1. Introduction

New-type construction industrialization is driven by next-generation information technology, primarily through systematic integrated design and lean production and construction throughout the entire life cycle of a project, integrating the entire industrial chain, value chain, and innovation chain of engineering projects to achieve high-efficiency, high-quality, low-consumption, and low-emission industrialized construction [

1]. Prefabricated buildings, which represent new-type construction industrialization, serve as the foundation and key carrier for realizing intelligent construction [

2]. Intelligent construction marks a new phase of deep integration between new-type construction industrialization and information technology [

3], and the two demonstrate a multidimensional, interactive, and mutually empowering relationship [

4]. Together, they drive high-quality development in the construction industry [

5]. Prefabricated buildings represent the direction of the new technological revolution and industrial transformation in the construction industry. They signify not only a major transformation in the traditional construction industry's building methods but also a key initiative in promoting supply-side structural reforms and a strong support for new urbanization [

6].

New-type construction industrialization is not merely equivalent to prefabricated building technology itself [

7,

8]; it requires the comprehensive application of various new construction engineering technologies and innovative uses in the construction industry to enhance the level of industrialization [

9]. At the same time, it is not only a technological issue. New-type construction industrialization is an industrial and comprehensive matter that also involves management issues, such as project organization and management models compatible with the technology, and the cultivation and development of supporting industries in the sector [

10]. Therefore, the progression from prefabricated buildings to intelligent construction, and from intelligent construction to new-type construction industrialization, reflects a deepening understanding of the construction industry's rules.

In recent years, during China's active exploration of the development of prefabricated buildings, several urgent issues have arisen regarding the top-level design of technical standards and regulations. As a result, China's related standards still lag significantly behind the advanced international standards for sustainable prefabricated construction methods [

11]. This project aims to formulate evaluation standards for new-type construction industrialization projects, establish a technical indicator system for project evaluation, and explore scientific and practical evaluation methods. The expected research outcomes will not only provide reference points for national and regional standards for industrialized construction projects and offer technical and management support for project design and construction but also highlight the application of information technology, guiding projects to continually improve labor productivity and construction quality. Furthermore, this research will offer important insights for the development of high-quality policies in the construction industry and for the potential prioritization of policy rewards. Additionally, this research project represents a valuable exploration and extension of the evaluation theory for improving the level of new-type construction industrialization.

2. Literature Review

2.1. Literature Overview

Through the analysis of the literature, it has been found that research on evaluating the development level of new-type construction industrialization is still relatively new. However, studies related to the construction industry and the evaluation of the impact of industrialized construction on the surrounding environment offer significant insights into the evaluation of the development level of new-type construction industrialization.

In terms of research related to the construction industry, Umberto used field surveys to obtain a series of data and compared three widely recognized evaluation indicator systems for construction industry development. The analysis revealed that energy consumption evaluation systems are the most important [

12]. Tatarc et al. developed a sustainable development system for the construction industry from an ecological perspective and conducted an evaluation focusing on the United States [

13]. Kucukvar et al. constructed an evaluation model from economic, environmental, and social aspects, assessing the sustainable development of the construction industry in the United States from a life-cycle perspective [

14]. Zhang Miao et al. found that regional overall development levels, development efficiency in the area, and the potential demonstrated during development should be key areas of focus. By evaluating these three aspects and combining them with Matlab software for indicator weight calculation and model construction, they provided scientific evaluations and practical development suggestions for the construction industry across various regions in China [

15]. Ye Haowen introduced the key technology system of intelligent construction and building industrialization and its practical exploration, discussing and forecasting BIM forward design, prefabricated buildings, intelligent factories, intelligent construction, smart construction sites, and their corresponding management models [

16].

In terms of evaluating the environmental impact of construction industrialization, Aye et al. conducted a quantitative analysis of the effects of prefabricated components on energy conservation, emission reduction, and resource savings. This was achieved by calculating the energy consumed by prefabricated steel structure buildings [

17]. Silva et al. demonstrated the specific application of prefabricated retrofit modules in renovation schemes, aiming to minimize the energy consumption and CO2 emissions of the final building compared to other construction types [

18]. Bonamente et al. conducted a field survey of an Italian company and obtained actual data, using the LCA (Life Cycle Assessment) method to study the environmental impact of industrial prefabricated houses, including energy consumption and CO2 emissions at each stage of the life cycle [

