1. Introduction

Brushed DC motors which are used in many subsystems in industries have become indispensable among the subcomponents because of their advantages as controlling in a wide speed range, having high starting and accelerating torques with good speed regulation, driving with cheaper and simpler drive systems compared to AC motors [

1,

2]. Especially in automotive industry it is a crucial problem that the brushed DC motor drive design used to control speed, position and direction of the brushed DC motors must be cost-effective, applicable to lots of components of a product i.e. door, mirror, seat etc., and has a high quality feature.

As mentioned in [

3], in systems that provide driving of light loads, motion capability can be provided by open-loop control of the armature voltage, while in systems that provide driving of heavy loads, closed-loop speed control is required. Because the position of the load and the location of the center of gravity are important factors in speed control. Automatic door steps or door systems used in the automotive industry are also examples of this situation.

In drive systems where closed-loop speed and position control is performed, hall-effect sensors or encoders are needed for position and speed information. However, it is emphasized in the literature that these sensors increase the system cost and complexity and that these sensors are affected by the operating conditions both physically and magnetically. For this reason, speed-sensorless systems have been widely recommended recently. Speed-estimation methods can be classified into two groups as stated in [

4]. First group is dynamic model-based observer/estimator and the second group is based on holding down and counting the ripple components of the stator current of the motor [

1].

In [

5], linear brushed DC motor dynamic model-based estimator is proposed in order to estimate the motor speed. But linear model-based estimator proposed in [

5] is sensitive to variations of resistance, inductance and back electromotive force (EMF) of the brushed DC motor occuring due to the operating conditions. Furthermore, other methods which are based on nonlinear model of the brushed DC motor or indirectly model the motor such as Kalman filter and neural network [

6,

7,

8] have more stable estimation performance regard to the linear model-based estimator by estimating the other parameters or states of the brushed DC motor. Bu this estimators have more complexity and require expertise. Therefore, it is difficult to implement in real-time brushed DC motor driver proposed for industrial systems.

In addition to the methods mentioned above, ripple components counting methods [

9,

10,

11] that are considered in the second group and in which the DC component and AC component also known as the ripple component in the measured motor current are analyzed and the motor speed information is obtained with the ripple component numbers are also proposed in the literature. In [

9], the ripple components of inductive current of the brushed DC motor measured when the motor is at standstill. In [

10,

11], stator current spikes are determined and counting with the propose of speed estimation while the brushed DC motor is operating in a range of speed. All the proposed ripple counting methods require different filter structures to count the ripple components of stator current of the brushed DC motor. The development process of these filter structures includes some difficulties, the hardware design of the drive system becomes complex and the software load and computational burden increase.

Speed control of brushed DC motors is achieved by changing the armature voltage in the operating range up to the rated speed, while it is achieved by weakening the flux in the field windings above the nominal speed. Different power electronic circuit topologies are required to provide control in both regions [

12]. DC motor drives can be classified into two groups as regenerative and non-regenerative, according to their regenerative braking capabilities, and they are also classified according to their input soruces as AC or DC powered [

2]. Drive systems that provide control in four quadrant and regenerative braking have more complex structures than the drive systems where the control of the direction of motor speed and induced torque can be provided by reversing the output terminal voltage of the converter with semiconductor or electromechanical switches in first and/or third quadrant. In the drive systems having three-phase or one-phose AC supply, controlled rectifier topologies are used, while PWM-controlled isolated (boost, Zeta, Sepic, Cuk) and non-isolated (flyback, forward, push-pull, bridge, interleaved) DC-DC converters are used in drive systems supplied by DC bus voltage [

13,

14]. DC-DC step-up converter are preferred for several applications in a wide power-range icluding low-power to high–power because of their essential control and circuit design and simple modelling.

Among step-up converters, due to its simple structure and low cost design, boost converters are recommended in many industrial applications requiring low power and practical applicability. In [

13,

15], many different approaches proposed in the literature on boost converter structures are examined, and the difficulty in preventing power losses during switching is stated as a disadvantage. However, it is stated that this problem can be solved by performing different soft switching techniques proposed in the literature [

16,

17]. The DC-DC boost converter can operate with high switching frequencies by providing the switching under zero voltage with snubber circuits one of the soft switching techniques. Thus the cost and the size of the converter design can be minimized as desired by the industrial manufacturer [

18].

Another widely preferred driver system in brushed DC motor control is the PWM controlled chopper-based power electronics topology [

2,

19,

20]. Chopper-fed brushed DC motor driver systems having less complex control characteristic than the other non-isolated power converters are mostly preferred in industrial driver systems where control is performed only in the first and third quadrants. In the literature there are lots of study to improve the control ability and efficiency of the chopper-fed brushed DC motor drive circuits as proved and examined in [

12]. These driver systems are based on the application of the chopper's supply bus voltage to the motor armature terminals with PWM, and for this reason, motor control can only be provided at voltage values below the supply bus voltage value in these types of driver systems. However, driver systems used in the industry require designs that will allow motor terminal voltages to exceed the nominal value with a certain tolerance in order to meet short-term high torque demands which occur depending on the operation conditions. In addition, design simplicity, ease of control, low cost and minimal size requirements are among the requirements of the industry. Considering these requirements, the bus voltages of chopper-based drivers need to be increased at the time of instant high torque demand. Especially the consistent variable operating conditions in the automotive industry are a factor on this necessity. Furthermore, in the automotive industry, it is demanded that a designed brushed DC motor driver be applicable to different systems and that this driver works stably with the controlled systems. For example, it is desired by the automotive manufacturer that a designed motor driver be usable in both sliding door systems, under door step systems, air conditioning systems, window and mirror automatics, and seat positioning systems. In addition, motor drive systems that provide repetitive movement on these moving systems must complete a previously determined task within a certain time and in a limited motion planning. Because of this, proposed and designed motor drive systems must have high-performance position and speed control capability.

The repetitive motion and positioning process realized with a brushed DC motor needs to be trained to the motor drive systems, thus ensuring a stable operating characteristic and detecting the possible errors and challenging situations that may occur during operation and terminating or changing the direction of the motor. Detailed studies on artificial intelligence and machine learning methods proposed in the literature for motion and position mapping processes in systems with repeated movement capabilities in various industrial fields such as mobile robots, robot arms, micro robots, automatic doors, autonomous vehicles, where DC motors and servo motors are mostly preferred, are presented in [

21,

22,

23,

24,

25,

26,

27,

28]. In artificial intelligence and machine learning-based methods such as rainforcement learning, supervised learning, deep learning, machine learning, learning from demonstration, neural network, and fuzz Q-learning suggested in the literature, online and offline trainings are carried out for the purpose of motion and position mapping with data obtained from measurements on controlled electromechanical systems. But the proposed artificial intelligence and machine learning-based training methods require expertise, lots of measured datas for best training, and their implementations are difficult with industrial microcontrollers because of their stochastic and mathematical complexity and they require micro computers having high memory capacities.

Especially in automotive industry it is exigence that the electromachanical system control including motor control and trainings for motion mapping are accomplished with the industrial microcontrollers having limited memory capacities and peripheral units. In this study, a low-cost brushed DC motor drive system is designed with a completely industrial approach by using a commercial industrial microcontroller Microchip's PIC18F25K22. The proposed drive system needs only the speed and motor current informations obtained from the motor shaft and armature terminal with an hall-effect sensor and a high precision hall-effect current transducer, respectively, in order to implement a novel adaptive learning approach for motion mapping and a stable repetitive operating characteristic of moving mechanical system of an under door step used in automotive inudstry. The main contributions of the proposed study are given as follows:

A PWM controlled DC-DC chopper based brushed DC motor driver which DC bus voltage can be increased with boost converter is developed using the DC-DC boost converter topology. Thus, a simple and stable driver structure is developed, and a completely industrial solution for automotive manufacturing is presented that can provide torque demand and speed control in the movement difficulties that occur depending on the operating conditions.

The operating range and motion mapping of the motor driver that provides control of the electromechanical system can be determined with a simpler learning algorithm, unlike the artificial intelligence-based learning algorithms available in the literature.

In order to verify that the proposed driver has long-term durability in industrial applications, the driver system has been subjected to 100000 cycle tests on the test setup created with the under door step mechanical system, and tests with such long cycle times have been carried out for the first time in the literature.

With the proposed brushed DC motor driver, due to the variable output power it is possible to provide mobility to different mechanical systems in the automotive industry.

This paper is organized as follows. After problem definition and the literature review in introduction, structure of the proposed drive system is introduced in

Section 2.

Section 3 describes the hardware design procedure of the proposed driver and the proposed novel ALA method that is simple and does not require heavy computational burden. Experimental results of the proposed drive system are given in

Section 4. Conclusions and discussions are given in

Section 5. The patent application related to the study is presented in

Section 6.

2. Structure of the Proposed Drive System

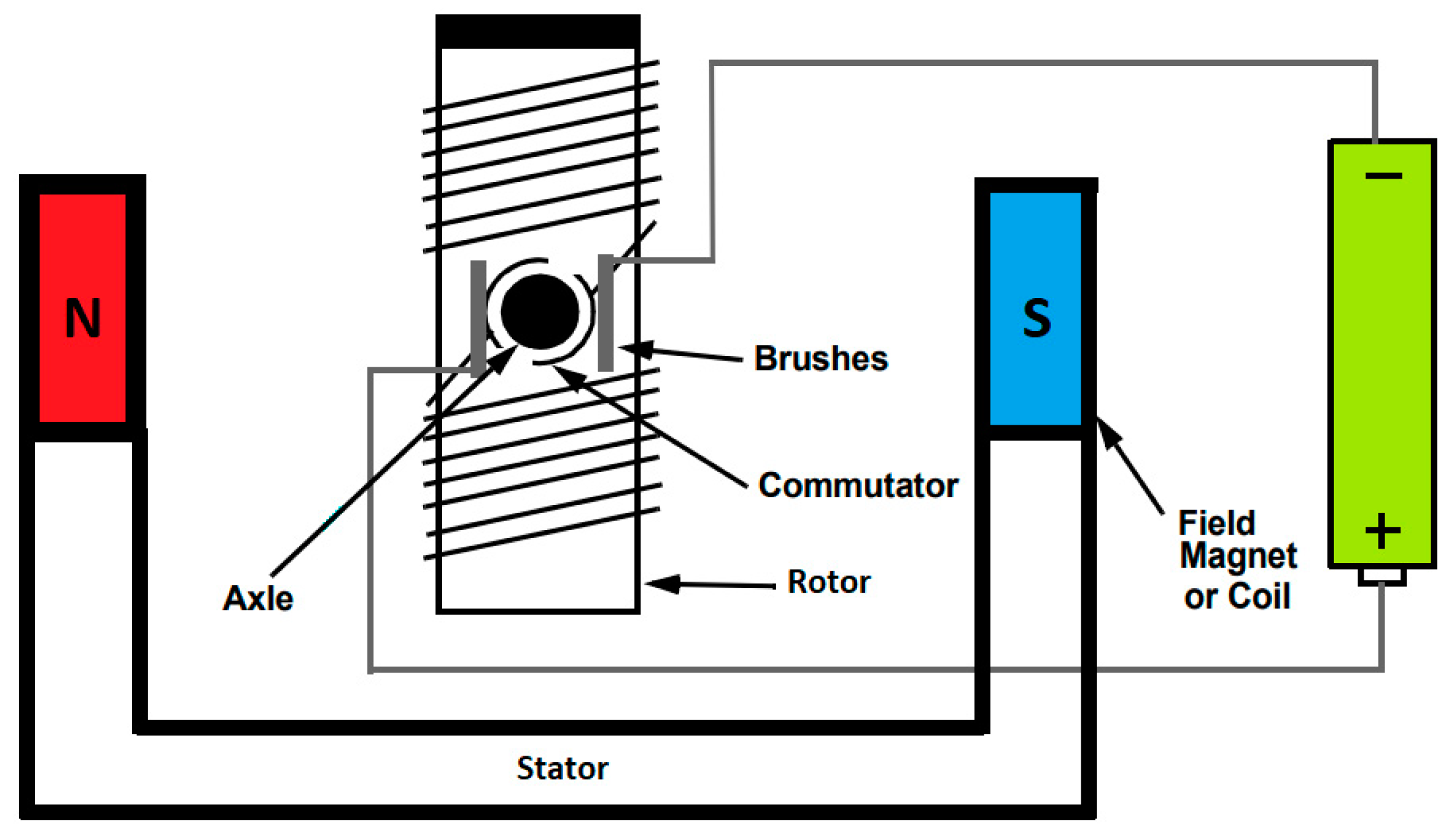

Structure of a brushed DC motor is shown on

Figure 1. Stator is the part of the brushed DC motor covers rotor and generates magnetic fields by using windings or magnets. Rotor or armature is a part which uses windings to be energized and rotates into the stator. Commutator is the part of the motor that ensures switcing of the poles and is located on the axle. Brushes are made of carbon and moves on commutator.

