1. Introduction

As global population trends upward, with projections nearing 10 billion by 2050, the construction industry faces unprecedented challenges in sustainability [

1]. The built environment’s outsized impact on greenhouse gas emissions accounting for three-quarters of the annual total underscores the urgent need for reform in building practices [

2]. The construction sector grapples with several key challenges. In New Zealand, construction and demolition generate 40-50% of landfill waste, with each new home producing approximately 4 tonnes of waste [

3]. Concrete production alone contributes 1.4 million tonnes of greenhouse emissions annually in the country [

4]. Buildings consume energy throughout their lifecycle, from construction to demolition, leading to natural resource depletion and significant greenhouse gas emissions [

5].

The regulatory landscape is evolving to address these issues. The Paris Agreement aims to limit temperature rise to 1.5°C, requiring a 40% reduction in global emissions by 2030 [

6]. New Zealand has introduced climate declarations for new construction projects, signaling a shift towards more sustainable practices [

7]. To improve sustainability, the industry is exploring several strategies. Simple waste sorting could divert at least half of construction waste from landfills, reducing project costs and environmental impact [

8]. Life Cycle Assessment (LCA) tools are being employed to calculate a building’s environmental impact from cradle to grave, aiding in decision-making between construction options and identifying major impact contributors [

9,

10].

Environmental Product Declarations (EPDs) have emerged as a key tool, providing transparent data on product environmental impacts. These follow product-specific guidelines (Product Category Rules) to ensure comparability (ISO, 2006). New Zealand’s proposed “Environmental Product Declarations” initiative aims to ensure the reliability of green product claims, potentially requiring third-party verification of environmental claims, including life-cycle considerations [

11]. However, implementing these strategies is not without challenges. Concerns have been raised about EPD reliability, with issues of limited scope, accuracy, and lack of standardization identified [

12]. Studies show significant missing information in many EPDs, affecting their comparability [

13]. There are also concerns about the quality and consistency of data in EPD assessments, with lack of transparency in data sources leading to doubts about product reliability [

14].

The ISO 14025 standard for EPDs serves as a framework but lacks standardization in certain aspects, creating gaps that need to be addressed [

11]. To move forward, the construction industry must invest in innovative waste reduction and recycling technologies, improve the accuracy and completeness of EPDs, develop more standardized approaches to life cycle assessments, enhance transparency in data collection and reporting, and collaborate across the supply chain to ensure consistent sustainability practices [

15]. Tackling these issues head-on, the construction sector can significantly reduce its environmental footprint and contribute to global sustainability goals. The path forward requires concerted effort, innovation, and a commitment to transparency and accuracy in environmental reporting. As the industry evolves, these efforts will be crucial in creating a more sustainable built environment for future generations. This study aims to conduct a comprehensive analysis of existing Environmental Product Declarations (EPDs) for construction products. The research objectives encompass identifying and evaluating EPD programs, categorizing product types, assessing the completeness of Life Cycle Assessment (LCA) information modules, and verifying the accuracy of declared environmental impact values.

2. Research Methodology

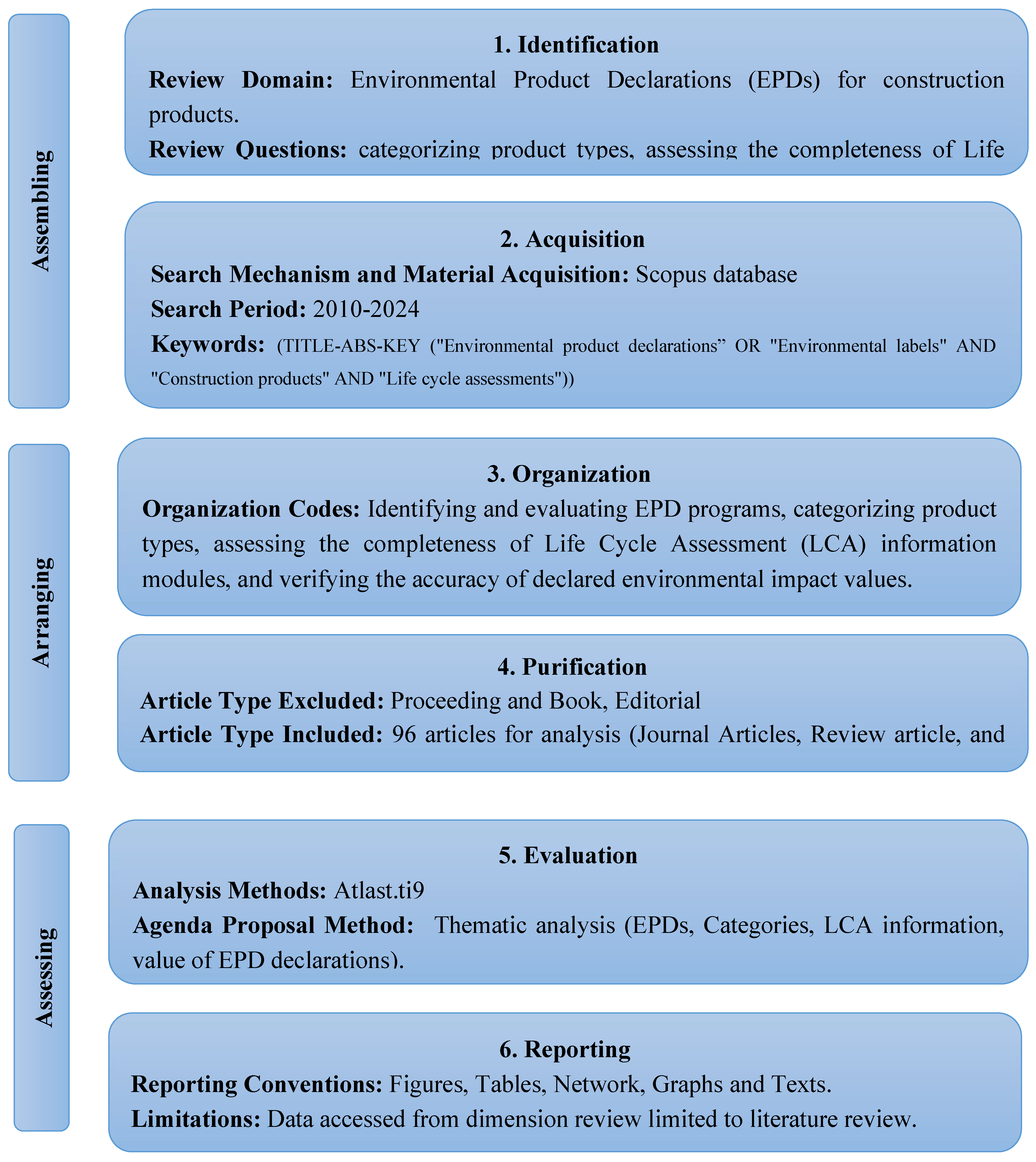

This paper use the “scientific procedures and rationales for systematic literature review (SPAR-4-SLR)” methodology developed by Paul et al. [

16] to comprehensively analyse significant research works from 2010 to 2024 in academic literature from Scopus database [

17]. The review process is structured into three distinct stages: 1) Identification and acquisition of relevant literature, 2) Organization and purification of the literary synthesis, and 3) Evaluation and reporting of the synthesized literature, as illustrated in

Figure 1 [

18]. This systematic approach ensures a thorough examination of the evolving landscape of environmental product declarations. Following these stages, the study conducts a comprehensive analysis of existing environmental product declarations for construction products. The following subsections describe the three key phases within the SPAR-4-SLR protocol employed for the study.

2.1.1. Assembling

The initial phase of the study, known as assembling, involved a comprehensive and systematic approach to literature collection. This process was designed to ensure a thorough and representative sample of relevant publications. The primary literature search was conducted in September 2024, utilizing multiple reputable academic databases to capture a broad spectrum of research. The Scopus database served as the primary source due to its extensive coverage of peer-reviewed literature in the field. Additionally, Google Scholar was employed to capture relevant publications that might not be indexed in Scopus, particularly conference proceedings and recent preprints.

The search strategy was carefully crafted to identify publications focusing on Environmental Product Declarations (EPDs), their evaluation, and related concepts within the construction industry. A combination of controlled vocabulary and free-text terms was used to maximize the sensitivity and specificity of the search. The search string included key terms such as “Environmental product declarations” OR “Environmental labels” AND “construction products” AND “life cycle assessments” along with their synonyms and related concepts.

The search encompassed works published from 2010 to September 2024, a timeframe chosen to capture the evolution of EPD programs and sustainable construction practices over a significant period. This temporal range allows for the identification of trends and developments in the field. The initial search yielded a total of 97 publications across all databases. After removing duplicates, the corpus was reduced to 96 unique publications. The Elsevier Mapping Initiative’s Science-Metrix classification system was employed to further refine the search results, enhancing the precision of literature identification. This classification system allowed for a more nuanced categorization of publications based on their research focus and methodological approaches [

19].

Following a rigorous preliminary screening process, a total of 96 articles were retained for in-depth analysis. This corpus comprised 54 articles from the Scopus database and 42 articles from Google Scholar, ensuring a comprehensive and diverse range of scholarly sources. This combination of databases allowed for a broad capture of both peer-reviewed journal articles and other relevant academic publications, providing a robust foundation for the study’s insights into Environmental Product Declarations (EPDs) and sustainable design practices in the construction industry.