19]. Ammar et al. performed simulation and analysis to measure the actual energy consumption of traditional and industrial building systems in Iraq, finding that IBS (Industrialized Building Systems) reduced energy consumption [

20]. Cao et al. studied the similarities and differences between prefabricated and cast-in-situ construction technologies, with results indicating that prefabricated technology causes less environmental damage on-site compared to traditional methods [

21]. Hong et al. analyzed the energy use of prefabricated components throughout their life cycle, finding that recycling prefabricated components could achieve energy savings of 16% to 24%, improving quality control and reducing overall life cycle energy consumption by 4% to 14% [

22]. Lei Yunxia analyzed the constraints on new-type construction industrialization from policy, technology, personnel, and market perspectives, and proposed ideas for improving new-type construction industrialization in Shenyang [

23].

In the evaluation of construction industrialization development, Guangbin Wang et al. adopted a multi-case study method and introduced the Excellence Model developed by the European Foundation for Quality Management (EFQM). They explored a maturity model for industrialized construction based on construction projects, focusing on organizational factors. Through literature reviews and expert interviews, the evaluation system was divided into two aspects: enablers and results. The maturity of industrialized construction was categorized into four levels: Initial, Improvement, Comprehensive, and Optimal [

24].

Tao Ma divided the life cycle of new construction industrialization into five stages: decision-making, design, production, construction, and operation and maintenance. By integrating the concepts of new construction industrialization and intelligent construction, he employed various research methods to establish an evaluation index system. He used the Cloud Matter-Element Evaluation Method to construct a cloud matter-element model to evaluate the development level of new construction industrialization from an intelligent construction perspective [

25].

Yang argued that the development of construction industrialization should first consider its economic benefits, while also emphasizing the importance of environmental protection. Technological advancements provide the foundation for the development of construction industrialization, and companies should improve their informatization levels in response to environmental changes. Based on this, accurate and reasonable assessments of construction industrialization development can be made [

26].

2.2. Issues in Current Research

Currently, under the promotion of central departments and local governments, industry practices in prefabricated buildings, intelligent construction, and new construction industrialization are very active. These practices have become new growth points and development directions in the construction industry, serving as important drivers of high-quality development. However, how to carry out new construction industrialization and how to organically integrate the concepts mentioned above to form synergy is still under exploration in practice, urgently requiring theoretical support and guidance. Through analysis and review of domestic and international literature, it is found that systematic research has been conducted on the construction industry chain, construction supply chain, green building industry chain, and their evaluation systems, yielding rich research results. However, there are still shortcomings in areas such as concept definition and research dimensions, specifically:

1. More Focus on Micro-Level Project Evaluation Systems

Existing research results mainly explain certain aspects or stages of the construction industry chain from a single dimension, lacking systematic analysis of the overall structural characteristics of the construction industry chain. There is little research on measuring the maturity of regional construction industry chain development, and the existing research mainly focuses on single stages or dimensions. Studies on the spatial agglomeration of construction industry chain maturity lack systematic analysis, and factors influencing spatial agglomeration have not yet considered regional spatial levels. The purpose of evaluation is for practical application, using the evaluation system as a benchmark to promote high-quality development in the industry. Therefore, the evaluation system should place more emphasis on the project level to enhance its applicability.

2. Evaluation Standards Should Reflect New Trends in Development

The integrated development of intelligent construction and new construction industrialization has been identified as a strategic direction for the construction industry, with high-quality development concepts elevated to unprecedented levels. The evaluation system for new construction industrialization should focus on the "new," incorporating new ideas and concepts into the evaluation indicators and prioritizing the construction of evaluation systems for new construction industrialization projects in the evaluation standards.

3. Room for Improvement in Evaluation Methods

Current evaluation methods mostly rely on subjective comprehensive scoring methods, with relatively little use of scientific research methods that combine subjective and objective evaluations. In addition, the development of the index system mainly relies on literature reviews and expert interviews, with few cases of multiple rounds of quantitative research being used to scientifically determine the index system and its weights.

This study is divided into three stages: (1) constructing the evaluation index system, (2) determining the weight of the evaluation indicators, and (3) establishing the evaluation model. The construction of the evaluation index system is carried out through methods such as literature review, policy research, and expert interviews. The workflow for determining the weight of evaluation indicators includes using the G1 method to calculate subjective weights, the entropy weight method to calculate objective weights, and the combined weighting method to calculate comprehensive weights. Finally, the cloud matter-element model is established for evaluation research.

