Submitted:

25 October 2024

Posted:

25 October 2024

You are already at the latest version

Abstract

Keywords:

1. Introduction

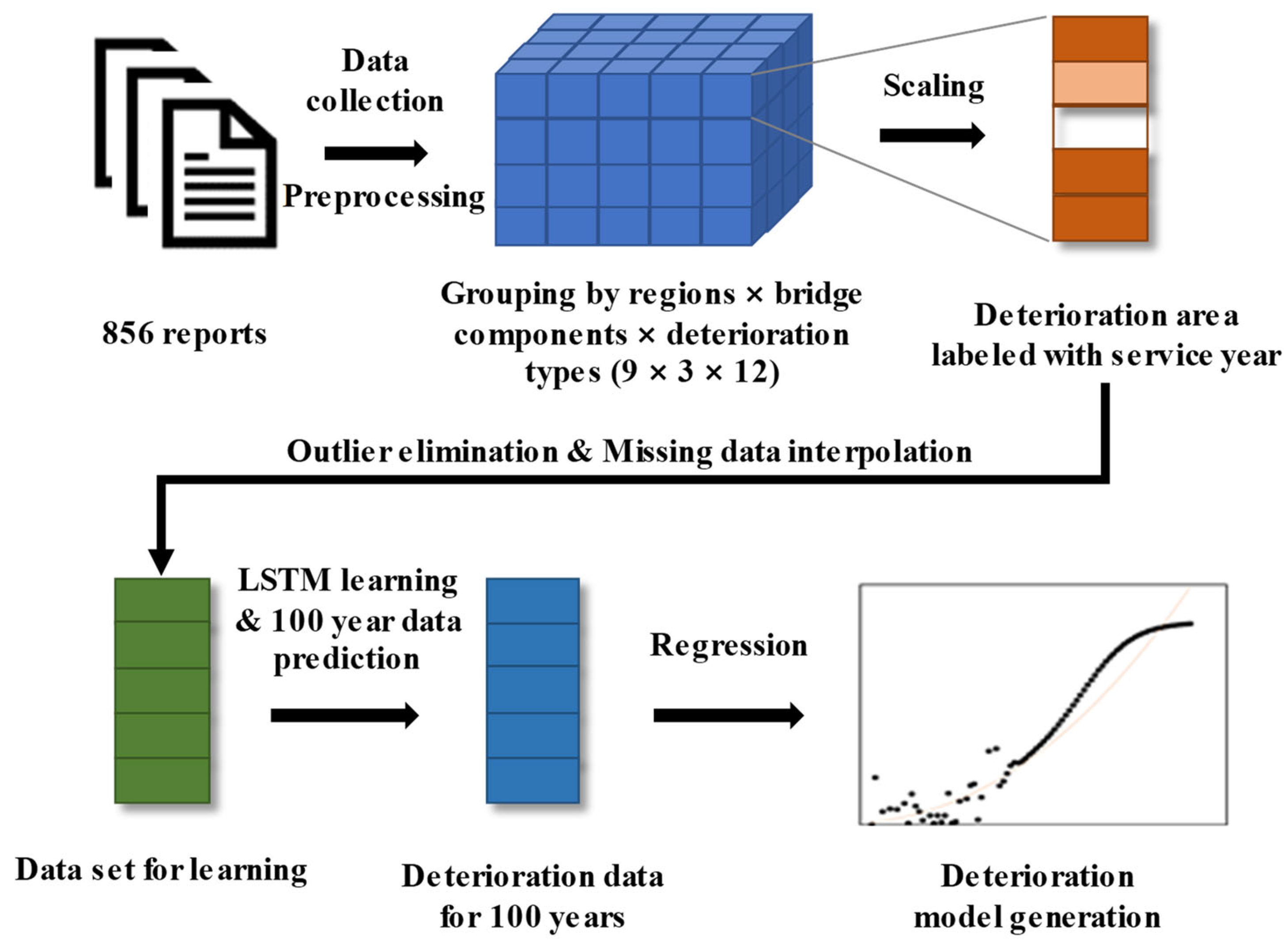

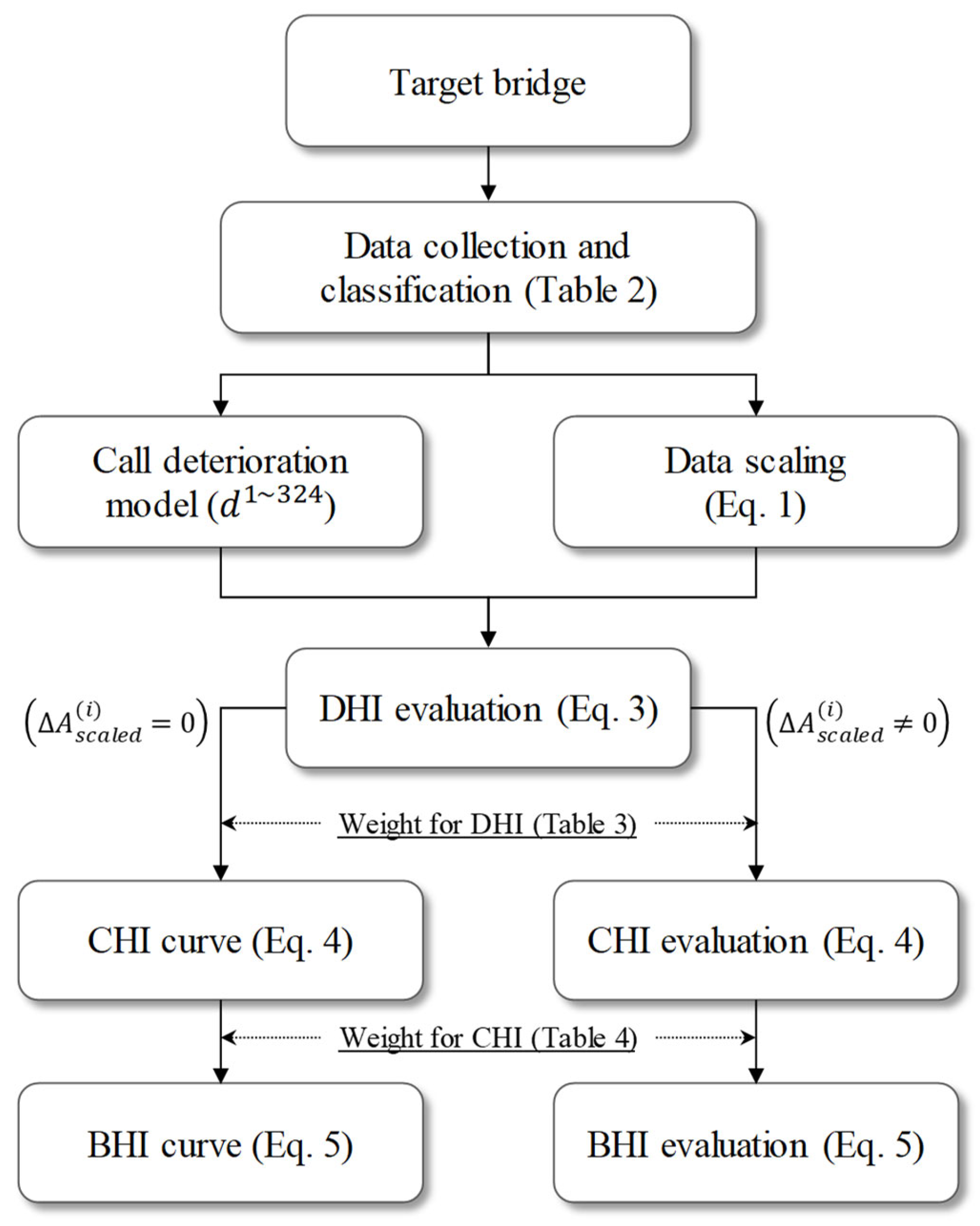

2. Materials and Methods

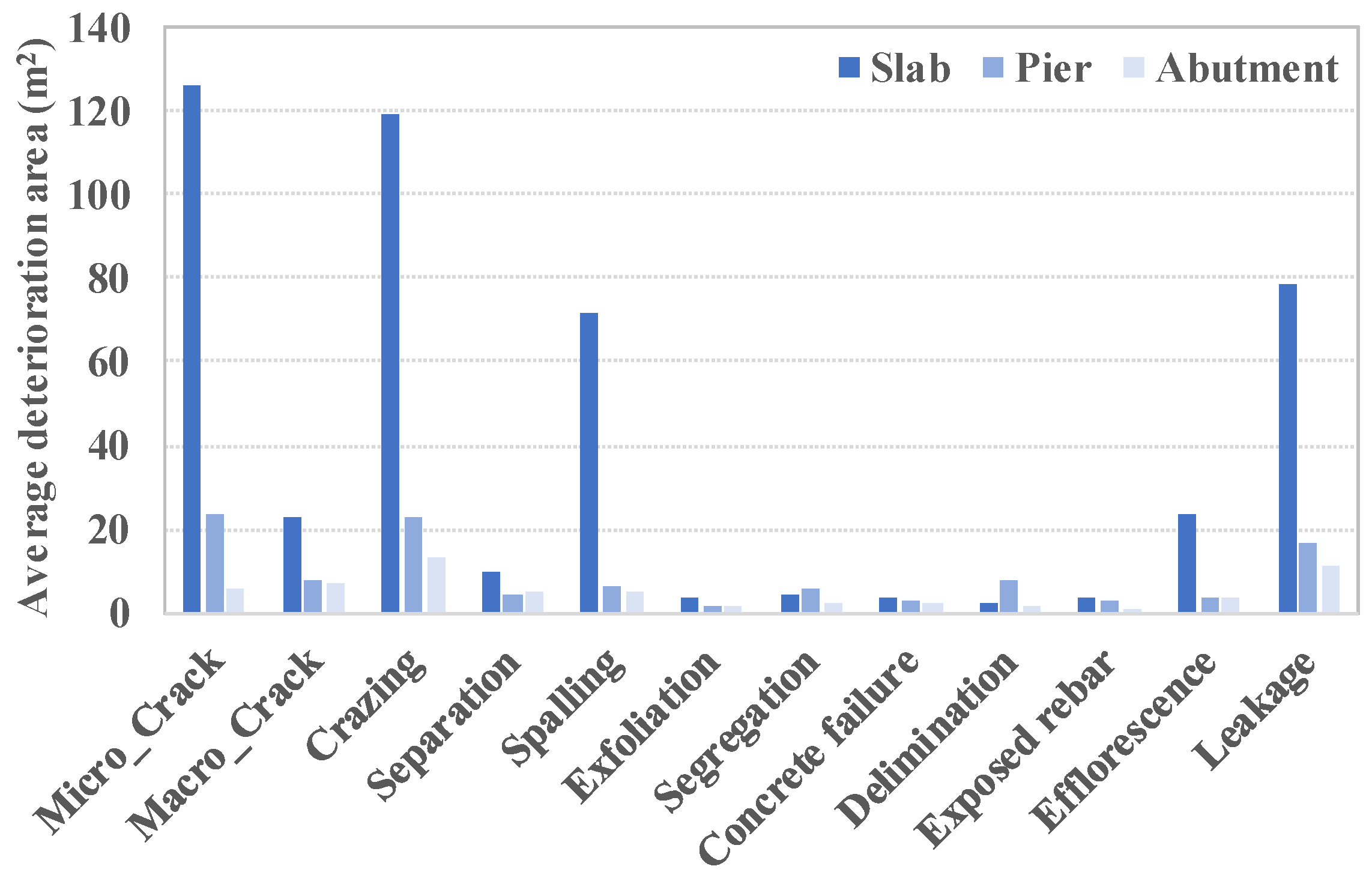