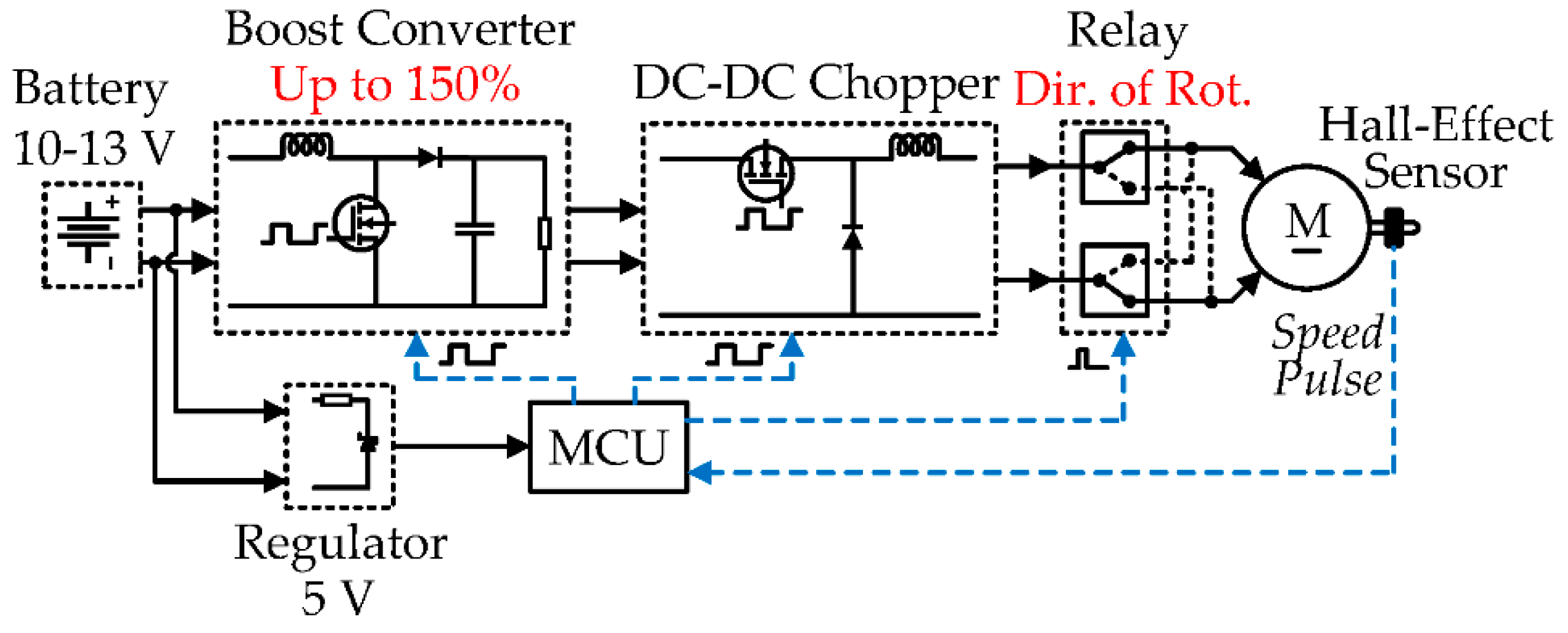

General scheme of the system is explained in

Figure 2.

Electronic subsystems used in the automotive industry usually use 12 V DC voltage. When a DC motor is examined, 120 VA power is consumed if 10 A current is drawn when 12 V voltage is applied. In the steady-state of the motor, 2-3 A of current is drawn. Since the DC motor is used in places where high torque is required, current is drawn several times more than the nominal load current of 10 A in cases such as transient state includes starting under load torque or overload due to an obstacle during operation. In direct current machines, the current drawn increases even more as the speed decreases. When the DC motor starts to operation, we encounter a torque arising from the inertia of the moving parts and the load. In order to start and accelerate, enough power must be applied to overcome this force, enough energy must be expended to overcome the potential caused by inertia and acceleration must be provided. These reasons may cause the DC motor to draw current up to several times its nominal current during the start. In a DC motor drive that can operate without ignoring these situations, the effects of these situations can be sensed, detected and eliminated with a MCU. In addition, this situation directly effects the structure of the design.

For the nominal operation of the DC motor, the harness between it and the 12 V power supply is generally capable of carrying 15-25 A. With the existing cable cross-sections used in automotive, the existing cable cross-sections will not be sufficient for the operation of the DC motor that will come in an optional product. For this reason, during the start of a 120 VA motor, the voltage at the motor terminals remains below 12 V. In addition, since the low voltage causes low speed, the motor has to draw much more current than necessary. In oorder to achieve the start-up process in a healthy way, it is necessary to ensure that the motor voltage is at least 12 V. For this reason, the bus voltage of the DC-DC chopper circuit can be controlled by a boost converter in which the PWM signals generated with MCU. With the boost converter, 20% more than the motor nominal voltage is generated and when applied to the motor, the motor speed is increased and the time consumption of the repetitive operation can be decreased and thus time depending operating scenario which described with users can be optimized.

In the proposed drive circuit in order to keep the bus voltage of the DC-DC chopper upper or equal to 12V, the proposed boost converter is activated especially during starting of the electromechanical system. In this case, during the motor nominal voltage can be kept at the nominal level, higher current is drawn from the input. With the MCU-based closed-loop control system, the bus voltage of the DC-DC chopper and output voltage of the boost converter can be measured and evaluated according to the situation. Control of the bus voltage of DC-DC chopper circuit, software controlled power modulation according to the current drawn from the source, it is possible to prevent excessive low voltage at the input. These are protection techniques that can be provided with software.

MOSFET is preferred as the switching element to control the output voltage of the boost converter. The gate voltage required for MOSFETs is used from the voltage generated from any other the boost circuit which is designed for voltage level shifting of the PWM outputs of the MCU. This voltage is measured approximately 15 V and the mosfet driver is fed with this voltage. The required PWM is applied to the MOSFET by the MCU.

With the purpose of changing the direction of the DC motor, double contact relays are used to change the direction of the armature current of the brushed DC motor so that the motor can rotate in both directions. These relays have an operating voltage of 12 V. While the motor is kept stationary or need to be stopped immediately, the contacts of the relays are connected in such a way as to short-circuit the motor armature terminals.

In addition to the rotation selection of the relay circuit, there is a DC-DC chopper circuit in which the output voltage is chopped and the power can be controlled with a MOSFET switched by PWM signal generated by the MCU in the form of different duty ratio (D) at constant frequency. The output voltage of the DC-DC chopper which is applied through the motor armature terminal can be detected by the MCU with coltage instrumentation unit designed with a differential amplifier circuit. Furthermore, filtering and snubber circuits are used to provide the soft switching under zero voltage.

In order to provide closed-loop control, a hall-effect current transducer is used to measure the current through the motor terminals. There is also a hall-effect sensor on the motor shaft that generates 6 pulses at each full revolution by using 6 magnets mounted around the motor shaft. The motor driver is expected to receive motion information via the hall-effect sensor until a certain power is reached within a certain period of time, and motion and speed control can be performed by interpreting whether this signal is due to a stall effect or not with the MCU.

It is seen from the

Figure 2, during the normal operation condition in which the driver needs rated 12 V bus voltage (V

SUPPLY), speed control of the brushed DC motor is possible with help of DC-DC chopper and the average output voltage (V

AVERAGE) is obtained with PWM at constant frequency and variable D in the proposed drive system. In DC-DC converters the main consideration is that low frequency may cause noisy motor response while high frequency control increases switching losses for switching components (MOSFET and BJT). The switching frequency ranging from 4 kHz to 20 kHz is considered as ideal range to avoid mentioned disadvantages. As mentioned before D symbolizes duty ratio of the PWM signal and multiplication of D by V

SUPPLY gives V

AVERAGE as follows [

29]:

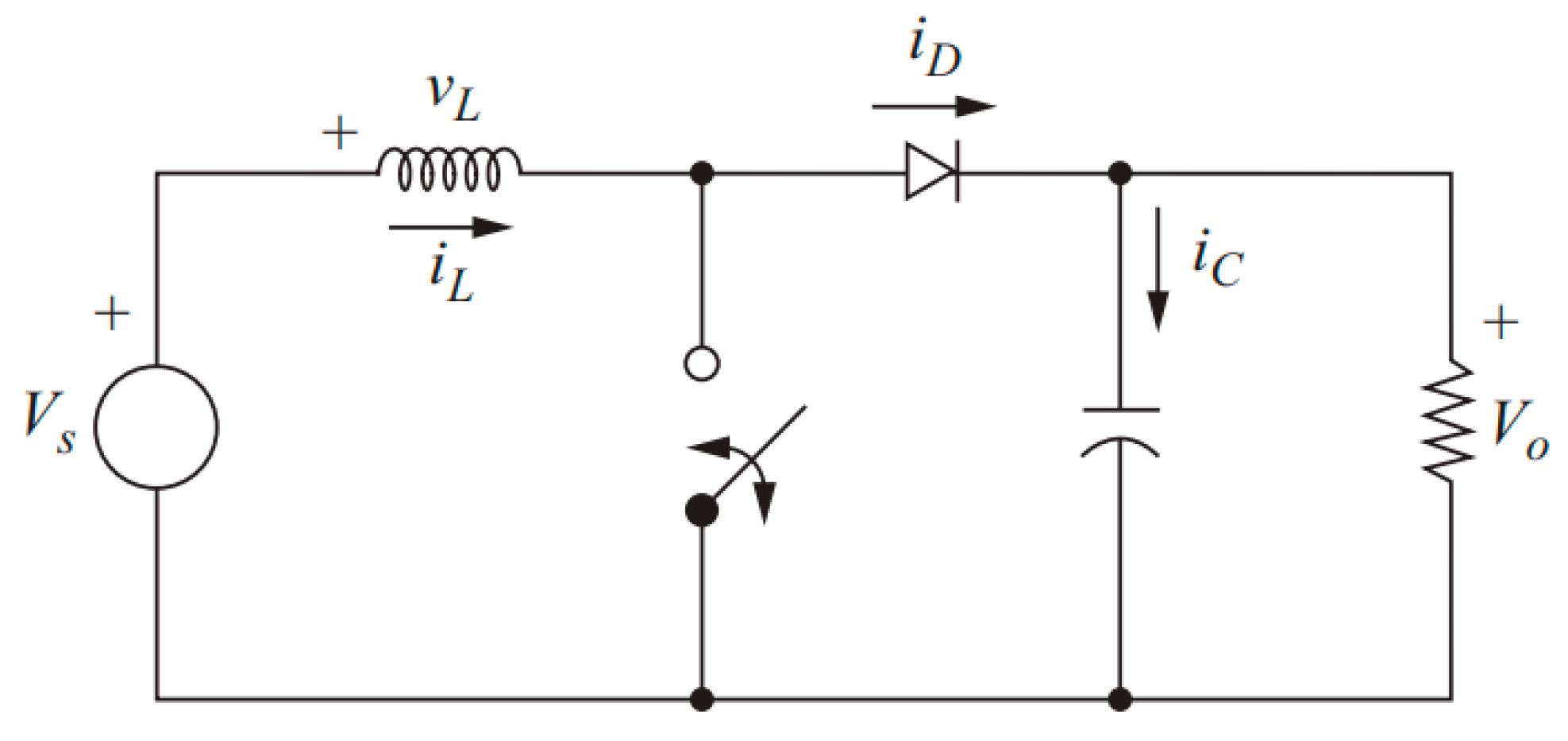

Boost converter is responsible for increasing an input voltage to a higher output voltage level. The energy is transferred to the output when the switching component is not conducting. Boost converter’s source voltage (V

S), output voltage (V

O), inductor(L) value and capacitor(C) and current ripple (ΔI

L) are calculated as given below [

30].