3. Construction of the Evaluation Index System

This paper determines the evaluation dimensions for new construction industrialization projects by studying domestic and international literature and relevant regulations and policies. Next, it identifies and summarizes the evaluation indicators, forming a preliminary evaluation index system for new construction industrialization projects. Finally, through expert consultation, the final evaluation index system for new construction industrialization projects is established.

3.1. Selection of Evaluation Dimensions

Using keywords such as “new construction industrialization technology application,” “evaluation of new construction industrialization,” “application effects of new construction industrialization,” and “on-site evaluation of new construction industrialization,” relevant literature was retrieved from databases including CNKI (China National Knowledge Infrastructure) and Fujian Province’s digital library. Over 100 domestic and international academic journal articles with high relevance to the research content were selected for detailed review and summary. Additionally, on the official website of the Ministry of Housing and Urban-Rural Development, a search using the keyword “new construction industrialization” yielded 32 relevant pieces of information and documents as of September 1, 2023.

Through the review and analysis of existing research and related policy documents, the dimensions of evaluation for new construction industrialization projects during the construction phase in domestic and international journal papers are mainly categorized into ten aspects: project management, cost management, quality management, safety management, personnel management, material management, machinery management, method management, environmental management, and information management.

In August 2020, the Ministry of Housing and Urban-Rural Development and nine other ministries issued the “Several Opinions on Accelerating the Development of New Construction Industrialization,” which detailed the concepts of new construction industrialization technologies in design, production, construction, and management, providing direction for the development of new construction industrialization industries and technologies in various regions.

In June 2023, the Fujian Provincial Department of Housing and Urban-Rural Development released the “Work Plan for Accelerating the Development of Intelligent Construction in Fujian Province,” further identifying “system substitution, machine substitution, and factory substitution for on-site work” as new models for the development of new construction industrialization.

Based on the existing research and expert discussions, this study merges dimensions with similar meanings and determines the evaluation dimensions for the application effects of new construction industrialization technology as follows:Whole process BIM application, smart site management, construction robots and intelligent equipment, prefabricated parts.

3.2. Determination of the Evaluation Index System

Based on this foundation, evaluation indicators were identified and summarized through literature research and in-depth interviews with experts, resulting in a preliminary set of 22 evaluation indicators for the application effects of new construction industrialization technologies. To reduce the potential for subjectivity in the selection of these indicators, the Delphi method was employed to refine the initial 22 indicators. A total of 6 experts in relevant fields were selected for this process, with an average age of 48.5 years. Among them, 66.7% hold postgraduate degrees or higher, 83.3% have more than 10 years of experience, and 66.7% hold senior professional titles. The basic information of the experts is shown in

Table 1.

The authority degree (C) of experts is determined by calculating the arithmetic average of cognitive accuracy (Ca) and criteria standard (Cs). This helps evaluate the experts' understanding of the field and the credibility of the consulting results. When the authority degree (C) is 0.7 or higher, it indicates a higher level of trustworthiness for the experts' judgments. The familiarity levels of the indicators are provided in

Table 2, and the basis for expert judgments is detailed in

Table 3.

The authority coefficients of the experts in both rounds of consultation were consistently above 0.90, indicating very high expert authority, as shown in

Table 4.

The importance levels of each indicator and their corresponding scores are shown in

Table 5.

In the results of the first round of expert Delphi consultation, except for the indicators “BIM-based Construction Management” under the “BIM Application Throughout the Process” dimension and “Prefabricated Electrical and Plumbing Lines” under the “Prefabricated Components and Parts” dimension, the average importance scores of the remaining indicators were all greater than 3, with a coefficient of variation (CV) of less than 20%. The Kendall coefficient passed the consistency test (p < 0.05), indicating good consistency. After discussing with experts, it was decided to merge the “BIM-based Construction Management” indicator from the “BIM Application Throughout the Process” dimension with the “Intelligent Construction Management” indicator from the “Smart Construction Site Management” dimension due to overlap. The combined indicator is now placed under the “Smart Construction Site Management” dimension, explained as: through 4D visualization technology, BIM technology, and real-time simulation models linked with on-site construction information, effective dynamic integration management of the construction site is achieved. Considering that the “Prefabricated Electrical and Plumbing Lines” indicator under the “Prefabricated Components and Parts” dimension does not align well with national conditions in practical engineering applications, experts recommended removing this indicator. Therefore, the indicators were revised, and the remaining 20 indicators were included in the second round of expert Delphi consultation. In the results of the second round, the average importance scores of the indicators were all greater than 3, with a coefficient of variation (CV) of less than 20%. The Kendall coefficient passed the consistency test (p < 0.05), indicating good consistency. The final evaluation indicator system for new construction industrialization projects, consisting of 20 indicators, is shown in

Table 6.