2.1. Data Collection

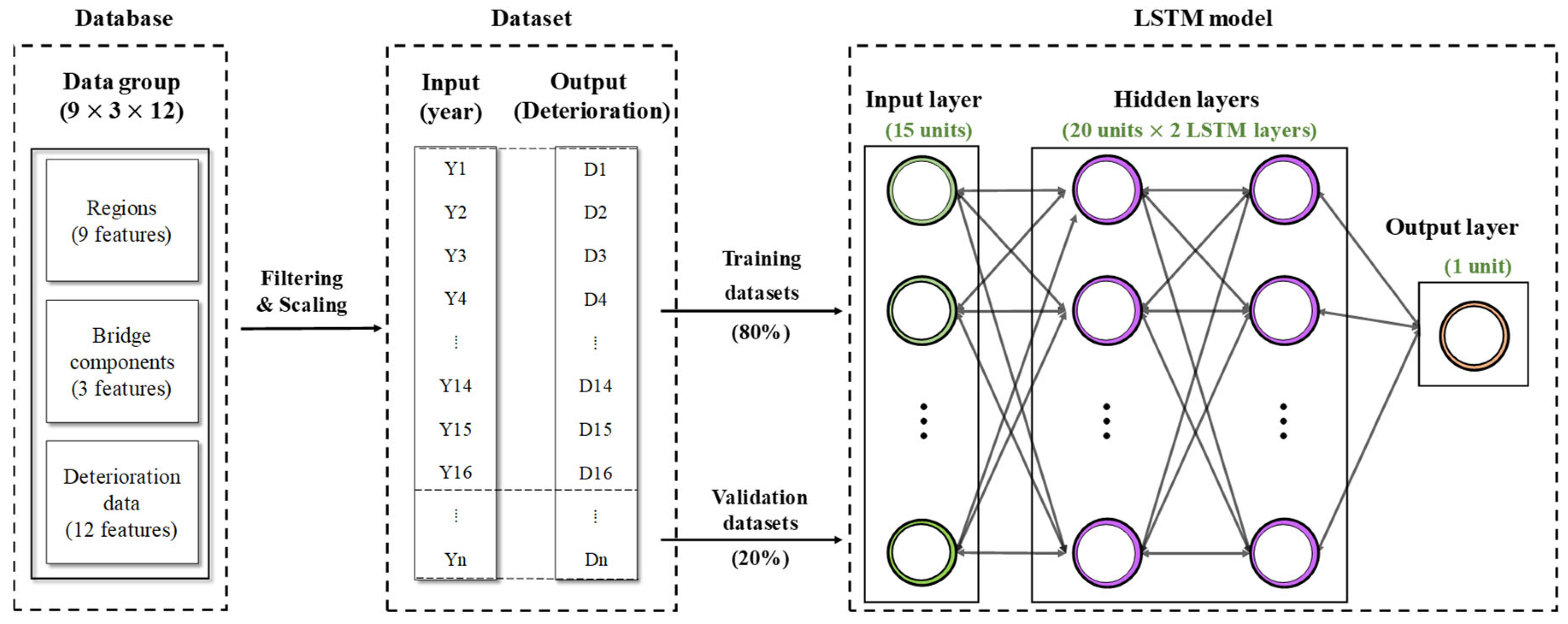

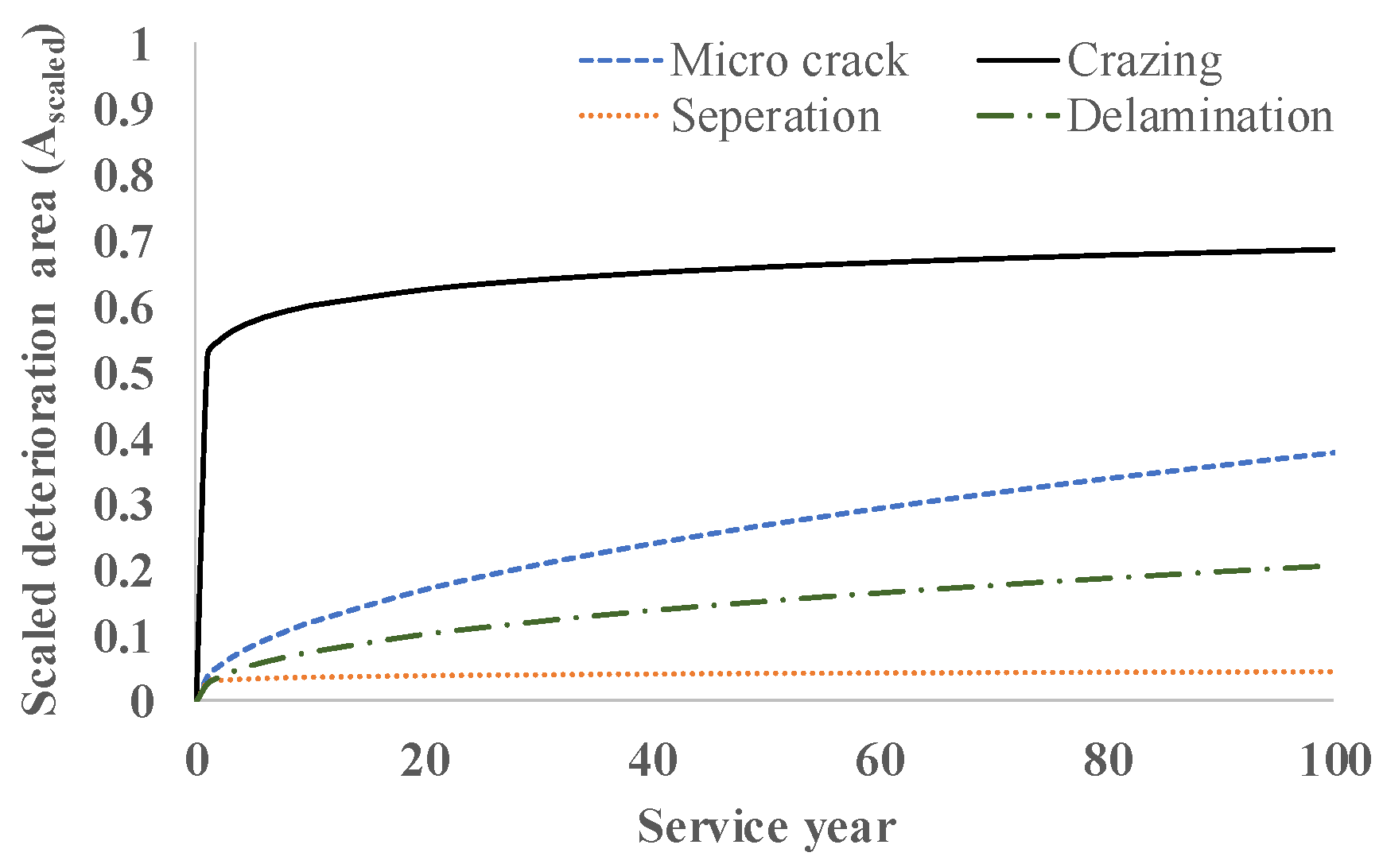

2.2. LSTM-Driven Deterioration Model

2.3. Bridge Assessments Using Health Index

2.3.1. Deterioration-Level HI (DHI)

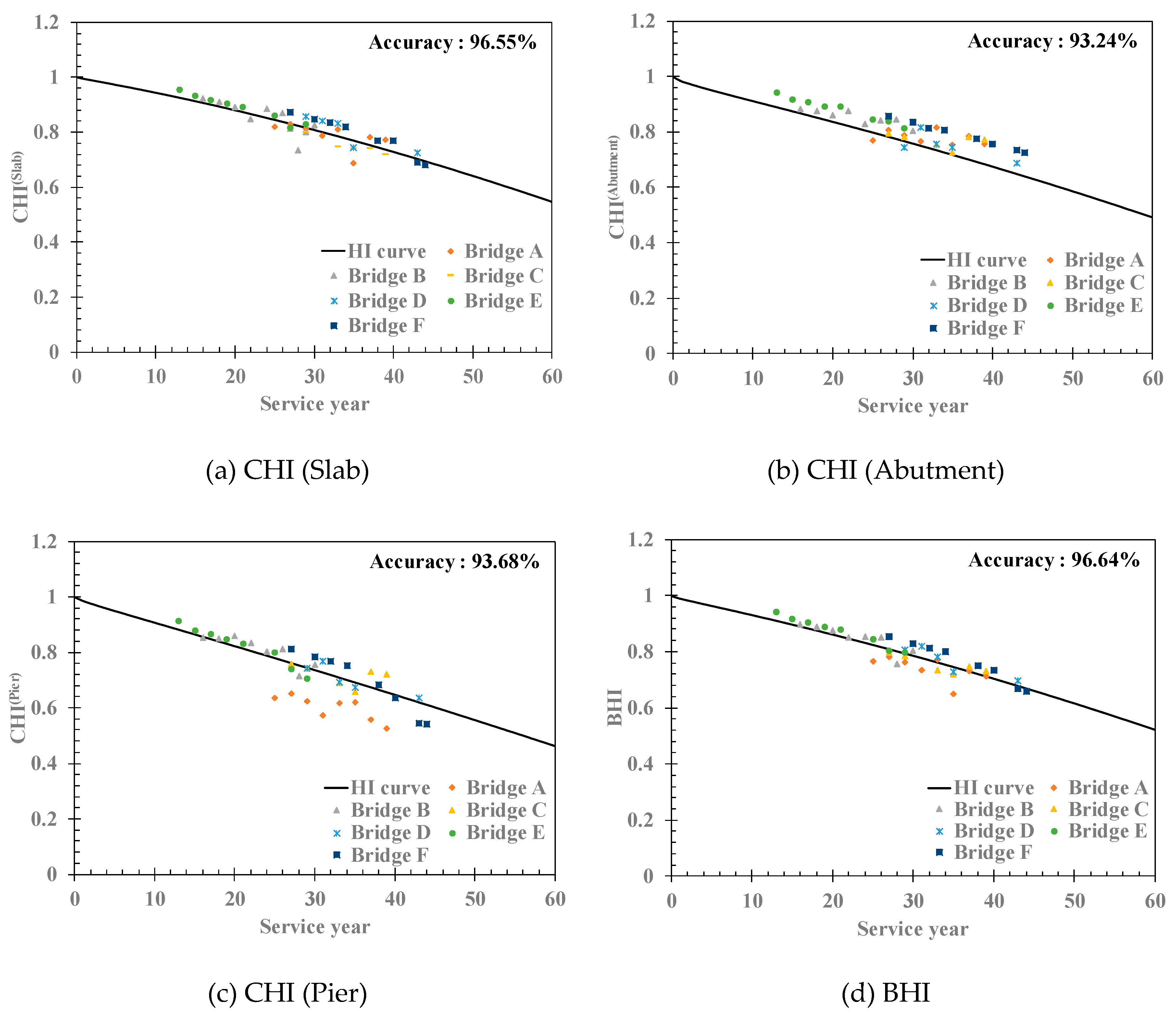

2.3.2. Component-Level HI (CHI)

2.3.3. Bridge-Level HI (BHI)

2.4. Case Study

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Korea Authority of Land and Infrastructure Safety (KALIS). Detailed Guideline for Safety and Maintenance Implementation of Facilities (Performance Evaluation); Korea Authority of Land and Infrastructure Safety (KALIS): Jinju, 2021. Available online: https://www.kalis.or.kr/www/brd/m_27/view.do?seq=117&srchFr=&srchTo=&srchWord=&srchTp=&itm_seq_1=0&itm_seq_2=0&multi_itm_seq=0&company_cd=&company_nm=.