The inclusion of articles from both Scopus and Google Scholar enhances the breadth and depth of the literature review, capturing a wide spectrum of research perspectives and methodologies. This comprehensive approach strengthens the validity of the findings and ensures a more holistic understanding of the current state of EPDs and sustainable construction practices. The selected articles underwent a systematic categorization process based on their central themes, employing a rigorous cross-referencing methodology to ensure consistency and relevance across the corpus [

20]. This process involved multiple iterations of detailed abstract analysis, supplemented by full-text reviews where necessary, to refine the literature base and align it precisely with the study’s objectives.

2.1.2. Arranging

The arranging phase involved a meticulous process of systematic organization and refinement of the selected articles, guided by clearly defined inclusion and exclusion criteria [

19]. This phase was crucial in ensuring the relevance and quality of the literature corpus for subsequent analysis. A comprehensive coding framework was developed, incorporating key metadata elements such as journal title, author name, publication year, research methodology, and thematic focus. This multi-dimensional coding strategy allowed for a more nuanced and granular analysis of the literature corpus [

21]. This methodical organization and coding strategy facilitates a thorough examination of trends and patterns in identifying and evaluating EPD programs, providing a solid foundation for subsequent analysis and synthesis of findings.

2.1.3. Assessing

The culminating phase of the study encompasses a comprehensive assessment, integrating rigorous evaluation and detailed reporting of findings [

17]. This phase is crucial for synthesizing insights and ensuring the reliability and validity of the research outcomes. The evaluation segment provides an in-depth overview of the analytical methodology employed, utilizing a mixed-methods approach that combines qualitative content analysis with quantitative bibliometric techniques. This multi-faceted analytical strategy allows for a nuanced understanding of both the thematic content and the meta-trends within the literature corpus.

For data analysis and trend identification, ATLAS.ti 9 software was utilized, leveraging its advanced capabilities in qualitative data analysis [

22]. This sophisticated tool facilitated a rigorous examination of patterns, themes, and relationships within the literature corpus. The software’s network analysis features were particularly valuable in mapping the interconnections between key concepts and identifying emerging research clusters. The study acknowledges its limitations, including the focus on English-language publications and the reliance on specific databases. These limitations are carefully considered in the interpretation of results to ensure balanced and contextualized conclusions.

Given that the review relied exclusively on publicly available secondary data accessed through reputable academic databases, ethical approval was not required for this research [

23]. Nevertheless, the study adhered to ethical standards in systematic review practices, ensuring transparency, reproducibility, and integrity throughout the research process. From the initial corpus of 96 articles (54 from Scopus and 42 from Google Scholar), all publications were subjected to in-depth analysis using ATLAS.ti 9 software. This advanced qualitative data analysis tool was employed to extract nuanced insights and identify emerging patterns within the literature [

24]. ATLAS.ti is widely recognized for its efficacy in qualitative analysis, particularly when dealing with substantial amounts of textual and graphical data [

25].

The results derived from the ATLAS.ti analyses are presented using a combination of narrative synthesis and visual representations. The visualizations are designed to facilitate easy understanding of complex relationships and temporal trends within the research field. This robust analytical approach ensures a thorough examination of the current state of knowledge regarding Environmental Product Declarations and sustainable practices in the construction industry, while also identifying gaps and opportunities for future research.

3. Critical Analysis of EPD Literature

3.1. Overview of Existing Environmental Product Declaration (EPD) Schemes

In New Zealand, the primary Environmental Product Declaration (EPD) program is operated by EPD Australasia, a collaborative initiative with Australia [

11]. This program plays a pivotal role in developing and managing EPDs for construction products across both nations, fostering sustainable building practices and environmental transparency in the region. EPD Australasia adheres to international standards, particularly ISO 14025 and EN 15804, ensuring that the EPDs produced are globally recognized and comparable [

26]. This alignment with international norms facilitates the integration of New Zealand and Australian products into global green building projects and sustainability initiatives. The program covers a wide range of construction materials and products, including but not limited to concrete, steel, timber, insulation, and various finishing materials [

27]. Providing comprehensive life cycle assessments, EPD Australasia enables manufacturers to communicate the environmental impacts of their products transparently and credibly [

28].

For the New Zealand construction industry, this program offers several significant benefits. Firstly, it allows local manufacturers to compete more effectively in international markets where EPDs are increasingly required or preferred [

29]. Secondly, it supports the country’s commitment to reducing carbon emissions and promoting sustainable development in the built environment. The EPD process involves rigorous data collection and analysis, covering aspects such as raw material extraction, manufacturing processes, transportation, installation, use phase, and end-of-life scenarios [

30]. This holistic approach provides valuable insights for product improvement and innovation, driving the industry towards more sustainable practices.

Furthermore, EPD Australasia actively engages with various stakeholders, including government bodies, industry associations, and academic institutions. This collaboration ensures that the program remains relevant and responsive to the evolving needs of the construction sector and environmental regulations in both New Zealand and Australia [

31]. As green building certifications like Green Star NZ gain prominence, EPDs are becoming increasingly important for project teams seeking to achieve higher ratings. The availability of local EPDs through EPD Australasia simplifies this process for New Zealand projects, promoting the use of environmentally preferable products and supporting evidence-based decision-making in sustainable construction [

32].

The development of general guidelines for scheme management and the application of Life Cycle Assessment (LCA) methodologies could significantly mitigate these obstacles. Furthermore, fostering mutual recognition among different schemes would contribute to a more unified approach [

27]. In this context, the European Commission has taken a step forward by publishing a guide that aims to promote consistency and compatibility across EPD programs [

33]. To illustrate the current landscape,

Table 1 provides an overview of the primary existing programs for EPD registration. This compilation highlights the diversity of schemes available, underscoring the need for harmonization efforts.

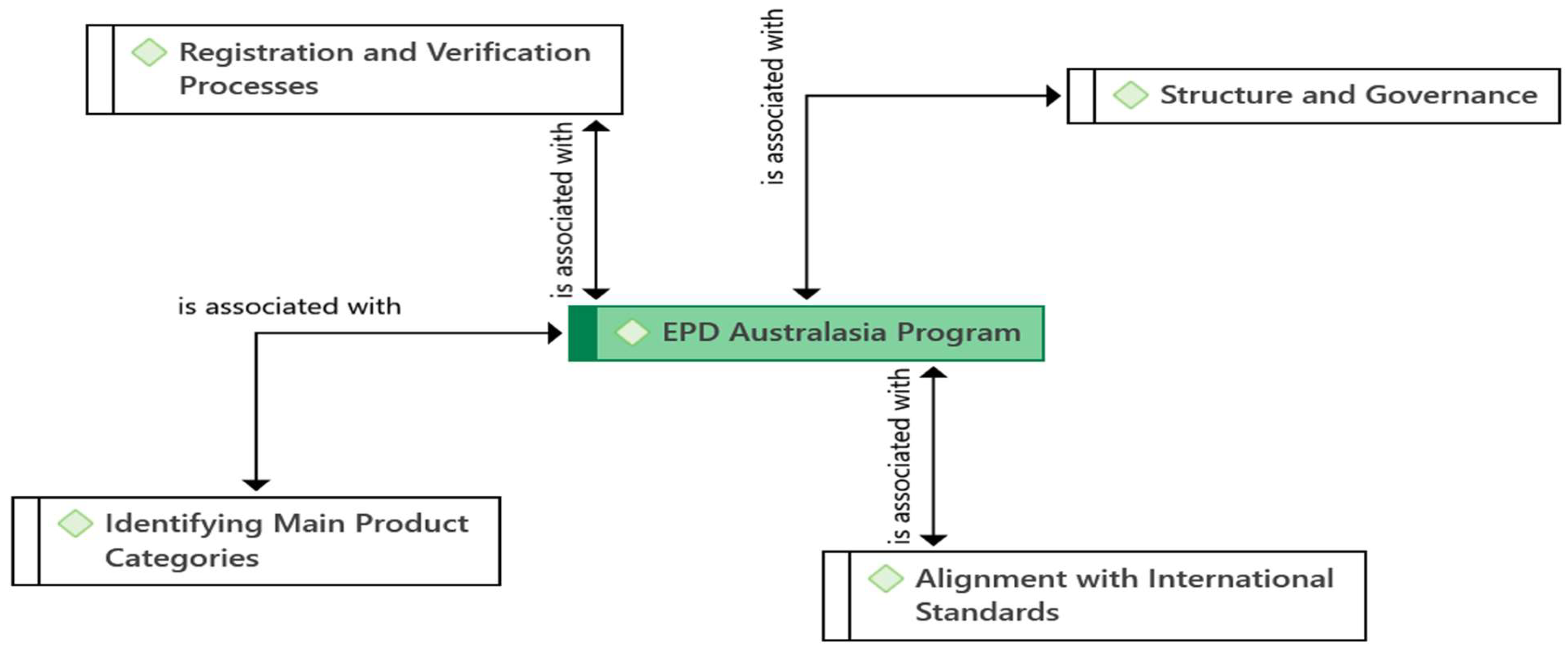

3.2. Overview of the Environmental Product Declaration (EPD) Australasia Program

The EPD Australasia Program is a regional initiative designed to develop and promote Environmental Product Declarations (EPDs) in Australia and New Zealand [

11]. EPDs are standardized documents that provide transparent, verified information about the environmental impact of products throughout their lifecycle.