4. Determination of Evaluation Indicator Weights

In this study, a combination of subjective and objective methods is used to assign weights to each level of evaluation indicators. The main steps are as follows:

1.Ordinal Relation Analysis Method This method does not require consistency checks and is simple and convenient for calculations. The ordinal relation analysis method is used to calculate the subjective weights of the indicators.

2. Entropy Weight Method This method is not restricted by the number of indicators, is widely applicable, and involves simple calculations. The entropy weight method is used to determine the objective weights of the indicators.

3. Lagrangian Extremum Method This method is used to calculate the combined weights of the evaluation indicators at each level.

4.1. Order Relation Analysis

The Ordinal Relation Analysis Method is an improved subjective weighting method derived from the Analytic Hierarchy Process (AHP). This method ranks the importance of evaluation indicators and determines their weights based on a specific algorithm. It is simple, convenient, and highly operational, without limitations on the number of indicators. The specific calculation steps are as follows:

Step 1: Determine the Ordinal Relationship of Evaluation Indicators. Assume Indicator Set contains n indicators at the same level. Experts select the most important indicator from these n indicators, denoted as , and then choose the most important indicator from the remaining indicators, denoted as , and so on. This process is repeated for all n indicators.After determining the final order, we obtain the evaluation indicator set, denoted as .

Step 2:Determine the Relative Importance of Indicators. Experts assess the importance of adjacent indicators

and

based on Table 8, It is represented by

as:

In the formula,

and

represent the weights of adjacent evaluation indicators

and

, respectively, and

represents the relative importance ratio between adjacent evaluation indicators

and

. The assignment of

can be referenced from

Table 7.

Step 3: Calculate Indicator Weights.Based on the values in

Table 8, calculate the weights of indicators at each level. The weight value of the

n-th indicator, denoted as

, is computed as follows:

4.2. Entropy Weight Method

The Entropy Weight Method is an objective weighting approach that determines the weights of evaluation indicators based on their impact on the overall system. It assesses the degree of variability of each indicator, with higher weights indicating more information and greater variability, and lower weights indicating less variability. The calculation process is illustrated in Figure 3. The specific steps are as follows:

Step 1: Generate the Initial Evaluation Matrix. First, classify the indicators into five levels of importance: Extremely Important (5), Important (4), General (3), Not Important (2), and Extremely Not Important (1). Then, invite n experts with relevant work experience to score each indicator. Summarize the scoring results to obtain the evaluation matrix

.

Where:

represents the evaluation score given by the i-th expert for the j-th indicator,

m represents the number of evaluation objects,

n represents the number of evaluation indicators.

Step 2: Calculate the Scores for Each Indicator .

Due to the varying professional backgrounds of the scoring experts, their perceptions of different evaluation indicators may differ. To eliminate this influence, the evaluation matrix needs to be normalized.

Step 3: Calculate the Information Entropy

for Each Evaluation Indicator.

Where:

represents the information entropy of the j-th indicator.

Step 4: Calculate the Entropy Weights for Each Evaluation Indicator

.

Where:

represents the entropy weight of the j-th evaluation indicator.

4.3. Combination Weight

This study uses the Lagrangian Extremum Method to determine the coefficients for the two types of weights, resulting in combined weights to ensure the accuracy of the evaluation indicator weight calculations. The calculation formula is as follows:

In the formula,

is the subjective weight coefficient and

is the objective weight coefficient. The Lagrangian Extremum Method is used to solve this, and the formula is as follows:

By calculating with the above formula, the two coefficients are determined as

α= 0.504148 and

β = 0.495852. Finally, the weights for each level of indicators are obtained, as shown in

Table 8.

Table 8.

Weights of Indicators at Each Level.

Table 8.

