1. Introduction

Sustainable Waste Indonesia (SWI) conducts research on waste in Indonesia that has not been managed optimally. This is supported by data showing that of the approximately 65 million tons of waste produced by Indonesia every day, around 15 million tons of waste still pollutes the environment and ecosystem, because it is not handled and processed optimally. Meanwhile, 7% of waste is recycled and 69% of waste is in final disposal sites (TPA).

A waste management system is a simple process that organizations use to dispose of, reduce, reuse, and prevent waste. Also known as waste disposal, this is an approach in which companies implement a comprehensive strategy to manage waste efficiently from origin to final disposal. Possible waste disposal methods are recycling, composting, incineration, landfilling, bioremediation, waste to energy, and waste minimization.

Waste management based on supply chain management can be a solution for handling waste, an example of the waste problem in Indonesia. Each country has a different waste problem management character because it takes into account several aspects such as supply chain management, processes and technology used in handling waste, culture or behavior of the community in handling waste, and the geographic conditions of a country. Therefore, there is a need for a macroergonomics study that considers several of these aspects. Macroergonomics concepts relate to the optimization of sociotechnical systems including organizational structures, policies and processes. Macroergonomics is also called sociotechnics, the study of the society/technology interface. The study of the consequences of technology on social relationships, processes, and institutions.

The incorporation of a supply chain waste management framework functions as a pivotal moderating factor between sustainable macro ergonomic methodologies and proficient waste management. This association is vital for the augmentation of operational effectiveness and environment sustainability across diverse industries.

The retail sector in the United States encounters considerable obstacles concerning supply chain waste, thereby requiring specific reduction strategies to alleviate costs and environmental repercussions [

1]. A decision-making framework for waste management underscores the significance of pre processing waste at its origin, which can facilitate more effective recycling and composting methodologies [

2].

Macro ergonomics emphasizes the critical interplay between individuals and systems, which is essential for the optimization of waste management methodologies. For example, the application of simulation software, such as Arena, can effectively model waste supply chains, enhancing understanding of human behaviour in waste processing [

3].

Waste-to-energy (WtE) facilities serve as a paradigm of sustainable waste management; however, their efficacy is frequently impeded by inefficiencies within the supply chain, especially in developing nations [

4]. The integration of sustainable supply chain management (SCM) practices can be aligned with the Sustainable Development Goals established by the United Nations, thereby fostering responsible resource utilization and mitigating environmental degradation. Although the proposed model delineates the advantages of amalgamating waste management with macro ergonomic frameworks, it is imperative to address the challenges presented by divergent regional policies and economic circumstances, which may significantly influence the execution of these strategies.

Several preliminary studies have been prepared by the research team in a planned manner that supports this research. The concept begins with food security research using various optimization methods towards achieving successful food products that consider the factors that cause success . This is supported by research on inorganic and organic waste based on Smart Waste Management (SWM). Several machine optimizations have also been carried out to support the appication of bioconversion technology. The following is a detailed explanation of the preliminary research mapping:Optimization of food security products based on Supply Chain Management (SCM) and supply chain network [

5,

6]; logistic optimization [

6]; Interpretive Structural Modeling (ISM), analytical network process, distribution optimization [

11,

12,

13]. Green Environment supports waste management of inorganic and organic waste [

7,

10]. A successful product supported by several factors that take into account Indonesian culture [

8,

9]. Based on previous research, the research question of this paper are follows:

1. How does culture society affect the supply chain management?

2. How does the technology tool affect the supply chain management?

3. How does the task process affect the supply chain management?

4. How does the marketing green environment affect the supply chain management?

5. How does the seasonal floods affect the supply chain management?

6. How the supply chain management affect waste management?

2. Materials and Methods

2.1. Cultural Society and Supply Chain Management

Cultural society exerts a profound influence on supply chain management by forming communication patterns, decision-making processes, and relational dynamics among international partners. A thorough understanding of these cultural dimensions is critical for fostering effective collaboration and achieving operational efficacy.

Cultural Communication Styles: High-context cultures tend to prefer indirect forms of communication, which may lead to potential misinterpretations with low-context cultures that advocate for straightforwardness [

14]. The establishment of trust differs significantly; cultures characterized by high uncertainty avoidance often depend on formalized agreements, whereas those with low uncertainty avoidance prioritize personal relationships [

15].

Decision-Making and Risk Management: Cultural orientations substantially influence risk management methodologies; collectivist cultures emphasize consensus and the cultivation of long-term relationships, in contrast to individualist cultures that prioritize efficiency [

16]. The approach toward uncertainty diverges, thereby determining whether organizations implement structured or adaptable risk management [

16].

Integration and Collaboration: Cultural factors have a significant impact on supply chain integration, with organizational cultures that advocate for transparency and inclusivity facilitating enhanced collaboration [

17]. Cultural intelligence is paramount for traversing these complexities, empowering organizations to harness diversity as a means of gaining competitive advantage [

17]. Although cultural influences may present challenges, they concurrently offer avenues for innovation and strengthened supply chain resilience when adeptly managed.