Figure 2 provides the overview of the EPD Australasia program.

3.2.1. Structure and Governance

EPD Australasia, established in 2014, is a non-profit organization dedicated to developing and managing an Environmental Product Declaration (EPD) Program for Australia and New Zealand [

34]. This structure reflects the collaborative nature of the initiative, bridging the sustainability efforts of both countries in the construction and manufacturing sectors. The organization’s governance is two-tiered, consisting of board of directors and an Advisory Panel [

35]. The board of directors is responsible for the overall strategic direction and management of EPD Australasia. They ensure that the organization maintains its non-profit status while fulfilling its mission to promote environmental transparency in product manufacturing [

36].

The Advisory Panel plays a crucial role in guiding the organization’s activities. Comprising industry experts from various fields related to construction, manufacturing, and environmental science, this panel provides valuable insights and recommendations [

37]. Their expertise helps ensure that the EPD Program remains relevant, scientifically sound, and aligned with industry needs and international best practices. This governance structure allows EPD Australasia to maintain a balance between operational efficiency and technical expertise [

38]. The board focuses on organizational management and strategic planning, while the Advisory Panel contributes specialized knowledge to inform program development and implementation [

39].

3.2.2. Registration and Verification Processes

The registration and verification processes for Environmental Product Declarations (EPDs) through EPD Australasia involve a comprehensive series of steps designed to ensure accuracy, compliance, and credibility [

40]. This rigorous approach is fundamental to maintaining the integrity of the EPD program in Australia and New Zealand. The process begins with an initial application from a company seeking to register an EPD [

27]. This step involves submitting basic information about the product and the organization, allowing EPD Australasia to assess the application’s suitability and provide guidance on the next steps [

41]. Following acceptance of the application, the EPD development phase commences. This crucial stage involves conducting a detailed life cycle assessment (LCA) of the product, following ISO 14040 and ISO 14044 standards. The LCA examines the product’s environmental impacts across its entire life cycle, from raw material extraction to end-of-life scenarios [

42,

43].

Once the EPD is developed, it undergoes a stringent verification process. EPD Australasia mandates that all EPDs be independently verified by a recognized third-party verifier. This requirement is a cornerstone of the program’s credibility [

44]. Verifiers, who must be approved by EPD Australasia, scrutinize the EPD and its underlying LCA data to ensure compliance with relevant standards such as ISO 14025 and EN 15804, as well as the specific program rules set by EPD Australasia.

The verification process typically involves:

A thorough review of the LCA methodology and calculations

Checking the consistency and accuracy of data used

Ensuring proper interpretation and presentation of results

Confirming adherence to EPD Australasia’s program rules.

After successful verification, the EPD moves to the final registration stage. EPD Australasia reviews the verified document, assigns a registration number, and officially publishes the EPD on its website, making it publicly accessible [

43]. This multi-step process, with its emphasis on independent verification, ensures that registered EPDs provide reliable, comparable, and transparent environmental information about products in the Australian and New Zealand markets.

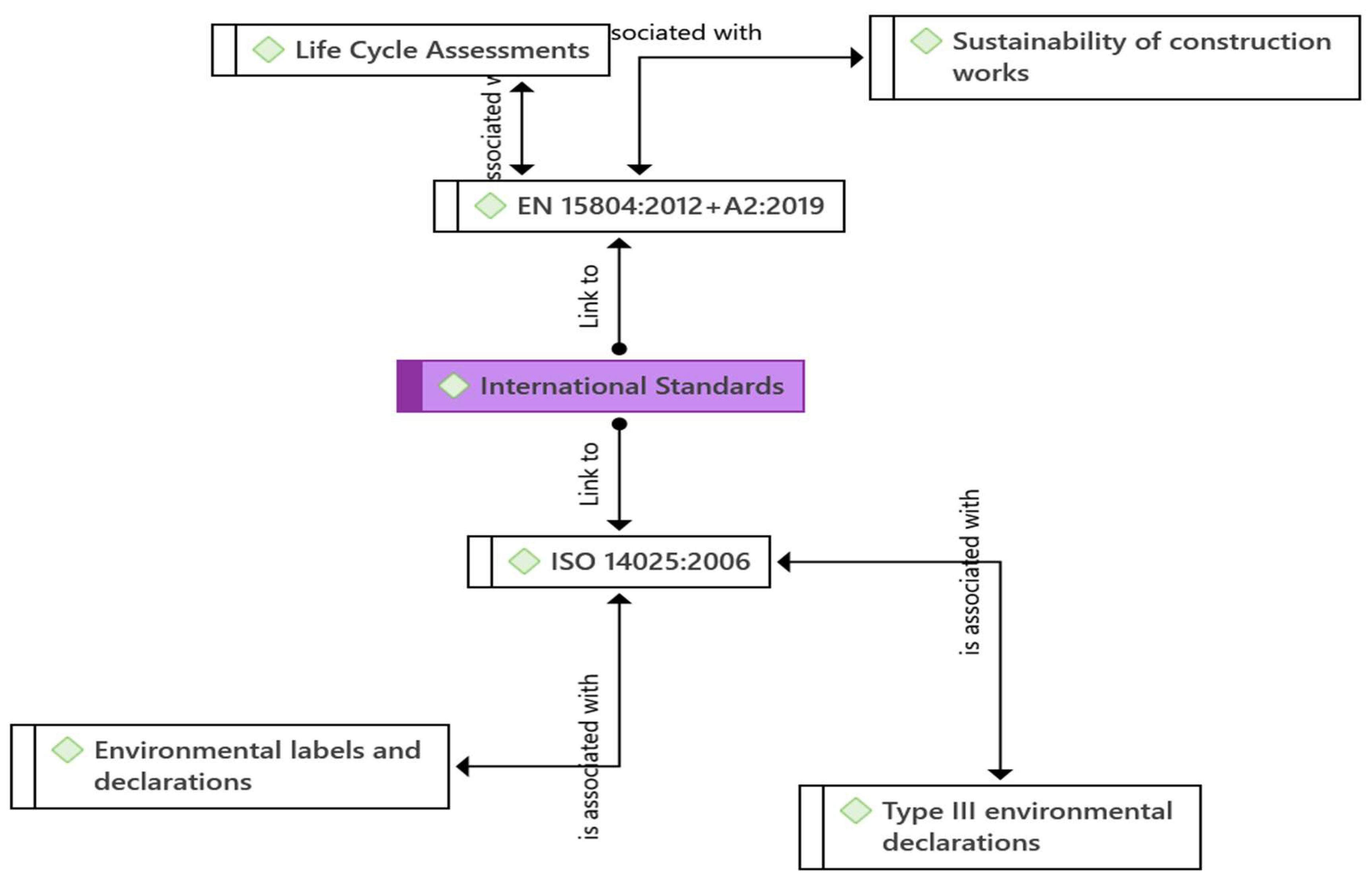

3.2.3. Alignment with International Standards

EPD Australasia’s alignment with key international standards is a cornerstone of its program, ensuring that Environmental Product Declarations (EPDs) produced in Australia and New Zealand are globally relevant and comparable [

45]. This alignment is particularly crucial in today’s interconnected global market, where construction products and materials frequently cross international borders. The program primarily focuses on two pivotal international standards.

The first is ISO 14025:2006 - Environmental labels and declarations - Type III environmental declarations - Principles and procedures [

46]. Developed by the International Organization for Standardization (ISO), this standard provides the fundamental framework for Type III environmental declarations, which include EPDs. It outlines the principles and procedures for developing these declarations, ensuring a consistent approach worldwide [

47]. Key aspects of ISO 14025 include defining the objectives of Type III environmental declarations, specifying requirements for EPD programs, and establishing procedures for data verification and declaration development [

48].

The second key standard is EN 15804:2012+A2:2019 - Sustainability of construction works - Environmental product declarations - Core rules for the product category of construction products [

49]. This European standard, developed by the European Committee for Standardization (CEN), provides specific rules for EPDs in the construction sector. Widely recognized beyond Europe, it serves as a benchmark for construction product EPDs globally [

50]. EN 15804 covers detailed requirements for conducting Life Cycle Assessments (LCAs) for construction products, specifications for reporting environmental impacts, resource use, and waste categories, and guidelines for ensuring consistency and comparability between EPDs for construction products [

51].

Adhering to these standards, EPD Australasia ensures that EPDs produced under its program are scientifically robust and credible, comparable with EPDs from other international programs, recognized and accepted in global markets, and aligned with best practices in environmental impact assessment and reporting [

31]. This alignment facilitates several benefits for Australian and New Zealand manufacturers. It enhances international market access, as their EPDs are recognized globally. It increases competitiveness in tenders and projects requiring standardized environmental information [

52]. The alignment also streamlines compliance with various green building rating systems worldwide and simplifies the process for obtaining EPDs valid in multiple markets. Furthermore, this standardization supports decision-makers, architects, and builders in making informed choices about construction materials across different international contexts, contributing to more sustainable building practices globally [

53]. Ensuring that EPDs from Australia and New Zealand are comparable with those from other countries, EPD Australasia plays a crucial role in facilitating transparency and sustainability in the global construction industry [

54].

Figure 3 depicts the international standards connected to EPDs.