Weights of Indicators at Each Level.

| Criterion Level |

Combined Weight |

Indicator Level |

Ordinal Relation Analysis Weight |

Entropy Weight Method Weight |

Combined Weight |

| Whole Process BIM Application |

0.2093 |

Forward Collaborative Design |

0.0747 |

0.0215 |

0.0484 |

| Construction Drawing Review |

0.0897 |

0.0917 |

0.0907 |

| Completion Delivery |

0.0680 |

0.0158 |

0.0421 |

| Promoting Smart Construction Site Management |

0.2732 |

Intelligent Progress Management |

0.0351 |

0.0341 |

0.0346 |

| Intelligent Cost Management |

0.0547 |

0.0772 |

0.0659 |

| Intelligent Construction Management |

0.0456 |

0.0401 |

0.0429 |

| Intelligent Safety Management |

0.0269 |

0.0545 |

0.0406 |

| Intelligent Environmental Management |

0.0350 |

0.0733 |

0.0540 |

| Intelligent Communication Management |

0.0350 |

0.0807 |

0.0576 |

| Digital Internal Document Management |

0.0385 |

0.0832 |

0.0607 |

| Application of Building Robots and Intelligent Equipment |

0.3423 |

Design Application Planning |

0.0444 |

0.0338 |

0.0391 |

| Optimization of Construction Plans |

0.0488 |

0.0436 |

0.0462 |

| Application of Building Robots |

0.0644 |

0.0511 |

0.0578 |

| Application of Intelligent Equipment |

0.0537 |

0.0442 |

0.0490 |

| Intelligent Monitoring Equipment |

0.0429 |

0.0436 |

0.0432 |

| Earthwork Measurement Drones |

0.0472 |

0.0511 |

0.0492 |

| Real Measurement Robots |

0.0330 |

0.0401 |

0.0365 |

| Prefabricated Construction |

0.1752 |

Site Assembly |

0.0554 |

0.0338 |

0.0447 |

| Prefabricated Decoration |

0.0609 |

0.0611 |

0.0610 |

| Tool-Based Templates |

0.0462 |

0.0255 |

0.0359 |

5. Construction of the Evaluation Model

The reasonableness of the evaluation model's construction is crucial for the accuracy of the evaluation results. Given the characteristics of evaluating new building industrialization projects, the evaluation model is constructed following these steps:

(1) Introduction of Matter Element Theory: This allows for the quantitative transformation of evaluation indicators using characteristic values. (2) Application of Cloud Modeling: The cloud model addresses the randomness and fuzziness issues that arise during the transformation process through its numerical characteristics. (3) Integration of Cloud Modeling and Matter Element Theory:This study combines cloud modeling with matter element theory to construct a cloud-matter-element evaluation model for comprehensive assessment of new building industrialization projects.

5.1. Cloud-Matter-Element Theory

In matter element theory, a matter element is expressed as R = (N, C, V), where N is the matter element object, C is the matter element characteristic, and V is the measured value of the matter element property.Matter element theory enables the quantitative conversion of qualitative indicators through the analysis of objects, characteristics, and measured values. However, due to the randomness and ambiguity of the problem, the quantitative values in the evaluation process cannot be accurately determined, which results in the inability to guarantee the accuracy of the final evaluation results. Therefore, the introduction of the cloud model into matter element theory allows for the consideration of randomness and ambiguity. By using expectation

, entropy

, and hyper-entropy

, uncertainty can be transformed into certainty, thereby improving the accuracy of the evaluation results [

27]. The expression is as follows:

In the cloud-matter-element model, the level of the evaluation indicators is represented by a fixed interval

corresponding to the score for each level.

represents the midpoint of the interval, and

is calculated based on the "

" rule of the normal cloud model. The formula is as follows:

Where

s is a constant that can be adjusted according to the degree of fuzziness of each indicator.

5.2. Construction of the Cloud-Matter-Element Model

By constructing the cloud-matter-element model, the evaluation and analysis of new building industrialization projects can be carried out. The specific calculation steps are as follows:

Step 1: Divide the Rating Standards

Currently, China has not yet developed a standardized evaluation system for new building industrialization projects. However, various provinces and cities have issued related policy documents. The evaluation dimensions mainly focus on areas such as BIM models, intelligent construction and evaluation, smart devices, and prefabricated components.