Output voltage and input voltage relation given as Eq.2

Minimum L value for the frequency calculated as Eq.3

Continuous Current has calculated in Eq.4

To calculate range of the current given as Eq.5

Minimum capacitance value can calculated as Eq.6

3. Hardware Design Procedure of the Proposed Driver and the Novel Adaptive Learning Method

Considering the software design, Microchip's low power consumption PIC18F25K22 microcontroller recommended for automotive designs is used in the proposed drive system. While chosing PIC18F25K22 micorcontroller, the internal peripherals of the microcontroller such as Timer, number of Analogue to Digital Converter (ADC) and PWM outputs are taken into consideration.

The main function of the designed brushed DC motor driver is to control the direction and speed of the motor which is mounted on the step to provide movement to the step under the door in a way to keep this driver and the upper system from which it draws power stable. Apart from these functions, the temperature is also continuously monitored. The step operates according to the limit switch data obtained from the automatic door of the vehicle. According to the status of this data, the necessary process is operated in the software loop. Another feature is that the speed of the vehicle is monitored and if the step is at on position over a certain speed, the off command will be sent.

In the proposed motor driver design, 2 communication protocols are used. One of them is the UART protocol, which can be monitored from computer ports with a very easy-to-find hardware such as USB cable, which is easy to monitor and widely useful with its simple structure. By using UART, armature current, armature voltage, DC bus voltage of the DC-DC chopper which is amplified with boost converter if it is necessary, motor speed measured by collecting the data of hall-effect sensor mounted on the shaft can be monitored. Another protocol is the CAN communication protocol, which is so common in the automotive industry that it can be considered indispensable. The designed hardware of the driver also supports this option.

3.1. Embedded System Design

Designed brushed DC motor driver has a modular structure. The DC link bus voltage of the DC-DC chopper can be controlled with a boost converter circuit. So, the speed of the brushed DC motor can be adjusted and the timing of the desired repetitive motion scenario can be adjusted practically by increasing the DC link bus voltage voltage. The current drawn by the motor is instantly captured and sent via UART. The input voltage of the driver and the DC link bus voltage of the DC-DC chopper increased by the boost converter are also captured and sent via UART. The temperature of the driver is continuously monitored with the help of Negative Temperature Coefficient thermistor (NTC). The position status of the motor is monitored with the help of the hall-effect sensor, and thus the status of the motor reaching the first and final position can be observed. CAN and UART communication protocols have been used so that the system can communicate with the main control system. The brushed DC motor is started to run when an external command triggers the driver, and then, in case of a problem due to current or the position of the motor, it moves in the opposite direction and returns to its initial position. So, it protects both the user, the motor driver hardware, mechanical system, and the electronic supply of the vehicle by preventing problems such as jamming, squeezing and excessive current. Another important function of the designed driver is to learn the maximum distance that the motor can drive step during the first start-up by making adaptive control and configuring its own settings accordingly. So, the limits of the step controlled by the brushed DC motor can be learnt and the acceleration and braking processes of the motor can be managed accordingly. Another advantage is that it can adapt to different systems and when it is used in a different system such as wiper, tailgate, etc., it will be able to learn its own limit and make acceleration and braking configurations accordingly.

The poposed driver is designed with the purpose of closing the door step automatically when a certain speed is reached by detecting the speed of the vehicle by receiving data from the vehicle's shaft. Another feature of this driver is that it monitors the status of the door with the help of a limit switch and automatically opens the step when the door is opened. Thus, when the door is opened, the step will open automatically without waiting for another command. The speed and position of the motor are determined by counting the hall-effect signals. The output torque of the motor required to open the step can be increased with a reducer while the shaft speed of the motor decreases.

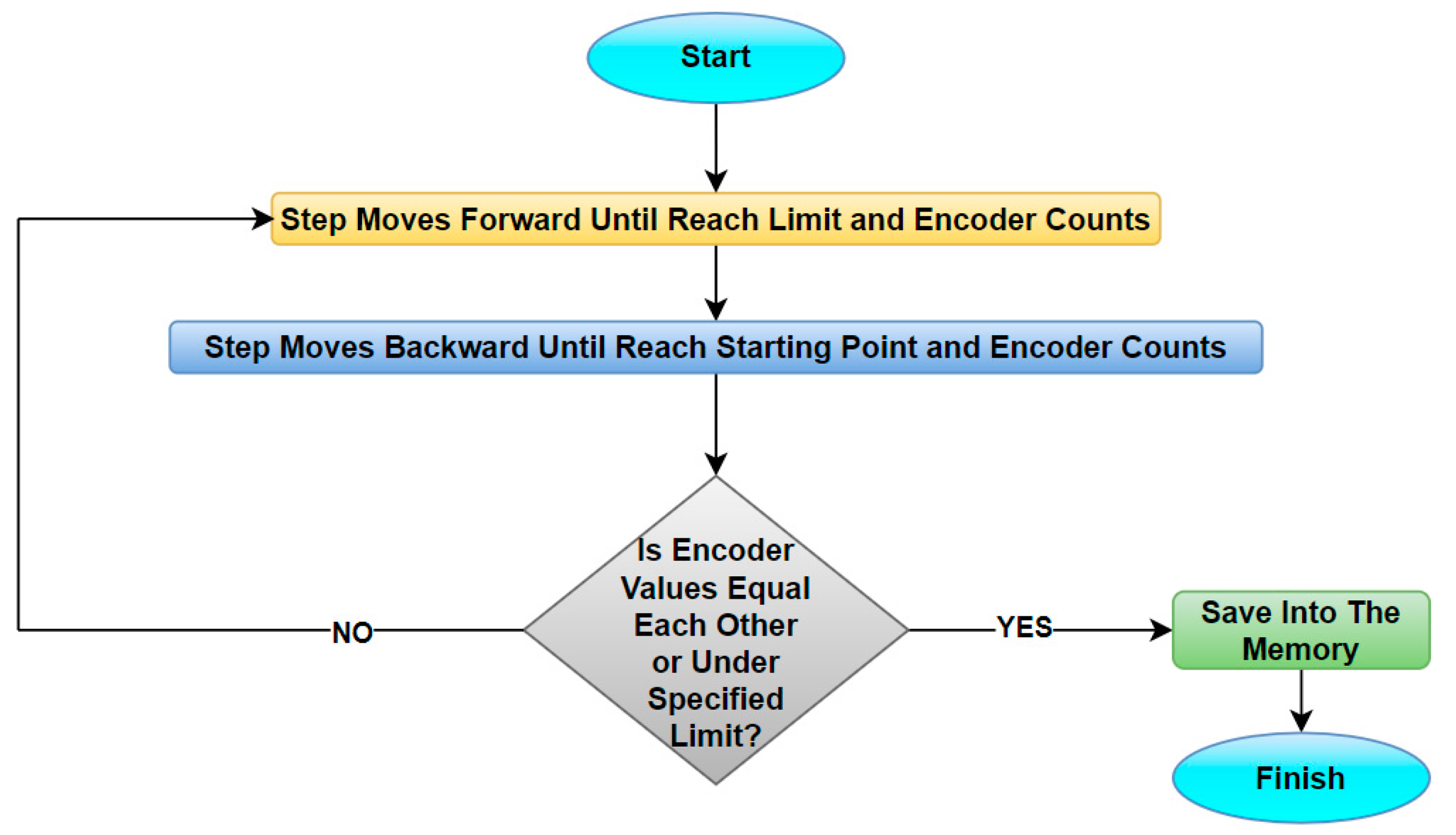

3.2. Adaptive Learning Algorithm

Thanks to the hall-effect sensor mounted on the motor shaft, the mechanical speed of the motor can be obtained by counting the output signal of the hall-effect sensor. Thus, so that it can be calculated how much angle of movement is provided by the brushed DC motor while the door step is opening.

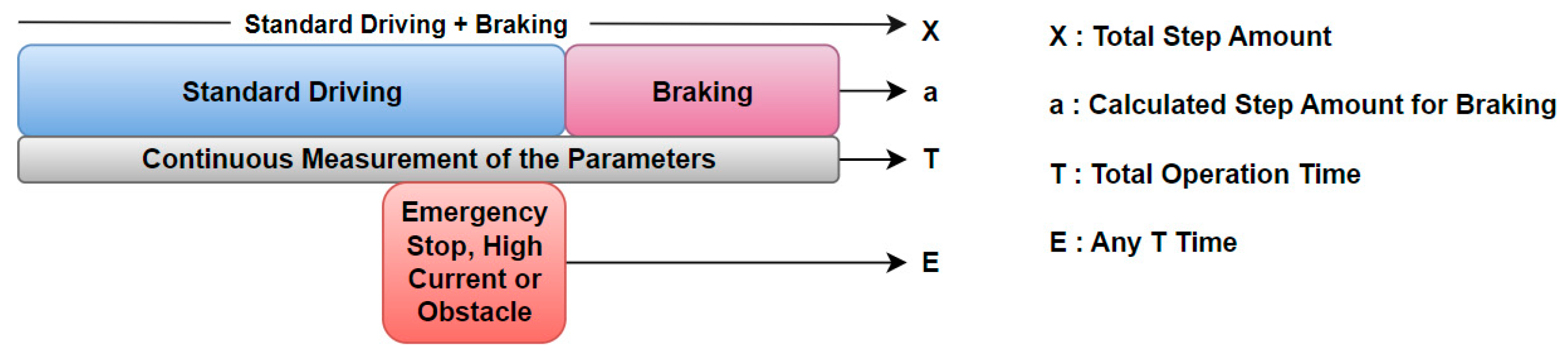

Figure 4 shows the flow chart of the ALA that automatically adjusts the working process of the motor driver system according to the limit value received from the hall-effect sensor. After the motor driver is mounted on the vehicle in which it is used, when the DC Motor is first started, the movement limit values are determined by monitoring only the current value drawn from the source and the hall-effect sensor data without any movement scenario. The hall-effect sensor data at the last detected point is temporarily recorded and the step returns to its initial position. Since the distance of the movement in both forward and reverse directions must be equal or very slightly different, the last values obtained from the hall-effect sensor as a result of the forward and reverse movement are compared. If the specified condition is not met, the algorithm does not exit the loop and tries to determine the correct data by working in the forward and reverse directions again. When a full match occurs between the forward and reverse movements or a deviation within the specified threshold value, the limit point data received from the hall-effect sensor is recorded in permanent memory. With the determination of the movement limits, the soft start, constant speed and soft deceleration and stopping operations of the motor are automatically configured.

Figure 5 shows the flow chart of the operation of the under-door step system, which is provided with the proposed motor driver and brushed DC motor. In

Figure 5, the limit position data of the mechanical step obtained from the hall-effect sensor is expressed as ‘X’. Here, ‘X’ represents the total number of pulses. The blue standard drive box contains the soft start and steady-state icluding operation at rated speed drive section. Under the operating conditions specified with the purple braking box, it starts braking when the limit position is approached and ensures a safe and damage-free stop without a hard hit when the limit position is reached. The ‘a’ variable represents the number of steps required for braking and braking starts when there are steps left until the limit position ‘a’. The gray box shows that the parameters are monitored with continuous measurements throughout the movement of the mechanical step. Thus, in an unexpected emergency situation, the red emergency stop process is operated due to high current or obstacle by considering the pre defined parameters as current and motion limits. The specified emergency stop process can occur at any ‘E’ moment within the ‘T’ time. The location of the red box is symbolic.

