Submitted:

07 October 2024

Posted:

09 October 2024

You are already at the latest version

Abstract

Keywords:

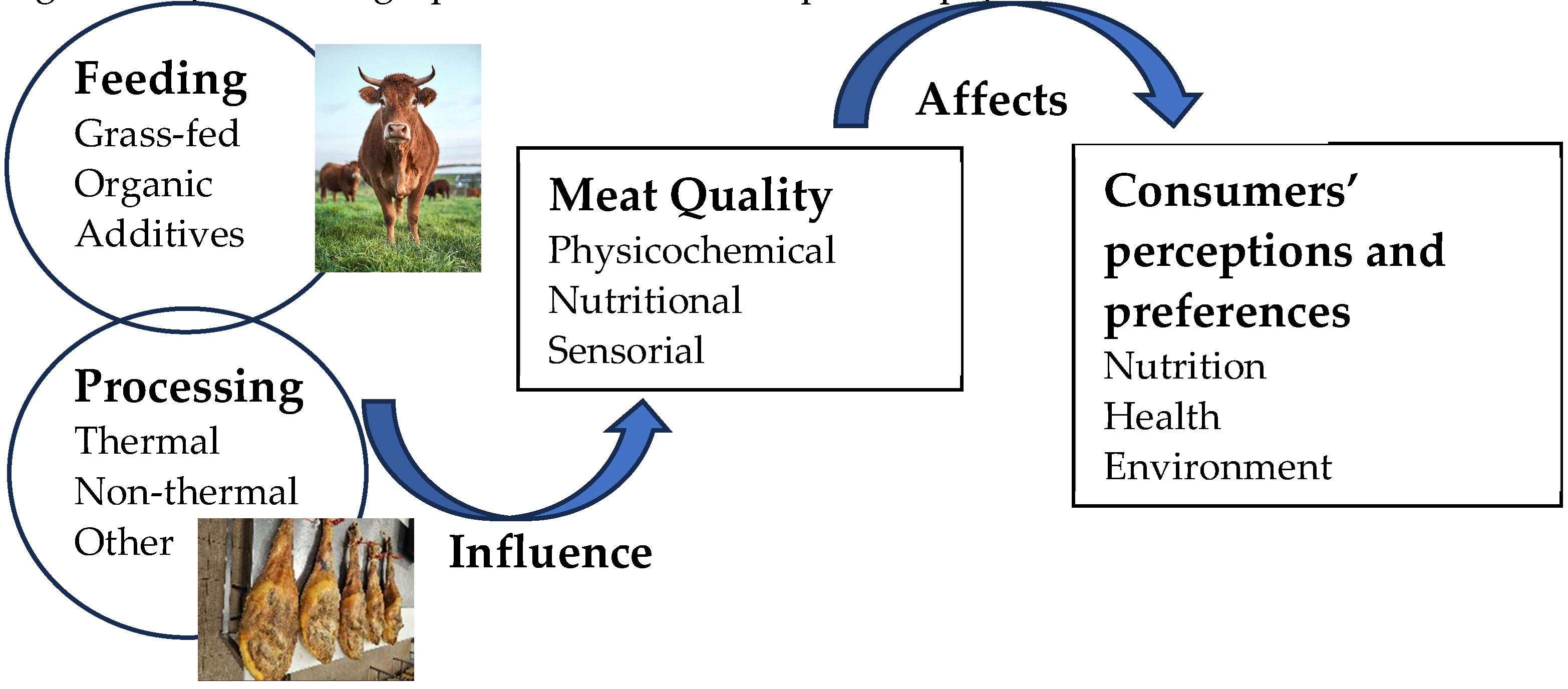

1. Introduction

2. Impact of Diet Composition and Feed Additives on Meat Quality Parameters

3. Advances in Processing Technologies and Their Effects on Meat Preservation and Sensory Characteristics

3.1. Thermal Processing

3.1.1. Dry-Aging

3.1.2. Sous-Vide Cooking

3.1.3. Freezing

3.2. Non-Thermal Processing

3.2.1. High Pressure Processing

3.2.2. Irradiation

3.2.3. Plasma Technology

3.3. Other Forms of Food Preservation

3.3.1. Chemical and Bio Preservatives

4. Interplay between Feeding Strategies and Processing for Enhanced Meat Safety and Sustainability

5. Consumer perception Related to Meat and Meat Products, from Different Feeding and Processing Practices, Quality

5.1. Feeding Approaches

5.2. Processing Approaches:

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grasso, G.; Rondoni, A.; Bari, R.; Smith, R.; Mansilla, N. Effect of information on consumers’ sensory evaluation of beef, plant-based and hybrid beef burgers. Food Quality and Preference 2022, 96, 104417. [Google Scholar] [CrossRef]

- de Araújo, P.D.; Araújo, W.M.C.; Patarata, L.; Fraqueza, M.J. Understanding the main factors that influence consumer quality perception and attitude towards meat and processed meat products. Meat Science 2022, 108952. [Google Scholar] [CrossRef] [PubMed]

- Cardona, M.; Izquierdo, D.; Barat, J.M.; Fernandez-Segovia, I. Intrinsic and extrinsic attributes that influence choice of meat and meat products: techniques used in their identification. Eur Food Res Technol 2023, 249, 2485–2514. [Google Scholar] [CrossRef]

- Teixeira, A., Rodrigues, S. Meat Quality, Brands and Consumer Trends. In: Lorenzo, J., Munekata, P., Barba, F., Toldrá, F. (eds) More than Beef, Pork and Chicken – The Production, Processing, and Quality Traits of Other Sources of Meat for Human Diet 2019, Springer, Cham. [CrossRef]

- Parlasca, M.C.; Qaim, M. Meat Consumption and Sustainability. Annu. Rev. Resour. Econ. 2022, 14, 17–41. [Google Scholar] [CrossRef]

- Albendea, P.; Tres, A.; Rafecas, M.; Vichi, S.; Solà-Oriol, D.; Verdú, M.; Guardiola, F. Effect of feeding olive pomace acid oil on pork lipid composition, oxidative stability, colour, and sensory acceptance. Animal 2023, 17, 100879. [Google Scholar] [CrossRef]

- Baelen, C.V.; Montagne, L.; Ferchaud, S.; Prunier, A.; Lebret, B. Feeding strategy in organic pig farming as a lever to improve various quality dimensions of pork. Animal 2024, 18, 101190. [Google Scholar] [CrossRef]

- Hashem, M.A.; Maruf, M.M.S.; Haque, M.; Akhter, S.; Arafath, M.S.; Rahman, M.M. Influence of different level of concentrate feeding on the productive performances and meat quality attributes of indigenous lam. Meat Research 2023, 3, 2790–1971. [Google Scholar] [CrossRef]

- Lu, N.; Ma, J.; Sun, D.-W. Enhancing physical and chemical quality attributes of frozen meat and meat products: Mechanisms, techniques and applications. Trends in Food Science & Technology 2022, 124, 63–85. [Google Scholar]

- Singh, P.; Sultan, Z.; Pandey, V.K.; Singh, R. Sous vide processing for food quality enhancement: A review. Food and Humanity 2023, 1, 543–552. [Google Scholar] [CrossRef]

- Gómez, I.; Janardhanan, R.; Ibañez, F.C.; Beriain, M.J. The effects of processing and preservation technologies on meat quality: sensory and nutritional aspects. Foods 2020, 9, 1416. [Google Scholar] [CrossRef]