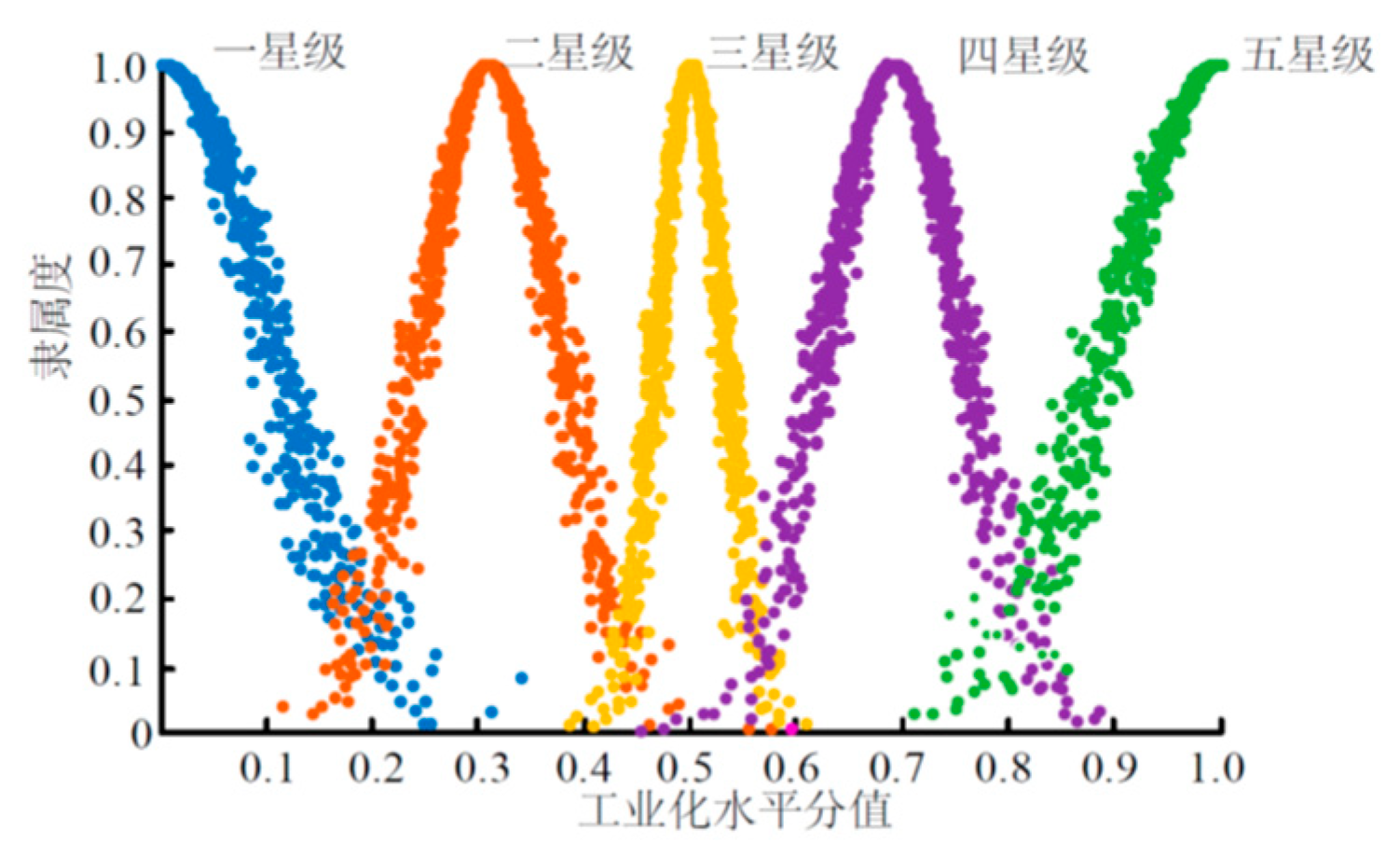

Based on literature research and expert opinions, the indicators are classified into five levels:One Star (Initial Level)、Two Stars (Promotional Level)、Three Stars(Comprehensive Level)、Four Stars (Next Best Level) and Five Stars (Optimal Level). To reflect the differences between levels, the golden ratio model is used to determine the scoring intervals within domain . The midpoint of domain 0.5 is set as the score for the evaluation level "Three Stars" .

According to the principle of the "

", the smaller value of adjacent clouds

and

is 0.618 times the larger value [

28]. The standard cloud model parameters for each evaluation level are determined by equations (13) and (14), as shown in

Table 9.

After determining the numerical characteristics for each evaluation level, MATLAB programming is used to establish the standard cloud model for evaluating new building industrialization projects. To improve accuracy and avoid errors due to high randomness, the number of cloud droplets D is set to 1000. This is illustrated in

Figure 5.