3.3. Sub-Elements of the System

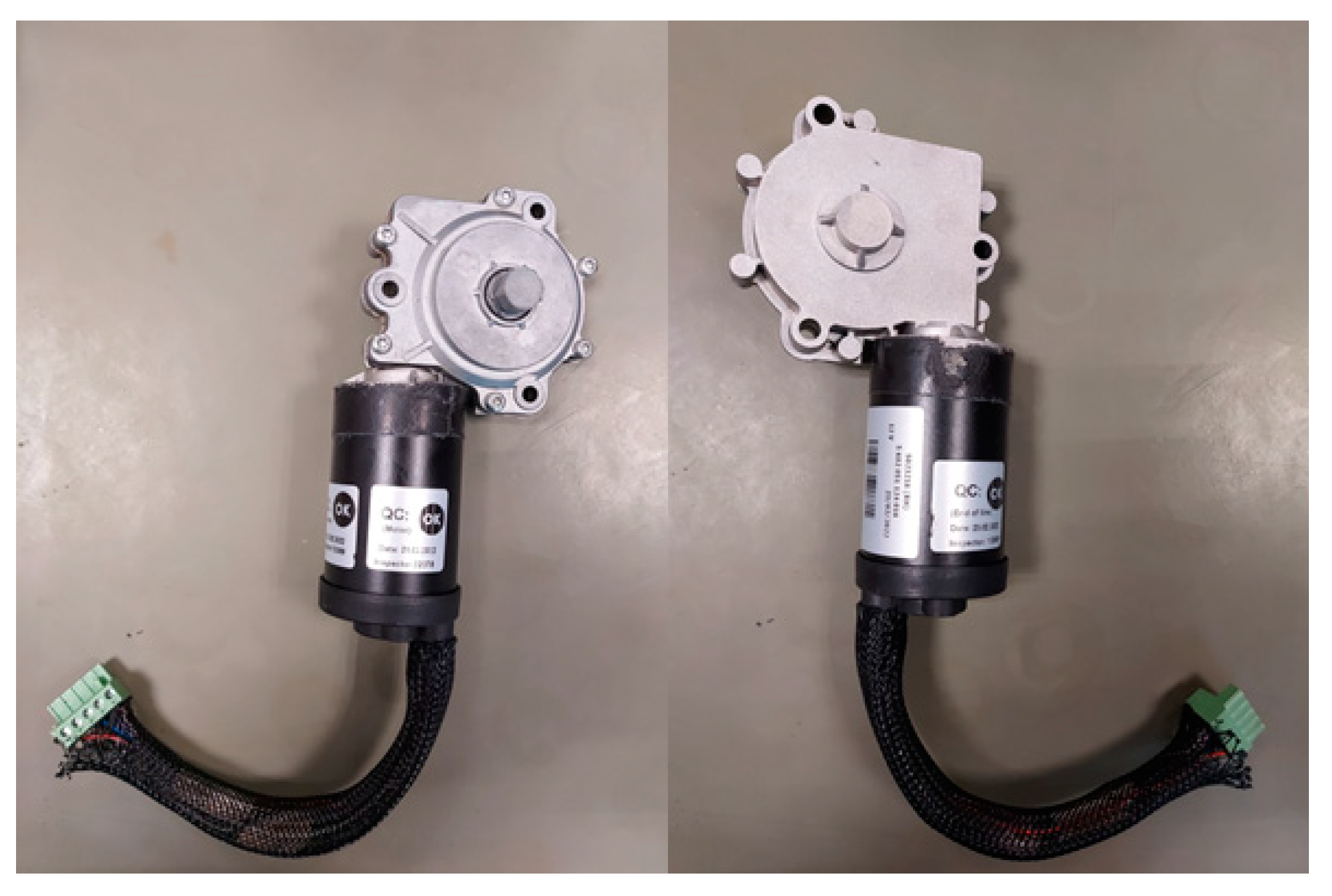

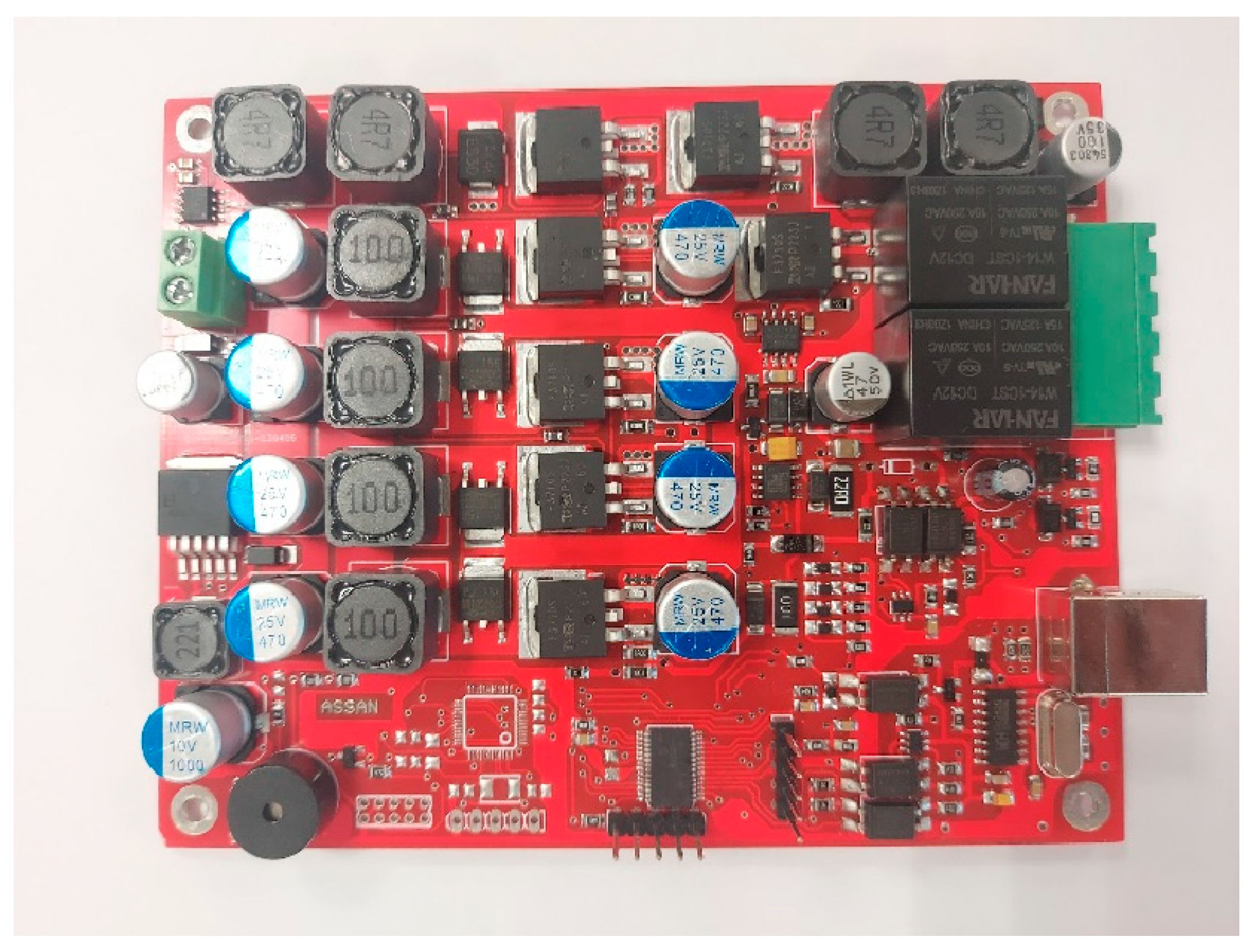

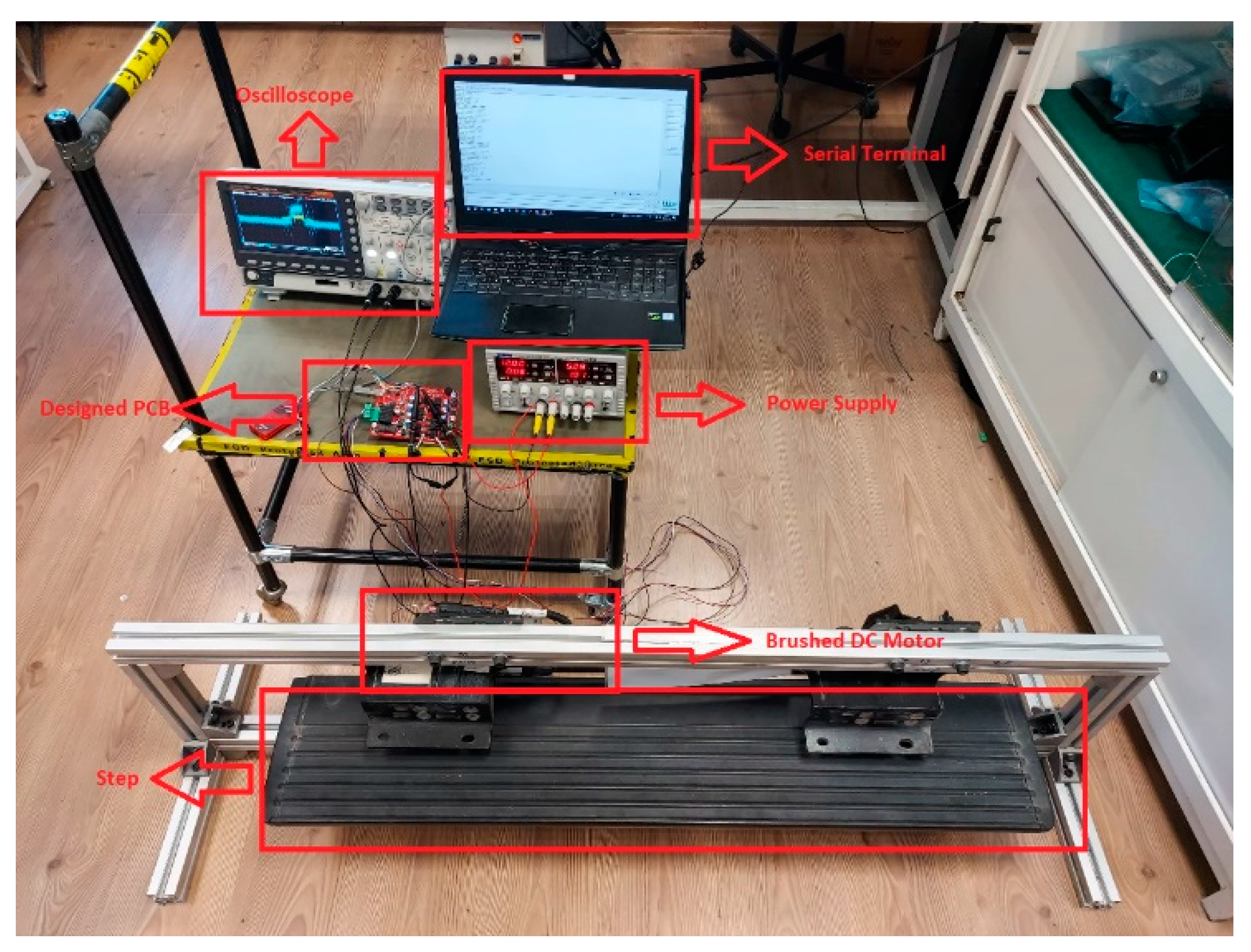

Real-time experimental tests of the proposed brushed DC motor driver containing the proposed ALA method are performed with a vehicle under-door step system. When the electromechanical under-door step system is examined, it can be divided into three main sub-sections. These are the brushed DC motor, mechanical under-door step and motor driver.