- Bolumar, T.; Orlien, V.; Sikes, A.; Aganovic, K.; Bak, K.H.; Guyon, C.; Stübler, A.S.; de Lamballerie, M.; Hertel, C.; Brüggemann, D.A. High-pressure processing of meat: molecular impacts and industrial applications. Comprehensive Reviews in Food Science and Food Safety 2021, 20, 332–368. [Google Scholar] [CrossRef] [PubMed]

- Indiarto, R.; Irawan, A.N.; Subroto, E. Meat Irradiation: A Comprehensive Review of Its Impact on Food Quality and Safety. Foods 2023, 12, 1845. [Google Scholar] [CrossRef] [PubMed]

- Akhtar, J.; Abrha, M.G.; Teklehaimanot, K.; Gebrekirstos, G. Cold plasma technology: fundamentals and effect on quality of meat and its products. Food and Agricultural Immunology 2022, 33, 451–478. [Google Scholar] [CrossRef]

- Arokiyaraj, S.; Dinakarkumar, Y.; Shin, H. A comprehensive overview on the preservation techniques and packaging of processed meat products: Emphasis on natural derivatives. Journal of King Saud University – Science 2024, 36, 103032. [Google Scholar] [CrossRef]

- Shurson, G.C.; Urriola, P.E. Sustainable swine feeding programs require the convergence of multiple dimensions of circular agriculture and food systems with One Health. Animal Frontiers 2022, 12, 30–40. [Google Scholar] [CrossRef]

- Liu, J.; Ellies-Oury, M.-P.; Stoyanchev, T.; Hocquette, J.-F. Consumer Perception of Beef Quality and How to Control, Improve and Predict It? Focus on Eating Quality. Foods 2022, 11, 1732. [Google Scholar] [CrossRef]

- Török, Á.; Yeh, CH.; Menozzi, D.; Balogh, P.; Czine, P. Consumers’ preferences for processed meat: a best–worst scaling approach in three European countries. Agric Econ 2023, 11, 33. [Google Scholar] [CrossRef]

- Hu, T.; Al Mamun, A.; Reza, M.N.H.; Wu, M.; Yang, Q. Examining consumers’ willingness to pay premium price for organic food. Humanit Soc Sci Commun 2024, 11, 1249. [Google Scholar] [CrossRef]

- Cardenia, V.; Rodriguez-Estrada, M.T.; Cumella, F.; Sardi, L.; Casa, G.D.; Lercker, G. Oxidative stability of pork meat lipids as related to high-oleic sunflower oil and vitamin E diet supplementation and storage conditions. Meat Sci. 2011, 88, 271–279. [Google Scholar] [CrossRef]

- Lebret, B.; čandek-Potokar, M. Review: Pork quality attributes from farm to fork. Part I. Carcass and fresh meat. Animal 2022, 16, 100402. [Google Scholar] [CrossRef]

- Belkova, J.; Rozkot, M.; Weisbauerova, E.; Truneckova, J. Influence of feed substitution with acorns on fattening performance, carcass characteristics, and meat composition of prestice black-pied pigs finished in a conventional indoor system. Cogent Food. Agric. 2023, 9, 2220182. [Google Scholar] [CrossRef]

- Mazur-Ku´snirek, M.; Antoszkiewicz, Z.; Lipi ´nski, K.; Kaliniewicz, J.; Kotlarczyk, S. The effect of polyphenols and vitamin E on the antioxidant status and meat quality of broiler chickens fed low-quality oil. Arch. Anim. Breed. 2019, 62, 287–296. [Google Scholar] [CrossRef] [PubMed]

- Lebedev, S.V.; Frolov, A.N.; Grechkina, V.V. Different classes of nutrients added to the diet influence meat quality in arbor acres meat cross broiker chicken (Gallus gallus L.). Agric. Biol. 2024, 59, 289–300. [Google Scholar]

- Zorn, V.E.; Brandebourg, T.D.; Mullenix, M.K.; Belk, A.D.; Ale, K.B.; Abrahamsen, F.W.; Gurung, N.K.; Sawyer, J.T. Influence of Hempseed Meal on Fresh Goat Meat Characteristics Stored in Vacuum Packaging. Animals 2023, 13, 2628. [Google Scholar] [CrossRef] [PubMed]

- Rahman, M.M.; Idris, N.; Umani, N. Effect of complete pellet containing Asystgasia gangetica leaf on intake, digestibility, growth, carcass composition and meat quality of Muscovy duck. Int. J. Fauna Biol. Stud. 2024, 11, 1–6. [Google Scholar]

- Syahrir, S.; Sugiarto, S.; Marfuah, N.; Teguh, M. Development and improvement of the quality of natural feed broiler chicken with the addition of garlic leaves meal to produce production performance, carcass quality, and healthy meat quality. Agroland: The Agric. Sci. J. 2024, 11, 24–35. [Google Scholar] [CrossRef]

- Flores, D.R.M.; Fonseca, A.F.P.; Schmitt, J.; Tonetto, C.J.; Junior, A.G.R.; Hammerschmitt, R.K.; Facco, D.B.; Brunetto, G.; Nornberg, J.L. Lambs fed with increasing levels of grape pom-ace silage: effects on meat quality. Small Rumin Res 106234, 195, 106234. [Google Scholar] [CrossRef]

- Luciano, G.; Pauselli, M.; Servili, M.; Mourvaki, E.; Serra, A.; Monahan, F.J.; Lanza, M.; Priolo, A.; Zinnai, A.; Mele, M. Dietary olive cake reduces the oxidation of lipids, including cholesterol, in lamb meat enriched in polyunsaturated fatty acids. Meat Sci. 2013, 93, 703–714. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, T.K.; Cha, J.Y.; Jang, H.W.; Yong, H.I.; Choi, Y.S. How to develop strategies to use insects as animal feed: digestibility, functionality, safety, and regulation. J Anim Sci Technol. 2022, 64, 409–431. [Google Scholar] [CrossRef]

- Biondi, L.; Luciano, G.; Cutello, D.; Natalello, A.; Mattioli, S.; Priolo, A.; Lanza, M.; Morbidini, L.; Gallo, A.; Valenti, B. Meat quality from pigs fed tomato processing waste. Meat Sci. 2020, 159, 107940. [Google Scholar] [CrossRef]

- Leite, A.; Domínguez, R.; Vasconcelos, L.; Ferreira, I.; Pereira, E.; Pinheiro, V.; Outor-Monteiro, D.; Rodrigues, S.; Lorenzo, J.M.; Santos, E.M.; et al. Can the Introduction of Different Olive Cakes Affect the Carcass, Meat and Fat Quality of Bísaro Pork? Foods 2022, 11, 1650. [Google Scholar] [CrossRef] [PubMed]

- Ciurescu, G.; Vasilachi, A.; Idriceanu, L.; Dumitru, M. Effects of corn replacement by sorghum in broiler chickens diets on performance, blood chemistry, and meat quality. Italian J. Anim. Sci. 2023, 22, 537–547. [Google Scholar] [CrossRef]

- Al-Soufi, S.; García, J.; Nicodemus, N.; Lorenzo, J.M.; Cegarra, E.; Muíños, A.; Losada, A.P.; Miranda, M.; López-Alonso, M. Marine macroalgae in rabbit feed – Effects on meat quality. Meat Sci. 2024, 216, 109584. [Google Scholar] [CrossRef] [PubMed]