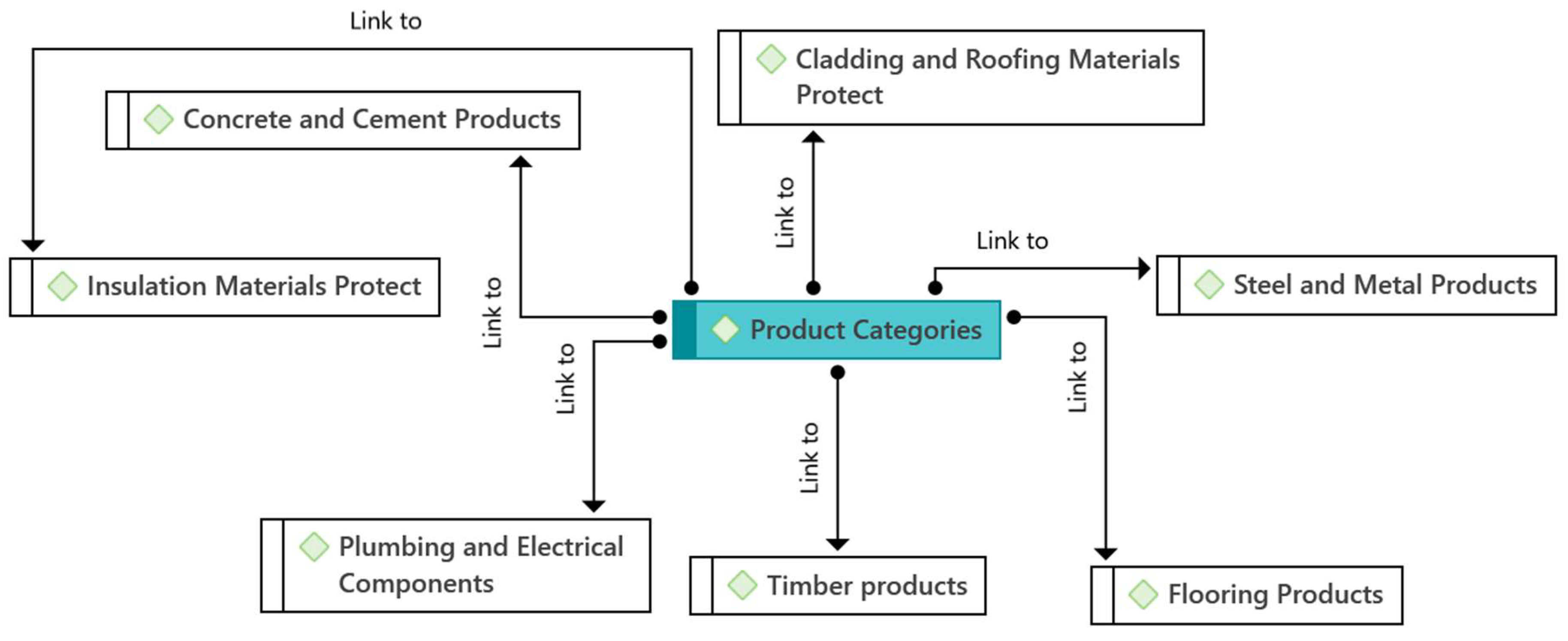

3.2.4. Identifying Main Product Categories

Understanding these product categories is crucial for stakeholders in the construction industry, including architects, builders, suppliers, and regulators. It allows for informed decision-making in material selection, considering factors such as performance, cost, sustainability, and compliance with building codes [

55]. Moreover, knowledge of these categories helps in identifying trends, forecasting demand, and developing strategies for innovation and improvement in the construction sector [

56]. The construction products used in New Zealand reflect a balance between local resources, environmental considerations, seismic requirements, and international best practices [

56]. As the industry evolves, there is an increasing focus on sustainable and innovative products that can meet the changing needs of the built environment while addressing challenges such as climate change and resource efficiency [

57].

Figure 4 provides the product categories of EPD.

Timber products are a crucial category in New Zealand’s construction industry, reflecting the country’s significant forestry sector. The abundance of local timber resources has led to a wide range of wood-based construction materials, including structural lumber, engineered wood products like laminated veneer lumber (LVL) and cross-laminated timber (CLT), as well as wood-based panels such as plywood and oriented strand board (OSB) [

58]. These products are extensively used in residential and commercial construction, offering sustainability benefits and aligning with New Zealand’s cultural and environmental values [

59].

Concrete and cement products form another vital category, including ready-mix concrete, precast concrete elements, cement-based mortars, and grouts. These materials are essential for foundations, structural elements, and various finishing applications [

60]. New Zealand’s seismic activity has influenced the development of specialized concrete products designed to withstand earthquakes.

Steel and metal products play a significant role in construction, particularly in commercial and industrial buildings. This category encompasses structural steel beams and columns, reinforcing steel for concrete, light gauge steel framing, and metal roofing and cladding materials. The durability and strength of these products make them indispensable in many construction projects [

61].

Insulation materials are crucial for energy efficiency and comfort in New Zealand’s varied climate. This category includes products like fiberglass bats, polyester insulation, foam boards, and reflective foil insulation. The emphasis on energy-efficient buildings has led to increased demand for high-performance insulation products [

62].

Cladding and roofing materials protect buildings from the elements and contribute to their aesthetic appeal. This category includes weatherboards (both timber and composite), brick and stone veneers, fiber cement sheets, metal cladding systems, concrete and clay roof tiles, and long-run metal roofing. The selection of these materials often reflects regional architectural styles and climate considerations [

62].

Flooring products encompass a wide range of materials used for both residential and commercial applications. This includes timber flooring, carpet, vinyl, ceramic tiles, and polished concrete. The choice of flooring materials often depends on the specific requirements of each space, considering factors like durability, maintenance, and aesthetic preferences [

63].

Plumbing and electrical components, while less visible, are essential for the functionality of buildings. This category includes pipes, fittings, wiring, switchgear, and fixtures. The rapid development of smart home technologies has led to the integration of more sophisticated electrical and plumbing systems in modern construction [

64]

3.3. Sustainable Development

The Earth’s biosphere provides essential resources that underpin human survival and societal progress. However, there’s growing concern that excessive consumption by current generations may deplete these vital supplies, potentially jeopardizing the well-being of future populations [

65]. The rapid industrialization of recent centuries has led to increasingly apparent negative consequences stemming from resource overexploitation. As awareness of these environmental and social issues has spread, the concept of ‘sustainability’ has gained prominence [

66]. At its core, sustainability aims to balance present needs with long-term ecological and social health. The United Nations defines it as “meeting the requirements of today without undermining the capacity of forthcoming generations to fulfill their own necessities” [

65].

Economic viability (ensuring financial stability and growth)

Environmental stewardship (preserving ecosystems and minimizing ecological harm)

Social responsibility (promoting equity, well-being, and community cohesion)

This framework is often referred to as the ‘Triple Bottom Line’ approach [

67]. It suggests that organizations should evaluate their performance not just in financial terms, but also by considering their environmental and social impacts. In the context of manufacturing, this means businesses are increasingly expected to integrate ecological and social considerations into their operations while maintaining profitability [