Figure 6 shows the brushed DC motor where the hall-effect sensor is mounted on the motor shaft and the induced output torque value is increased by increased by reducing the speed with the reducer.

Figure 7 shows the images of the under-door step when it is at initial (closed) and fully forward (open) positions.

The printed circuit board (PCB) of the motor driver system, which can operate under the specified voltage and current values, change the motor direction, determine and learn the operating map of the system with the proposed ALA method bu using the current and speed measurements obtained forom instrumentation units it contains, with the cascade voltage control structure created by combining the boost converter and DC-DC chopper topologies together in its design, is shown in

Figure 8. It must be noted that the components used to create the designing of the PCB have automotive grade feature.

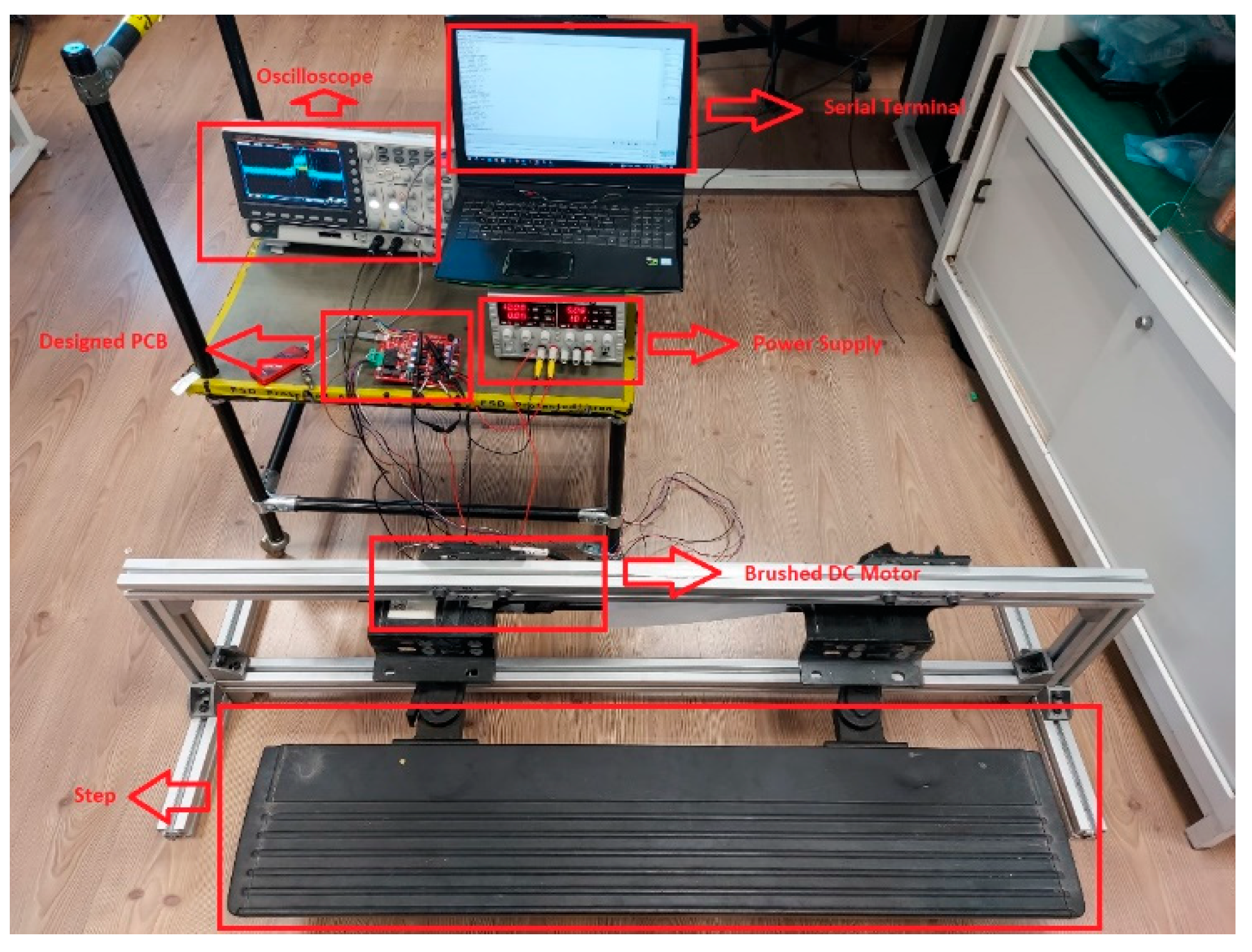

The experimental test setup implemented in a laboratory environment is presented in

Figure 9 and

Figure 10.

4. Experimental Results

In this section, experimental results of the proposed brushed DC motor drive system are given. The proposed brushed DC motor driver is tested experimentally with a under-door step system of a vehicle. In this test setup, the brushed DC motor provides mobility to mechanical under-door step system. The captured and measured datas from the brushed DC motor driver is sent to software interface via UART and this datas are recorded.

After learning the motion map defining the motion limits in the range of when the door step electormechanical mechanism is open and close position with the proposed driver system, it is tested whether the previously determined motion scenario can be realized with the proposed motor driver. In this motion scenario, the electromechanical door step must reach its final position from its initial position within the defined time and during this working process, the motor driver must ensure that the motor starts with a soft start and stops with a soft stop in order to prevent the excessive current draw from the source. In case of sudden strains that may occur on the step at the moment of opening, the step should stop suddenly and return to its initial position. In case of a strain that may occur at the moment of closing, the step should stop and remain at standstill and complete its movement after the excessive strain is removed. All of this specified working scenario is realized by the proposed brushed DC motor driver. As can be understood from this scenario, in order to complete the repetitive motion in a specified time, the motor speed must be controlled depending on the variable operating conditions. In this case, the DC-DC chopper bus voltage may also need to be increased. In the experimental tests, the performance of the boost type converter is tested together with the DC-DC chopper.