- Conway, E.; Sweeney, T.; Dowley, A.; Rajauria, G.; Vigors, S.; Yadav, S.; Wilson, J.; Gabrielli, W.; O´Doherty, J.V. The influence of duration of feeding dietary vitamin D2 enriched mushroom powder to finisher pigs on growth performance and meat quality parameters. Anim. Feed Sci.Tech. 2022, 288, 115315. [Google Scholar] [CrossRef]

- Scerra, M.; Foti, F.; Caparra, P.; Cilione, C.; Bognanno, M.; Paolo, F.; Paolo, C.; Natalello, A.; Musati, M.; Chies, L. Effects of feeding bergamot pulp and olive leaves on performance and meat quality in Apulo-Calabrase pigs. Vet. Anim. Sci. 2024, 23, 100336. [Google Scholar] [CrossRef]

- Bhatt, R.S.; Sarkar, S.; Sharma, S.R.; Soni, A. Use of Moringa oleifera leaves (sole or combined with concentrate) in rabbit feedings: Effects on performance, carcass characteristics and meat quality attributes. Meat Sci. 2023, 198, 109108. [Google Scholar] [CrossRef]

- Zaremba, I.; Grabowicz, M.; Biesek, J. Effect of beet pulp silage and various feeding methods on the performance and meat quality of broiler ducks. Anim. Fee.d Sci. Tech. 2024, 308, 115879. [Google Scholar] [CrossRef]

- Kim, Y.H.B.; Meyers, B.; Kim, H.W.; Liceaga, A.M.; Lemenager, R. Effects of stepwise dry/wet-aging and freezing on meat quality of beef loins. Meat Sci. 2017, 123, 57–63. [Google Scholar] [CrossRef]

- Dinçer, E.A. Dried meat products obtained by different methods from past to present. Food Rev Int. 2021, 1–20. [Google Scholar] [CrossRef]

- Kim, Y.H.B.; Kemp, R.; Samuelsson, L.M. Effects of dry-aging on meat quality attributes and metabolite profiles of beef loins. Meat Sci. 2016, 111, 168–176. [Google Scholar] [CrossRef]

- Musielak, G.; Mierzwa, D.; Kroehnke, J. Food drying enhancement by ultrasound—a review. Trends Food Sci Technol. 2016, 56, 126–141. [Google Scholar] [CrossRef]

- An, K.; Zhao, D.; Wang, Z.; Wu, J.; Xu, Y.; Xiao, G. Comparison of different drying methods on Chinese ginger (Zingiber officinale Roscoe): changes in volatiles, chemical profile, antioxidant properties, and microstructure. Food Chem. 2016, 197, 1292–1300. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.L.; Zhang, M.; Wang, L.P.; Mujumdar, A.S.; Sun, D.F. Influence of combination drying methods on composition, texture, aroma and microstructure of apple slices. LWT Food Sci Technol. 2012, 47, 183–188. [Google Scholar] [CrossRef]

- Campbell, R.E.; Hunt, M.C.; Levis, P.; Chambers, E. Dry-aging effects on palatability of beef longissimus muscle. J Food Sci. 2001, 66, 196–199. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Sabikun, N.; Ismail, I.; Joo, S.T. Changes in sensory compounds during dry aging of pork cuts. Food Sci. Anim. Resour. 2019, 39, 379–387. [Google Scholar] [CrossRef]

- Hwang, Y.H.; Sabikun, N.; Ismail, I.; Joo, S.T. Comparison of meat quality characteristics of wet- and dry-aging pork belly and shoulder blade. Korean J Food Sci Anim Resour. 2018, 2018. 38, 950–958. [Google Scholar] [CrossRef]

- Savini, F.; Indio, V.; Giacometti, F.; Mekkonnen, Y.T.; De Cesare, A.; Prandini, L.; Marrone, R.; Seguino, A.; Di Paolo, M.G.; Vuoso, V.; et al. Microbiological safety of dry-aged meat: a critical review of data gaps and research needs to define process hygiene and safety criteria. Italian Journal of Food Safety 2024. [Google Scholar] [CrossRef]

- Schellekens, M. New research issues in sous-vide cooking. Trends Food Sci. Technol. 1996, 7, 256–262. [Google Scholar] [CrossRef]

- Ayub, H.; Ahmad, A. Physicochemical changes in sous-vide and conventionally cooked meat. Int. J. Gastron. Food Sci. 2019, 17, 100145. [Google Scholar] [CrossRef]

- Ruiz-Carrascal, J.; Roldan, M.; Refolio, F.; Perez-Palacios, T.; Antequera, T. Sous-vide cooking of meat: a Maillarized approach. Int. J. Gastron. Food Sci. 2019, 16, 100138. [Google Scholar] [CrossRef]

- Baldwin, D.E. Sous Vide Cooking: A Review. Int. J. Gastronomy Food Sci. 2012, 1, 15–30. [Google Scholar] [CrossRef]

- Baldwin, D. 2021. Chapter, Sous Vide Cooking. Book, Handbook of Molecular Gastronomy, 1st Edition, CRC Press, Pages5, eBook ISBN9780429168703. [CrossRef]

- Park, C.H.; Lee, B.; Oh, E.; Kim, Y.S.; Choi, Y.M. Combined effects of sous-vide cooking conditions on meat and sensory quality characteristics of chicken breast meat. Poult. Sci. 2020, 99, 3286–3291. [Google Scholar] [CrossRef]

- Pérez-Juan, M.; Kondjoyan, A.; Picouet, P.; Realini, C.E. Effect of Marination and Microwave Heating on the Quality of Semimembranosus and Semitendinosus Muscles from Friesian Mature Cows. Meat Sci. 2012, 92, 107–114. [Google Scholar] [CrossRef] [PubMed]

- Gómez, I.; Ibañez, F.C.; Beriain, M.J. Physicochemical and sensory properties of sous vide meat and meat analog products marinated and cooked at different temperature-time combinations. International Journal of Food Properties 2019, 22, 1693–1708. [Google Scholar] [CrossRef]

- Pandita, G.; Bhosale, Y.; Choudhary, P. Sous Vide: A Proposition to Nutritious and Superior Quality Cooked Food. ACS Food Science & Technology 2023, 3, 592–599. [Google Scholar] [CrossRef]

- Rahman, U.; Sahar, A.; Ishaq, A.; Aadil, R.M.; Zahoor, T.; Ahmad, M.H. Advanced meat preservation methods: A mini review. J Food Saf. 2018, 12467. [Google Scholar] [CrossRef]

- Jo, Y.-J.; Min-Young, J.; You-Kyoung, J.; Jae-hyeong, K.; Jun-Bo, S.; Ji-Yeon, C.; Seon-Mi, Y.; Gui-Jung, H.; Sang-Gi, M. Effect of Novel Quick Freezing Techniques Combined with Different Thawing Processes on Beef Quality. Korean Journal for Food Science of Animal Resources 2014, 34, 777–783. [Google Scholar] [CrossRef]

- Beltran, A. , Belles, M. Effect of freezing on the quality of meat. Encyclopedia Food Secur. Sustain. 2019, 2, 493–497. [Google Scholar] [CrossRef]

- Leygonie, C.; Britz, T.J.; Hoffman, L.C. Impact of freezing and thawing on the quality of meat: Review. Meat Science 2012, 91, 93–98. [Google Scholar] [CrossRef]

- Chen, X.; Tume, R.K.; Xiong, Y.; Xu, X.; Zhou, G.; Chen, C.; Nishiumi, T. Structural modification of myofibrillar proteins by high-pressure processing for functionally improved, value-added, and healthy muscle gelled foods. Crit. Rev. Food Sci. Nutr. 2018, 58, 2981–3003. [Google Scholar] [CrossRef]

- Tobin, A.; McDonnell, C.; Olivier, S.; & Knoerzer, K.; & Sikes, A. 2020. Review of emerging (food industry) clean technologies for potential high-value red meat opportunities. Report by CSIRO NORTH SYDNEY NSW. Available online: https://www.mla.com.au/globalassets/mla-corporate/research-and-development/final-reports/2020/v.rmh.0110-final-report.pdf (accessed on 15 September 2024).