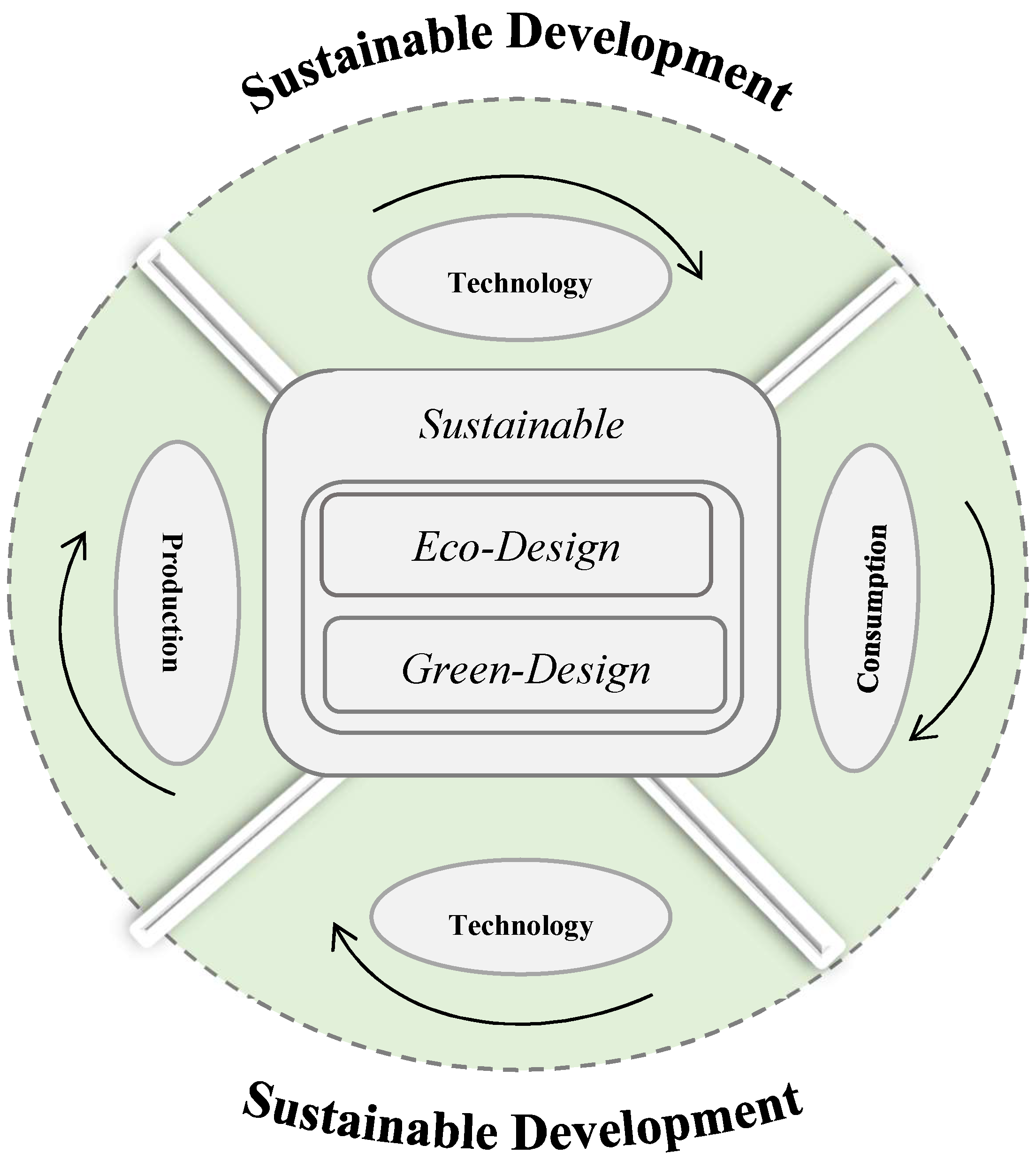

68]. The goal is to foster a more holistic approach to industrial practices that aligns with broader sustainability objectives. The relationship between sustainable design principles and the overarching aim of sustainable development is complex and multifaceted as shown in

Figure 5, involving numerous interconnected factors and stakeholders.

3.3.1. Sustainable Design Products

Sustainable design, a crucial component of the broader sustainable development framework, has gained traction in corporate environments due to its potential for both environmental stewardship and business advantages [

69]. These benefits often include operational cost reductions and enhanced market appeal [

70]. As organizations increasingly recognize the value of sustainable practices, they are integrating these principles into their product development processes and overall business strategies [

71]. Within the product development lifecycle, the design phase plays a pivotal role in shaping a product’s environmental impact. Designers, particularly those in industrial and product fields, wield significant influence over critical factors such as material selection, manufacturing processes, energy efficiency, product lifespan, and end-of-life considerations [

72]. This positioning allows designers to be key drivers of sustainability initiatives, as their decisions can dramatically affect a product’s overall ecological footprint [

73].

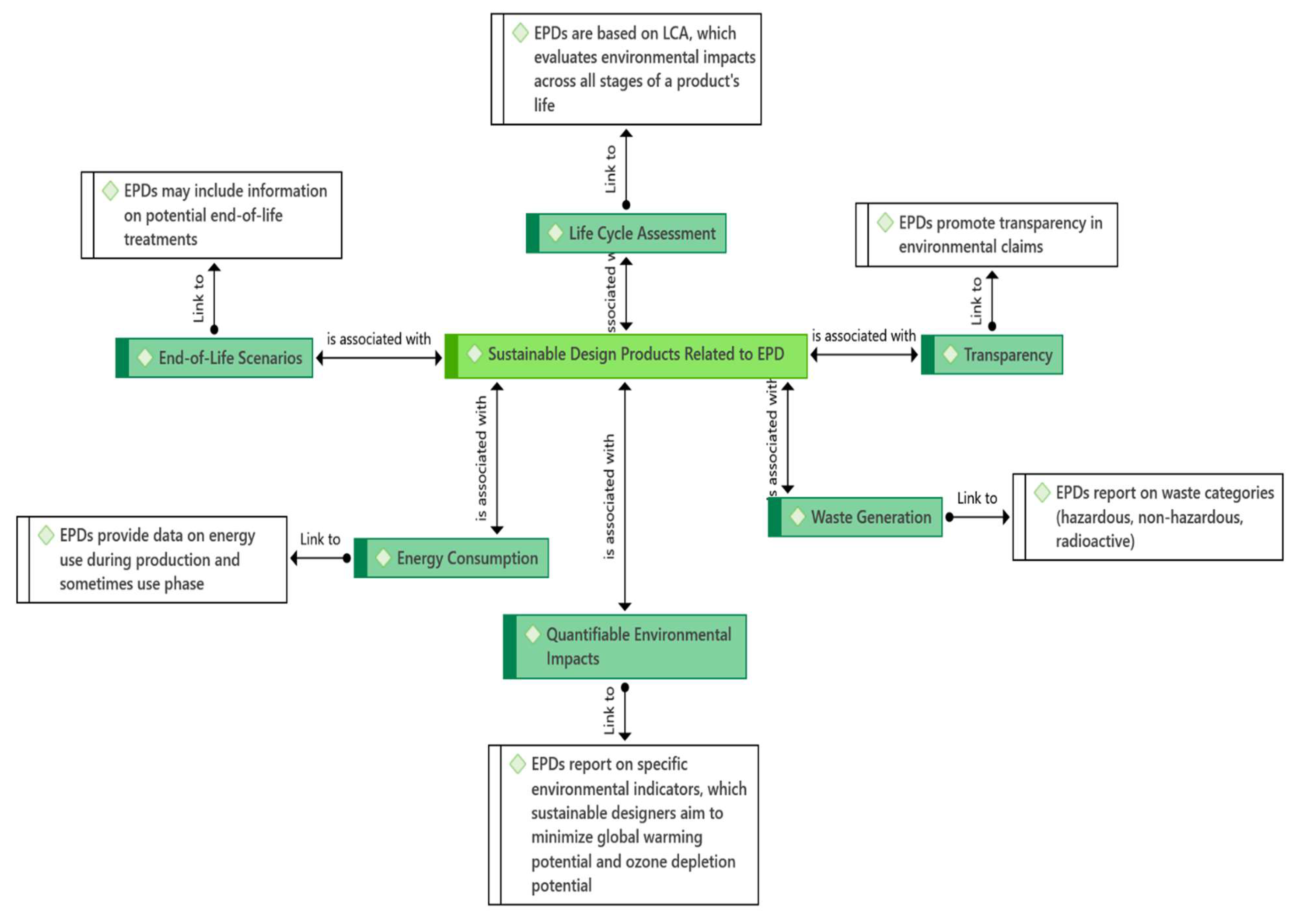

Figure 6 provides the sustainable design outputs of EPD.

The concept of sustainable design has evolved over time, with various interpretations and approaches emerging. These can be broadly categorized into three main philosophies: green design, eco-design, and design for sustainability [

74]. Green design typically focuses on reducing obvious environmental impacts, often through material substitution or incremental improvements. Eco-design takes a more holistic approach, considering the entire product lifecycle and aiming to minimize overall environmental impact. Design for sustainability expands beyond environmental concerns to include social and economic factors, aligning with the triple bottom line concept [

75]. This progression from green design to eco-design and then to design for sustainability reflects a shift from narrow, problem-specific solutions to more comprehensive, systems-level thinking in design practices [

76]. Green design often addresses immediate and visible environmental issues, while eco-design broadens the scope to consider less obvious impacts throughout a product’s life. Design for sustainability takes this even further, integrating environmental considerations with social responsibility and economic viability [

77].

As the understanding of sustainability challenges deepens, design philosophies continue to evolve, pushing towards more integrated and impactful solutions. Modern sustainable design practices increasingly emphasize circular economy principles [

78], regenerative design [

79], and biomimicry [

80], among other innovative approaches. These evolving concepts reflect a growing recognition that truly sustainable design must not only minimize negative impacts but actively contribute to environmental and social well-being [

81]. The role of designers in this evolution cannot be overstated. As sustainability becomes increasingly central to business strategies and consumer preferences, designers are tasked with balancing aesthetic and functional requirements with environmental and social considerations [

82]. This demands a broader skill set and knowledge base, encompassing not just traditional design principles but also an understanding of materials science, lifecycle analysis, and social impact assessment [

83]. Sustainable design represents a dynamic and crucial field within the broader context of sustainable development. Its evolution from simple green design principles to comprehensive sustainability frameworks mirrors our growing awareness of environmental and social challenges [

74]. As we move forward, the integration of sustainable design practices into all aspects of product development and business strategy will likely become not just a competitive advantage, but a necessity for long-term success in a resource-constrained world [

84].

3.3.2. Eco-Design Products

Eco-design has emerged as a crucial approach in sustainable product development, focusing on integrating environmental considerations throughout the design process. According to Pigosso and McAloone [

72], eco-design can be defined as “a proactive management approach that integrates environmental concerns into product development processes” (p. 413). This strategy aims to minimize resource consumption and environmental impact across a product’s entire lifecycle, from raw material extraction to end-of-life disposal.

It’s important to distinguish eco-design from its predecessor, green design. While green design typically addresses specific environmental issues, eco-design takes a more comprehensive approach. Ceschin and Gaziulusoy [

74] emphasize that eco-design considers the full spectrum of environmental impacts, encompassing production, distribution, use phases, and eventual disposal. This holistic perspective allows for more effective mitigation of environmental harm and often leads to innovative solutions that benefit both the environment and the product’s overall performance.