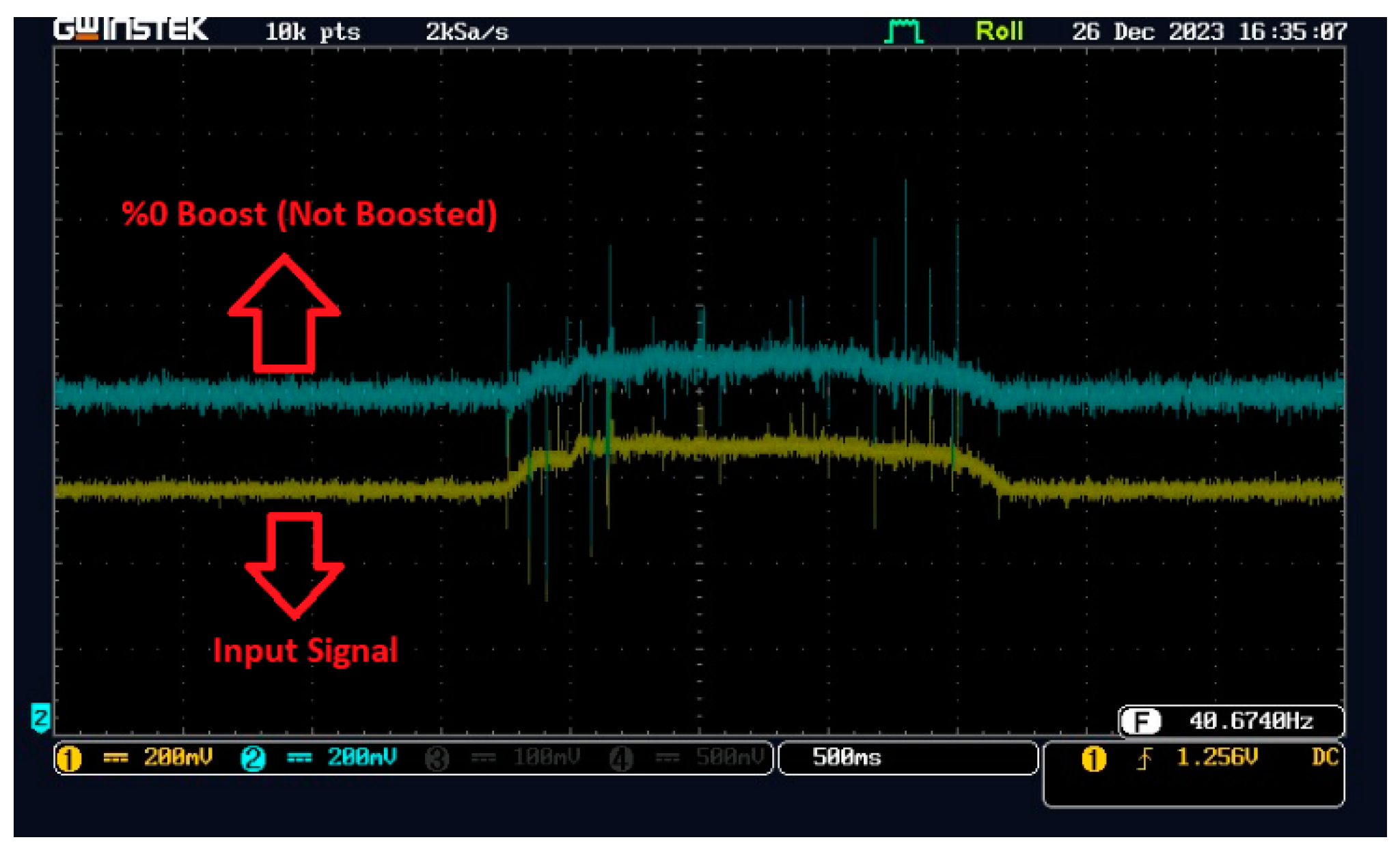

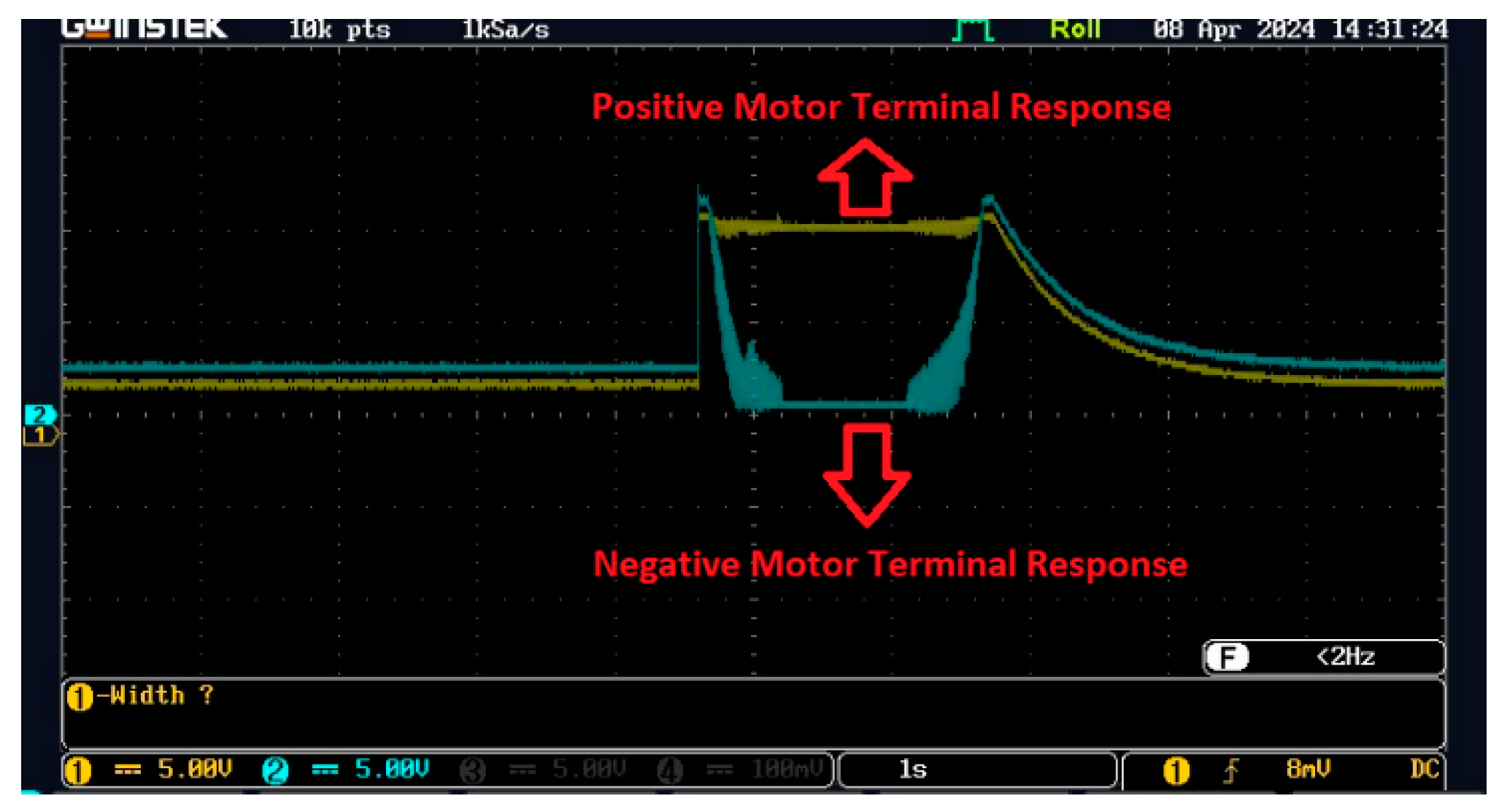

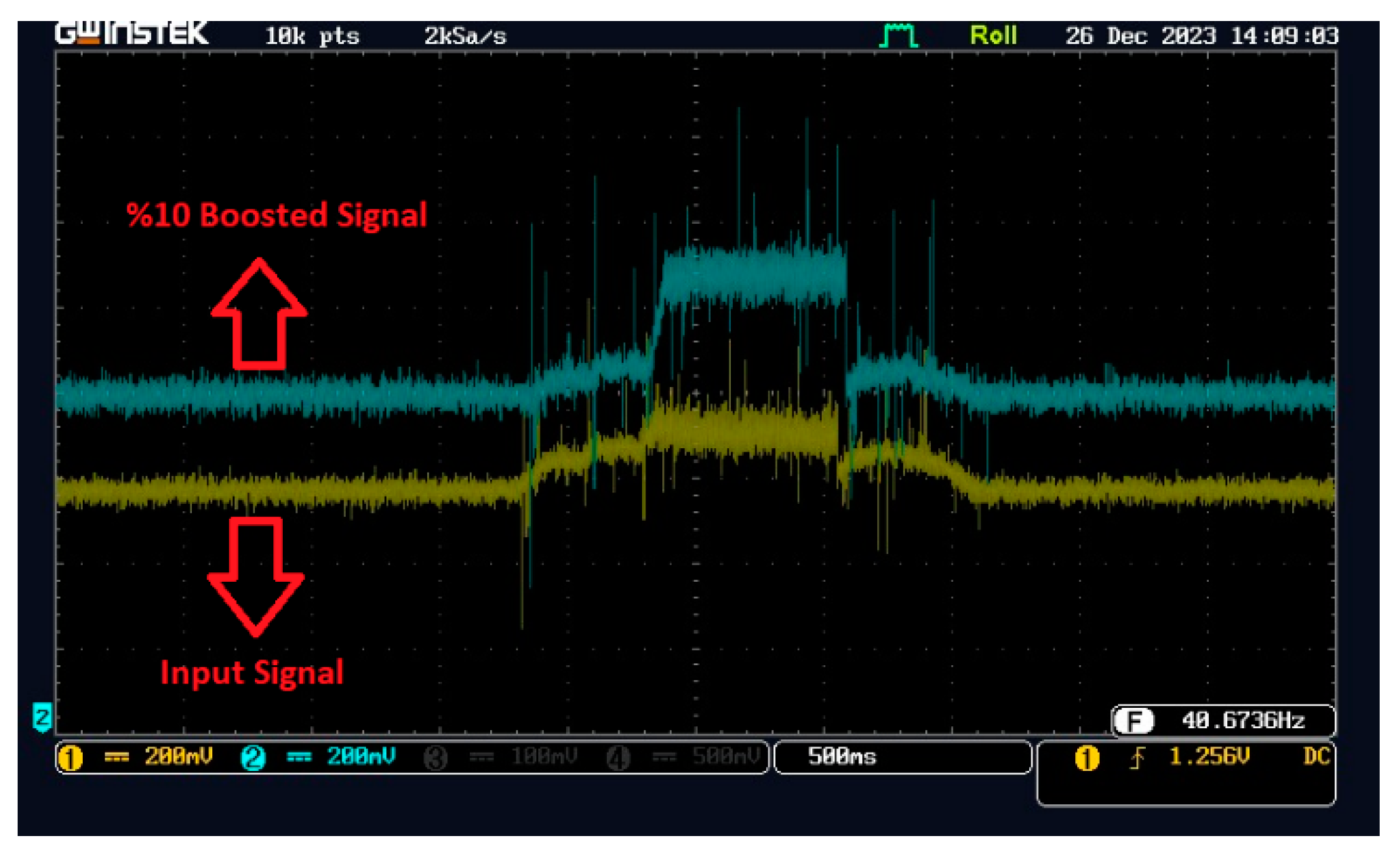

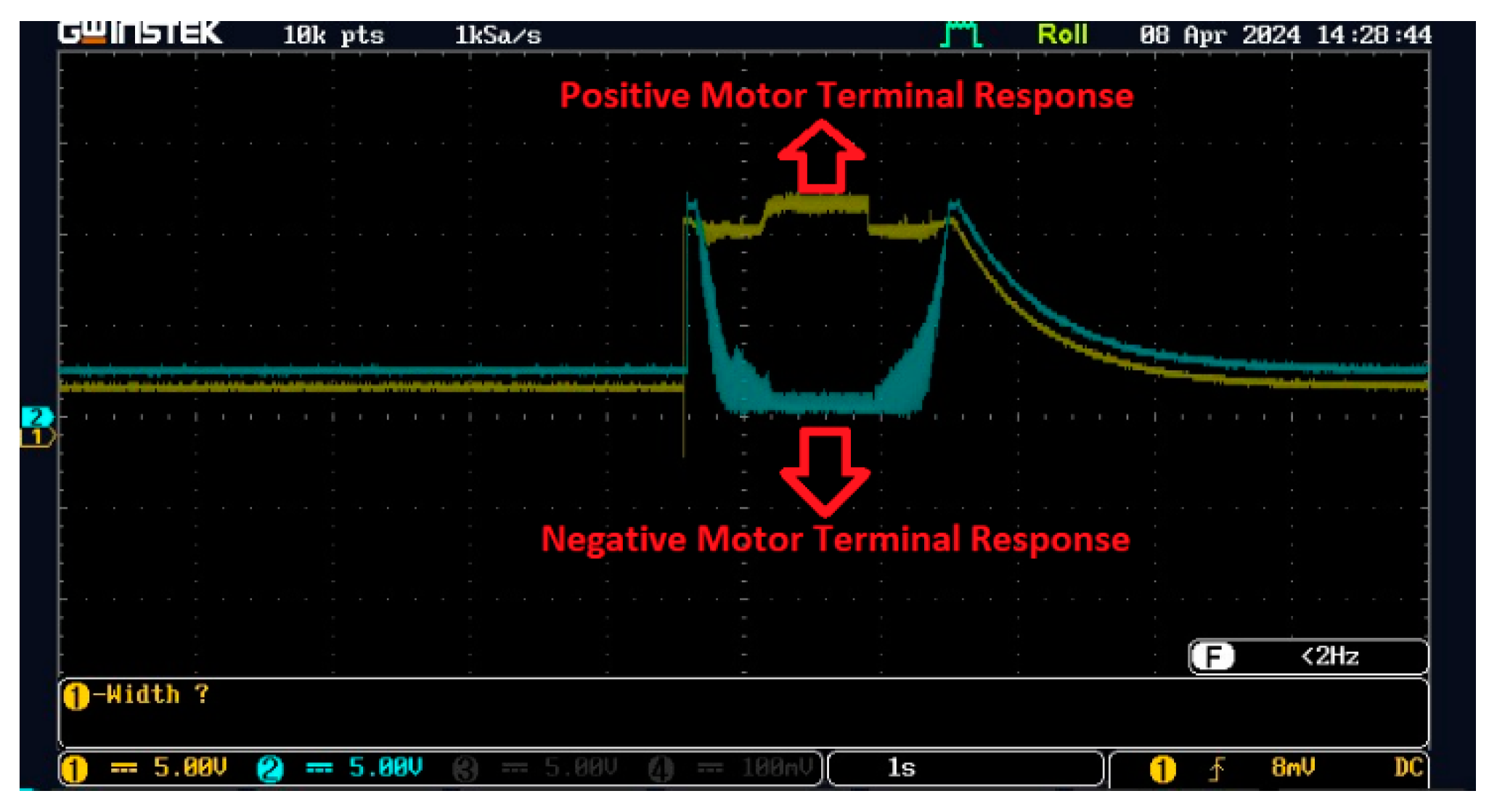

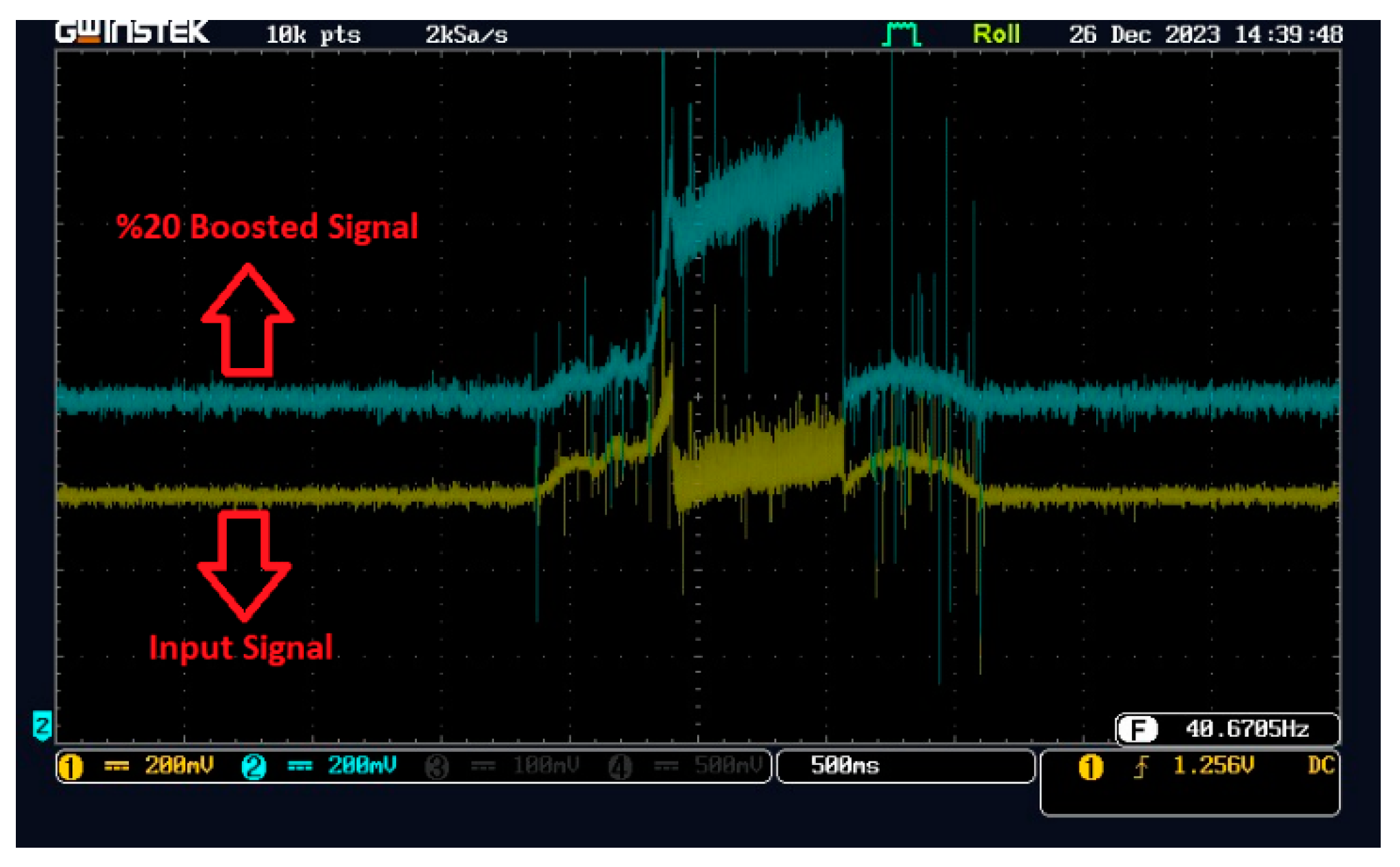

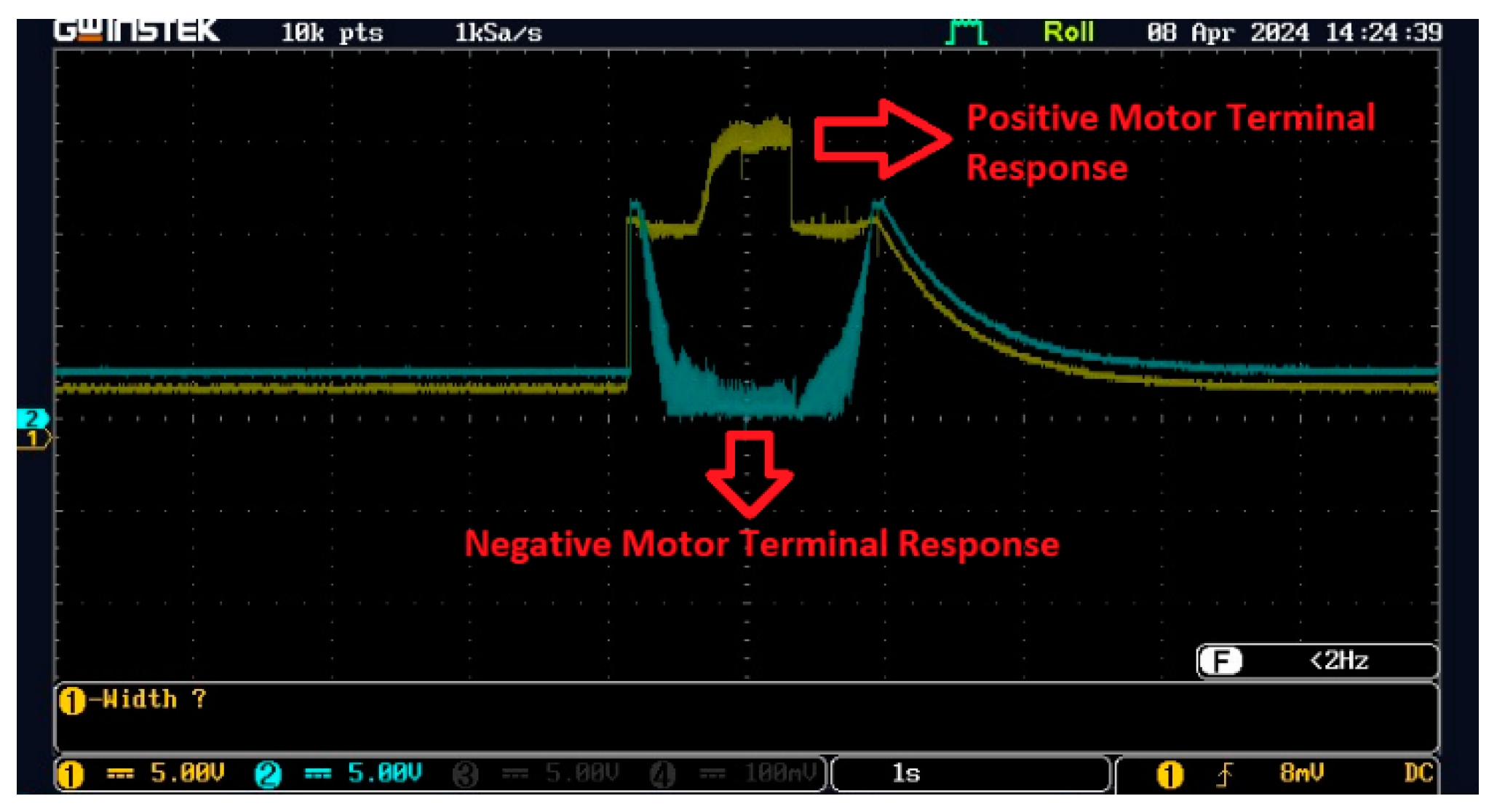

During the experiemntal tests, source current value will always be checked to keep the system power in safe range and under control. By using NTCs which are located near critical components to see temperature of the driver hardware circuit. Operation time of the system depends on voltage. If the DC link voltage of the DC-DC chopper is boosted by increasing the duty cycle of the boost converter in a limit, operation time of the repetitive motion of the electromechanical system decreases. It is observed that the operation time of the repetitive motion of the system takes 2039 ms, 1876 ms and 1824 ms while the duty cycle of the boost converter is applied as 0%, 10%, and 20%, respectively. In

Figure 12,

Figure 14 and

Figure 16 yellow signals show the input voltage while the blue signals show boosted voltage which applied to DC-DC chopper as DC link voltage. DC voltage level is seen low on the oscilloscope because of the voltage divider circuit which is designed for voltage level adaptation to voltage level of ADC of MCU. In

Figure 11,

Figure 13 and

Figure 15 yellow signal shows motor response measured on positive terminal while blue signal shows negative terminal response.

In the proposed drive system, the duty cylce of the boost converter is determined with a PI-type controller [

31] by comparing the operation time with the reference timing signal and also comparing the encoder instant value with the encoder value limits learned in the motion mapping with the ALA to ensure timing optimization. In

Table 1,

Table 2 and

Table 3, experimental results contain the supply voltage of the driver, current drawn from the source, output voltage of the boost converter, temperature of the driver, encoder value for speed measurement, and time consumption for repetitive motion of the under-door step while it is opening or closing. With the proposed brushed DC motor driver system, time dependent operation can be achieved by boosting the DC link voltage of the DC-DC chopper. It can be seen form

Table 1,

Table 2 and

Table 3 that the time consumption of one operating cycle of the under-door step defining as opening or closing the mechanical system under movement limits can be reduced and optimized regard to reference operation timing input.

Robustness of the proposed brushed DC motor drive system providing mobility to the under-door step mechanism and ALA proved by running 100.000 cycle long test which is operated approximately 20 days continuously and only a small part of the result presented in

Table 4.

5. Conclusions and Discussions

In this study, it is aimed to design a battery-fed brushed DC motor driver which capable of learning the operation conditions and movement limits adaptively. This is the most impressive feature of the proposed study. The proposed brushed DC motor driver is suitable for use in the automotive industry. For this purpose, a motor driver circuit including a cascade topology consisting of boost converter and DC-DC chopper is designed to carry the required current and voltage values for soft start, soft speed up or acceleration, and soft stop operations of the brushed DC motor. This PCB is designed according to the hardware and software requirements of the automotive standards considering the commercial potential production and tested with an serial excited DC motor with reducer developed for under-door steps of commercial and luxury vehicles.