- Zhou, G.H.; Xu, X.L.; Liu, Y. Preservation technologies for fresh meat – A review. Meat Sci 2010, 86, 119–128. [Google Scholar] [CrossRef] [PubMed]

- Sazonova, S.; Galoburda, R.; Gamatina, I. (2017) Application of high-pressure processing for safety and shelf-life quality of meat—a review. In: 11th Baltic Conference on Food Science and Technology “FOODBALT 2017”. Latvia. [CrossRef]

- Margosch, D.; Ganzle, M.; Ehrmann, M.A.; Vogel, R.F. Pressure Inactivation of Bacillus Endospores. Appl. Environ. Microbiol. 2004, 70, 7321–7328. [Google Scholar] [CrossRef] [PubMed]

- Silva, D.R.G.; Haddad, G.B.S.; de Moura, A.P.; de Souza, P.M.; Ramos, A.L.S.; Hopkins, D.L.; Ramos, E.M. Safe cured meat using gamma radiation: Effects on spores of Clostridium sporogenes and technological and sensorial characteristics of low nitrite cooked ham. LWT – Food Science and Technology 2021, 137, 110392. [Google Scholar] [CrossRef]

- Islam, M.A.; Hossain, M.A.; Sadakuzzaman, M.; Khan, M.; Rahman, M.M.; Hashem, M.A. Effect of gamma irradiation on the shelf life and quality of mutton. Turkish Journal of Agriculture-Food Science and Technology 2022, 10, 117–124. [Google Scholar] [CrossRef]

- Ehlermann, D.A.E. 2014. Safety of Food and Beverages: Safety of Irradiated Foods. In Encyclopedia of Food Safety; Motarjemi, YBT., Ed.; Academic Press: Waltham, MA, USA, Volume 3, pp. 447–452, ISBN 9780123786128.

- Harder, M.N.C.; Arthur, V.; Arthur, P.B. Irradiation of foods: Processing technology and effects on nutrients: Effect of ionizing radiation on food components. Encyclopedia of Food and Health 2016, 476–481. [Google Scholar] [CrossRef]

- Lima, F.; Vieira, K.; Santos, M.; de Souza, P.M. Effects of radiation technologies on food nutritional quality. Descriptive Food Science 2018, 1, 17. [Google Scholar] [CrossRef]

- Woodside, J.V. Nutritional aspects of irradiated food. Stewart Postharvest Review. 2015, 11, 1–6. [Google Scholar] [CrossRef]

- Feng, X.; Moon, S.; Lee, H.; Ahn, D.U. Effect of irradiation on the parameters that influence quality characteristics of uncured and cured cooked turkey meat products. Poultry Science 2016, 95, 2986–2992. [Google Scholar] [CrossRef]

- Maherani, B.; Hossain, F.; Criado, P.; Ben-Fadhel, Y.; Salmieri, S.; Lacroix, M. World market development and consumer acceptance of irradiation technology. Foods 2016, 5, 79. [Google Scholar] [CrossRef]

- Turgis, M.; Borsa, J.; Millette, M.; Salmieri, S.; Lacroix, M. Effect of selected plant essential oils or their constituents and modified atmosphere packaging on the radiosensitivity of Escherichia coli O157: H7 and Salmonella Typhi in ground beef. Journal of Food Protection 2008, 71, 516–521. [Google Scholar] [CrossRef]

- Umair, M.; Jabbar, S.; Ayub, Z.; Muhammad Aadil, R.; Abid, M.; Zhang, J. Recent advances in plasma technology: Influence of atmospheric cold plasma on spore inactivation. Food Reviews International 2021. [Google Scholar] [CrossRef]

- Han, L.; Boehm, D.; Amias, E.; Milosavljević, V.; Cullen, P.J.; Bourke, P. Atmospheric cold plasma interactions with modified atmosphere packaging inducer gases for safe food preservation. Innovative Food Science & Emerging Technologies 2016, 38, 384–392. [Google Scholar] [CrossRef]

- Zhou, R.; Rezaeimotlagh, A.; Zhou, R.; Zhang, T.; Wang, P.; Hong, J.; Soltani, B.; Mai-Prochnow, A.; Liao, X.; Ding, T.; et al. In-package plasma: From reactive chemistry to innovative food preservation technologies. Trends in Food Science & Technology 2022, 120, 59–74. [Google Scholar] [CrossRef]

- Raviteja, T.; Dayam, S.K.; Yashwanth, J. A Study on Cold Plasma for Food Preservation. Journal of Scientific Research & Reports 2019, 23, 1–14. [Google Scholar] [CrossRef]

- Ucar, Y.; Ceylan, Z.; Durmus, M.; Tomar, O.; Cetinkaya, T. Application of cold plasma technology in the food industry and its combination with other emerging technologies. Trends Food Sci. Technol. 2021, 114, 355–371. [Google Scholar] [CrossRef]

- Yong, H.I.; Lee, H.; Park, S.; Park, J.; Choe, W.; Jung, S.; Jo, C. Flexible thin-layer plasma inactivation of bacteria and mold survival in beef jerky packaging and its effects on the meat’s physicochemical properties. Meat Sci. 2017, 123, 151–156. [Google Scholar] [CrossRef]

- Moutiq, R.; Misra, N.N.; Mendonça, A.; Keener, K. In-package decontamination of chicken breast using cold plasma technology: Microbial, quality and storage studies. Meat Sci. 2020, 159, 107942. [Google Scholar] [CrossRef]

- Jayasena, D.D.; Kang, T.; Wijayasekara, K.N.; Jo, C. Innovative Application of Cold Plasma Technology in Meat and Its Products. Food Sci. Anim. Resour. 2023, 43, 1087–1110. [Google Scholar] [CrossRef]

- Kruk, Z.A.; Yun, H.; Rutley, D.L.; Lee, E.J.; Kim, Y.J.; Jo, C. The effect of high pressure on microbial population, meat quality and sensory characteristics of chicken breast fillet. Food Control 2011, 22, 6–12. [Google Scholar] [CrossRef]

- Roobab, U.; Chacha, J.S.; Abida, A.; Rashid, S.; Muhammad Madni, G.; Lorenzo, J.M.; Zeng, X.A.; Aadil, R.M. Emerging trends for nonthermal decontamination of raw and processed meat: Ozonation, high-hydrostatic pressure and cold plasma. Foods 2022, 11, 2173. [Google Scholar] [CrossRef]

- Jo, K.; Lee, S.; Jo, C.; Jeon, H.J.; Choe, J.H.; Choi, Y.S.; Jung, S. Utility of winter mushroom treated by atmospheric non-thermal plasma as an alternative for synthetic nitrite and phosphate in ground ham. Meat Sci. 2020, 166, 108151. [Google Scholar] [CrossRef] [PubMed]