- American Association of State Highway and Transportation Officials (AASHTO). Manual for Bridge Evaluation with 2020 Interim Revisions; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, 2018. Available online: https://store.transportation.org/Item/CollectionDetail?ID=179.

- Highways England. CS 454 Assessment of highway bridges and structures; Highways England: London, 2022. Available online: https://www.standardsforhighways.co.uk/dmrb/search/96569268-6c26-4263-a1f7-bc09a9e3977f.

- Korea Authority of Land and Infrastructure Safety, (KALIS). Detailed Guideline for Safety and Maintenance Implementation of Facilities (Safety Inspection and Diagnosis); Korea Authority of Land and Infrastructure Safety (KALIS): Jinju, 2021. Available online: https://www.kalis.or.kr/www/brd/m_27/view.do?seq=117&srchFr=&srchTo=&srchWord=&srchTp=&itm_seq_1=0&itm_seq_2=0&multi_itm_seq=0&company_cd=&company_nm=.

- Ritto, T. G. , & Rochinha, F. A. Digital twin, physics-based model, and machine learning applied to damage detection in structures. Mechanical Systems and Signal Processing 2021, 155. [Google Scholar] [CrossRef]

- Mahmoodian, M. , Shahrivar, F., Setunge, S., & Mazaheri, S. Development of Digital Twin for Intelligent Maintenance of Civil Infrastructure. Development of Digital Twin for Intelligent Maintenance of Civil Infrastructure. Sustainability 2022, 14. [Google Scholar] [CrossRef]

- Errandonea, I., Beltrán. Digital Twin for maintenance: A literature review. Computers in Industry 2020. [Google Scholar] [CrossRef]

- Opoku, D. G. J., Perera. Digital twin application in the construction industry: A literature review. Journal of Building Engineering 2021. [Google Scholar] [CrossRef]

- Jeon, C. H. , Shim, C. S., Lee, Y. H., & Schooling, J. Prescriptive maintenance of prestressed concrete bridges considering digital twin and key performance indicator. Engineering Structures 2024, 117383, 117383. [Google Scholar] [CrossRef]

- Huang, Y.-H. Artificial Neural Network Model of Bridge Deterioration. Journal of Performance of Constructed Facilities 2010, 24, 597–602. [Google Scholar] [CrossRef]

- Ali, G. , Elsayegh, A. , Assaad, R., El-Adaway, I. H., & Abotaleb, I. S. Artificial neural network model for bridge deterioration and assessment. In Proceedings of Canadian Society for Civil Engineering, June 2019. [Google Scholar]

- Assaad, R., & El-adaway. Bridge Infrastructure Asset Management System: Comparative Computational Machine Learning Approach for Evaluating and Predicting Deck Deterioration Conditions. Journal of Infrastructure Systems 2020, 26, 1–17. [Google Scholar] [CrossRef]

- Liu, H. , & Zhang, Y. Bridge condition rating data modeling using deep learning algorithm. Structure and Infrastructure Engineering, 2020, 16, 1447–1460. [Google Scholar] [CrossRef]

- Kumar, A. , Singla, S., Kumar, A., Bansal, A., & Kaur, A.. Efficient Prediction of Bridge Conditions Using Modified Convolutional Neural Network. Wireless Personal Communications 2022, 125, 29–43. [Google Scholar] [CrossRef]

- Fiorillo, G. , & Nassif, H. Improving the conversion accuracy between bridge element conditions and NBI ratings using deep convolutional neural networks. Structure and Infrastructure Engineering, 2020, 16, 1669–1682. [Google Scholar] [CrossRef]

- Zhu, J. , & Wang, Y. Feature Selection and Deep Learning for Deterioration Prediction of the Bridges. Journal of Performance of Constructed Facilities 2021, 35. [Google Scholar] [CrossRef]

- Choi, Y. , & Kong, J. Development of Data-based Hierarchical Learning Model for Predicting Condition Rating of Bridge Members over Time. KSCE Journal of Civil Engineering 2023, 27, 4406–4426. [Google Scholar] [CrossRef]

- Saremi, S. G. , Goulias, D., & Zhao, Y. Alternative Sequence Classification of Neural Networks for Bridge Deck Condition Rating. Journal of Performance of Constructed Facilities 2023, 37, 1–15. [Google Scholar] [CrossRef]

- Miao, P. , Yokota, H., & Zhang, Y. Deterioration prediction of existing concrete bridges using a LSTM recurrent neural network. Structure and Infrastructure Engineering 2023, 19, 475–489. [Google Scholar] [CrossRef]

- Xia, Y. , Lei, X., Wang, P., & Sun, L. A data-driven approach for regional bridge condition assessment using inspection reports. Structural Control and Health Monitoring 2022, 29, 1–18. [Google Scholar] [CrossRef]

- Federal Highway Administration (FHWA). Recording and coding guide for the structure inventory and appraisal ofthe nation’s bridges; FHWA: Washington, DC, 1995. [Google Scholar]

- Highways Agency. DMRB Volume 3Section 1Part 4 (BD 63/07) Highway structures: Inspection and maintenance. 1 Part 4 (BD 63/07) Highway structures: Inspection and maintenance. 2007. Available online: https, 2007. Available online: https://www.thenbs.com/PublicationIndex/documents/details?Pub=HA&DocId=281590.

- Hsien-Ke, L., Jallow. Comparison of bridge inspection methodologies and evaluation criteria in Taiwan and foreign practices. In Proceedings of the 34th International Symposium on Automation and Robotics in Construction; 2017; pp. 317–324. [Google Scholar] [CrossRef]

- Roads, N. P., & Administration. Handbook for Bridge Inspections. online: https, 2005. Available online: https://www.tsp2.org/library-tsp2/uploads/48/Handbook_of_Bridge_Inspections_Part_1.pdf.

- Chase, S. B., Adu-Gyamfi. Synthesis of National and International Methodologies Used for Bridge Health Indices. Federal Highway Administration. 1508. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/structures/bridge/15081/index.cfm.