Step 2: Membership Degree Calculation

(1) Membership Degree Calculation at the Indicator Level

For each evaluation indicator value xxx, treat it as a cloud droplet. Using MATLAB 2016b, calculate the association degree of each indicator value xxx with each evaluation level. The expression for this calculation is as follows:

Where

is a normally distributed random number determined by the expectation

and the standard deviation

. Criteria Layer Membership Degree Calculation: By weighting the calculated indicator layer membership relationships, the membership degree for the criteria layer

can be determined.

Where is the membership degree of the p-th criterion element with respect to the j-th application effect level.

(2) Objective Layer Membership Degree Calculation: By weighting the calculated membership degrees at the criteria layer, the membership degree for the objective layer

is obtained.

Step 3: Determine Evaluation Level

Based on the membership degrees of the evaluation indicators calculated using the above formula, the application effect level for the criteria layer, indicator layer, and objective layer can be determined using the maximum membership degree principle. The formula is as follows:

6. Conclusions

This paper constructs an evaluation index system for new building industrialization projects and develops a project-level cloud-matter-element evaluation model using a combination weighting method that integrates ordinal relationship analysis and entropy weight methods. By analyzing and building an evaluation model for the application effects of intelligent construction technology, it provides effective guidance for the application of new building industrialization technologies.The transition from prefabricated buildings to intelligent construction, and from intelligent construction to new building industrialization, represents a deepening understanding of the principles of the construction industry. In the context of high-quality development, the evaluation standards and index system for new building industrialization projects need to align more closely with the requirements of high-quality development. Therefore, incorporating new concepts such as integrated design, intelligent construction, refined management, and management information technology as evaluation indicators for building industrialization reflects the new demands of the era.

Future research will focus on the following areas:

1. Research Perspective: While this study primarily evaluates the effects of intelligent building technologies during the construction phase, future research will extend to assess the application effects of these technologies during the decision, design, and post-operation stages, covering the entire lifecycle.

2. Evaluation Standards: Given that China has yet to fully establish a comprehensive evaluation standard system for intelligent buildings, future research will aim to compile the latest domestic and international policy documents related to intelligent building evaluation standards and work towards refining this evaluation system.

3. Indicator System: As the integration of information technology into new building industrialization becomes the industry’s overall trend, future research will track new developments in informatization, intelligence, and high-quality development. This will involve continuously updating and adjusting the evaluation indicator system to align with national strategies and improve implementation conditions and methods.

Author Contributions

Conceptualization, Z.Z. and Z.K.; methodology, Z.Z.; validation, Z.Z.; investigation, Z.K.; writing, Z.Z and Z.K; supervision, Z.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Zhangzhou Vocational and Technical College Doctoral Research Start-up Fund (ZZYB2302), Fujian Provincial Education System Philosophy and Social Sciences Research Fund (JAS22323), and Zhangzhou Vocational and Technical College Science and Technology Faculty Research Innovation Team Fund (ZZYT23009)

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request from the authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Zhao, J.; Wang, D.; Xu, Y. Research on the Obstacles to the Development of New Building Industrialization Based on the Fuzzy ISM-MICMAC Model. J. Beijing Univ. Civil Eng. Archit. 2021, 37, 103–112. [CrossRef]

- Liu, M.; Li, W.; Cao, Y.; et al. Comparative Analysis of Urban District-Level Prefabricated Building Industry Chain Demand Guidance Policies. J. Build. Struct. 2022, 52, 1–6. [CrossRef]

- Li, C.; Hu, M.; Xiao, B.; et al. Mapping the Knowledge Domains of Emerging Advanced Technologies in the Management of Prefabricated Construction. Sustainability 2021, 13. [CrossRef]

- Wen, Y. Research on the Intelligent Construction of Prefabricated Building and Personnel Training Based on BIM5D. J. Intell. Fuzzy Syst. 2021, 1–9. [CrossRef]

- Li, T.; Yan, X. Collaborative Development System and Mechanism of Intelligent Construction and Building Industrialization. J. Civil Eng. Manage. 2022, 39, 131–136, 143. [CrossRef]

- Ye, H. Thoughts and Countermeasures on New Building Industrialization. J. Eng. Manage. 2016, 30, 1–6. [CrossRef]

- Li, X.; You, W. Research on the Development Level of Prefabricated Building Industry in China. J. Build. Econ. 2021, 42, 62–66. [CrossRef]

- Wang, L.; Zhao, Q.S. Review of Research in the Field of Prefabricated Building Management in China. Proj. Manage. Technol. 2022, 20, 10–14.