- Chorianopoulos, N.G.; Giaouris, E.D.; Skandamis, P.N.; Haroutounian, S.A.; Nychas, G.J.E. Disinfectant test against monoculture and mixed-culture biofilms composed of technological, spoilage and pathogenic bacteria: bactericidal effect of essential oil and hydrosol of Satureja thymbra and comparison with standard acid-base sanitizers. J Appl Microbiol 2008, 104, 1586–1596. [Google Scholar] [CrossRef] [PubMed]

- Khatun, M.M.; Hossain, M.A.; Ali, M.S.; Rahman, M.M.; Azad, M.A.K.; Hashem, M.A. Formulation of value-added chicken nuggets using carrot and ginger as a source of dietary fiber and natural antioxidant. SAARC J. Agric. 2022, 20, 185–196. [Google Scholar] [CrossRef]

- Azad, M.A.K.; Kikusato, M.; Zulkifli, I.; Rahman, M.M.; Ali, M.S.; Hashem, M.A.; Toyomizu, M. Comparative study of certain antioxidants - electrolyzed reduced water, tocotrienol and vitamin E on heat-induced oxidative damage and performance in broilers. Meat Research 2021, 1, 7. [Google Scholar] [CrossRef]

- Scotter, M.J.; Castle, L. Chemical interactions between additives in foodstuffs: A review. Food Addit. Contam. 2004, 21, 93–124. [Google Scholar] [CrossRef]

- Ferreira, T.A.; Rodriguez, J.A.; Sánchez-Ortega, I.; Lorenzo, J.M.; Santos, E.M. Antioxidant Activity of Bougainvillea spectabilis Bracts as an Alternative to Nitrites in Cooked Pork Ham. Foods 2024, 13, 3070. [Google Scholar] [CrossRef]

- Das, A.; Hashem, M.A.; Azad, M.A.K.; Rahman, M.M. Edible oil marination in broiler meat for short term preservation. Meat Research. 2022, 2, 22. [Google Scholar] [CrossRef]

- Nowak, A.; Danuta, K.; Krala, L.; Piotrowska, M.; Czyzowska, A. The effects of thyme (Thymus vulgaris) and rosemary (Rosmarinus officinalis) essential oils on Brochothrix thermosphacta and on the shelf life of beef packaged in high-oxygen modified atmosphere. Food Microbiol. 2012, 32, 212–216. [Google Scholar] [CrossRef]

- Ali, M.S.; Rahman, M.M.; Habib, M.; Kabir, M.H.; Hashem, M.A.; Azad, M.A.K.; Rahman, M.M. Quality of spent hen sausages incorporated with bee honey. Meat Research 2022, 2, 9. [Google Scholar] [CrossRef]

- Nair, M.S.; Nair, D.V.T.; Johny, A.K.; Venkitanarayanan, k. Use of food preservatives and additives in meat and their detection techniques. Meat Quality Anal 2020, 187–213. [Google Scholar]

- Montaño-Sánchez, E.; Torres-Martínez, B.D.M.; Vargas-Sánchez, R.D.; Huerta-Leidenz, N.; Sánchez-Escalante, A.; Beriain, M.J.; Torrescano-Urrutia, G.R. Effects of chitosan coating with green tea aqueous extract on lipid oxidation and microbial growth in pork chops during chilled storage. Foods 2020, 9, 766. [Google Scholar] [CrossRef] [PubMed]

- Salami, S.A.; Luciano, G.; O’Grady, M.N.; Biondi, L.; Newbold, C.J.; Kerry, J.P.; Priolo, A. Sustainability of feeding plant by-products: a review of the implications for ruminant meat production. Animal Feed Science and Technology 2019, 251, 37–55. [Google Scholar] [CrossRef]

- Ponnampalam, E.; Holman, B. (2023). Sustainability II: Sustainable animal production and meat processing. Editor(s): Fidel Toldrá, In Woodhead Publishing Series in Food Science, Technology and Nutrition, Lawrie’s Meat Science (Ninth Edition), Woodhead Publishing, Pages 727-798. [CrossRef]

- Rojas-Downing, M.M.; Nejadhashemi, A.P.; Harrigan, T.M.; Woznicki, S.A. Climate change and livestock: Impacts, adaptation, and mitigation. Climate Risk Management 2017, 16, 145–163. [Google Scholar] [CrossRef]

- Bernabucci, U. Climate change: impact on livestock and how can we adapt. Anim Front. 2019, 9, 3–5. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Gholami, M.; Chamani, M.; Seidavi, A.; Sadeghi, A.A.; Aminafschar, M. Effects of stocking density and environmental conditions on performance, immunity, carcase characteristics, blood constitutes, and economical parameters of cobb 500 strain broiler chickens. Italian Journal of Animal Science 2020, 19, 524–535. [Google Scholar] [CrossRef]

- Anderson, M.G.; Campbell, A.M.; Crump, A.; Arnott, G.; Newberry, R.C.; Jacobs, L. Effect of Environmental Complexity and Stocking Density on Fear and Anxiety in Broiler Chickens. Animals 2021, 11, 2383. [Google Scholar] [CrossRef]

- Paié-Ribeiro, J.; Baptista, F.; Teixeira, J.; Guedes, C.; Gomes, M.J.; Teixeira, A.; Barros, A.N.; Pinheiro, V.; Outor-Monteiro, D. From Waste to Resource: Compositional Analysis of Olive Cake’s Fatty Acids, Nutrients and Antinutrients. Appl. Sci. 2024, 14, 5586. [Google Scholar] [CrossRef]

- Leite, A.; Domínguez, R.; Vasconcelos, L.; Ferreira, I.; Pereira, E.; Pinheiro, V.; Outor-Monteiro, D.; Rodrigues, S.; Lorenzo, J.M.; Santos, E.M.; et al. Can the Introduction of Different Olive Cakes Affect the Carcass, Meat and Fat Quality of Bísaro Pork? Foods 2022, 11, 1650. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Leite, A.; Vasconcelos, L.; Lopez, S.; Outor-Monteiro, D.; Pinheiro, V.; Rodrigues, S.; Teixeira, A. Incorporating Olive By-Products in Bísaro Pig Diets: Effect on Dry-Cured Product Quality. Foods 2024, 13, 2579. [Google Scholar] [CrossRef]

- Mantovani, A.; Aquilina, G.; Cubadda, F.; Marcon, F. Risk-Benefit Assessment of Feed Additives in the One Health Perspective. Front Nutr. 2022, 9, 843124. [Google Scholar] [CrossRef] [PubMed]

- Pandey, A.K.; Kumar, P.; Saxena, M.J. (2019). Feed Additives in Animal Health. In: Gupta, R., Srivastava, A., Lall, R. (eds) Nutraceuticals in Veterinary Medicine. Springer, Cham. [CrossRef]

- Parlasca, M.C.; Qaim, M. Meat Consumption and Sustainability. Annual Review of Resource Economics 2022, 14, 17–41. [Google Scholar] [CrossRef]

- Leite, A.; Vasconcelos, L.; Ferreira, I.; Domínguez, R.; Pereira, E.; Rodrigues, S.; Lorenzo, J.M.; Teixeira, A. Effect of the Inclusion of Olive Cake in the Diet on the Physicochemical Characteristics of Dry-Cured Loin and Dry-Cured “Cachaço” of Bísaro Pig. Appl. Sci. 2023, 13, 1439. [Google Scholar] [CrossRef]