Questionnaire questions related to culture society affect the supply chain management are: Strict government policies and regulations regarding waste management; Willing to carry out waste management without considering the money that will be obtained from the management process; Continue to manage waste even though other people do not have the awareness to manage waste; Carrying out waste management with the aim of improving environmental quality in the future; Carrying out waste management for the future of our children and grandchildren

H1: How does culture society affect waste management supply chain?

2.2. The Technology Tool dan The Supply Chain Management

The incorporation of technological instruments profoundly augments supply chain management by enhancing transparency, efficiency, and collaboration among various stakeholders. A multitude of technologies, such as blockchain, artificial intelligence, and data analytics, assume critical roles in the transformation of conventional supply chain methodologies.

Blockchain technology offers a decentralized ledger that significantly bolsters traceability and security, enabling stakeholders to observe the flow of products in real-time [18,19} . It facilitates the automation of processes, including the monitoring of expiration dates in the pharmaceutical sector, thereby minimizing human error and associated costs [

19].

Information technology instruments enhance the quality and dissemination of information, which are essential for the effective management of supply chains [

20]. Improved communication among supply chain partners fosters greater operational efficiency and confers a competitive advantage [

20].

The digital transformation of supply chains, facilitated by technologies such as the Internet of Things (IoT) and artificial intelligence (AI), optimizes operations ranging from demand forecasting to delivery, culminating in heightened efficiency [

21]. These advancements permit rapid responses to fluctuations in market conditions, thus further refining supply chain strategies [

21].

Despite the considerable advantages offered by technological tools, challenges such as adherence to regulatory frameworks and the intricacies of technology must be addressed to fully harness their potential within supply chain management [

22].

Questionnaire questions related to does the technology tool affect the supply chain management, namely : Information systems are used in waste management; The behavior of sorting organic and inorganic waste is implemented when disposing of waste ; Separate trash bins based on type of waste ; The mode of transportation (vehicles) used for waste collection is optimized ; Capacity of TPS (Temporary Waste Disposal) & TPA (Final Waste Disposal) is optimized.

H2 : How does the technology tool affect waste management supply chain?

2.3. The Task Process and The Supply Chain Management

The procedural dynamics associated with task processing exert a substantial impact on supply chain management by augmenting efficiency, precision, and responsiveness. A variety of methodologies and frameworks have been established to refine task processing, which subsequently facilitates the optimization of supply chain operations.

Task processing techniques, such as those that employ robotic systems, are capable of mitigating congestion at designated locations, thus enhancing the efficiency of goods processing [

23]. Systems that allocate distinct task identification codes serve to improve the precision of distribution activities, culminating in superior task execution and an elevated user experience [

24].

Task processing driven by blockchain technology promotes organic organizational relationships, enabling employees to autonomously accept and fulfill tasks, which in turn enhances overall operational efficiency and fluidity [

25]. The amalgamation of task processing systems with communicative platforms guarantees that task-related data is disseminated effectively across various business systems, further bolstering operational efficiency.

Although these technological advancements offer significant advantages, challenges such as the necessity for a robust technological infrastructure and comprehensive employee training remain pivotal for the successful execution of these systems.

Questions related to the task process affect the supply chain management are: The waste sorting process is used in waste management implementation of a routine household waste collection schedule regulation and optimization of waste management flow: from household to TPS to TPA optimizing the distance traveled for waste collection to make waste management time and costs more effective Organic & inorganic waste management activities into marketable derivative products

H3 : How does the task process affect waste management supply chain?

2.4. The Marketing Green Environment dan The Supply Chain Management

The marketing of a green environment significantly influences supply chain management (SCM) by integrating sustainability into operational practices, enhancing competitive advantage, and fostering consumer engagement. This multifaceted approach not only addresses environmental concerns but also aligns with market demands for eco-friendly products.

Green supply chain management (GSCM) incorporates sustainable practices such as green design, procurement, and recycling, which optimize resource use and minimize environmental impact [

26]. Companies adopting GSCM can achieve long-term viability and competitive advantage by improving operational performance through sustainable practices [

27].

Increased consumer awareness of environmental issues drives demand for green products, necessitating that companies align their marketing strategies with sustainability principles [

28]. Effective green marketing can enhance brand loyalty and customer satisfaction, as consumers are more likely to support businesses that demonstrate environmental responsibility [

29].

While GSCM presents opportunities for innovation and market differentiation, it also introduces complexities in management and requires a shift in traditional SCM practices [

26]. The integration of green marketing and supply chain strategies is still evolving, with on going research needed to fully understand their interconnections (“Green Marketing and its Impact on Supply Chain Management in Industrial Markets”, 2024).

In contrast, some argue that the focus on green marketing may lead to greenwashing, where companies exaggerate their environmental efforts without substantial changes in their supply chain practices. This could undermine consumer trust and the overall effectiveness of green initiatives.