Several key strategies characterize the eco-design approach. These include optimizing material efficiency by selecting environmentally preferable materials and minimizing material use [

85], enhancing energy efficiency by reducing consumption during production and use phases [

86], and extending product lifespan through designs that promote durability, repairability, and upgradability [

87]. Additionally, eco-design focuses on facilitating end-of-life management by incorporating features that support recycling or biodegradability [

88] and minimizing the use of toxic substances in both product composition and manufacturing processes [

89].

De los Rios and Charnley [

82] further expand on these strategies, suggesting that successful eco-design also involves close collaboration between designers, engineers, and environmental specialists. This interdisciplinary approach ensures a holistic consideration of sustainability throughout the product development process. By bringing together diverse expertise, companies can more effectively navigate the complex challenges of balancing environmental concerns with functional requirements and market demands.

The implementation of eco-design principles has shown tangible benefits beyond environmental improvements. A study by Plouffe et al. [

90] demonstrated that companies adopting eco-design practices experienced improvements in product quality, cost reduction, and market share. These findings suggest that eco-design can be a driver of innovation and competitive advantage, aligning environmental responsibility with business success.

As the field evolves, eco-design is increasingly intersecting with other cutting-edge concepts in sustainable design. For instance, principles of circular economy are being integrated into eco-design practices, emphasizing closed-loop systems where products and materials are reused, refurbished, and recycled [

78]. Similarly, biomimicry – the practice of emulating nature’s time-tested patterns and strategies – is providing new inspiration for eco-design solutions [

80]. These intersections are pushing the boundaries of sustainable product development even further, opening up new possibilities for creating products that not only minimize harm but potentially contribute positively to environmental and social systems. Eco-design represents a significant evolution in sustainable product development. Considering environmental impacts throughout a product’s lifecycle and integrating this consideration into the core of the design process, eco-design offers a pathway to more sustainable production and consumption patterns. As environmental challenges continue to grow in urgency and complexity, the principles and practices of eco-design are likely to become increasingly central to product development across industries.

3.3.3. Green Design Products

The environmental impact of product manufacturing and consumption has become a pressing concern in recent decades. The pollution generated throughout a product’s lifecycle has been linked to various ecological issues, prompting a shift in design philosophies towards more sustainable practices [

74]. This shift has led to the emergence and evolution of green design principles, which aim to mitigate the environmental harm caused by industrial activities.

Contrary to popular belief, the concept of green design predates the modern environmental movement. Spangenberg, Fuad-Luke, and Blincoe [

91] note that elements of green design can be traced back to pre-industrial practices, where resource scarcity often necessitated efficient and localized production methods. However, it was the increasing awareness of environmental degradation in the late 20th century that brought green design to the forefront of industrial practices. This heightened consciousness catalyzed a more formal and systematic approach to incorporating environmental considerations into product design.

Green design, as a formal concept, emerged as an initial response to mounting environmental concerns. It typically focuses on addressing specific environmental issues within the product development process. According to Pichette et al. [

92], early green design strategies often centered on singular aspects such as material selection, energy efficiency, or end-of-life considerations. These targeted approaches allowed businesses to take concrete steps towards reducing their environmental impact without necessitating a complete overhaul of their production processes.

Some common strategies employed in green design include sourcing materials locally to reduce transportation-related emissions [

50], designing products for easy disassembly to facilitate recycling [

93], selecting materials with lower environmental impact [

94], and minimizing or eliminating the use of hazardous substances [

89]. These strategies represent practical, implementable solutions that can yield tangible environmental benefits. Focusing on specific aspects of the product lifecycle, companies can make meaningful progress towards sustainability goals while gradually building the capacity for more comprehensive environmental initiatives.

While these approaches represent significant steps towards reducing environmental impact, it’s important to note the limitations of green design. Pigosso, McAloone, and Rozenfeld [

95] point out that green design often addresses environmental issues in isolation, potentially overlooking the complex interplay of factors that contribute to a product’s overall ecological footprint. This narrow focus, while beneficial in its own right, may not always capture the full spectrum of environmental implications associated with a product’s lifecycle.

As understanding of environmental systems grow, so has the approach to sustainable design. Modern perspectives, as outlined by Ceschin and Gaziulusoy [

74], advocate for a more holistic approach that considers the entire product lifecycle and its broader systemic impacts. This evolution has led to the development of more comprehensive frameworks such as eco-design and design for sustainability. These advanced approaches build upon the foundations laid by green design, expanding the scope to encompass a wider range of environmental, social, and economic factors.

Despite its limitations, green design remains a valuable starting point for companies beginning their journey towards more sustainable practices [

96]. It offers tangible, implementable strategies that can yield immediate environmental benefits while paving the way for more comprehensive sustainability initiatives. As businesses become more adept at incorporating these initial green design principles, they often find themselves better equipped to tackle more complex sustainability challenges [97]. In this way, green design serves not only as a means of reducing immediate environmental impacts but also as a steppingstone towards more holistic and transformative approaches to sustainable product development.

4. Conclusions

Environmental Product Declarations (EPDs) have emerged as a crucial tool in combating greenwashing and promoting genuine sustainability in the construction industry, particularly in New Zealand and Australia. The EPD Australasia program, aligned with international standards ISO 14025 and EN 15804, provides a robust framework for transparent and credible environmental impact reporting of construction products. The evolution from green design to eco-design and design for sustainability reflects a growing understanding of the complex interplay between environmental, social, and economic factors in product development. This progression has led to more holistic approaches in sustainable design, emphasizing lifecycle thinking, circular economy principles, and broader systemic impacts. The construction industry in New Zealand and Australia has made significant strides in adopting EPDs across various product categories, including timber, concrete, steel, insulation, cladding, flooring, and plumbing materials. This adoption reflects a commitment to transparency and sustainability in the built environment sector.

The adoption of EPDs has far-reaching implications for the construction industry and beyond. It enhances the competitiveness of New Zealand and Australian products in global markets where environmental credentials are increasingly valued. The growing use of EPDs may influence future building regulations and green building certification systems, potentially leading to more stringent environmental requirements. The detailed lifecycle assessments required for EPDs can drive innovation in product design and manufacturing processes, leading to more sustainable construction practices. EPDs also promote greater transparency throughout the supply chain, encouraging suppliers to improve their environmental performance. Furthermore, the availability of standardized environmental information through EPDs can educate consumers and professionals, leading to more informed decision-making in construction projects.

Therefore, to further advance the field of sustainable construction and EPDs, several areas of future research are proposed. Long-term impact assessment studies are needed to evaluate the environmental and economic effects of widespread EPD adoption in the construction industry. Comparative analyses could explore the effectiveness of EPDs versus other environmental certification schemes in driving sustainable practices. Investigating the potential for integrating EPD data with Building Information Modeling (BIM) systems could facilitate more sustainable design decisions. Research into methodologies for incorporating social impact assessments into EPDs would move towards a more comprehensive sustainability evaluation. Exploring how EPDs can be adapted or extended to better support circular economy principles in construction is another crucial area for investigation. Studies on the challenges faced by small and medium enterprises in implementing EPDs and strategies to overcome these barriers would be valuable. Research on consumer understanding and the effectiveness of EPDs in influencing decision-making in construction projects could provide insights for improving communication and adoption.

Efforts to improve the harmonization of EPD schemes globally to enhance comparability and reduce market barriers are also needed. Exploring the potential of AI and machine learning in streamlining the EPD development and verification process could lead to more efficient and accurate assessments. Finally, assessing the impact of EPD adoption on national and international environmental policies related to construction and manufacturing would provide valuable insights for policymakers and industry leaders. These research directions could significantly contribute to the advancement of sustainable practices in the construction industry and enhance the effectiveness of EPDs as a tool for environmental transparency and improvement. As the field of sustainable construction continues to evolve, ongoing research and development in these areas will be significant in addressing the complex challenges of building a more sustainable future.

References

- O’Sullivan, J.N. Demographic delusions: World population growth is exceeding most projections and jeopardising scenarios for sustainable futures. World 2023, 4, 545–568. [Google Scholar] [CrossRef]

- Goubran, S.; Walker, T.; Cucuzzella, C.; Schwartz, T. Green building standards and the united nations’ sustainable development goals. J. Environ. Manage. 2023, 326, 116552. [Google Scholar] [CrossRef] [PubMed]

- Environment, N.Z.M.F.T. Material use Material use. pp. 1–5, 2024.

- Council, N.Z.G.B. Annual Review. Annu. Rev. Novemb. 2022, 2, 1–4, Available: http://www.ifpri.org/themes/gssp/gssp.htm%0Ahttp://files/171/Cardon - 2008 - Coaching d’équipe.pdf%0Ahttp://journal.um-surabaya.ac.id/index.php/JKM/article/view/2203%0Ahttp://mpoc.org.my/malaysian-palm-oil-industry/%0Ahttps://doi.org/10.1080/23322039.2017. [Google Scholar] [CrossRef]

- Albsoul, H.; Doan, D.T.; GhaffarianHoseini, A. Estimating construction waste in New Zealand: a focus on urban areas, residential and non-residential building activities. Environ. Res. Commun. 2024, 6, 35009. [Google Scholar] [CrossRef]

- Matemilola, S.; Fadeyi, O.; Sijuade, T. Paris agreement. Encycl. Sustain. Manag. 2020, 2020, 1. [Google Scholar]

- Report, N.C.P. National Construction Pipeline Report | Ministry of Business, Innovation & Employment. 2022. https://www.mbie.govt.nz/building-and-energy/building/supporting-a-skilled-and-productive-workforce/national-construction-pipeline-report/. (accessed on 26 September 2022).