Some states and parameters like armature current, armature voltage, repetitive operation time and hall-effect data for speed measurement of the drive system are monitored with UART communication protocol. The real-time performance tests prove the effectiveness of the proposed brushed DC motor drive system.

The proposed drive system is designed for general use and its modular structure is convenient to new developments in order to be adaptable to many different application areas in industry especially in automotive production field. Future studies will be carried out to make the proposed driver design integrated into the motor body and it is aimed to design a brushed DC motor with driver mounted inside of the body of the motor and has the feature of electomagnetic compatibility in order to use it practically in automotive production on different part productions.

6. Patents

A patent application has been done to Turkish Patent Institute for the proposed brushed DC motor drive system which includes proposed adaptive learning algorithm.

Author Contributions

Conceptualization, H.E.E., H.A and R.İ.; Data curation, H.E.E, H.A. and R.İ.; Formal analysis, R.İ. and H.A.; Funding acquisition, R.İ.; Investigation, H.A., R.İ and H.E.E.; Methodology, H.A., R.İ and H.E.E.; Project Administration, R.İ and H.A.; Resources, H.E.E., H.A. and R.İ.; Software H.E.E. and H.A.; Supervision, R.İ. and H.A.; Validation, H.E.E and H.A.; Visualization, H.E.E. and R.İ.; Writing - original draft, H.E.E.; Writing - review & editing, R.İ., H.A. and H.E.E.

Funding

This research was funded by ASSAN EMS Technologies R&D Center’s own financial sources and shared as result of Version 1.0. product of commercial and luxury vehicle DC Motor Driver project which completed in 2023.

Conflicts of Interest

The authors declare that there is no conflict of interest. During design of the PCB all the financial expenses supported by ASSAN EMS Technologies.

References

- Vidlak, M., Gorel, L., Makys, P., Stano, M.,Sensorless Speed Control of Brushed DC Motor Based at New Current Ripple Component Signal Processing. Energies, vol. 14, no. 17, pp. 5359, 2021, . [CrossRef]

- Barkas, D . A., Ioannidis, G. C., Psomopoulos, C. S., Kaminaris, S. D., Vokas, G. A. Brushed DC Motor Drives for Industrial and Automobile Applications with Emphasis on Control Techniques: A Comprehensive Review. Electronics, vol. 9, no. 6, pp. 887, 2020, . [CrossRef]

- Salmaninejad, A., Mayorga, R. V. Sensor-less Brushed DC Motor Speed Control with Intelligent Controllers. WSEAS Transactions on Systems, vol. 20, no. 6, pp. 140-148, 2021, . [CrossRef]

- Vazquez-Sanchez, E., Sottile, J., Gomez-Gil, J. A Novel Method for Sensorless Speed Detection of Brushed DC Motors. Applied Sciences, vol. 7, no. 1, pp. 14, 2017, . [CrossRef]

- Kowal, D.; Patan, M.; Paszke, W.; Romanek, A. Sequential design for model calibration in iterative learning control of DC motor. In Proceedings of the 20th International Conference on Methods and Models in Automation and Robotics (MMAR), Miedzydroje, Poland, 24–27 August 2015; pp. 794–799.