Questions related to the marketing green environment affect the supply chain management, namely: Support waste management programs to create a friendly environment (Green Environment); Actively involved in organic and inorganic waste management programs; Actively involved in waste processing activities into marketable derivative products (e.g., bags from plastic waste, flowers from bottle waste, organic waste into maggots, organic waste into fertilizer); Actively involved in selling derivative products with marketable value (e.g., bags from plastic waste, flowers from bottle waste, organic waste into maggots, organic waste into fertilizer); Use of online shops in selling derivative products from processed organic & inorganic waste

H4 : How does the marketing green environment affect waste management supply chain?

2.5. The Seasonal Floods and the Supply Chain Management

Seasonal floods significantly disrupt the management of supply chains, thereby necessitating the implementation of robust strategies aimed at fostering resilience and facilitating recovery. The ramifications of floods on supply chains can be comprehensively analyzed through various dimensions, encompassing forecasting, resilience frameworks, and operational management.

The accurate forecasting of flood occurrences is imperative for effective supply chain planning. Empirical studies suggest that the application of grey models can significantly improve disaster prediction capabilities, thus enabling organizations to proactively prepare their logistics and inventory [

30].

The establishment of a comprehensive framework for flood resilience is of paramount importance. Elements such as the strategic placement of facilities, the diversification of procurement sources, and the cultivation of collaborative partnerships can effectively mitigate risks and strengthen recovery capabilities in the face of flooding events [

31,

32].

An efficiently structured supply chain management system is crucial during operations aimed at flood relief. This encompasses aspects such as inventory management, alignment of demand and supply, and the utilization of data visualization tools to guarantee the prompt delivery of humanitarian assistance [

33]. Furthermore, promoting collaboration among stakeholders and adapting strategies in response to evolving circumstances during the flood event can significantly enhance resilience [

34].

Conversely, while these strategies possess the potential to augment resilience, the inherent unpredictability of floods and the divergent objectives of stakeholders may complicate the effective management of supply chains, thereby underscoring the necessity for ongoing adaptation and learning.

Questions related to the seasonal floods affect the supply chain management, namely : The importance of optimizing the process of managing organic & inorganic waste which is the impact of seasonal floods; The importance of a firm waste management policy from the government which is the impact of seasonal floods; The importance of optimizing waste management facilities and infrastructure which is the impact of seasonal floods ;The importance of optimizing technology (information systems) for waste management which is the impact of seasonal floods; The importance of efforts to support the creation of derivative products of organic & inorganic waste with sales value which is the impact of seasonal floods.

H5: How does the seasonal floods affect waste management supply chain?

2.6. The Supply Chain Management and Waste Management

The interaction between supply chain management and waste management is imperative for advancing sustainability and operational efficiency within waste processing systems. Efficient supply chain methodologies possess the capability to substantially diminish waste production and elevate recycling rates, thus alleviating environmental repercussions.

Waste-to-Energy (WtE) Facilities: An effectively organized supply chain is essential for the operational success of WtE facilities, especially in developing nations where numerous initiatives have faltered due to insufficient supply chain management [

4].

Optimization Techniques: The application of hybrid methodologies such as genetic algorithms and fuzzy logic can enhance solid waste management networks, thereby increasing operational efficiency and mitigating pollution [

35].

Holistic Analysis: An all-encompassing decision framework for waste management enterprises underscores the significance of preprocessing waste and understanding market dynamics, which can bolster recycling initiatives and lower disposal expenditures [

2].

Industry 4.0: The incorporation of digital technologies within supply chains can optimize waste management processes, facilitating improved waste segregation and reducing emissions [

37].

Conversely, although optimized supply chains can improve waste management practices, inadequately designed systems may exacerbate waste challenges, underscoring the necessity for customized strategies that consider regional characteristics and the types of waste involved.

Questionnaire questions related to supply chain management affect waste management, namely : Optimizing the capacity of the TPS/TPA capacity and the capacity of vehicle transportation modes that transport waste; Optimizing waste collection schedules and times to expedite waste distribution; Optimizing the waste processing process into marketable derivative products; Optimizing organic & inorganic waste management costs; Initial waste management in households; Management of waste collection sites (TPS/TPA); Management of recycling storage areas; Management of organic and inorganic waste recycling facilities; Management of the production process for marketable derivative products (e.g., bags from plastic waste, flowers from bottle waste, organic waste into maggots, organic waste into fertilizer)

H6 : How waste management supply chain affect waste management?

3. Results

Respondent Profile

This research was conducted from July 2024 to September 2024. The respondents were residents of the city of Semarang who were involved in waste management. A total of 224 respondents. Detail sampel analysis were obtained as follows (

Table 1)

Sample data shows that when looking at gender, the majority of respondents are women at 58% and the dominant respondents have an age range of 18 to 31 years.

4. Findings

4.1. Location

The location chosen was the people of the Semarang region, Central Java, Indonesia. We chose the Semarang location as the research object related to Supply Chain Waste Management Model: A Moderating Variable Between Sustainable Macro Ergonomics Process and Waste Management We used PLS-SEM (Oststeinbek, Germany) as a data analysis tool. The reason The use of PLS-SEM is very simple, with the second most common reason being abnormal data. Model complexity and formative construction are now the two most common reasons explanatory research and small samples are tied to the third [

37,

38].