- Kwon, T. H. , Kim, J., Park, K. T., & Jung, K. S. Long Short-Term Memory-Based Methodology for Predicting Carbonation Models of Reinforced Concrete Slab Bridges: Case Study in South Korea. Applied Sciences 2022, 12. [Google Scholar] [CrossRef]

- Fang, J. , Ishida, T., Fathalla, E., & Tsuchiya, S. Full-scale fatigue simulation of the deterioration mechanism of reinforced concrete road bridge slabs under dry and wet conditions. Engineering Structures 2021, 245, 112988. [Google Scholar] [CrossRef]

| Country | Condition rating | Description |

|---|---|---|

| U.S. | 0–9 | 9: excellent, 0: fail |

| Denmark | 0–5 | 0: insignificant deterioration, 5: no longer functional |

| Sweden | 0–3 | 0: repair after 10 years, 3: repairs required now |

| Germany | 0–4 | 0: defect has no effect, 4: structural strength is lost |

| Norway | 1–4 | 1: minor damage, 4: critical damage |

| Japan | 1–4 | 1: emergency action required, 4: healthy |

| England | 1–5 (Severity) | 1: no significant defects, 5: non-functional/fail |

| A–E (Extent) | A: no significant defects, E: >50% surface area affected | |

| China | 1–5 | 1: excellent, 5: fail |

| South Korea | A–E | A: excellent, E: fail |

| Target components |

Region | Type of deterioration data (measured by area, m2) |

Bridge features |

|---|---|---|---|

| Slab Pier Abutment |

Region A Region B Region C Region D Region E Region F Region G Region H Region I |

Micro-crack (width < 0.03 mm) Macro-crack (width ≥ 0.03 mm) Crazing (two-way crack) Separation Spalling Exfoliation Segregation Concrete failure Delamination Efflorescence Leakage Exposed rebar |

Height Width Length Service year |

| Deterioration type | Deterioration weight | Module | Module weight |

|---|---|---|---|

| Microcrack | 0.25 | Cracking defects | 0.3 |

| Macrocrack | 0.375 | ||

| Crazing | 0.375 | ||

| Separation | 0.167 | Materials defects | 0.15 |

| Spalling | 0.167 | ||

| Concrete failure | 0.167 | ||

| Exfoliation | 0.167 | ||

| Segregation | 0.167 | ||

| Delamination | 0.167 | ||

| Efflorescence | 0.5 | Other types of defects | 0.15 |

| Leakage | 0.5 | ||

| Exposed rebar | 1 | Corrosion defect | 0.4 |

| Bridge component | Weight |

|---|---|

| Slab | 0.64 |

| Pier | 0.18 |

| Abutment | 0.18 |

| Name | Construction year | No. of inspection reports | Width (m) |

Length (m) | Height (m) |

|---|---|---|---|---|---|

| Bridge A | 1978 | 8 | 30 | 34 | 6 |

| Bridge B | 1988 | 8 | 26 | 59 | 5 |

| Bridge C | 1987 | 7 | 40 | 31 | 4 |

| Bridge D | 1972 | 6 | 25 | 48 | 4 |

| Bridge E | 1981 | 6 | 30 | 47 | 4 |

| Bridge F | 1989 | 8 | 30 | 40 | 5 |

| Bridge | Service year | Component | Microcracks | Macrocracks | Crazing | Material defects |

Efflorescence | Leakage | Rebar exposure |

|---|---|---|---|---|---|---|---|---|---|

| A | 25 | Slab | 0.00 | 0.00 | 0.00 | 0.03 | 31.75 | 0.00 | 1.00 |

| Abutment | 0.00 | 0.00 | 0.00 | 0.10 | 27.00 | 14.91 | 0.20 | ||

| Pier | 5.90 | 0.90 | 0.00 | 15.84 | 0.00 | 11.80 | 0.00 | ||

| 27 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.10 | 1.74 | 16.20 | 0.00 | ||

| Pier | 0.30 | 0.60 | 0.00 | 0.60 | 0.10 | 0.00 | 0.00 | ||

| 29 | Slab | 0.00 | 0.00 | 1.00 | 0.00 | 0.00 | 15.59 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.10 | 3.61 | 0.00 | 0.00 | ||

| Pier | 0.30 | 0.60 | 0.00 | 0.01 | 0.00 | 0.00 | 0.00 | ||

| 31 | Slab | 0.00 | 0.00 | 0.00 | 3.00 | 11.56 | 1.00 | 0.00 | |

| Abutment | 1.50 | 6.60 | 0.00 | 0.35 | 2.13 | 4.38 | 0.00 | ||

| Pier | 1.50 | 6.60 | 0.00 | 6.76 | 2.13 | 4.38 | 0.00 | ||

| 33 | Slab | 0.40 | 0.00 | 0.00 | 2.80 | 3.96 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 1.21 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 3.32 | 0.00 | 0.00 | 0.00 | ||

| 35 | Slab | 0.40 | 5.87 | 0.00 | 0.00 | 0.00 | 0.00 | 0.32 | |

| Abutment | 31.00 | 0.00 | 0.00 | 0.35 | 1.46 | 1.50 | 0.00 | ||

| Pier | 5.80 | 2.00 | 0.00 | 18.31 | 0.00 | 0.00 | 0.00 | ||

| 37 | Slab | 0.40 | 0.00 | 0.00 | 0.00 | 3.94 | 0.00 | 0.30 | |

| Abutment | 16.15 | 0.00 | 0.40 | 0.35 | 3.00 | 0.75 | 0.00 | ||

| Pier | 16.15 | 0.00 | 0.40 | 4.95 | 3.00 | 0.75 | 0.00 | ||

| 39 | Slab | 0.00 | 0.00 | 0.00 | 19.02 | 14.45 | 0.00 | 0.80 | |

| Abutment | 17.90 | 0.50 | 0.40 | 15.95 | 1.00 | 0.75 | 0.00 | ||

| Pier | 17.90 | 0.50 | 0.40 | 17.35 | 1.00 | 0.75 | 0.00 | ||

| B | 16 | Slab | 49.70 | 44.10 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Abutment | 5.24 | 10.88 | 0.00 | 0.00 | 0.05 | 0.36 | 3.06 | ||