- BRANZ, “Accelerating industry action on waste management. p. 2024, 2024.

- Moncaster, A.M.; Pomponi, F.; Symons, K.E.; Guthrie, P.M. Why method matters: Temporal, spatial and physical variations in LCA and their impact on choice of structural system. Energy Build. 2018, 173, 389–398. [Google Scholar] [CrossRef]

- Anderson, J.; Jones, D. Real and apparent variations in embodied carbon impacts provided in EPD for construction products. in The Routledge Handbook of Embodied Carbon in the Built Environment, Routledge, 2023, pp. 335–358.

- Marzocchini, M.; Echazarreta, J.M.; Gulivart, V.; Mathisen, M.L. Environmental Product Declarations worldwide: a case study in Argentina. Int. J. Life Cycle Assess. 2023, 28, 955–966. [Google Scholar] [CrossRef]

- Mondello, G.; Salomone, R.; Ioppolo, G.; Saija, G.; Sparacia, S.; Lucchetti, M.C. Comparative LCA of alternative scenarios for waste treatment: The case of food waste production by the mass-retail sector. Sustainability 2017, 9, 827. [Google Scholar] [CrossRef]

- Moré, F.B.; Galindro, B.M.; Soares, S.R. Assessing the completeness and comparability of environmental product declarations. J. Clean. Prod. 2022, 375, 133999. [Google Scholar] [CrossRef]

- Ibáñez-Forés, V.; Pacheco-Blanco, B.; Capuz-Rizo, S.F.; Bovea, M.D. Environmental Product Declarations: exploring their evolution and the factors affecting their demand in Europe. J. Clean. Prod. 2016, 116, 157–169. [Google Scholar] [CrossRef]

- Global, A.B.C. Global status report for buildings and construction. Glob. Alliance Build. Constr., 2020.

- Paul, J.; Lim, W.M.; O’Cass, A.; Hao, A.W.; Bresciani, S. Scientific procedures and rationales for systematic literature reviews (SPAR-4-SLR). Int. J. Consum. Stud. 2021, 45, O1–O16. [Google Scholar]

- Xiao, Y.; Watson, M. Guidance on conducting a systematic literature review. J. Plan. Educ. Res. 2019, 39, 93–112. [Google Scholar] [CrossRef]

- Sreenivasan, A.; Suresh, M.; Nedungadi, P. Mapping analytical hierarchy process research to sustainable development goals: Bibliometric and social network analysis. Heliyon, 2023, 9.

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Booth, A.; James, M.-S.; Clowes, M.; Sutton, A. Systematic approaches to a successful literature review. 2021.

- Waltman, L.; Boyack, K.W.; Colavizza, G.; van Eck, N.J. A principled methodology for comparing relatedness measures for clustering publications. Quant. Sci. Stud. 2020, 1, 691–713. [Google Scholar] [CrossRef]

- Zhang, L.; Wider, W.; Fauzi, M.A.; Jiang, L.; Tanucan, J.C.M.; Udang, L.N. Psychological capital research in HEIs: Bibliometric analysis of current and future trends. Heliyon, 2024.

- Soratto, J.; de Pires, D.E.P.; Friese, S. Thematic content analysis using ATLAS. ti software: Potentialities for researchs in health. Revista Brasileira de Enfermagem, 2020; 73. [Google Scholar]

- Moshood, T.D.; Nawanir, G.; Mahmud, F. Sustainability of biodegradable plastics: a review on social, economic, and environmental factors. Crit. Rev. Biotechnol. 2021, 1–21. [Google Scholar] [CrossRef]

- McLaren, S.J.; Singh, R.; Clothier, B. Environmental Certification: Adding Value For New Zealand’s Primary Producers, Or A Waste Of Time And Money?. Sci. policy Nutr. Manag. challenges next Gener., 2017.

- Anderson, J. Reducing embodied carbon in the built environment: the role of Environmental Product Declarations.” The Open University, 2023.

- Yanuar, A.I.; Hasrito, E.S.; Sihombing, A.L.; Bahua, H.; Wijayanti, S.P.; Sasongko, N.A. Comparison study of environmental product declarations to develop passenger train in Indonesia. in IOP Conference Series: Earth and Environmental Science 2022, 1108, 12028. [Google Scholar]

- Kassim, M.B.A. , The Impact of Environmental Product Declarations (EPDs) on Green Bio-Composite Strategic Marketing. University of Exeter (United Kingdom), 2020.

- ShahMohammadi, A. Low carbon Emissions for Future-Build Houses in Timber and Light-Gauge Steel framing: A comprehensive Whole Life Cycle Assessment of the Housing Construction in Aotearoa New Zealand.” ResearchSpace@ Auckland, 2022.

- Hernandez, J. Development of a Roadmap for Materials Passport Creation. 2024.

- Olanrewaju, O.I.; Enegbuma, W.I.; Donn, M. Operational, embodied and whole life cycle assessment credits in green building certification systems: Desktop analysis and natural language processing approach. Build. Environ. 2024, 111569. [Google Scholar] [CrossRef]

- Del Borghi, A. LCA and communication: environmental product declaration. The International Journal of Life Cycle Assessment 2013, 18, 293–295. [Google Scholar] [CrossRef]

- MacGregor, C.; Dowdell, D.C.; Jaques, R.A.; Bint, L.; Berg, B.L. , The built environment and climate change: A review of research, challenges and the future. BRANZ Jugendford, New Zealand, 2018.

- Agrawal, A.; Parvez, N. Assessment Frameworks for Promoting Sustainable Development in Educational Institutions. in Sustainability in Higher Education: Strategies, Performance and Future Challenges, Springer, 2024, pp. 231–262.

- Gajendran, T.; et al. Fostering an Australia–India Zero-Carbon Building Construction Network. 2024.

- Hore, A.; McNally, C.; Adeleke, A.Q.; Saif, W. Supporting the delivery of Information Management and BIM in Ireland: Learnings from Selected International Regions. 2023.

- Kainila, V. Issues in the EPD verification process of a pre-verified EPD generator and the definition of verification points. 2021.

- Dowdell, D.C.; Berg, B.L.; Zealand whole-building whole-of-life framework, N. , 2016.

- Rangelov, M.; Dylla, H.; Sivaneswaran, N. Environmental product declarations (EPDs)/product category rules (PCRs) of waste plastics and recycled materials in roads. in Plastic Waste for Sustainable Asphalt Roads, Elsevier, 2022, pp. 303–334.

- Fuhler, M.R.; Panozzo, B.D.; Dodd, B.R.; Pasley, D.A.; Young, A.R. The importance of Environmental Product Declarations in the decarbonization effort. 2023.

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The new international standards for life cycle assessment: ISO 14040 and ISO 14044. Int. J. life cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Konradsen, F.; Hansen, K.S.H.; Ghose, A.; Pizzol, M. Same product, different score: how methodological differences affect EPD results. Int. J. Life Cycle Assess. 2024, 29, 291–307. [Google Scholar] [CrossRef]

- Van Gulck, L.; Wastiels, L.; Steeman, M. How to evaluate circularity through an LCA study based on the standards EN 15804 and EN 15978. Int. J. Life Cycle Assess. 2022, 27, 1249–1266. [Google Scholar] [CrossRef]

- Hansen, E.; Juslin, H. Strategic marketing in the global forest industries. 2023.

- Minkov, N.; Schneider, L.; Lehmann, A.; Finkbeiner, M. Type III Environmental Declaration Programmes and harmonization of product category rules: status quo and practical challenges. J. Clean. Prod. 2015, 94, 235–246. [Google Scholar] [CrossRef]

- Minkov, N.; Bach, V.; Finkbeiner, M. Characterization of the cradle to cradle certifiedTM products program in the context of eco-labels and environmental declarations. Sustainability 2018, 10, 738. [Google Scholar] [CrossRef]

- Minkov, N.; Lehmann, A.; Winter, L.; Finkbeiner, M. Characterization of environmental labels beyond the criteria of ISO 14020 series. Int. J. Life Cycle Assess. 2020, 25, 840–855. [Google Scholar] [CrossRef]

- EN, B.S. 15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. Br. Stand. Inst., 2012.

- Durão, V.; Silvestre, J.D.; Mateus, R.; de Brito, J. Assessment and communication of the environmental performance of construction products in Europe: Comparison between PEF and EN 15804 compliant EPD schemes. Resour. Conserv. Recycl. 2020, 156, 104703. [Google Scholar] [CrossRef]

- Sipari, A. Comparative assessment of product calculation rules and their impacts on comparability of environmental product declarations: comparison of additional requirements of product calculation rules of RTS, EPD Norge and IES. 2023.

- Rangelov, M.; Dylla, H.; Mukherjee, A.; Sivaneswaran, N. Use of environmental product declarations (EPDs) of pavement materials in the United States of America (USA) to ensure environmental impact reductions. J. Clean. Prod. 2021, 283, 124619. [Google Scholar] [CrossRef]

- Andresen, V.L.; Zimmer, H.F.G. Environmental Product Declaration as a Mobilizer to Achieve Competitive Advantages.” University of Agder, 2022.