4.2. Outer Model Testing (Measurement Model)

4.2.1. Convergent Validity

Convergent validity can be determined using loading factor values. The definition of factor loadings is a value that indicates the relationship among the values of a statement item through a construct indicator that measures the construct. The validity criterion is the factor loading >0.7 [

37]. Using Smart-PLS version 3.0, loading factor values were obtained as follows (

Table 2).

Convergent validity can be determined using factor loading values. The definition of factor loadings is a value that shows the relationship between the values of an item statement through construct indicators that measure the construct. The validity criterion is a factor loading value > 0.7. By using Smart-PLS version 3.0, the Loading Factor values are obtained as follows (

Table 3).

The table above shows the cross loading values. Cross-loading is another method for determining discriminant validity. If the loading value of each item on the construct is greater than the cross-loading value, then the standard is met.

The next convergent validity value is AVE (

Table 4). the model is said to be valid if the AVE value is greater than 0.5. From the output results in the table it can be concluded that the model has met the requirements.

The Fornell Larcker value represents the root of the AVE value (

Table 5). Discriminant validity is met if the square root value of AVE for each construct is greater than the relationship with other constructs.

Heterotraits and Monotraits describes a test of discriminant validity (

Table 6). Validity meets standards if the HTMT value is less than 0.9.

4.2.2. Hypothesis Test

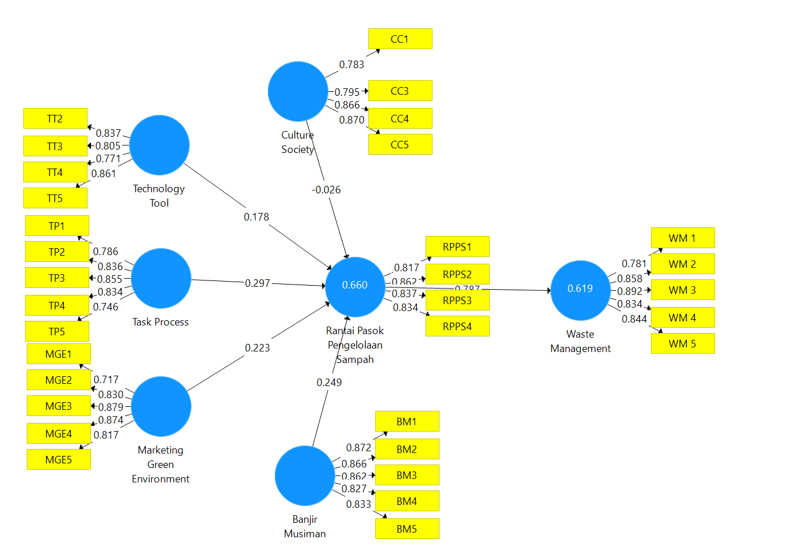

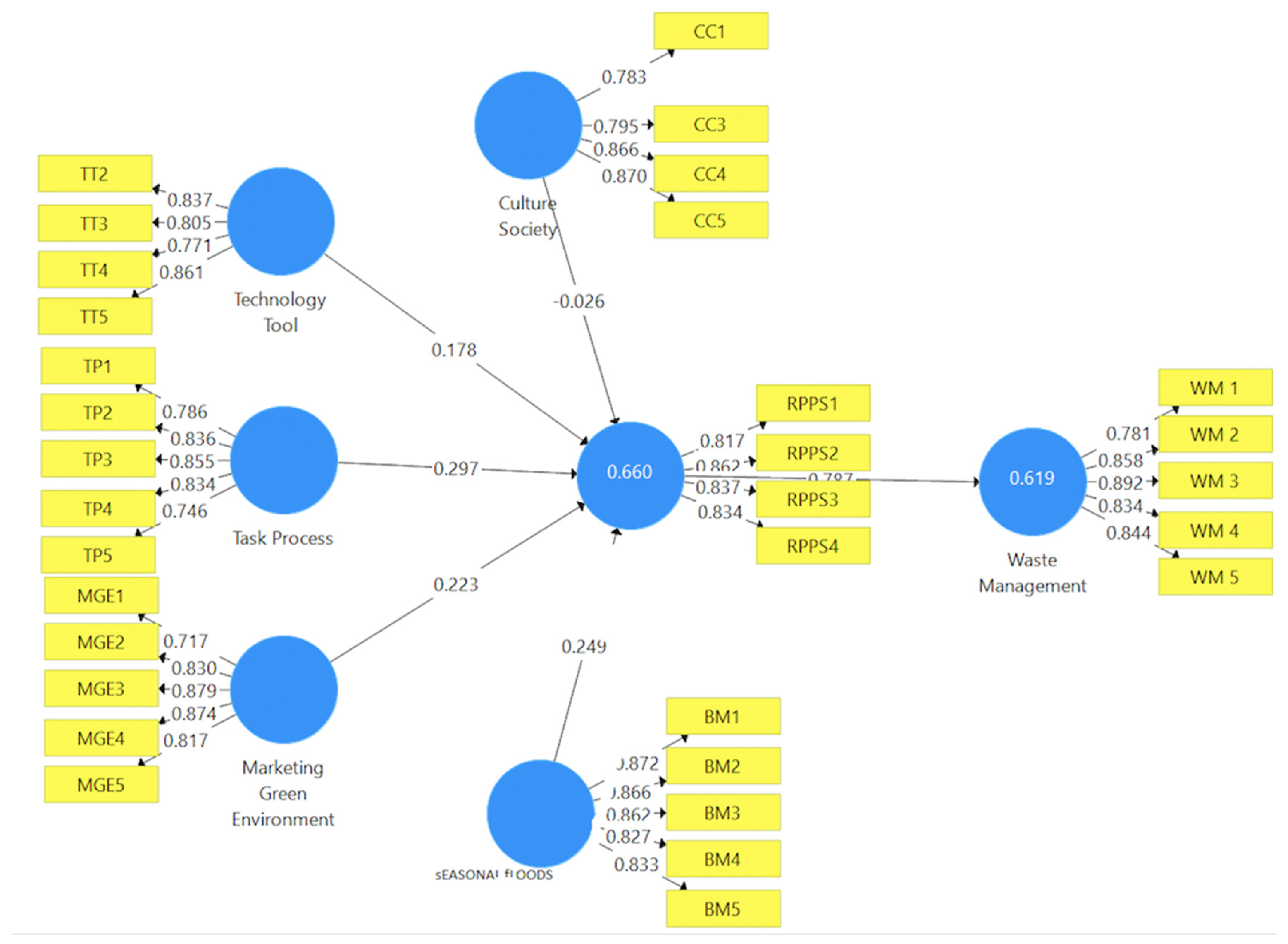

We undertake hypothesis tests to assess the inner structural model, which consists of coefficients parameter, and T-statistics. The significance values amongst constructs, T-statistics, and p -values need to be considered. The test utilizes Smart-PLS SEM 3.0 software through bootstrapping testing. The criteria used in this research were a T-statistic larger than 1.96, and a significance level of p -value is 0.05 coupled with a positive beta coefficient. The results depict the model in

Figure 1. The hypotheses are significantly proven, except the content quality variable (

Table 7).