- Cupertino, F.; Pellegrino, G.; Giangrande, P.; Salvatore, L. Sensorless Position Control of Permanent-Magnet Motors With Pulsating Current Injection and Compensation of Motor End Effects. IEEE Trans. Ind. Appl., vol. 47, no. 3, pp. 1371–1379, 2011, . [CrossRef]

- Razi, R.; Monfared, M. Simple control scheme for single-phase uninterruptible power supply inverters with Kalman filter-based estimation of the output voltage. IET Power Electron., vol. 8, no. 9, pp. 1817–1824, 2015, . [CrossRef]

- Dini, P.; Saponara, S. Design of Adaptive Controller Exploiting Learning Concepts Applied to a BLDC-Based Drive System. Energies, vol. 13, no. 10, pp. 2512, 2020, . [CrossRef]

- Radcliffe, P.; Kumar, D. Sensorless speed measurement for brushed DC motors. IET Power Electron., vol. 8, no. 11, pp. 2223–2228, 2015, . [CrossRef]

- Vazquez-Sanchez, E.; Sottile, J.; Gomez-Gil, J. A Novel Method for Sensorless Speed Detection of Brushed DC Motors. Appl. Sci., vol. 7, no. 1, pp. 14, 2016, . [CrossRef]

- Vidlak, M.; Makys, P.; Stano, M. Comparison between model based and non-model based sensorless methods of brushed DC motor. Transp. Res. Procedia, vol. 55, pp. 911–918, 2021, . [CrossRef]

- Ismail, A. A. A, Elnady, A. A. Advanced Drive System for DC Motor Using Multilevel DC/DC Buck Converter Circuit. IEEE Access., vol. 7, pp. 54167–54178, 2019, . [CrossRef]

- Forouzesh, M., Siwakoti, Y. P., Gorji, S. A., Blaabjerg, F., Lehman, B. Step-Up DC–DC Converters: A Comprehensive Review of Voltage-Boosting Techniques, Topologies, and Applications. IEEE Tran. Power Electronics, vol. 32, no. 12, pp. 9143-9178, 2017, . [CrossRef]

- Raghavendra, K. V. G., Zeb, K., Muthusamy, A., Krishna, T. N. V., Prabhudeva Kumar, S. V. S. V., Kim D. H., Kim, M. S., Cho, H. G., Kim, H. J. A Comprehensive Review of DC–DC Converter Topologies and Modulation Strategies with Recent Advances in Solar Photovoltaic Systems. Electronics, vol. 9, no. 1, pp. 31, 2020, . [CrossRef]

- Safayatullah, M.D., Elrais, M. T., Ghosh, S., Rezaii, R. A Comprehensive Review of Power Converter Topologies and Control Methods for Electric Vehicle Fast Charging Applications. IEEE Access, vol. 10, pp. 40753-40793, 2022, . [CrossRef]

- Soltani, M., Mostaan, A., Siwakoti, Y. P., Davari, P., Blaabjerg, F. Family of step-up DC/DC converters with fast dynamic response for low power applications. IET Power Electron., vol. 9, no. 14, pp. 2665–2673, 2016.

- Mallik, A., Ding, W., Shi, C., Khaligh, A.. Input voltage sensorless duty compensation control for a three-phase boost PFC converter. IEEE Trans. Ind. Appl., vol. 53, no. 2, pp. 1527-1537, 2017, . [CrossRef]

- Tofoli, F. L., de Castro Pereira, D., de Paula, W. J., de Sousa Oliveira J´unior, D. Survey on non-isolated high-voltage step-up DC-DC topologies based on the boost converter. IET Power Electron., vol. 8, no. 10, pp. 2044–2057, 2015, . [CrossRef]

- Adam, A., Elnady, A., Ghias, A. A novel multilevel DC chopper supplying DC motor,. in Proc. 5th Int. Conf. Electron. Devices, Syst. Appl. (ICEDSA), Ras al Khaimah, United Arab Emirates, pp. 1-5, Dec. 2016.

- Sira-Ramírez, H., Oliver-Salazar, M. A. On the robust control of buckconverter DC-motor combinations. IEEE Trans. Power Electron., vol. 28, no. 8, pp. 3912-3922, 2013, . [CrossRef]

- Wang, Y., Wang, L., Zhao, Y. Research on Door Opening Operation of Mobile Robotic Arm Based on Reinforcement Learning. Applied Sciences, vol. 22, no. 10, pp. 5204, 2022, . [CrossRef]

- Kiru, M. U., Belaton, B., Mohamed, S. M. S., Usman, G. M., Kazaure, A. A. Intelligent Automatic Door System based on Supervised Learning. In Proceedings of the 2020 IEEE Conf. on Open Systems (ICOS); November 2020; pp. 43–47.

- Xu, S., Liu, J., Yang, C., Wu, X., Xu, T. A Learning-Based Stable Servo Control Strategy Using Broad Learning System Applied for Microrobotic Control. IEEE Tran. on Cybernetics, vol. 52, no. 12, pp. 13727-13737, 2022, . [CrossRef]

- Qiu, W., Zhao, X., Tyrrell, A., Perinpanayagam, S., Niu, S., Wen, G. Application of Artificial Intelligence-Based Technique in Electric Motors: A Review. IEEE Tran. on Power Electronics, vol. 39, no. 10, pp. 13543-13568, 2024, . [CrossRef]

- Sheng, J., Tang, Y., Xu, S., Tan, F., Hou, R., Xu, T. A Stable Learning-Based Method for Robotic Assembly With Motion and Force Measurements. IEEE Tran. on Industrial Electronics, vol. 71, no. 9, pp. 11093-11103, 2024, . [CrossRef]

- Liu, Z., Yu, X., Lin, W., Rodriguez-Andina, J. J. Iterative Learning Observer-Based High-Precision Motion Control for Repetitive Motion Tasks of Linear Motor-Driven Systems. IEEE Open Journal of the Industrial Electronics Society, vol. 5, pp. 54-66, 2024, . [CrossRef]

- Lan, J., Dong. X. Improved Q-Learning-Based Motion Control for Basketball Intelligent Robots Under Multi-Sensor Data Fusion. IEEE Access, vol. 12, pp. 57059-57070, 2024, . [CrossRef]

- Scheidel, H., Asadi, H., Bellmann, T., Seefried, A., Mohamed, S., Nahavandi, S., A Deep Reinforcement Learning Based Motion Cueing Algorithm for Vehicle Driving Simulation. IEEE Tran. on Vehicular Technology, vol. 73, no. 7, no. 9, pp. 9696-9705, 2024, . [CrossRef]

- Condit, R. Brushed DC Motor Fundamentals. 2010.

- Hart, D.W. Power Electronics; McGraw-Hill: New York, 2011; ISBN 978-0-07-338067-4.

- Liang, J., Lu, Y., Wang, F., Yin, G., Zhu, X., Lİ, Y. A Robust Dynamic Game-Based Control Framework for Integrated Torque Vectoring and Active Front-Wheel Steering System. IEEE Tran. on Intelligent Transportation Systems, vol. 24, no. 7, pp. 7328-7341, 2023, . [CrossRef]

Figure 1.

Brushed DC Motor.

Figure 1.

Brushed DC Motor.

Figure 2.

General scheme of the System.

Figure 2.

General scheme of the System.

Figure 3.

Boost Converter basic principles.

Figure 3.

Boost Converter basic principles.

Figure 4.

Movement and position learning algorithm.

Figure 4.

Movement and position learning algorithm.

Figure 5.

Working principle of the proposed drive system.

Figure 5.

Working principle of the proposed drive system.

Figure 6.

Brushed DC Motor with reducer which is used for design of the system.

Figure 6.

Brushed DC Motor with reducer which is used for design of the system.

Figure 7.

Mechanical setup of step.

Figure 7.

Mechanical setup of step.

Figure 8.

Designed motor driver PCB.

Figure 8.

Designed motor driver PCB.

Figure 9.

General view of the system while the step is operating in reverse direction.

Figure 9.

General view of the system while the step is operating in reverse direction.

Figure 10.

General view of the system while the step is operating in forward direction.

Figure 10.

General view of the system while the step is operating in forward direction.

Figure 11.

Input(yellow) and boosted(blue) voltage for %0 Boost.

Figure 11.

Input(yellow) and boosted(blue) voltage for %0 Boost.

Figure 12.

Motor response for %0 Boost.

Figure 12.

Motor response for %0 Boost.

Figure 13.

Input(yellow) and boosted(blue) voltage for %10 Boost.

Figure 13.

Input(yellow) and boosted(blue) voltage for %10 Boost.

Figure 14.

Motor response for %10 Boost.

Figure 14.

Motor response for %10 Boost.

Figure 15.

Input(yellow) and boosted(blue) voltage for %20 Boost.

Figure 15.

Input(yellow) and boosted(blue) voltage for %20 Boost.

Figure 16.

Motor response for %20 Boost.

Figure 16.

Motor response for %20 Boost.

Table 1.

The proposed driver is working while the duty cycle of the boost converter is %0.

Table 1.

The proposed driver is working while the duty cycle of the boost converter is %0.

| %0 Boost |

I |

II |

III |

IV |

| Input Voltage |

11836 mV |

11880 mV |

11880 mV |

12056 mV |

| Input Current |

4.37 A |

3.76 A |

4.02 A |

0.0 A |

| Boost Voltage |

11264 mV |

11308 mV |

11308 mV |

11748 mV |

| NTC Temperature |

26.47 |

26.47 |

26.47 |

26.47 |

| Hall-effect Count |

71 |

100 |

184 |

302 |

| Operation Time |

-- |

-- |

-- |

2039 ms |

Table 2.

The proposed driver is working while the duty cycle of the boost converter is %10.

Table 2.

The proposed driver is working while the duty cycle of the boost converter is %10.

| %10 Boost |

I |

II |

III |

IV |

| Input Voltage |

11792 mV |

11660 mV |

12056 mV |

12056 mV |

| Input Current |

6.1 A |

5.28 A |

0.0 A |

0.0 A |

| Boost Voltage |

12804 mV |

13068 mV |

11748mV |

11748 mV |

| NTC Temperature |

27.07 |

27.37 |

27.37 |

27.07 |

| Hall-effect Count |

75 |

116 |

300 |

309 |

| Operation Time |

-- |

-- |

-- |

1876 ms |

Table 3.

The proposed driver is working while the duty cycle of the boost converter is %20.

Table 3.

The proposed driver is working while the duty cycle of the boost converter is %20.

| %20 Boost |

I |

II |

III |

IV |

| Input Voltage |

12056 mV |

9856 mV |

9944 mV |

12056 mV |

| Input Current |

0.0 A |

7.31 A |

7.31 A |

0.0 A |

| Boost Voltage |

11748 mV |

13288 mV |

13816 mV |

11748 mV |

| NTC Temperature |

26.77 |

26.77 |

29.22 |

26.77 |

| Hall-effect Count |

6 |

76 |

114 |

311 |

| Operation Time |

-- |

-- |

-- |

1824 ms |

Table 4.

A small part of 100.000 cycle test for proposed motor driver pcb and result of each 10.000 cycle.

Table 4.

A small part of 100.000 cycle test for proposed motor driver pcb and result of each 10.000 cycle.

| Cycle |

Current |

NTC

Temperature |

Time |

Input

Voltage |

| 10.000 (Forward) |

3.34 A |

48.8 |

1.82 s |

11.48 V |

| 10.000 (Backward) |

3.19 A |

48.8 |

1.91 s |

11.62 V |

| 20.000 (Forward) |

2.26 A |

38.14 |

1.56 s |

11.84 V |

| 20.000 (Backward) |

2.17 A |

38.14 |

1,63 s |

11.88 V |

30.000 (Forward)

30.000 (Backward)

40.000 (Forward)

40.000 (Backward)

|

2.1 A

2.1 A

2.57 A

2.38 A |

39.59

39.59

40.32

40.32 |

1.58 s

1.62 s

1.52 s

1.52 s |

11.79 V

11.92 V

11.84 V

11.88 V |

50.000 (Forward)

50.000 (Backward)

|

2.44 A

2.16 A |

38.14

38.14 |

1.58 s

1.57 s |

11.84 V

11.75 V |

60.000 (Forward)

60.000 (Backward)

70.000 (Forward)

70.000 (Backward)

|

2.62 A

2.27 A

2.46 A

2.18 A |

39.22

39.59

38.86

38.86 |

1.6 s

1.59 s

1.58 s

1.59 s |

11.84 V

11.88 V

11.79 V

11.84 V |

80.000 (Forward)

80.000 (Backward)

90.000 (Forward)

90.000 (Backward)

100.000 (Forward)

100.000 (Backward)

|

2.4 A

2.21 A

2.65 A

2.33 A

2.98 A

2.46 A |

40.69

40.32

41.43

41.43

37.78

37.78 |

1.58 s

1.6 s

1.58 s

1.61 s

1.68 s

1.66 s |

11.79 V

11.84 V

11.79 V

11.88 V

11.75 V

11.75 V |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).