisaki, K.; Watanabe, K. Effects of high-voltage electric field treatment on wheat dough and bread-making properties. Cereal Chem. 1992, 69, 465–467. [Google Scholar]

- Shin, J.K. Inactivation of Saccharomyces cerevisiae by high voltage pulsed electric fields. Ph.D. thesis, Yonsei Univ., Seoul, Korea, 2000. [Google Scholar]

- American Association Cereal Chemists. 10-10.03 Optimized Straight-Dough Bread-Baking Method. In Approved Methods of Analysis, 9th ed.; AACC International: St. Paul, MN, USA, 1995. [Google Scholar]

- Campbell, A.; Penfield, M.; Griswold, R. The experimental study of food; Houghton Mifflin: Boston, MA, USA, 1979; p. 459. [Google Scholar]

- Magoffin, C.D.; Hoseney, R.C. A review of fermentation. Baker’s Dig. 1974, 48, 22–29. [Google Scholar]

- Kim, E.J.; Kim, S.M. Bread properties utilizing extracts of pine needle according to preparation method. Korean J. Food Sci. Technol. 1998, 30, 542–547. [Google Scholar]

- Kim, W.M.; Lee, G.H. Comparison of imported wheat flour bread making properties and Korean wheat flour bread making properties made by various bread making methods. J. Korean Soc. Food Sci. Nutr. 2015, 44, 434–441. [Google Scholar] [CrossRef]

- Paton, D.; Larocque, G.M.; Holme, J. Development of cake structure: Influence of ingredients on the measurement of cohesive force during baking. Cereal Chem. 1981, 58, 527–529. [Google Scholar]

- Jang, N.H.; Roh, H.S.; Kang, S.T. 2018. Quality characteristics of sponge cake made with aronia powder. Korean J. Food Sci. Technol. 2018, 50, 69–75. [Google Scholar]

- Esaki, K.; Ninomiya, F.; Hisaki, K.; Higasa, T.; Shibata, K.; Murata, K.; Aibara, S. Effects of high-voltage electric field treatment on the water activity of bread. Biosci. Biotech. Biochem. 1996, 60, 1444–1449. [Google Scholar] [CrossRef]

- Giannou, V.; Kessoglou, V.; Tzia, C. Quality and safety characteristics of bread made from frozen dough. Trends Food Sci. Technol. 2003, 14, 99–108. [Google Scholar] [CrossRef]

- Jung, H.S.; Noh, K.H.; Go, M.K.; Song, Y.S. Effect of leek (Allium tuberosum) powder on physicochemical and sensory characteristics of breads. J. Korean Soc. Food Sci. Nutr. 1999, 28, 113–117. [Google Scholar]

- Sych, J.; Castaigne, F.; Lacroix, C. 1987. Effects of initial moisture content and storage relative humidity on textural changes of layer cakes during storage. J. Food Sci. 1987, 52, 1604–1610. [Google Scholar] [CrossRef]

- He, H.; Hoseney, R.C. Changes in bread firmness and moisture during long-term storage. Cereal Chem. 1990, 67, 603–605. [Google Scholar]

- Aibara, S.; Esaki, K. Effects of high-voltage electric field treatment on bread starch. Biosci. Biotechnol. Biochem. 1998, 62, 2194–2198. [Google Scholar] [CrossRef]

- Nimeroff, I. Colorimetry. Natl. Bur. Stand. Monogr. 1968, 104, 4–32. [Google Scholar]

- Bashford, L.L.; Hartung, v.T.E. Rheological properties related to bread freshness. J. Food Sci. 1976, 41, 446–447. [Google Scholar] [CrossRef]

- Stampfli, L.; Nersten, B. Emulsifiers in bread making. Food Chem. 1995, 52, 353–360. [Google Scholar] [CrossRef]

- Cornejo, F.; Rosell, CM. Physicochemical properties of long rice grain varieties in relation to gluten free bread quality. LWT Food Sci. Technol. 2015, 62, 1203–1210. [Google Scholar] [CrossRef]

- Onyango, C.; Mutungi, C.; Unbehend, G.; Lindhauer, M.G. Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT Food Sci. Technol. 2011, 44, 681–686. [Google Scholar] [CrossRef]

- Lee, S.Y.; Kim, Y.N. Food Rheology: Principle and application; Soohaksa Co.: Seoul, Korea, 2017; pp. 153–154. [Google Scholar]

- Zhao, Z.; Mu, T.; Sun, H. Microbial characterization of five Chinese traditional sourdoughs by high-throughput sequencing and their impact on the quality of potato steamed bread. Food Chem. 2019, 274, 710–717. [Google Scholar] [CrossRef]

- Salinas, M.V.; Puppo, M.C. Bread staling: Changes during storage caused by the addition of calcium salts and inulin to wheat flour. Food Bioprocess Technol. 2018, 11, 2067–2078. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).