The SEM-PLS methodology constitutes an analytical approach characterized by minimal reliance on extensive presuppositions. It allows for the analysis of data that may not conform to a normal distribution and can encompass nominal, ordinal, or interval-to-ratio measurement scales. SEM-PLS serves as a robust framework for validating theoretical constructs and elucidating the existence of relationships among latent variables. The processing of SEM-PLS utilizing smart PLS 3 is executed in a bifurcated manner: (1) The initial phase involves an assessment of the outer model. (2) The subsequent phase focuses on an evaluation of the inner model. This latter phase aims to ascertain whether a significant influence exists among the variables. The assessment was conducted employing the t-test. The subsequent section presents the estimated values for each interrelationship among the research variables; based on the ensuing table, the following interpretations can be drawn:

Table 8.

Path Coefficient Result.

Table 8.

Path Coefficient Result.

| Hypotheses |

|

Relationship |

Original Sample (O) |

Statistik t (O/STDEV) |

Value P |

Hypothesis accept |

| Seasonal Floods |

→ |

Waste Management Supply Chain |

0,249 |

3,326 |

0,001 |

Accepted |

| Culture Society |

→ |

Waste Management Supply Chain |

-0,026 |

0,312 |

0.755 |

Rejected |

| Marketing Green Environment |

→ |

Waste Management Supply Chain |

0,223 |

3,453 |

0.001 |

Accepted |

| Waste Management Supply Chain |

→ |

Waste Management |

0,787 |

17,934 |

0.000 |

Accepted |

| Task Process |

→ |

Waste Management Supply Chain |

0,297 |

3,289 |

0.001 |

Accepted |

| Technology Tool |

→ |

Waste Management Supply Chain |

0,178 |

2,332 |

0.020 |

Accepted |

Testing goodness of fit: Internal model analysis/structural analysis model is carried out to ensure that the structural model is strong and accurate. Internal model evaluation can be seen from several indicators which include: Coefficient of determination (R2) Structural model testing is carried out by looking at the R2 value which is a model goodness-fit test. The inner model test is seen from the R2 value in the equation between latent variables. The R2 value explains how much the exogenous (independent) variables in the model are able to explain the endogenous variables.

Table 9.

R Square.

| |

R Square |

R Square Adjusted |

| Waste Management Supply Chain |

0,660 |

0,652 |

| Waste Management |

0,619 |

0,617 |

5. Discussion

Statistical calculations using Smart-PLS version 3 reveal that supply chain waste management has a significant effect on waste management. This is in line with previous research which states the interplay between supply chain management and waste management is essential for promoting sustainability and enhancing operational efficiency within waste processing systems [

2,

4,

35,

36].