- Ponnampalam, E.N., Bekhit, A.E.D., Bruce, H., Scollan, N.D., Muchenje, V., Silva, P., Jacobs, J.L. Chapter 2 - Production Strategies and Processing Systems of Meat: Current Status and Future Outlook for Innovation – A Global Perspective, Editor(s): Charis M. Galanakis, Sustainable Meat Production and Processing, Academic Press, 2019, Pages 17-44, ISBN 9780128148747. [CrossRef]

- Ponnampalam, E.N., Holman, B.W.B. Chapter 22 - Sustainability II: Sustainable animal production and meat processing, Editor(s): Fidel Toldrá, In Woodhead Publishing Series in Food Science, Technology and Nutrition, Lawrie’s Meat Science (Ninth Edition), Woodhead Publishing, 2023, Pages 727-798. [CrossRef]

- Knorr, D.; Augustin, M.A.; Tiwari, B. Advancing the Role of Food Processing for Improved Integration in Sustainable Food Chains. Front Nutr. 2020, 7, 34. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Font-i-Furnols, M.; Guerrero, L. Consumer preference, behavior and perception about meat and meat products: An overview. Meat Sci. 2014, 98, 361–371. [Google Scholar] [CrossRef] [PubMed]

- Magalhães, D.R.; Maza, M.T.; Prado, I.N.D.; Fiorentini, G.; Kirinus, J.K.; Campo, M.D.M. An exploratory study of the purchase and consumption of beef: Geographical and cultural differences between Spain and Brazil. Foods 2022, 11, 129. [Google Scholar] [CrossRef]

- Tomasevic, I.; Novakovic, S.; Solowiej, B.; Zdolec, N.; Skunca, D.; Krocko, M.; …Djekic, I. Consumer’s perceptions, attitudes and perceived quality of game meat in ten European countries. Meat Sci. 2018, 142, 5–13. [CrossRef]

- Kessler, F.; Nielsen, M.B.R.; Tøstesen, M.; Duelund, L.; Clausen, M.P.; Giacalone, D. Consumer perception of snack sausages enriched with umami-tasting meat protein hydrolysates. Meat Sci. 2019, 150, 65–76. [Google Scholar] [CrossRef]

- Altmann, B.A.; Gertheiss, J.; Tomasevic, I.; Engelkes, C.; Glaesener, T.; Meyer, J.; …M¨orlein, D. Human perception of color differences using computer vision system measurements of raw pork loin. Meat Sci. 2022, 188, 108766. [CrossRef]

- Petrescu, D.C.; Vermeir, I.; Petrescu-Mag, R.M. Consumer Understanding of Food Quality, Healthiness, and Environmental Impact: A Cross-National Perspective. Int J Environ Res Public Health 2019, 17, 169. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- Greenheck, J.; Johnson, B.; Graves, A.; Oak, A. Giving meat meaning: Creating value-based connections with consumers. Animal Frontiers 2018, 8, 11–15. [Google Scholar] [CrossRef]

- Alonso, M.E.; González-Montaña, J.R.; Lomillos, J.M. Consumers’ concerns and perceptions of farm animal welfare. Animals 2020, 10, 385. [Google Scholar] [CrossRef] [PubMed]

- Teixeira, A.; Rodrigues, S. Consumer perceptions towards healthier meat products. Current Opinion in Food Science 2021, 38, 147–154. [Google Scholar] [CrossRef]

- Williams, V.; Flannery, O.; Patel, A. Eco-score labels on meat products: Consumer perceptions and attitudes towards sustainable choices, Food Quality and Preference 2023, 111, 104973, ISSN 0950-3293. [CrossRef]

- Thorslund, C.A.H.; Sandøe, P.; Aaslyng, M.D.; Lassen, J. A good taste in the meat, a good taste in the mouth – Animal welfare as an aspect of pork quality in three European countries. Livestock Science 2016, 193, 58–65. [Google Scholar] [CrossRef]

- Munekata, P.E.S.; Rocchetti, G.; Pateiro, M.; Lucini, L.; Domínguez, R.; Lorenzo, J.M. Addition of plant extracts to meat and meat products to extend shelf-life and health-promoting attributes: an overview. Curr. Opin. Food Sci. 2020, 31, 81–87. [Google Scholar] [CrossRef]

- Argemí-Armengol, I.; Villalba, D.; Ripoll, G.; Teixeira, A.; Alvarez-Rodríguez, J. Credences cues of pork are more important than consumers’ culinary skills to boost their purchasing intention. Meat Sci. 2019, 154, 11–21. [Google Scholar] [CrossRef]

- Stampa, E.; Schipmann-Schwarze, C.; Hamm, U. Consumer perceptions, preferences, and behavior regarding pasture-raised livestock products: A review. Food Quality and Preference 2020, 82103872. [Google Scholar] [CrossRef]

- Brito, G.F.D.; Ponnampalam, E.; Hopkins, D. The Effect of Extensive Feeding Systems on Growth Rate, Carcass Traits, and Meat Quality of Finishing Lambs. Comprehensive reviews in food science and food safety 2017, 16, 23–38. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; Chen, Y.; Liu, X.; Liu, K.; Zhang, Y.; Luo, H. Carcass Traits, Meat Quality, and Volatile Compounds of Lamb Meat from Different Restricted Grazing Time and Indoor Supplementary Feeding Systems. Foods 2021, 10. [Google Scholar] [CrossRef]

- Lee, J.H.; Vanguru, M.; Moore, D.A.; Kannan, G.; Terrill, T.H.; Kouakou, B. Flavor compounds and quality parameters of chevon as influenced by sericea lespedeza hay. Journal of Agricultural and Food Chemistry 2012, 60, 3934–3939. [Google Scholar] [CrossRef]

- de Araújo, T.L.A.C.; Pereira, E.S.; Mizubuti, I.Y.; Campos, A.C.N.; Pereira, M.W.F.; Heinzen, E.L.; Magalhães, H.C.R.; Bezerra, L.R.; da Silva, L.P.; Oliveira, R.L. Effects of quantitative feed restriction and sex on carcass traits, meat quality and meat lipid profile of Morada Nova lambs. J Anim Sci Biotechnol. 2017, 8, 46. [Google Scholar] [CrossRef] [PubMed] [PubMed Central]

- O’Donovan, P.; McCarthy, M. Irish consumer preference for organic meat. British Food Journal 2002, 104, 353–370. [Google Scholar] [CrossRef]

- Lee, J.H.; Wildeus, S.; Lemma, B.B.; Kouakou, B. Carcass and meat quality characteristics of purebred (hair) and crossbred (wool × hair) sheep lambs grazing fescue pasture as influenced by breed type, sex, and supplementation. Journal of Applied Animal Research 2024, 52, 142024. [Google Scholar] [CrossRef]

- Petrescu, D.; Petrescu-Mag, R. Consumer behaviour related to rabbit meat as functional food. World Rabbit Science 2018, 26, 321–333. [Google Scholar] [CrossRef]

- Skinner, L.; Levesque, C.L.; Wey, D.; Rudar, M.; Zhu, J.; Hooda, S.; Lange, C.F.M.D. Impact of nursery feeding program on subsequent growth performance, carcass quality, meat quality, and physical and chemical body composition of growing-finishing pigs. Journal of animal science 2014, 92 3, 1044–1054. [Google Scholar] [CrossRef]

- Argemí-Armengol, I.; Álvarez-Rodríguez, J.; Tor, M.; Salada, L.; Leite, A.; Vasconcelos, L.; Teixeira, A.; Rodrigues, S.S.Q. A Preliminary Evaluation of Sex and Dietary Field Pea Effects on Sensory Characteristics of Dry-Cured Loins. Animals 2024, 14, 739. [Google Scholar] [CrossRef] [PubMed]