| Pier | 7.86 | 16.32 | 0.00 | 5.21 | 0.08 | 0.54 | 4.60 | ||

| 18 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 20 | Slab | 45.40 | 5.40 | 0.00 | 2.12 | 41.17 | 0.00 | 0.00 | |

| Abutment | 4.28 | 2.64 | 0.00 | 2.79 | 0.05 | 1.80 | 0.00 | ||

| Pier | 6.42 | 3.96 | 0.00 | 6.97 | 0.08 | 2.70 | 0.00 | ||

| 22 | Slab | 326.20 | 511.20 | 0.00 | 2.12 | 41.17 | 0.00 | 0.00 | |

| Abutment | 4.28 | 2.64 | 0.20 | 5.58 | 0.05 | 1.80 | 0.00 | ||

| Pier | 6.42 | 3.96 | 0.30 | 6.97 | 0.08 | 2.70 | 0.00 | ||

| 24 | Slab | 32.40 | 0.00 | 0.00 | 2.45 | 0.02 | 0.00 | 0.00 | |

| Abutment | 19.70 | 6.90 | 0.00 | 5.59 | 0.00 | 2.70 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 4.24 | 0.00 | 0.00 | 3.96 | ||

| 26 | Slab | 2.53 | 0.00 | 0.00 | 3.59 | 2.80 | 0.00 | 0.00 | |

| Abutment | 6.50 | 5.90 | 0.00 | 6.09 | 0.00 | 2.88 | 0.00 | ||

| Pier | 6.50 | 2.50 | 0.00 | 4.61 | 0.00 | 0.00 | 4.00 | ||

| 28 | Slab | 35.80 | 0.00 | 1.50 | 82.19 | 0.01 | 0.00 | 0.00 | |

| Abutment | 10.50 | 5.20 | 1.40 | 10.01 | 0.00 | 3.24 | 0.00 | ||

| Pier | 13.70 | 0.00 | 0.00 | 4.42 | 0.00 | 0.00 | 1.00 | ||

| 30 | Slab | 24.50 | 0.00 | 31.50 | 32.48 | 0.08 | 0.00 | 0.00 | |

| Abutment | 35.70 | 12.70 | 1.40 | 10.12 | 0.06 | 2.20 | 0.00 | ||

| Pier | 55.80 | 0.00 | 0.00 | 1.75 | 0.00 | 0.00 | 0.00 | ||

| C | 27 | Slab | 0.00 | 0.00 | 0.00 | 7.10 | 6.00 | 0.00 | 0.00 |

| Abutment | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 60.00 | 0.25 | ||

| Pier | 0.00 | 0.00 | 0.00 | 3.00 | 0.00 | 3.00 | 0.00 | ||

| 29 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 6.30 | 0.00 | 0.30 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.00 | 10.50 | 21.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 31 | Slab | 15.00 | 0.00 | 71.00 | 0.00 | 7.30 | 0.00 | 0.51 | |

| Abutment | 3.50 | 10.10 | 0.00 | 3.71 | 0.25 | 27.88 | 0.00 | ||

| Pier | 3.50 | 10.10 | 0.00 | 31.83 | 0.25 | 27.88 | 0.00 | ||

| 33 | Slab | 4.00 | 0.00 | 70.00 | 0.00 | 9.00 | 0.00 | 3.63 | |

| Abutment | 6.00 | 0.00 | 0.03 | 1.72 | 0.00 | 6.00 | 0.00 | ||

| Pier | 2.00 | 0.00 | 0.39 | 7.59 | 0.00 | 6.00 | 0.00 | ||

| 35 | Slab | 0.00 | 70.00 | 0.00 | 0.00 | 0.00 | 0.00 | 6.51 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.30 | 7.00 | 49.40 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 9.29 | 3.70 | 0.00 | 5.00 | ||

| 37 | Slab | 0.00 | 1.00 | 0.00 | 0.10 | 21.50 | 5.11 | 0.00 | |

| Abutment | 0.00 | 4.00 | 0.00 | 2.61 | 7.00 | 58.40 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 19.95 | 0.20 | 7.50 | 0.00 | ||

| 39 | Slab | 8.00 | 0.00 | 41.60 | 46.01 | 0.00 | 0.00 | 0.00 | |

| Abutment | 3.00 | 0.00 | 0.00 | 0.45 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 29 | Slab | 0.00 | 2.50 | 0.00 | 0.00 | 0.00 | 1.25 | 0.00 | |

| Abutment | 0.60 | 0.00 | 0.00 | 0.08 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 4.77 | 0.00 | 4.60 | 0.00 | ||

| D | 31 | Slab | 3.00 | 3.50 | 21.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Abutment | 1.80 | 0.00 | 0.00 | 30.80 | 0.60 | 0.00 | 0.00 | ||

| Pier | 0.00 | 1.00 | 0.00 | 62.61 | 0.00 | 0.00 | 0.00 | ||

| 33 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 5.57 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 11.14 | 0.00 | 0.00 | 0.00 | ||

| 35 | Slab | 0.00 | 0.00 | 8.00 | 0.00 | 0.00 | 0.00 | 27.40 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.52 | 0.00 | 10.80 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 22.65 | 0.00 | 21.60 | 0.00 | ||

| 43 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 28.89 | 0.00 | 2.50 | |

| Abutment | 0.00 | 0.33 | 0.00 | 2.40 | 3.73 | 0.00 | 0.67 | ||

| Pier | 0.00 | 0.67 | 0.00 | 13.63 | 7.47 | 0.00 | 1.33 | ||

| 45 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 67.29 | 0.00 | 4.15 | |

| Abutment | 0.00 | 0.00 | 2.00 | 0.18 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 58.96 | 11.68 | 6.00 | 5.48 | ||