A Moderating variable between sustainable macro ergonomics process and waste management were test. Macro ergonomic sustainable factors that influence waste management include Indonesian culture society, waste management technology tools, task process in waste management, marketing green environment, waste management supply chain and seasonal flooding.

This study used SEM-PLS method to analyze the waste supply chain management in Semarang. The results show that factors such as seasonal flooding, green marketing, work process, and technology have a significant effect on waste management, while culture society has no significant effect. Technology and efficient work processes improve the effectiveness of waste management, especially in the face of seasonal flooding. Green marketing also helps increase community awareness and participation.

First, the research shows that culture society does not have a significant influence on the waste management supply chain in Semarang city. Cultural factors such as power distance index and individualism did not show a strong correlation with waste management. Although culture usually influences environmental awareness, there is a gap between such awareness and its implementation in daily waste management. Waste management in Semarang is more influenced by technology, work processes, and environmental policies than cultural values. To increase community participation, education programs that emphasize the relationship between culture and waste management practices are needed.

The culture affect waste management supply chain based on hypotheses result is rejected. This is in line with previous research which state that the cultural influences may present challenges, they concurrently offer avenues for innovation and strengthened supply chain resilience when adeptly managed [

14].

Second, the technology tool has a significant influence on the waste management supply chain. The use of waste segregation tools, landfill capacity, and supportive transportation modes play an important role in improving efficiency and effectiveness. Theoretically, technology optimizes waste collection, transportation, treatment, and enables better data management. As such, technology can reduce costs, speed up processes, and increase waste management capacity. The implementation of technology is essential in facing the increasingly complex challenges of urban waste. The technology tool affect waste management supply chain. The incorporation of technological instruments profoundly augments supply chain management by enhancing transparency, efficiency, and collaboration among various stakeholders. This is congruent with previous research [

19,

20,

21].

Third, the task process significantly influences the waste management supply chain. Activities like waste collection schedules, management flows, and derivative product processing ensure smooth waste management. Organized workflows improve efficiency and reduce bottlenecks in the supply chain, with better coordination between households, waste haulers, and treatment facilities. It can be done with proper schedules and clear flows to help minimize waste piles and optimize resources, thereby improving waste management performance. The task proses affect waste management supply chain. The procedural dynamics associated with task processing exert a substantial impact on supply chain management by augmenting efficiency, precision, and responsiveness. This is congruent with previous research [

23,

24,

25].

Fourth, the marketing of green environment significantly influences the waste management supply chain. Marketing focusing on waste management programs, derivative products, and e-commerce can improve supply chain effectiveness. Green marketing supports sustainability and creates awareness and demand for environmentally friendly products. In practical terms, it creates economic opportunities from waste, such as valuable recycled products, and encourages community participation. It also strengthens supply chains by increasing demand and adding value to waste-derived products. The marketing green environment affect waste management supply chain. The marketing of a green environment significantly influences supply chain management (SCM) by integrating sustainability into operational practices, enhancing competitive advantage, and fostering consumer engagement. This is in line with previous research [

26,

27,

28,

29].

Fifth, seasonal floods significantly influence the waste management supply chain. Floods increase the volume of waste and disrupt collection, transportation, and disposal processes. In other words, flooding adds to the complexity of management as infrastructure is often unable to handle the surge in waste. Flexibility in the supply chain is essential to deal with disruptions due to natural disasters. As such, flooding slows waste treatment and increases the risk of infrastructure damage. Therefore, mitigation strategies, such as contingency planning and infrastructure capacity building, are needed to address the impact of flooding.

Indonesian regions, especially Central Java, often experience seasonal flood disasters. This affects the waste supply chain management system. The results of statistical tests show that The seasonal flooding affect waste management supply chain. Seasonal floods significantly disrupt the management of supply chains, thereby necessitating the implementation of robust strategies aimed at fostering resilience and facilitating recovery. These results are also supported by several similar previous studies [

30,

31,

32,

34].

Sixth, the waste management supply chain has a very significant influence on the overall waste management process. An efficient supply chain, including capacity optimization, collection, treatment, and cost, directly impacts the system’s success. The supply chain is the backbone of an effective waste management system, with each stage playing a critical role in maintaining efficiency and sustainability. In practical terms, good supply chain management reduces waste accumulation, lowers costs, and improves service quality, making management faster, cost-effective, and environmentally friendly.

This research highlights the importance of a structured supply chain in achieving sustainability and efficiency in waste management.

7. Conclusions

In conclusion, this study shows that factors such as seasonal floods, marketing green environment, task processes, and technology tools significantly influence the waste management supply chain. In contrast, cultural society does not have a significant influence. It underscores the importance of using technology and structured work processes to improve waste management effectiveness, especially in seasonal floods. In addition, green marketing strategies are essential in creating public awareness and encouraging participation in more sustainable waste management efforts. An effective waste management supply chain directly contributes to the overall success of waste management by optimizing collection, treatment, and cost reduction processes, ultimately supporting sustainability and efficiency goals.