- Corzo, A.; Schilling, M.; Loar, R.E.; Jackson, V.; Kin, S.; Radhakrishnan, V. The effects of feeding distillers dried grains with solubles on broiler meat quality. Poultry Science 2009, 88, 432–439. [Google Scholar] [CrossRef] [PubMed]

- Farghly, M.; Alagawany, M.; El-Hack, M.A.A. Feeding time can alleviate negative effects of heat stress on performance, meat quality and health status of turkey. British Poultry Science 2018, 59, 205–210. [Google Scholar] [CrossRef]

- Zhang, R.; Realini, C.E.; Kim, Y.H.B.; Farouk, M.M. Challenges and processing strategies to produce high quality frozen meat. Meat Sci. 2023, 205, 109311. [Google Scholar] [CrossRef]

- Hung, Y.; de Kok, T.M.; Verbeke, W. Consumer attitude and purchase intention towards processed meat products with natural compounds and a reduced level of nitrite. Meat Sci. 2016, 21, 119–126. [Google Scholar] [CrossRef]

- Barone, A.M.; Banovic, M.; Asioli, D.; Wallace, E.; Ruiz-Capillas, C.; Grasso, S. The usual suspect: How to co-create healthier meat products. Food Research International 2021, 143, 110304. [Google Scholar] [CrossRef]

- Shan, L.C.; De Brún, A.; Henchion, M.; Li, C.; Murrin, C.; Wall, P.G.; Monahan, F.J. Consumer evaluations of processed meat products reformulated to be healthier – a conjoint analysis study. Meat Sci. 2017, 131, 82–89. [Google Scholar] [CrossRef] [PubMed]

- do Prado, M.E.A.; Queiroz, V.A.V.; Correia, V.T.V.; Neves, E.O.; Ronchetia, E.F.S.; Gonçalves, A.C.A.; de Menezes, C.B.; de Oliveira, F.C.E. Physicochemical and sensorial characteristics of beef burgers with added tannin and tannin-free whole sorghum flours as isolated soy protein replacer. Meat Sci. 2019, 150, 93–100. [Google Scholar] [CrossRef] [PubMed]

- Paglarini, C.S.; Vidal, V.A.S.; Ribeiro, W.; Ribeiro, A.P.B.; Bernardinelli, O.D.; Herrero, A.M.; Ruiz-Capillas, C.; Sabadini, E.; Pollonio, M.A.R. Using inulin-based emulsion gels as fat substitute in salt reduced Bologna sausage. J Sci Food Agric 2020, 1–13. [Google Scholar]

- Rodrigues, S.; Almeida, S.; Pereira, E.; Teixeira, A. How does the added fat source affect sensory quality of sheep and goat pâtés? Ciência Rural 2019, 49, e20190029. [Google Scholar] [CrossRef]

- Barretto, T.L.; Pollonio, M.A.R.; Telis-Romero, J.; Barretto, A.C.S. Improving sensory acceptance and physicochemical properties by ultrasound application to restructured cooked ham with salt (NaCl) reduction. Meat Sci. 2018, 145, 55–62. [Google Scholar] [CrossRef]

- Ozaki, M.M.; Munekata, P.E.S.; Lopes, A.S.; Nascimento, M.S.; Pateiro, M.; Lorenzo, J.M.; Pollonio, M.A.R. Using chitosan and radish powder to improve stability of fermented cooked sausages. Meat Sci. 2020, 167, 108165. [Google Scholar] [CrossRef]

- Berger, J.; Kim, Y.H.B.; Legako, J.F.; Martini, S.; Lee, J. , Ebner, P., Zuelly, S.M.S. Dry-aging improves meat quality attributes of grass-fed beef loins. Meat Sci. 2018, 145, 285–291. [Google Scholar] [CrossRef]

- Cardona, M.; Gorriz, A.; Barat, J.M.; Fernandez-Segovia, I. Perception of fat and other quality parameters in minced and burger meat from Spanish consumer studies. Meat Sci. 2020, 166, 108138. [Google Scholar] [CrossRef]

- Muela, E.; Monge, P.; Sañudo, C.; Campo, M.M.; Beltrán, J.A. Sensory quality of lamb following long-term frozen storage. Meat Sci. 2016, 114, 32–37. [Google Scholar] [CrossRef]

- Hati, S.R.H.; Zulianti, I.; Achyar, A.; Safira, A. Perceptions of nutritional value, sensory appeal, and price influencing customer intention to purchase frozen beef: Evidence from Indonesia. Meat Sci. 2021, 172, e108306. [Google Scholar] [CrossRef]

- Cap, M.; Lires, C.; Cingolani, C.; Mozgovoj, M.; Soteras, T.; Gentiluomo, J.; Principe, F.; Sucari, A.; Horak, C.; Signorini, M.; et al. Identification of the gamma irradiation dose applied to ground beef that reduces Shiga toxin producing Escherichia coli but has no impact on consumer acceptance. Meat Sci. 2021, 174, 108414. [Google Scholar] [CrossRef] [PubMed]

- Michel, F.; Knaapila, A.; Hartmann, C.; Siegrist, M. A multi-national comparison of meat eaters’ attitudes and expectations for burgers containing beef, pea or algae protein. Food Quality and Preference 2021, 91, 104195. [Google Scholar] [CrossRef]

- Di Vita, G.; Zanchini, R.; Spina, D.; Maesano, G.; LaVia, G.; D’Amico, M. Exploring Purchasing Determinants for a Low Fat Content Salami: Are Consumers Willing to Pay for an Additional Premium? Frontiers in Sustainable Food System. Sec. Nutrition and Sustainable Diets 2022. [Google Scholar] [CrossRef]

- Vidal, V.A.S.; Paglarini, C.S.; Freitas, M.Q.; Coimbra, L.O.; Esmerino, E.A.; Pollonio, M.A.R.; Cruz, A.G. Q Methodology: An interesting strategy for concept profile and sensory description of low sodium salted meat. Meat Sci. 2020, 161, 108000. [Google Scholar] [CrossRef]

- Patarata, L.; Carvalho, F.; Fraqueza, M.J. Nitrite-free implications on consumer acceptance and the behavior of pathogens in cured pork loins. Foods 2022, 11, 1–14. [Google Scholar] [CrossRef]

| Breed | Feed | Impact on meat quality | Reference | |

|---|---|---|---|---|

| Lamb | Concentrates | Higher flavor, juiciness, and overall acceptability | With 1.5% concentrate feed, the lamb performed better in terms of the physicochemical, sensory, and instrumental color parameters of the lamb meat | [8] |

| Grape pomace | Higher total lipids levels, higher participation of polyunsaturated fatty acids (18:2n6 and CLA), and greater oxidative stability | No changes in the sensory parameters | [28] | |

| Olive cake | Increased concentration of vitamin E in muscle and extended meat oxidative stability | Did not compromise animal growth, carcass weight, or muscle fat content | [29] | |

| Pork | Shredded acorns | Slightly lower lean meat content and higher measured backfat thickness | Improvements in the fatty acid profiles away from SFAs towards MUFAs | [22] |

| Insect (Tenebria molitor) | Improvement of immunity and prevention of infection by pathogenic bacteria | Lower digestibility | [30] | |

| Tomato pomace | Increased concentration of vitamin A in meat, reduced the deposition of intramuscular fat | Did not affect animal performance | [31] | |