- Dou, Y.; Xue, X.; Wang, Y.; et al. Evaluation of Enterprise Technology Innovation Capability in Prefabricated Construction in China. Constr. Innov. 2021, ahead-of-print. [CrossRef]

- Duan, Z.; Shi, D.W. Research on Influencing Factors of New Building Industrialization Based on Comprehensive Evaluation Model. J. Hulunbuir Univ. 2022, 30, 106–113.

- Zhang, L. Analysis of the Application of Informatization in Construction Project Management. Guangzhou Build. 2022, 50, 72–74.

- Berardi, U. Sustainability Assessment in the Construction Sector: Rating Systems and Rated Buildings. Sustainable Dev. 2012, No. 6, 411–424. [CrossRef]

- Tatari, O.; Kucukvar, M. Sustainability Assessment of U.S. Construction Sectors: Ecosystems Perspective. J. Constr. Eng. Manage. 2012, 138, 918–922. [CrossRef]

- Kucukvar, M.; Tatari, O. Towards a Triple Bottom-Line Sustainability Assessment of the U.S. Construction Industry. Int. J. Life Cycle Assess. 2013, No. 5, 958–972. [CrossRef]

- Zhang, M.; Qin, Y.; Liu, J.J. Regional Construction Industry Sustainable Development Evaluation Based on TOPSIS and Grey Relational Analysis. J. Civil Eng. Manage. 2018, 35, 189–193.

- Ye, H. Key Technologies and Practice Exploration of Intelligent Construction and Building Industrialization. Build. 2021, No. 12, 21–23.

- Aye, L.; Ngo, T.; Crawford, R.H.; et al. Life Cycle Greenhouse Gas Emissions and Energy Analysis of Prefabricated Reusable Building Modules. *Energy Build.* 2012, No. 1, 159–168. [CrossRef]

- Silva, P.C.; Almeida, M.; Bragança, L.; et al. Development of Prefabricated Retrofit Module Towards Nearly Zero Energy Buildings. Energy Build. 2013, No. 1, 115–125. [CrossRef]

- Bonamente, E.; Merico, M.C.; Rinaldi, S.; et al. Environmental Impact of Industrial Prefabricated Buildings: Carbon and Energy Footprint Analysis Based on an LCA Approach. Energy Procedia 2014, 2841–2844. [CrossRef]

- Abbood, A.W.; Al-Obaidi, K.M.; Awang, H.; et al. Achieving Energy Efficiency through Industrialized Building System for Residential Buildings in Iraq. Int. J. Sustain. Built Environ. 2015, No. 1, 78–90. [CrossRef]

- Cao, X.; Li, X.; Zhu, Y.; Zhang, Z. A Comparative Study of Environmental Performance Between Prefabricated and Traditional Residential Buildings in China. J. Cleaner Prod. 2015, 109, 131–143. [CrossRef]

- Niu, F.L. The Study and Measurement of the Evaluation Index System on Energy Industry Competitiveness Based on Evolution Mechanism of Self-Organization. Adv. Mater. Res. 2014, 2523–2528. [CrossRef]

- Lei, Y. Research on Constraints and Improvement Paths of New Building Industrialization Development: A Case Study of Shenyang City. Build. Budget 2022, No. 09, 7–9.

- Wang, G.; Liu, H.; Li, H.; et al. A Building Project-Based Industrialized Construction Maturity Model Involving Organizational Enablers: A Multi-Case Study in China. Sustainability 2020, 12. [CrossRef]

- Ma, T. Evaluation of the Development Level of New Building Industrialization from the Perspective of Intelligent Construction; Anhui Jianzhu University: Anhui, China, 2022.

- Yang, J.; Liu, W.; Jia, X. A Study on Evaluation Index System of New-Type Industrialization. In Proceedings of the 2009 International Conference on E-Learning, E-Business, Enterprise Information Systems, and E-Government; IEEE: 2009; pp. 312–316. [CrossRef]

- Li, C.S.; Zhou, K.P.; Lin, Y. Vulnerability Assessment of Waterlogging Disaster in Old Communities Based on Cloud Matter-Element. J. Saf. Sci. Technol. 2022, 18, 217–223.

- Wang, G.; Xu, C.; Li, D. Generic Normal Cloud Model. Inf. Sci. 2014, 280, 1–15. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).