Future research is encouraged to delve deeper into the role of culture society in waste management. This could provide valuable insights and lead to the development of more effective mitigation strategies to address the impact of seasonal flooding on waste management supply chains.

8. Limitation

This research was conducted in the Central Java region, precisely in the city of Semarang, with a waste processing system in that area.

Author Contributions

Software, N.A.P. and U.; Validation, A.; Data curation, Y.W. and A.N.C.;Writing—Original draft, V.D.W.A.; Funding acquisition, I.D.P. All authors have read and agreed to the published version of the manuscript.

Funding

007/LL6/P.Katalis/AL/04/2024, Katalis research by Indonesia Ministry of Education, Culture and Research.

Grant number

007/LL6/P.Katalis/AL/04/2024, Katalis research by Indonesia Ministry of Education, Culture and Research.

Acknowledgments

The authors would like to express their gratitude to katalis scheme under the auspices of the Indonesian Ministry of Education, Culture, Research, and Technology for the generous research fund.

Data Availability Statement

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lkpe, V; Shamsuddoha, M. Functional model of supply chain waste reduction and control strategies for retailers-the USA retail industry. Logistics 2024.93(22), 1-17. [CrossRef]

- Chintapalli, P; Vakharia, A.J The waste management supply chain: A decision framework, Decision Science : A Journal of Decision Science Institute, 2023. [CrossRef]

- Setyaningrum, R; Sari, P.N. Organic waste management based on supply chain management using arena simulation and macro ergonomics approach, OPSI 2023, 16(2), 217-224. [CrossRef]

- Ghosh, S.K;a, Parlikar ,U.P; Zorpas , A>A; Papamichael, I.Sustainable supply chain for waste-to-energy facilities, Advances in Biofuels Production, Optimization and Applications 2024, 297-313. [CrossRef]

- Silvia, D.I; Setyaningrum, R; Izzhati, D.N. Identification of Potato Supply Chain Network Design To Increase Farmer’s Income, The International Seminar on Application for Technology of Information and Communication, Indonesia, 17-18 Oktober 2022. [CrossRef]

- Yusianto, R; Marimin; Supriyatin; Hardjomidjojo. Intelligent Spatial Logistics DSS for tracking and tracing in horticultural food security, The International Seminar on Application for Technology of Information and Communication, Indonesia, 21-22 September 2019. [CrossRef]

- Setyaningrum, R., Vania, Izzhati, D.N (2021), Penerapan Manajemen Administrasi Pengelolaan Sampah Berbasis Android untuk Meningkatkan Produktivitas Pada Bank Sampah Resik Becik (International Conference, 8th Anuual Conference on Industrial and System Engineering (ACISE) 2021 and 1st International Conference on Ergonomics Safety and Healty (ICESH), 13-15 Juli 2021).

- Setyaningrum, R; Subagyo, Wijaya, A.R. A Matematical Model of Factor Driving Product Success in an Indonesian market using Design of Experiment, Internasional Journal of Technology 2022, 11 (2),322-332. [CrossRef]

- Setyaningrum, R., Subagyo, Wijaya, A.R. A Mathematical Model of Successful-Product Development by Considering The Indonesian Culture, Internasional Journal of Technology 2022, 13 (3),665-663. [CrossRef]

- Setyaningrum, R; Arsiwi, P; Talitha, T; Ramdhani, S; Jazuli; Suhailah,I; Sari, P.N; Nashir, A. Supply Chain Flow Information System and Community Behaviour in Waste Management based on Industry 4.0; The International Seminar on Application for Technology of Information and Communication, Indonesia, 16-17 September 2023. [CrossRef]

- Arsiwi, P; Adi, P. W. Interpretive Structural Modeling to Increase the Competitiveness of the Mina Indo Sejahtera SME Supply Chain. Jurnal PAST 2020, 14(1), 26–36. [CrossRef]

- Arsiwi, P., & Adi, P. W.Strategy to Increase the Competitive Advantage of SMEs Mina Indo Sejahtera Using Interpretive Structural Modeling and Analytic Network Process Methods. JURNAL TEKNIK INDUSTRI 2020, 10(3). [CrossRef]

- Siswaningsih, N; Arsiwi, P; Talitha, T. Supply Chain and Value Chain Analysis of Manyung Smoked Fish Products in Increasing Sales at the “Asap Indah” Fish Processing Center, Wonosari Village, Demak. Opsi 2021, 14(2). [CrossRef]

- Reynolds, S. The Influence of cultural factors on supply chain integration in multinational corporations. Preprints.org 2024, 1–9. [Google Scholar] [CrossRef]

- Reynolds, S. Understanding the Role of Culture in supply chain collaboration. Preprints.org 2024, 1–16. [Google Scholar] [CrossRef]

- Halloway, S. Sustainable supply chain as a marketing differentiator: qualitative insights from industry leaders. Preprints.org 2024, 1–9. [Google Scholar] [CrossRef]