| Olive cake | Increased muscle length | Did not affect the carcass characteristics or the meat and fat quality | [32] | |

| Vitamin D2 enriched mushroom powder | Improved feed efficiency | Highest antioxidant activity and improved the overall color stability of fresh pork. | [35] | |

| Bergamot pulp | Greater oxidative stability | No effect of diet was observed on animal performance and on the fatty acid composition of meat | [36] | |

| Olive pomace acid oil | Color and overall acceptance of pork were not significantly affected by any of the diets | Negative impact on pork’s oxidative parameters | [6] | |

| Chicken | Plant polyphenolic compounds | Increased lightness and increased crude fat; | Reduced lipid peroxidation during storage | [23] |

| Diets supplemented with proteins, fats, and carbohydrates | The casein supplement increased the content of dry matter, protein, and stearic acid | The dextrose supplement increased the content of dry matter, oleic acid, and amino acids | [24] | |

| Garlic leaves | Higher protein digestibility and metabolic energy (thereby increasing body weight) | The treatment lowered the abdominal fat content lower than the control | [27] | |

| Sorghum grain | Results indicated that this cereal could modify plasmalipids and improve some meat quality traits in broilers | Did not affect the carcass, breast, and legs’ yield as well as organ size. | [33] | |

| Goat | Hempseed meal | Various inclusion levels of this supplement have no impact on carcass characteristics | Its use did affect some measures of meat quality over the shelf-life. | [25] |

| Ducks | Asytasia gangetica | Improved nutrient intake and digestibility | No significant differences were observed growth performance of ducks | [26] |

| Ad libitum beet pulp silage | More efficient nutrient utilization | The feeding approach had no adverse effects on most carcass and qualitative physicochemical characteristics of the muscles, except water-holding capacity in leg muscles. | [38] | |

| Rabbits | Marine macroalgae products | Positively modified the fatty acid profile, by increasing the proportion of omega 3 | Did not negatively affect the sensorial properties | [34] |

| Moringa oleifera leaves | Improved growth performance, feed conversion ratio and functional attributes of meat as compared to cowpea hay | To obtain positive results, feed should not exceed 700 g/kg feed | [37] | |

| Type of process | Process | Main findings | Reference |

|---|---|---|---|

| Thermal | Dry-aging | Concentration of free amino acids. Improvement of meat palatability. | [46] |

| Changes in meat color, water retention capacity, tenderness, lipid oxidation, and protein degradation | [47] | ||

| Reduces Salmonella and E. coli levels but is ineffective against Listeria monocytogenes and Yersinia enterocolitica. | [48] | ||

| Sous-vide cooking | Applied at low temperatures for a long time, it maintains meat’s nutritional composition and color. At moderate temperatures, sous-vide cooked meat retains its structure. Low flavor can be a drawback. |

[50] | |

| Roasting in the oven before or after sous-vide cooking of lamb meat leads to a browner surface and a more intense cooked meat flavor. | [51] | ||

| The cooking temperature and time of sous-vide significantly influenced chicken breast’s physicochemical and palatability characteristics. | [54] | ||

| Freezing | The freezing and thawing combinations did not cause remarkable changes in the quality parameters; rapid freezing, in the order of Cryogenic Freezing, Individual Quick Freezing, and Natural Convention Freezing, minimizes the quality deterioration. | [59] | |

| Consumer perception is neither direct nor clear regarding the safety and technological benefits associated with cold technologies. More research is needed to explore the potential of these methods. |

[58] | ||

| Non-thermal | High Hydrostatic Pressure | Used to microbiological safety without high temperature. Maintaining organoleptic characteristics. | [63] |

| Preserved nutritional value and shelf life extended without the use of preservatives or reduced additives | [62,65] | ||

| Irradiation | Effective destroying pathogenic and spoilage microbes and improved organoleptic characteristics | [67] | |

| Not recommended for use with foods with a high-fat content as it accelerates lipid oxidation. | [73] | ||

| Plasma Technology | Can be applied to the disinfection of air, water, and food surfaces with low-cost investment. | [80,81] | |

| Other | Chemical and Bio preservatives | Easily adapted to different food products to prevent oxidation, antimicrobials, and extend shelf life | [89,95] |

| Product | Main findings | Reference |

|---|---|---|

| Dry-aged grass-fed beef loins | Dry-aging has the potential to enhance the eating quality of low-marbled grass-fed beef without negatively impacting its microbial characteristics. Consumer survey data reveal that, although the market is small, there is a niche segment where consumers are willing to pay premium prices for dry-aged grass-fed beef. | [147] |

| Minced and burger meat (beef-pork or chicken-turkey) using different packaging (on trays, bulk). | Most respondents overestimated the fat content in various types of minced meat, as fat differences within a range of ±2% could not be detected. The color and appearance of the products were crucial for consumers, who placed little importance on the presence of additives. Unpackaged beef-pork meat was seen as more natural but also perceived as fattier and less healthy. Chicken-turkey meat was associated with healthiness and low-fat content but also with dislike, suggesting that additional processing should be done to improve appearance. | [148] |

| Long-term frozen storage of lamb meat | Consumers rated meat frozen stored for 21 months the lowest in terms of acceptability, while they preferred meat stored for 1 month. Despite this, all meats were considered ‘acceptable’. Interestingly, a third of consumers gave fresh meat the lowest acceptance after consumption, even though its visual appeal lasted 3 days longer than most thawed meats. Thawed and fresh meats were equally preferred when displayed for a short period, suggesting that concerns about thawed meat might need to be reconsidered. | [149] |

| Frozen meat | When consumers perceive frozen meat as having better nutritional content, appealing sensory qualities, and reasonable pricing, their attitudes towards these products improve, which in turn boosts their intention to purchase. | [150] |

| Gamma irradiated ground beef | A consumer acceptance analysis was conducted on samples treated with 2.5 kGy of gamma irradiation. The results showed no significant differences between the irradiated and control samples. Consequently, 2.5 kGy was determined to be the optimal gamma irradiation dose for reducing STEC in ground beef without affecting consumer acceptance. | [151] |

| Burger containing beef, pea, or algae protein | Participants in all three countries expected pea and algae burgers to be less tasty but healthier and more eco-friendly than beef burgers. These expectations were negatively impacted by higher meat commitment, negative attitudes towards vegetarian and vegan lifestyles, and higher food neophobia. | [152] |

| Processed meat products with reduced levels of nitrite | Consumers were generally unaware of nitrite in meat products but still showed positive attitudes and purchase intentions towards new processed meats. Purchase intention was positively linked to favorable attitudes, preference for natural additives, perceived harm of chemical additives, risk importance, innovativeness, awareness of nitrite, education, health interest, and frequency of processed meat consumption. | [139] |

| Low fat content salami | Consumers showed favorable acceptance of reduced-fat salami, indicated by their willingness to pay more for it. This highlights that health awareness is a key factor in marketing cured meats. | [153] |

| Low-sodium salted meat | Regular sodium salted meats were linked to health concerns and described as too salty, fatty, having a salty and strange taste, and contributing to high blood pressure. In contrast, low-sodium samples were associated with a good appearance, a metallic taste, and healthiness. | [154] |

| Nitrite-free cured pork loins | Producing nitrite-free cured loins is feasible if pathogen control is ensured, though the product may have a weaker color. However, consumers value sensory qualities beyond color, and the positive perception of an “additive-free” label can support the production of nitrite-free cured loins. | [155] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).