| 26 | Slab | 2.53 | 0.00 | 0.00 | 3.59 | 2.80 | 0.00 | 0.00 | |

| Abutment | 6.50 | 5.90 | 0.00 | 6.09 | 0.00 | 2.88 | 0.00 | ||

| Pier | 6.50 | 2.50 | 0.00 | 4.61 | 0.00 | 0.00 | 4.00 | ||

| 28 | Slab | 35.80 | 0.00 | 1.50 | 82.19 | 0.01 | 0.00 | 0.00 | |

| Abutment | 10.50 | 5.20 | 1.40 | 10.01 | 0.00 | 3.24 | 0.00 | ||

| Pier | 13.70 | 0.00 | 0.00 | 4.42 | 0.00 | 0.00 | 1.00 | ||

| 30 | Slab | 24.50 | 0.00 | 31.50 | 32.48 | 0.08 | 0.00 | 0.00 | |

| Abutment | 35.70 | 12.70 | 1.40 | 10.12 | 0.06 | 2.20 | 0.00 | ||

| Pier | 55.80 | 0.00 | 0.00 | 1.75 | 0.00 | 0.00 | 0.00 | ||

| E | 22 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 4.00 | 0.00 | 0.00 |

| Abutment | 2.50 | 0.00 | 0.00 | 0.16 | 15.80 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 25 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.16 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | ||

| 27 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 1.00 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.24 | 0.00 | 0.92 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 2.00 | 0.00 | 1.83 | 0.00 | ||

| 29 | Slab | 0.00 | 0.00 | 0.00 | 0.00 | 4.40 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.84 | 0.00 | 1.67 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 4.53 | 0.00 | 3.33 | 0.00 | ||

| 35 | Slab | 0.00 | 0.00 | 0.00 | 0.30 | 32.60 | 0.00 | 1.00 | |

| Abutment | 0.00 | 0.67 | 1.33 | 1.04 | 1.20 | 4.53 | 0.00 | ||

| Pier | 0.00 | 1.33 | 2.67 | 13.07 | 2.40 | 9.07 | 0.00 | ||

| 37 | Slab | 0.00 | 0.00 | 0.00 | 20.33 | 41.44 | 16.00 | 0.16 | |

| Abutment | 0.00 | 0.00 | 0.00 | 2.44 | 0.30 | 12.30 | 0.00 | ||

| Pier | 16.70 | 0.00 | 0.00 | 1.78 | 0.00 | 0.00 | 0.00 | ||

| 13 | Slab | 0.00 | 0.00 | 0.00 | 0.21 | 0.55 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 0.04 | 0.34 | 0.00 | 0.00 | ||

| Pier | 7.65 | 0.40 | 0.00 | 1.66 | 0.98 | 0.00 | 0.00 | ||

| 15 | Slab | 2.70 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Abutment | 0.55 | 3.50 | 0.00 | 14.08 | 0.00 | 0.00 | 0.00 | ||

| Pier | 0.55 | 3.50 | 0.00 | 14.04 | 0.00 | 0.00 | 0.00 | ||

| F | 17 | Slab | 2.57 | 2.50 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Abutment | 2.20 | 0.50 | 0.00 | 3.48 | 0.00 | 0.00 | 0.00 | ||

| Pier | 2.20 | 0.50 | 0.00 | 3.44 | 0.00 | 0.00 | 0.00 | ||

| 19 | Slab | 2.57 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | |

| Abutment | 1.70 | 0.50 | 0.00 | 8.78 | 0.00 | 0.00 | 0.00 | ||

| Pier | 1.70 | 0.50 | 0.00 | 8.67 | 0.00 | 0.00 | 0.00 | ||

| 21 | Slab | 36.80 | 4.60 | 0.00 | 2.54 | 0.30 | 0.00 | 0.00 | |

| Abutment | 6.10 | 1.65 | 0.00 | 0.34 | 0.00 | 0.00 | 0.00 | ||

| Pier | 6.10 | 1.65 | 0.00 | 0.15 | 0.00 | 0.00 | 0.00 | ||

| 25 | Slab | 59.40 | 2.50 | 0.00 | 3.87 | 7.01 | 0.00 | 0.02 | |

| Abutment | 21.40 | 0.00 | 0.00 | 3.19 | 0.00 | 15.00 | 0.00 | ||

| Pier | 18.90 | 0.00 | 0.00 | 3.67 | 0.00 | 0.00 | 0.00 | ||

| 27 | Slab | 58.50 | 3.00 | 0.00 | 3.87 | 0.41 | 0.00 | 0.00 | |

| Abutment | 21.70 | 0.00 | 0.00 | 6.54 | 0.00 | 0.87 | 0.10 | ||

| Pier | 17.20 | 0.60 | 0.00 | 7.02 | 0.00 | 0.00 | 0.00 | ||

| 29 | Slab | 22.60 | 1.50 | 0.00 | 48.00 | 0.25 | 0.00 | 0.00 | |

| Abutment | 0.00 | 0.00 | 0.00 | 7.14 | 0.00 | 0.57 | 0.00 | ||

| Pier | 0.00 | 0.00 | 0.00 | 6.20 | 0.00 | 0.00 | 0.00 | ||

| 28 | Slab | 35.80 | 0.00 | 1.50 | 82.19 | 0.01 | 0.00 | 0.00 | |

| Abutment | 10.50 | 5.20 | 1.40 | 10.01 | 0.00 | 3.24 | 0.00 | ||

| Pier | 13.70 | 0.00 | 0.00 | 4.42 | 0.00 | 0.00 | 1.00 | ||

| 30 | Slab | 24.50 | 0.00 | 31.50 | 32.48 | 0.08 | 0.00 | 0.00 | |

| Abutment | 35.70 | 12.70 | 1.40 | 10.12 | 0.06 | 2.20 | 0.00 | ||

| Pier | 55.80 | 0.00 | 0.00 | 1.75 | 0.00 | 0.00 | 0.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).