- Reynolds, S. Examining the influence of cultural factors on supply chain integration. Preprints.org 2024, 1–9. [Google Scholar] [CrossRef]

- ha, ; Raul, A; Taneja, H; Dalvi, V; Varader, U. Supply chain management using block chain technology. International Research Journal on Advanced Engineering Hub (IRJAEH) 2024, 2, 1931-1936. [CrossRef]

- Chauhan, V; Chauhan, A.Blockchain technology in supply chain management, International Journal of Scientific Reasearch in Engineering and Management (IJSREM) 2024, 8, 1-8. [CrossRef]

- Sinoimeri,D; Teta, J; Prifti, V; Lazaj, A. Information Technology in Supply Chain Management. Case Study, HomeProceedings of the Joint International Conference: 10th Textile Conference and 4th Conference on Engineering and Entrepreneurship, 10 January 2024, 35–44. [CrossRef]

- Aarasse, S; Idelhakkar, B. Technological tools and the impact of digitalisation on the supply chain, European Journal of Economic and Financial Research 2023, 7, 1-14. [CrossRef]

- Grant, O. Evaluating the effectiveness of supplier relationship management tools in r-commerce. Preprints.org 2024, 1–9. [Google Scholar] [CrossRef]

- Yifan, P; Xin, A. Task processing method, control terminal, robot, warehousing system and storage medium. Patent, 05 Jan 2021 : https://typeset.io/papers/task-processing-method-control-terminal-robot-warehousing-3dbw8ttv9c.

- Lei, H.Task processing method, device, electronic device, and computer-readable storage medium, Patent. 25 Jan 2019: https://typeset.io/papers/task-processing-method-device-electronic-device-and-computer-3guy9rz0cg.

- Tao, L; Zhongyang, Y; Maohua, C; Bowenm M. Task processing method and system based on block chain, Patent, 5 Jan 2021: https://typeset.io/papers/task-processing-method-control-terminal-robot-warehousing-3dbw8ttv9c.

- Li, F. Challenges and opportunities for sustainable supply chain management. Frontiers in Business, Economics and Management 2024. 15(1), 1-4. [CrossRef]

- Tsikada, C; Imran, S; Masengu, R; Mugoni, E. Effect of green supply chain management practices and operational performance on sustainable competitive advantage. Brazilian Journal of Development. 1-33. [CrossRef]

- Sukla, B; Gupta, J; Krishanappa, R; Nijaguna. Building sustainability into the heart of green marketing. Educational Administration : Theory and Practice. 30(5),10636-10644. [CrossRef]

- Mukhlis, I.R. Enhancing competitive edge : green commerce and digital marketing implementation in supply chain industry 2024. 5(1),15-28.

- Rajesh, R and Rajendran, C, 2019, Grey- and rough-set-based seasonal disaster predictions: an analysis of flood data in India, Natural Hazards, 97 (1), pp.395-435. [CrossRef]

- Chaidilok, W; Olapiriyakul,S. A framework of factors affecting supply chain flood resilience,” 2017 IEEE International Conference on Smart Grid and Smart Cities (ICSGSC), Singapore, 2017, pp. 84-88. [CrossRef]

- Haraguchi, M; Lall, U. Flood risk and impacts: A case study of Thailands floods in 2011 and research questions for supply chain decision making, International Journal of Disaster Risk Reduction 2015, 14, 256-272. [CrossRef]

- Husain, W; Koon, L.W; Zhao, L.T; Aziz, N.T.A. A proposed framework for enhancing a supply chain management system to support flood disaster relief operation, 2016 3rd International Conference On Computer And Information Sciences (ICCOINS).

- Xu, W; Xiong, S; Proverbs, D; Zhnong, Z. Evaluation of humanitarian supply chain resilience in flood disaster, Water 2021. 13, 1-31. [CrossRef]

- Oyebode, o.J; Abdulazeez, Z.O. Optimization of supply chain network in solid waste management using a hybrid approach of genetic algorithm and fuzzy logic: a case study of lagos State, Nature Environment Pollution Technology 2023, 22(4), 1707-1722. [CrossRef]

- Alshari, H; Gurtu, A. Nexus of Industry 4.0 and circular economy in solid waste management supply chains: a literature review, Environmentally Responsible Supply Chains in an Era of Digital Transformation 2024, 218-237. [CrossRef]

- Hair, J.; Hollingsworth, C.L.; Randolph, A.B.; Chong, A.Y.L. An updated and expanded assessment of PLS-SEM in information systems research. Ind. Manag. Data Syst. 2017, 117, 442–458. [Google Scholar] [CrossRef]

- Wismantoro, Y; Aryanto, V.D.W; Pamungkas, I.D; Purusa, N.A; Amron; Chasanah, A.N; Usman. Virtual reality destination experiences model: a moderating variable between Wisesa Sustainable tourism behavior and tourists intention to visit. Sustainability, 2023, 15, 1-13. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).