- Harvey, J.T.; Butt, A.A. Recommended Approach for Use of Cradle-to-Gate Environmental Product Declarations (EPDs) in Procurement of Civil Infrastructure Materials. 2023.

- Guerra, B.C.; Leite, F. Circular economy in the construction industry: An overview of United States stakeholders’ awareness, major challenges, and enablers. Resour. Conserv. Recycl. 2021, 170, 105617. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Das, B.B. Life Cycle Assessment of construction materials: Methodologies, applications and future directions for sustainable decision-making. Case Stud. Constr. Mater. 2023, e02326. [Google Scholar] [CrossRef]

- Diaz, A.; Schöggl, J.-P.; Reyes, T.; Baumgartner, R.J. Sustainable product development in a circular economy: implications for products, actors, decision-making support and lifecycle information management. Sustain. Prod. Consum., 2021.

- Czarnowus, A. New Zealand Medievalism. 2024.

- Zaman, A.; Chan, Y.-Q.; Jonescu, E.; Stewart, I. Critical challenges and potential for widespread adoption of mass timber construction in Australia—An analysis of industry perceptions. Buildings 2022, 12, 1405. [Google Scholar] [CrossRef]

- Makul, N.; et al. Use of recycled concrete aggregates in production of green cement-based concrete composites: A review. Crystals 2021, 11, 232. [Google Scholar] [CrossRef]

- Chaudhari, T.; MacRae, G.; Bull, D.; Clifton, G.C.; Hicks, S.J. A Simple Mechanical Model for Steel Beam–Column Slab Subassembly Nonlinear Cyclic Behaviour. J. Earthq. Eng. 2023, 27, 3518–3535. [Google Scholar] [CrossRef]

- Al-Radhi, Y.; Roy, K.; Liang, H.; Ghosh, K.; Clifton, G.C.; Lim, J.B.P. Thermal performance of different construction materials used in New Zealand dwellings comparatively to international practice–A systematic literature review. J. Build. Eng. 2023, 72, 106346. [Google Scholar] [CrossRef]

- O’Brien, K. , Wellbeing for the IB PYP: Teaching for Success. Hachette UK, 2020.

- Wang, M.; Wang, C.C.; Sepasgozar, S.; Zlatanova, S. A systematic review of digital technology adoption in off-site construction: Current status and future direction towards industry 4.0. Buildings 2020, 10, 204. [Google Scholar] [CrossRef]

- Nyangchak, N. Emerging green industry toward net-zero economy: A systematic review. J. Clean. Prod. 2022, 378, 134622. [Google Scholar] [CrossRef]

- Ahmad, F.; Saeed, Q.; Shah, S.M.U.; Gondal, M.A.; Mumtaz, S. Environmental sustainability: challenges and approaches. Nat. Resour. Conserv. Adv. Sustain. 2022, 243–270. [Google Scholar]

- Svensson, G.; Høgevold, N.; Ferro, C.; Varela, J.C.S.; Padin, C.; Wagner, B. A triple bottom line dominant logic for business sustainability: Framework and empirical findings. J. Business-to-bus. Mark. 2016, 23, 153–188. [Google Scholar] [CrossRef]

- Froy, F.; Heroy, S.; Uyarra, E.; O’Clery, N. What drives the creation of green jobs, products and technologies in cities and regions? Insights from recent research on green industrial transitions. Local Econ. 2022, 37, 584–601. [Google Scholar] [CrossRef]

- Naidoo, M.; Gasparatos, A. Corporate environmental sustainability in the retail sector: Drivers, strategies and performance measurement. J. Clean. Prod. 2018, 203, 125–142. [Google Scholar] [CrossRef]

- Klewitz, J.; Hansen, E.G. Sustainability-oriented innovation of SMEs: a systematic review. J. Clean. Prod. 2014, 65, 57–75. [Google Scholar] [CrossRef]

- Nidumolu, U.; Lim-Camacho, L.; Gaillard, E.; Hayman, P.; Howden, M. Linking climate forecasts to rural livelihoods: Mapping decisions, information networks and value chains. Weather Clim. Extrem. 2020, 27, 100174. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; McAloone, T.C. Supporting the development of environmentally sustainable PSS by means of the ecodesign maturity model. Procedia CIRP 2015, 30, 173–178. [Google Scholar] [CrossRef]

- Ceschin, F.; Gaziulusoy, I. Evolution of design for sustainability: From product design to design for system innovations and transitions. Des. Stud. 2016, 47, 118–163. [Google Scholar] [CrossRef]

- Ceschin, F.; Gaziulusoy, İ. , Design for sustainability: a multi-level framework from products to socio-technical systems. Routledge, 2019.

- Miemczyk, J.; Luzzini, D. Achieving triple bottom line sustainability in supply chains: The role of environmental, social and risk assessment practices. Int. J. Oper. Prod. Manag. 2019, 39, 238–259. [Google Scholar] [CrossRef]

- Schöggl, J.-P.; Stumpf, L.; Baumgartner, R.J. The narrative of sustainability and circular economy-A longitudinal review of two decades of research. Resour. Conserv. Recycl. 2020, 163, 105073. [Google Scholar] [CrossRef]

- Baldassarre, B.; Keskin, D.; Diehl, J.C.; Bocken, N.; Calabretta, G. Implementing sustainable design theory in business practice: A call to action. J. Clean. Prod. 2020, 273, 123113. [Google Scholar] [CrossRef]

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy–A new sustainability paradigm?. J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Mang, P.; Reed, B. Designing from place: A regenerative framework and methodology. Build. Res. Inf. 2012, 40, 23–38. [Google Scholar] [CrossRef]

- Lurie-Luke, E. Product and technology innovation: What can biomimicry inspire? Biotechnol. Adv. 2014, 32, 1494–1505. [Google Scholar] [CrossRef]

- Wahl, D.C.; Press, D.R.C.T. , 2016.

- De los Rios, I.C.; Charnley, F.J.S. Skills and capabilities for a sustainable and circular economy: The changing role of design. J. Clean. Prod. 2017, 160, 109–122. [Google Scholar] [CrossRef]

- Rocha, C.S.; Antunes, P.; Partidário, P. Design for sustainability models: A multiperspective review. J. Clean. Prod. 2019, 234, 1428–1445. [Google Scholar] [CrossRef]

- Filho, W.L.; et al. Sustainable Development Goals and sustainability teaching at universities: Falling behind or getting ahead of the pack? J. Clean. Prod. 2019, 232, 285–294. [Google Scholar] [CrossRef]

- Rossi, M.; Favi, C.; Russo, A.C.; Germani, M. An eco-knowledge tool to support eco-design implementation inside design departments. in Proceedings of the Design Society: International Conference on Engineering Design 2019, 1, 3151–3160. [Google Scholar] [CrossRef]

- Prendeville, S.M.; O’Connor, F.; Bocken, N.M.P.; Bakker, C. Uncovering ecodesign dilemmas: A path to business model innovation. J. Clean. Prod. 2017, 143, 1327–1339. [Google Scholar] [CrossRef]

- Bakker, C.; Wang, F.; Huisman, J.; Den Hollander, M. Products that go round: exploring product life extension through design. J. Clean. Prod. 2014, 69, 10–16. [Google Scholar] [CrossRef]

- Bocken, N.M.P.; De Pauw, I.; Bakker, C.; Van Der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef]

- Lofthouse, V.; Prendeville, S. Human-centred design of products and services for the circular economy–a review. Des. J. 2018, 21, 451–476. [Google Scholar] [CrossRef]

- Plouffe, S.; Lanoie, P.; Berneman, C.; Vernier, M.-F. Economic benefits tied to ecodesign. J. Clean. Prod. 2011, 19, 573–579. [Google Scholar] [CrossRef]

- Spangenberg, J.H.; Fuad-Luke, A.; Blincoe, K. Design for Sustainability (DfS): the interface of sustainable production and consumption. J. Clean. Prod. 2010, 18, 1485–1493. [Google Scholar] [CrossRef]

- Pichette, G.; Blanchet, P.; Essoua, G.G.E.; Breton, C. Environmental Product Declaration (EPD) Usage in Early Building Design Stages: Review of Effects on the Environmental Life Cycle of a Multi-Residential Building. BioResources 2023, 18. [Google Scholar] [CrossRef]

- Vladimirov, V.; Bica, I. Methodology and calculation model for recycling of composite construction products. in E3S Web of Conferences, 2019, 85, 7016. [Google Scholar] [CrossRef]

- Bribián, I.Z.; Capilla, A.V.; Usón, A.A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140. [Google Scholar] [CrossRef]

- Pigosso, D.C.A.; McAloone, T.C.; Rozenfeld, H. Characterization of the state-of-the-art and identification of main trends for Ecodesign Tools and Methods: Classifying three decades of research and implementation. Indian Inst. Sci. J. 2015, 94, 405–427. [Google Scholar]

- Soust-Verdaguer, B.; et al. The use of environmental product declarations of construction products as a data source to conduct a building life-cycle assessment in Spain. Sustainability 2023, 15, 1284. [Google Scholar] [CrossRef]

- Anderson, J.; Rønning, A. Using standards to maximise the benefit of digitisation of construction product Environmental Product Declaration (EPD) to reduce Building Life Cycle Impacts. E 3S Web of Conferences 2022, 349, 10003. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).